Patents

Literature

188results about How to "Full chemical reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Land restoration method for abandoned sand mining field

ActiveCN104641755AThe ingredients of land restoration are scientific and reasonableQuality improvementSoil-working methodsQuality assuranceEcosystem

The invention discloses a land restoration method for an abandoned sand mining field and relates to the technical field of abandoned land recycling methods. The restoration method includes the following steps: raw materials are transported to the field, the raw materials are smashed for preparation, the smashed raw materials are mixed and stirred, the stirred raw materials are fermented, and the processed raw materials are paved and rolled so that the abandoned sand mining field is filled and leveled up. The land restoration method for the abandoned sand mining field has the advantages that the land restoration burdening is scientific and reasonable, the quality of comprehensive backfill is high, and the physical properties of the land such as the bearing capacity and the shear force and the physical and chemical indexes of soil are fully considered. Therefore, the land restoration method for the abandoned sand mining field fully ensures the stability of the land topography restoration and the good cultivation function, provides quality assurance for the restoration and reconstruction of the ecological system, facilitates inspection and management, and is high in economic benefits, ecological benefits and environmental protection benefits.

Owner:北京天地丰源环保科技有限公司 +1

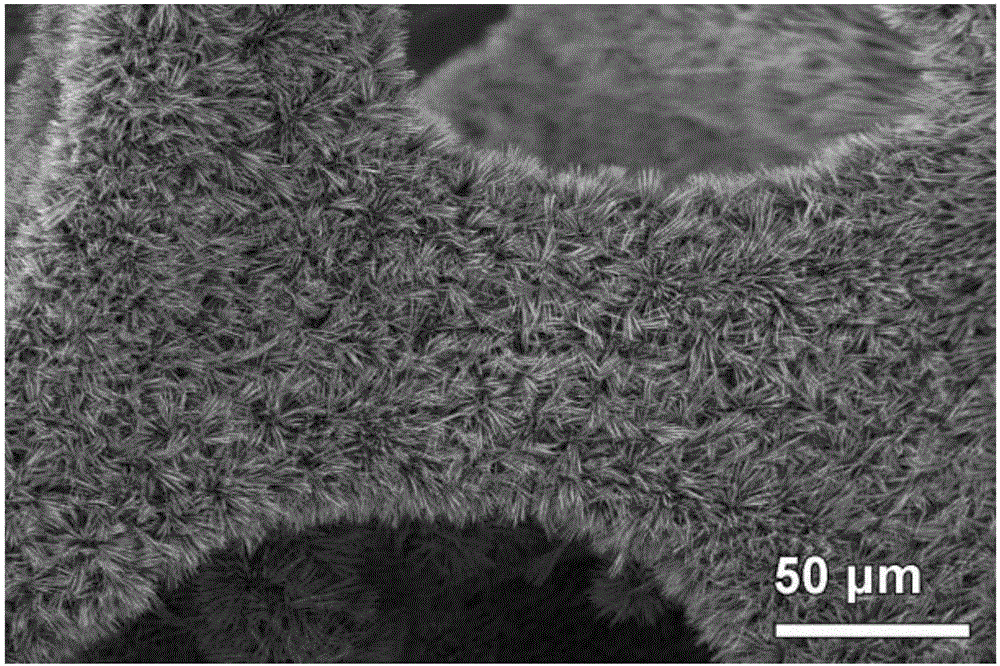

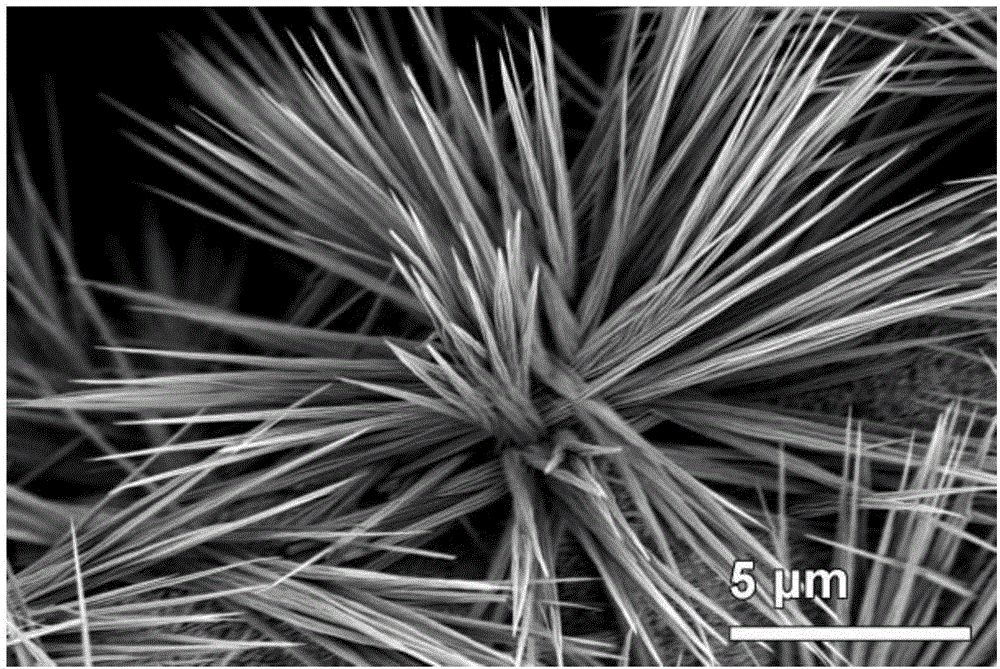

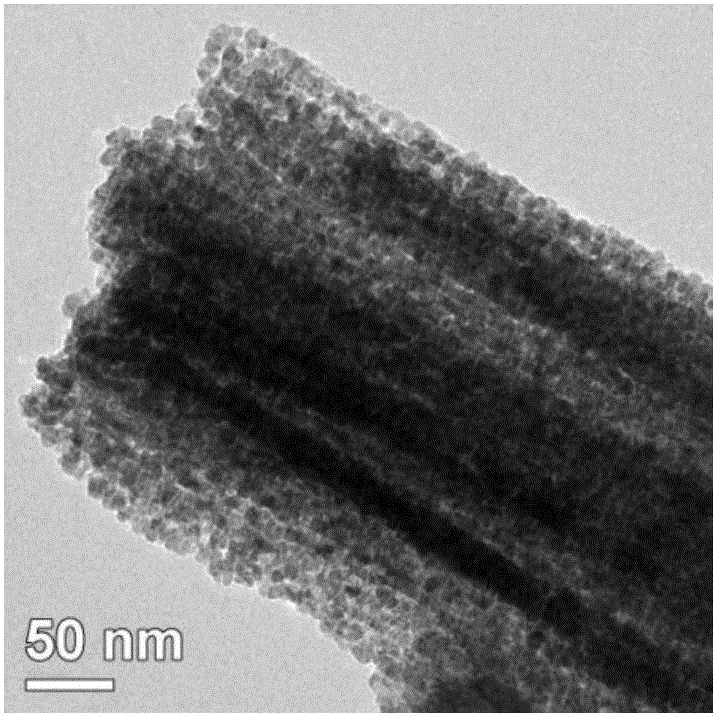

Foam copper-supported porous copper oxide nanowire composite material and preparation method and application thereof

The invention discloses a foam copper-supported porous copper oxide nanowire composite material. The material comprises a foam copper substrate and a copper oxide nanowire supported on the surface, wherein the copper oxide nanowires are 8 to 12 mum in lengths, and are 150 to 250 nanometers in widths; the nanowires do not crack or fall easily; microscopically, the nanowires have porous structures, and pore diameters are 2 to 4 nanometers; macroscopically, the nanowires are distributed radially, and every 60 to 150 nanowires constitute a copper oxide micro-flower. The obtained composite material has a multi-grade and porous structure, and the whole three-dimensional structure is rich in apertures which are suitable for the permission of light rays and ion transport. When the composite material is taken as a photocatalytic degradation organic dye, the degradation efficiency can be increased by over 10 times; when the composite material is taken as a negative electrode material of a lithium ion battery, the capacity retention ratio can be increased by over 30 percent.

Owner:HEBEI UNIV OF TECH

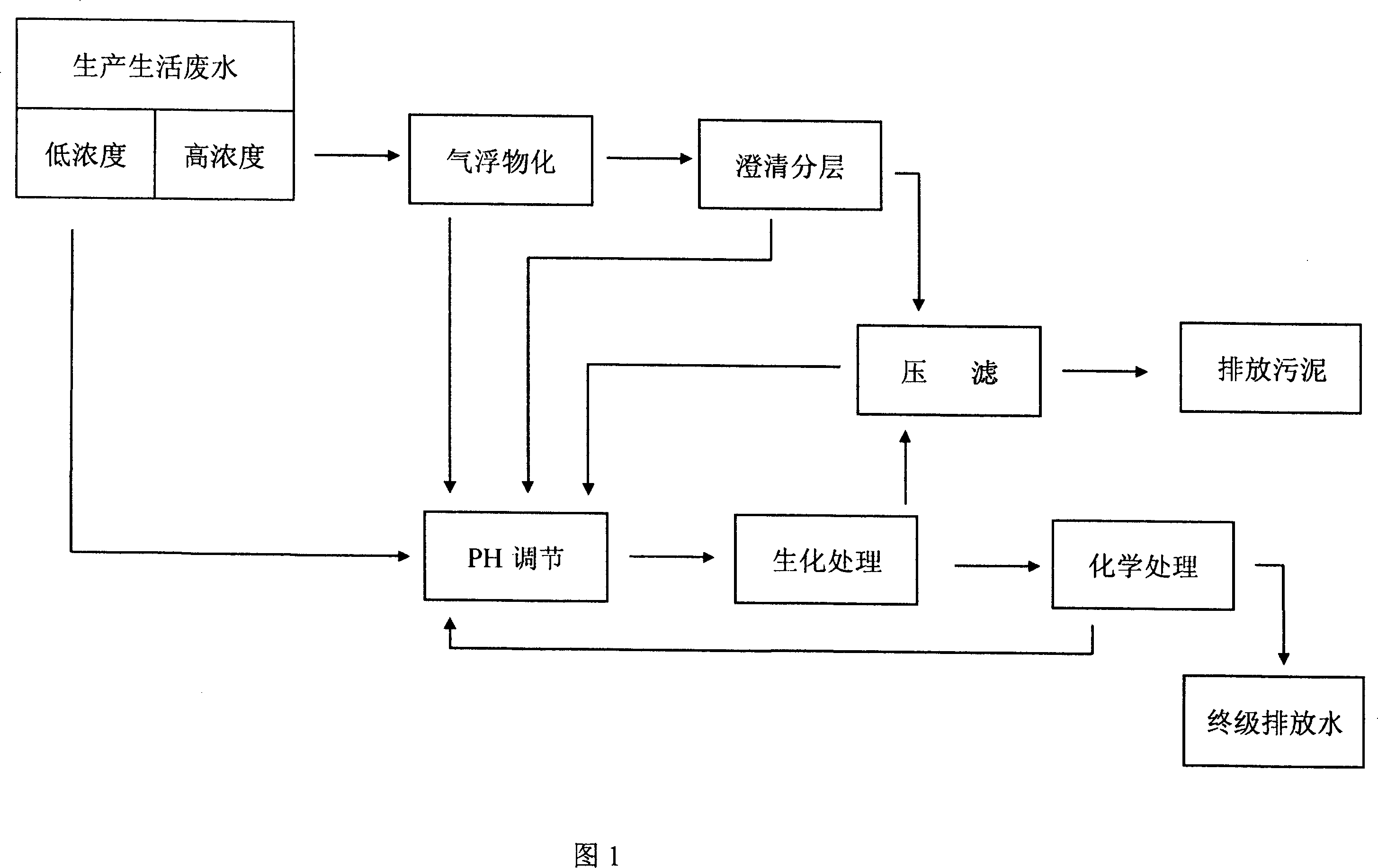

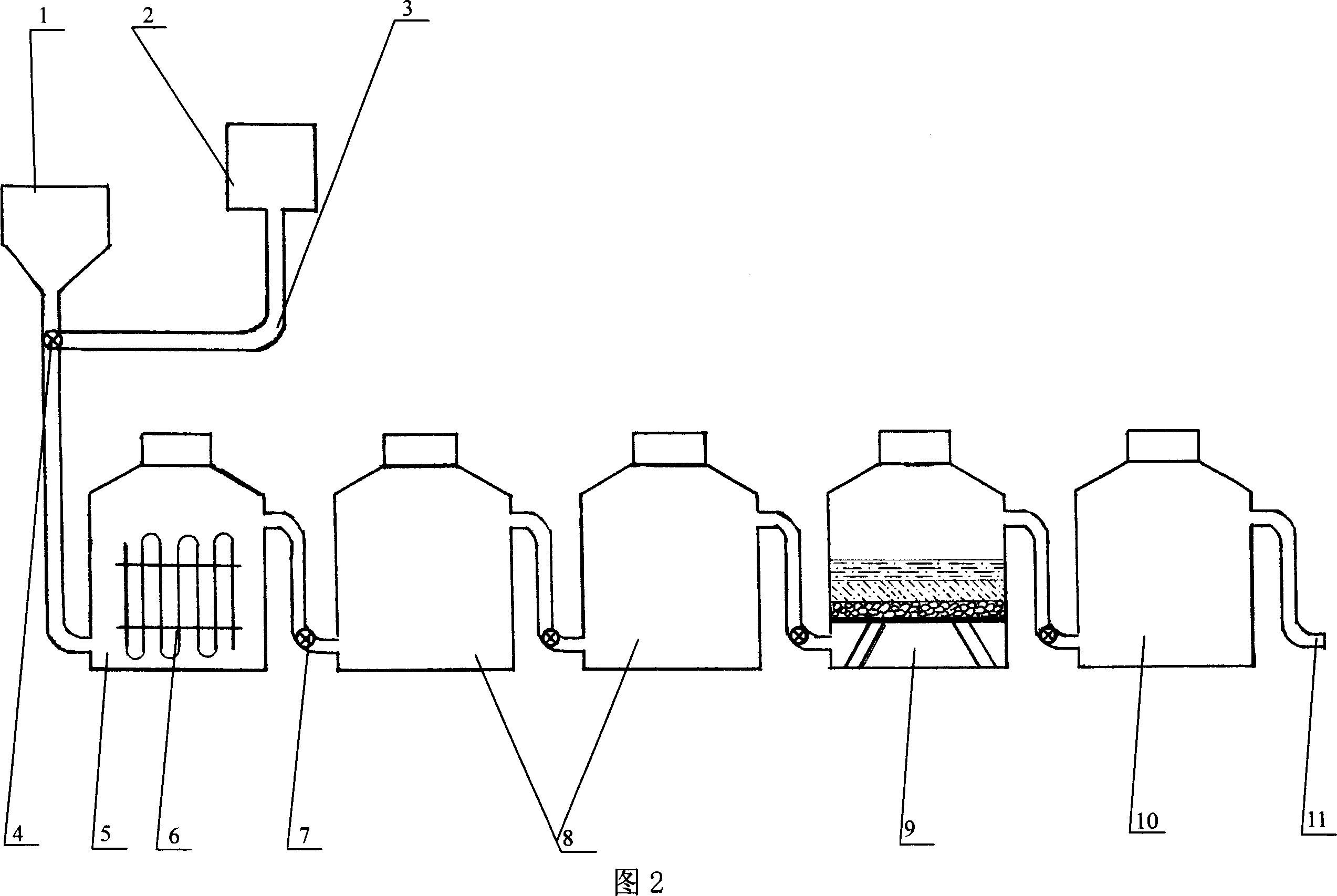

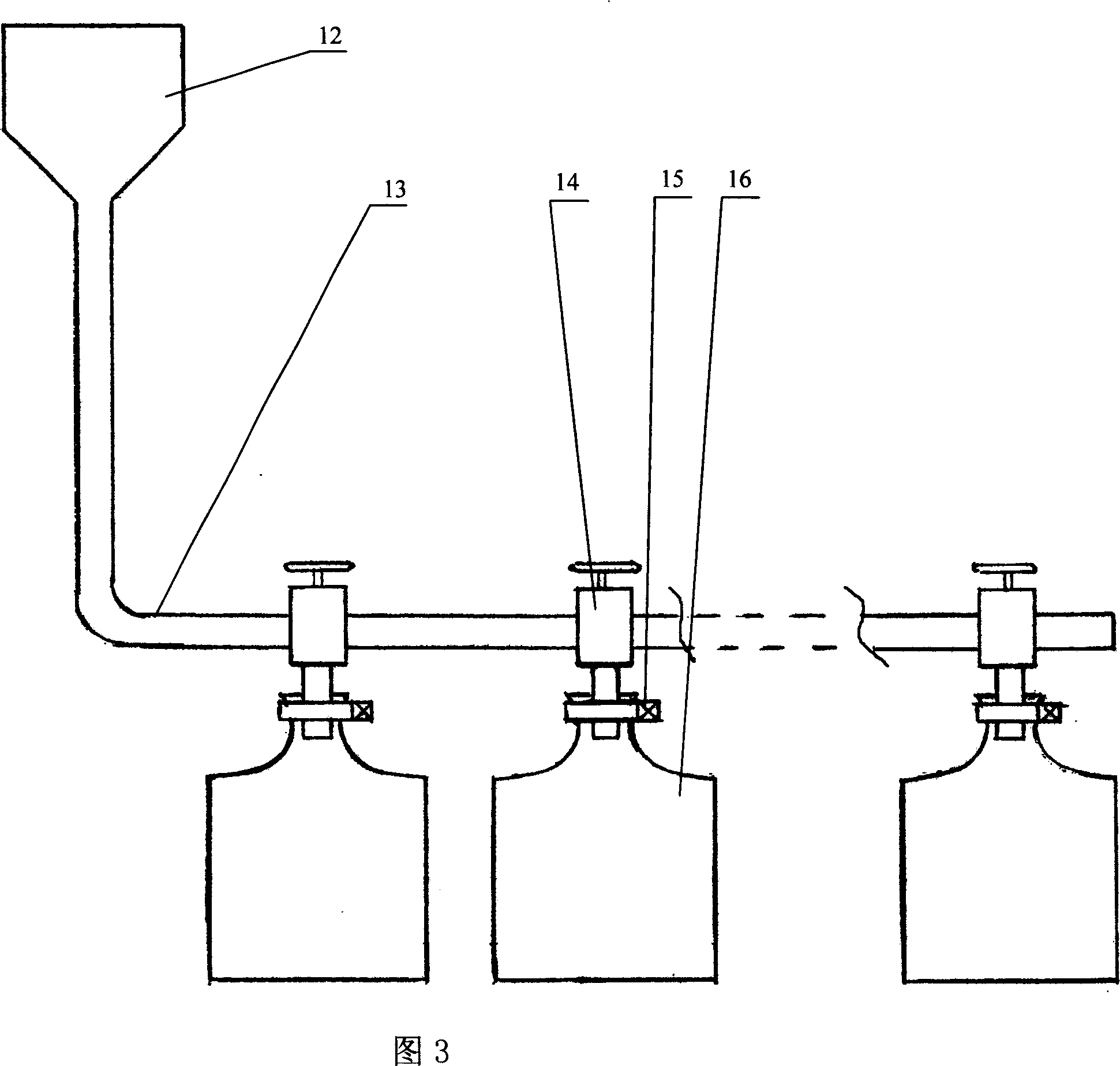

Method for treating waste water

InactiveCN101085695AImprove protectionPromote sustainable developmentMultistage water/sewage treatmentEnergy based wastewater treatmentChemical treatmentResource protection

The invention belongs to wastewater treatment field, especially relates to printing and dyeing mill wastewater treatment. The invention employs sorting and collecting physico-chemical treatment, automatic- pressure filtering and separating wastewater and further chemical treatment for active sludge, to reduce the COD concentration in primary discharged water by 15%, and meet national standard. The invention is characterized by greatly saved energy and resource and benefit for environmental and resource protection and sustainable development.

