Patents

Literature

70results about How to "Constant ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

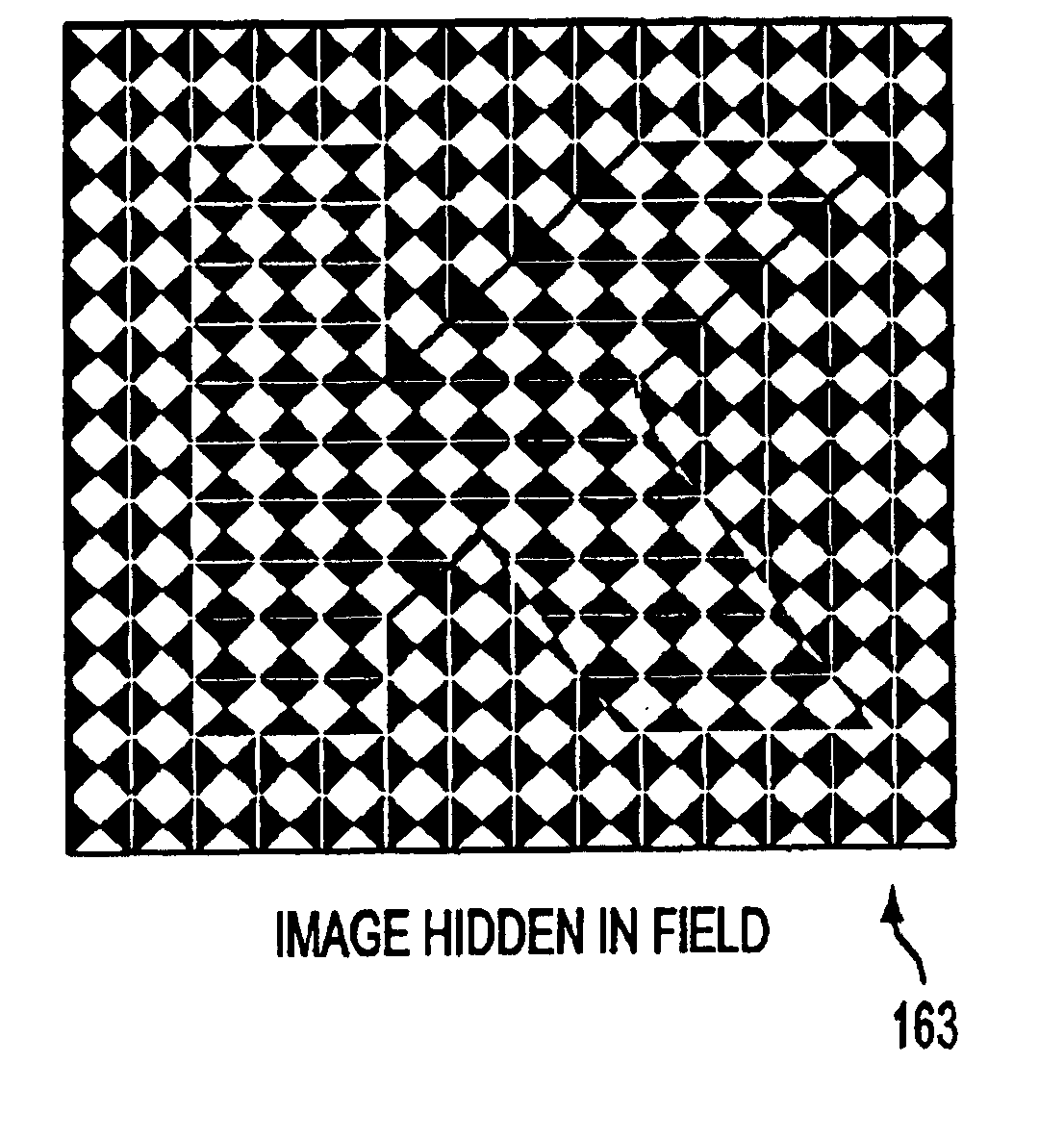

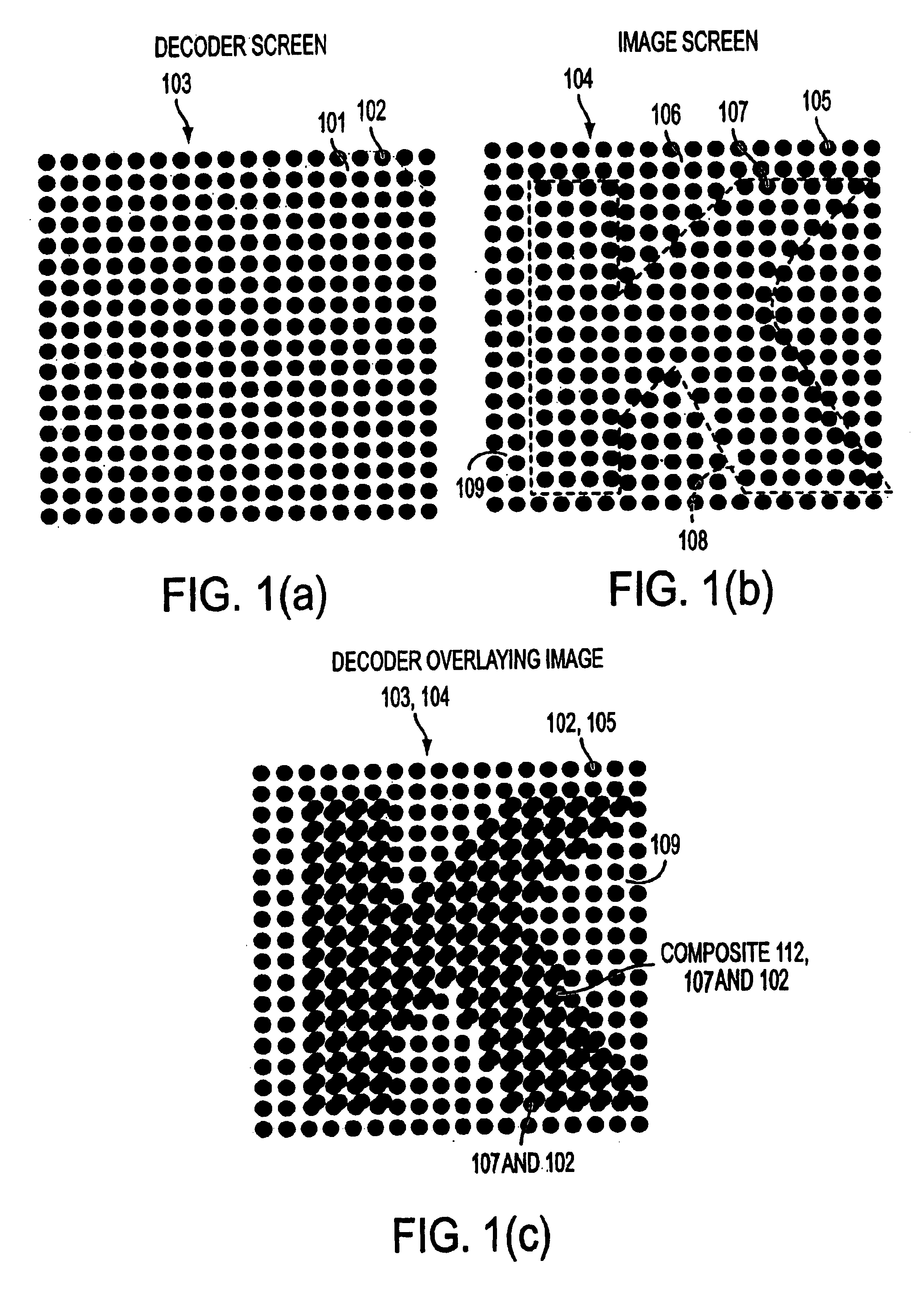

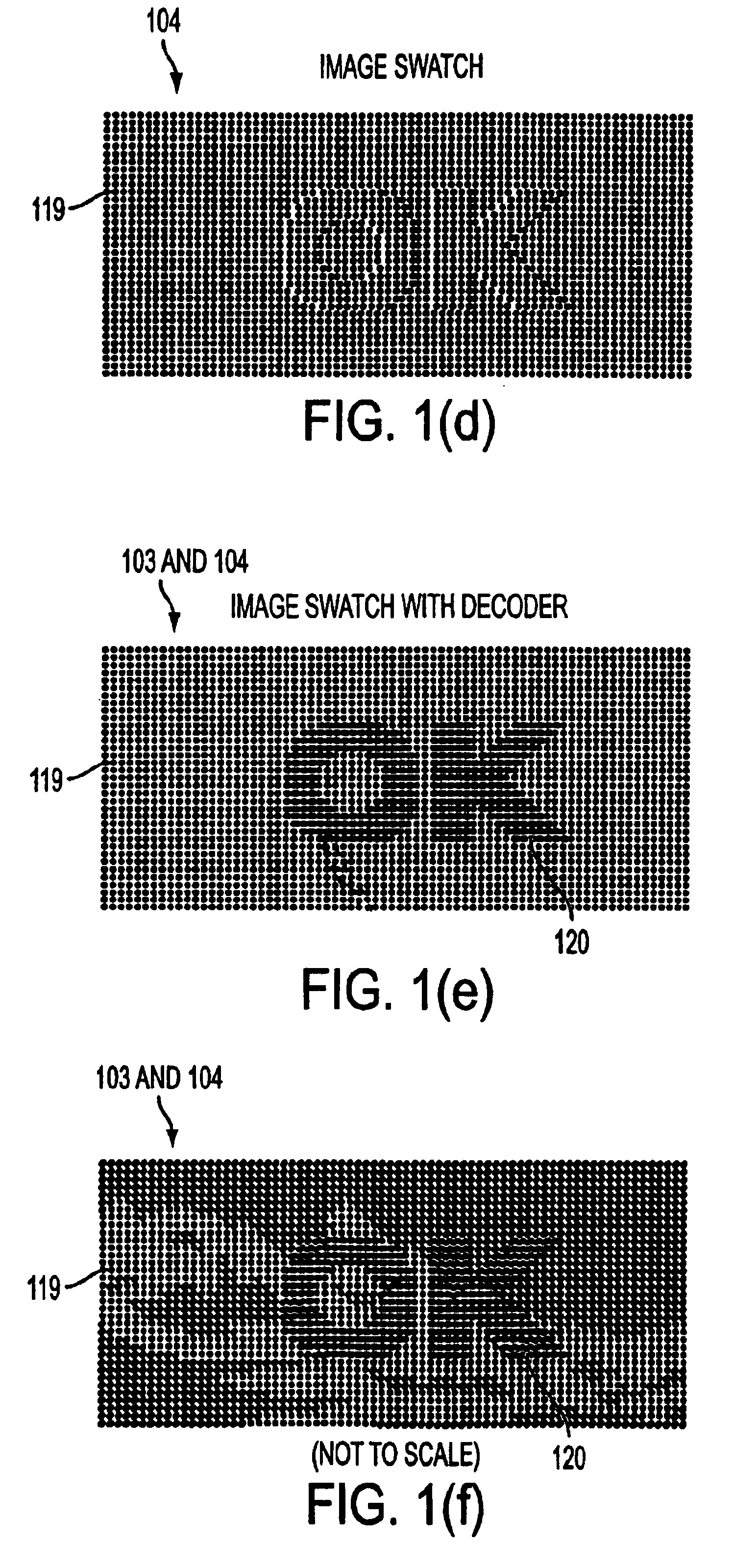

System and method for encoding and decoding an image or document and document encoded thereby

InactiveUS6865001B2Improve securityConstant ratioOther printing matterPaper-money testing devicesGraphicsDocumentation

Holographic and diffractive security devices and documents carrying security devices as well as system, apparatus, and method for making and using security devices. Security devices provide at least one type of security feature in form of secret, hidden, or covert security feature, not visible to a normal unaided human eye. Covert security features may be any graphic or symbolic representation. One or multiple security features may be provided on any single security device in any combination. Covert feature is revealed either when a decoder device is used with the security device, or when the security device is oriented and viewed in predetermined manner. Embodiments may provide a second overt or non-covert security device in the form of a diffractive or holographic image or graphic that is visible to the unaided eye without use of any decoder or special viewing conditions.

Owner:PACIFIC HOLOGRAPHICS

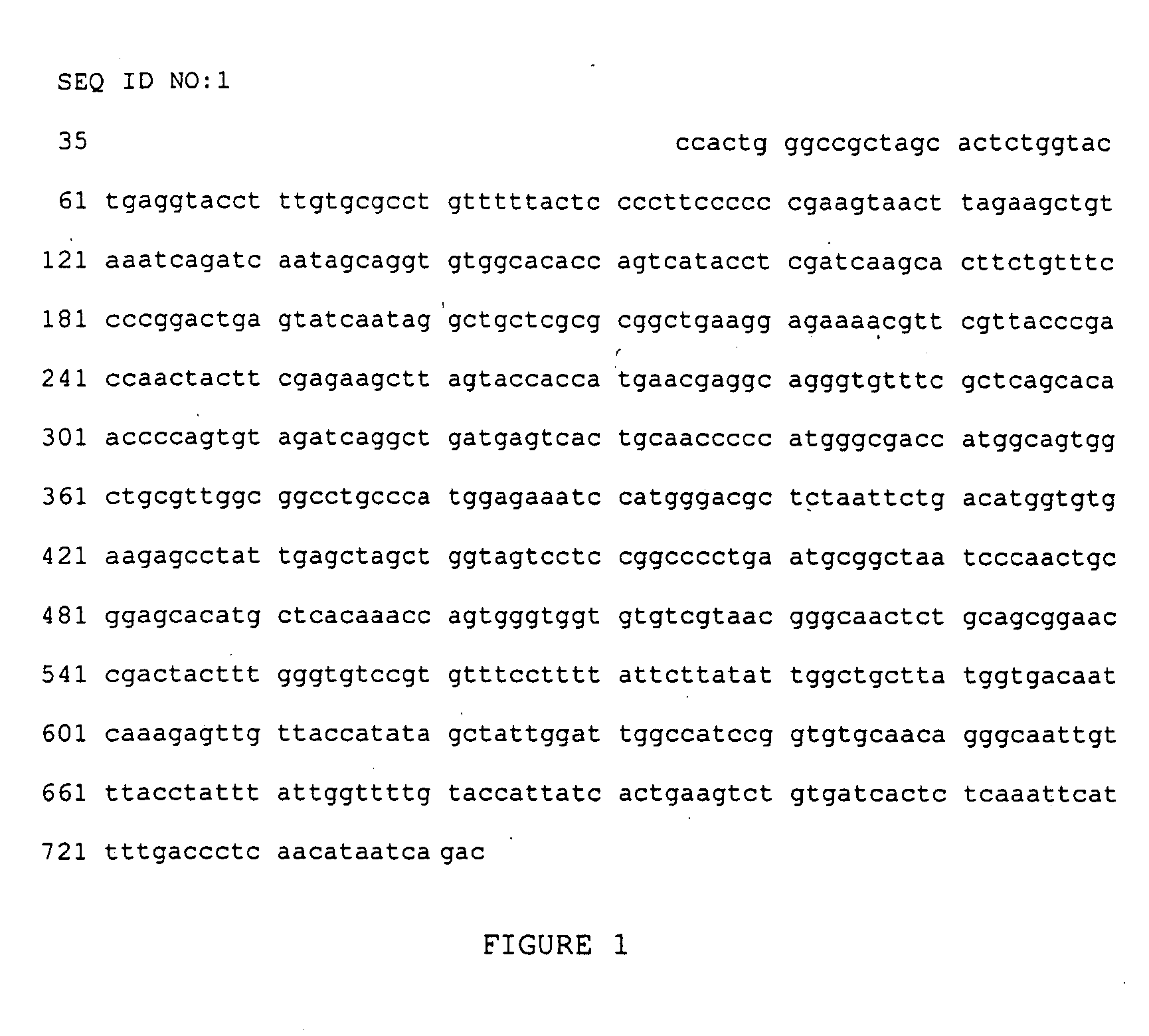

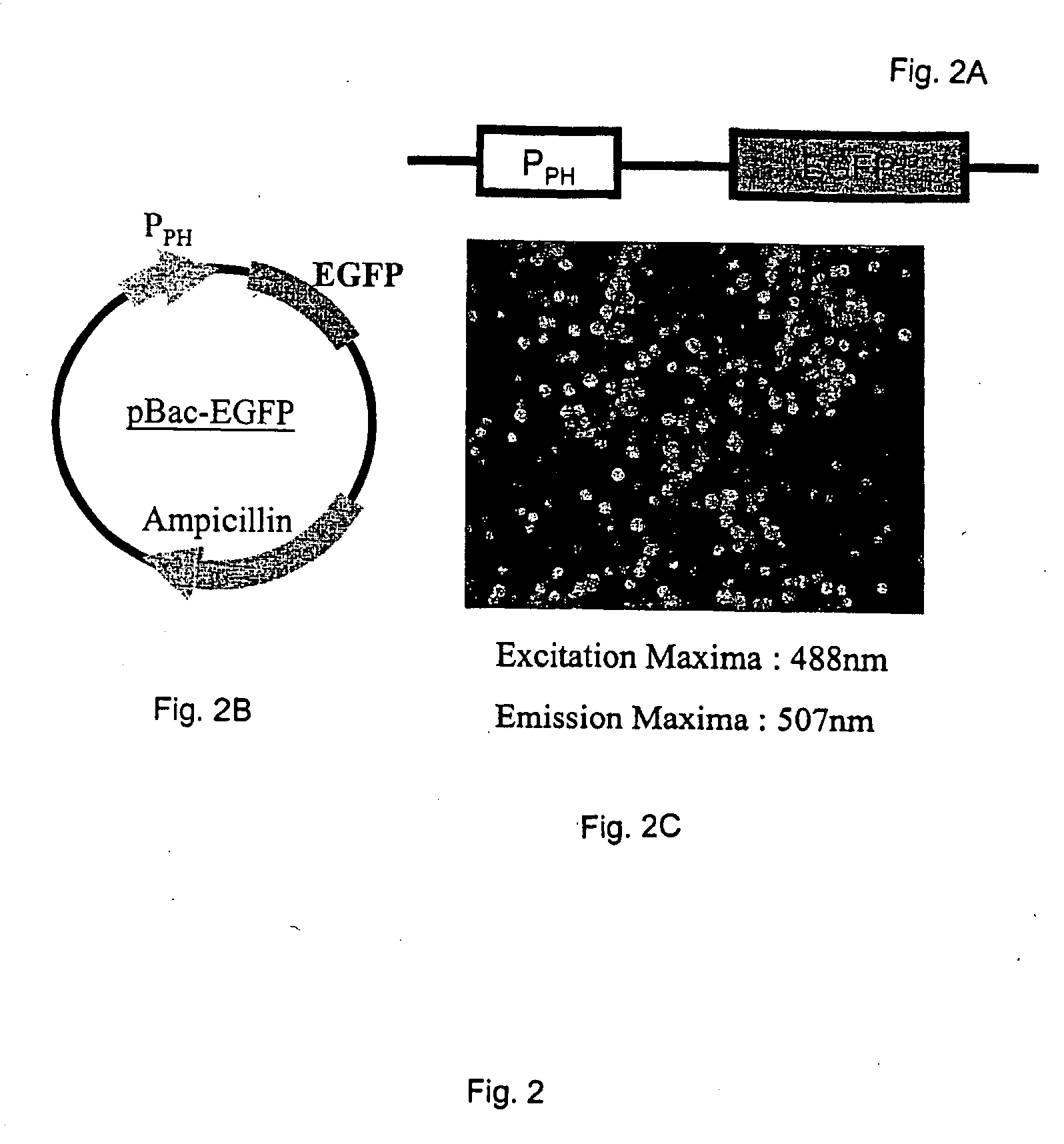

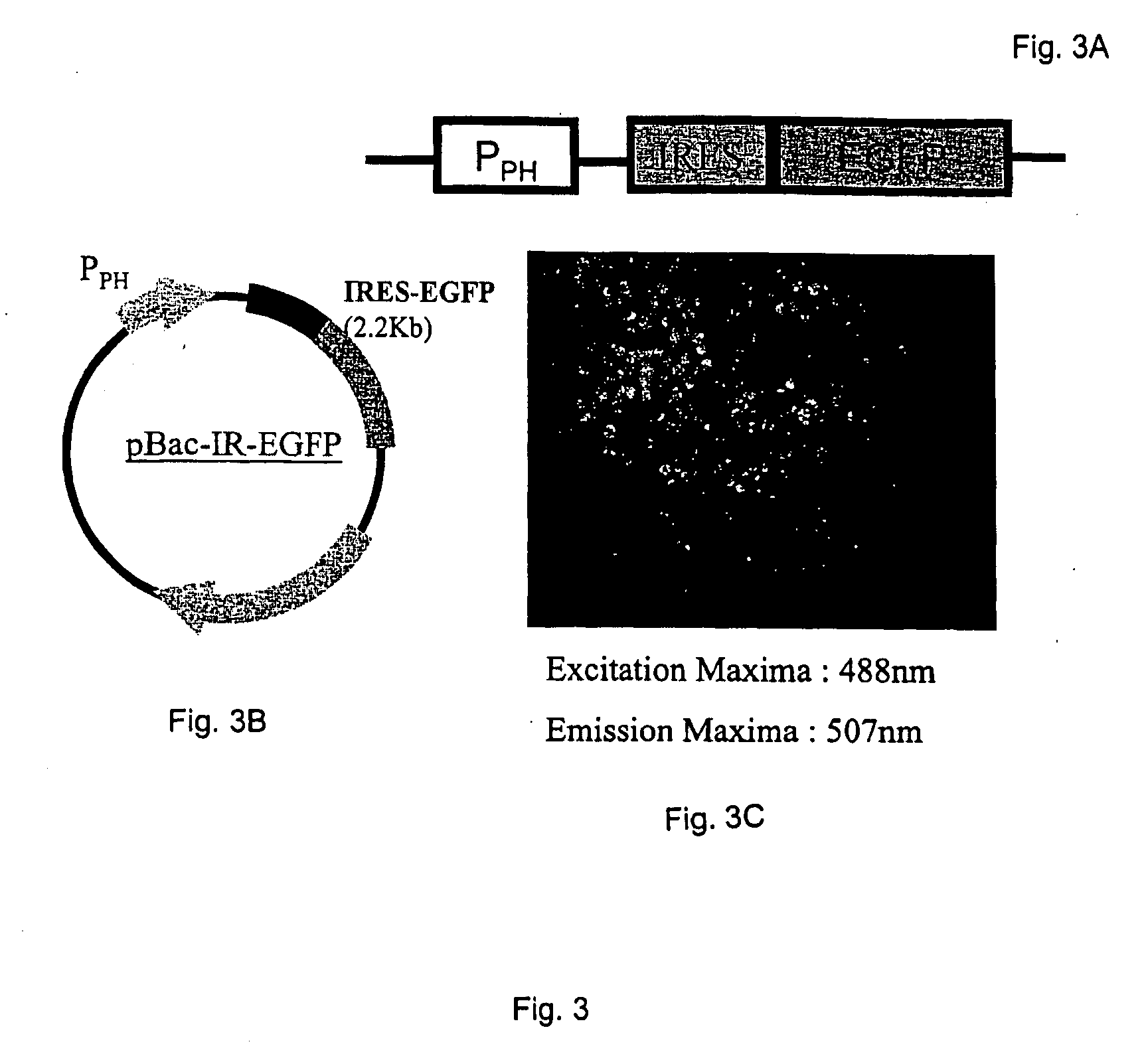

Internal ribosome entry sites for recombinant protein expression

InactiveUS20050112095A1Efficiently translatedConstant ratioBiocideSsRNA viruses positive-senseInternal ribosome entry siteEnterovirus 71

The invention describes compositions and methods for recombinant protein expression in a wide range of cell types, including mammalian, insect, and bacterial cells. The compositions comprise a viral IRES sequence selected from enterovirus 71 (EV71), hepatitis C virus (HCV), or encephalomyocarditis virus (EMCV), or a variant or fragment thereof, or alternatively, a homolog of a viral IRES selected from EV71, HCV, or EMCV, or a variant or fragment thereof. Methods of using the compositions are also described.

