Preparation method of wear-resistant self-repairing sulfur-metal nanoparticles

A metal nanoparticle, self-healing technology, applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of unstable stability, easy introduction of impurities, complicated purification operation steps, etc., and achieve complete surface modification and simple method. Ease of operation, no by-product contamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention provides a kind of preparation method of anti-wear and self-repairing sulfur-metal nanoparticles, which comprises the following steps:

[0026] ①Put the thiol compound in a container, raise the temperature and keep the temperature at 60℃~150℃;

[0027] ② Using the metal salt as the metal source, add the metal salt into the container and stir evenly, the stirring rate is 400rpm-1500rpm, and the temperature range is between 60°C-150°C;

[0028] ③Stir the temperature of the mixture in step ② at 60°C to 150°C for 1h to 3h, and react to obtain sulfur-metal nanoparticle viscous liquid;

[0029] ④ Place the viscous liquid of sulfur-metal nanoparticles at room temperature and cool for 6h-10h to obtain solid sulfur-metal nanoparticles, that is, to obtain sulfur-metal nanoparticles.

[0030] In step ①, the thiol compound should be in a liquid state at normal temperature, and it is also in a liquid state when the temperature rises to 60°C-150°C. Specifically...

Embodiment 1

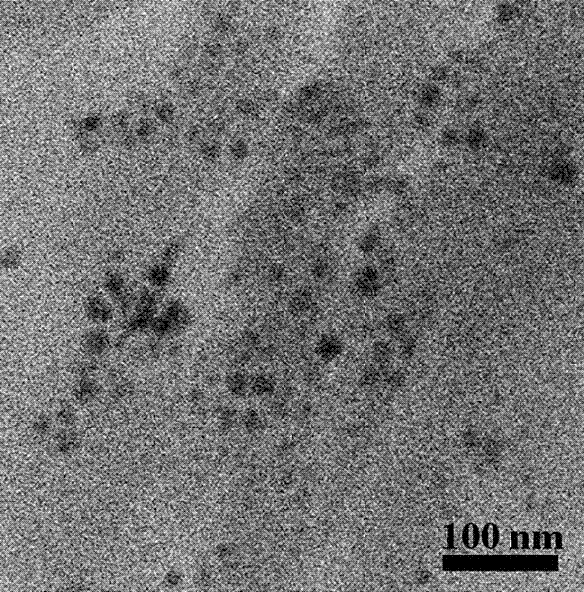

[0036] Using copper chloride as the metal source, slowly add 100g of copper chloride into a 900ml cetyl mercaptan beaker at a temperature of 60°C, stir the mixed liquid vigorously at a stirring rate of 1500 rpm, and release a large amount of After stirring for 1 hour, there is basically no gas release, the solution in the beaker of the reaction vessel becomes black viscous, and then the viscous solution is cooled at room temperature, and the viscous product turns into a black solid after 8 hours , to obtain sulfur-metal nanoparticles. figure 1 This is a transmission electron microscope (TEM) photo of the carbon nanoparticles prepared in Example 1. It can be seen that the nanoparticles are uniformly dispersed and have a diameter of 5 nm to 20 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com