Owner:SHANGHAI XINHONG DYEING & FINISHING

High-dehydration curing plugging agent and preparation method thereof

The invention provides a high-dehydration curing plugging agent. The high-dehydration curing plugging agent is characterized by comprising the following components in parts by weight: 25-70 parts of fly ash or coke ash or lime fly ash or coal cinder, 40-75 parts of gypsum, 10-25 parts of sodium soil or pottery clay or calcium soil, 10 parts of paper fiber or leather fiber, 3-6 parts of sodium silicate or magnesium silicate or aluminum silicate or silicon oxide, 5-15 parts of calcium chloride or lime or calcium carbonate and 1.6-6 parts of sodium hydroxide. The plugging agent is a novel plugging material, water is added into the plugging agent and stirred by virtue of a stirrer to obtain a mixture, the mixture is pumped into the leakage formation, the plugging agent is rapidly dehydrated to form a cured product and thus the leakage formation is plugged and the difficult problem that the compressive strength after the leakage formation is plugged by the general plugging agent is not high is solved.

Owner:JIANGXI PINGXIANG ANHUA BIOTECH

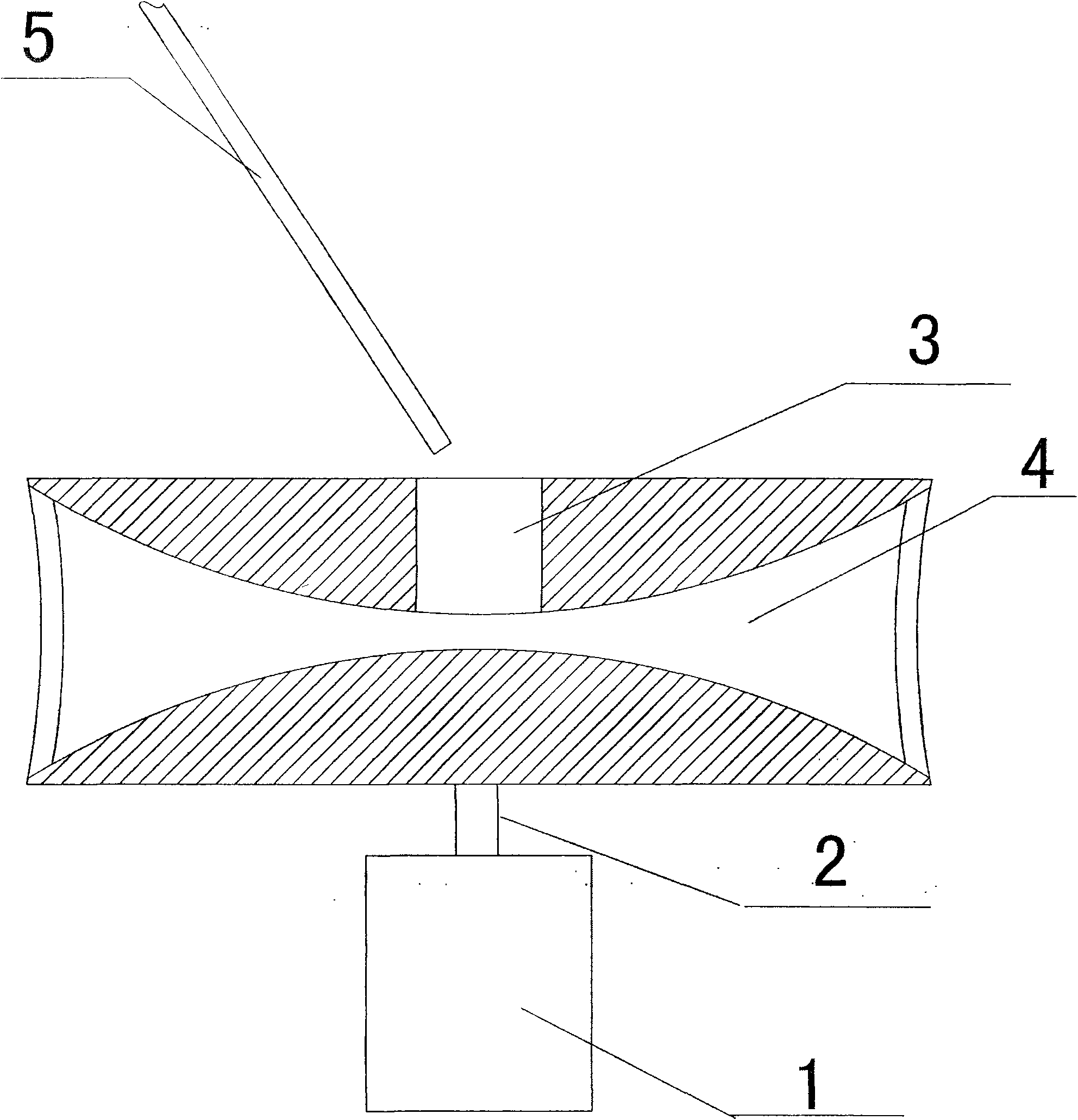

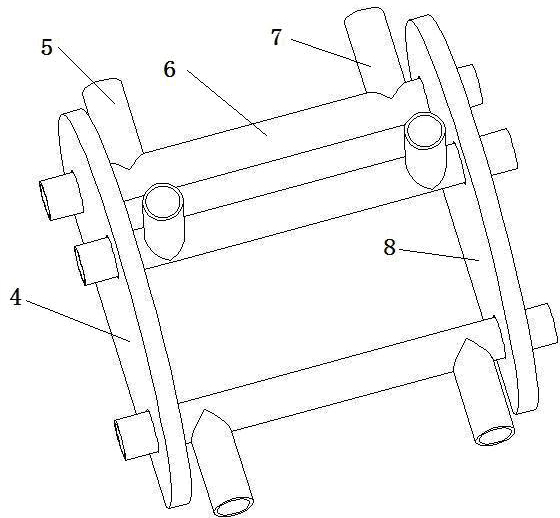

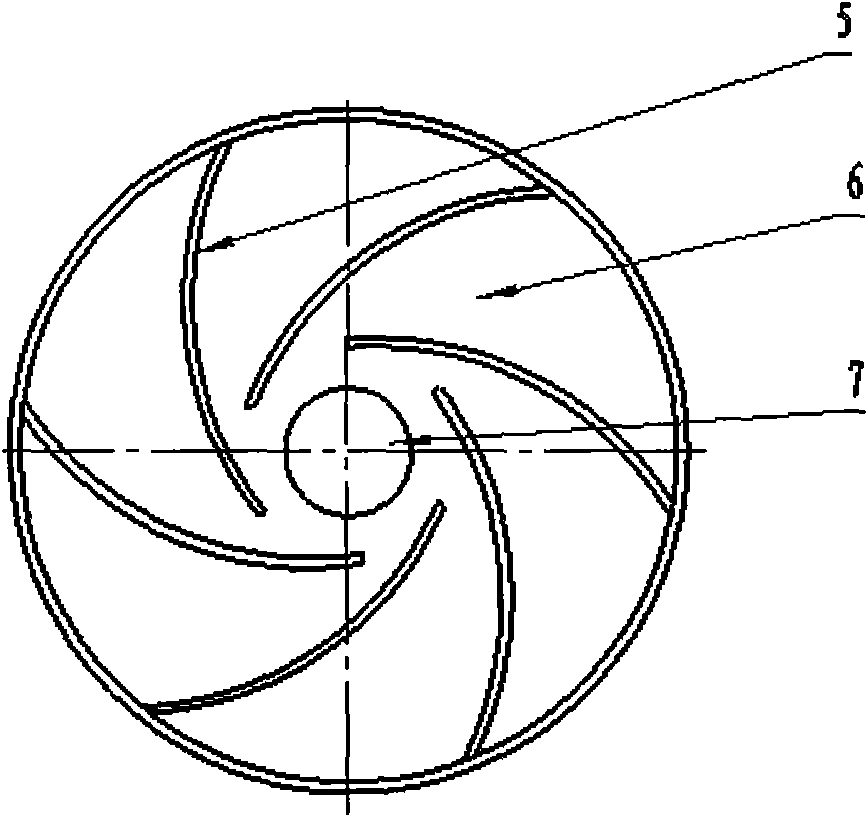

Axial flow device

InactiveCN102734175AUniform irrigationRealize micro-sprayPump componentsAxial flow pumpsImpellerSuction equipment

The invention provides an axial flow device comprising a shell and a transmission device. The shell is provided with the transmission device and is internally provided with a shell cavity; a vortex tube impeller is arranged in the shell cavity; the transmission device is connected with a vortex tube impeller; the vortex tube impeller is provided with a vortex tube which is provided with an impeller opening A and an impeller opening B and is internally provided with a wheel body, and the wheel body is provided with a guide blade; an inclined angle is formed between the guide blade and a rotating shaft of the vortex tube impeller; the guide blade is connected to the inner wall of the vortex tube; a shell cavity opening A is arranged at one end, which corresponds to the impeller opening A, of the shell cavity; and a shell cavity opening B is arranged at the other end of the shell cavity. The axial flow device is more energy-saving and can be used for pressurizing and conveying fluid. The axial flow device can serve as a water pump, vacuum equipment, air suction equipment, an air blower, a compressor, atomizing equipment, sprinkling equipment, a reactor, air blowing equipment, propelling equipment, a sewage processor, a dust remover, a dust collector, dressing equipment, a steam turbine, a water turbine, a wind turbine, a vortex pressurizing device utilizing residual heat of an engine, foam material manufacturing equipment, nano material manufacturing equipment and the like; and the axial flow device can be used for manufacturing a brand new foam material.

Owner:陈久斌

Novel method for synthesizing quaternary ammonium salts

ActiveCN101624347AIncrease profitReduce dosageOrganic compound preparationAmino compound preparationQuaternary ammonium cationReaction temperature

The invention discloses a novel method for synthesizing quaternary ammonium salt, which is characterized in that methyl-containing quaternary ammonium salts are prepared through the reaction of dimethyl carbonate, tertiary amine and inorganic acid or organic acid. The method specifically comprises the steps: putting tertiary amine in proportion in a reactor; pumping a corresponding amount of mixture of inorganic acid or organic acid, polar solvent and ionic liquid catalyst in appropriate controlled flow into the reactor; stirring for reaction at an appropriate temperature in nitrogen atmosphere; putting vacuum-dried products after reaction is completed in the reactor; blowing and washing the reactor with nitrogen; pumping the mixture of dimethyl carbonate and polar solvent in appropriate controlled flow into the reactor for hermetic reaction; performing reaction under the pressure between 0.5 and 3 MPa at reaction temperature between 100 and 200 DEG C; stirring till reaction is completed; and obtaining reaction products which are the methyl-containing quaternary ammonium salts. The method greatly improves the utilization rate of catalysts and is small in the amount of catalysts, and the reaction yield and purity of the method are over 99 percent.

Owner:包珣

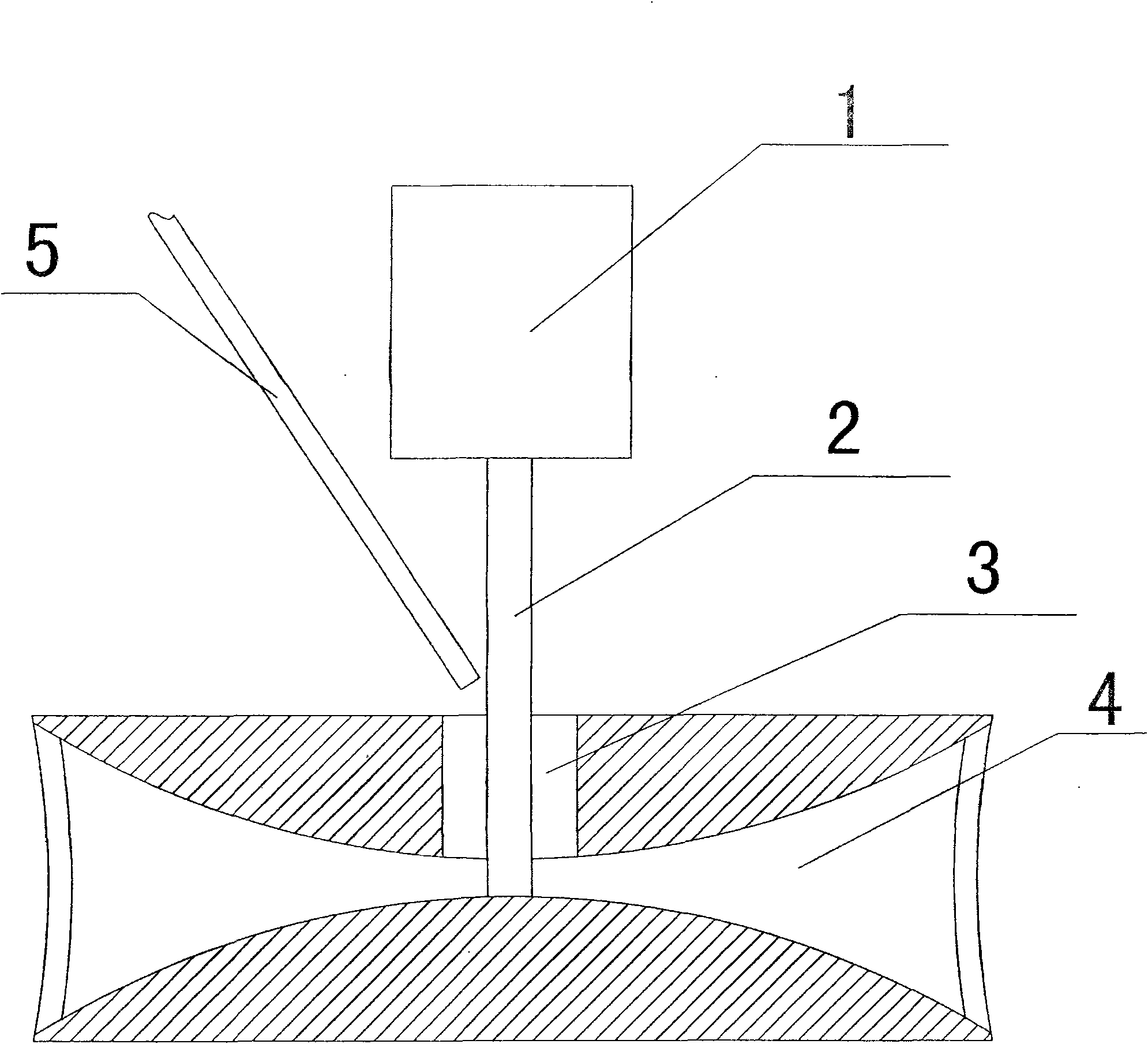

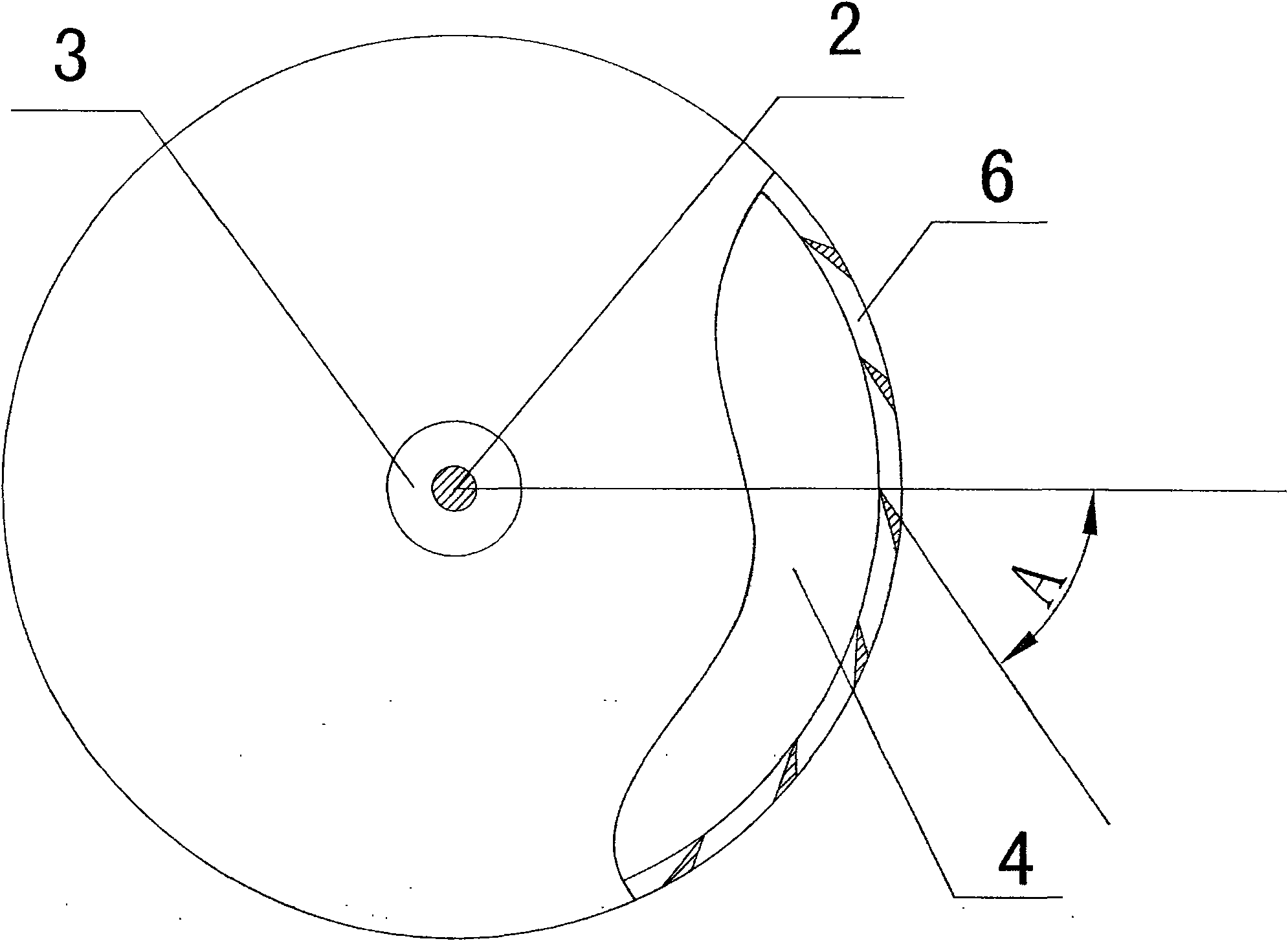

Atomizer

InactiveCN101642735AWell mixedFull chemical reactionDispersed particle separationLiquid spraying apparatusChemical industryChemical reaction

The invention relates to an atomizer which adopts a new atomizing way and a new atomizing principle and sufficiently utilizes fluid motion and vortexes to enable materials and gases to be automatically absorbed to the vortexes from a vortex center area, uniformly mixed by being influenced by the vortexes in the moving process from a vortex center to vortex periphery and thrown out from the atomizer under the action of circular motion centrifugal force to form aerial fog. The atomizer comprises a power machine and a rotating shaft, wherein the rotating shaft is provided with an atomizing chamber, the middle of the atomizing chamber is provided with a gas inlet, and the periphery of the atomizing chamber is provided with a gas outlet. The invention can be used for various fields needing atomizing equipment, can be used for producing the powder of multiple nano materials and can be applied to fields, i.e. material industry, atomizing cooling, smoke gas purification, atomizing drying, refining oil and heavy oil catalytic cracking, chemical reaction, fuel atomization, heavy oil atomization, boiler water deoxygenation, atomized water, pesticide spraying, extinguishment spraying, humidification, sterilization, odour removal, fog making, medicine preparation, medical treatment, chemical industry production, and the like.