Owner:NAT INST OF HEALTH REPRESENTED BY THE SEC OF THE DEPT OF HEALTH & HUMAN SERVICES NAT INST OF HEALTH

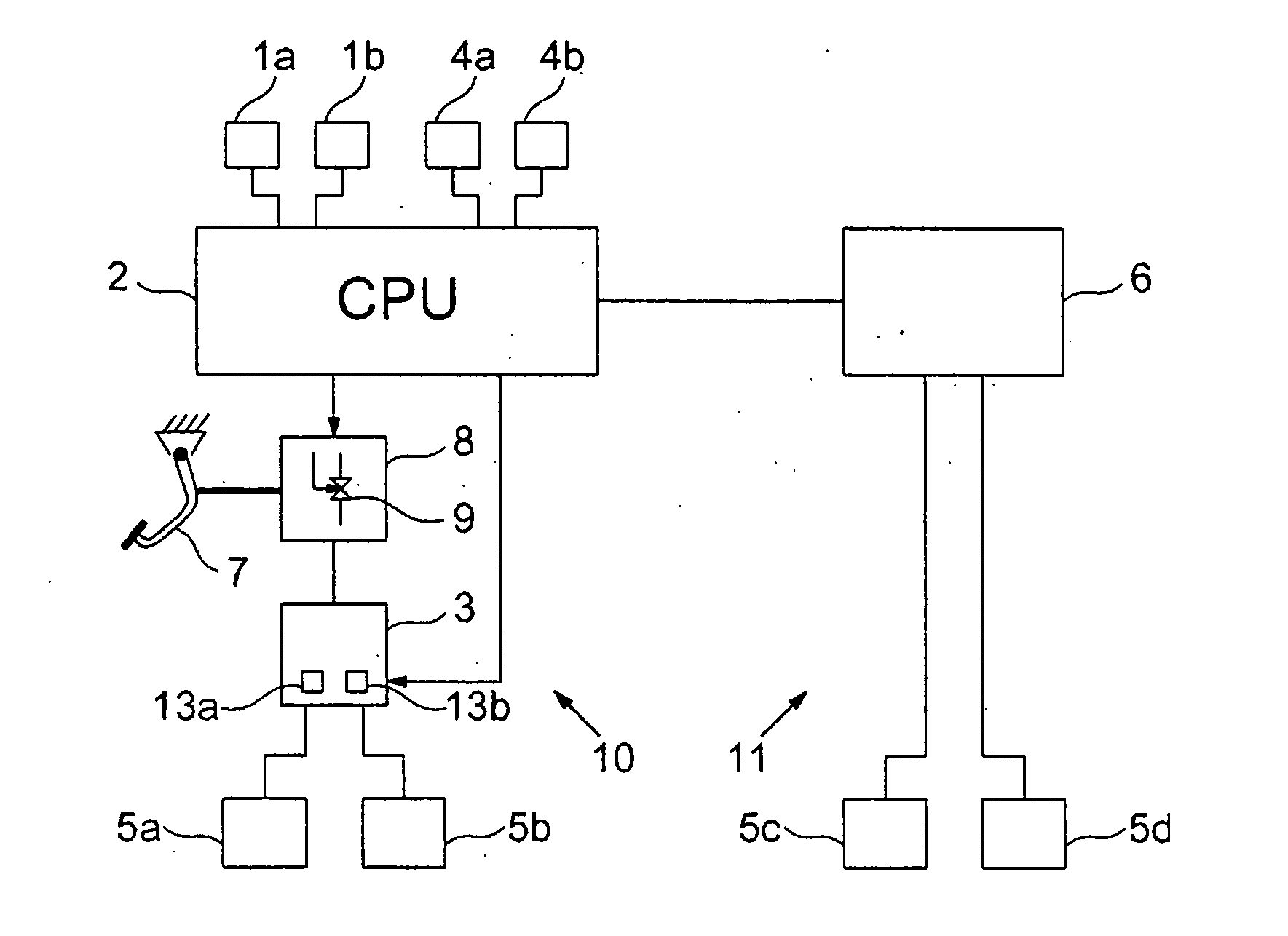

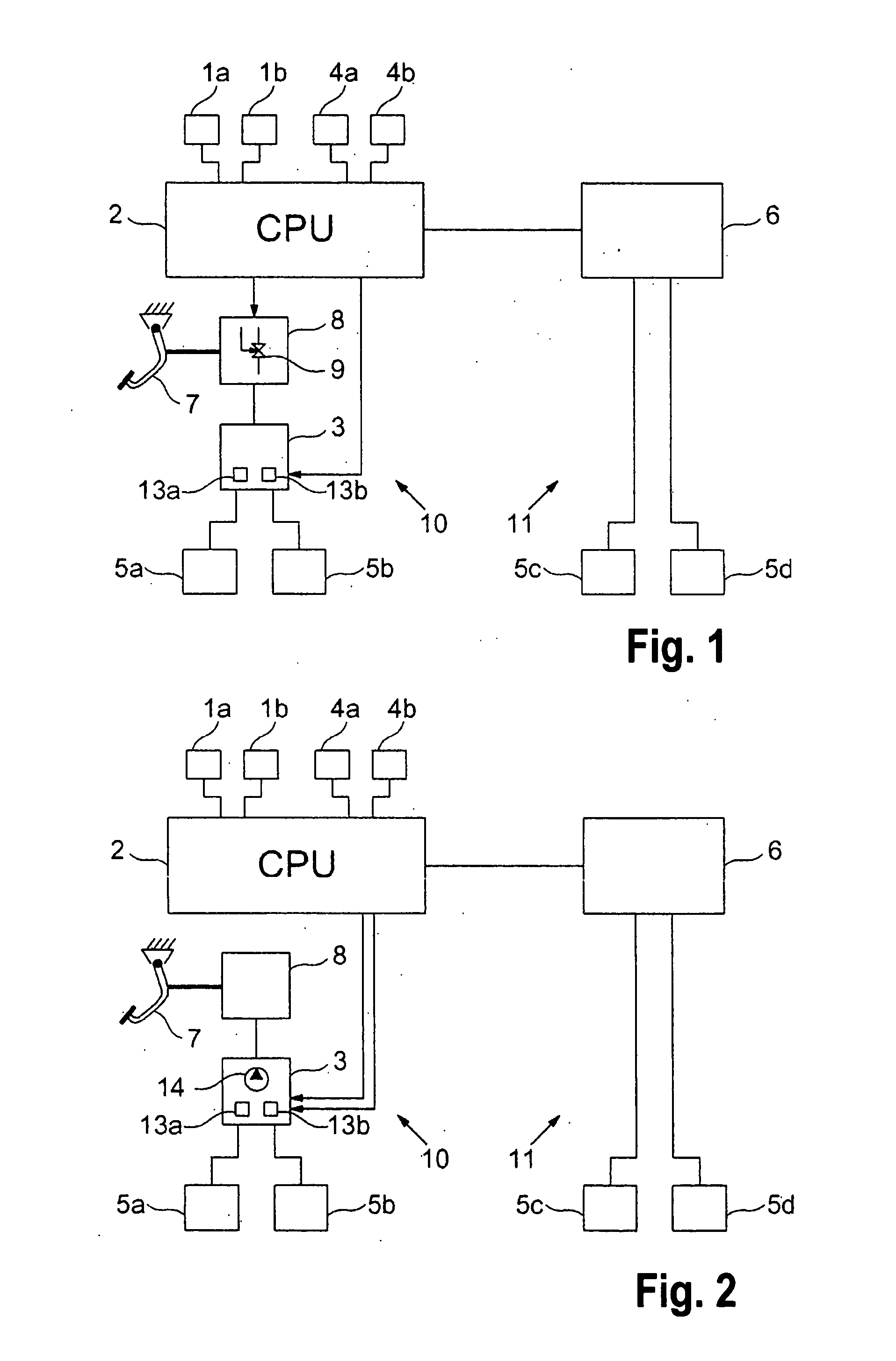

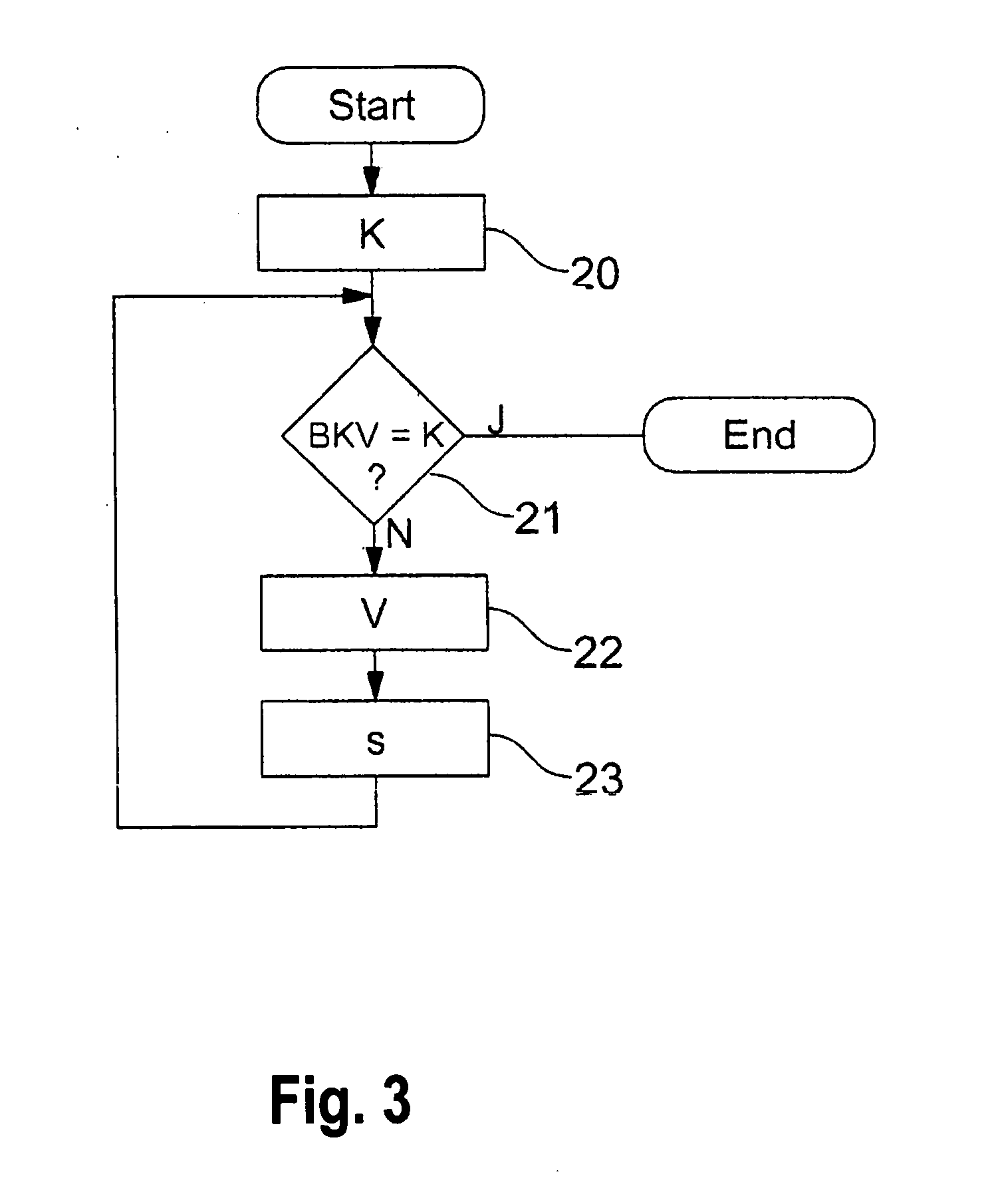

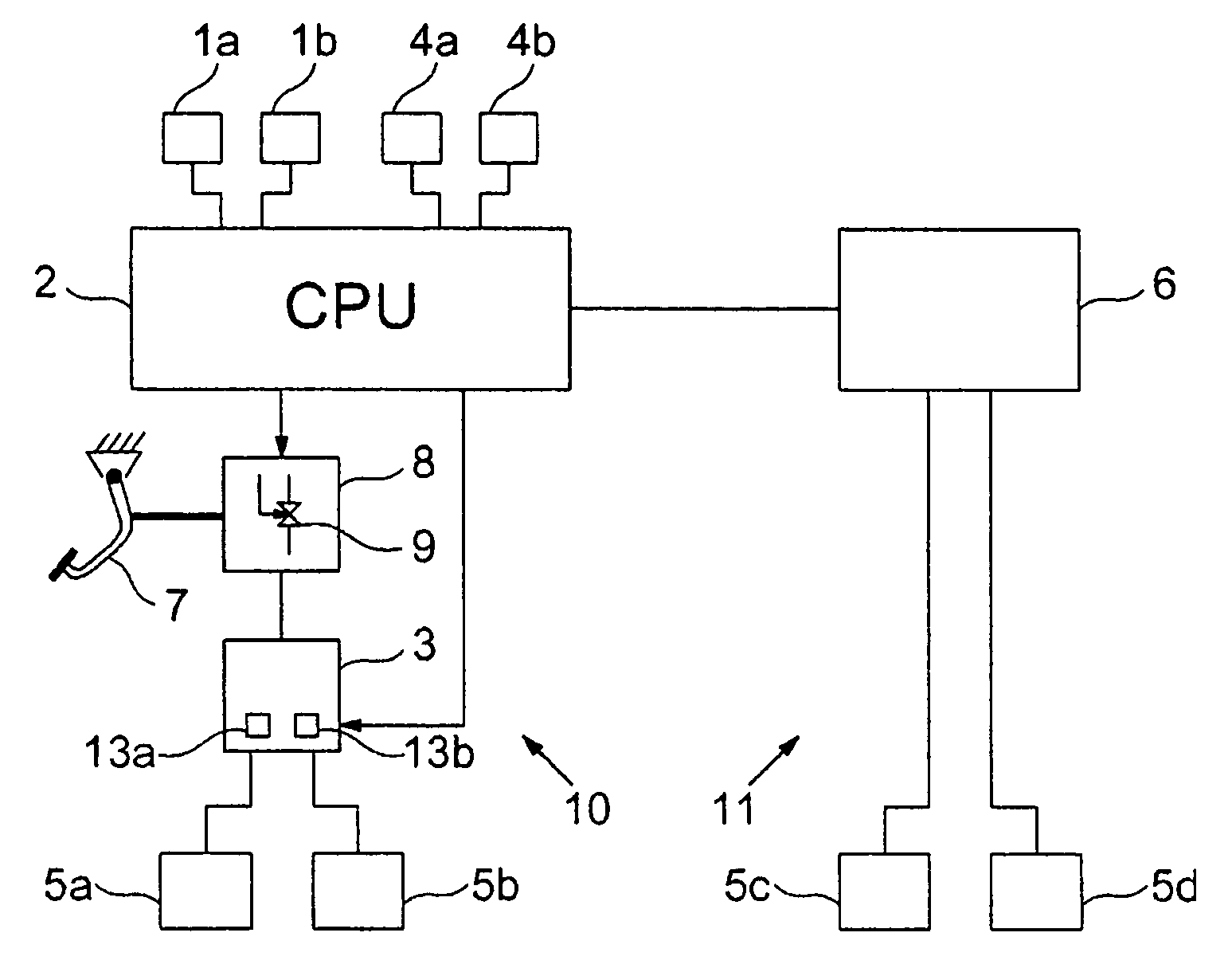

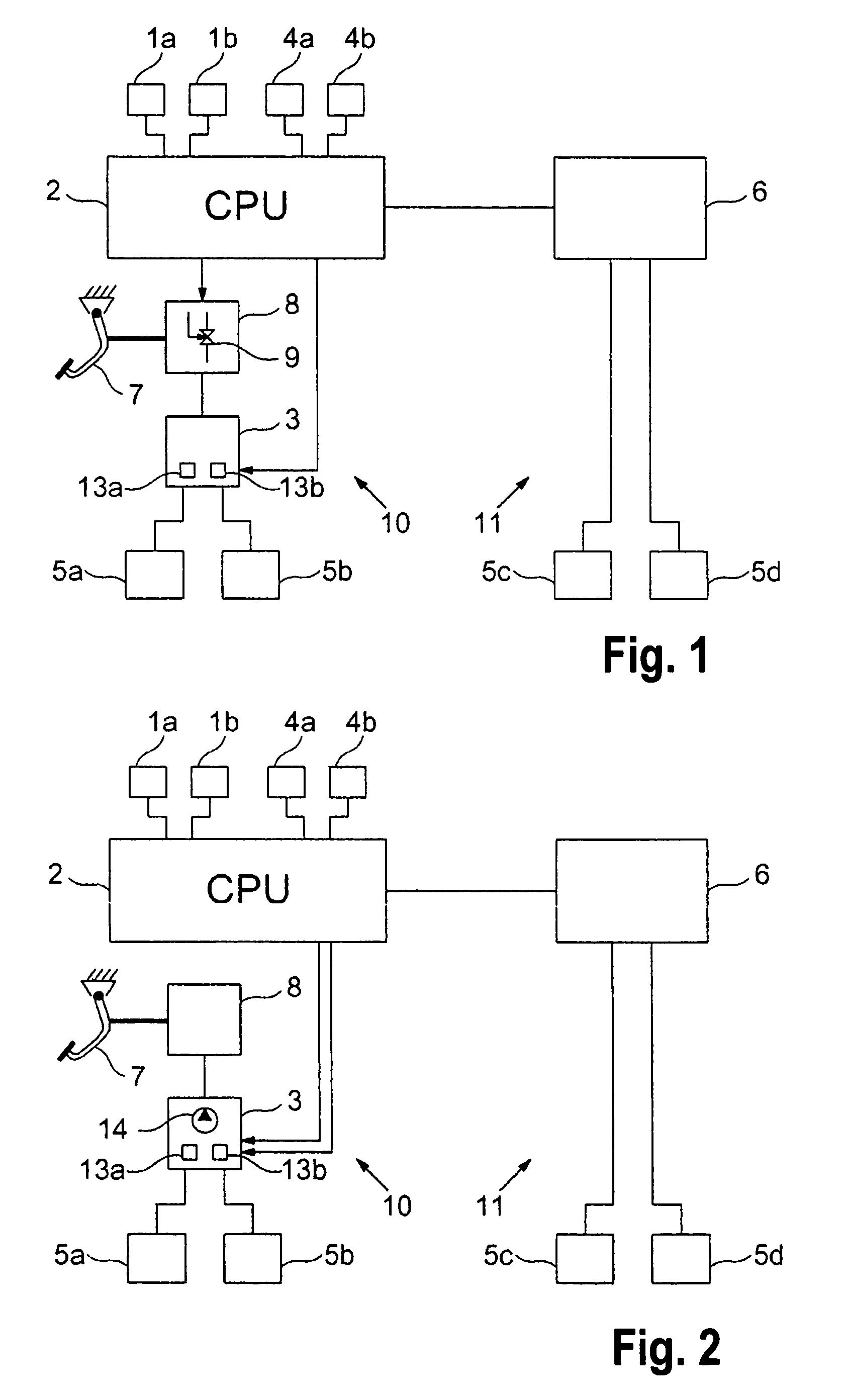

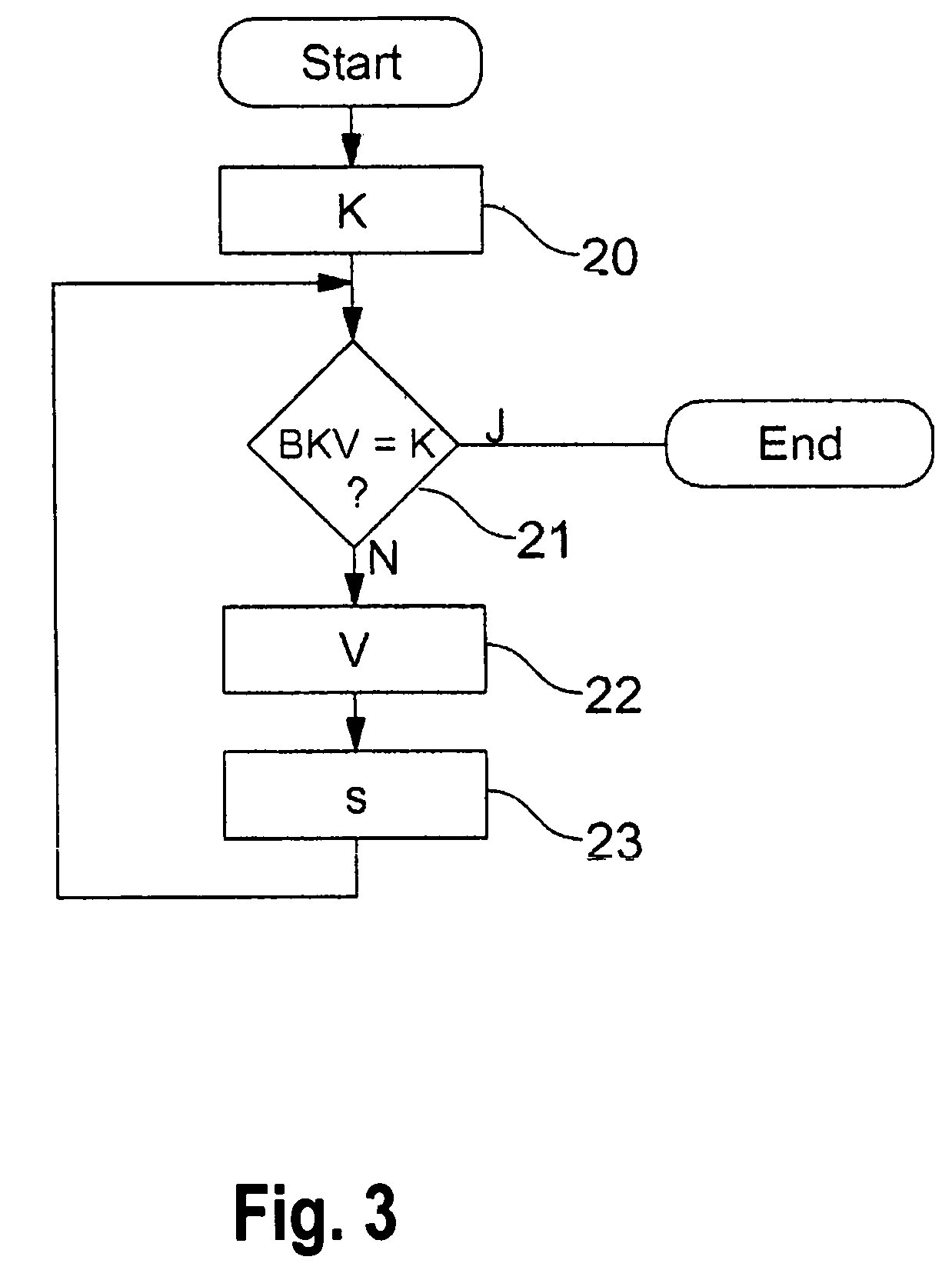

Device and method for adjusting the pedal characteristic curve of a hybrid braking system during modified braking-force distribution

ActiveUS20050017574A1Increasing and reducing pressureConstant ratioBraking action transmissionBrake control systemsEngineeringBraking system

A braking system for a vehicle is described, including a hydraulic service braking system and an electric service braking system having wheel brakes, to which braking pressure is applied when a brake pedal is operated. To maintain essentially constant vehicle braking behavior during a change in the braking-force distribution between the hydraulic and the electric service braking systems, it is proposed to provide a control unit, which is capable of varying the braking-force distribution and to equip the hydraulic service braking system with a braking pressure modulator that is controlled by the control unit and is able to effect a variable braking-force distribution as a function of the control by the control unit.

Owner:ROBERT BOSCH GMBH

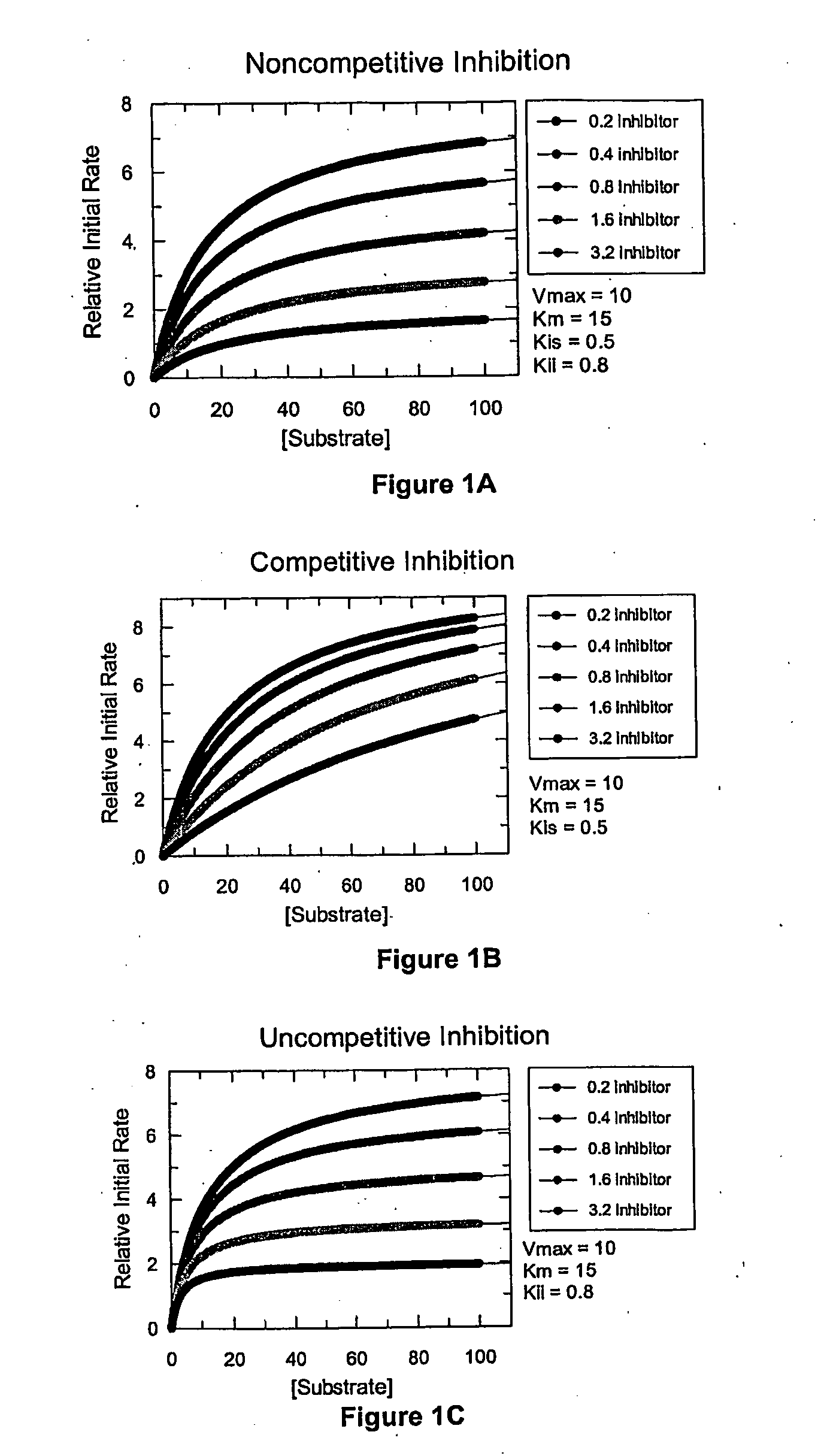

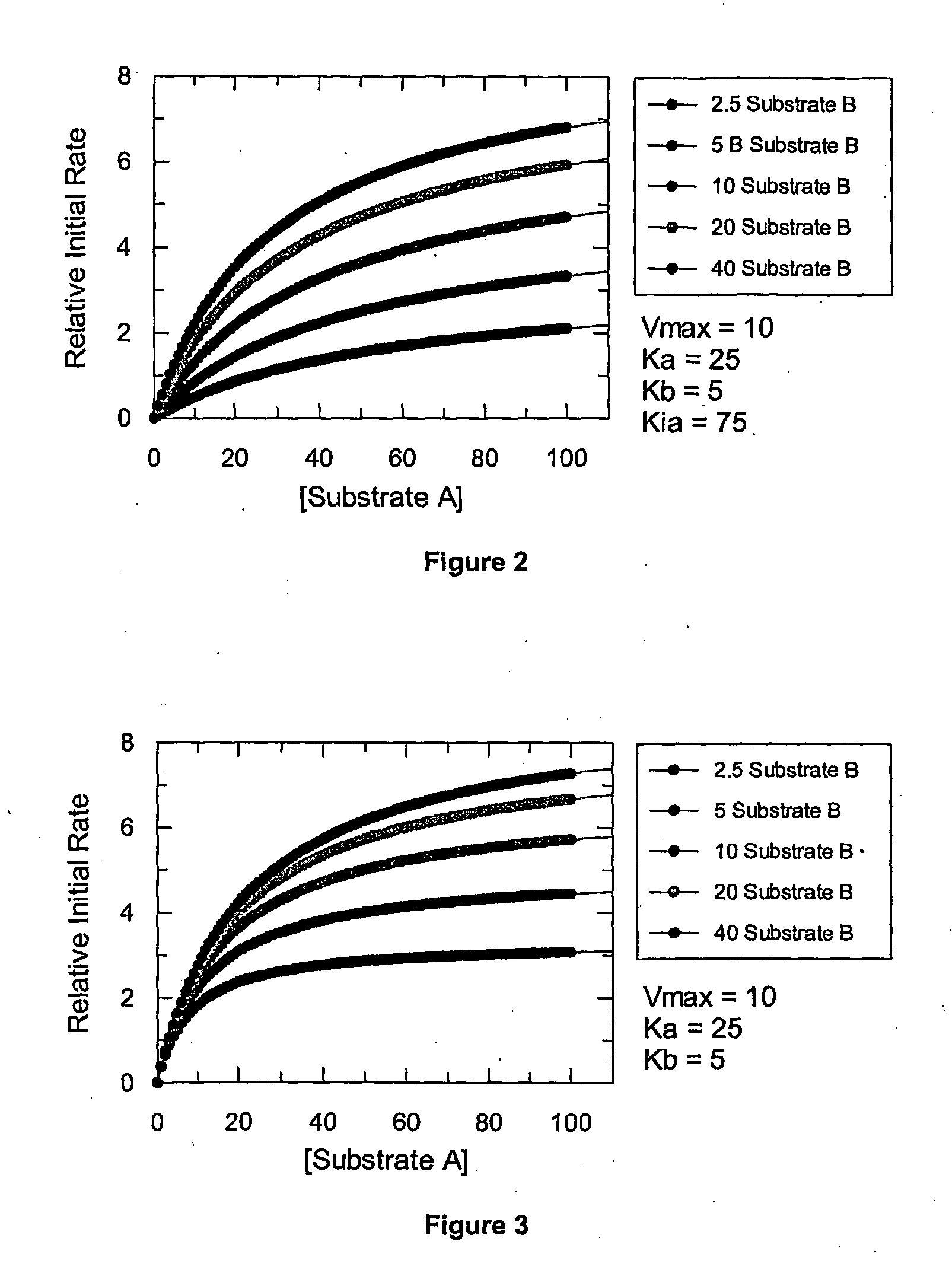

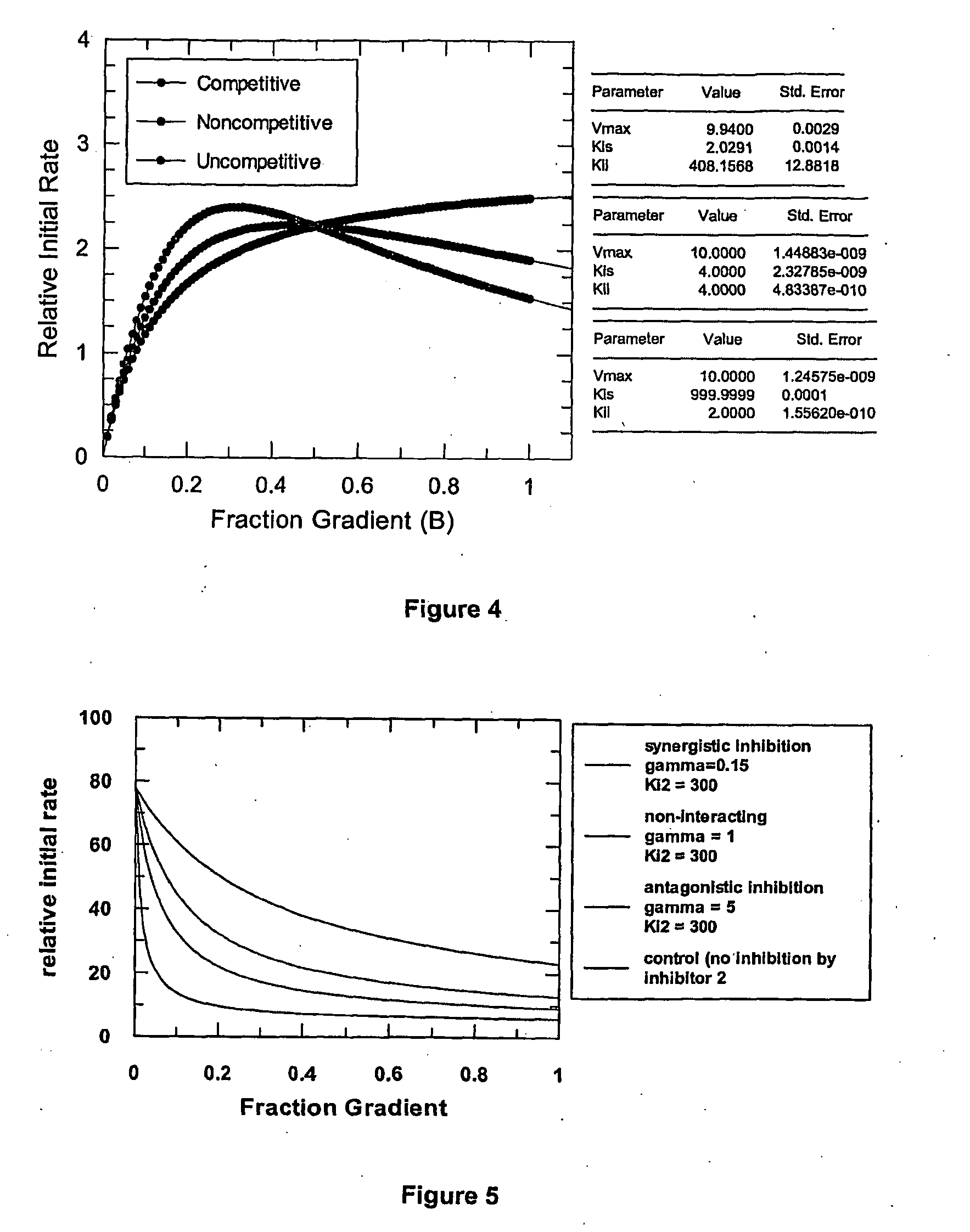

Methods for characterizing biological molecule modulators

ActiveUS20090148858A1Change concentrationConstant ratioCompound screeningApoptosis detectionConcentration gradientBiological activation

Methods for characterizing a biochemical reaction and analysis of reaction products by establishing continuously variable concentration gradients of one or more reagents of the biochemical reaction are provided. Methods for determining mechanism of inhibition or activation, potency of inhibition or activation, or both of an enzyme inhibitor or activator, respectively, are also provided. The continuously variable concentration gradients can be established in a microfluidic chip.

Owner:SCIEX

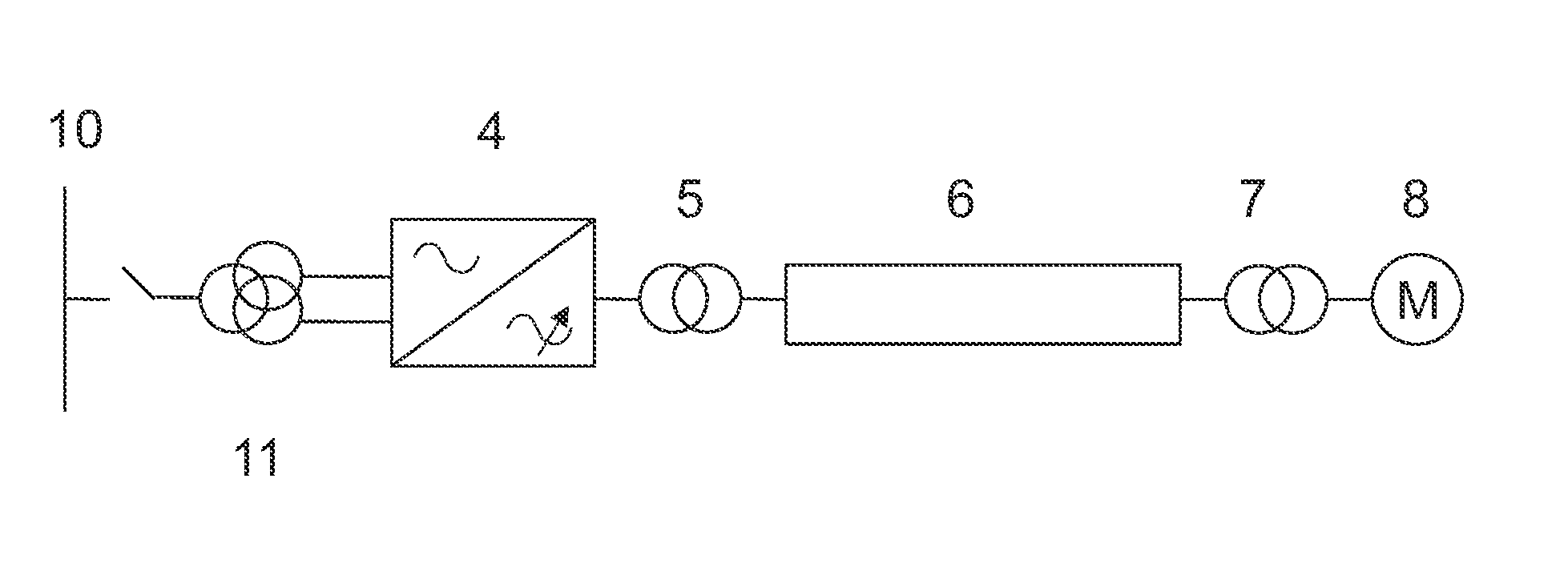

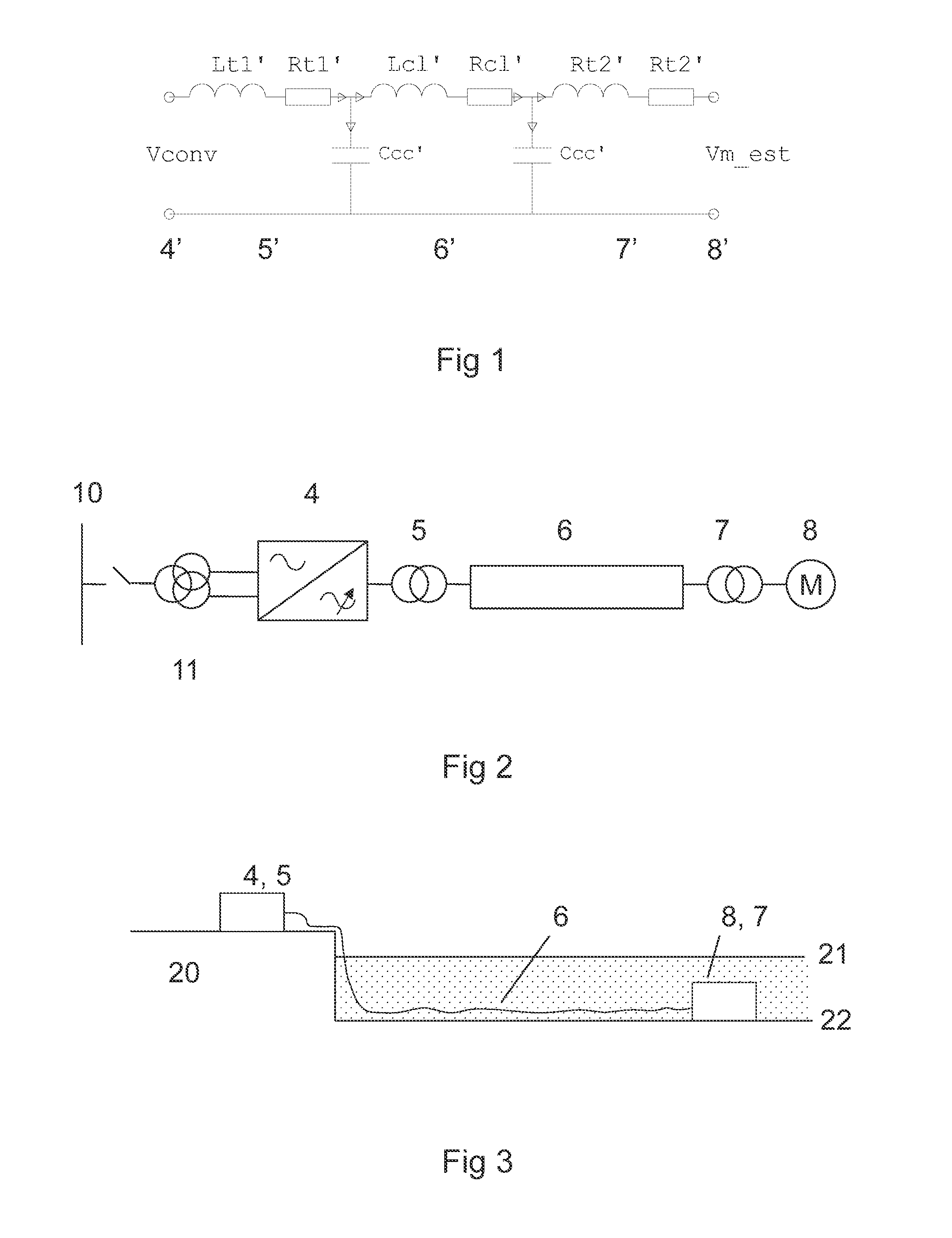

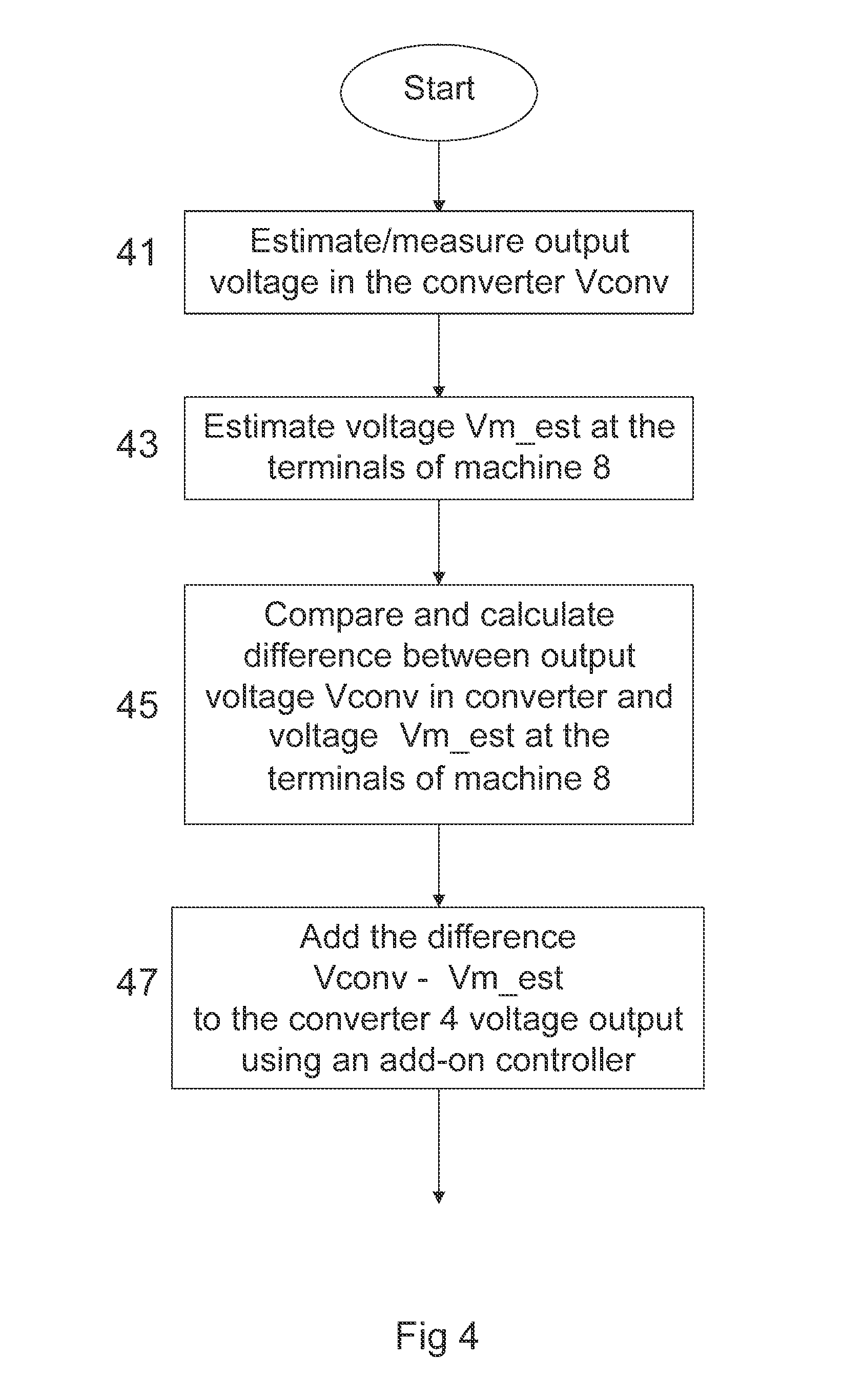

Method For Controlling A Machine Or An Electrical Load Supplied With Electric Power Over A Long Line

ActiveUS20120319628A1Constant ratioDC motor speed/torque controlSynchronous motors startersAC powerControl theory

A drive controller arranged to provide electrical power from a power supply to a machine or load over a long AC power cable of the order of kilometers. The drive controller is arranged with circuits and / or control processes to provide AC current at a constant ratio of voltage and frequency to said machine or load. The drive controller maintains voltage and frequency at the machine terminals despite fluctuations in voltage and / or frequency that would ordinarily be caused by the load. This is done by estimating the voltage and current at the machine terminals and adapting the drive controller output accordingly to actively vary the converter output dependent on the load of the machine or other load. In other aspects of the invention a method and a computer program for carrying out the method are described.

