Energy-saving environment-friendly commercial stove

An energy-saving, environment-friendly, and commercial technology, which is applied in the direction of household stoves/stoves, household stoves, applications, etc., can solve the problems of low gas utilization rate, improve combustion efficiency, prevent hypoxia or excessive temperature, and improve combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

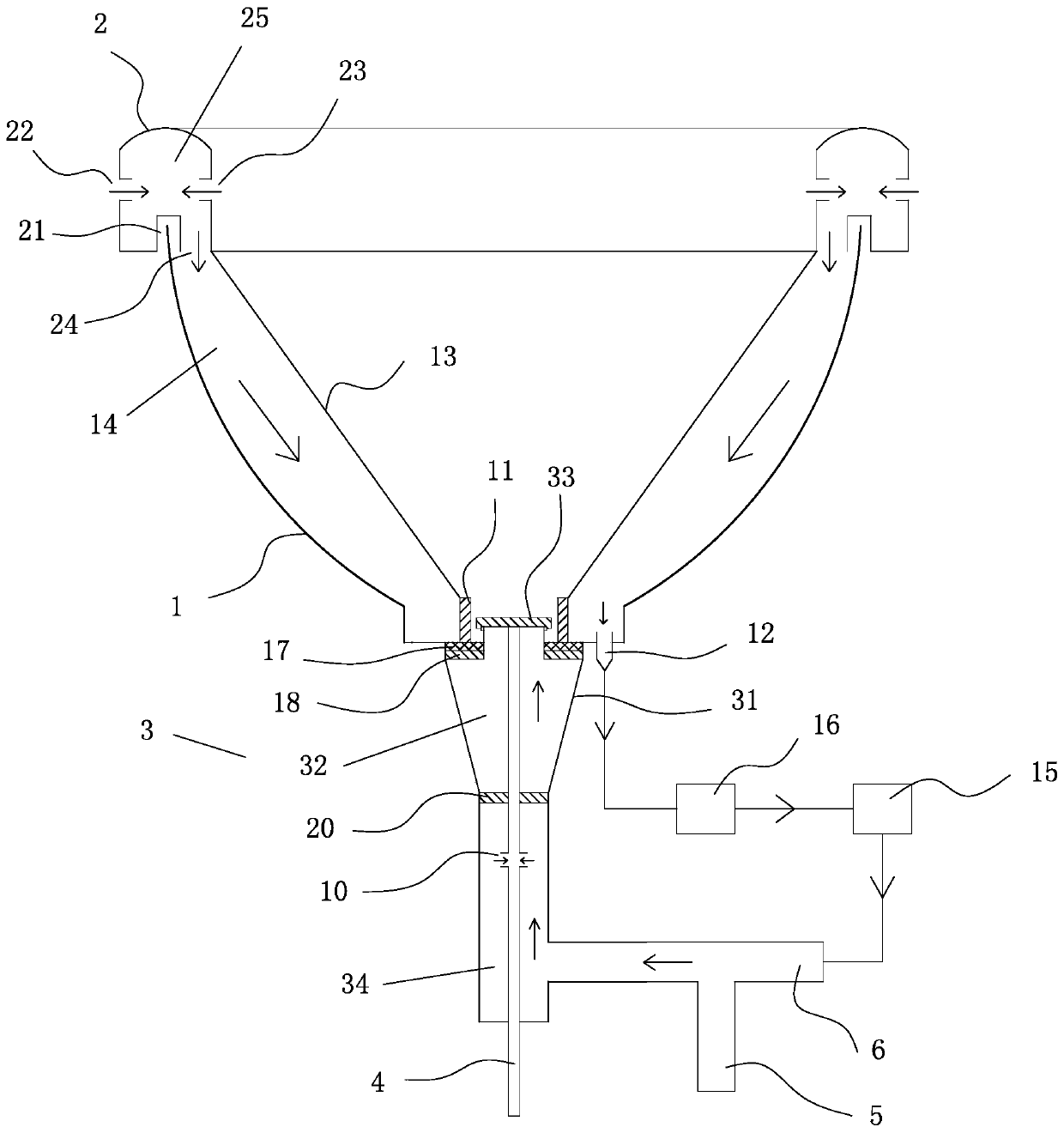

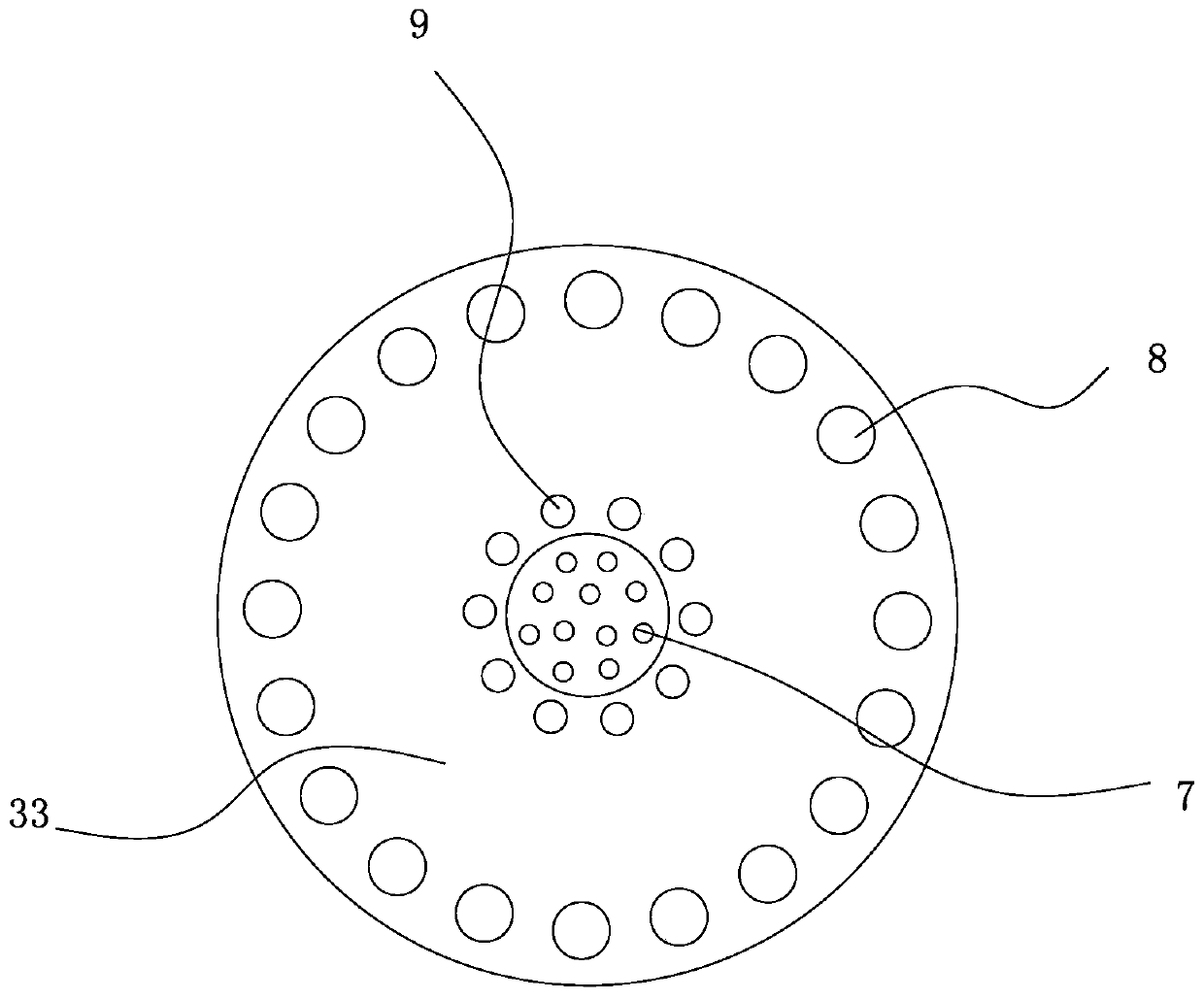

[0024] refer to figure 1 and figure 2, an energy-saving and environment-friendly commercial stove, comprising a furnace 1 with an opening on the upper part, and an annular support frame 2 is arranged on the furnace 1, and the lower part of the support frame 2 has a support groove 21 for supporting the upper end of the furnace 1, A number of first air inlets 22 are evenly arranged around the outer surface of the support frame 2, and an annular air outlet 24 is provided on the lower surface of the support frame 2 inside the furnace 1. An air inlet 22 and a flow channel 25 of the air outlet 24, a plurality of second air inlets 23 are evenly arranged around the inner surface of the support frame 2, and the second air inlet 23 communicates with the flow channel 25, and the furnace 2 The bottom of the bottom is provided with a through hole, and the said through hole is provided with a burner 3, and said burner 3 is respectively provided with a kindling gas inlet pipe 4, a main fir...