Owner:陈久斌

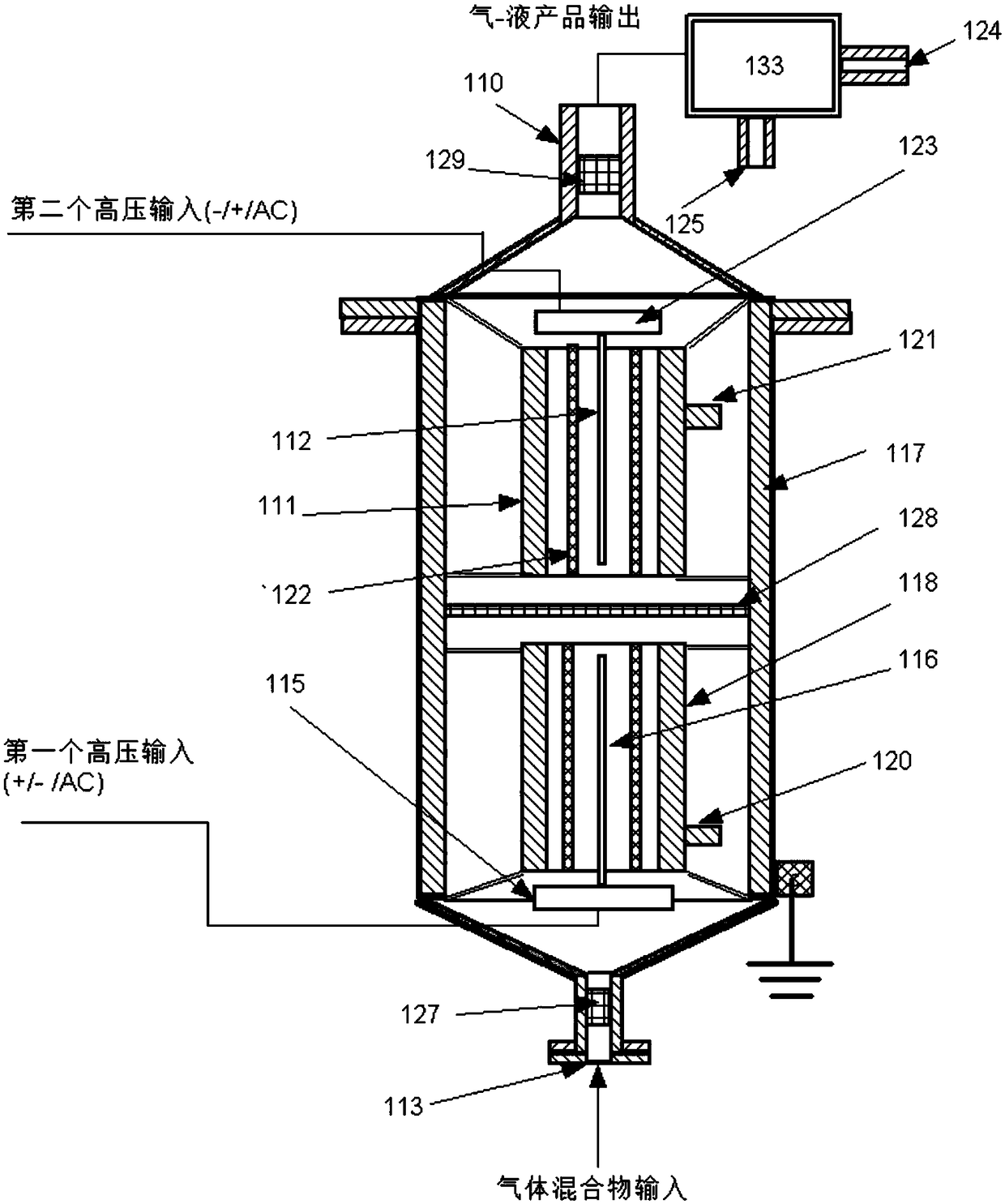

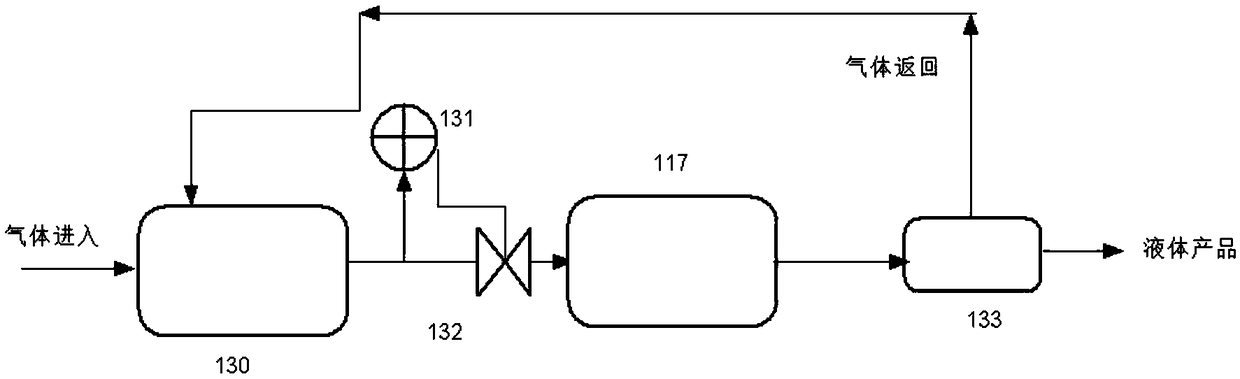

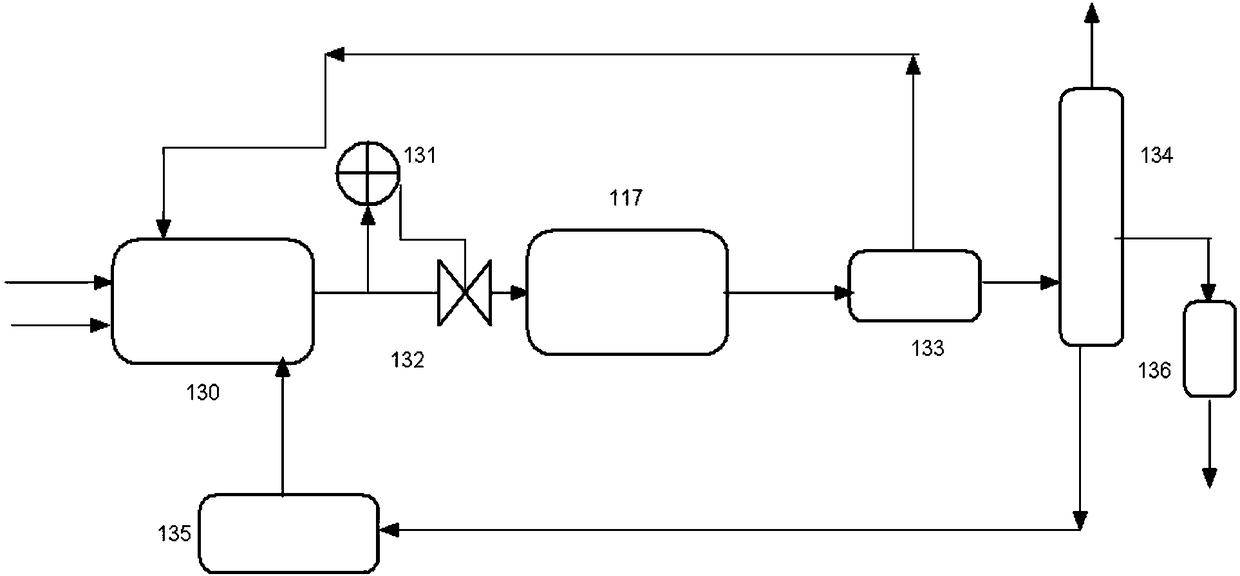

Method for low temperature plasma dual-electric field assisted treatment of gas containing carbon dioxide and/or carbon monoxide to synthesize compounds

InactiveCN109200969AHigh speedFully convertedHydrogenOrganic compound preparationHigh carbonInorganic compound

The invention provides a method for low temperature plasma dual-electric field assisted treatment of gas containing carbon dioxide and / or carbon monoxide to synthesize compounds. According to the method, two corona discharge electric fields with different electric polarities in a plasma assisted reactor are used for forming plasma dual electric fields, reaction gas is fed into the reactor, and thereactor contains corona discharge dual electric fields; the dual electric fields include a first electric field and a second electric field, the first electric field is a positive corona discharge electric field, or an alternating corona discharge electric field, or other electric field sources that can provide enough energy to oxidize and decompose reaction gas molecules into atoms, ions, free radicals and the like; the second electric field is a negative corona discharge electric field, and organic compounds such as fatty hydrocarbons, high-carbon ethers, high-carbon alcohols, high-carbon esters and low-carbon alcohols are obtained through reforming and reduction; inorganic compounds such as N2, O2, H2SO4 and NH3 can also be obtained.

Owner:HYCHAR HLDG LTD

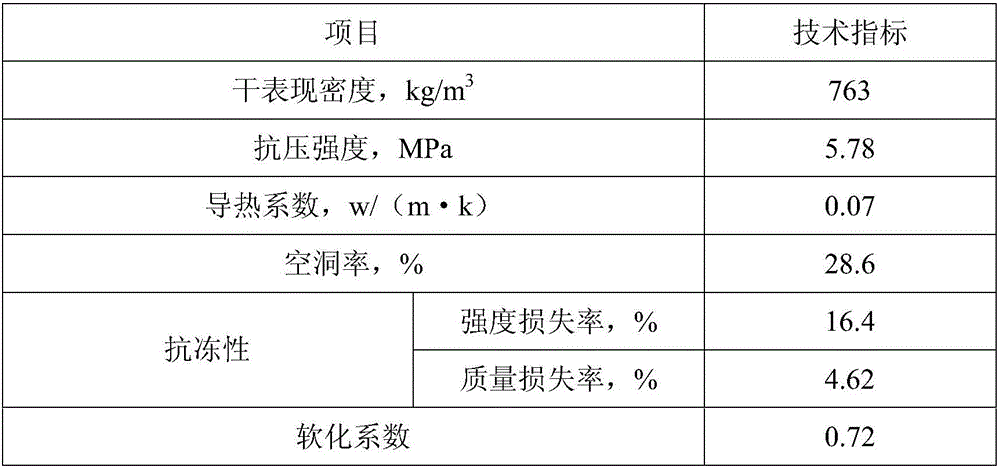

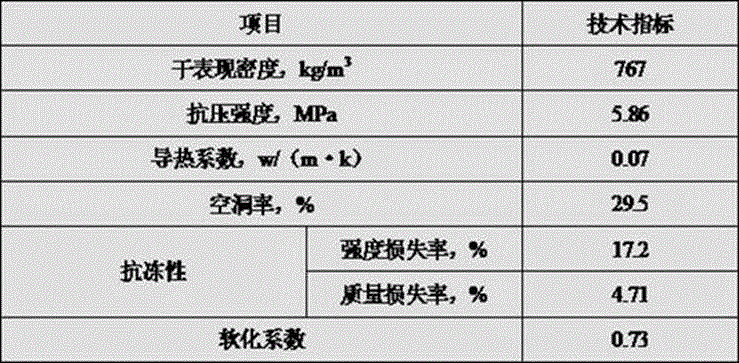

Core-shell foamed concrete insulating brick and preparation method thereof

ActiveCN104310882ALightweight and compressiveFull chemical reactionConstruction materialCeramicwareFoam concreteBrick

The invention discloses a core-shell foamed concrete insulating brick which comprises a hollow brick used as a brick shell and a cement foamed material filled in the brick cavity. The cement foamed material comprises the following components in parts by weight: 30-40 parts of cement, 1-2 parts of water reducing agent, 1-2 parts of calcium chloride, 0.5-1 part of aluminum sulfate, 0.1-1 part of foam stabilizer, 20-25 parts of oxydol, 1-2 parts of sodium sulfate and 150-200 parts of water. The cement foamed material and hollow brick body can be well cured and solidified together, thereby ensuring the enduring combination firmness. The insulating brick has the characteristics of high durability, favorable wind pressure resistance, favorable impact resistance and high compression strength. The insulating brick has the advantages of excellent heat insulating property, excellent sound insulation effect, light weight, compression resistance and the like. The method for preparing the insulating brick has the advantages of no need of autoclave curing, small equipment investment and simple technique, and is simple to operate and convenient for popularization; and the produced product has stable quality.

Owner:GUANGXI HONGFA BUILDING MATERIALS TECH

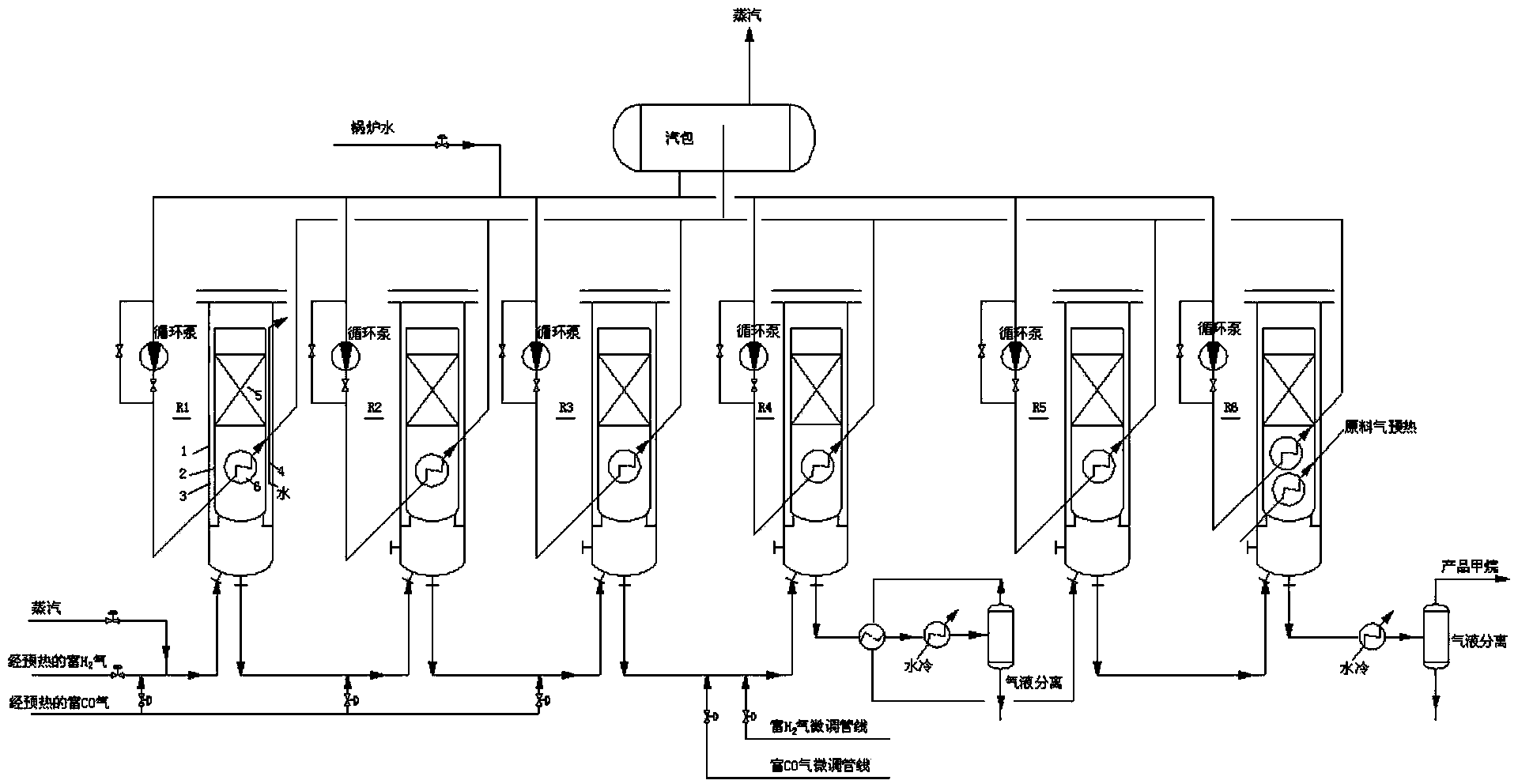

Circulation-free methanation system

The invention discloses a circulation-free methanation system which comprises a gas distribution methanation stage and a supplementation methanation stage, wherein in the gas distribution methanation stage, 1 to 3 stages of serially connected high-temperature reactors are adopted; in the supplementation methanation stage, 2 to 3 stages of serially connected low and medium-temperature reactors are adopted; the final-stage reactor in the gas distribution methanation stage is connected in series with the head-stage reactor in the supplementation methanation stage; technical gas discharged by the former stage of the reactor is used as part of or all the synthesized gas of the next stage of the reactor; technical gas discharged by the final-stage reactor is subjected to cooling separation to obtain a final methane product. The technical system is simple, and the reaction is steady, safe and reliable; the running cost and the manufacturing cost are low.