Owner:ABB (SCHWEIZ) AG

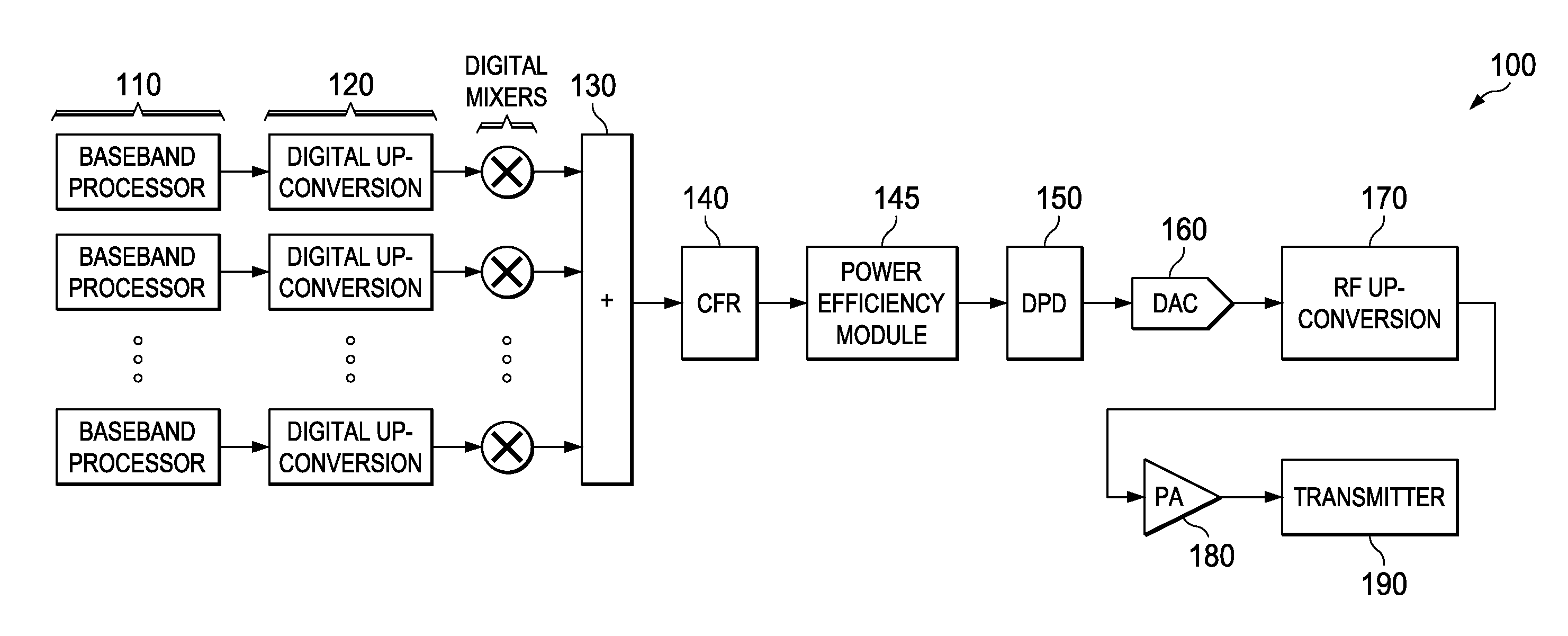

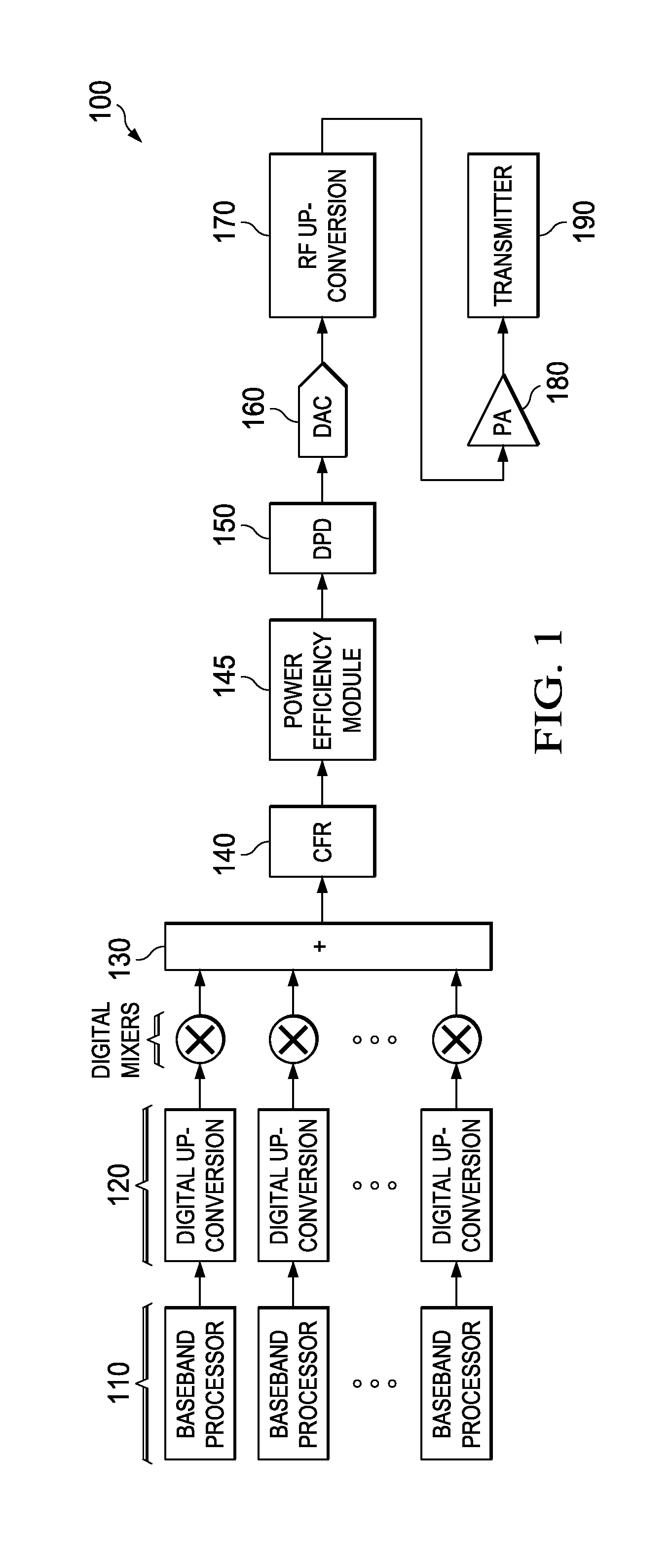

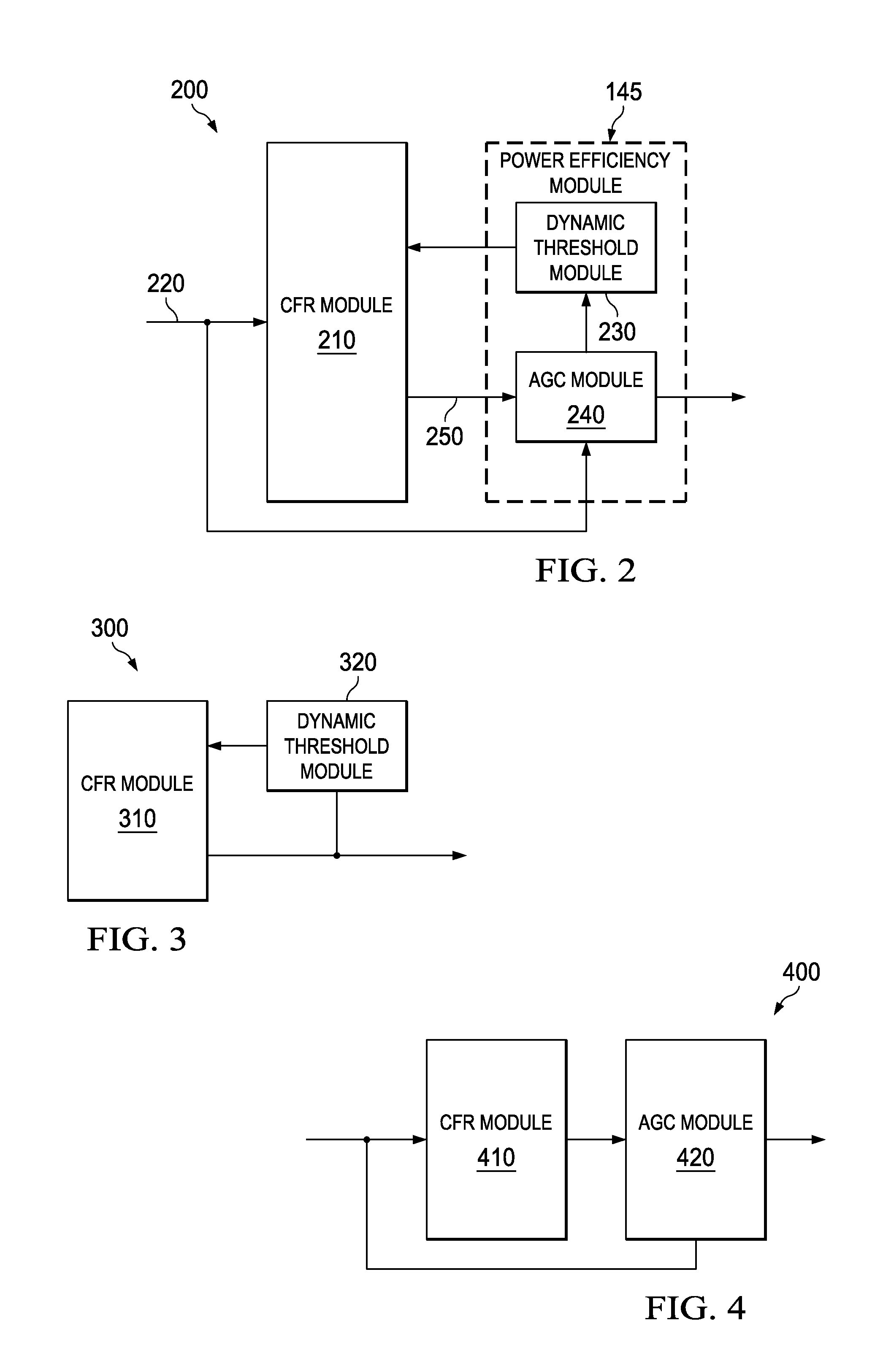

Systems and Methods of Improved Power Amplifier Efficiency Through Adjustments in Crest Factor Reduction

ActiveUS20120134399A1Improve power amplifier efficiencyConstant ratioGain controlVolume compression/expansion in digital/coded amplifiersAudio power amplifierEngineering

Crest factor reduction algorithms described herein may be used to improve power amplifier efficiency during low signal power conditions compared to traditional static threshold techniques. Techniques described herein insure that the signal power level at the output of the crest fact reduction block is held constant relative to the input power level under all signal power level conditions. Two different solutions may be implemented together or separately to achieve the desired conditions. The first technique provides constant ratio between input power and output power. Constant ratio of peak and average output levels keeps the amount of crest factor reduction applied to the signal constant, irrespective of the signal power level. A second technique is to hold signal power level constant in respect to the amount of crest factor reduction applied.

Owner:TEXAS INSTR INC

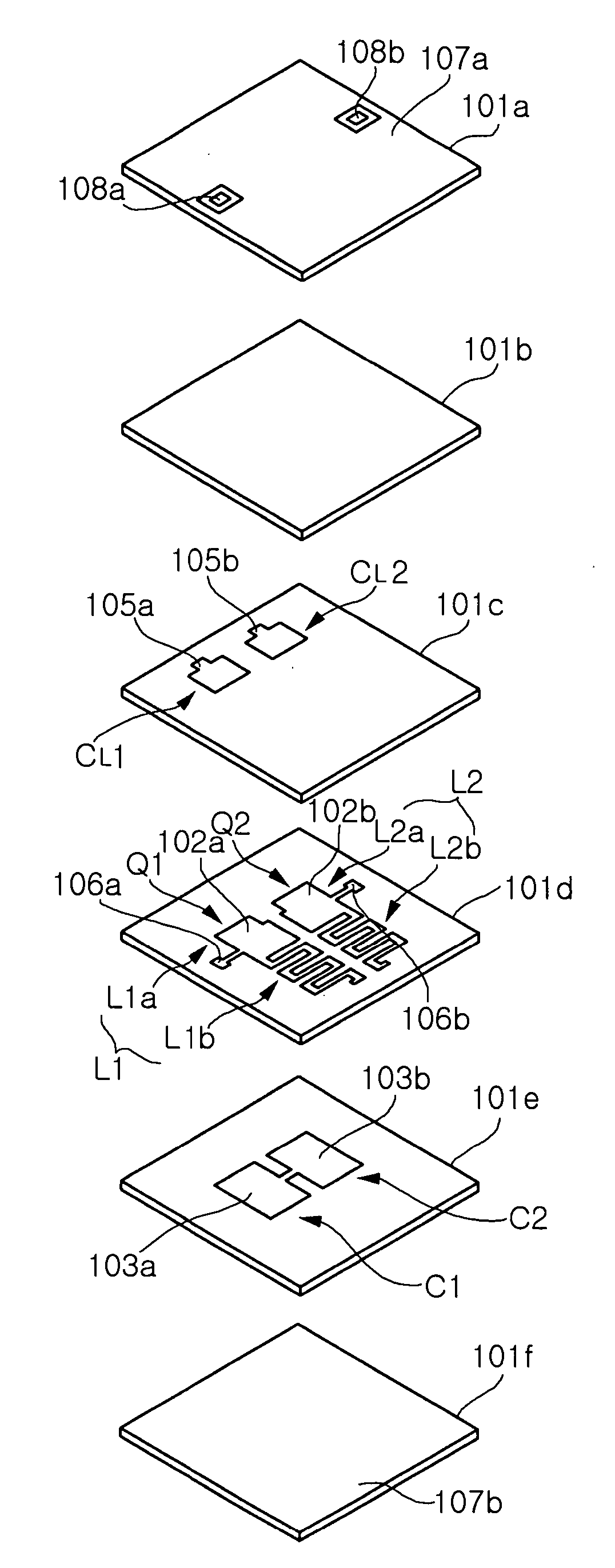

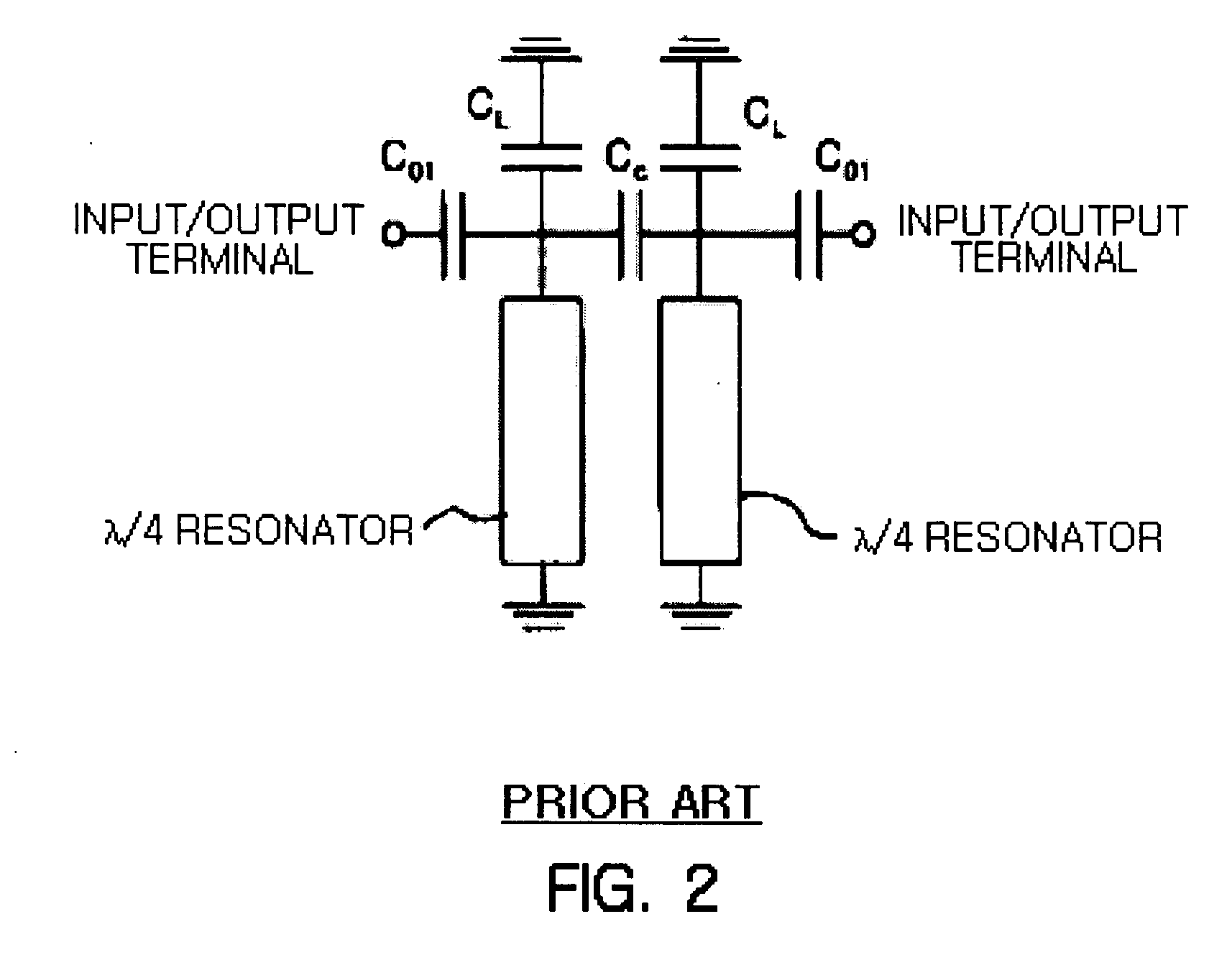

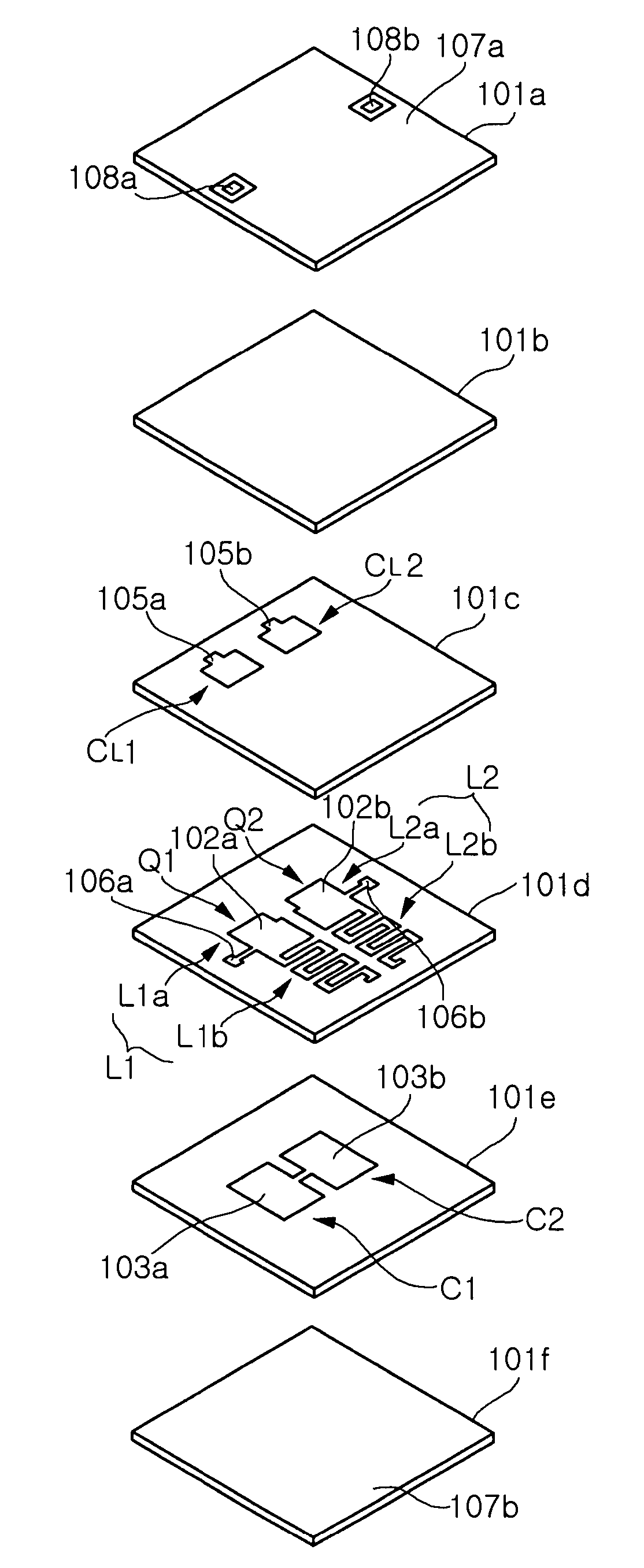

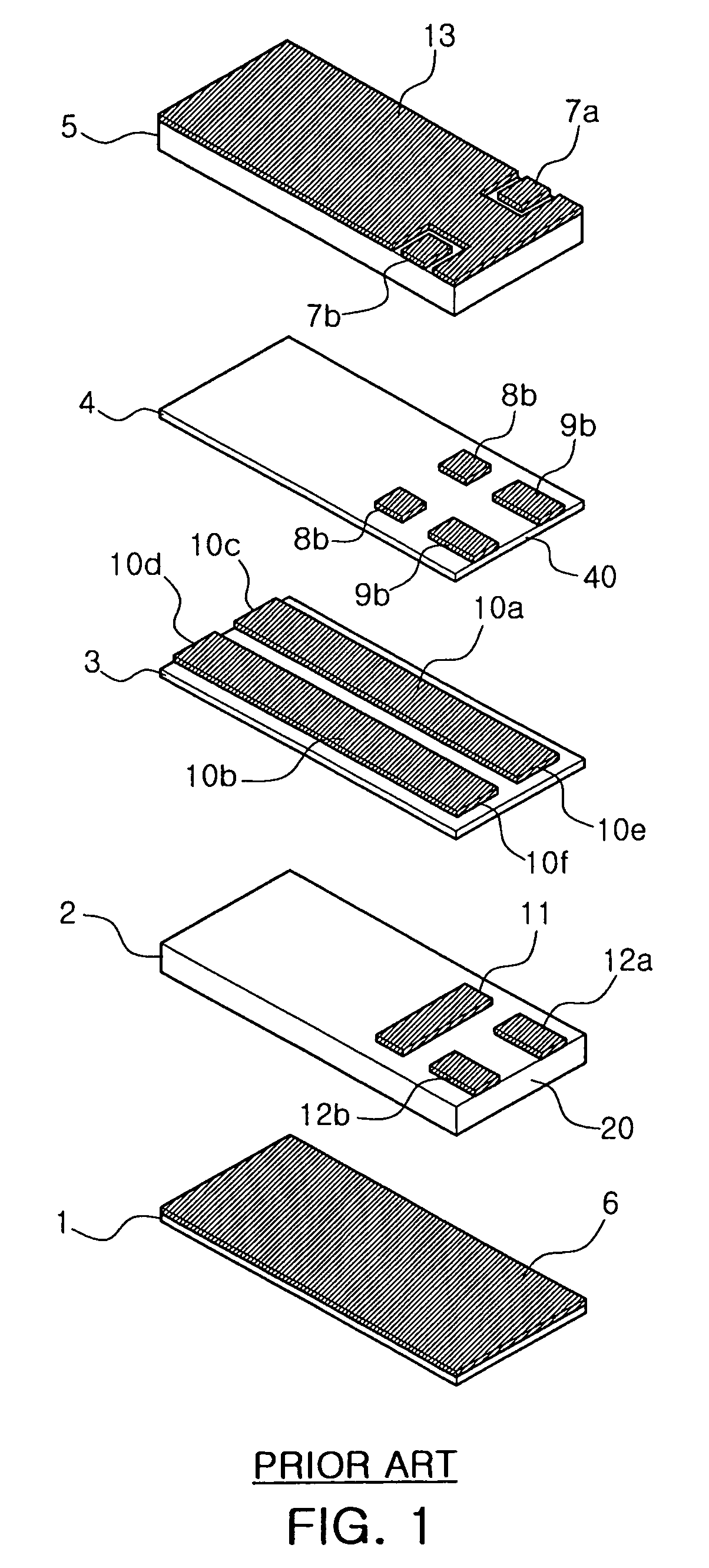

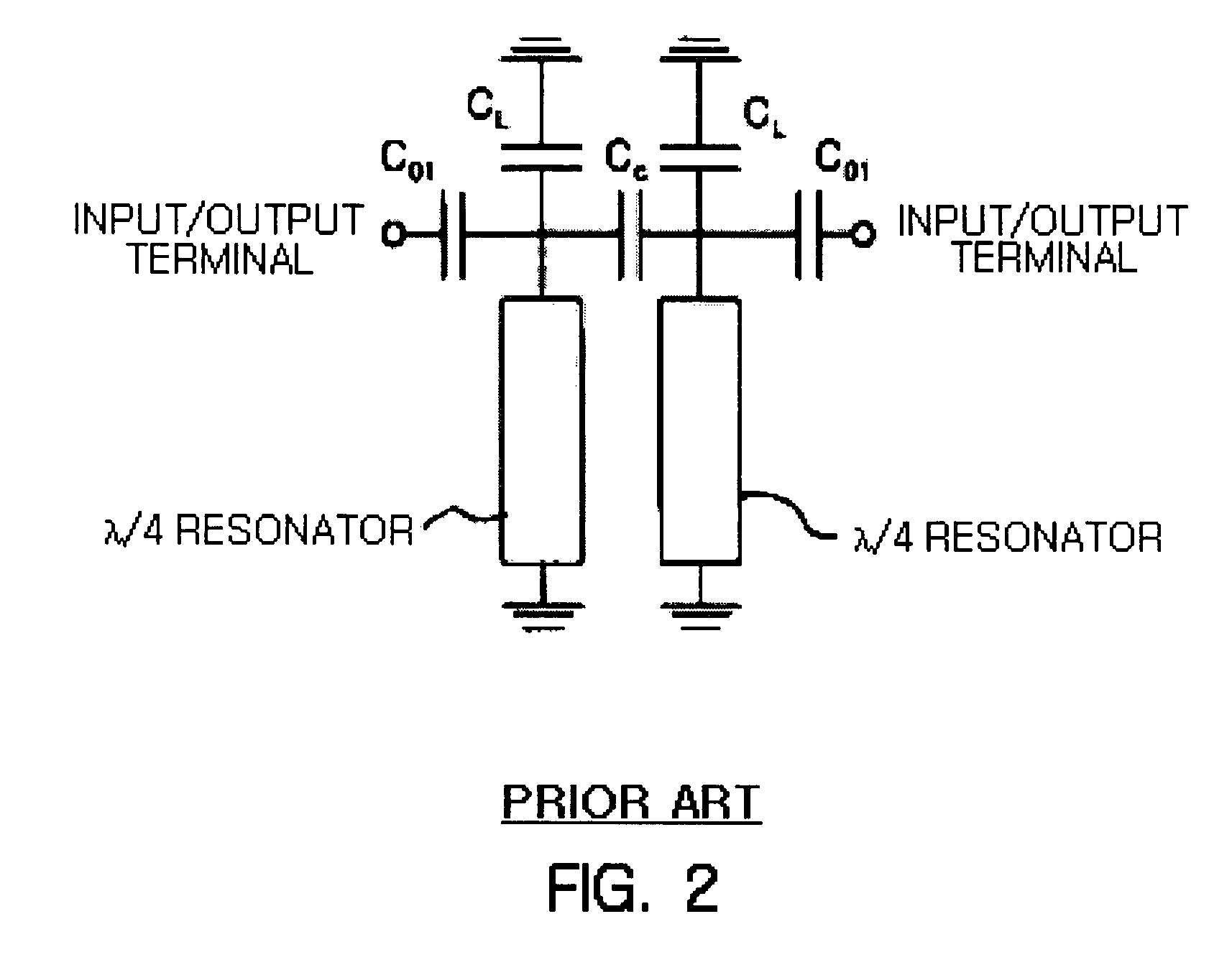

Multi-layered band pass filter

InactiveUS20080100401A1Stop characteristicSmall sizeMultiple-port networksWaveguidesCapacitanceMeander

There is provided a multi-layered band pass filter capable of improving a stop characteristic out of a pass band and reducing the entire size of the filter. The multi-layered band pass filter includes a ceramic laminated body having at least first to fifth dielectric layers laminated sequentially therein; first and second resonators having symmetrical patterns of first and second inductors formed on the first dielectric layer, and symmetrical patterns of first and second capacitors formed on the second dielectric layer so that they are at least partially overlapped with the patterns of the first and second inductors; a pattern of first and second load capacitors electrically capacitively coupled respectively to ends of the first and second resonators formed on the third dielectric layer; a pattern of first and second notching capacitors electrically capacitively coupled respectively to the other ends of the first and second resonators formed on the third dielectric layer; and first and second ground planes formed respectively on the fourth and fifth dielectric layers, wherein each of the patterns of the first and second inductors is composed of a low impedance portion formed of wide-width lines and a high impedance portion formed of meander-type narrow-width lines from the low impedance portion

