Bidirectional shear test device for metal plates

A two-way shearing and testing device technology, which is applied in measuring devices, using stable shear force to test the strength of materials, analyzing materials, etc., can solve the problems of less performance research, high cost, and material performance impact, and achieve the triangle Accurate transformation, no relative displacement, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

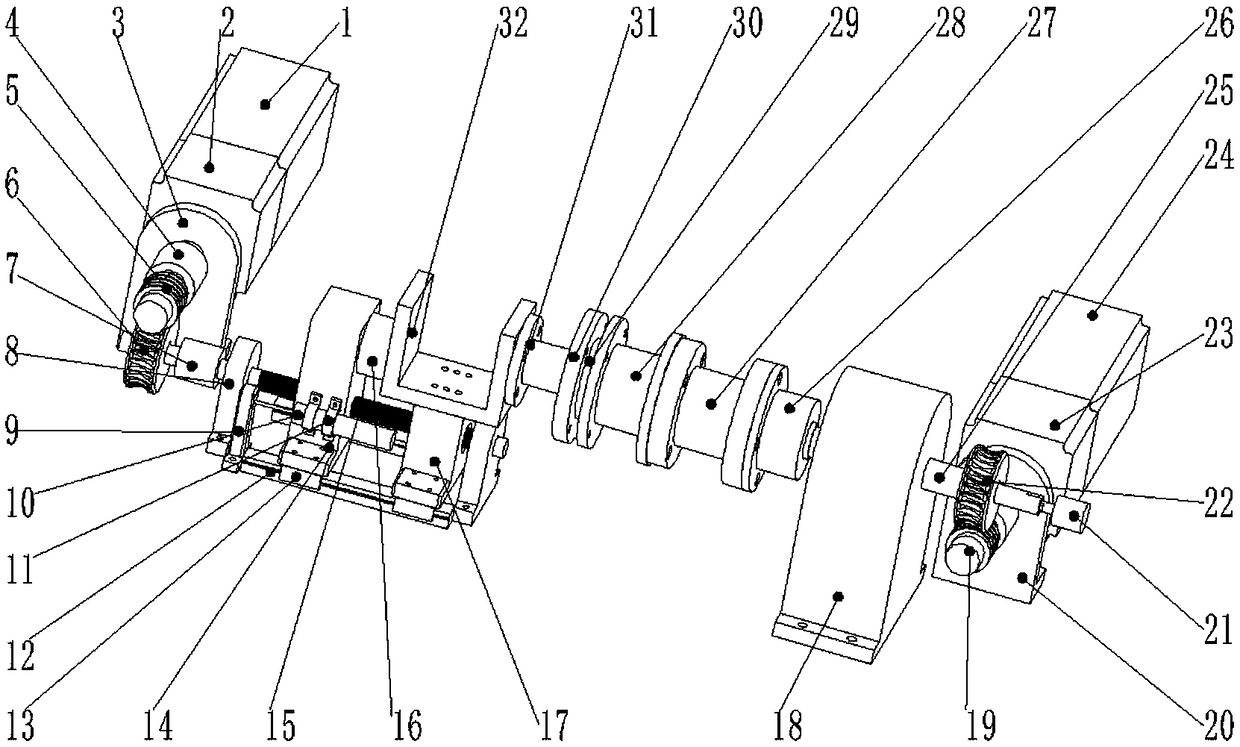

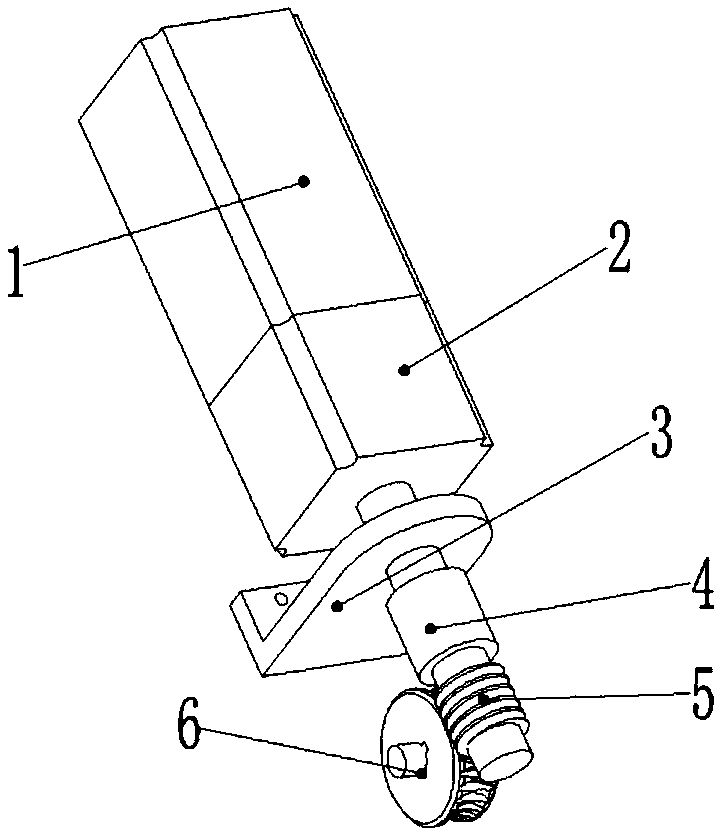

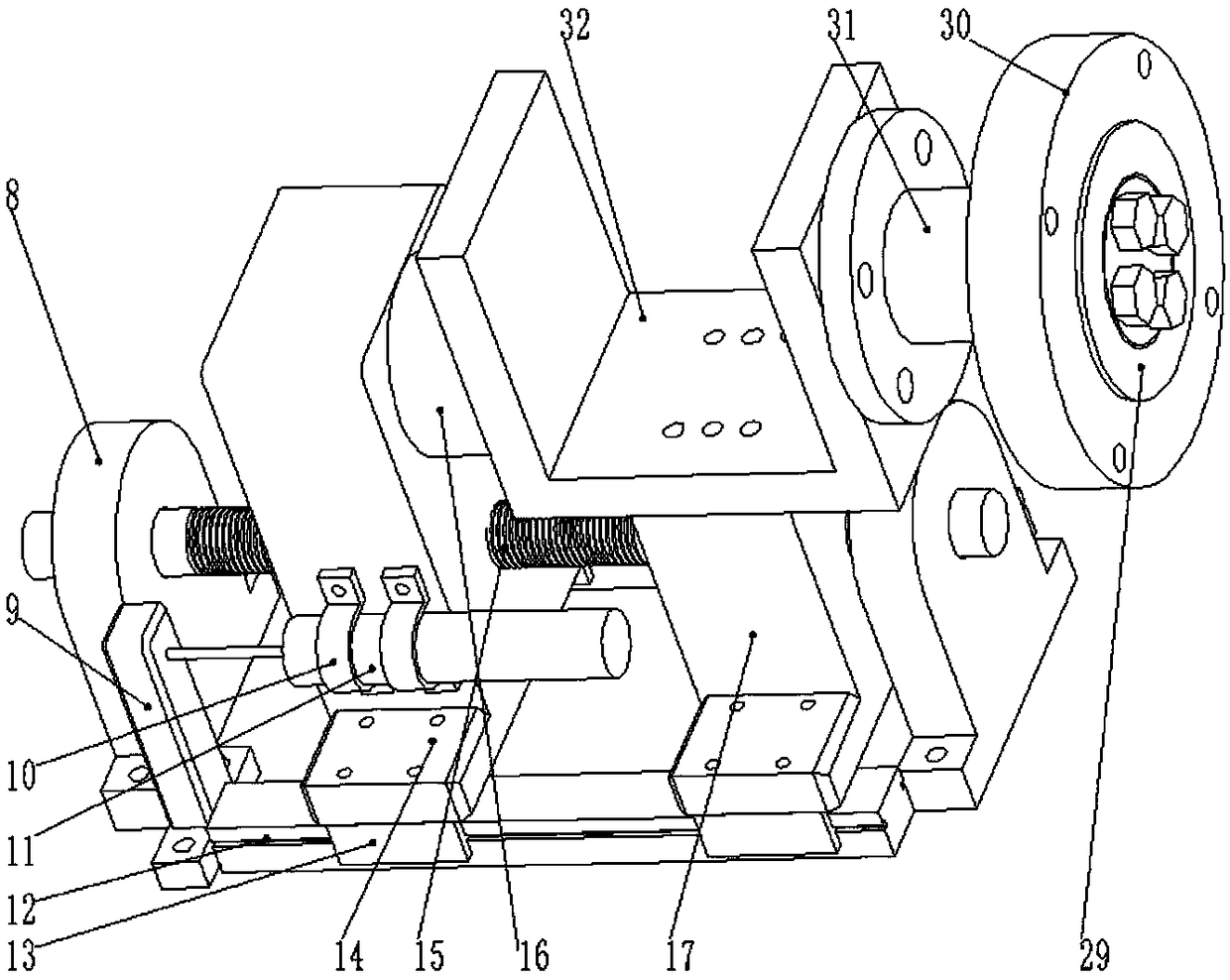

[0029] see figure 1 , the present invention is a metal plate two-way shearing test device, including a servo motor, a speed reduction mechanism, a measuring instrument, a pulling, compressing and shearing mechanism and a rotating mechanism. The servo motor is used to provide the power of the entire two-way shearing device, and the forward and reverse rotation of the servo motor can be realized by programming, so as to perform tensile shear or compression shear and rotational shear deformation, and study the forward and reverse shear performance of materials. The two-way shear specimen is a circular plate-shaped structure, and coaxial annular grooves are arranged at the same position on both ends of the specimen.

[0030] Since a small movement speed is required for the shear test, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com