Owner:BEIJING HUAFU ENG +2

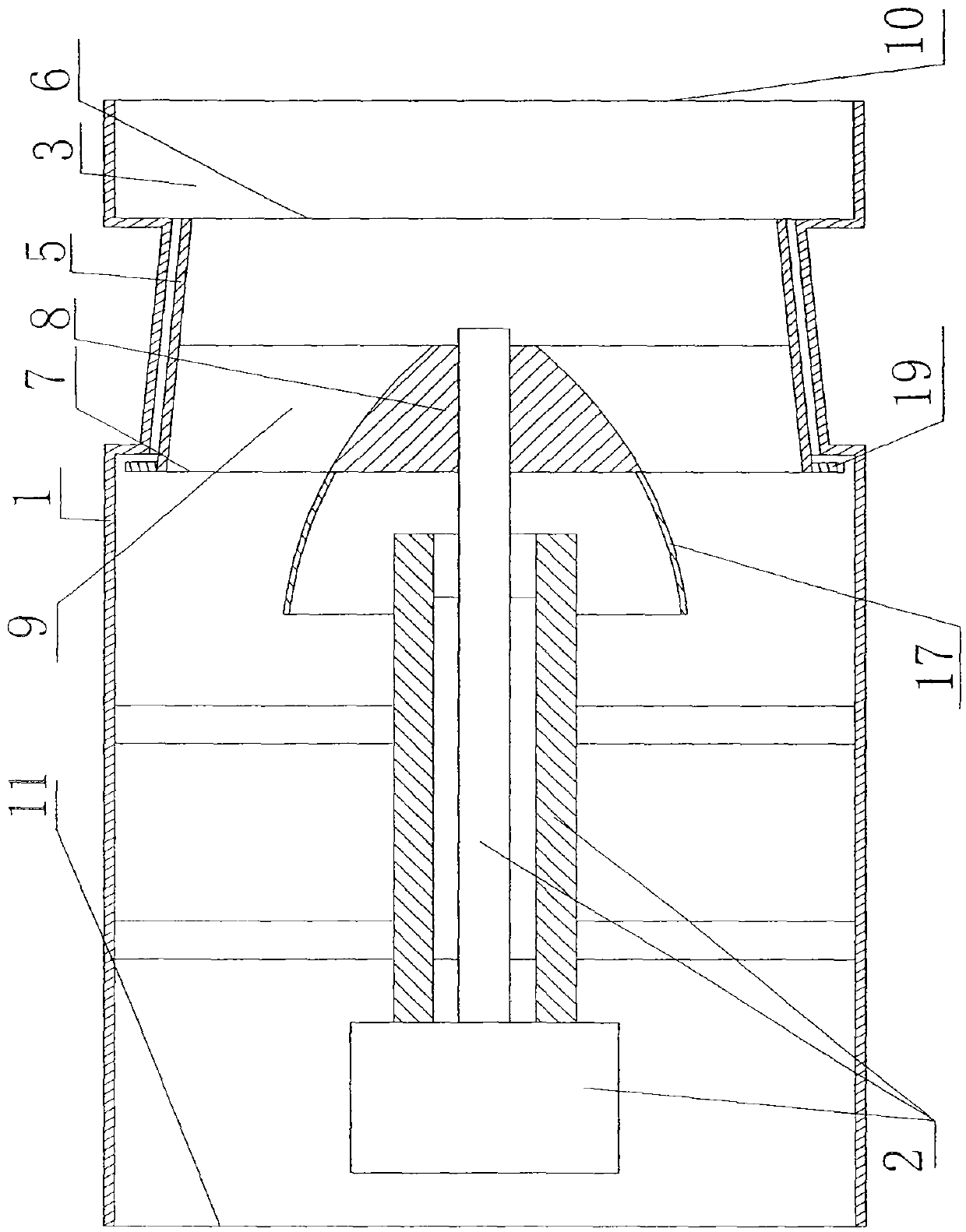

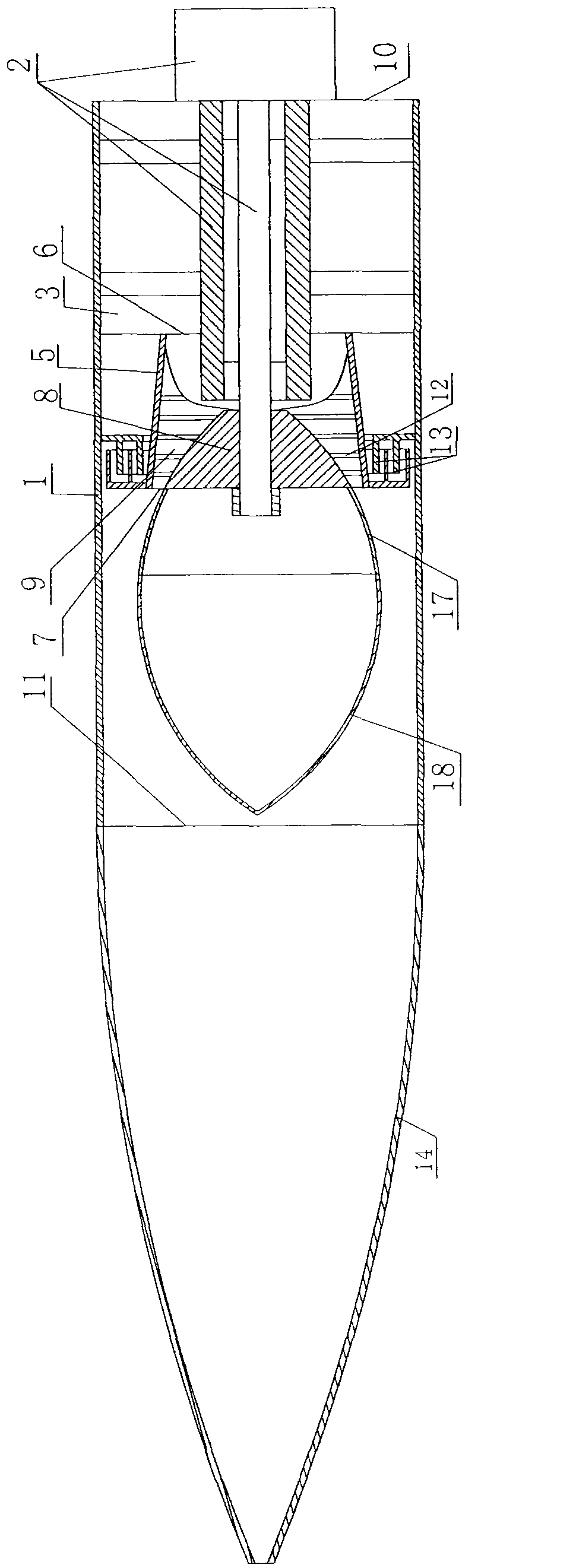

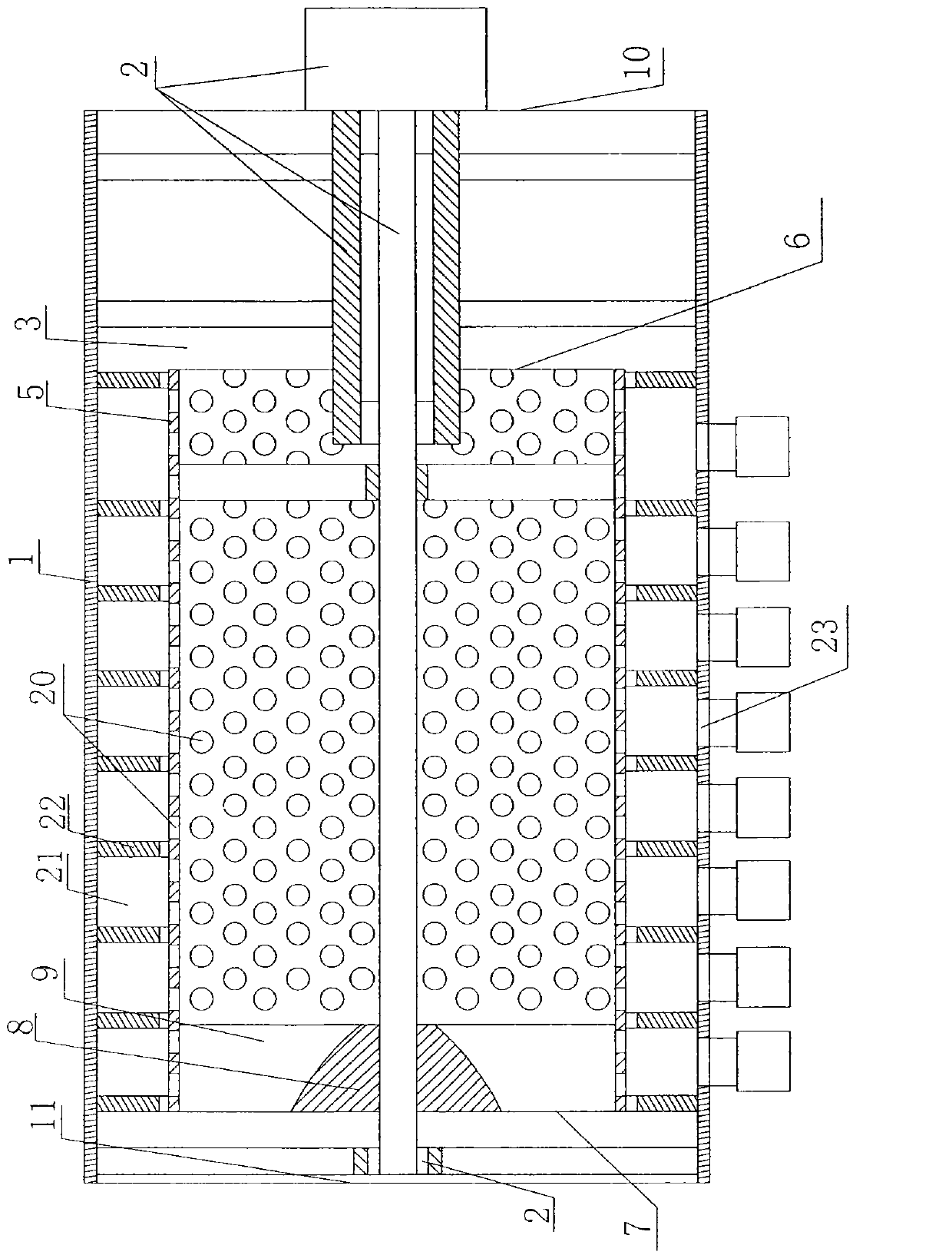

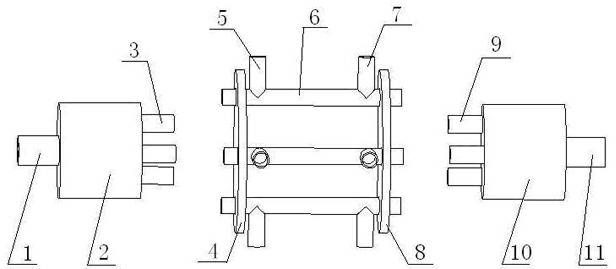

Low-temperature plasma cooperating two-phase catalyzing device and harmful exhaust gas processing method

ActiveCN102166474AReduce PM particle emissionsReduce back pressureExhaust apparatusDispersed particle separationExhaust gasProduct gas

The invention discloses a low-temperature plasma cooperating two-phase catalyzing device and a harmful exhaust gas processing method, belonging to the technical field of purification of harmful exhaust gas from a diesel engine. The device provided by the invention comprises a main air inlet (1), an oxide phase catalyzing device (2), an air outlet A (3), a support A (4), a plasma generator (6), a support B (8), an air inlet B (9), a reduction phase catalyzing device (10) and a main air outlet (11). The method provided by the invention comprises the following steps of: firstly, catalyzing the oxide phase of the harmful exhaust gas through the oxide phase catalyzing device (2); secondly, dividing the gas into three or more than three flows, respectively introducing the gas flows into a double-dielectric-barrier-discharge low-temperature plasma generator to perform low-temperature plasma dielectric barrier discharge on the gas; and finally, catalyzing the reduction phase of the gas through the reduction phase catalyzing device. In the invention, two-phase catalyzing devices are combined, the conversion efficiency of the exhaust gas is further increased, and the harmful emission of thediesel engine is reduced.

Owner:JIANGSU UNIV

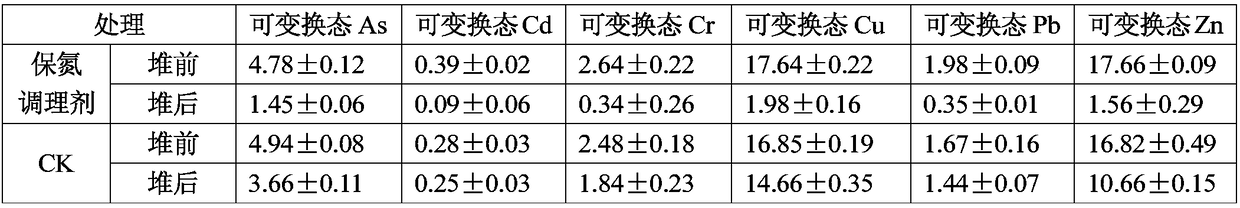

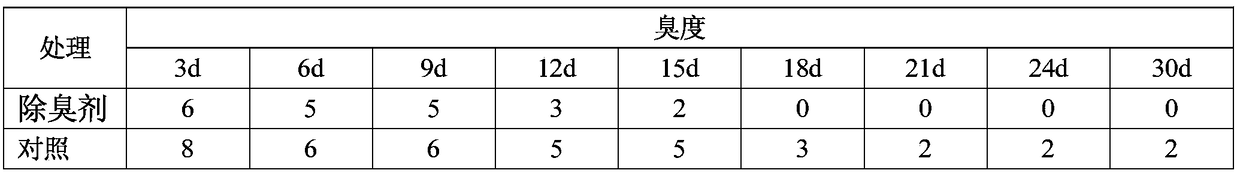

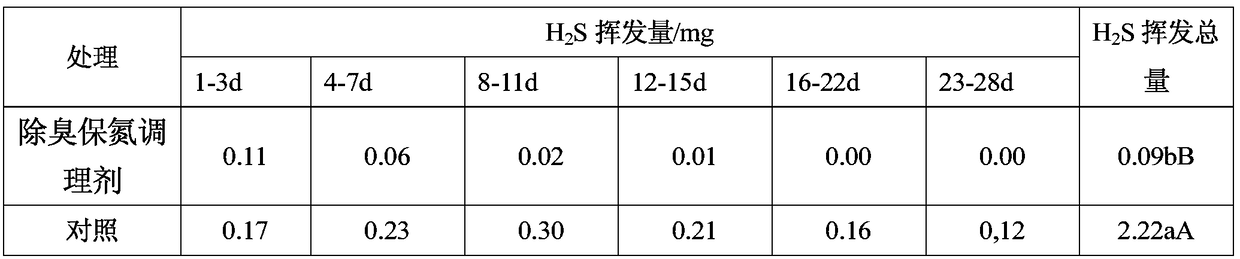

Production method of odorless high-nitrogen livestock and poultry manure fermented organic fertilizer

InactiveCN109279953AInhibition of growth and reproductionImprove the immunityBio-organic fraction processingExcrement fertilisersMicrobial agentAnimal feces

The invention discloses a production method of an odorless high-nitrogen livestock and poultry manure fermented organic fertilizer. The production method comprises the following steps: step 1, uniformly mixing animal manure with crushed straw or stalks of other crops according to a weight ratio of (2-8):1, adding water after uniform mixing, and controlling the water content to be 60-65% to obtaina fermented material; and step 2, adding a prepared microbial agent solution, zeolite powder and calcium chloride respectively according to mass percentages of 2.5%, 3% and 4%.

Owner:内蒙古金地隆农业科技发展有限公司

Pesticide residue quantity detection device for agricultural products

InactiveCN106908442ASimple structureEasy to operateAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorChemical reactionPesticide residue

The invention discloses a detection device for pesticide residues used in agricultural products. A heating device is arranged on a base; Unicom has a reagent adding tube and a feeding tube set at an angle; a liquid outlet pipe is provided on the lower side of the detection container, and a sealing tube is provided at the lower end of the liquid outlet pipe; a stirring shaft is provided in the detection container; a stirring blade is provided on the stirring shaft; The rotating motor is set above the detection container, and the rotating shaft of the rotating motor passes through the square groove at the upper end of the detecting container and is connected to the stirring shaft; the base is located on the side of the heating device and is also provided with a rotating shaft for driving the rotating motor to move left and right in the square groove The left and right driving mechanism of the invention can make the stirring blade move back and forth, so that the reagents and agricultural products can fully react, and at the same time, it can also be heated at the bottom of the detection container to further ensure the sufficient chemical reaction and the accuracy of detection.