Embodiment 2

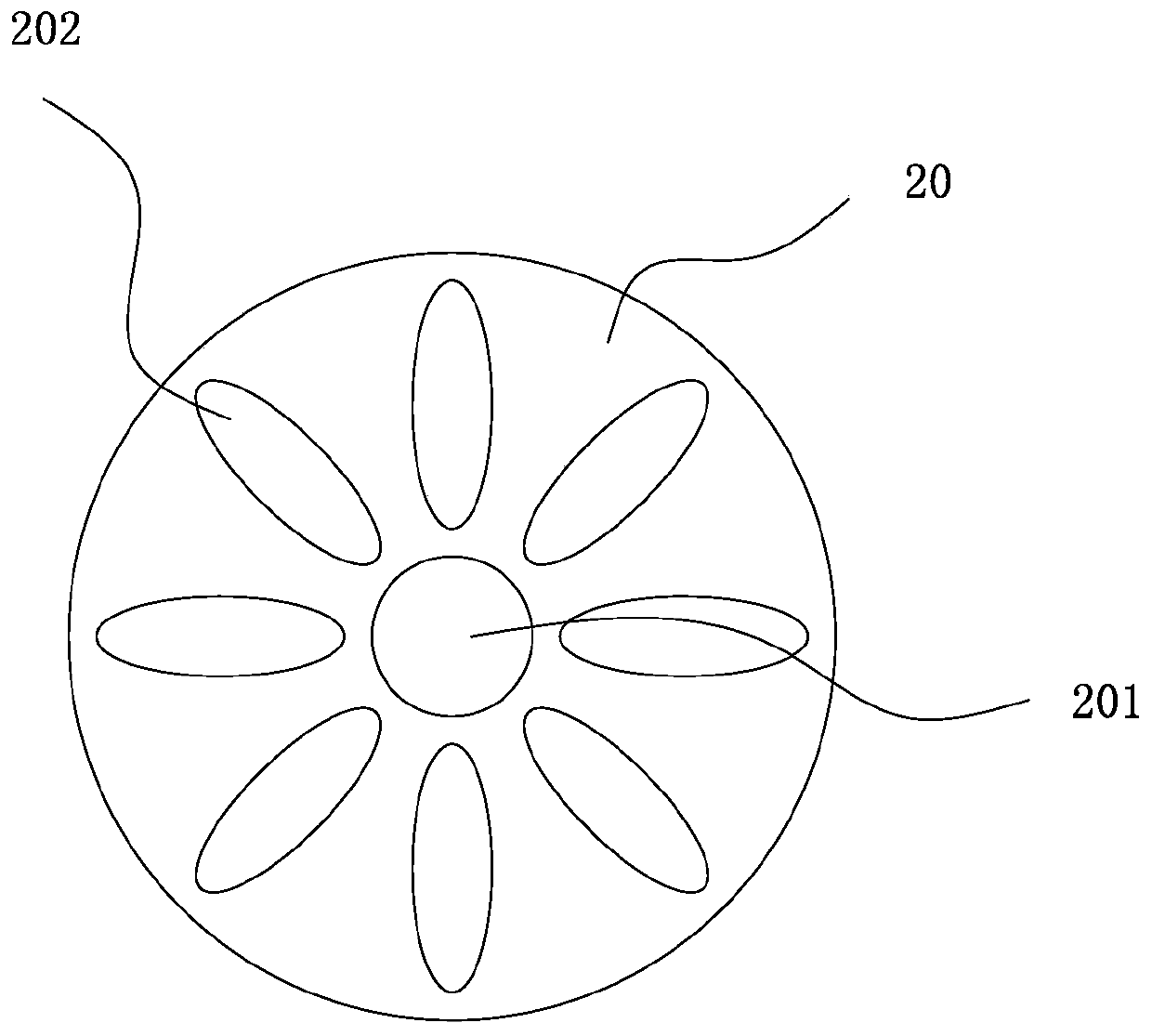

[0034] refer to Figure 4 , an energy-saving and environment-friendly commercial stove, the technical features of which are basically the same as those of Embodiment 1, and the main difference is that a mixing piece 20 is arranged between the mixing chamber 32 and the pre-mixing chamber 34, and the mixing The sheet 20 is a circular sheet-shaped body, and the middle part of the mixing sheet 20 is provided with a circular hole 201 for the ignition inlet pipe 4 to pass through, and the mixing sheet 20 is arranged in a circular matrix with the circular hole 201 as the center. There are eight mixing holes 202 , and each of the mixing holes 202 is an S-shaped structure with a large opening in the middle and gradually decreases toward both ends along the diameter direction of the mixing sheet 20 .

[0035] The working method of the present invention is: the energy-saving and environment-friendly commercial stove, the mixing hole 202 is an S-shaped structure, when the gas passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com