A kind of quartz tailing insulation brick and its preparation method

A technology of quartz tailings and quartz tailings powder, which is applied in the field of building materials, can solve the problems of incomplete utilization of beneficial ingredients, waste of intermediate products of raw materials in chemical plants, and lack of development and utilization of resources, so as to improve heat preservation Performance and waterproof performance, achieve recycling, enhance the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Quartz tailing insulation brick, the raw materials are 8% cement, 45% crushed stone, 8% light aggregate and 39% quartz tailing powder in mass percentage. The lightweight aggregate uses expanded vitrified microbeads with a vitrification rate of 60%, and the expanded vitrified microbeads are doped with polyurethane accounting for 3% of the mass of the expanded vitrified microbeads. Quartz tailings powder is ground fluorite tailings waste and passed through a 100-mesh sieve; crushed stone is crushed to a particle size of 2mm. Portland cement used in cement.

[0025] The preparation method comprises the following steps:

[0026] (1) Prepare crushed stone and quartz tailings powder to obtain a raw material mixture; mix lightweight aggregate and cement with water with a mass ratio of 10-15%, and then fully stir with the raw material mixture to obtain clinker;

[0027] (2) Send the clinker into the buffer hopper through the conveyor, carry out two-way hydraulic forming throu...

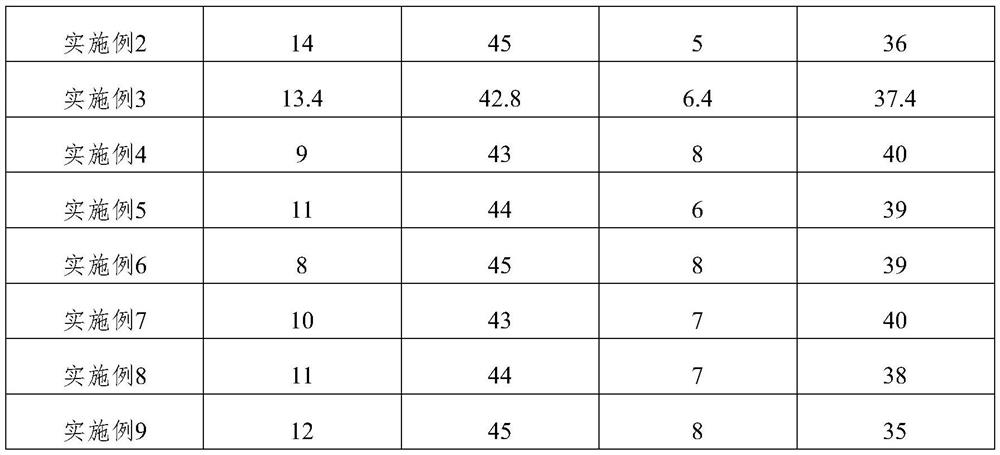

Embodiment 2-9

[0029] On the basis of embodiment 1, others are all operated with the operation method of embodiment 1, and raw material composition preparation is adjusted according to the change in following table 1:

[0030] Table 1

[0031]

[0032]

Embodiment 10-14

[0034] On the basis of embodiment 1, others are all the same as embodiment 1, and the relevant parameters adopted in embodiment 1 are adjusted in the following table 2:

[0035] Table 2

[0036] Example 10 Example 11 Example 12 Example 13 Example 14 Gravel particle size (mm) 1 3 4 3.5 5 Sieve quartz tailings powder (mesh) 50 150 200 210 220 Polyurethane content (%) 8 5 8 2 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com