Owner:SUZHOU JINGWEI AGRI PROD

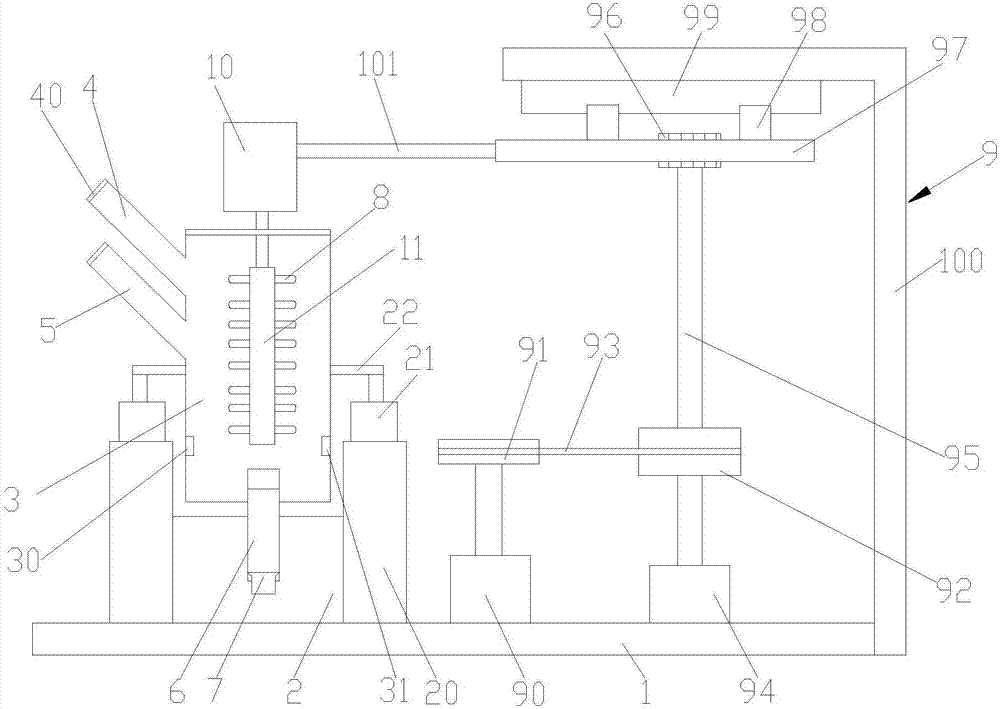

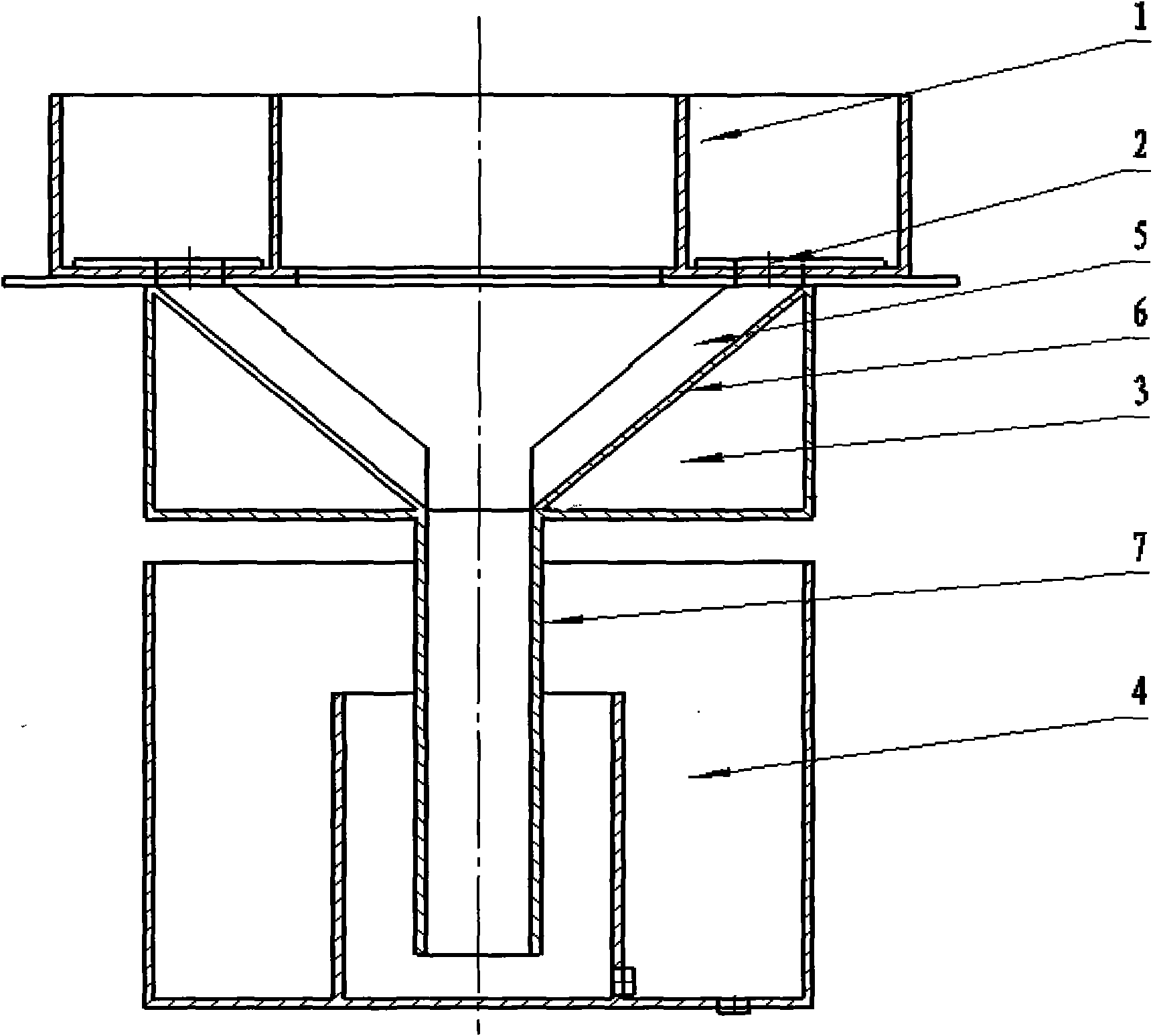

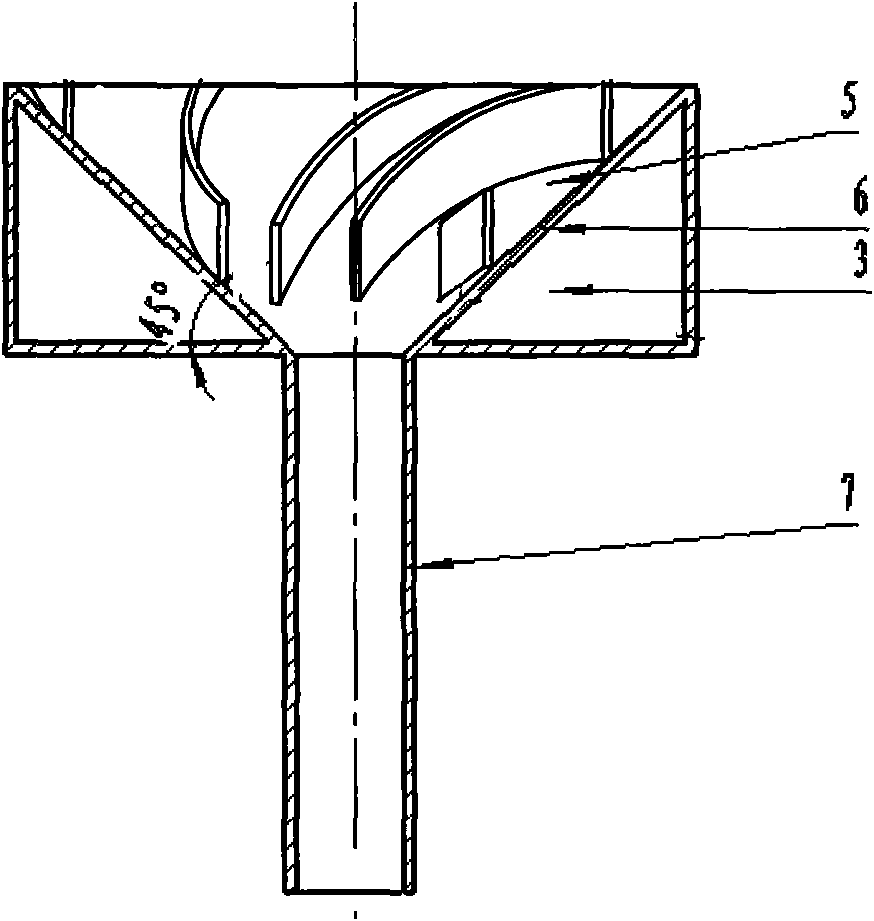

Metal smelting device driven by gravitational potential energy and method thereof

InactiveCN101550468AFull chemical reactionImprove the mixing effectEngineeringGravitational potential

The invention relates to a metal smelting device driven by gravitational potential energy and a method thereof, relating to the field of metallurgical technology. The device comprises a teeming device, a funnel-shaped cyclone generator and an overflow trough; the upper side of the overflow trough is provided with the funnel-shaped cyclone generator on which the teeming device is arranged; the funnel-shaped cyclone generator consists of a cone-shaped body, a hybrid tube and a guide plate; and the cone-shaped inner side of the cone-shaped body is connected guide plates, and the hybrid tube of the funnel-shaped cyclone generator is inserted into the overflow trough. The application method comprises the following steps: under the action of gravity, molten metal is poured between the guide plates of the funnel-shaped cyclone generator, and then the molten metal flows to the hybrid tube along the guide plate and enters the overflow trough. The device is simple in structure and convenient in operation, thereby achieving the purposes of saving energy and reducing cost.

Owner:NORTHEASTERN UNIV

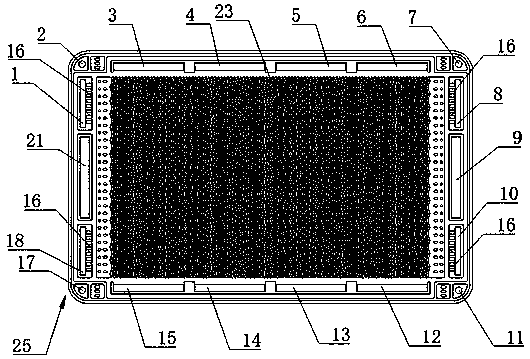

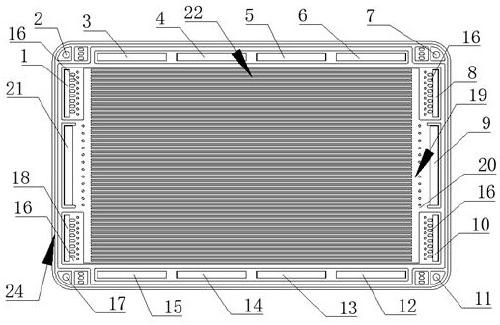

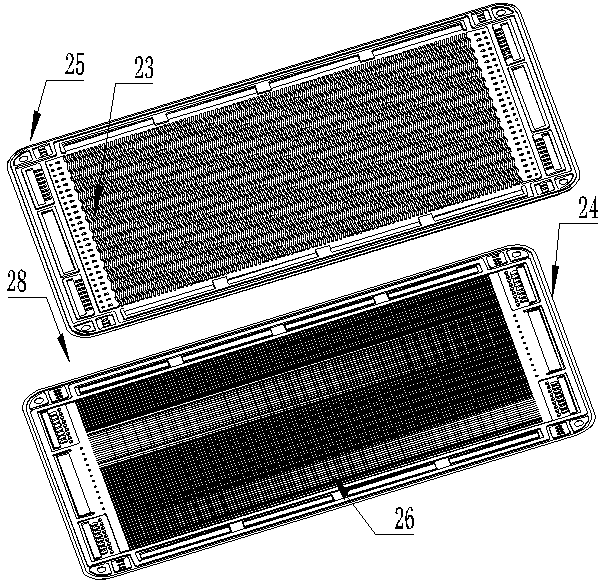

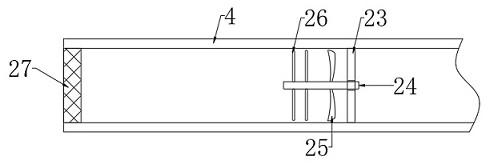

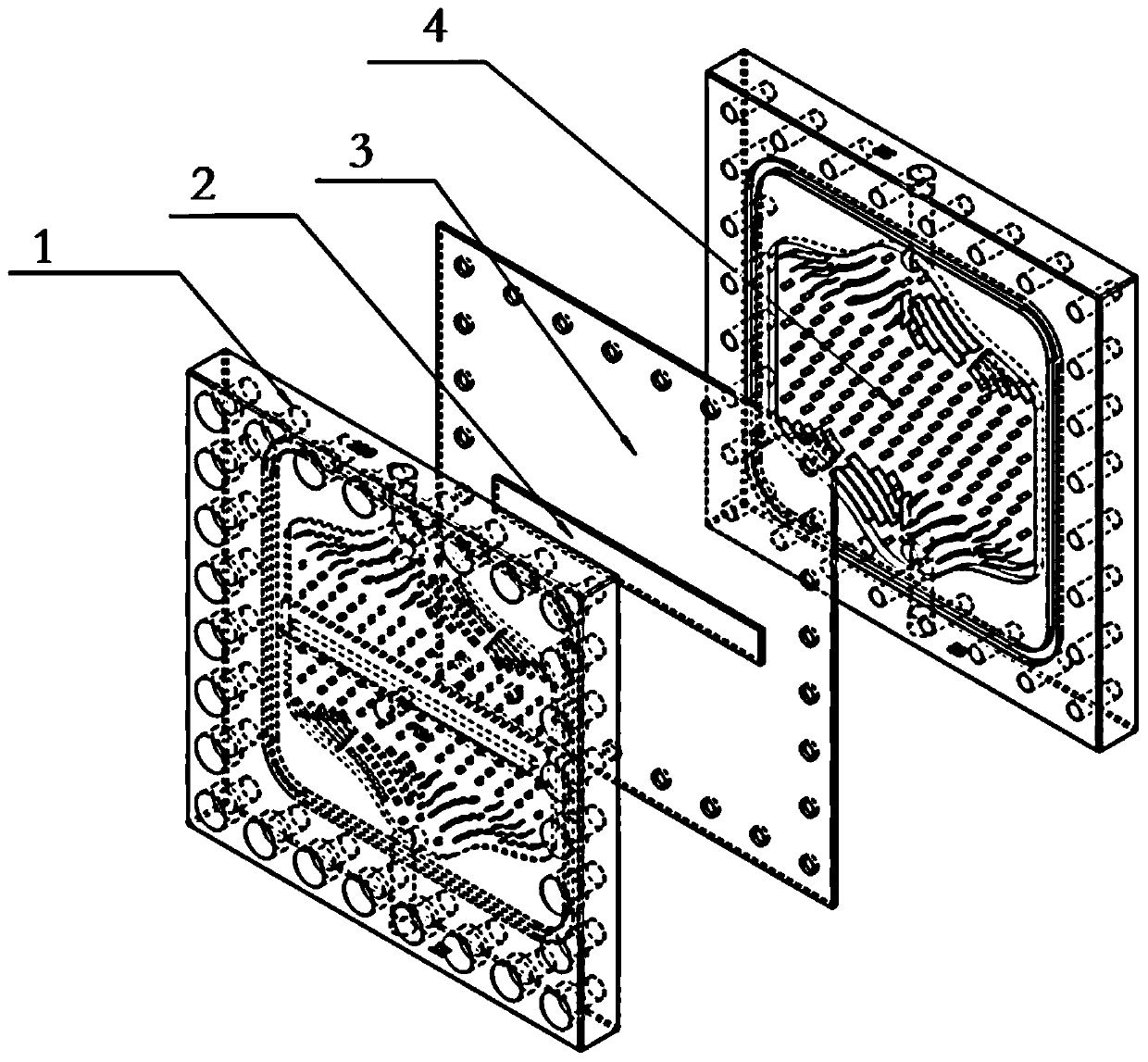

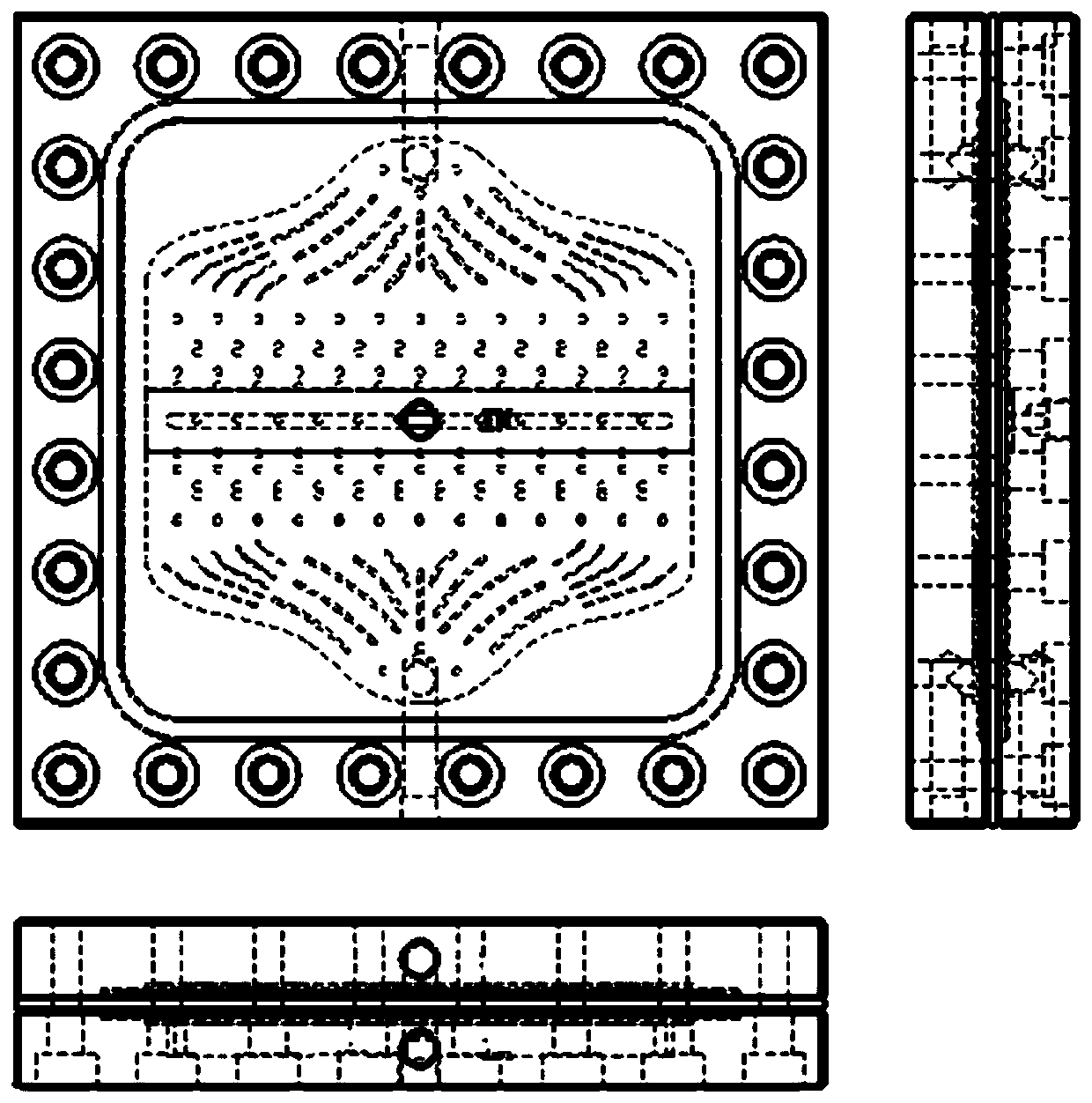

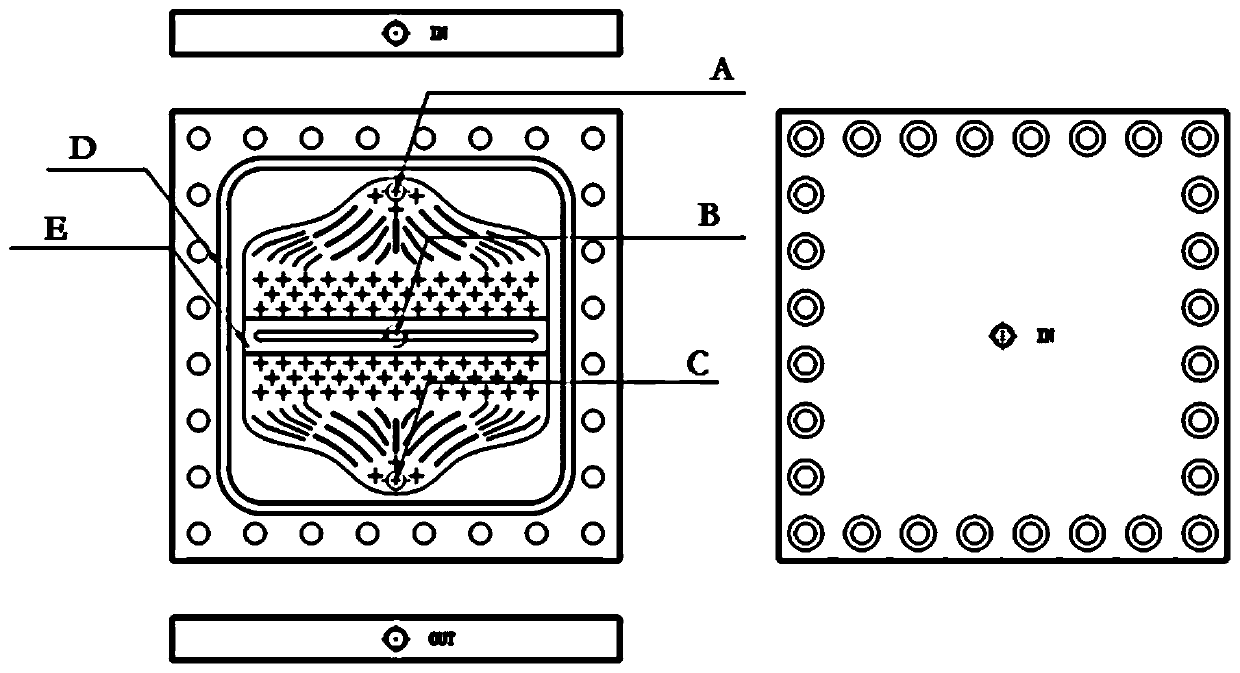

Fuel cell metal bipolar plate and fuel cell

PendingCN111146473AImprove power generation efficiencyImprove output performanceCollectors/separatorsFuel cellsMaterials science

The invention discloses a fuel cell metal bipolar plate and a fuel cell. The bipolar plate comprises a cathode plate (25), an anode plate (24) and a cooling liquid flow field (28) formed between the cathode plate (25) and the anode plate (24); a plurality of parallel wavy flow channels (23) are arranged in the middle of the cathode plate (25), and a plurality of parallel straight flow channels (22) are arranged in the middle of the anode plate (24). According to the metal bipolar plate of the fuel cell, reaction gas can uniformly flow in a flow field, so the reaction is sufficient, and the output performance of the fuel cell is further improved.

