Light oil sulfur, chlorine, nitrogen quartz cracking tube

A cracking tube, light oil technology, applied in the field of chemical analysis and quantitative analysis, can solve the problems of incomplete reaction, unstable conversion efficiency and difficult to control, short residence time, etc., to improve detection sensitivity, high cracking conversion efficiency, and residence time. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

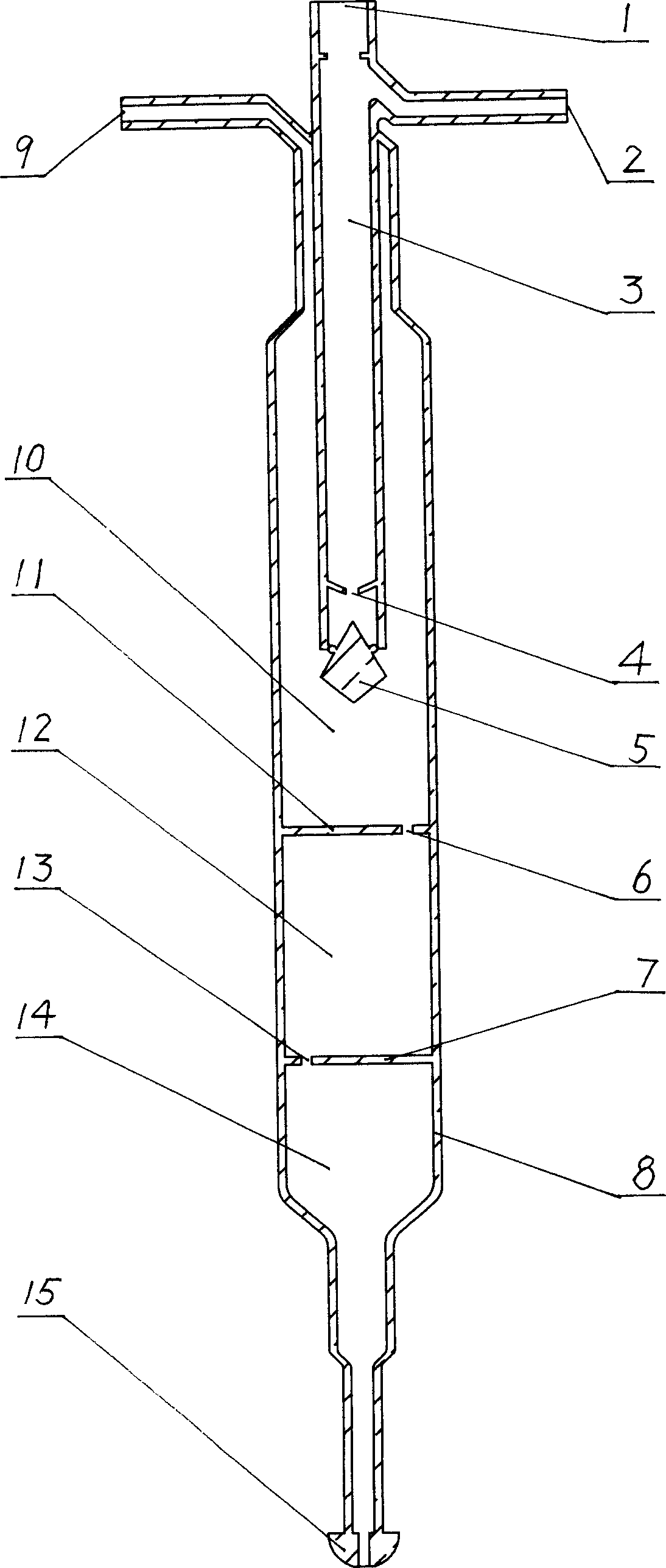

[0009] Referring to the accompanying drawings, the inlet position of the quartz cracking tube body 8 has a sample inlet 1 and a carrier gas inlet 2 that are communicated with the vaporization chamber 3, and an oxygen inlet 9 that is communicated with the first reaction chamber 10 is arranged, and the vaporization chamber outlet position is provided simultaneously. There are capillary holes 4 and a conical diffuser 5 . There is a first partition 11 with a through hole 6 between the first reaction chamber 10 and the second reaction chamber 12, and a second partition 7 with a through hole 13 between the second reaction chamber 12 and the third reaction chamber 14. The through hole 6 and the oxygen inlet 9 are located on the opposite side of the cracking tube, and the through hole 13 and the through hole 6 are also located on the opposite side. There is a ball mill joint 15 at the outlet end of the pipe body. In this embodiment, the diameter of the quartz tube in the reaction cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com