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

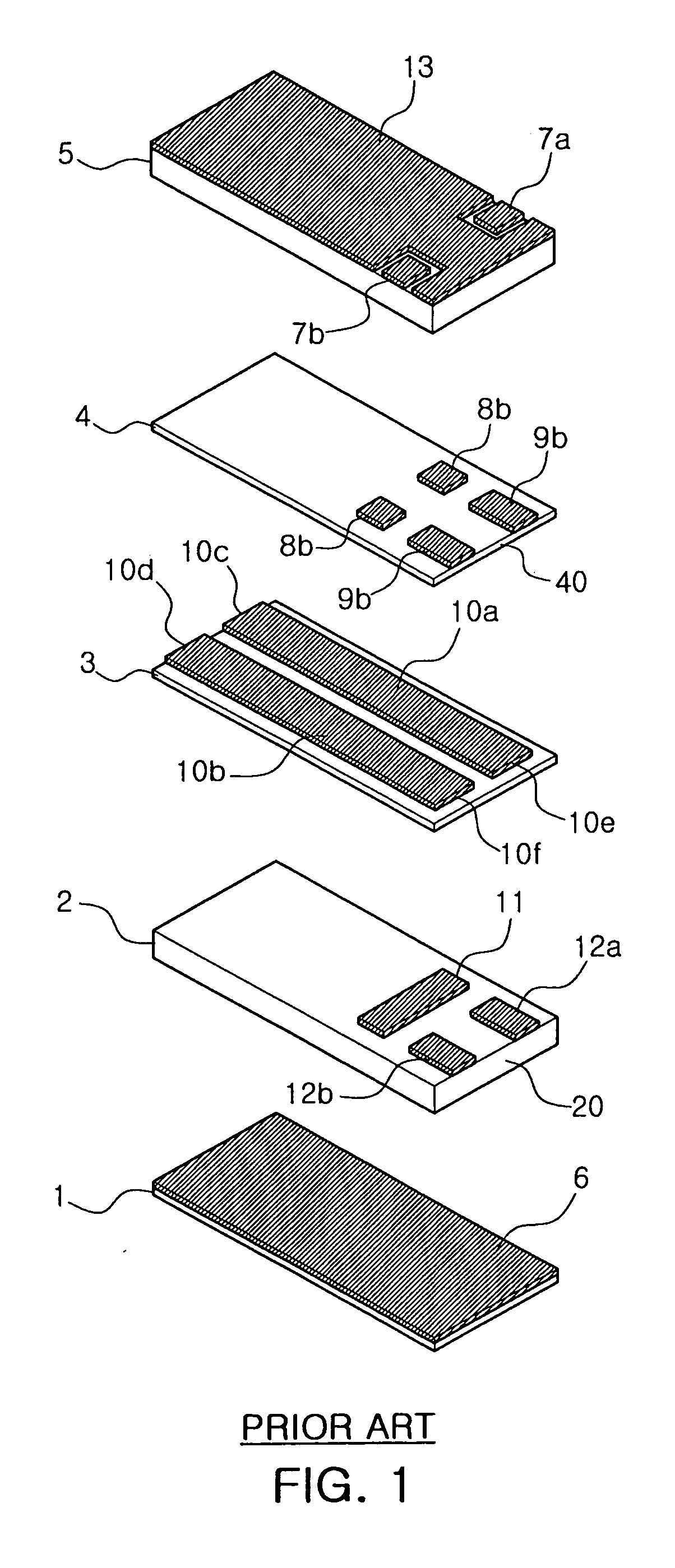

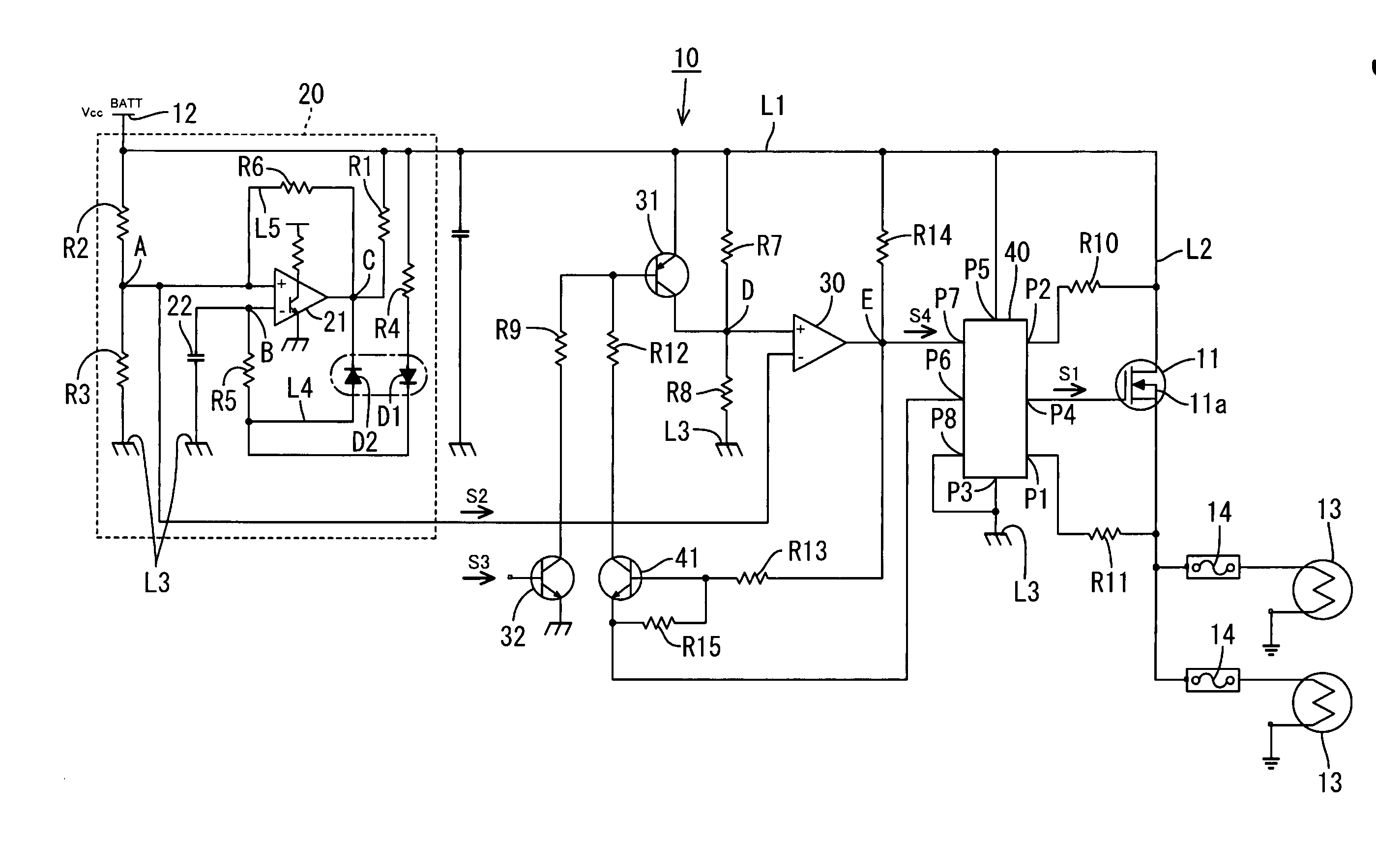

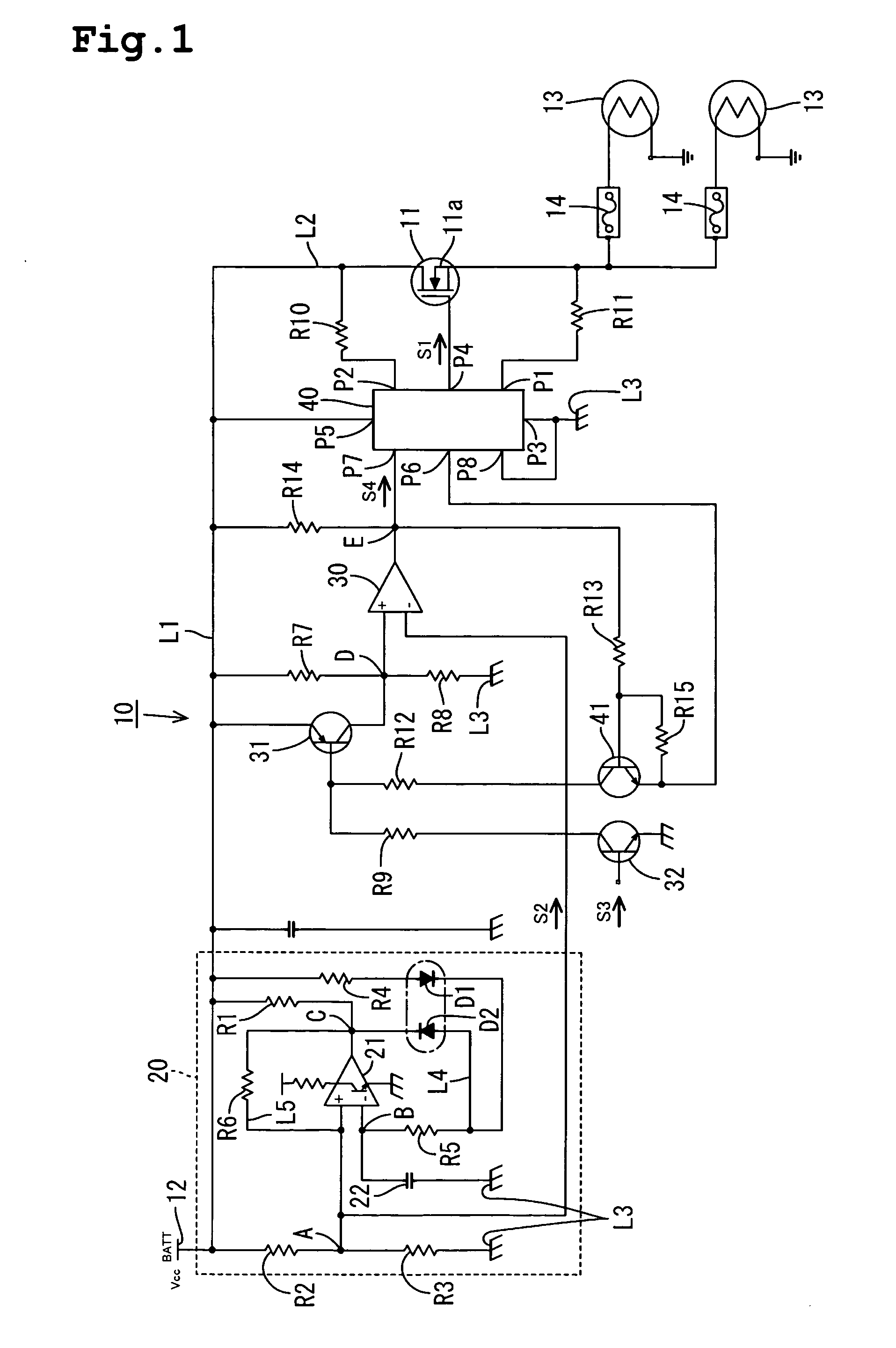

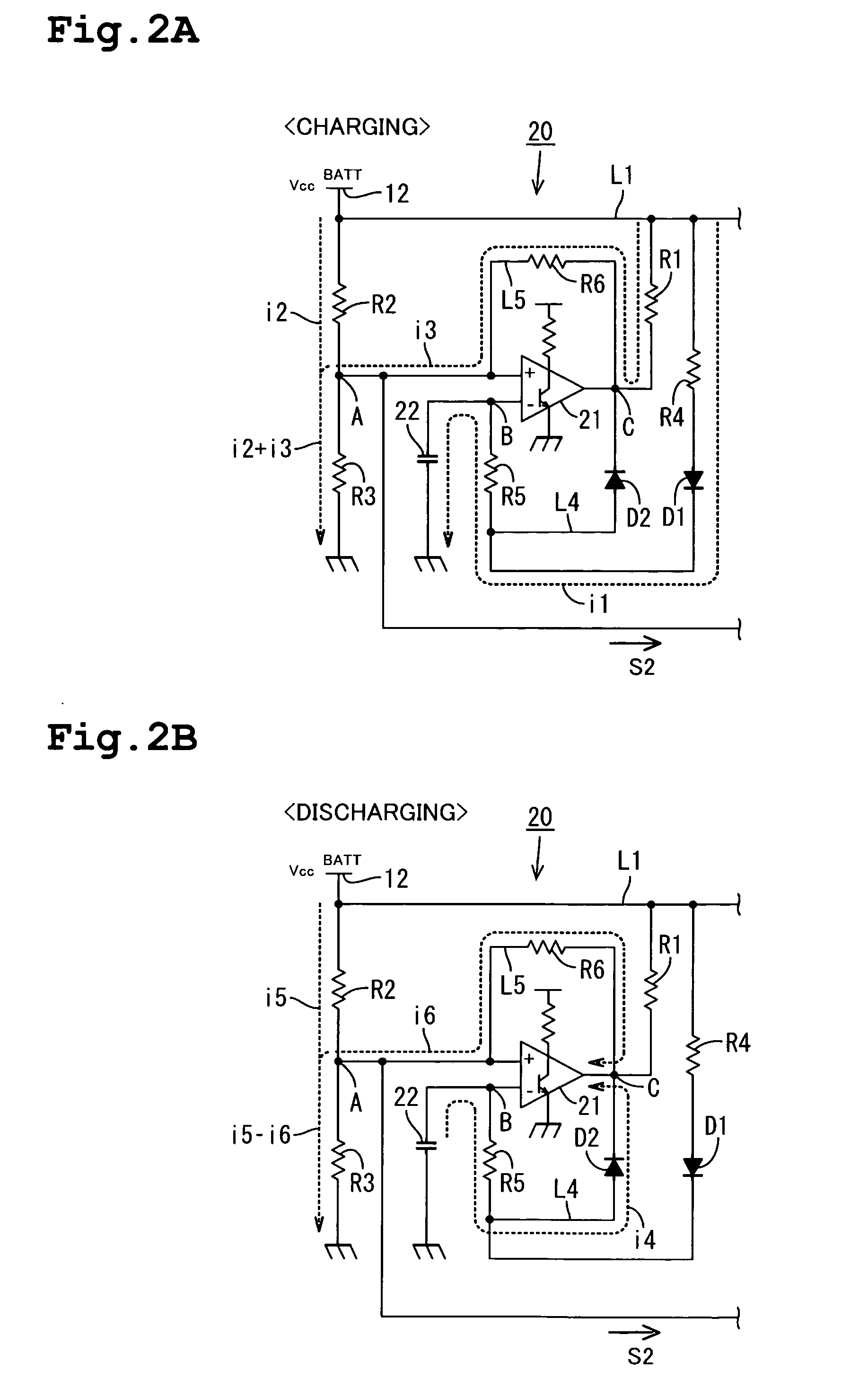

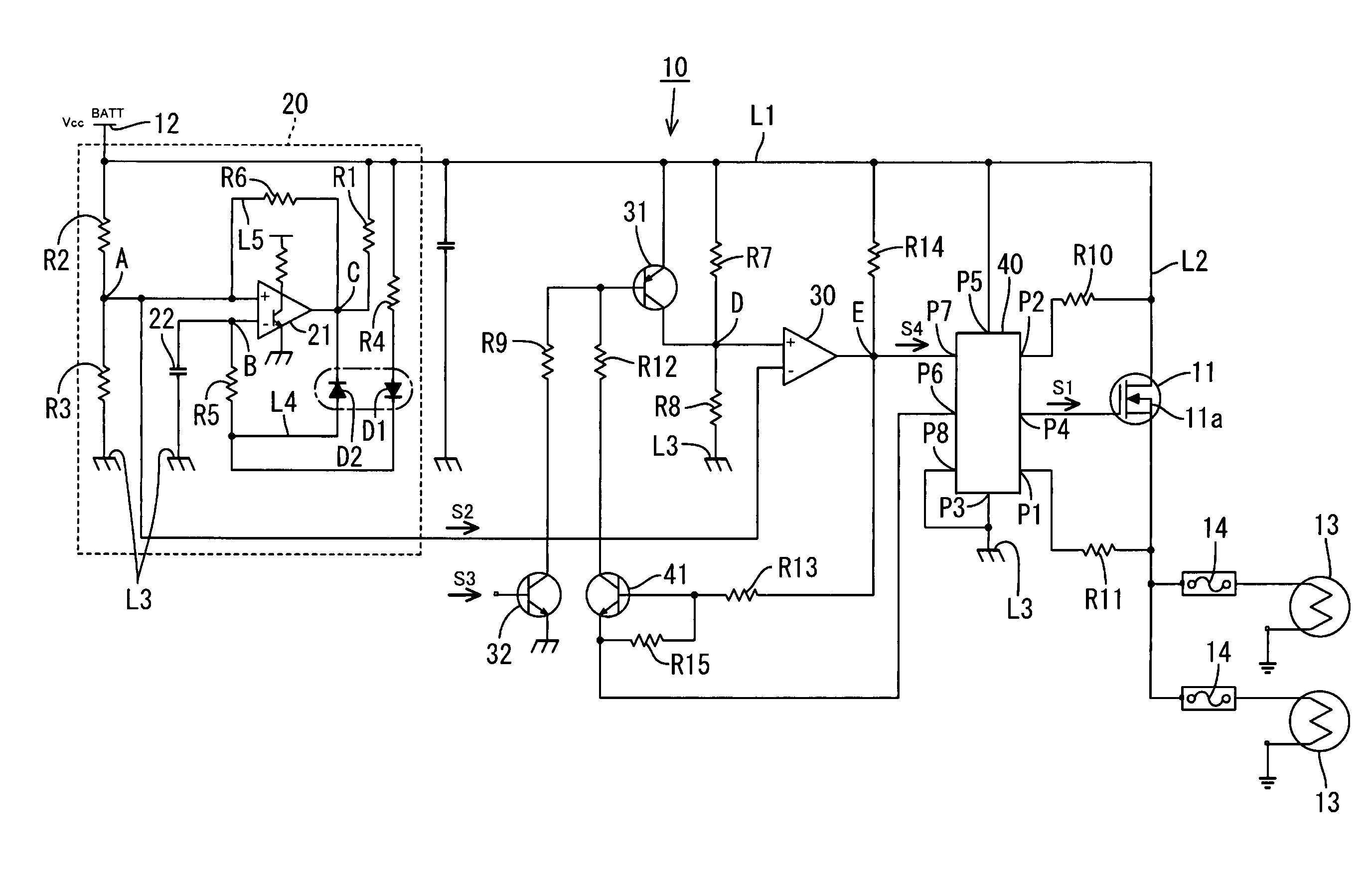

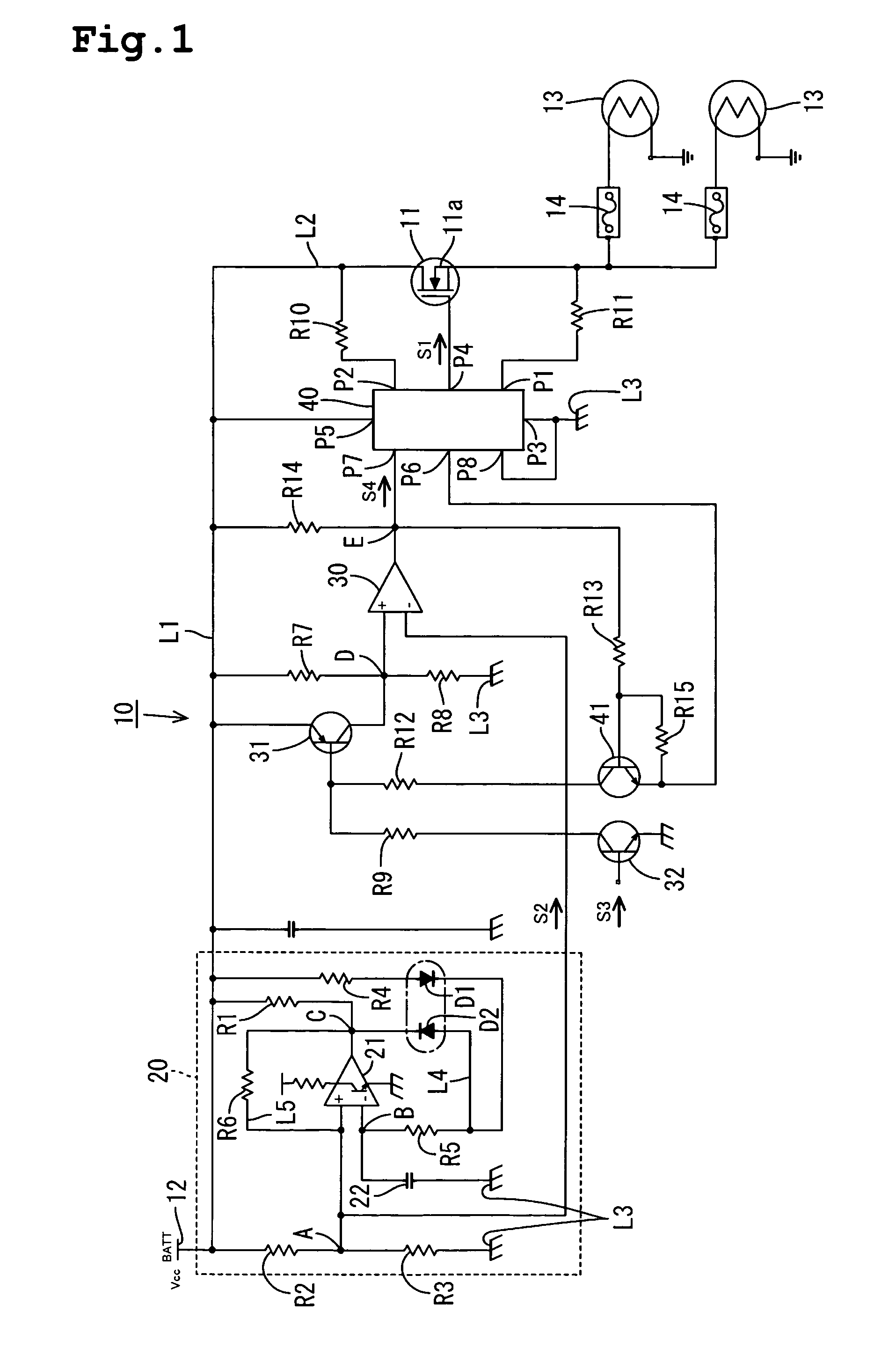

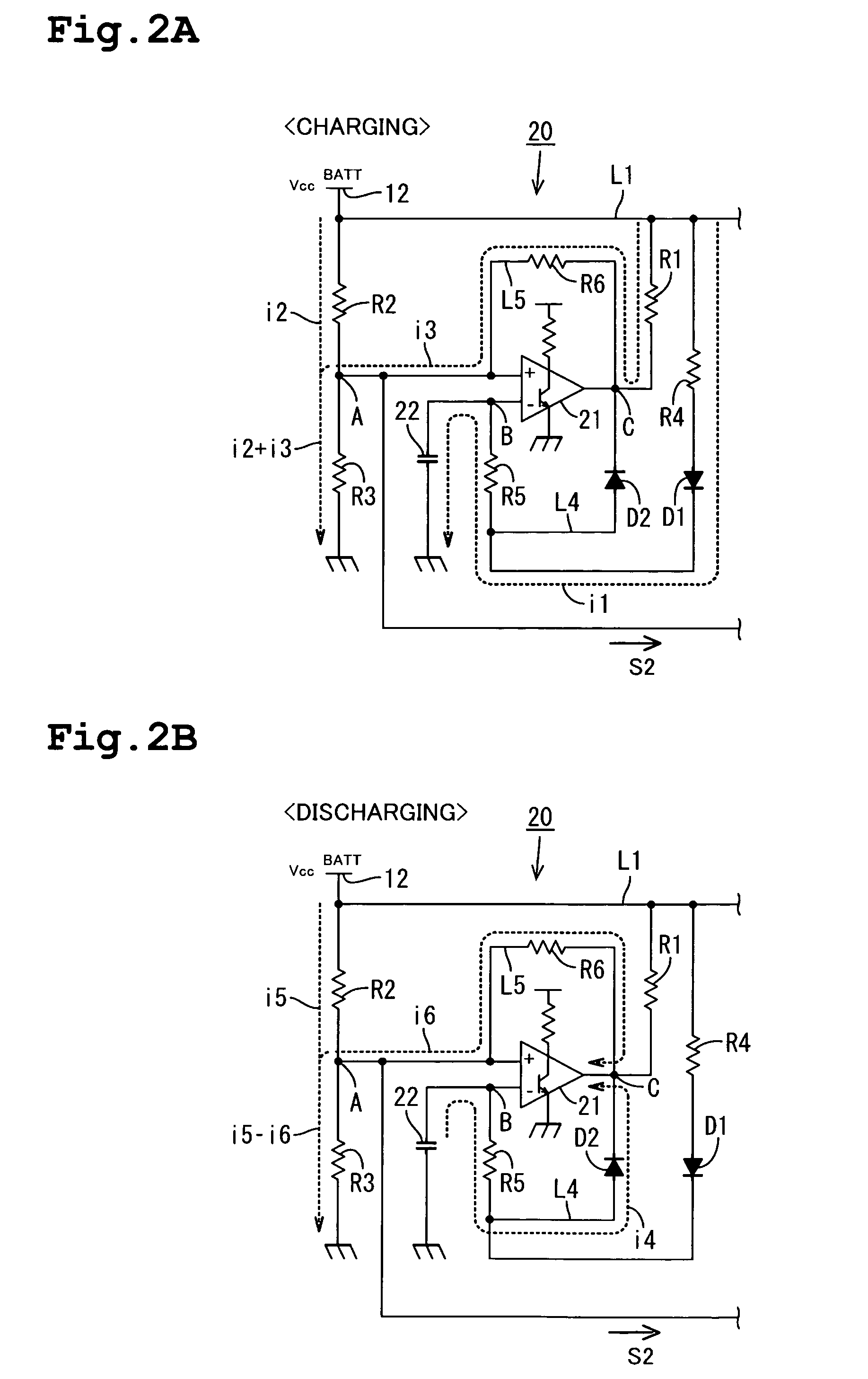

PWM signal generation circuit and PWM control circuit

InactiveUS20060097765A1Reduce chargeEasy to adjustElectric pulse generatorPulse shapingEngineeringPwm signals

A PWM signal generation circuit and a PWM control circuit are provided in which the duty ratio is easily changed and which can also avoid adverse impact from ambient temperature changes and the like. At the beginning of charging a capacitor with a current flow, a voltage level at a connection point between the negative input terminal of a comparator and the capacitor is still below a charging threshold. When the charging threshold is exceeded, the comparator is inverted to a low state and a current flows into an output point of the comparator to start discharging the capacitor. At the beginning of discharging from the capacitor, the voltage level at the connection point is still above the discharging threshold. However, when the voltage level falls below the discharging threshold, the comparator returns to a high state, and the charging operation again takes over.

Owner:AUTONETWORKS TECH LTD +2

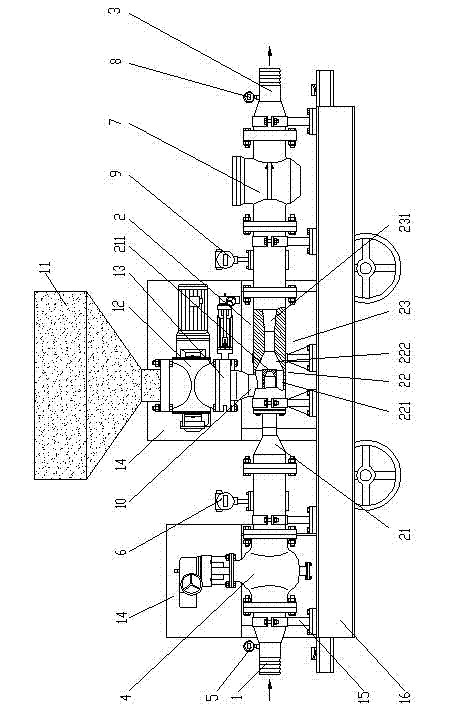

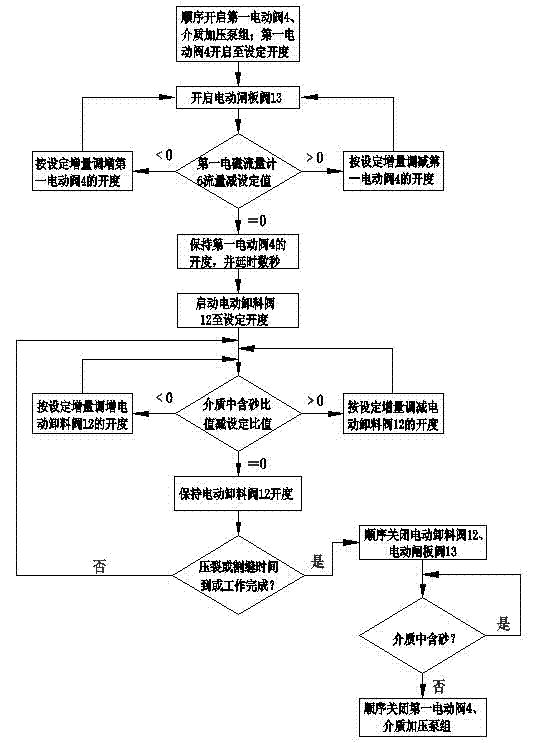

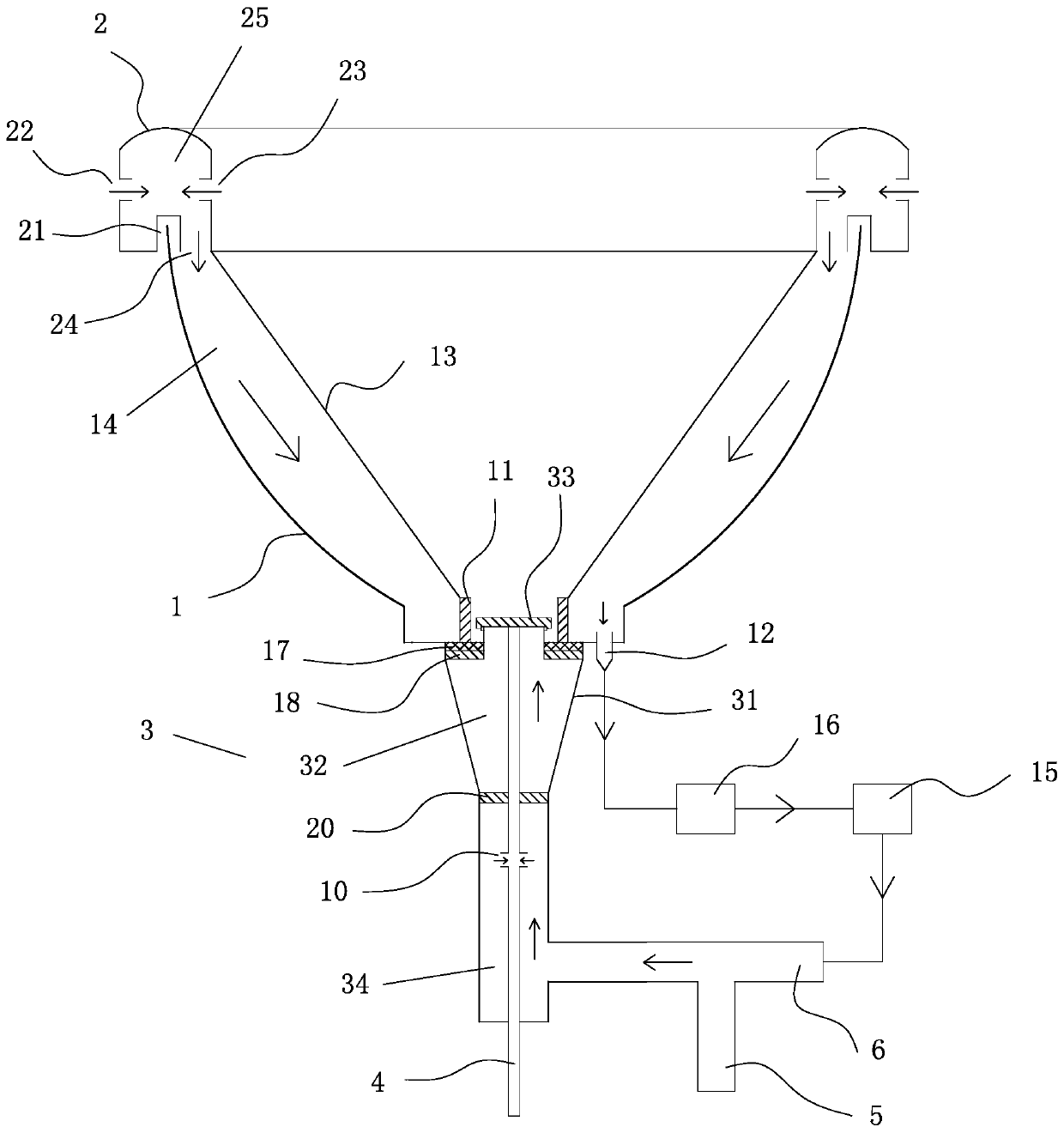

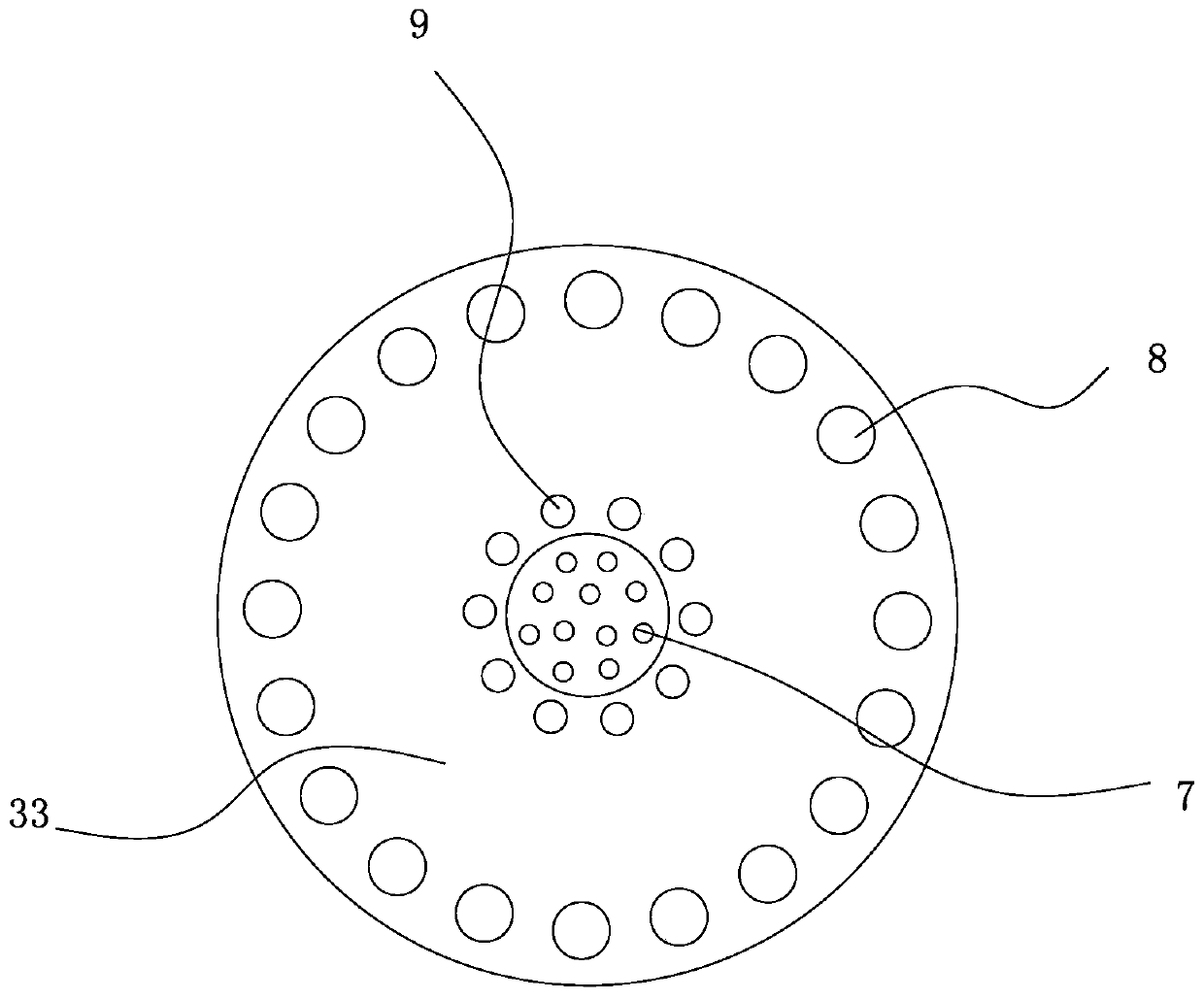

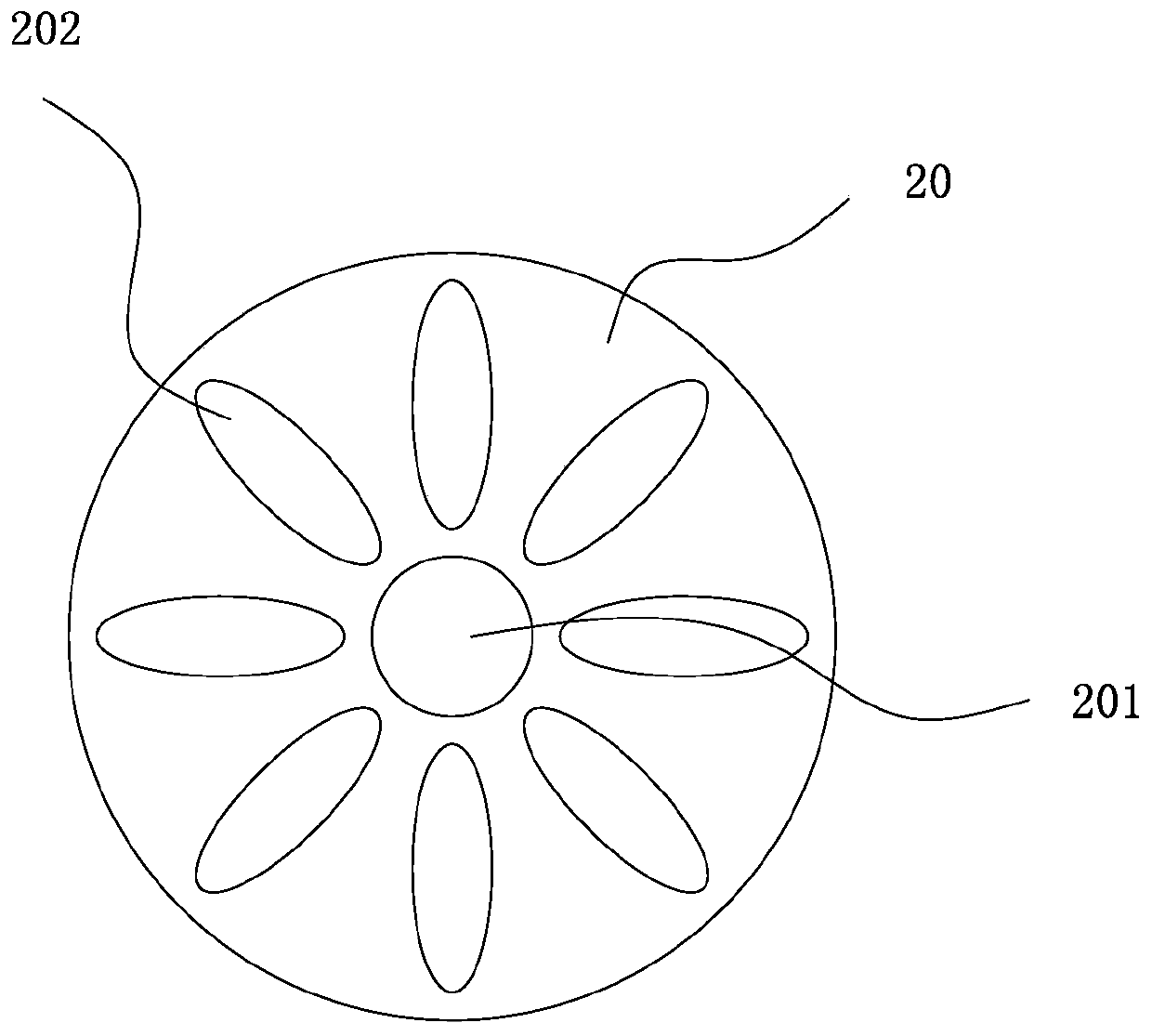

Sand charging device used during fracturing or slotting under coal mine and sand charging control method

InactiveCN102900417AGuaranteed tightnessImprove stabilityFluid removalGas removalMining engineeringCharge control

The invention discloses a sand charging device used during fracturing or slotting under a coal mine and a sand charging control method. The device comprises a water inlet pipe, a mixing pipe and a water outlet pipe which are sequentially connected, wherein a first electric valve, a first digital pressure meter, a first electromagnetic flowmeter are arranged on a pipeline of the water inlet pipe; an outlet end of the water outlet pipe is connected with a medium inlet of a medium booster pump; a check valve, a second digital pressure meter and a second electromagnetic flowmeter are arranged on a pipeline of the water outlet pipe; a hopper for accommodating sand is communicated with the upper part of the mixing pipe through a sand feeding pipe, and an electric unloading valve and an electric gate valve are arranged on a pipeline of the sand feeding pipe; the first electric valve, the electric unloading valve and the electric gate valve are anti-explosive; and the water inlet pipe, the mixing pipe and the water outlet pipe are respectively fixed on a flat mine vehicle. By the device, the sand charging time and sand charging amount are controlled by the conventional control technology. The sand charging device is simple in structure, small in size and safely used; and by the method, the coal seam cracking efficiency can be improved, and an anti-reflection effect of cracked coal and rock mass is guaranteed.