Owner:GREE ELECTRIC APPLIANCES INC

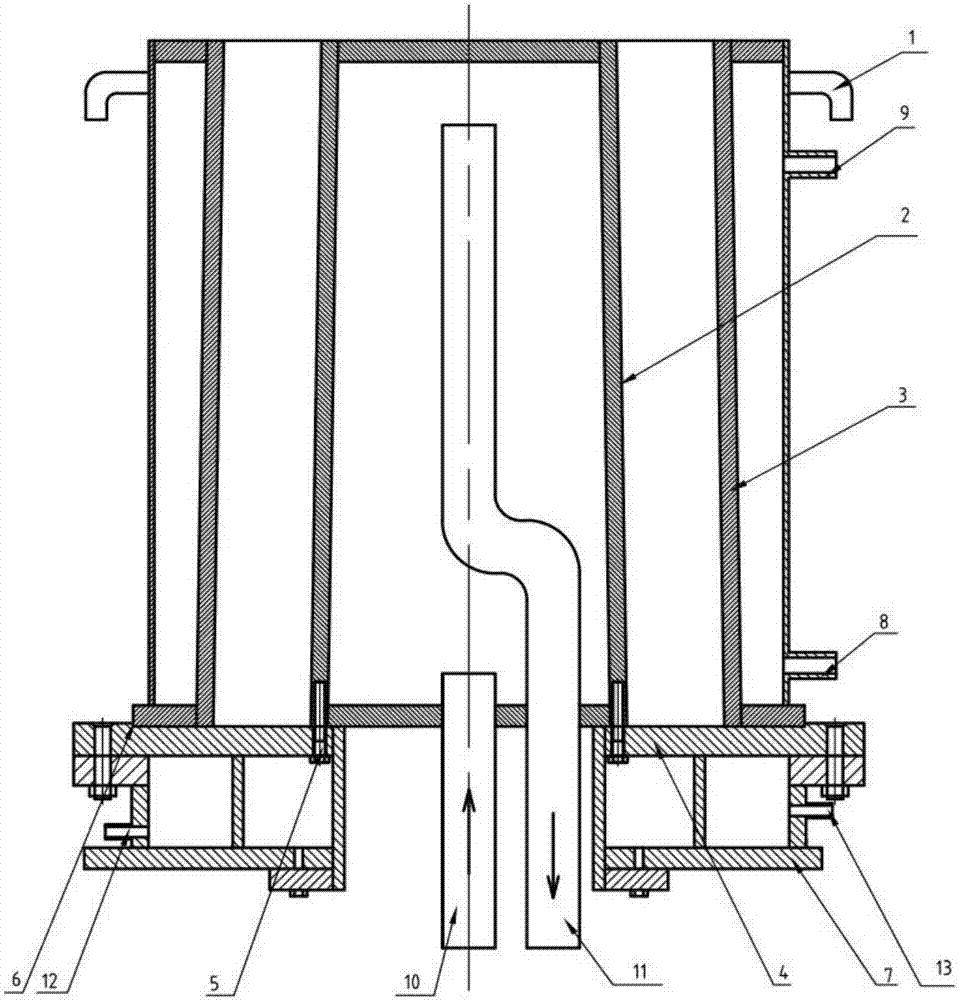

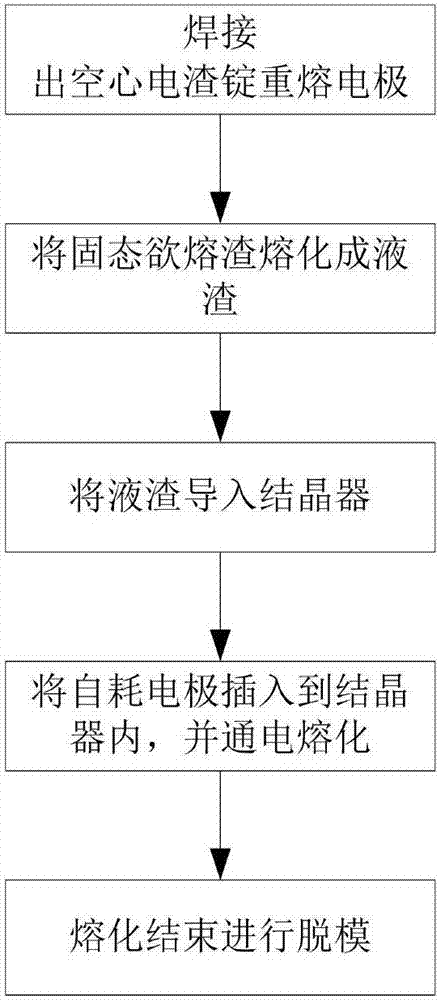

Device and method for producing small hollow electroslag ingot

The invention discloses a device and a method for producing a small hollow electroslag ingot, belongs to the technical field of hollow electroslag ingot melting, and solves the technical problems of incapacity of ensuring the concentricity of the hollow electroslag ingot, incapacity of ensuring a high filling ratio, complex structure, high production cost and inapplicability to a small hollow electroslag ingot in the prior art. According to the device disclosed by the invention, an inner crystallizer is fixed to a bottom water tank, and an outer crystallizer is of a movable structure. The method disclosed by the invention comprises the following steps: welding a re-melting electrode of the hollow electroslag ingot; melting a solid pre-melting slag; pouring the liquid slag into the crystallizers in the invention, and carrying out electrifying melting; and carrying out die release after the melting is concluded. The device disclosed by the invention has the advantages of being simple in structure, easy to produce, simple to operate during a melting process, and low in production cost.

Owner:凌远科技股份有限公司

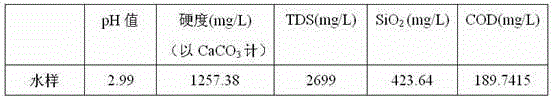

Pretreatment technology of high-salinity wastewater

InactiveCN104556475AResistant to shock loadsFull chemical reactionWater contaminantsWater softeningChemical reactionSludge

The invention discloses a pretreatment technology of high-salinity wastewater. The technology comprises the following steps: feeding sewage into a chemical reaction pond, feeding sodium carbonate and soda lime to water according to the sewage quality characteristics, and rapidly reacting with raw material, crystallizing and separating out kinds of scale forming matters in water, and removing the hardness in water; feeding the sewage to a coagulation dosing pool, feeding a magnesia mixture to the sewage which is subjected to hardness treatment in the step 1, reacting with SiO2 and the magnesia mixture in the sewage, participating and separating out; destabilizing colloid under the action of a coagulant and forming a precipitable flocculent body; feeding the sewage to a flocculent precipitation-concentration pond system, separating alumen ustum from water, accelerating concentration of the sludge participating at the bottom of the pond by virtue of a concentration stirrer with a mud scraper system; and continuously circulating partial sludge into a flocculation basin, simultaneously extracting the residual sludge at regular periods, and feeding to a sludge treatment system. The technology disclosed by the invention has the advantages of full chemical reaction, low residual hardness, good flocculent precipitation effect and impact load resistance and the like; and agents are saved.

Owner:BEIJING SCINOR WATER TECH CO LTD

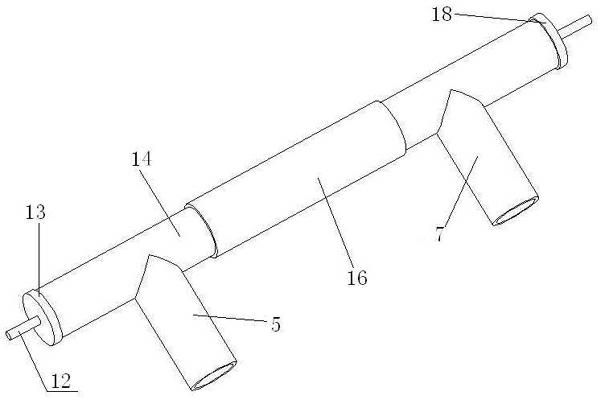

Light oil sulfur, chlorine, nitrogen quartz cracking tube

InactiveCN1970153AExtended stayAvoid pollutionThermal non-catalytic crackingPreparing sample for investigationLower limitDecomposition

It relates to a sulfur, chlorine and nitrogen quartz cracking tube in chemical quantitative analysis field. There are carburetor and reactor chamber inside the tube, sample entry and carrier gas intake connected with carburetor at the tube opening, oxygen intake connected with the reactor chamber that have three altogether with adjacent ones barricaded with through holes, and the opening of the carburetor having capillary holes and conical diffuser. It used for decomposition transformation of samples in chemical analysis with sufficient mixing of sample gas and the oxygen and high efficiency in decomposition, easy controllable transformation, with long idling of the samples and complete reaction, improved meter testing sensitivity, lowest testing limit reaching 0.05mg / L.

Owner:JIANGSU JIANGFEN ELECTROANALYTICAL INSTR

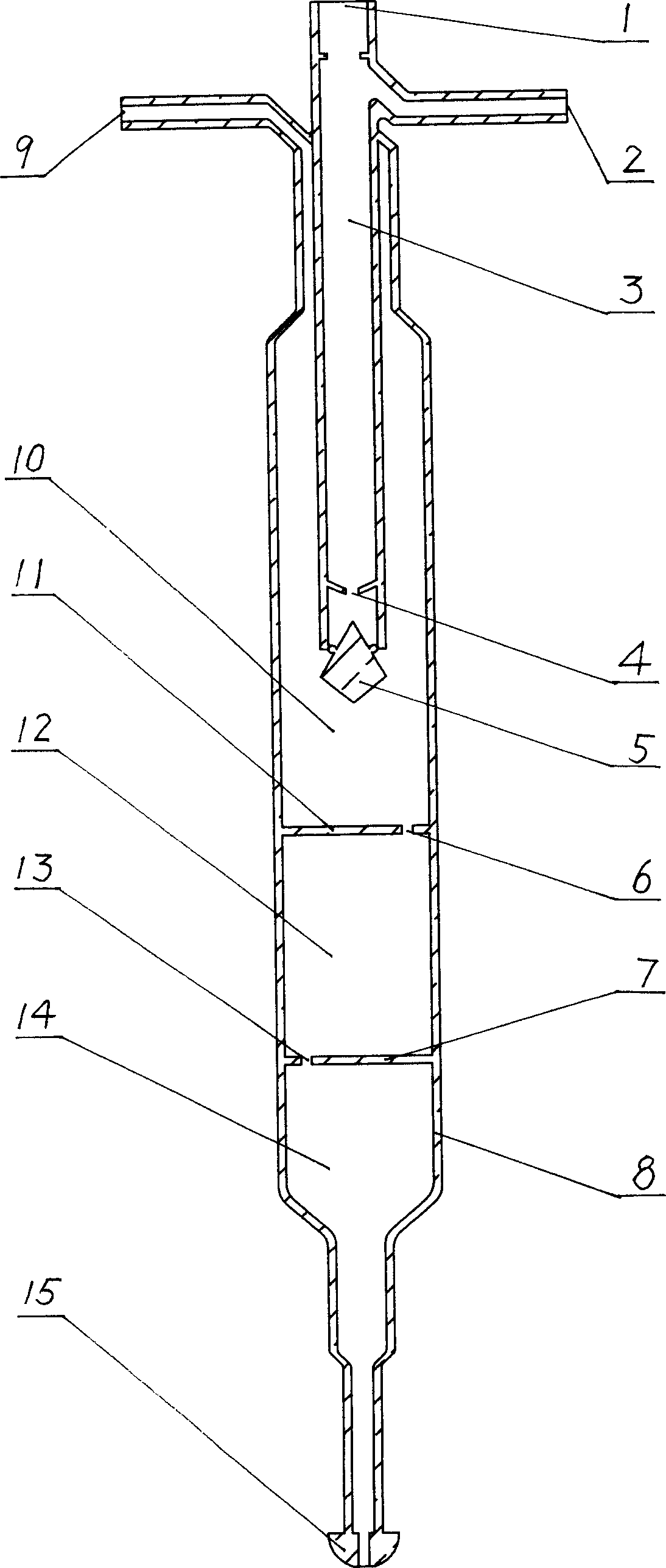

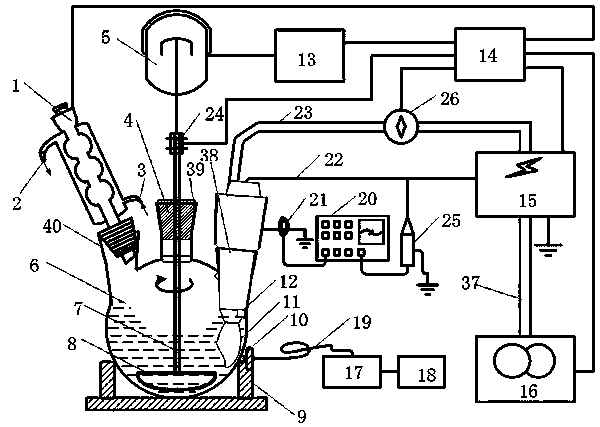

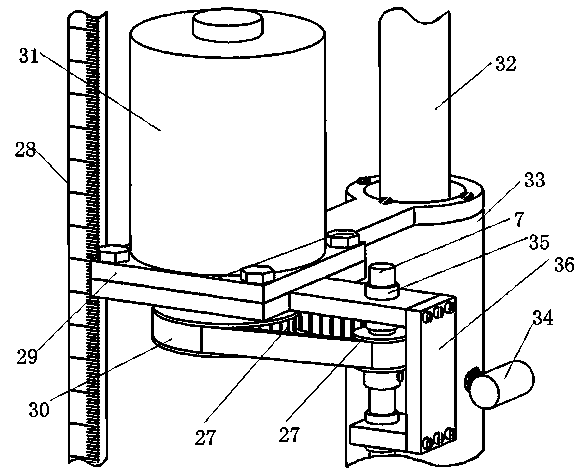

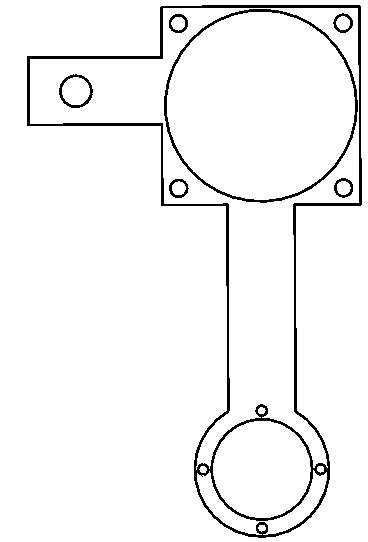

Air plasma jet water treatment experiment research device

ActiveCN103482727AEfficient use ofStrong control abilityWater/sewage treatment by irradiationWater/sewage treatment by electrochemical methodsHigh concentrationPlasma jet

The invention discloses an air plasma jet water treatment experiment research device. The air plasma jet water treatment experiment research device is characterized by comprising a reactor, a plasma jet generation device and a stirring device, wherein the reactor is used for containing waste water; the plasma jet generation device is used for generating air plasma jet and discharging the air plasma jet in the waste water in the reactor; the stirring device is used for stirring the waste water in the reactor. According to the air plasma jet water treatment experiment research device with a stirring function, stable and high-concentration plasma active particles can be generated, and the efficient plasma utilization and the full chemical action during water treatment are realized. The air plasma jet water treatment experiment research device is high in controllability and good in treatment effect.

Owner:HOHAI UNIV CHANGZHOU

Method for manufacturing water-based metal antirust agents

The invention relates to the technical field of metal rust protection, in particular to a method for manufacturing water-based metal antirust agents. The method comprises the following steps that caprolactam and sodium hydroxide are put into water according to the molar ratio of 1:0.8 to 1.5, temperature rises to 60 DEG C to 100 DEG C, and the temperature is kept for three hours to ten hours; (2) the temperature is cooled to 0 DEG C to 20 DEG C, and 1 / 5 to 1 / 3 of the molar weight of caprolactam is put according to the step (1), cyanuric chloride is added, heat preservation is carried out for one to three hours, sodium hydroxide is added, and the PH value is adjusted to 7.5 to 12; (3) temperature rises to 70 DEG C to 100 DEG C, the temperature is kept for five hours, and the sodium hydroxide is used for adjusting the PH value to 7.5 to 12; (4) the temperature is cooled to 30 DEG C to 50 DEG C, solutions are filtered, then, hydrochloric acid is added to enable the PH value to one to three, circulating stirring is carried out, and the heat preservation is carried out for one to five hours at the temperature of 30 DEG C to 60 DEG C. The method for manufacturing the water-based metal antirust agents has the advantages of being environmentally friendly, high in yield, high in product purity, excellent in product performance and low in cost.

