Heat preservation brick

A technology for insulating bricks and hollow bricks, applied in the field of insulating bricks, can solve problems such as poor durability and impact resistance, and achieve the effects of stable product quality, good wind pressure resistance, and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the insulation brick comprises the following steps:

[0037] S1: Preparation of hollow bricks

[0038] Mix cement, construction waste soil, ceramsite, lime, and perlite, and stir evenly at a speed of 200-400r / min to make hollow bricks;

[0039] S2: Preparation of cement foam material

[0040] S21: Stir cement, glyoxal and water evenly at a speed of 100-300r / min to prepare a slurry;

[0041] S22: Calcium carbonate, calcium sulfate, condensate, calcium borate, corn straw powder, AR glass fiber, carboxymethyl cellulose, water reducer, foaming agent, foam regulator, catalyst, crosslinking agent and foam stabilizer The agent is stirred for 2-3 hours at a speed of 60-100r / min to obtain a foam liquid;

[0042] S23: Add the foam liquid prepared in step S22 to the slurry prepared in step S21, and stir evenly at a rotating speed of 150-200r / min to obtain a cement foam material;

[0043] S3: Preparation of insulation bricks

[0044] Fill the cement f...

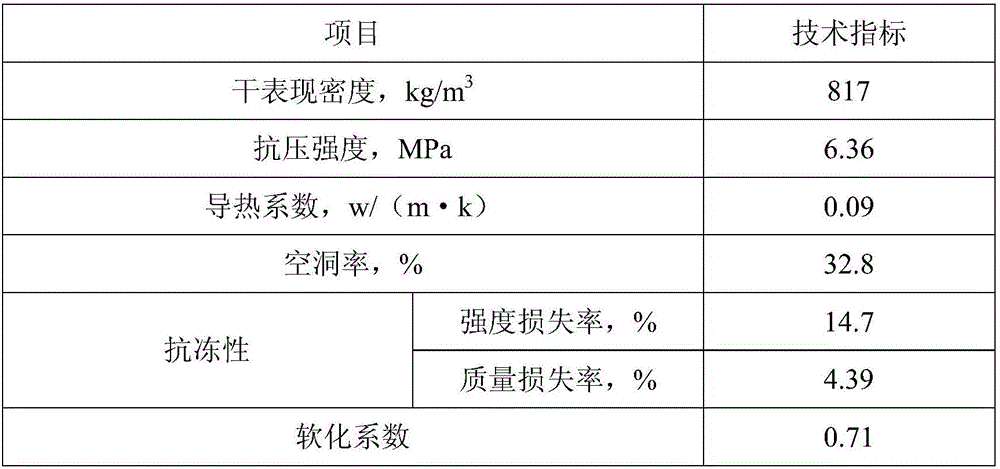

Embodiment 1

[0047] A thermal insulation brick, comprising a hollow brick as a brick shell and a cement foam material filled in the cavity of the brick body, the hollow brick includes the following raw materials in parts by weight: 53 parts of cement, 35 parts of construction waste soil, pottery 25 parts of grains, 6 parts of lime, 9 parts of perlite; the cement foaming material is in parts by weight, including the following raw materials: 35 parts of cement, 3 parts of calcium carbonate, 2 parts of calcium sulfate, 2.8 parts of congealed stone, calcium borate 1.5 parts, 2 parts of corn stalk powder, 0.8 parts of AR glass fiber, 0.6 parts of carboxymethyl cellulose, 2 parts of water reducer, 0.6 parts of foaming agent, 0.4 parts of foam regulator, 0.2 parts of catalyst, 0.5 parts of crosslinking agent parts, 0.3 parts of foam stabilizer, 25 parts of glyoxal, and 280 parts of water.

[0048] The particle diameter of the corn stalk powder is ≤300 μm, and the moisture content is ≤14%.

[004...

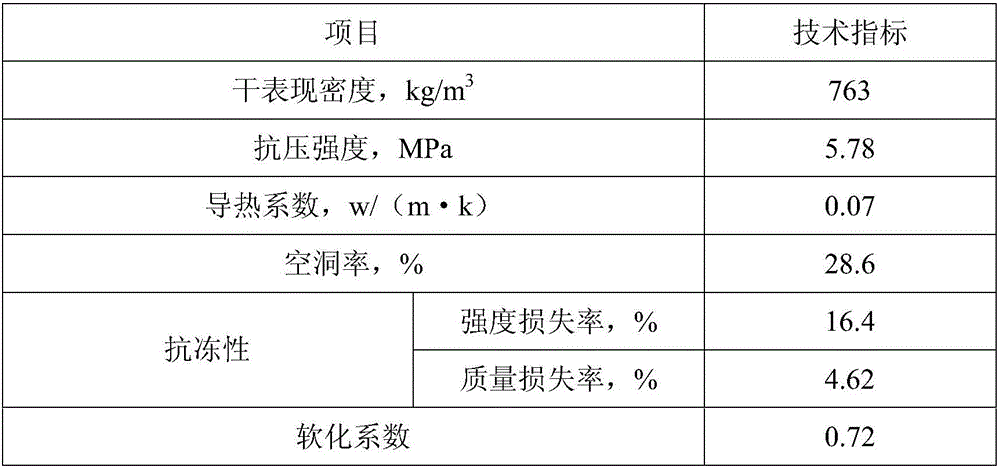

Embodiment 2

[0067] A thermal insulation brick, comprising a hollow brick as a brick shell and a cement foam material filled in the cavity of the brick body, the hollow brick includes the following raw materials in parts by weight: 45 parts of cement, 30 parts of construction waste soil, pottery 20 parts of grains, 4 parts of lime, 6 parts of perlite; the cement foaming material is in parts by weight, including the following raw materials: 25 parts of cement, 2 parts of calcium carbonate, 2 parts of calcium sulfate, 2.5 parts of condensate, calcium borate 1.2 parts, 1 part of corn stalk powder, 0.6 parts of AR glass fiber, 0.4 parts of carboxymethyl cellulose, 1.5 parts of water reducer, 0.2 parts of foaming agent, 0.2 parts of foam regulator, 0.1 part of catalyst, 0.3 parts of crosslinking agent part, 0.1 part of foam stabilizer, 20 parts of glyoxal, and 240 parts of water.

[0068] The particle diameter of the corn stalk powder is ≤300 μm, and the moisture content is ≤14%.

[0069] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com