Owner:重庆市能源投资集团科技有限责任公司

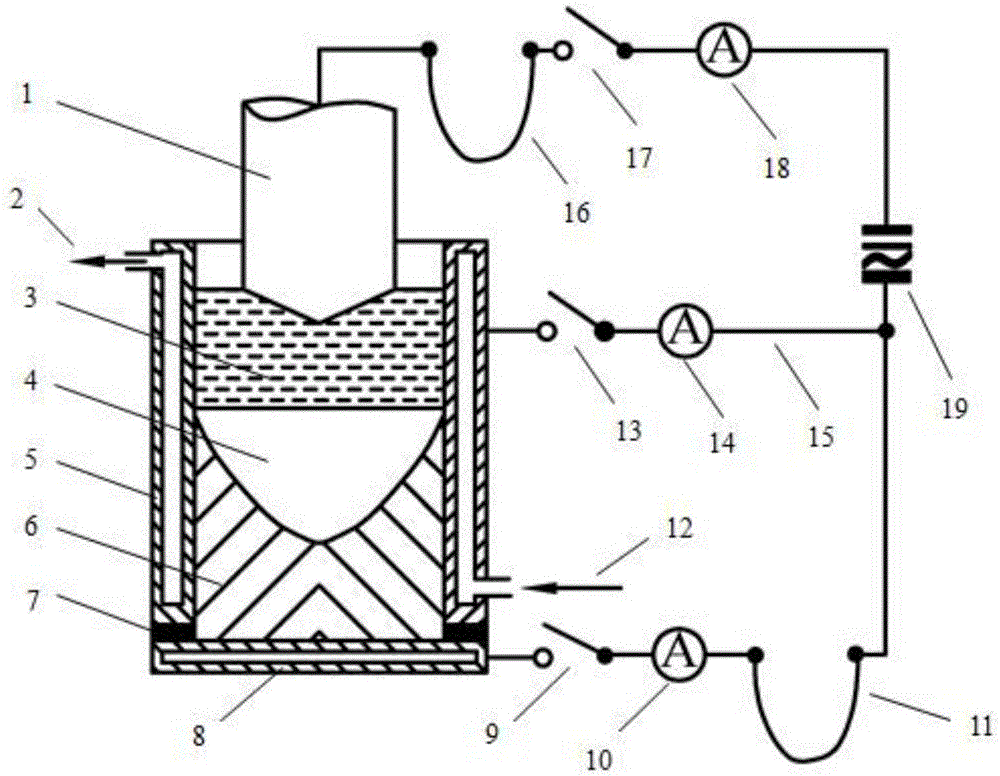

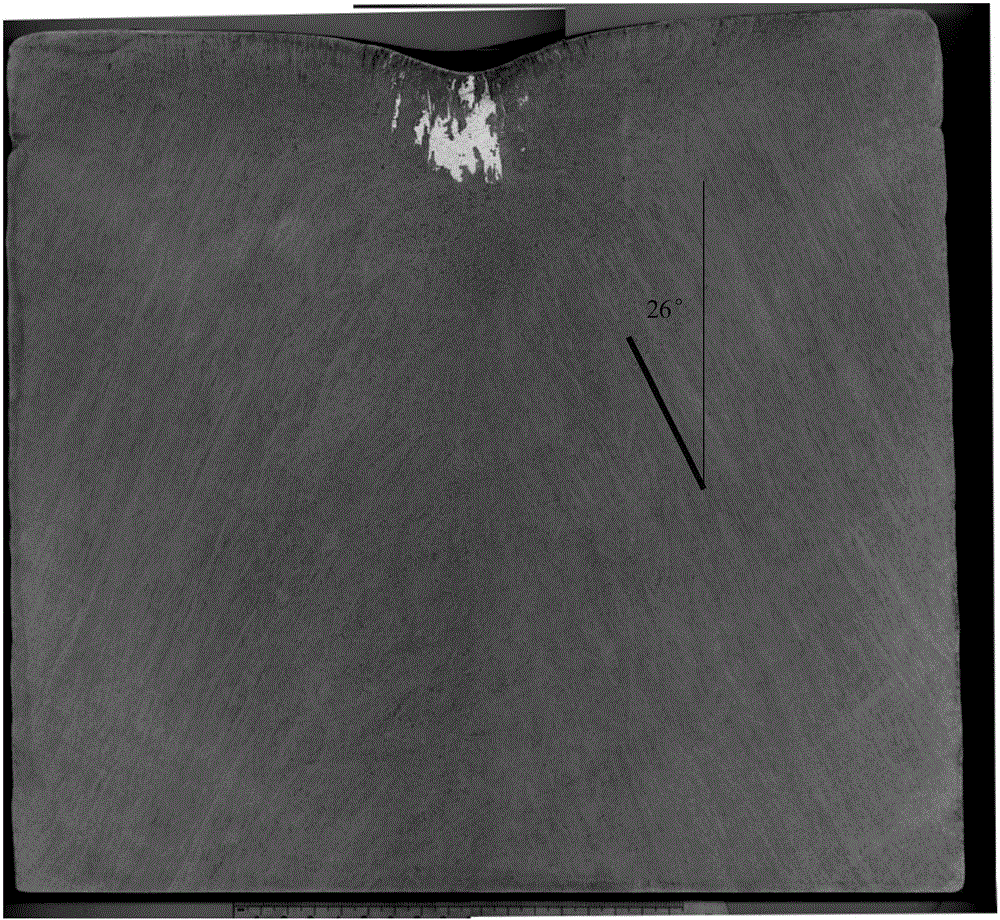

Method for controlling direction of solidification structure of cast ingot through electricity conductive crystallizer electroslag remelting

The invention discloses a method for controlling the direction of a solidification structure of a cast ingot through electricity conductive crystallizer electroslag remelting and belongs to the technical field of metallurgy. The method comprises the steps that (1) a slag material with the high conductivity is prepared and then baked; (2) the filling rate and the insertion depth of an electrode are determined, and a base wad, an arc striking agent and an electricity conductive crystallizer are right placed; and (3) a path of an electric current flowing through a power source, the consumable electrode, the slag material, a bottom water tank and the power source is selected, and arc striking, material charging and slag melting are conducted; after the slag material is melted down, a remelting electric current and the remelting voltage are set; the path of the electric current is set through closing of a switch in the electroslag remelting process, the distribution ratio of electric currents flowing through the crystallizer and the bottom water tank is controlled, the shape and the depth of a metallic molten pool are changed, and the direction of the solidification structure is controlled; and in the later period of remelting, electricity is cut off after electroslag remelting feeding operation, cooling is conducted, and the remelted cast ingot is obtained. According to the method for controlling the direction of the solidification structure of the cast ingot through electricity conductive crystallizer electroslag remelting, a slag system with the high conductivity distribution ratio is adopted, and the tendency of axial crystallization of the solidification structure of the cast ingot is improved; and the crystallization direction of the solidification structure of the cast ingot is controlled in the remelting process, and the prepared cast ingot has good surface quality.

Owner:NORTHEASTERN UNIV

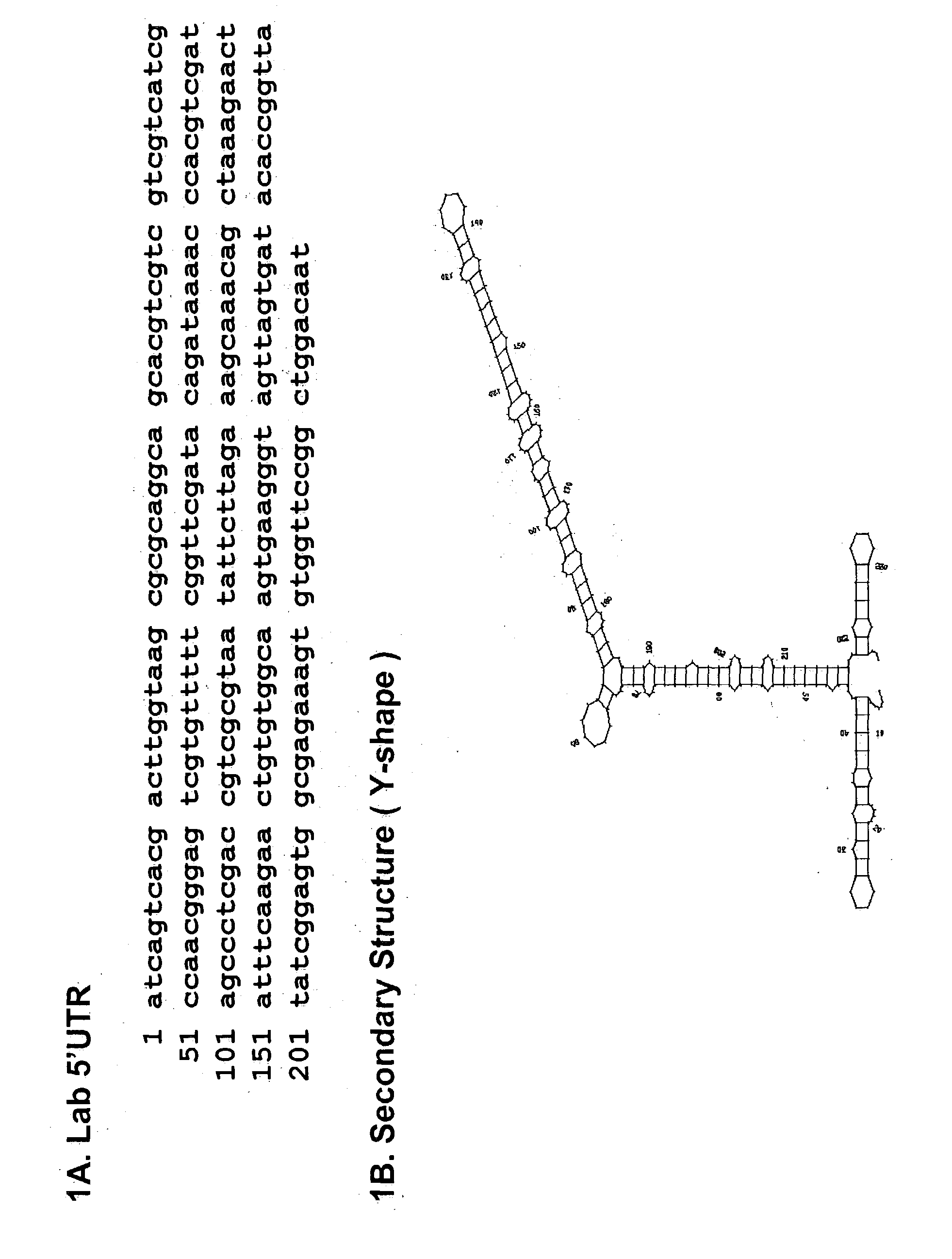

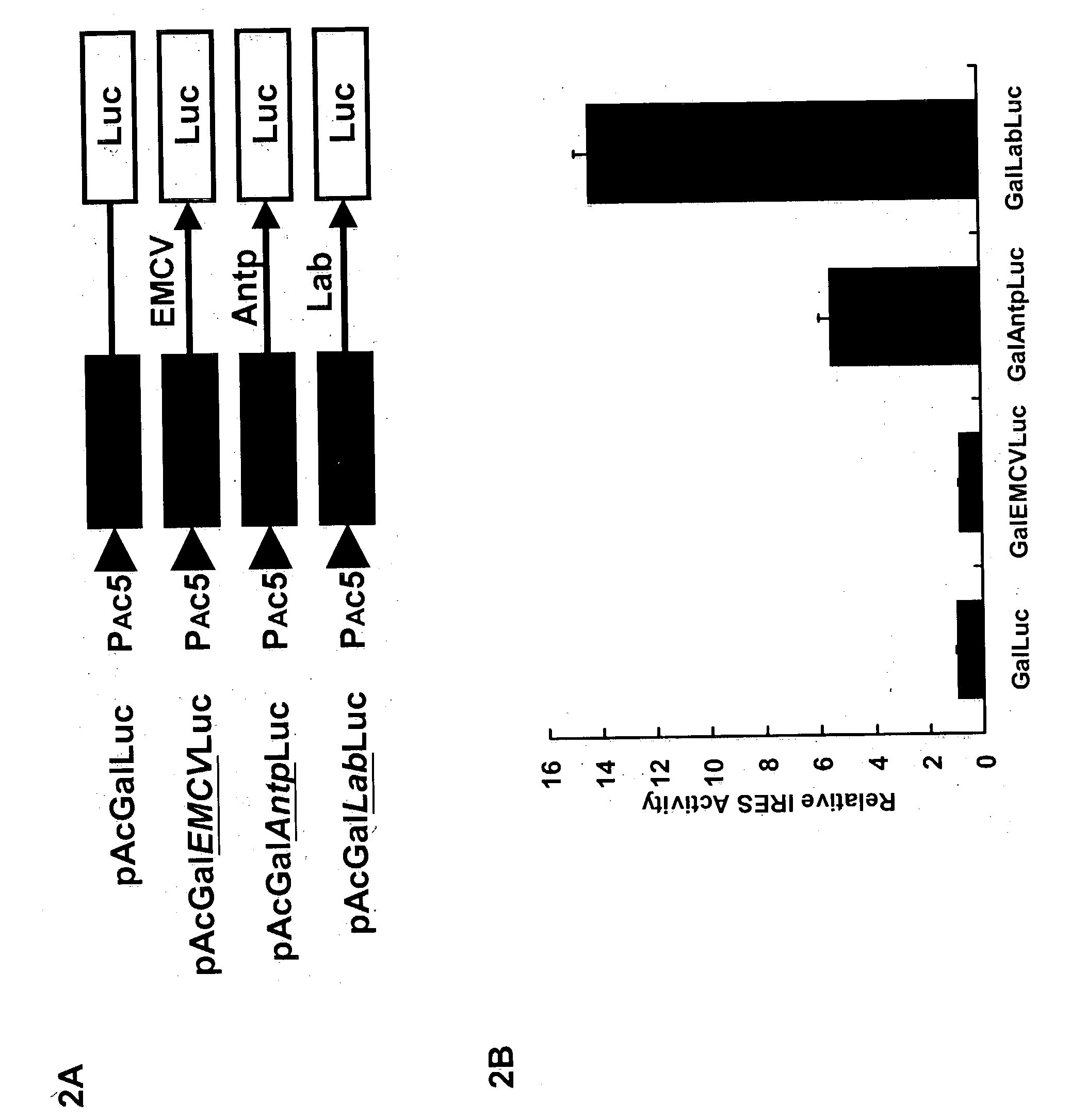

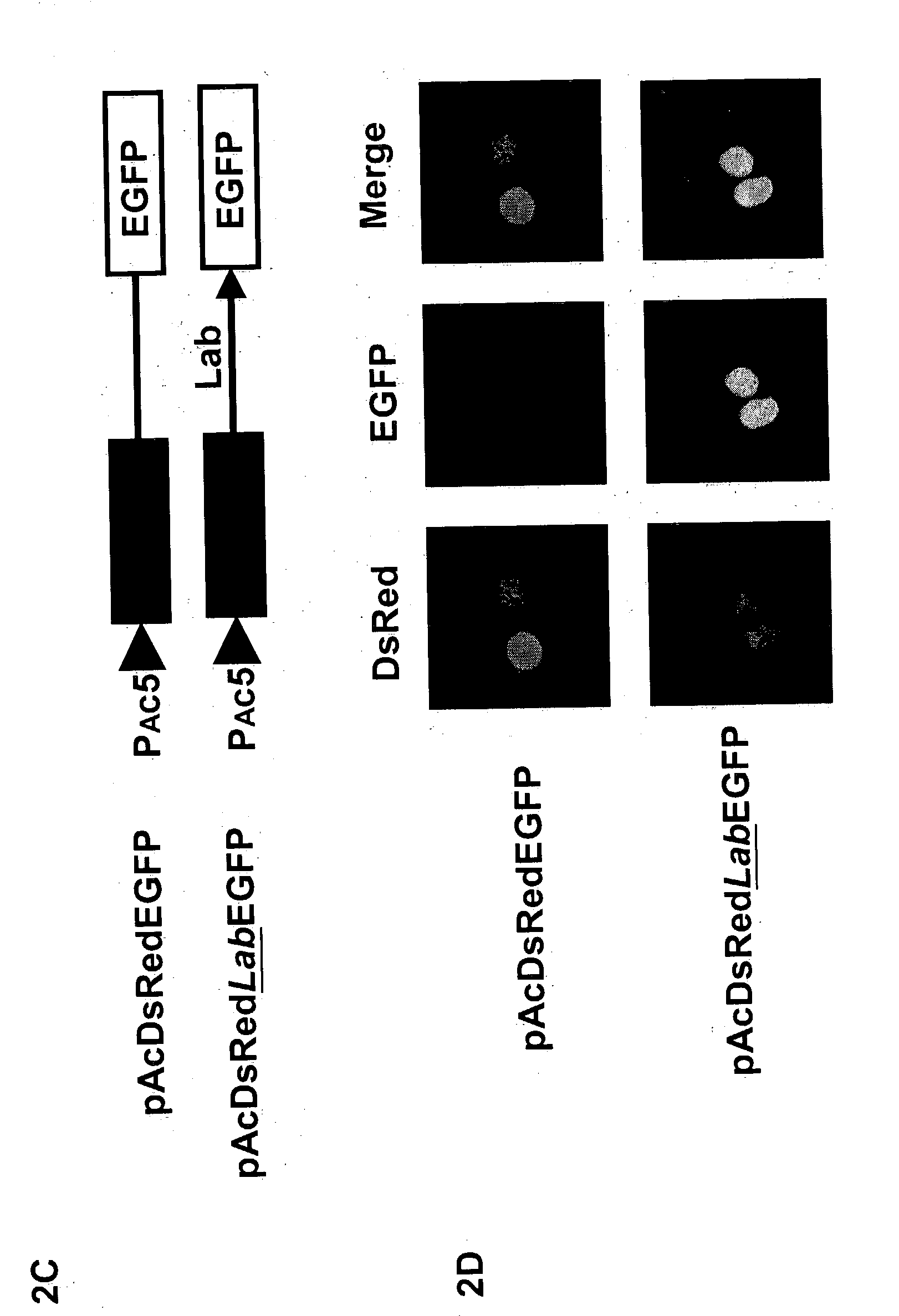

Internal ribosome entry site of the labial gene for protein expression

InactiveUS20040082034A1Efficiently translatedConstant ratioAnimal cellsVectorsInternal ribosome entry siteCell type

The invention describes compositions and methods for recombinant protein expression in a wide range of cell types. The compositions comprise an IRES sequence from the Drosophila labial (lab) gene, or a variant or fragment thereof, or alternatively, a homolog of a lab IRES, or a variant or fragment thereof. Methods of using the compositions are also described.