Owner:徐立庶

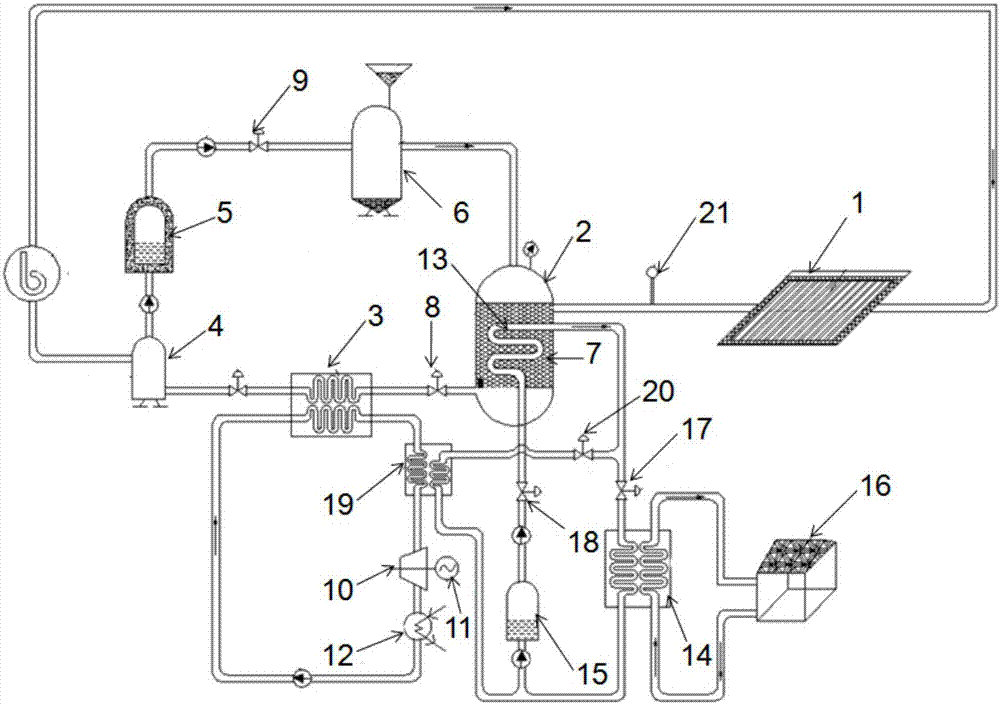

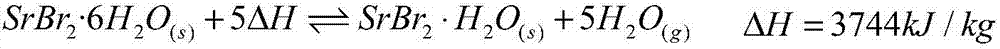

Heat and electricity dual-purpose system based on hydrous salt chemical heat storage and using method thereof

InactiveCN107120628AEasy to transportEasy to storeSteam engine plantsSteam generation using solar heatElectricityVapor–liquid separator

The invention discloses a heat and electricity dual-purpose system based on hydrous salt chemical heat storage and a using method thereof. The system comprises a heat storage system, a first power generation system and a heat supply system. The heat storage system comprises a solar air heat collector, a reactor, a first heat exchanger, a gas-liquid separator, a heat preserving water tank and a flash chamber. The first power generation system comprises a turbine motor, a generator and a condenser. The heat supply system comprises a heat exchange coiler arranged in the reactor, a second heat exchanger and a water storing tank. According to the dual-purpose system, latent heat of steam condensing can be fully utilized through the first power generation system, the benefit is increased, and by selecting a suitable energy storing material and conforming to the actual operation situation, feasibility of work is improved. In addition, power generation and heat supply are brought into the whole system and used in parallel, and the system can be used for supplying electricity or heat according to needs during different hours.

Owner:SHANGHAI MARITIME UNIVERSITY

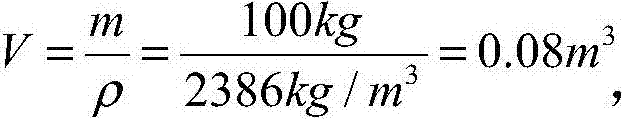

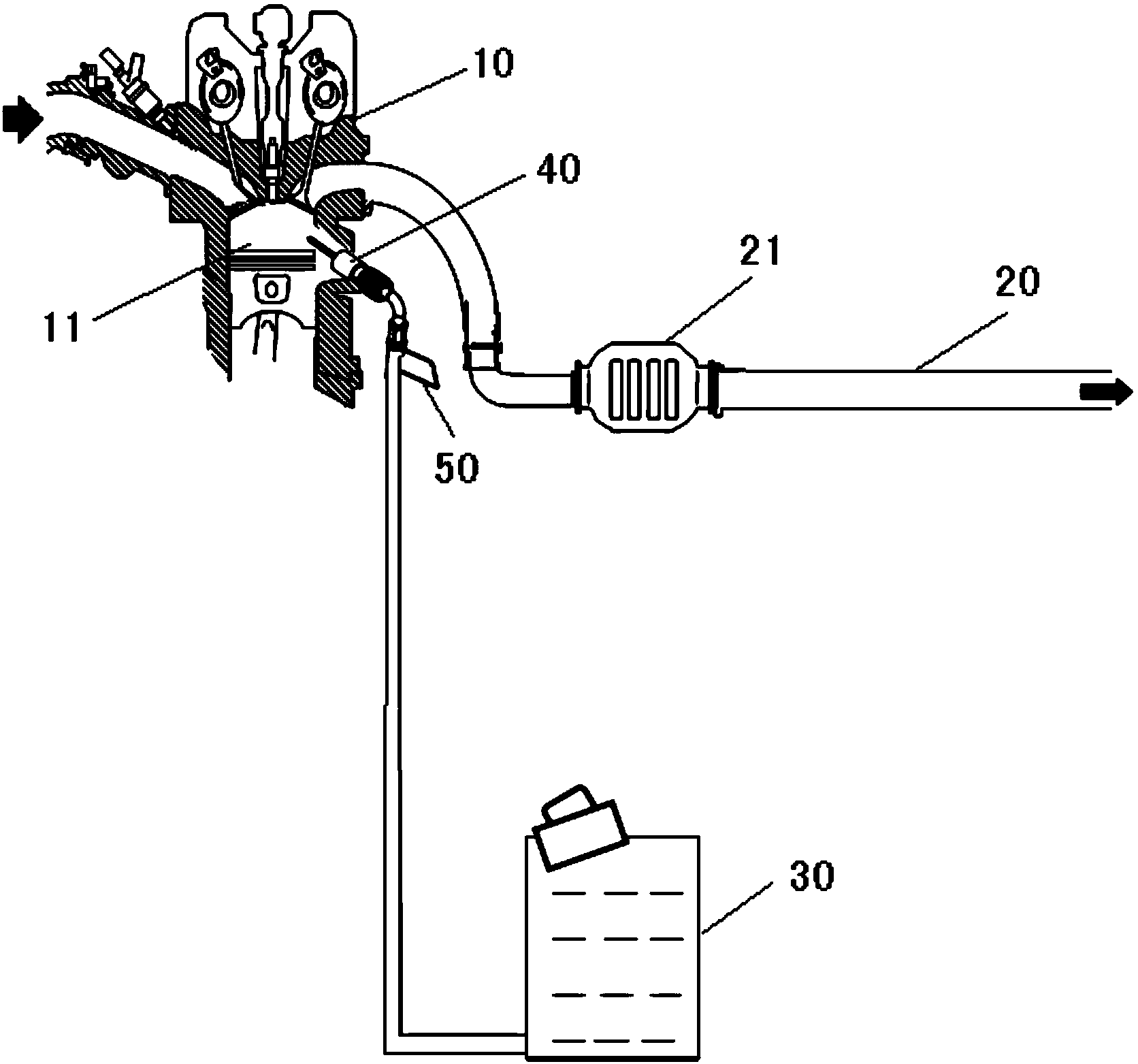

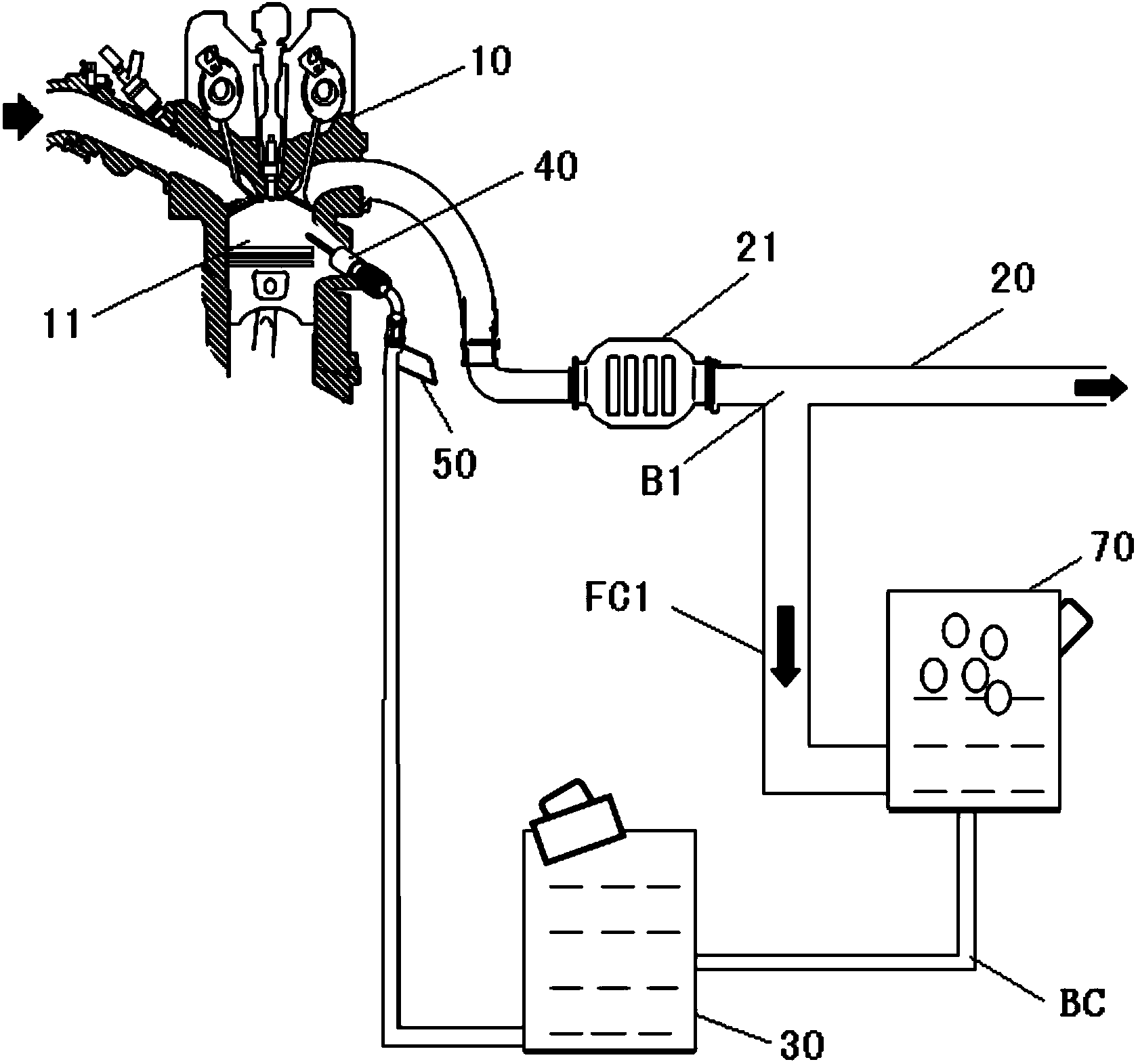

Engine system and control method thereof

InactiveCN104295350AFull chemical reactionLess quantityExhaust apparatusSilencing apparatusChemical reactionSpray nozzle

Disclosed are an engine system and a control method thereof. Nitrogen oxides in the exhaust gas exhausted from an exhaust pipe of an engine can be effectively reduced. The engine system comprises the engine and the exhaust pipe; the engine comprises a cylinder; the exhaust gas produced in the cylinder of the engine is discharged through the exhaust pipe; the engine system also comprises a urea storage box and a spray nozzle; the urea storage box is used for storing urea; the spray nozzle is arranged in the cylinder and communicated with the urea storage box through an injection control valve. According to the engine system, the urea is injected into the cylinder through the spray nozzle and accordingly the injected urea liquid can be instantly atomized through the high temperature in the cylinder to enable the urea to be fully mixed with the exhaust gas and accordingly the chemical reaction between the nitrogen oxides contained in the urea and the exhaust gas is full and the nitrogen oxides in the exhaust gas exhausted from the exhaust pipe can be effectively reduced.

Owner:HITACHI AUTOMOTIVE SYST SUZHOU

Process for synthesizing the nanometer Fe3O4 magnetic powder body with indoor temperature solid phase method

InactiveCN101017719AWell mixedFull chemical reactionInorganic material magnetismInductances/transformers/magnets manufactureIron saltsRoom temperature

The provided preparation method for nano Fe3O4 magnetic powdery material comprises: 1. mixing solid Fe2+ material, Fe3+ material by mole ratio as 1:1.8~1:2; 2. adding solid strong base with mole number as 4~10 times to iron salt, as well as 0~10% dispersant and 0~5% surface protectant; 3. holding mixed material at room temperature, grinding in sealed tank for 0.5~14h; and 4. cleaning, separating and drying to obtain target product with advantages of even grain, adequate quality and no impurity phase. This invention is simple and low cost.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

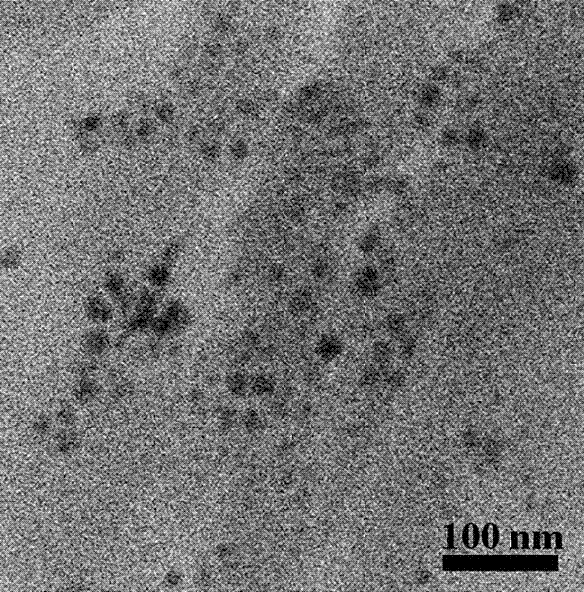

Preparation method of wear-resistant self-repairing sulfur-metal nanoparticles

The invention discloses a preparation method of wear-resistant self-repairing sulfur-metal nanoparticles. The preparation method comprises the following steps of: slowly adding a metal salt into a thiol compound of which the temperature is 60-150DEG C; vigorously stirring to obtain viscous fluid; and cooling the viscous fluid to obtain a solid namely the sulfur-metal nanoparticles. The sulfur-metal nanoparticles prepared by the method is small in diameter which is between 5 and 20 nm, has a good effect of repairing great abrasions including scratches and the like, can generate a full chemical reaction at a repaired part due to the small diameter, and also has a good effect of repairing fine abrasions including surface abrasions and the like; the surfaces of the sulfur-metal nanoparticles are provided with sulfur-bearing radicals, so that agglomeration of the nanoparticles cannot be generated easily, the metal nanoparticles can be kept in a monodisperse state in a short period or a long period of time, and the stability of the metal nanoparticles in oil phase media including lubricating oil and the like is lasting. The preparation method is simple and feasible, the purity of the product is high, and raw materials are easy to obtain and low in price.

Owner:SUZHOU FANGSHENG OPTOELECTRONICS CO LTD

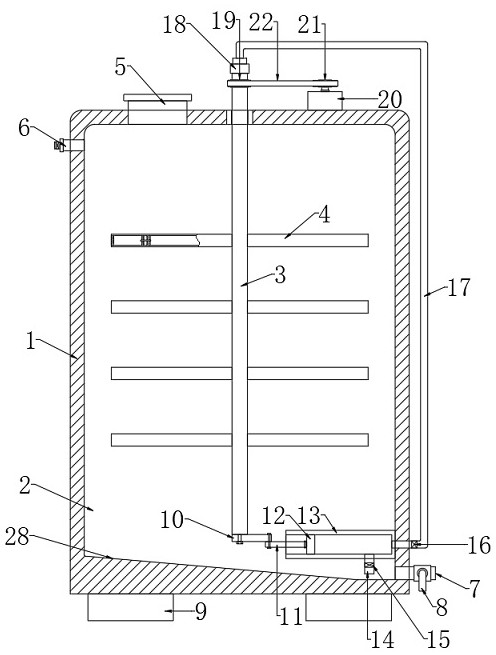

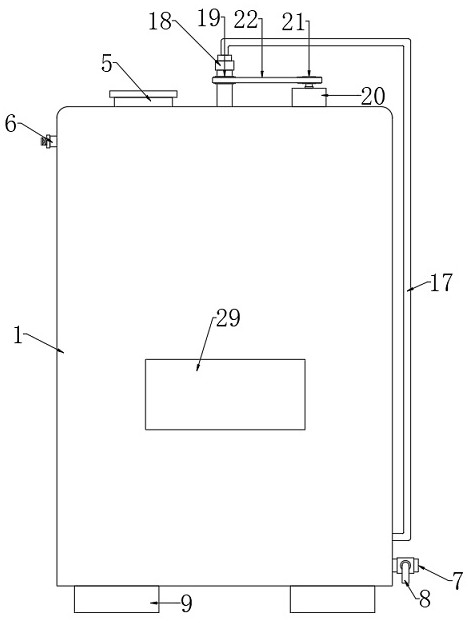

Chemical reaction kettle with sufficient reaction

InactiveCN112169737AAdequate responseWell mixedChemical/physical/physico-chemical stationary reactorsStationary filtering element filtersChemical reactionEngineering

The invention relates to a chemical reaction kettle with sufficient reaction, which comprises a reaction kettle body, a liquid adding pipe is installed at the upper end of the reaction kettle body ina penetrating mode, a sealing cover is installed at an end opening of the liquid adding pipe, a hollow pipe rotationally connected with the reaction kettle body is arranged at the upper end of the reaction kettle body in a penetrating mode, a power mechanism is arranged between the hollow pipe and the upper end of the reaction kettle body, connecting pipe communicating with the hollow pipes are fixedly connected to the hollow pipes, blocking nets are fixedly connected to end openings of the ends, away from the hollow pipes, of the connecting pipes, automatic stirring mechanisms are installed on the inner walls of the connecting pipes, a heating device is installed on the reaction kettle, and a piston cylinder is installed on the inner wall of the reaction kettle; and a piston is slidably connected into the piston cylinder. The chemical reaction kettle is reasonable in structure and capable of circularly mixing and stirring a solvent, so that the chemical reaction is more sufficient, the efficiency is higher, the reaction dissolution efficiency of solid chemical materials can be improved, and the practicability is good.

