Tobacco feeding method for improving uniformity of cigarette blending

A feeding method and uniformity technology, which is applied in the field of tobacco leaf feeding to improve the uniformity of cigarette formula, can solve the problems of sensory and chemical composition instability, and achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

[0019] The invention provides a tobacco leaf feeding method for improving the uniformity of cigarette formula, comprising the following steps:

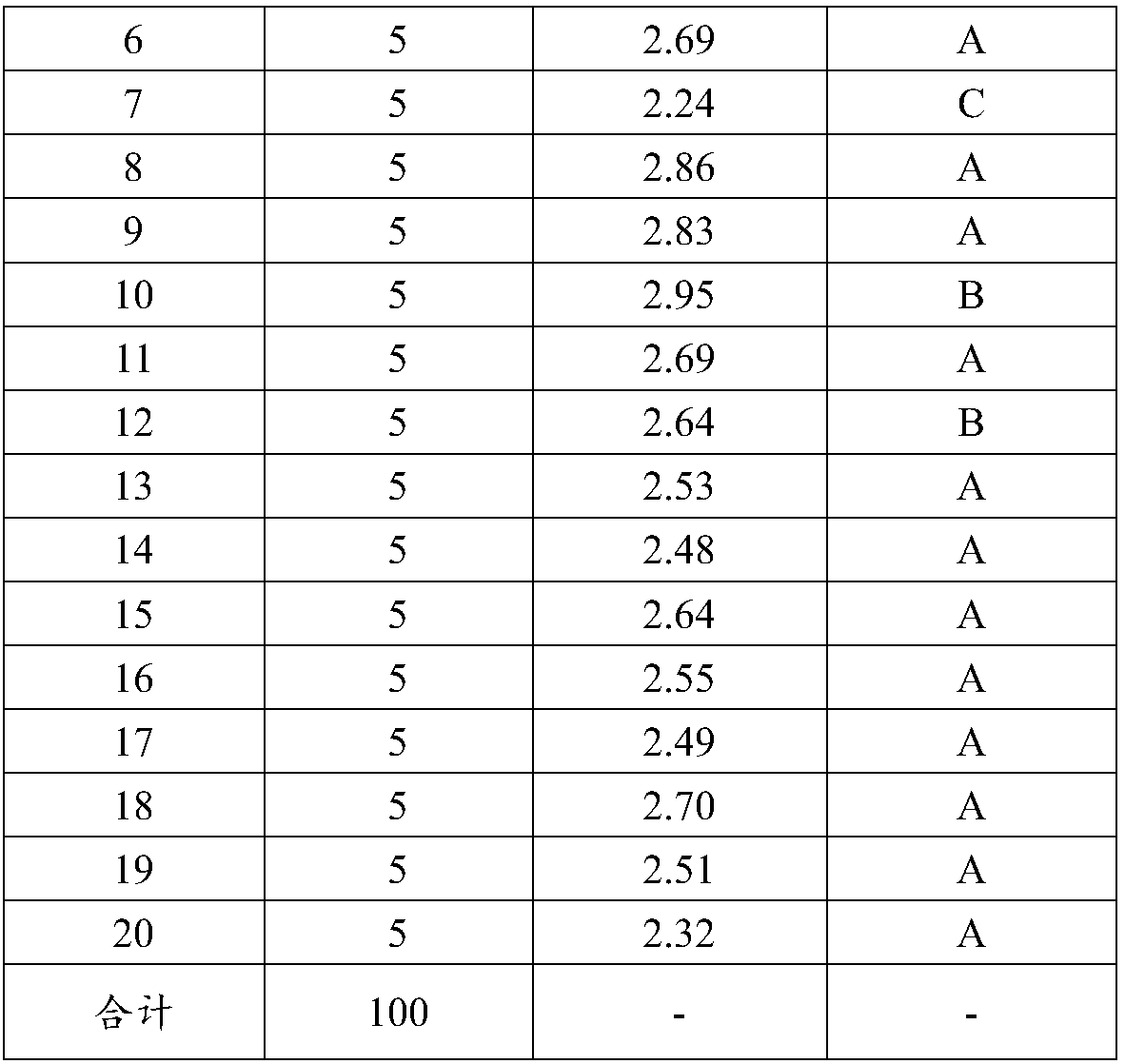

[0020] (1) Classification of “categories” in tobacco leaf formula: classify known formula tobacco leaves into feature main class A, feature auxiliary class B and feature coordination class C;

[0021] (2) Determination of the feeding order of "categories": set the weights of the characteristic main category A, the characteristic auxiliary category B and the characteristic coordination category C as Ma, Mb and Mc respectively, and convert the weights of the three categories into a proportional relationship a:b: c. According to rounding and converting to an integer ratio, the "category" with the largest ratio value is ranked second for feeding, the "category" wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com