Owner:NAT INST OF HEALTH REPRESENTED BY THE SEC OF THE DEPT OF HEALTH & HUMAN SERVICES NAT INST OF HEALTH

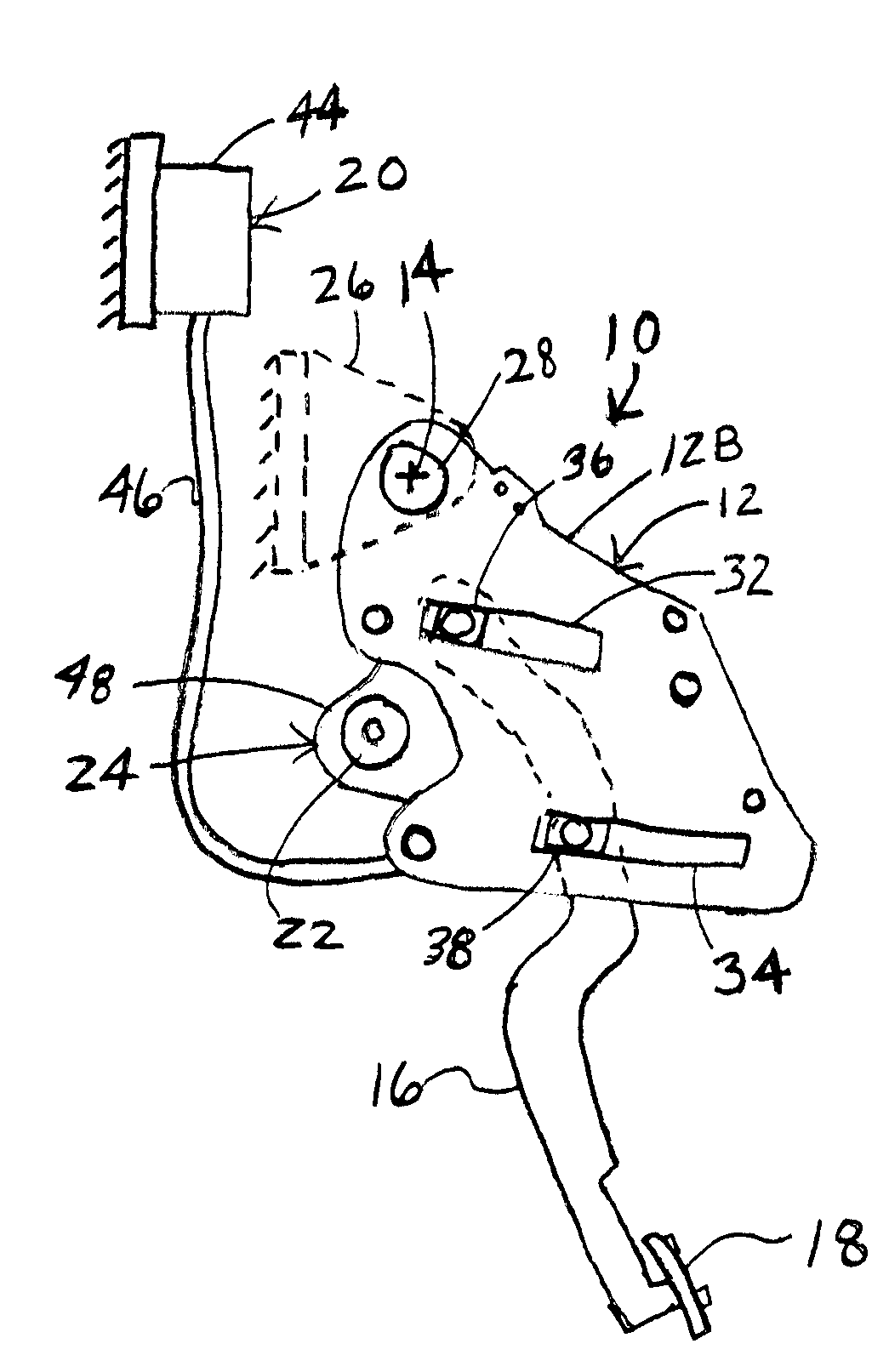

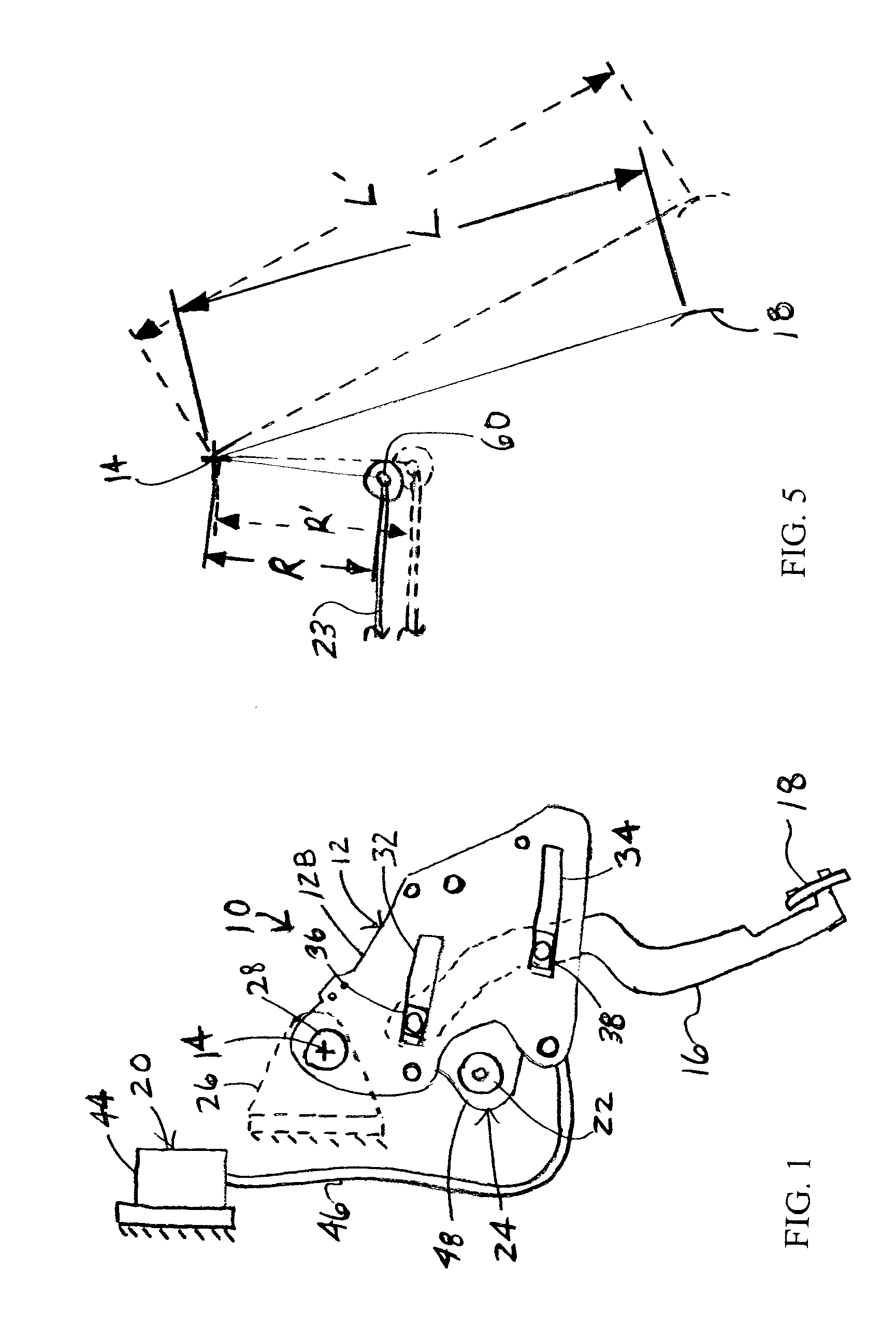

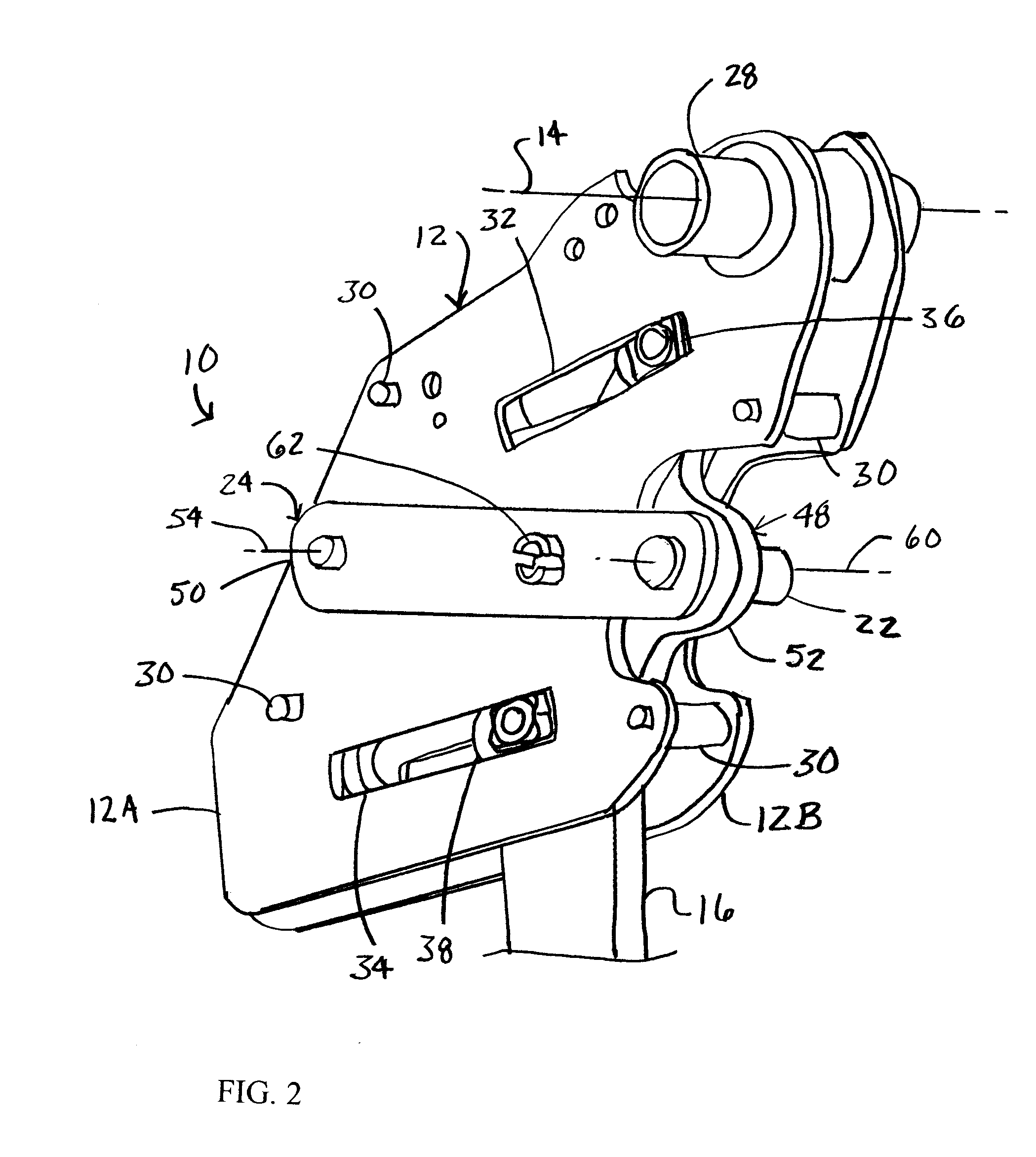

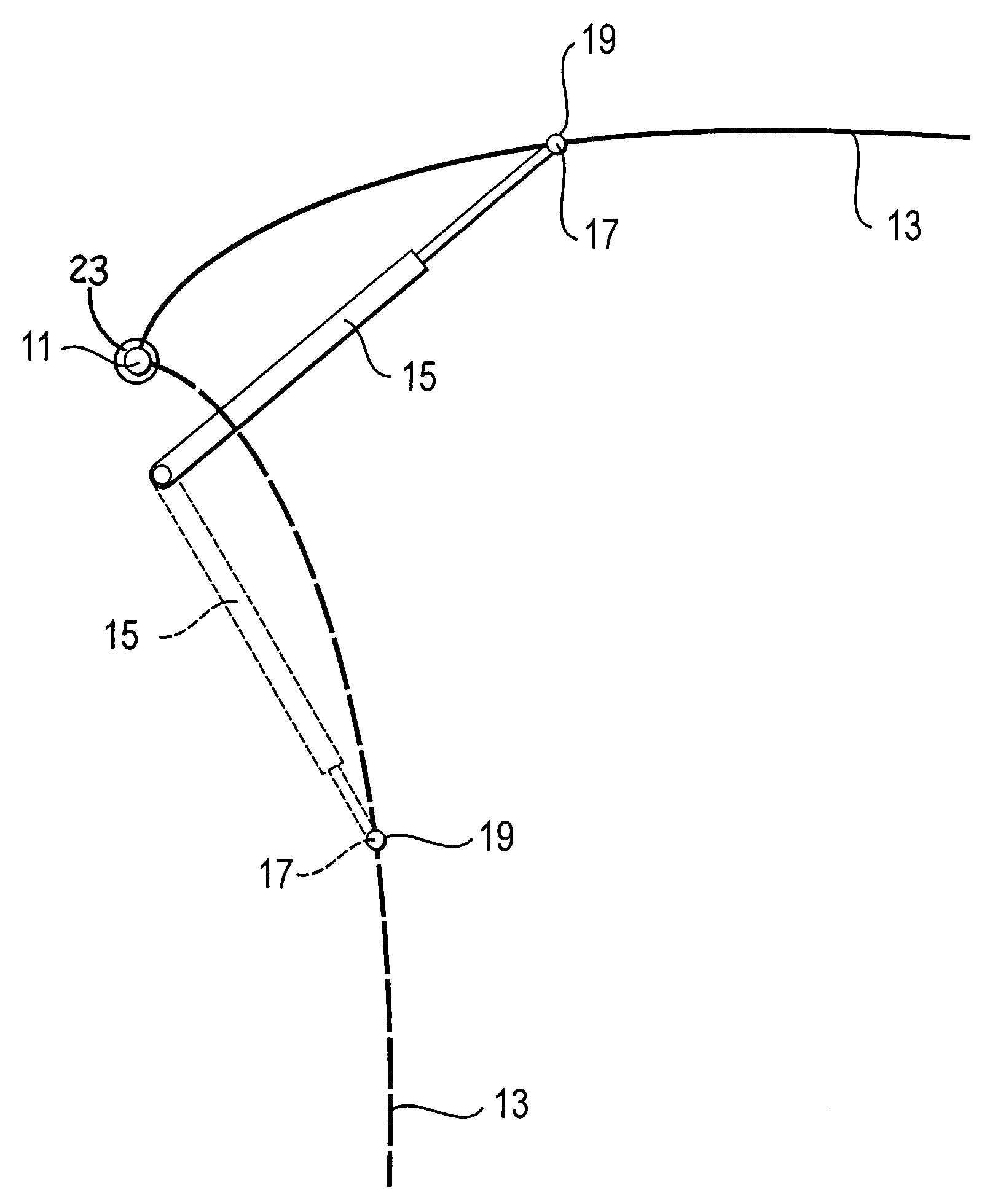

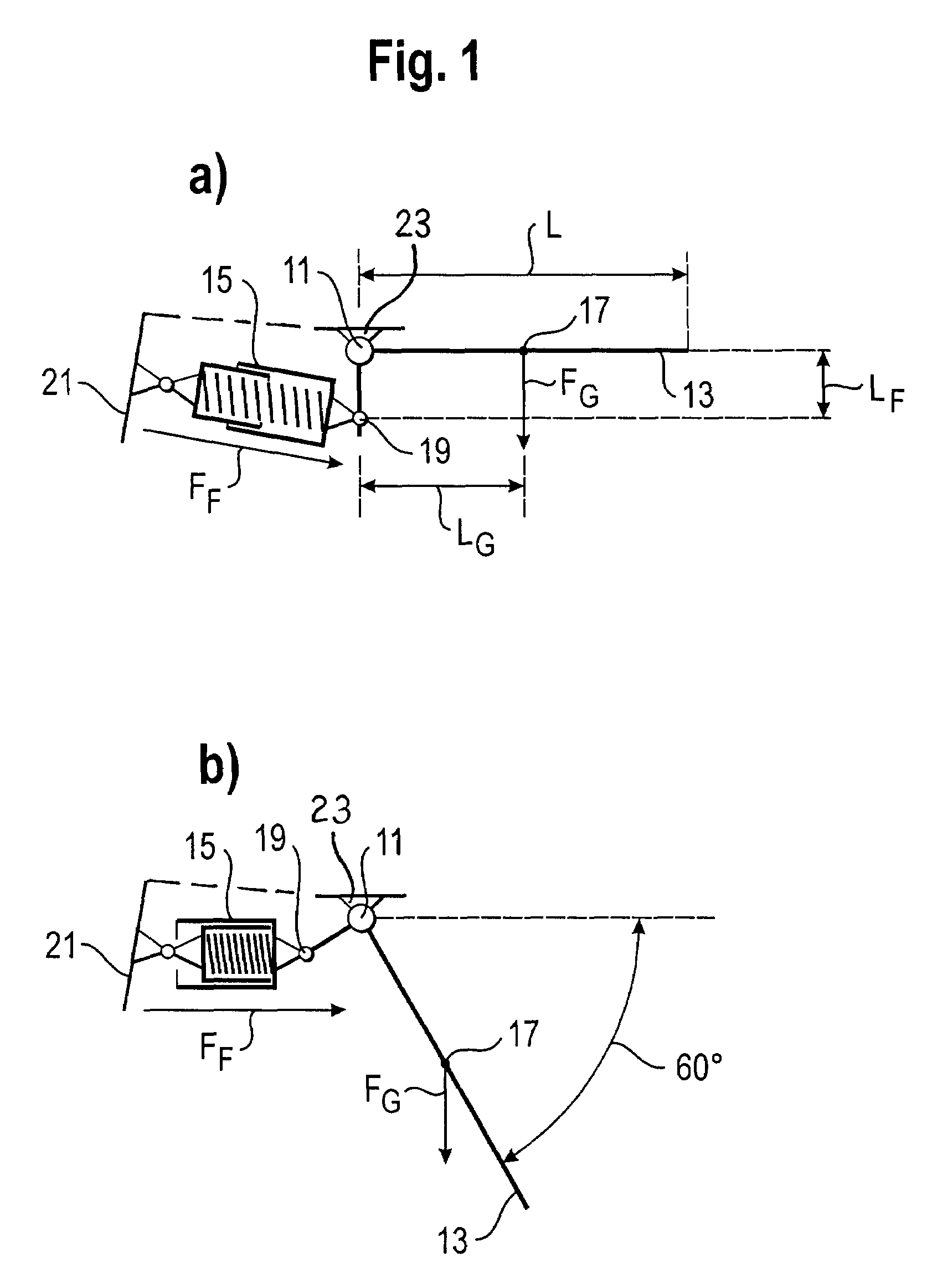

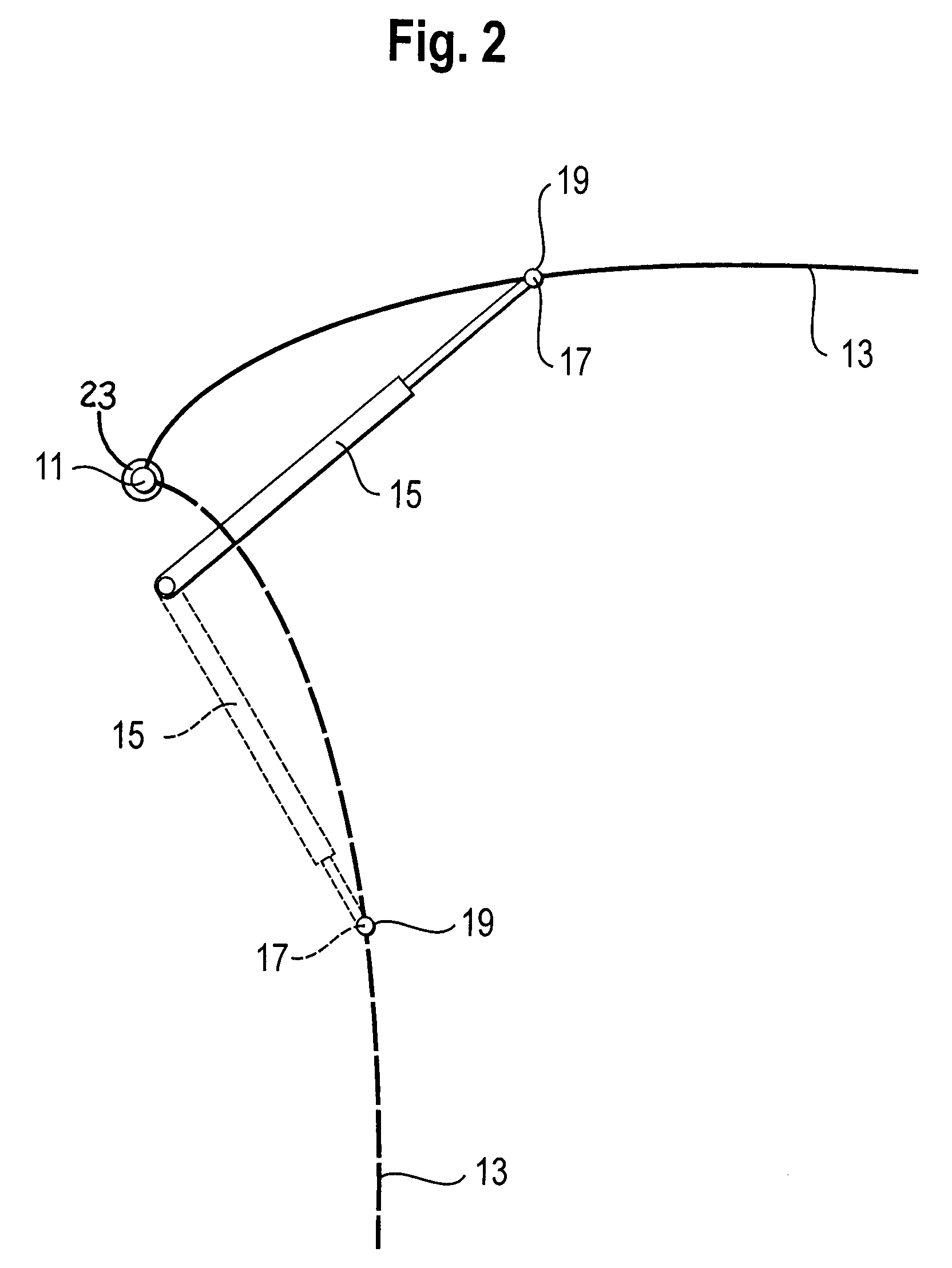

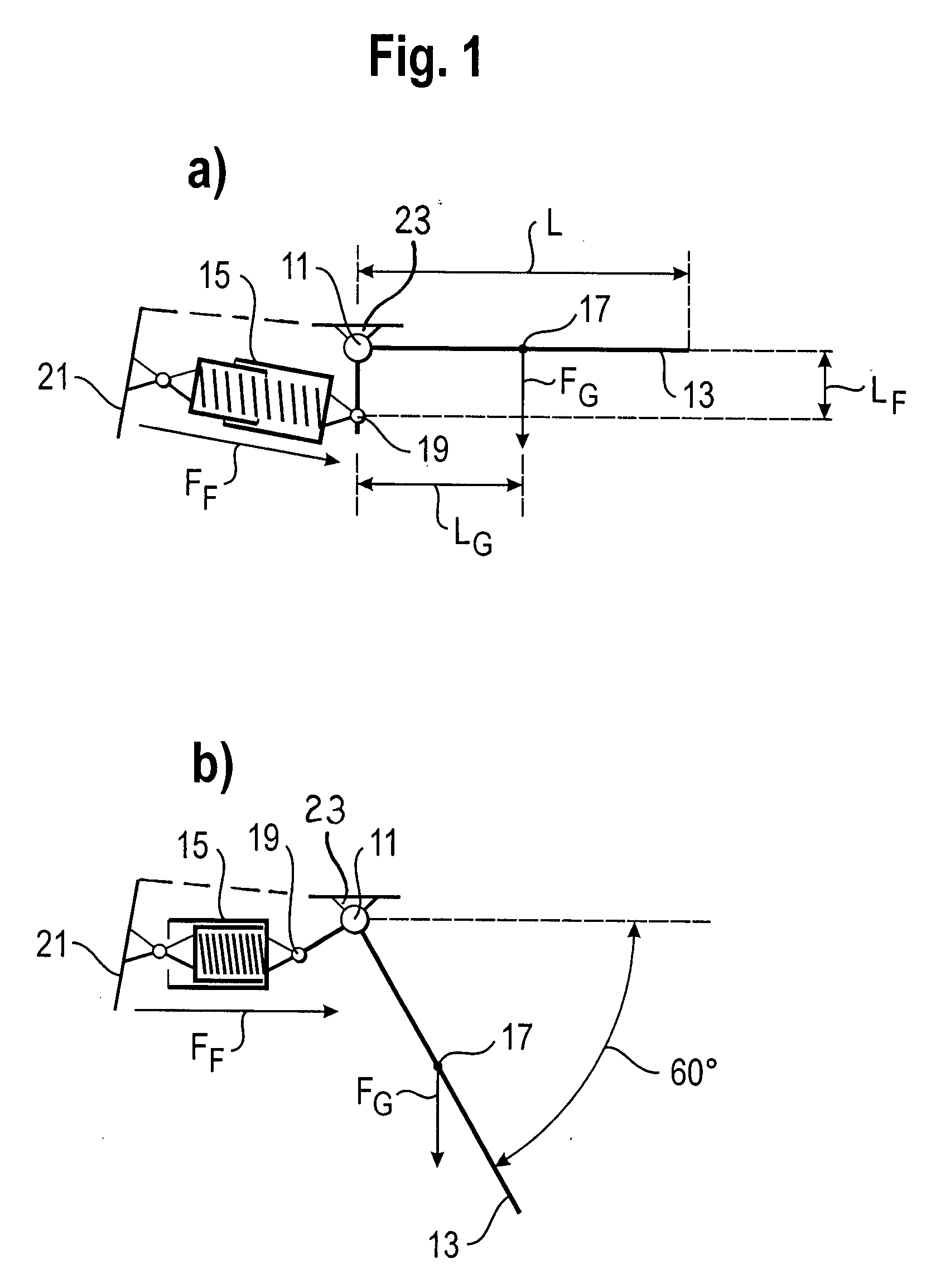

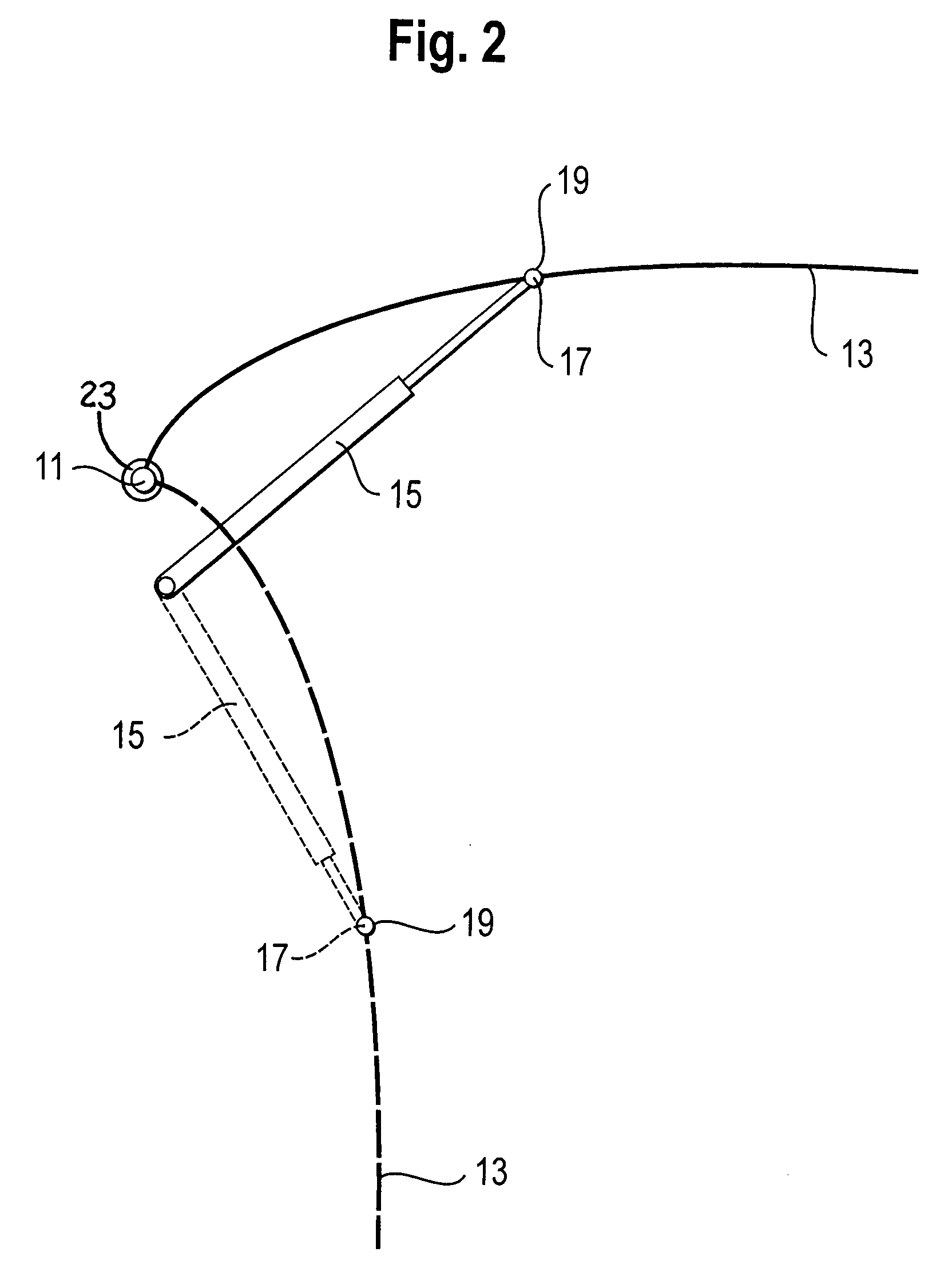

Adjustable pedal system with ratio modifier

InactiveUS20090025505A1Quality improvementConstant ratioControlling membersMechanical apparatusControl signalControl theory

An adjustable control pedal includes an upper arm and a lower arm carrying a pedal. The lower arm can be selectively moved relative to the upper arm to adjust the position of the pedal between a forward position and a rearward position. A control pin is operably connected to the upper arm for rotation with the upper arm to supply a control signal when force is applied to the pedal. An adjuster is operably connected to the control pin to adjust the position of the control pin relative to the pivot axis so that a ratio of a distance between the pivot axis and the pedal and a distance between the pivot axis and the control pin remains constant as the pedal is adjusted between the forward position and the rearward position.

Owner:DUS OPERATING INC

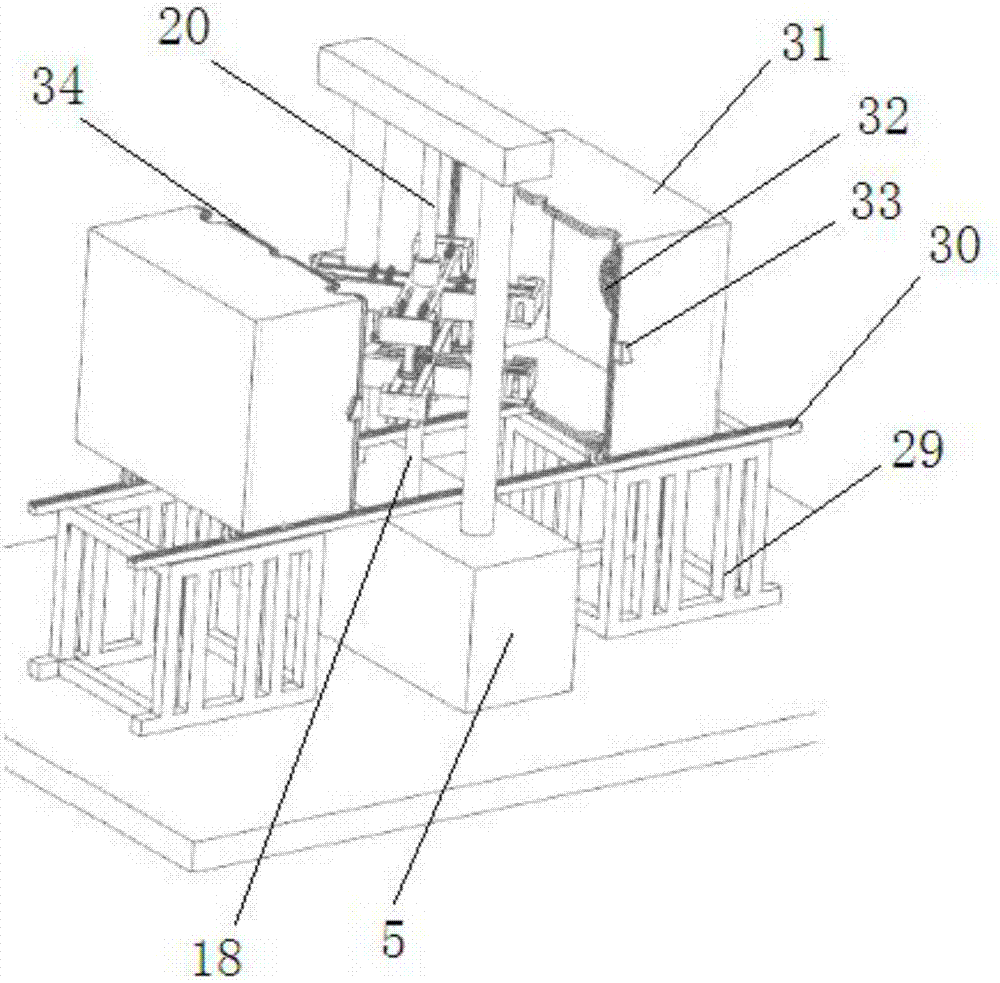

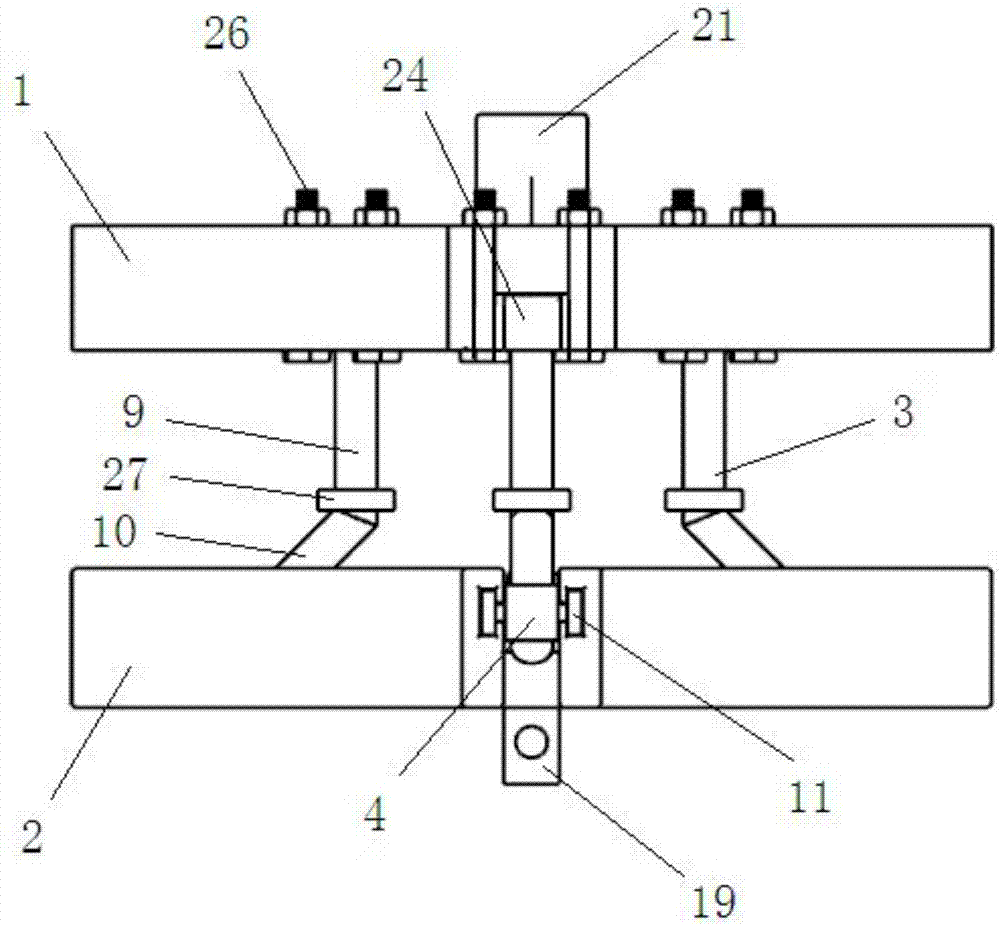

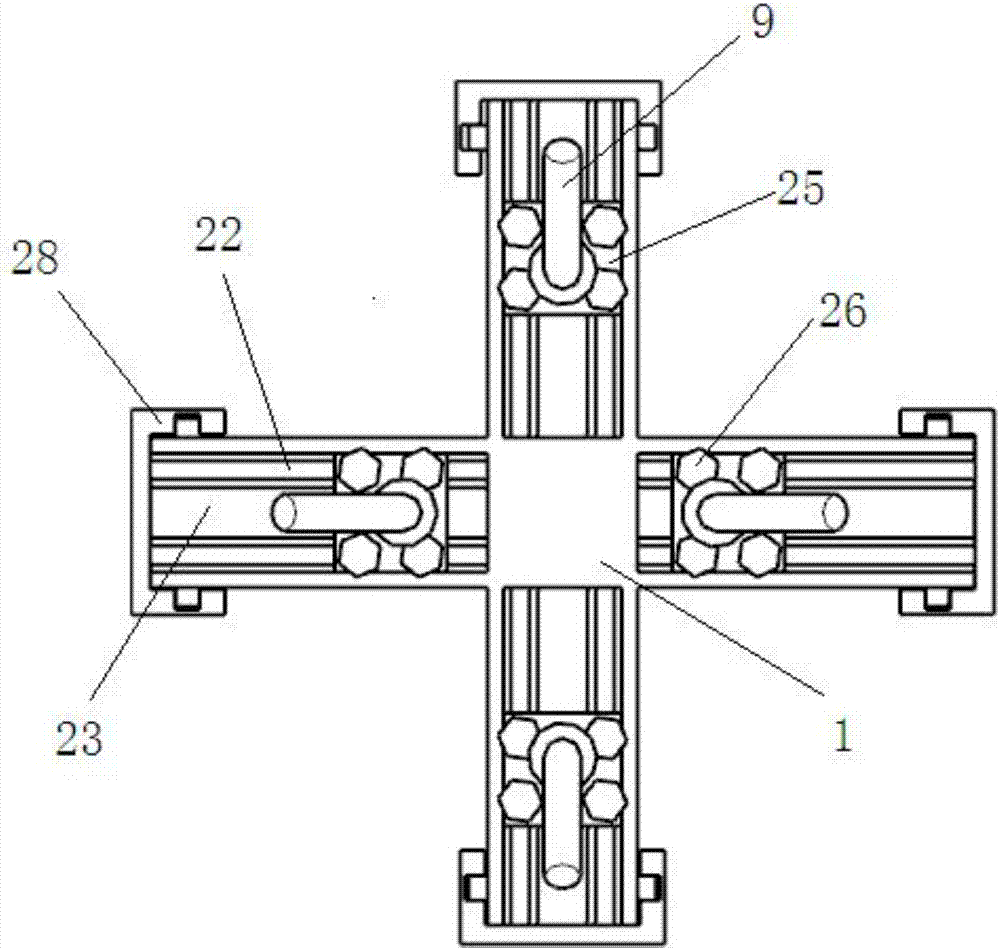

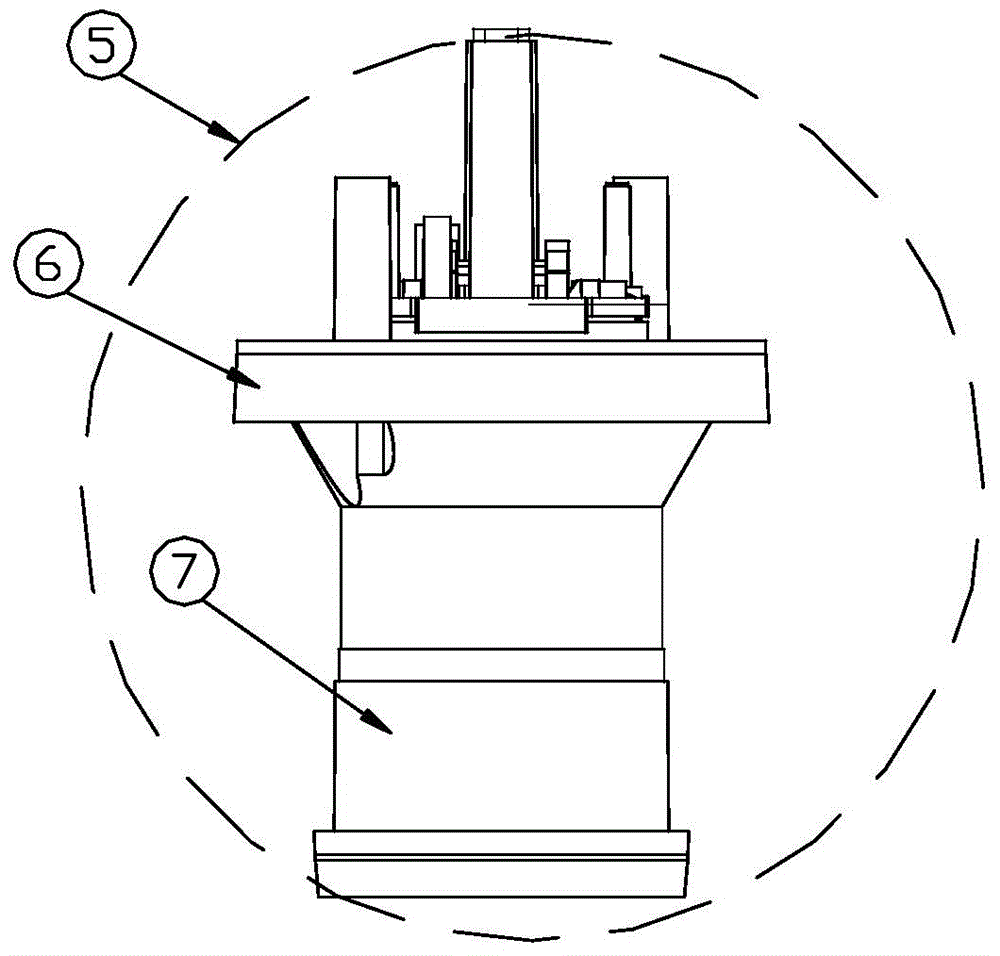

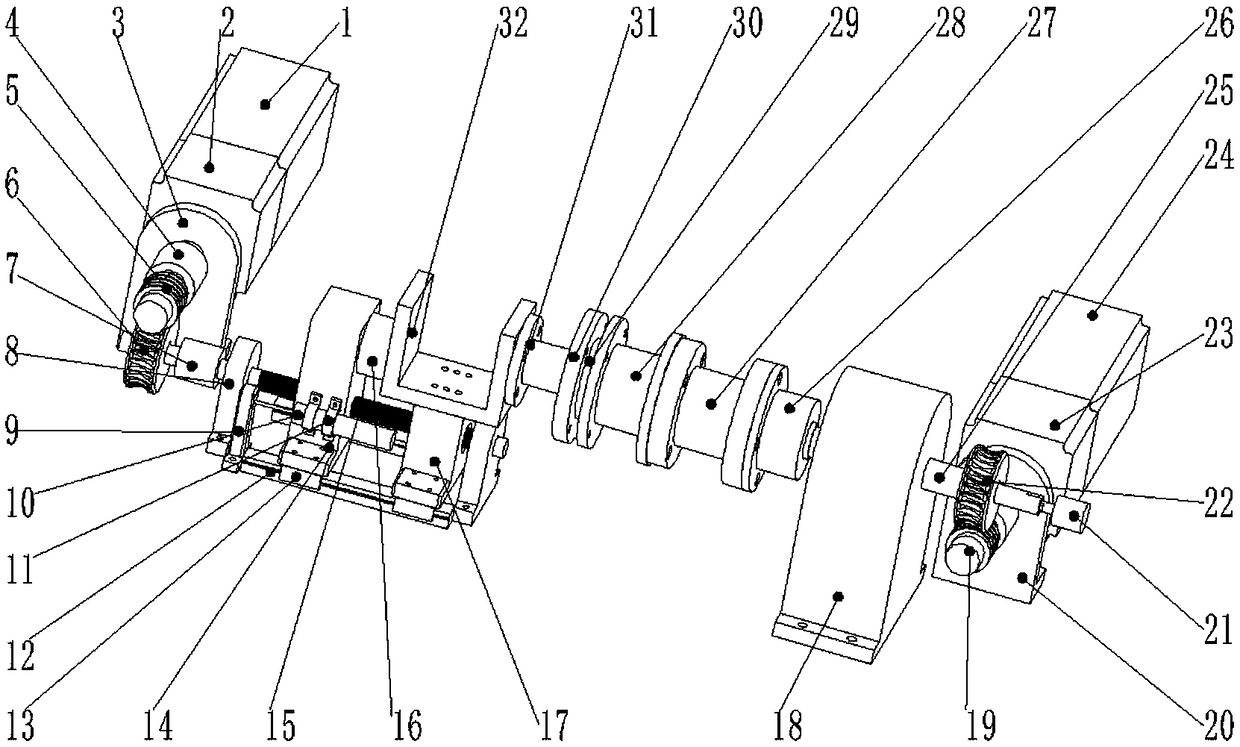

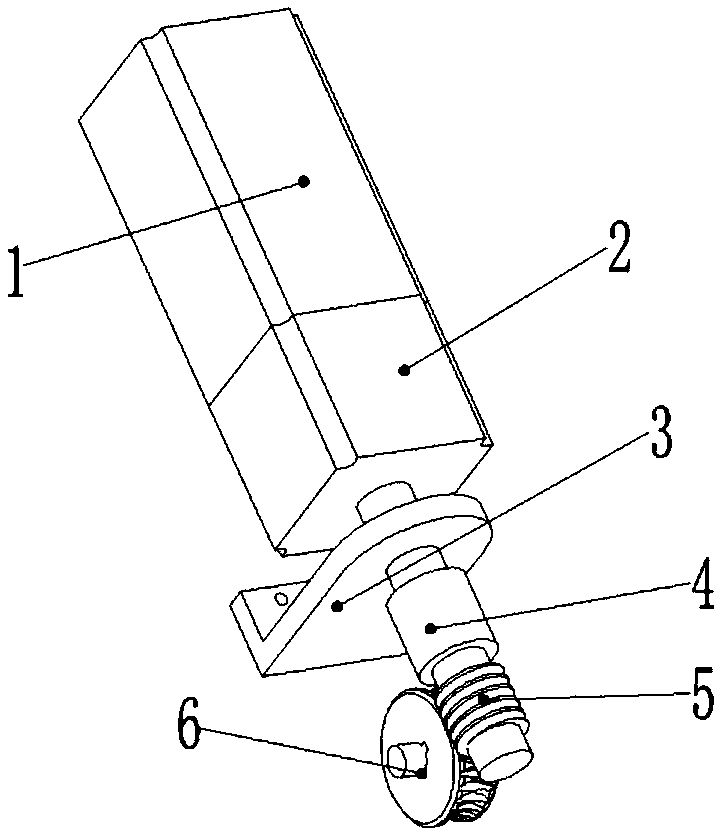

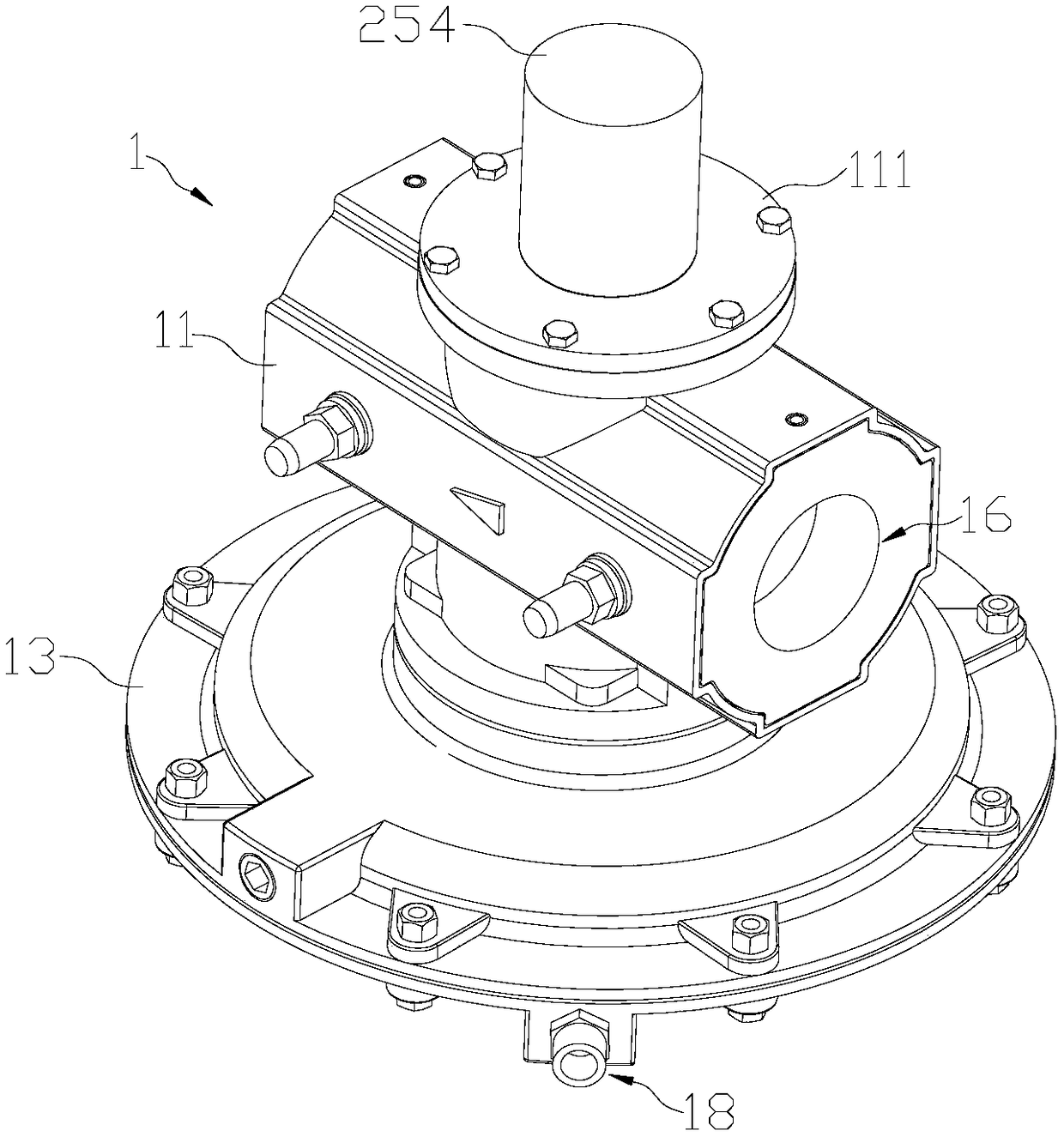

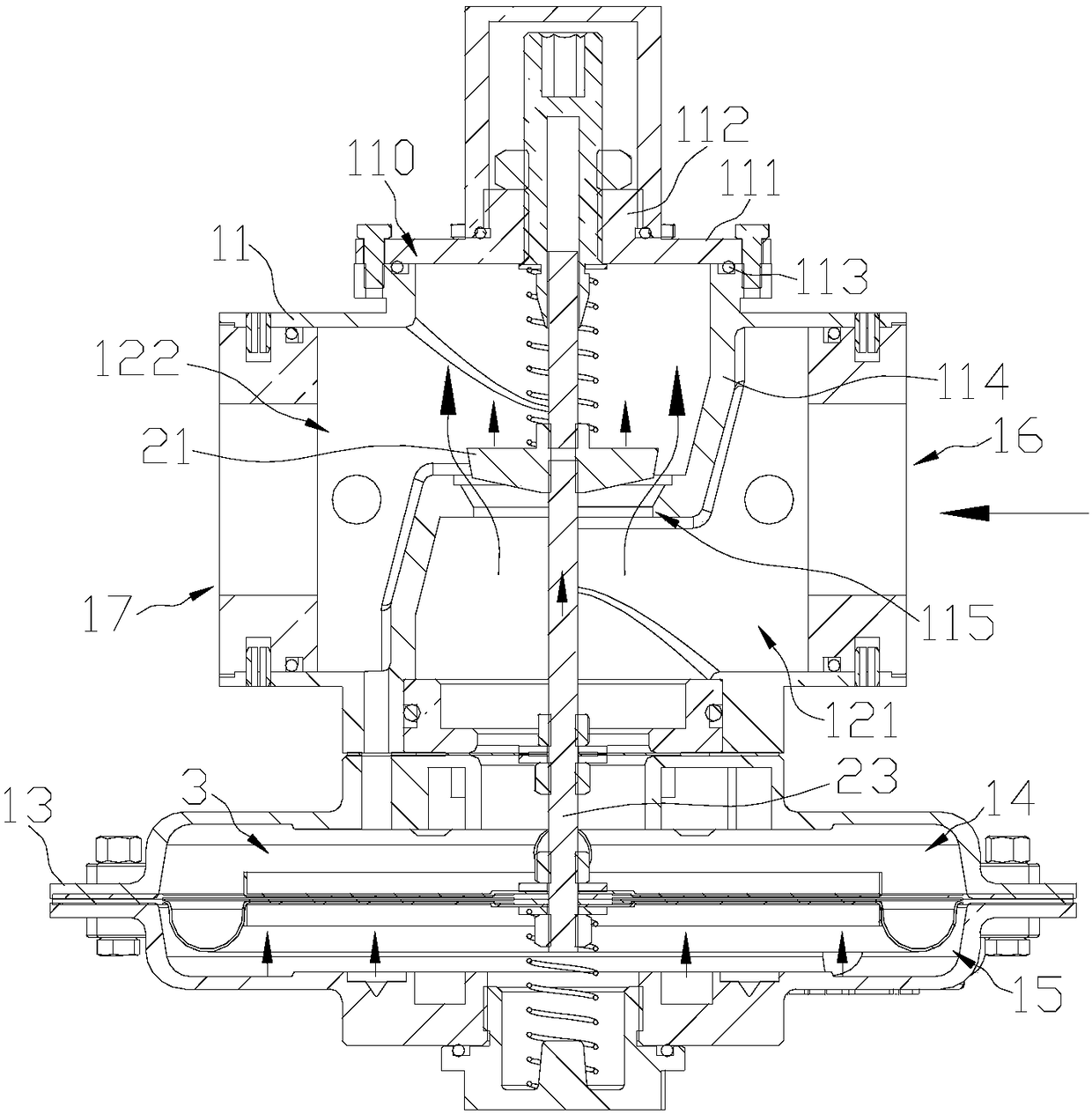

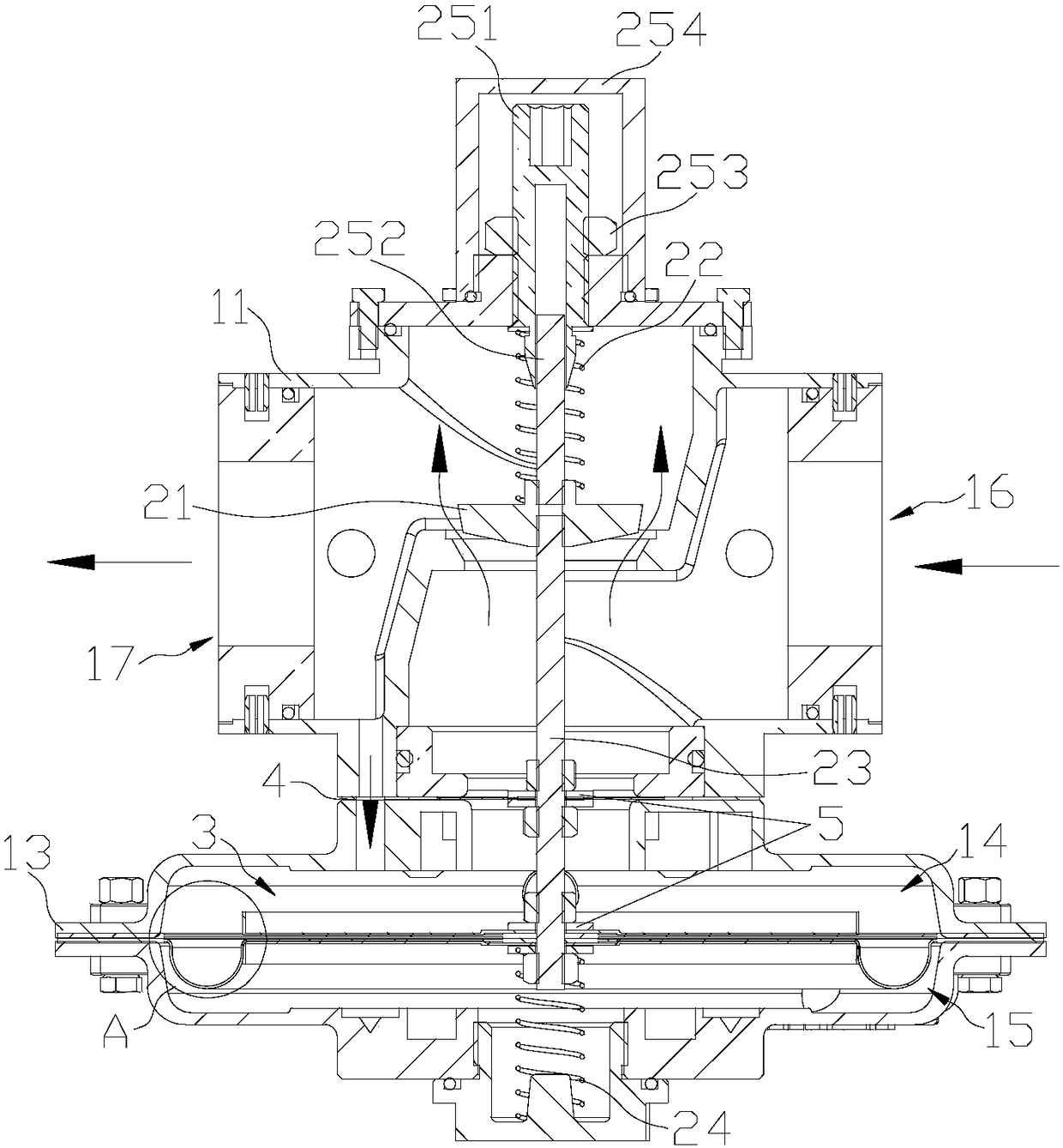

Creep aging bidirectional tension-compression testing device

ActiveCN107255587AOvercome the shortcoming of only two-way tensile testConstant ratioStrength propertiesPull forceEngineering

The invention provides a creep aging bidirectional tension-compression testing device which comprises an upper component, a lower component, a guide column component as well as a temperature box, wherein the upper component and the lower component are arranged according to a same central axis; the guide column component is arranged between the upper component and the lower component; the lower component and the upper component are respectively connected with a lower connecting rod and an upper connecting rod of a tension machine; the upper connecting rod is used for providing upright tension to the upper component; a second groove for holding a cross test piece is formed in the upper surface of the lower component; sliding grooves are respectively formed in end parts of four free ends of the second groove; sliding block components are arranged inside the sliding grooves; the guide column component comprises a straight guide column and an inclined guide column from top to bottom in a serial connection manner; upper and lower ends of the straight guide column are respectively fixed with the upper component and the upper end part of the inclined guide column; the lower part of the inclined guide column and the free ends of the cross test piece are both connected with the sliding block components; and the temperature box is used for providing different temperatures. By adopting the device, testing of bidirectional tension, bidirectional compression and tension and compression upon the cross test piece can be carried out at different temperatures.