Owner:金丽琴

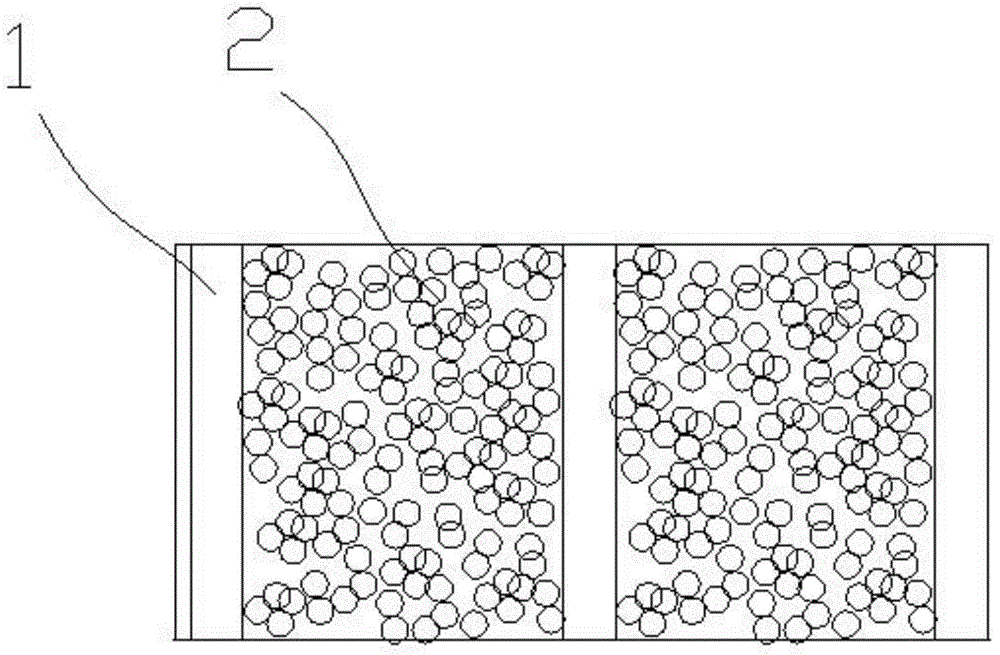

Gas-liquid microreactor, device, system and method

InactiveCN110152573AImprove general performanceSimple structureChemical/physical/physico-chemical microreactorsMicroreactorMicro perforated plate

The invention provides a gas-liquid microreactor. The microreactor comprises a reaction chamber and a heat exchange chamber, the reaction chamber is provided with a microporous plate, the reaction chamber is provided with at least two inlets and an outlet, gas can enter from a first inlet, and after the gas passes through the microporous plate, a microbubble flow is formed under flushing of a liquid entering from a second inlet and is discharged from the outlet; and the heat exchange chamber is provided with an inlet and a discharge outlet, and circulation of a heat exchange medium from the inlet to the discharge outlet is utilized to realize the heat exchange function and provide a temperature environment for the reaction chamber. The microreactor provided by the invention can increase acontact area of a liquid phase and a gas phase, and effectively enhance mass transfer mixing, thereby facilitating full progress of a chemical reaction.

Owner:HIMILE MECHANICAL MFG +1

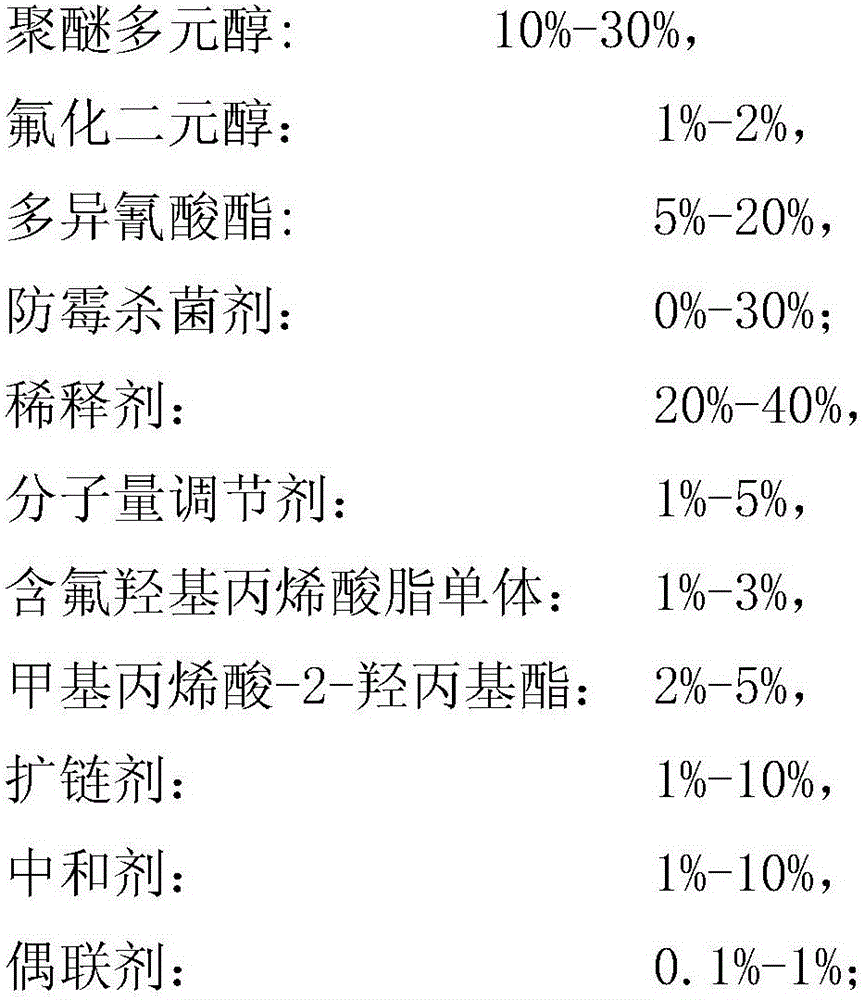

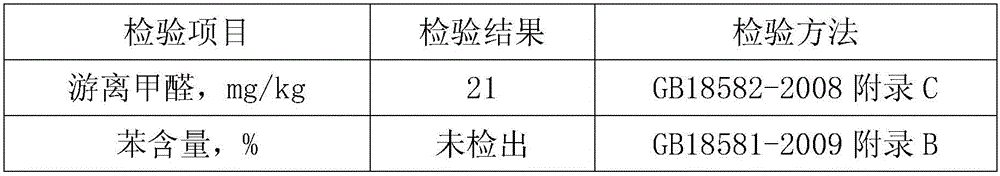

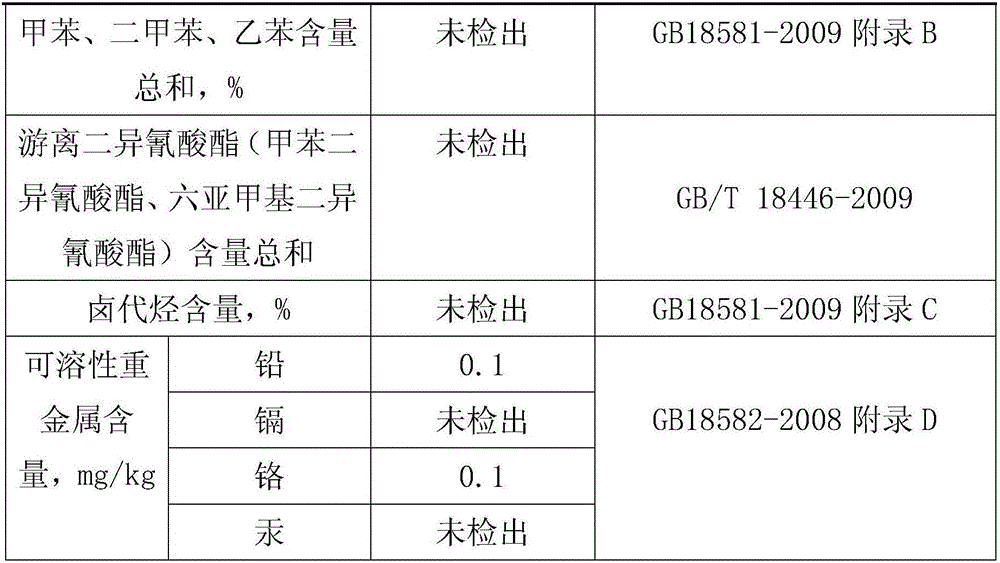

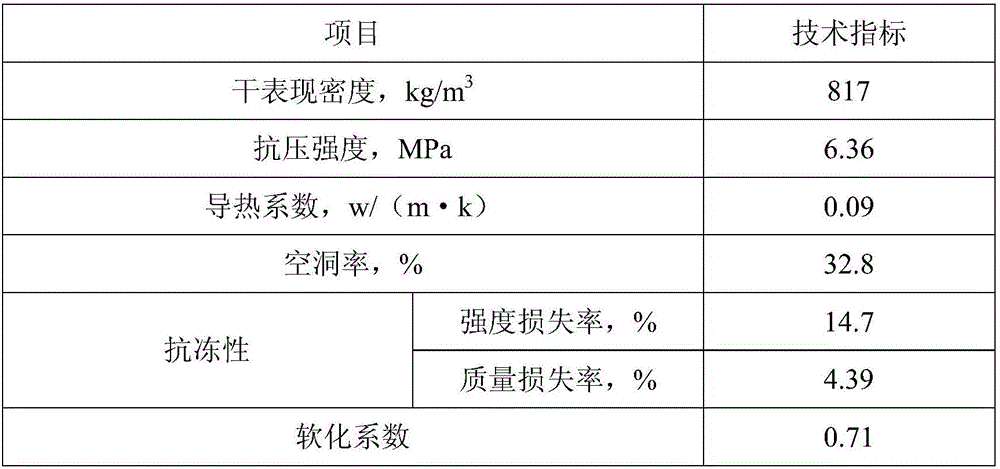

Normal-temperature cured water-based polyurethane and preparation method and application thereof

InactiveCN106188474AHigh water resistance and stain resistanceStrong adhesionAntifouling/underwater paintsPaints with biocidesDouble bondChemistry

The invention discloses normal-temperature cured water-based polyurethane and a preparation method and application thereof. The polyurethane is prepared from polyether polyol, fluoride glycol, polyisocyanate, anti-mildew bactericide dimethyl fumarate, diluent, molecular weight modifier, fluorine-containing hydroxyl acrylate monomer, methacrylic acid-2-hydroxypropyl ester, chain extender, neutralizer and coupling agent. By means of the addition polymerization mode of unsaturated double bond containing polyether polyol, polyalkoxy silicon base and fluorine-containing hydroxyl acrylate are chemically bonded into polyurethane chains, novel water-soluble polyurethane resin of a polyalkoxy silicon base fluoro modified acrylic resin-polyurethane interpenetrating polymer networks (IPN) structure is synthesized and is made to have the common advantages of water-based polyurethane paint and polyacrylate emulsion, and the polyurethane is cured at normal temperature, has oil resistance and stain resistance, is suitable for waterproof and anti-foul coating on surface layers of leather, plastic, wood, metal, external walls and the like, and is environmentally friendly, high in industrial practicability and high in economic benefit.

Owner:CHENGDU KAITE ORGANOSILICON NEW MATERIALS TECH

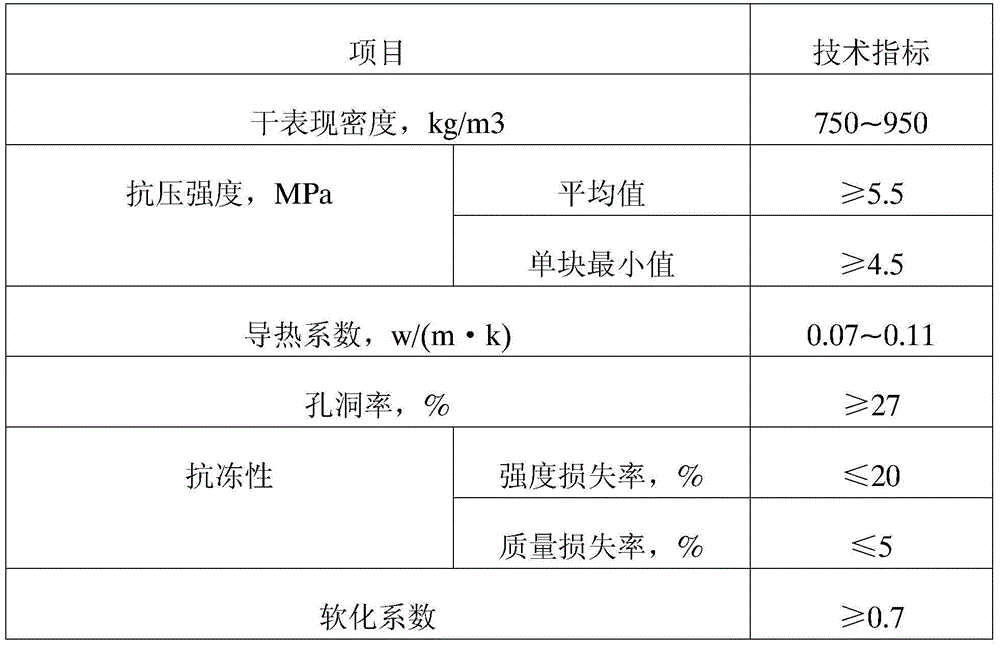

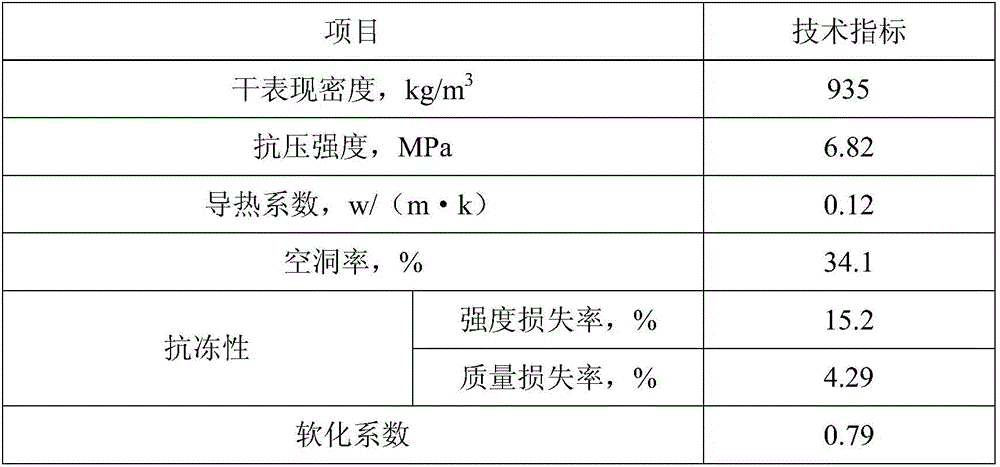

Heat preservation brick

The invention discloses a heat preservation brick which comprises a hollow brick serving as a brick body shell and a cement foam material accommodated in the cavity of the brick body, wherein the hollow brick comprises the following raw materials: cement, construction waste earth, ceramsite, lime and perlite; the cement foam material comprises the following raw materials: cement, calcium carbonate, calcium sulfate, sialite, calcium borate, corn stalk powder, AR glass fiber, carboxymethyl cellulose, a water reducing agent, a foaming agent, a foaming regulator, a catalyst, a crosslinking agent, a foam stabilizer, glyoxal and water. The heat preservation brick has the advantages of being excellent in heat preservation and insulation, sound insulation effect, compression resistance and the like, and is light in weight; a method for preparing the heat preservation brick does not need autoclaved curing, is low in equipment investment, simple in process, simple and convenient to operate, convenient to popularize, and stable in product quality.

Owner:张莘蔓

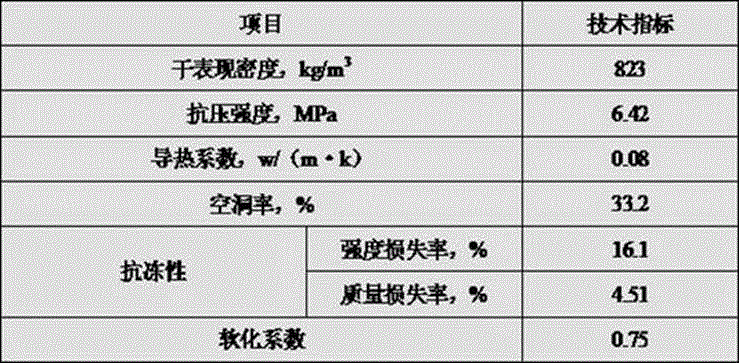

Light-weight heat-insulating material taking granite waste as raw material and preparation method thereof

InactiveCN103396153AWide variety of sourcesAvoid pollutionSolid waste disposalCeramicwareSodium sulfateBall mill

The invention relates to a light-weight heat-insulating material taking granite waste as a raw material and preparation method thereof. The technical scheme comprises the following steps: mixing 50-65wt% of granite waste fine powder, 10-20wt% of chunk glass powder, 1-5wt% of limestone powder, 5-13wt% of potassium chloride, 5-15wt% of sodium chloride used as raw materials; performing heat treatment at 800-1200 DEG C for 0.5-2 hours, and grounding until the particle size is less than 0.045mm; adding limestone powder, industrial sodium carbonate, white carbon black and sodium sulfate which respectively account for 0.5-3wt%, 5-10wt%, 1-5wt% and 1-10wt% of the raw materials into the ground material, and performing ball milling for 2-5 hours; and adding water which accounts for 3-10wt% of the raw materials into the ball milled material, stirring, pressing into a blank, drying, performing heat treatment at 800-1200 DEG C for 2-5 hours, naturally cooling, soaking with water, and drying at 80-110 DEG C, thus preparing the light-weight heat-insulating material taking granite waste as a raw material. The invention is simple in process, low in production cost, beneficial to comprehensive utilization of resources and friendly to environment; and the product is low in volume density, low in heat conductivity coefficient and high in compression strength.

Owner:WUHAN UNIV OF SCI & TECH

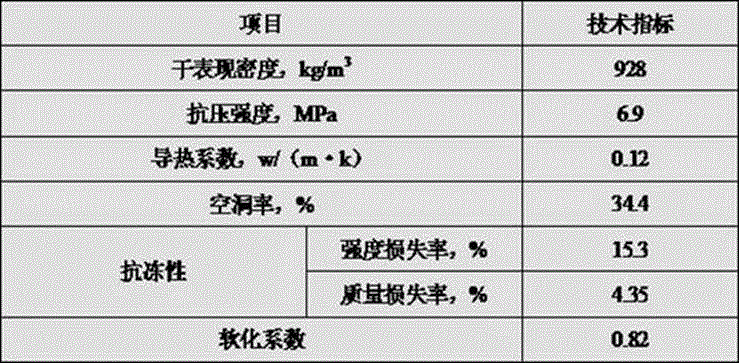

Environment-friendly brick

The invention discloses an environmentally friendly brick, which comprises a hollow brick as a brick shell and a cement foam material filled in the cavity of the brick body. The hollow brick includes the following raw materials: cement, shale ore, fly ash, tailing sand, Kaolin; the cement foaming material includes the following raw materials: cement, calcium silicate, calcium sulfate, bentonite, magnesium borate, corn straw powder, AR glass fiber, carbon fiber, water reducer, foaming agent, foaming regulator agent, catalyst, crosslinking agent, foam stabilizer, glyoxal, water. The environmental protection brick of the present invention has the advantages of excellent thermal insulation, sound insulation effect, light weight and pressure resistance, etc.; the method for preparing the environmental protection brick does not require autoclave curing, small investment in equipment, simple process, easy operation, easy promotion, and production The product quality is stable.

Owner:张莘蔓

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com