Device and method for producing small hollow electroslag ingot

A production device and electroslag ingot technology are applied in the field of production devices for small hollow electroslag ingots, and can solve the problems of inability to guarantee the concentricity of hollow electroslag ingots, unsuitable for small hollow electroslag ingots, and inability to guarantee a large filling ratio. , to achieve good power-on effect, simple structure, and the effect of ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

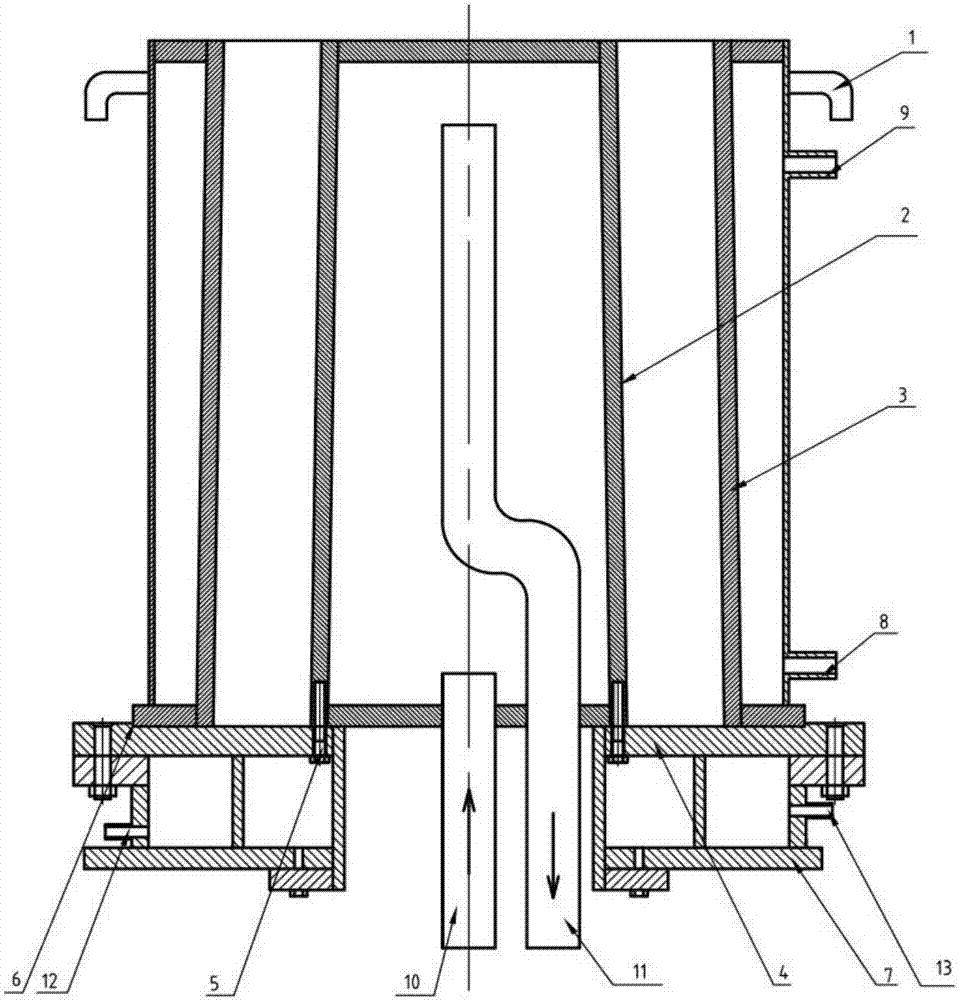

[0030] Attached below figure 1 The present invention is further elaborated.

[0031] see attached figure 1 and attached figure 2 , the production device of the small hollow electroslag ingot of the present invention includes an outer crystallizer 3, an inner crystallizer 2, a bottom water tank 7, a copper plate 4 and a circulating cooling system; the inner crystallizer 2 is fixed in the bottom water tank 7, and the outer crystallizer 3 is a movable formula structure;

[0032] The circulating cooling system includes a water distribution tank, a return water tank, an inner crystallizer cooling system, an outer crystallizer cooling system and a bottom water tank cooling system; the bottom water tank cooling system: the bottom water tank 7 is provided with a bottom water tank water inlet and a bottom water tank water outlet on both sides. ; The water inlet of the bottom water tank is connected to the water distribution tank through a high-pressure hose; the water outlet of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com