Owner:CENT SOUTH UNIV

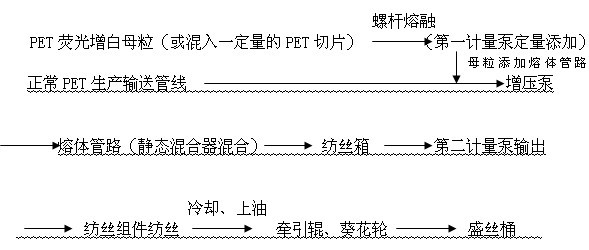

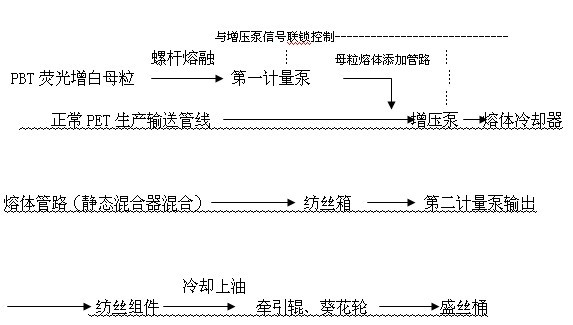

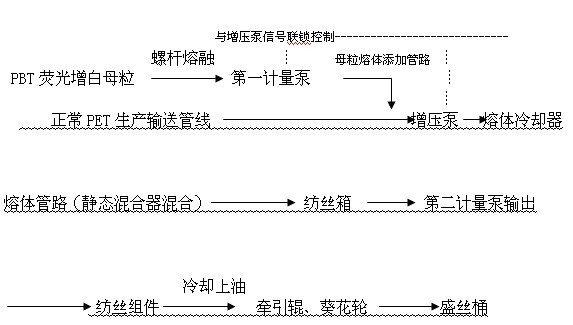

Method for controlling homogeneity of fluorescent-whitened polyester staple fiber product

InactiveCN102134756AStable addition ratioAdd the same proportionFilament forming substance formingSpinning head liquid feederFiberTemperature control

The invention relates to a method for controlling homogeneity of a fluorescent-whitened polyester staple fiber product, which comprises the following process procedures of fusing and extruding a PBT (polybutylece terephthalate) fluorescent-whitening master batch by a screw extruder, quantitatively adding the extrudate to a PET (Positron Emission Tomography) fusant of a normal PET production and delivery pipeline through a first metering pump and a master batch fusant pipeline, pressurizing the extrudate through a booster pump to lead the extrudate to enter a fusant cooler to be cooled to normal spinning temperature, then leading the cooled extrudate to enter the fusant pipeline, mixing the extrudate through a static mixer to make the extrudate into a blending fusant of the PBT fluorescent-whitening master batch and PET, leading the blending fusant to enter a spinning box, metering the blending fusant by a second metering pump, leading the blending fusant to enter a spinning component for spinning, cooling and oiling spun silks, and dragging the spun silks by a dragging roller and a sunflower wheel to be sent into a silk holding barrel. The rotation speed of the booster pump and the first metering pump adopts signal interlock control; the master batch fusant pipeline and the first metering pump are respectively provided with a heat tracing temperature control system; and heat tracing media of the heat tracing temperature control systems adopt the primary heating medium series control of a heat tracing temperature control system of a normal PET fusant pipeline. By the control method, the addition proportion of a fluorescent whitening ingredient can be ensured to be a set value when production capacity is changed.

Owner:江苏华西村股份有限公司

Device and method for adjusting the pedal characteristic curve of a hybrid braking system during modified braking-force distribution

ActiveUS7040721B2Increasing and reducing pressureConstant ratioBraking action transmissionBrake control systemsBraking systemVehicle brake

A braking system for a vehicle is described, including a hydraulic service braking system and an electric service braking system having wheel brakes, to which braking pressure is applied when a brake pedal is operated. To maintain essentially constant vehicle braking behavior during a change in the braking-force distribution between the hydraulic and the electric service braking systems, it is proposed to provide a control unit, which is capable of varying the braking-force distribution and to equip the hydraulic service braking system with a braking pressure modulator that is controlled by the control unit and is able to effect a variable braking-force distribution as a function of the control by the control unit.

Owner:ROBERT BOSCH GMBH

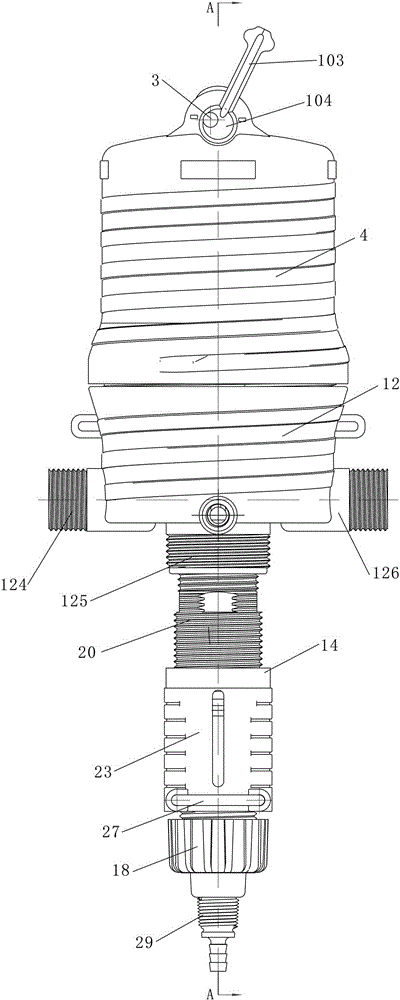

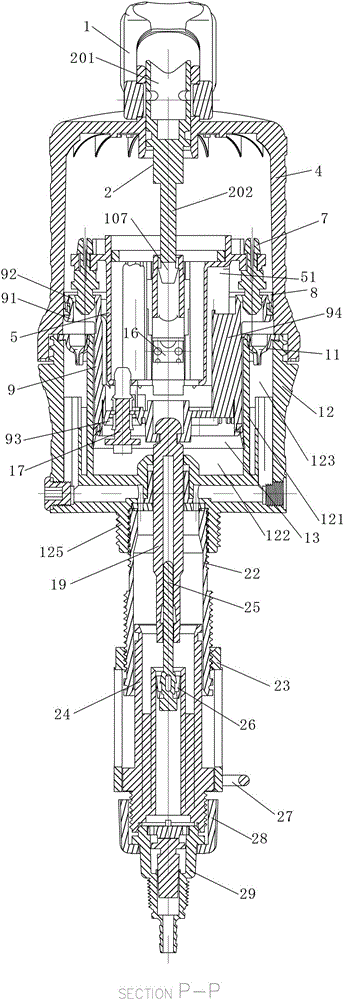

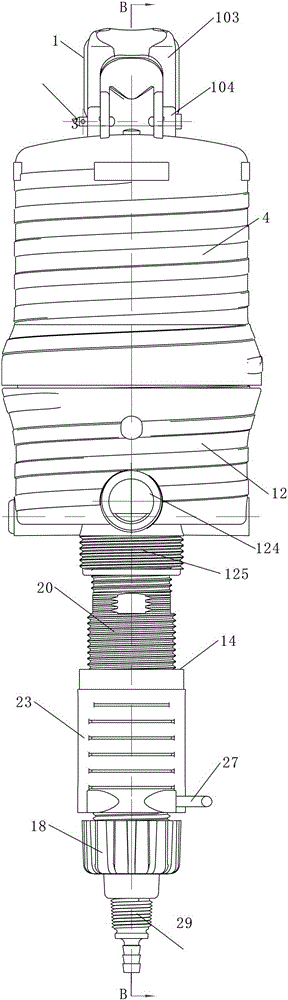

Water power proportioning pump

ActiveCN106050597AConstant ratioDrive water pressure requirement is smallPositive displacement pump componentsPumpsEngineeringInjection device

The invention provides a water power proportioning pump. An inner cover is arranged in a lower outer shell and divides the lower outer shell into an inner cavity chamber and an outer cavity chamber. An inner cavity of a suction and injection device communicates with the outer cavity chamber. The inner cavity chamber and the outer cavity chamber communicate with an inner cavity of an upper outer shell. A water stop ring plate is integrally arranged on the outer edge of the opening end of an outer piston. The bottom of an upper long rod is connected with a sliding block. A through hole is formed in the middle portion of the sliding block and composed of an upper through hole body section and a lower through hole body section. The diameter of the upper through hole body section is smaller than that of the lower through hole body section. A barb is arranged at the lower end of the upper long rod and penetrates the upper through hole body section in an inserted manner to stretch into the lower through hole body section. One end of a reversing telescopic piece abuts against an arc concave groove, and the other end of the reversing telescopic piece abuts against an arc groove. An upper blockage piece used for blocking a liquid outlet hole is arranged on the outer edge of the upper end of an inner piston, and a lower blockage piece used for blocking a liquid inlet hole is arranged at the bottom of the inner piston. The water power proportioning pump has the beneficial effects that according to the chemical adding mode, chemical adding is achieved outside a cavity, the liquid chemical does not enter the chemical adding device cavity, and the cleaning frequency can be reduced.

Owner:济宁市嘉易通塑料科技发展有限公司 +1

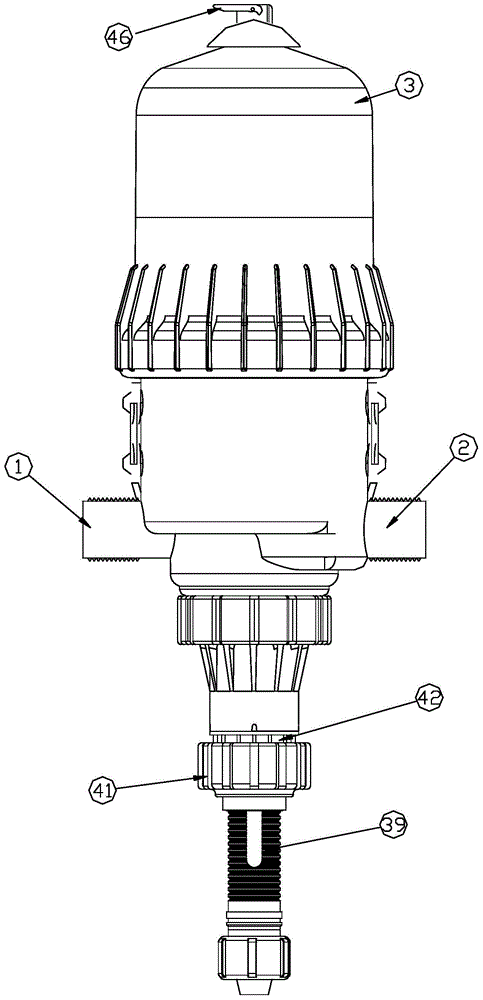

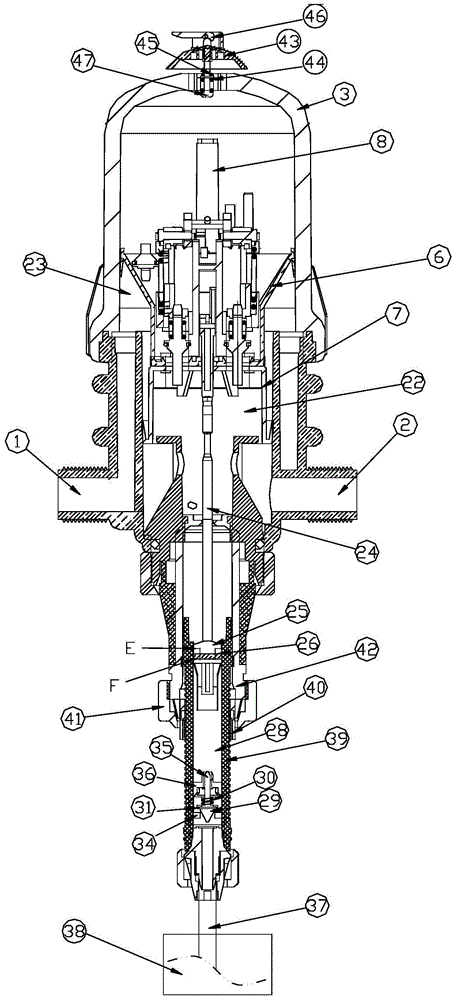

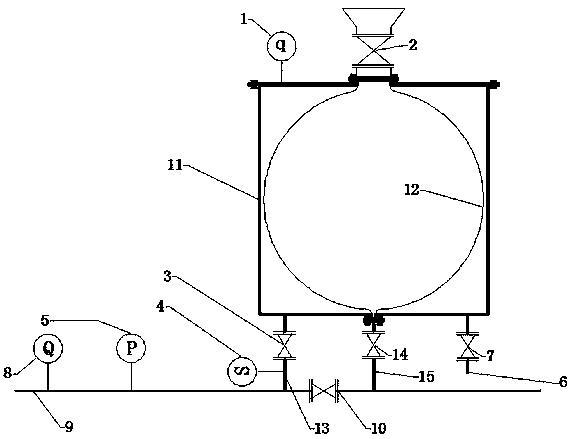

Piston type fertilizer sucking and chemical feeding device achieving accurate proportion adjustment function and fertilizer sucking and chemical feeding method

ActiveCN104982136ALower requirementWater pressure (energy) loss is smallPressurised distribution of liquid fertiliserInsect catchers and killersFertilizerPiston

The invention discloses a piston type fertilizer sucking and chemical feeding device achieving an accurate proportion adjustment function and a fertilizer sucking and chemical feeding method. The piston type fertilizer sucking and chemical feeding device comprises a shell, a water inlet and a water outlet, wherein the water inlet and the water outlet are communicated with the shell. A water inlet cavity communicated with the water inlet is formed in the shell. A fertilizer mixing cavity used for mixing fertilizer and water is formed in the shell and communicated with the water outlet. A fertilizer feeding system used for feeding the fertilizer into the fertilizer mixing cavity is arranged below the fertilizer mixing cavity. The feeding amount of the fertilizer is adjustable. A piston assembly used for controlling water to enter the fertilizer mixing cavity from the water inlet is arranged above the fertilizer mixing cavity. The piston type fertilizer sucking and chemical feeding device is arranged in a water pipe, water flow in the water pipe drives the piston type fertilizer sucking and chemical feeding device to work, and power source drive is not needed. The proportion of the fed fertilizer can be adjusted according to actual conditions. No matter how the water pressure and the water amount in the pipe change, the amount of sucked chemicals is always in direct proportion to the volume of water entering the device, and it is guaranteed that the proportion of mixed liquid is constant.

Owner:上海华维可控农业科技集团股份有限公司

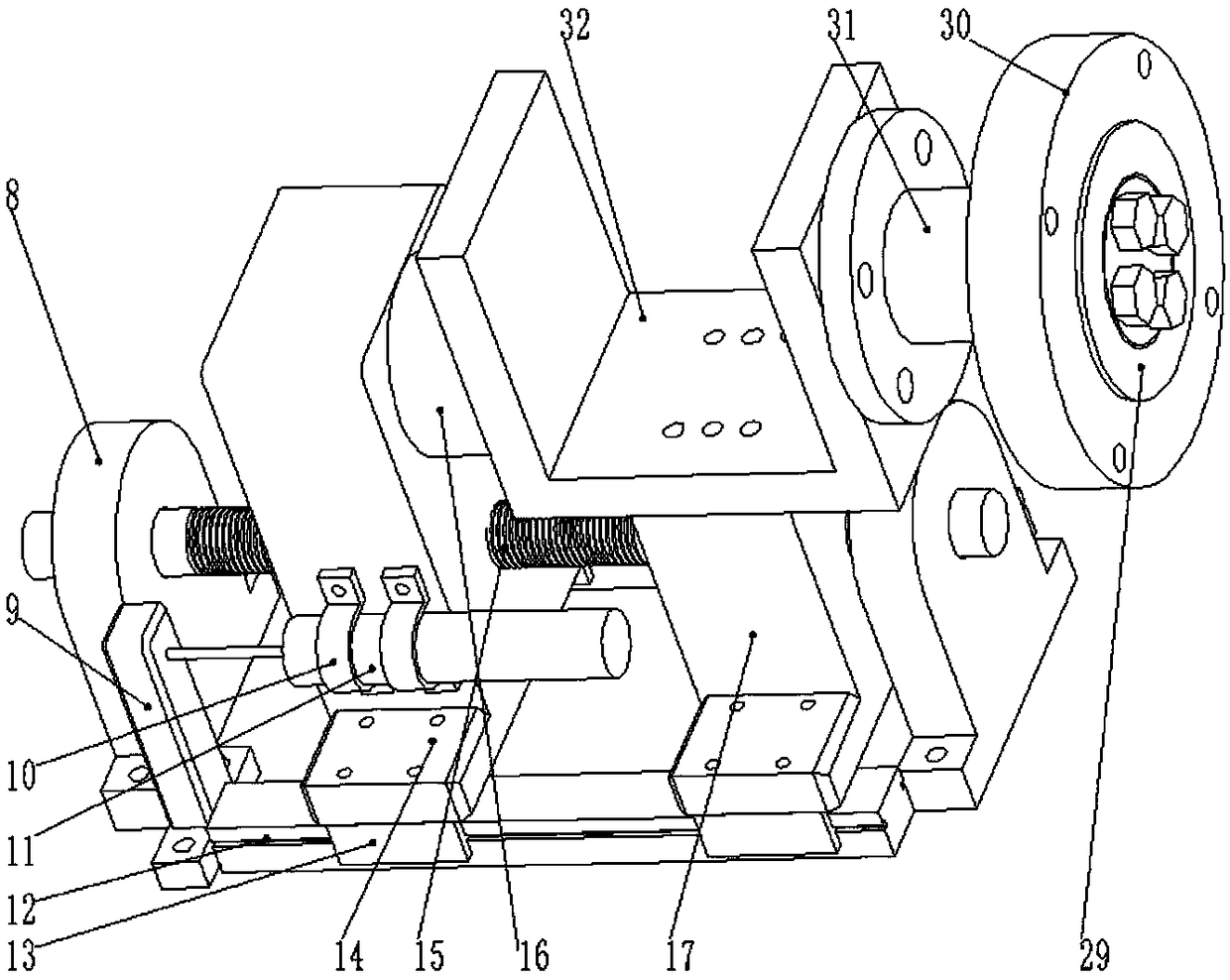

Bidirectional shear test device for metal plates

ActiveCN109283067AEasy to testConstant ratioMaterial strength using steady shearing forcesMotor driveLow speed

The invention discloses a bidirectional shear test device for metal plates, comprising a servo motor, a speed reduction mechanism, a measuring instrument, a tension and compression shearing mechanismand a rotary shearing mechanism, wherein the servo motor supplies power to the whole device to drive the operation of the whole device; the speed reduction mechanism is configured to convert the high-speed motor rotation into low-speed shearing motion; the measuring instrument is configured to measure the force and deformation generated during the test; and the tension and compression shearing mechanism and the rotary shearing mechanism are the actuators of the entire test device in order to achieve shear deformation in both directions of the bidirectional shear test piece. The motor drive canrealize the constant tension, compression shear deformation and rotational shear deformation at any ratio during bidirectional shearing, and improve the reliability of the test results. The forward and reverse shearing of the metal plates can be realized by the forward and reverse rotation of the drive system to obtain a more comprehensive study of material properties.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Energy-saving environment-friendly commercial stove

ActiveCN109827197AImprove combustion efficiencyImprove energy saving and environmental protection performanceDomestic stoves or rangesCooking fumes removalCombustorEngineering

The invention relates to an energy-saving environment-friendly commercial stove. The problem that in the prior art, the gas utilization rate is low is mainly solved. The stove comprises a hearth whichis provided with a supporting frame, and the lower portion of the supporting frame is provided with a supporting groove; the outer side surface of the supporting frame is annularly and uniformly provided with first air inlets, and the supporting frame is provided with an annular air outlet; the supporting frame is internally provided with a circulating channel communicating with the first air inlets and the air outlet; the bottom of the hearth is provided with a through hole, ad a combustor is arranged at the through hole and provided with a kindling gas feeding pipe, a main fire gas feedingpipe and an air feeding pipe; a fire collecting ring surrounding the combustor is arranged in the hearth; the bottom of the hearth is provided with an outlet, a fire collecting plate is arranged in the hearth, and the hearth, the supporting frame, the fire collecting plate and the fire collecting ring form a cavity; the air outlet and the outlet both communicate with the cavity; the outlet communicates with the input end of an exhaust fan, the output end of the exhaust fan communicates with the air feeding pipe, and a fireproof explosion-proof device is arranged between the exhaust fan and theair feeding pipe.

Owner:福建万聚通节能科技股份公司

Actuation device for vehicle panel

InactiveUS7556304B2Facilitates holdingLow costBuilding braking devicesMan-operated mechanismMobile vehicleFriction torque

Arrangement, in particular for a motor vehicle, having a closing device which can be pivoted about an axis between a closed and an open position, for example a boot lid or a tailgate, a compensating device acting on the closing device, in particular at least one gas-pressure spring, which is pretensioned and a counter-force opposes the weight of the closing device, and a motor-driven drive which can be operated at least unidirectionally, in particular bidirectionally, in order to pivot the closing device about the axis in at least one direction, wherein the motor-driven drive is designed to be repellable, in order to facilitate manual actuation of the closing device. Friction means are provided, which act on the closing device both during manual actuation of the closing device and during actuation by the drive at a preset friction torque, wherein the friction torque within the pivoting range of the closing device or of a part range thereof is greater than the extent of the difference of a first torque produced by the weight of the closing device and a second torque produced by the counter-force of the compensating device.

Owner:STRATTEC POWER ACCESS

PWM signal generation circuit and PWM control circuit

InactiveUS7327203B2Reduce chargeEasy to adjustElectric pulse generatorPulse shapingEngineeringControl circuit

A PWM signal generation circuit and a PWM control circuit are provided in which the duty ratio is easily changed and which can also avoid adverse impact from ambient temperature changes and the like. At the beginning of charging a capacitor with a current flow, a voltage level at a connection point between the negative input terminal of a comparator and the capacitor is still below a charging threshold. When the charging threshold is exceeded, the comparator is inverted to a low state and a current flows into an output point of the comparator to start discharging the capacitor. At the beginning of discharging from the capacitor, the voltage level at the connection point is still above the discharging threshold. However, when the voltage level falls below the discharging threshold, the comparator returns to a high state, and the charging operation again takes over.

Owner:AUTONETWORKS TECH LTD +2

Band pass filter

There is provided a multi-layered band pass filter capable of improving a stop characteristic out of a pass band and reducing the entire size of the filter. The multi-layered band pass filter includes a ceramic laminated body having at least first to fifth dielectric layers laminated sequentially therein; first and second resonators having symmetrical patterns of first and second inductors formed on the first dielectric layer, and symmetrical patterns of first and second capacitors formed on the second dielectric layer so that they are at least partially overlapped with the patterns of the first and second inductors; a pattern of first and second load capacitors electrically capacitively coupled respectively to ends of the first and second resonators formed on the third dielectric layer; a pattern of first and second notching capacitors electrically capacitively coupled respectively to the other ends of the first and second resonators formed on the third dielectric layer; and first and second ground planes formed respectively on the fourth and fifth dielectric layers, wherein each of the patterns of the first and second inductors is composed of a low impedance portion formed of wide-width lines and a high impedance portion formed of meander-type narrow-width lines from the low impedance portion.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

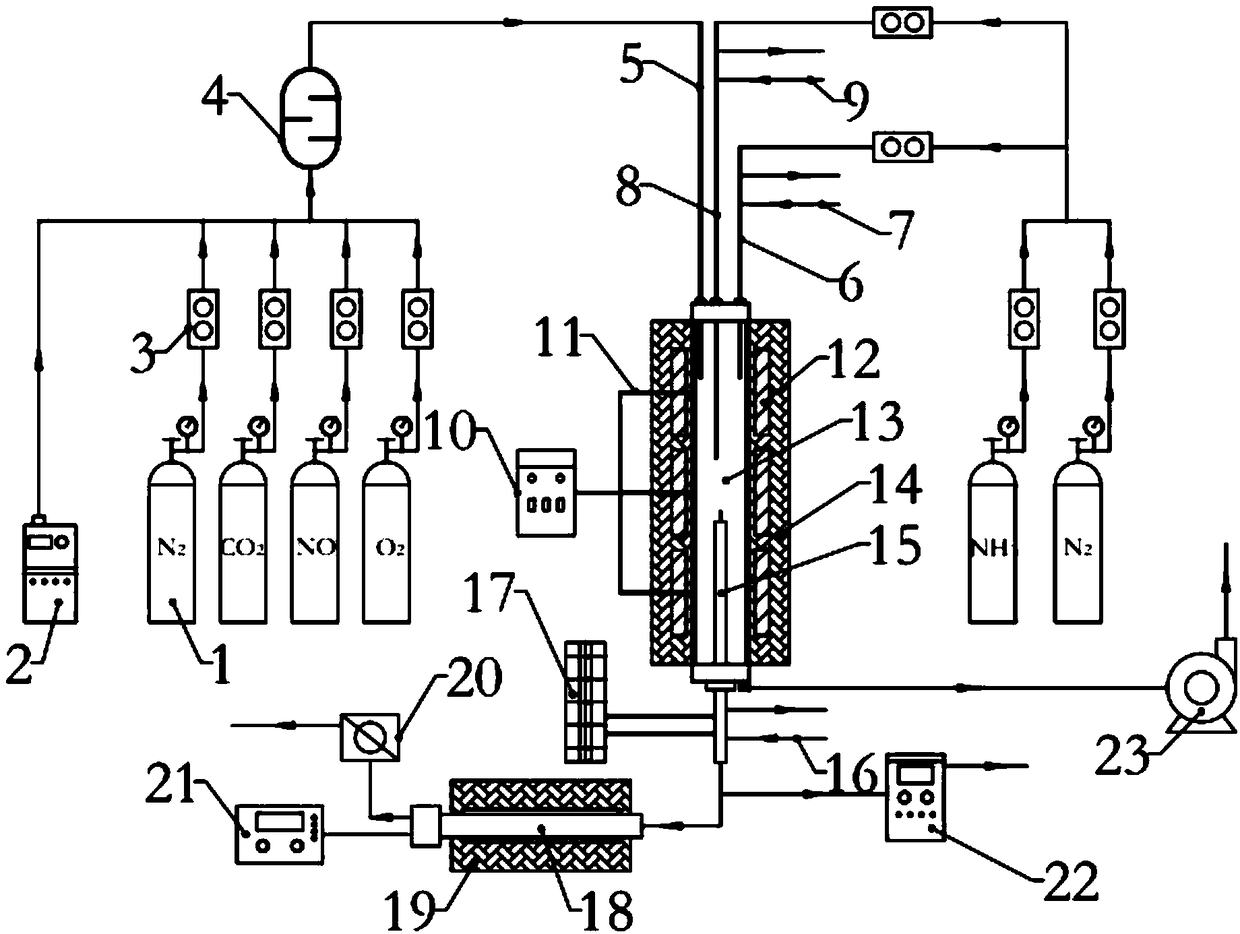

SNCR (Selective Non-Catalytic Reduction) denitrification technology test bench

PendingCN109060704AConstant ratioGuaranteed repeatabilityWithdrawing sample devicesMaterial analysis by optical meansGas cylinderNitric oxide

The invention provides an SNCR (Selective Non-Catalytic Reduction) denitrification technology test bench. The SNCR denitrification technology test bench comprises a gas distribution and intake system,a plunger flow reactor system and a sampling and testing system, wherein the plunger flow reactor system comprises a furnace tube with an electric heater arranged outside; a fan for air extraction isconnected to the bottom of the furnace tube; the gas distribution and intake system comprises a gas distribution cylinder consisting of two groups of gas cylinders; the first group comprises a nitrogen cylinder, an oxygen cylinder, a carbon dioxide cylinder and a nitric oxide cylinder; the gas outlet of each gas cylinder is connected with a pressure relief valve and a mass flowmeter in sequence,and then connected in parallel with a metering steam generator to the inlet of a mixed gas preheater; the outlet of the mixed gas preheater is connected with the furnace tube through a mixed samplinggun; the second group comprises a nitrogen cylinder and an ammonia cylinder of which the gas outlets are connected with the pressure relief valve and the mass flowmeter in sequence respectively, and then connected with the furnace tube through an ammonia gas sampling gun; and the sampling test system is connected with the furnace tube, and used for measuring the concentration of ammonia in flue gas after denitrification. By simulation of the flue gas with gas distribution, the flue gas composition can be stabilized, and the test conditions are highly repeatable.

Owner:CHINA HUANENG GRP CO LTD +1

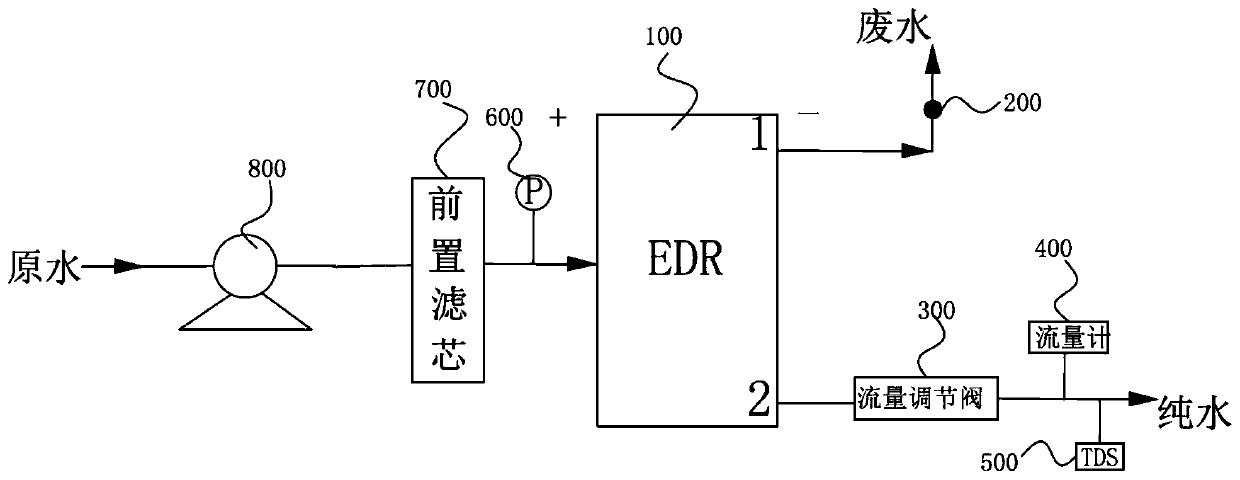

Water purification system with constant pure water/wastewater proportion and water purifier

PendingCN111003765AGuaranteed uptimeStable ratioWater treatment parameter controlDispersed particle separationStream flowDesalination

The invention discloses a water purification system with a constant pure water / wastewater proportion and a water purifier. The water purifier is used for desalting and water purifying through the water purification system with a constant pure water / wastewater proportion; the water purification system is provided with an EDR unit, a concentrated water plug for controlling the flow rate of concentrated water, a flow regulating valve for regulating the flow rate of pure water and a booster pump for increasing the flow rate of raw water; the booster pump is assembled at the communication part of the raw water pipeline and the water inlet of the EDR unit; the first water outlet of the EDR unit is connected with a concentrated water pipeline, the concentrated water plug is assembled at the pipeline of the concentrated water pipeline, the second water outlet of the EDR unit is communicated with the water inlet end of the flow regulating valve through a pipeline, the water outlet end of the flow regulating valve is communicated with a pure water pipeline, and the water inlet of the EDR unit is communicated with the raw water pipeline. A certain pressure is applied to raw water through thebooster pump arranged in front of the EDR unit, and the flow of produced water of the EDR unit is regulated and controlled in combination with a flow regulating valve at a water outlet of the EDR unit, so that the pure water / wastewater proportion of the produced water of the water purification system is constant, and the user experience is improved.

Owner:GUANGDONG LIZI TECH CO LTD

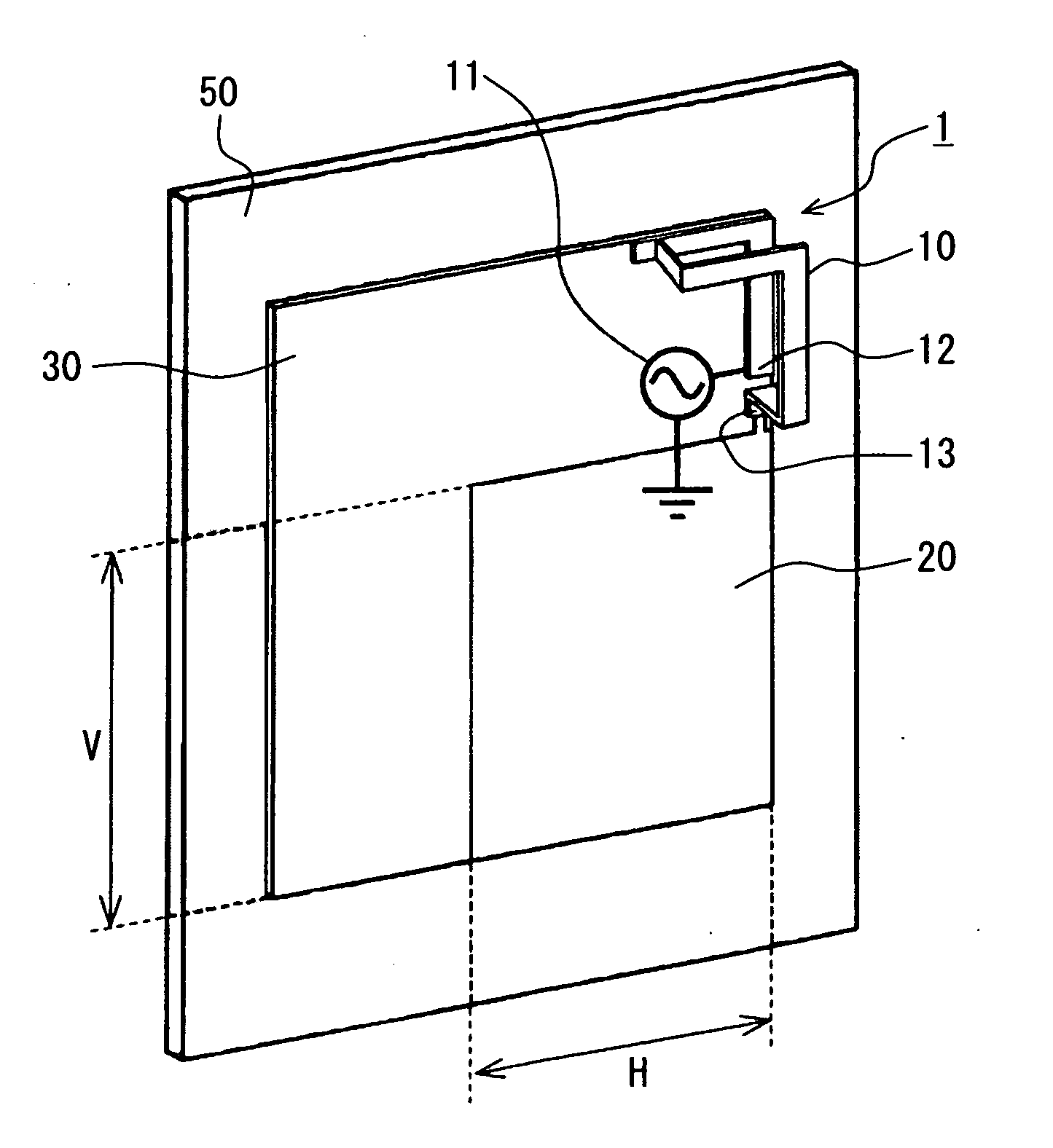

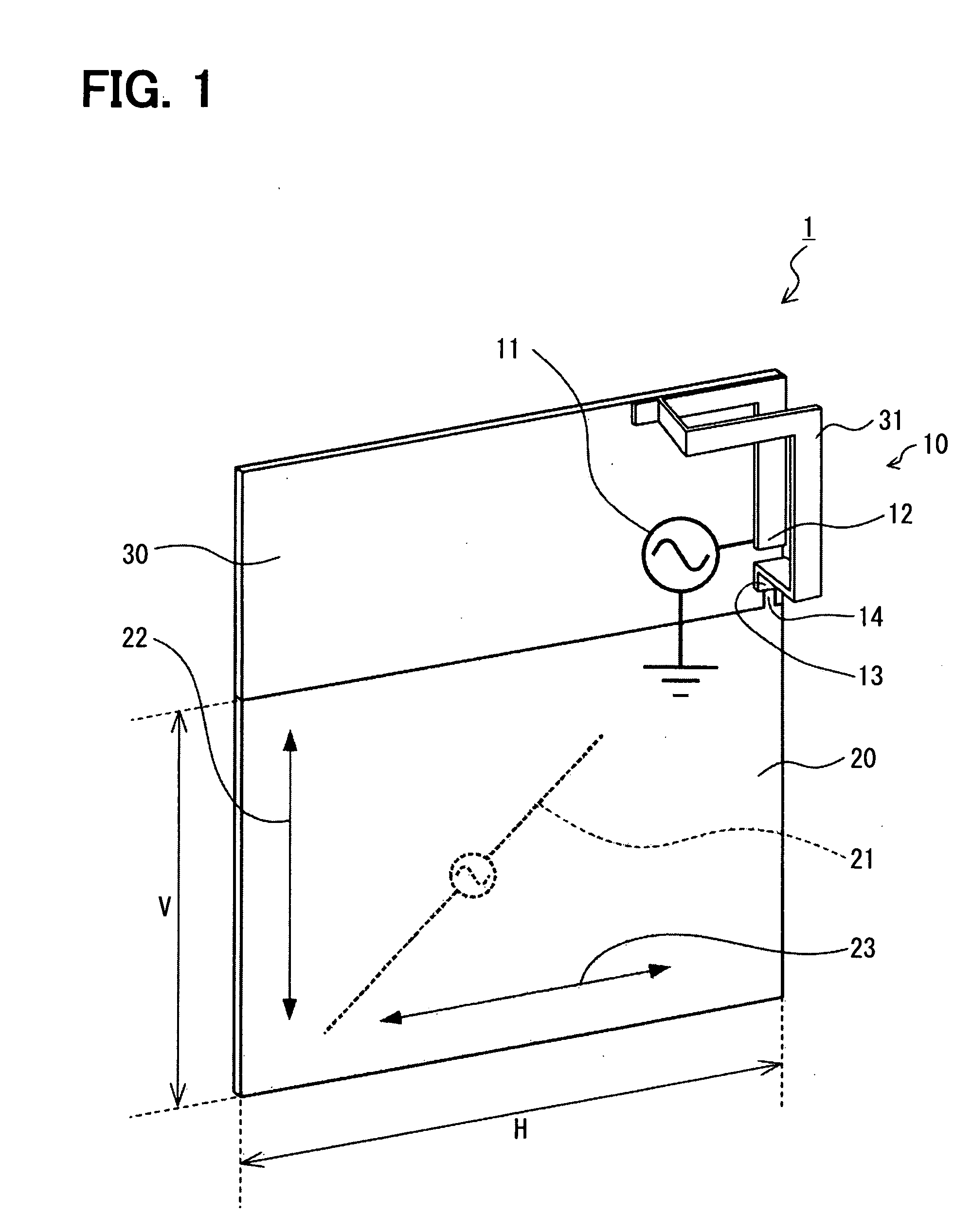

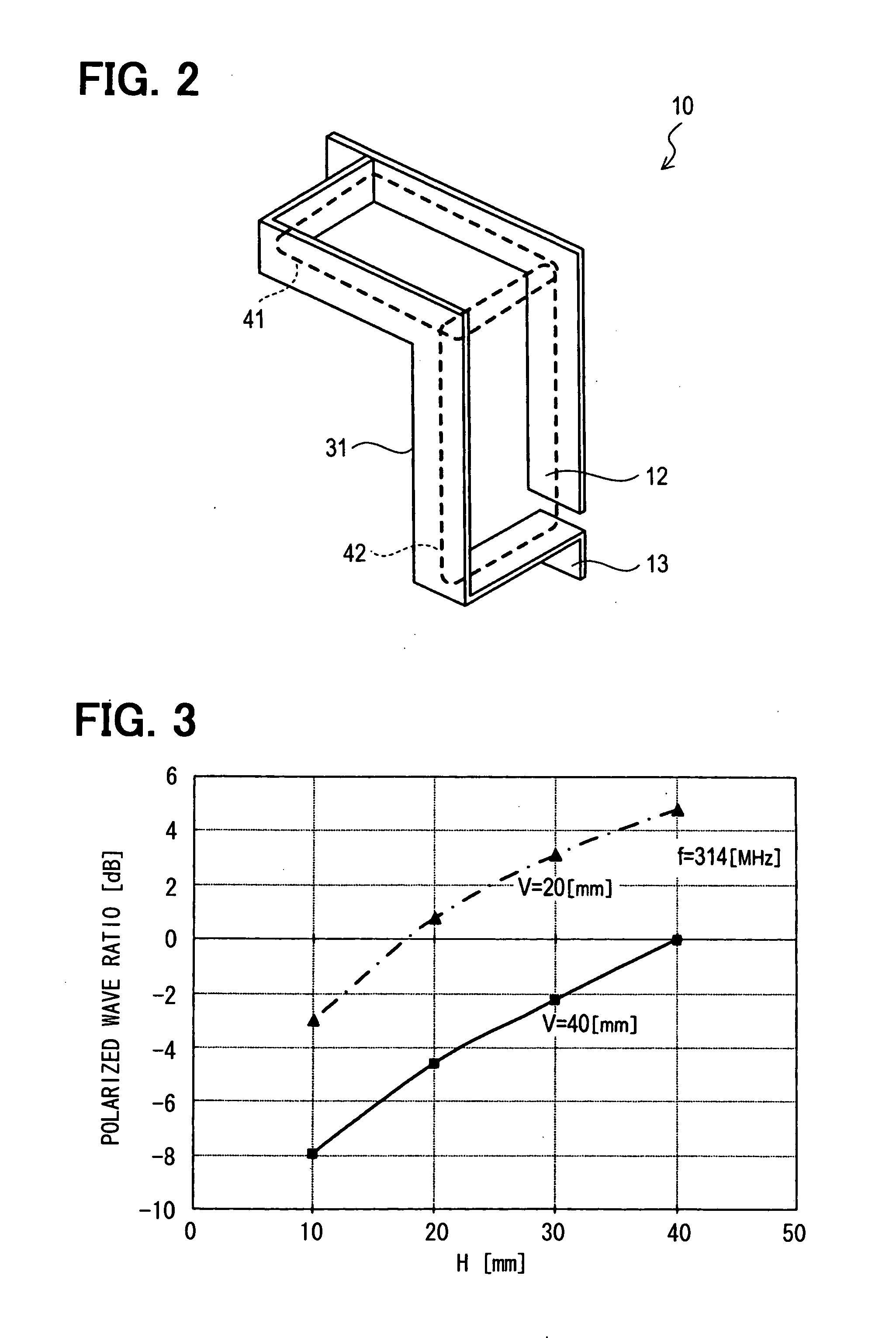

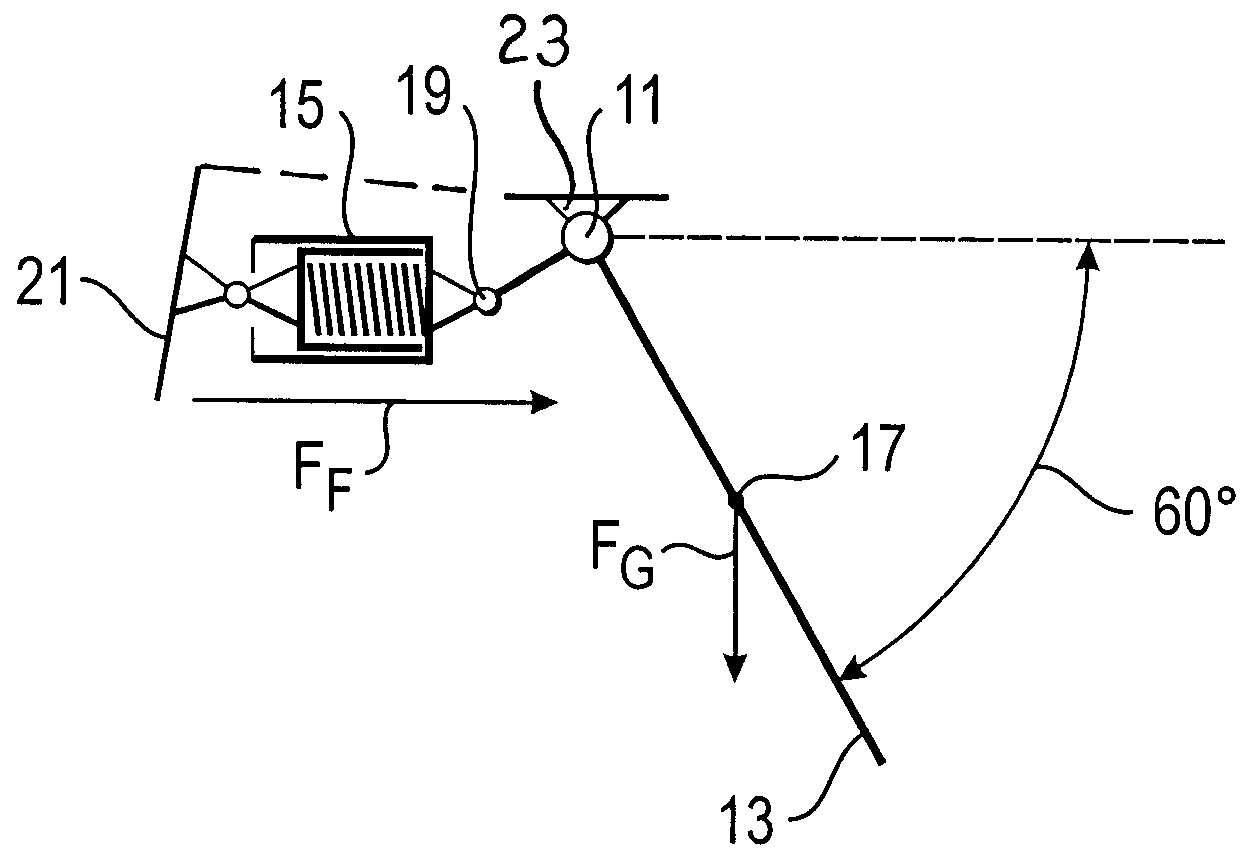

Antenna apparatus

ActiveUS20100245192A1Reduce functionHigh gainAntenna arraysAntenna earthingsClassical mechanicsSlot antenna

An antenna apparatus includes: a ground substrate; and a loop antenna having first and second polarized wave surfaces, which are perpendicular to the substrate. The substrate provides an antenna, which is excited and vibrated together with the loop antenna. The antenna has a first polarized wave component in parallel to the first polarized wave surface and a second polarized wave component in parallel to the second polarized wave surface. A polarized wave ratio between the first polarized wave component and the second polarized wave component in the substrate is substantially equal to a polarized wave ratio between the first polarized wave surface and the second polarized wave surface in the loop antenna.

Owner:DENSO CORP +1

Actuation device for vehicle panel

InactiveUS20070214602A1Facilitates holdingLow costBuilding braking devicesPower-operated mechanismMobile vehicleMotor drive

Arrangement, in particular for a motor vehicle, having a closing device which can be pivoted about an axis between a closed and an open position, for example a boot lid or a tailgate, a compensating device acting on the closing device, in particular at least one gas-pressure spring, which is pretensioned and a counter-force opposes the weight of the closing device, and a motor-driven drive which can be operated at least unidirectionally, in particular bidirectionally, in order to pivot the closing device about the axis in at least one direction, wherein the motor-driven drive is designed to be repellable, in order to facilitate manual actuation of the closing device. Friction means are provided, which act on the closing device both during manual actuation of the closing device and during actuation by the drive at a preset friction torque, wherein the friction torque within the pivoting range of the closing device or of a part range thereof is greater than the extent of the difference of a first torque produced by the weight of the closing device and a second torque produced by the counter-force of the compensating device.

Owner:STRATTEC POWER ACCESS

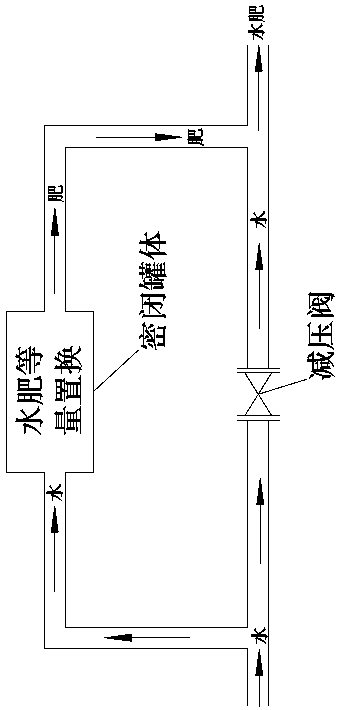

Proportion decreasing fertilizer device and application method thereof

InactiveCN108738615AUniform fertilization concentrationLose weight completelyLiquid fertiliser regulation systemsPressurised distribution of liquid fertiliserAgricultural engineeringPressure difference

The invention relates to a fertilizing device, in particular to a proportion decreasing fertilizer device: a fertilizer solution is loaded into a deformable fertilizer bag, and the fertilizer bag is placed in a closed pressure tank, the pressure tank is connected to a water main and a fertilizer bag outlet is connected to a water pipe. An adjustable pressure reducing valve is arranged at the middle of two connectors of the water main to form a certain pressure difference between the two ends, when the tank body is full of water, the pressure in the closed pressure tank is greater than the pressure of a pipe at an outlet of the fertilizer solution, and the fertilizer solution can be dripped into the water pipe. The proportion decreasing fertilizer device also discloses an application methodthereof. The proportion decreasing fertilizer device has the advantages of simple structure, uniform fertilization, low-energy consumption and controllable proportionality.

Owner:YANGZHOU UNIV

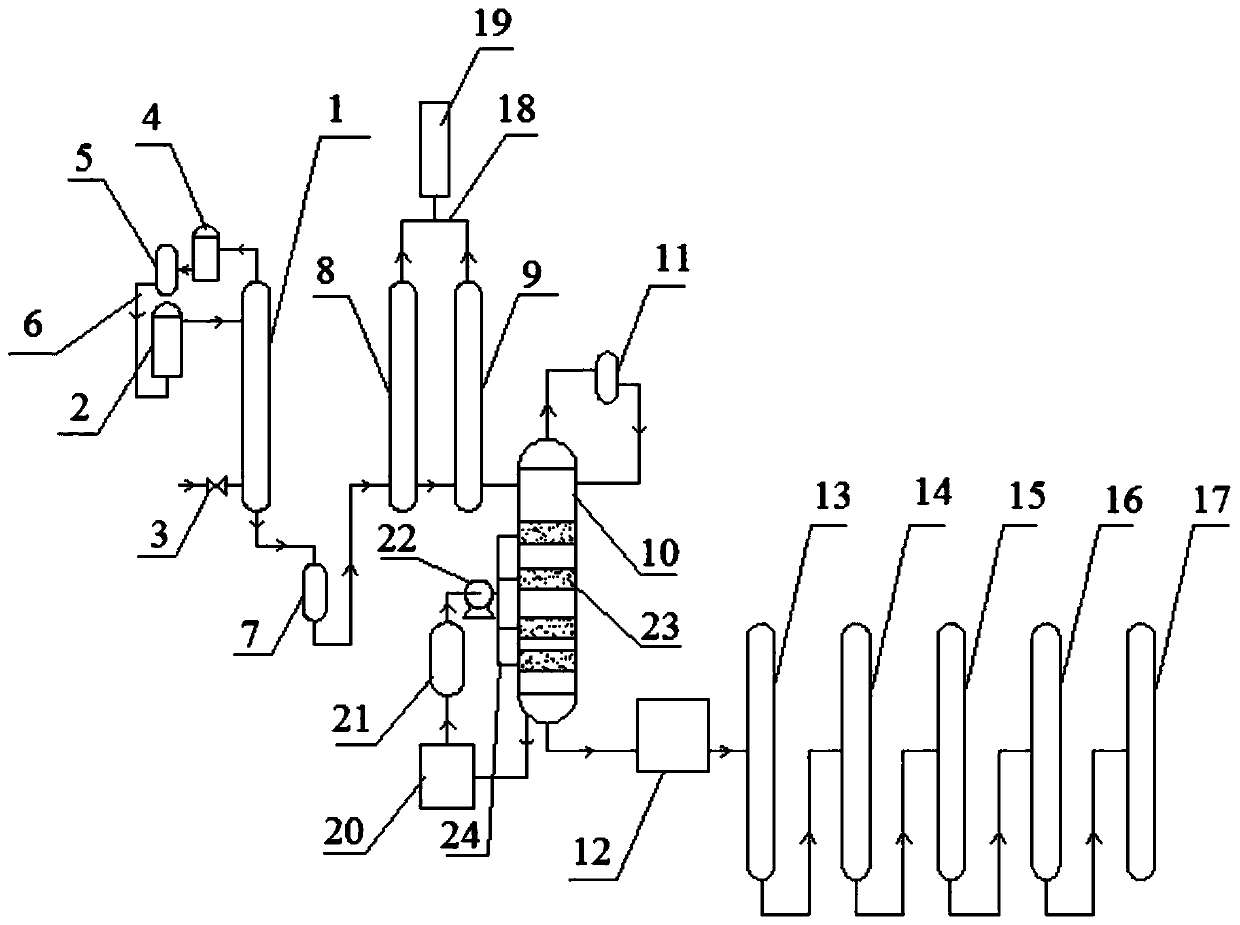

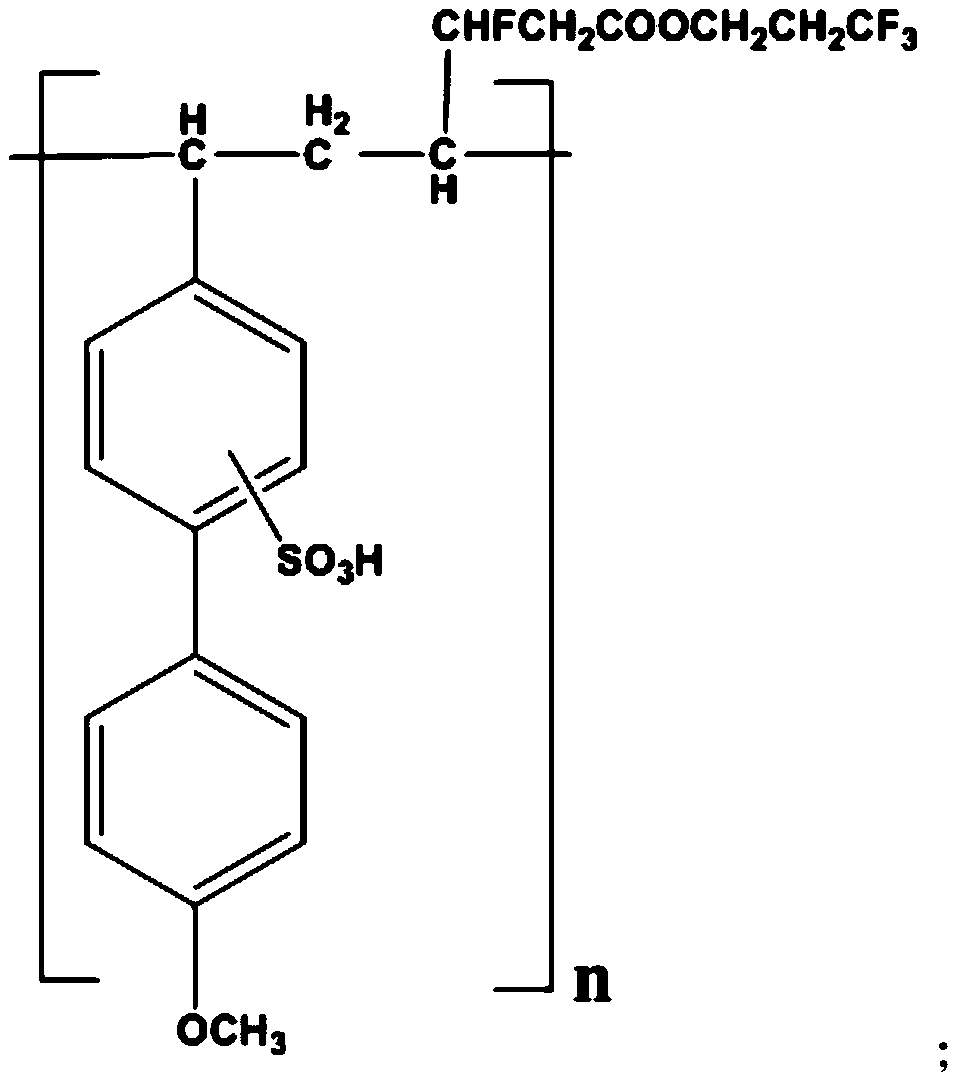

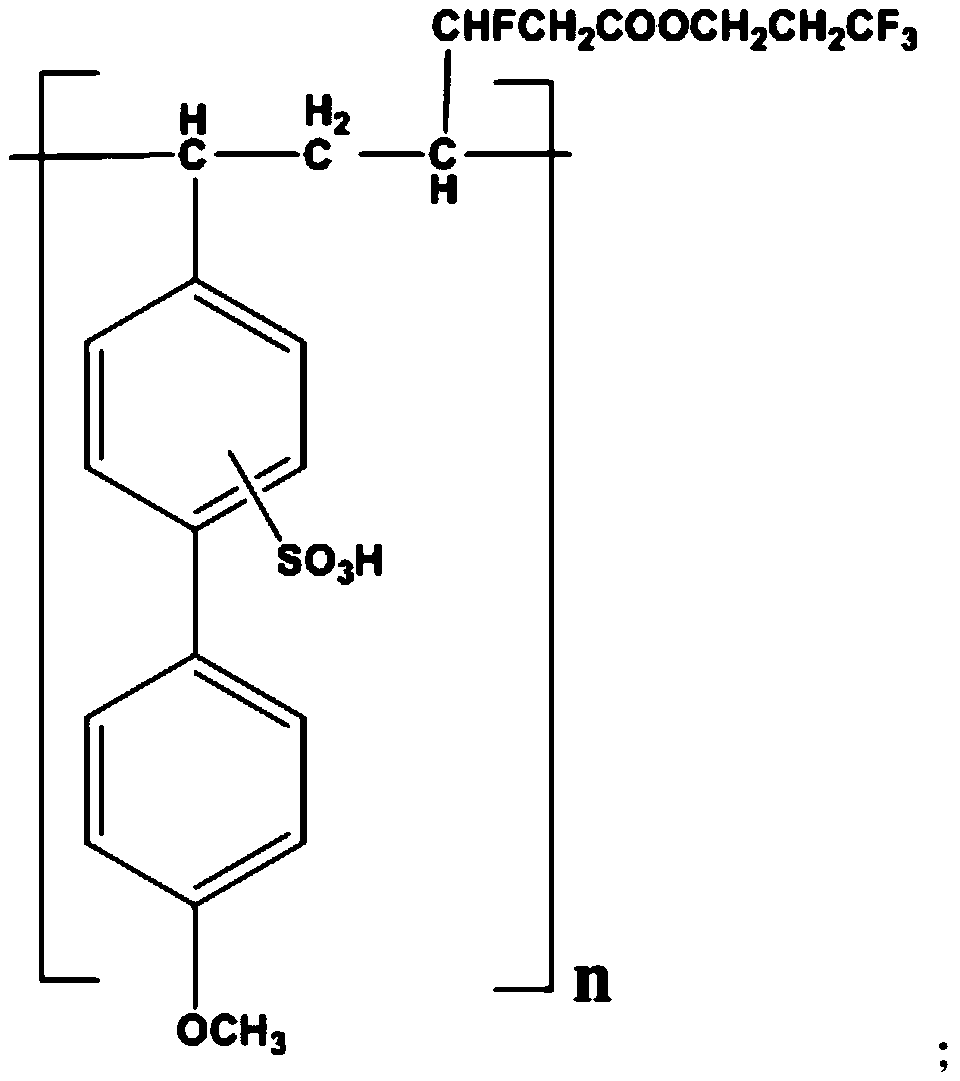

Manufacturing method of phenol and acetone

InactiveCN109776274ALower surface energyPlay a role of shielding protectionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic decompositionEvaporation

The invention discloses a manufacturing method for phenol and acetone, and relates to the technical field of chemical raw material synthesis. The manufacturing method comprises the steps that improvement is conducted on the basis of an existing method that phenol and acetone are synthesized through isopropyl benzene oxidation and selective acid catalytic decomposition, isopropyl benzene obtained after alkalization and pressurized air are subjected to a countercurrent contact reaction in an oxidation tower, falling film evaporation and two times of concentration are conducted, and then refinedcumene hydroperoxide is obtained; the refined cumene hydroperoxide is decomposed into the phenol and acetone in a moving bed reactor through catalysis of an acid resin catalyst, and then the refined phenol and acetone are obtained through water washing for deacidification, acetone roughing, acetone refining, coke cutting and secondary dealkylation. The manufacturing method has the good selectivityand yield of the phenol and acetone, the reaction conditions are not harsh and easy to control, the resin catalyst can be reused multiple times after collection and regeneration, and thus the production cost is lowered.

Owner:实友化工(扬州)有限公司

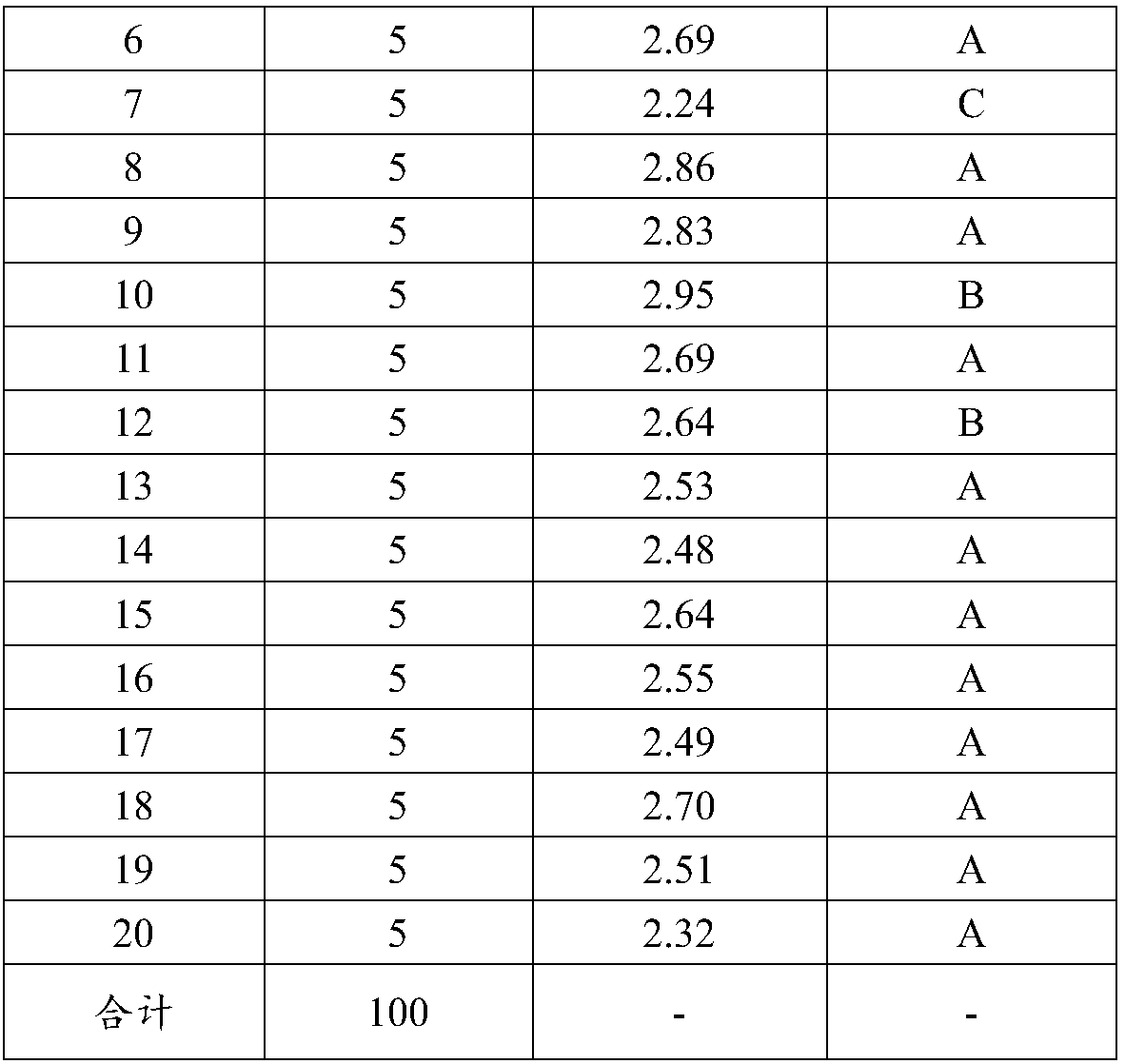

Tobacco feeding method for improving uniformity of cigarette blending

ActiveCN107822192AImprove uniformityConstant ratioTobacco preparationTransportation and packagingEngineeringOrganoleptic

The invention provides a tobacco feeding method for improving the uniformity of cigarette blending. The method comprises the following steps that 1, the grades of all tobacco leaves in tobacco blending are divided into three types according to sensory characteristics, wherein the three types comprise a characteristic main type A, a characteristic auxiliary type B and a characteristic cooperative type C; 2, according to the relation between the total amounts of all the types and the total amount of tobacco leaves, the feeding sequence of the types is determined; the weights of the characteristic main type A, the characteristic auxiliary type B and the characteristic cooperative type C are set to be Ma, Mb and Mc respectively, the weights of the three types are converted to the proportion relation a to b to c, the proportion relation is converted to be the integer proportion according to rounding off, the type with the maximum proportion value ranks second in feeding order, the type withthe minimum proportion value ranks third in feeding order, and the type with the middle proportion value ranks first in feeding order; 3, through a mode that the single-layer material laying area ina tobacco storage cabinet is adjusted, it is guaranteed that the proportions of the three types of all the vertical cross sections are equal or similar; 4, the tobacco leaves are fed according to thehigh-low sequence of the alkali content of total plants. According to the tobacco feeding method, the uniformity of tobacco blending is improved, so that the production uniformity of the following process is higher.

Owner:HUBEI CHINA TOBACCO IND

Air control valve

PendingCN108106446AReduce risk of leakageAvoid pollutionControl devices for furnacesAir conditioningControl valves

The invention provides an air control valve. The air control valve comprises an outer shell. An upper cavity and a lower cavity are arranged in the outer shell. A connecting structure is arranged in the upper cavity and used for controlling the air flux in the upper cavity. An elastic film structure is arranged in the lower cavity and connected with the connecting structure through a transmissionrod. The lower cavity is externally connected with an external fuel gas pipeline which can input fuel gas to the lower cavity. The elastic film structure deforms under the pressure action of the fuelgas to drive the transmission rod, and therefore the opening degree of the connecting structure is adjusted. The air control valve is high in control response speed and good in control effect.

Owner:佛山市诺一燃控科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com