Patents

Literature

61results about How to "Reliable and easy to manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

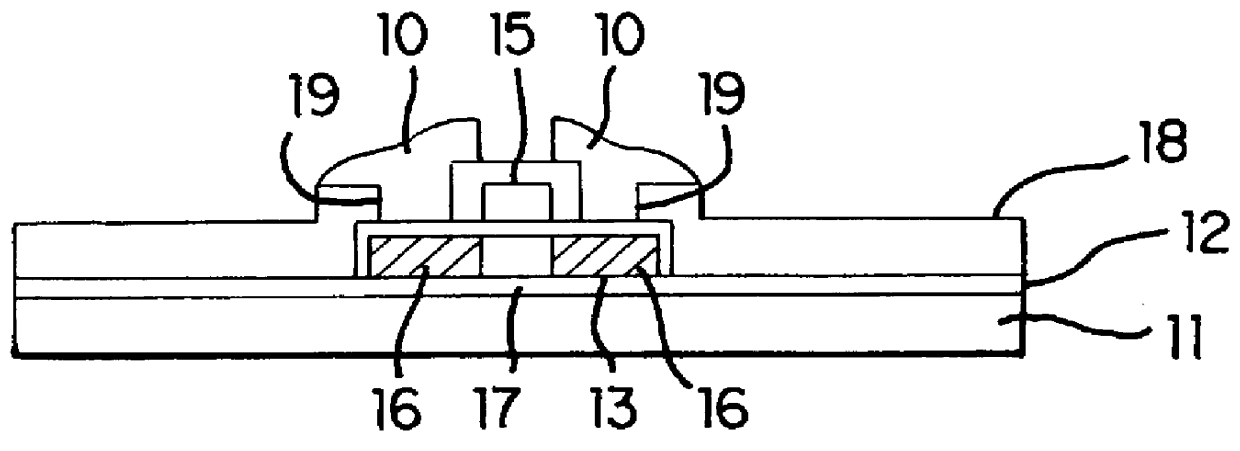

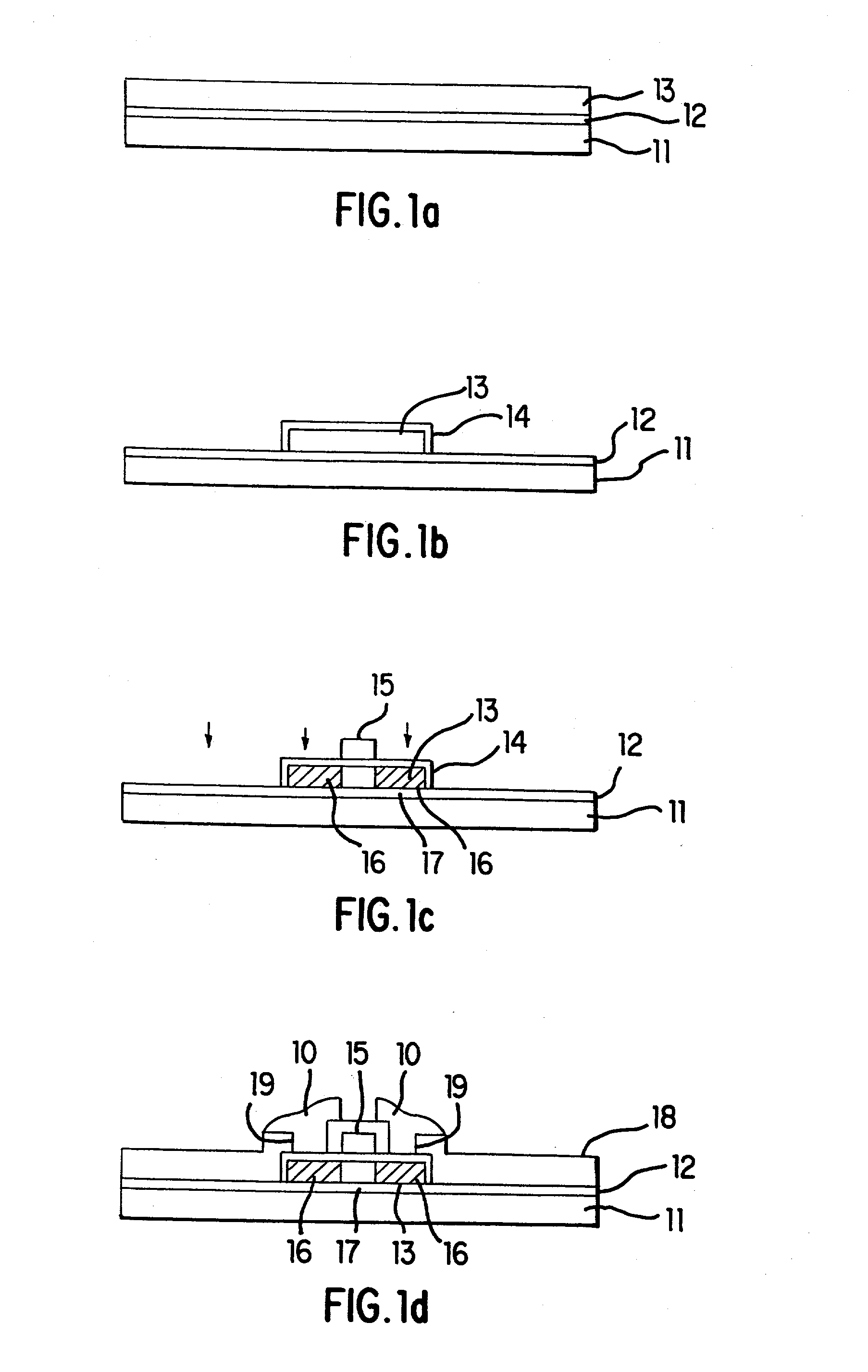

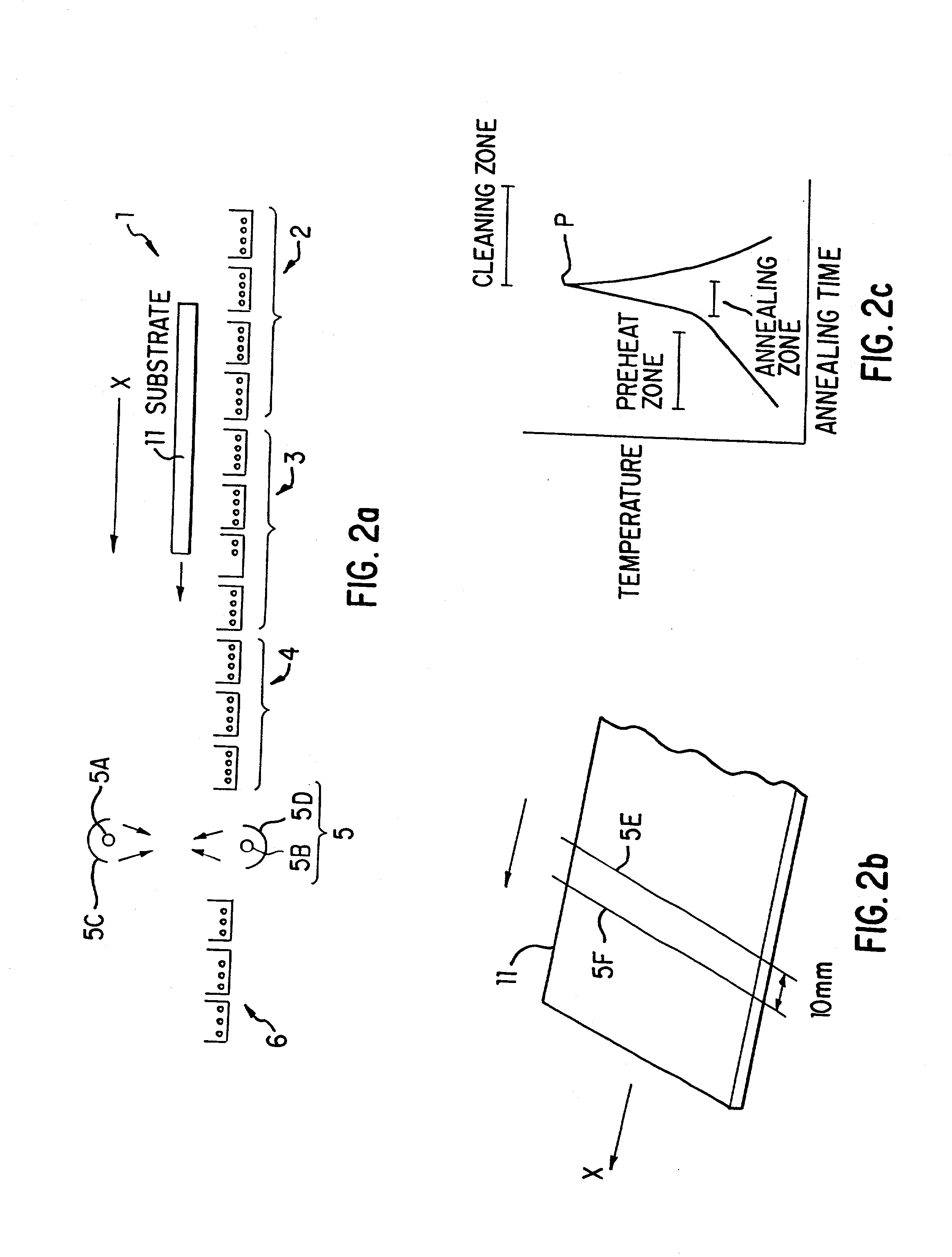

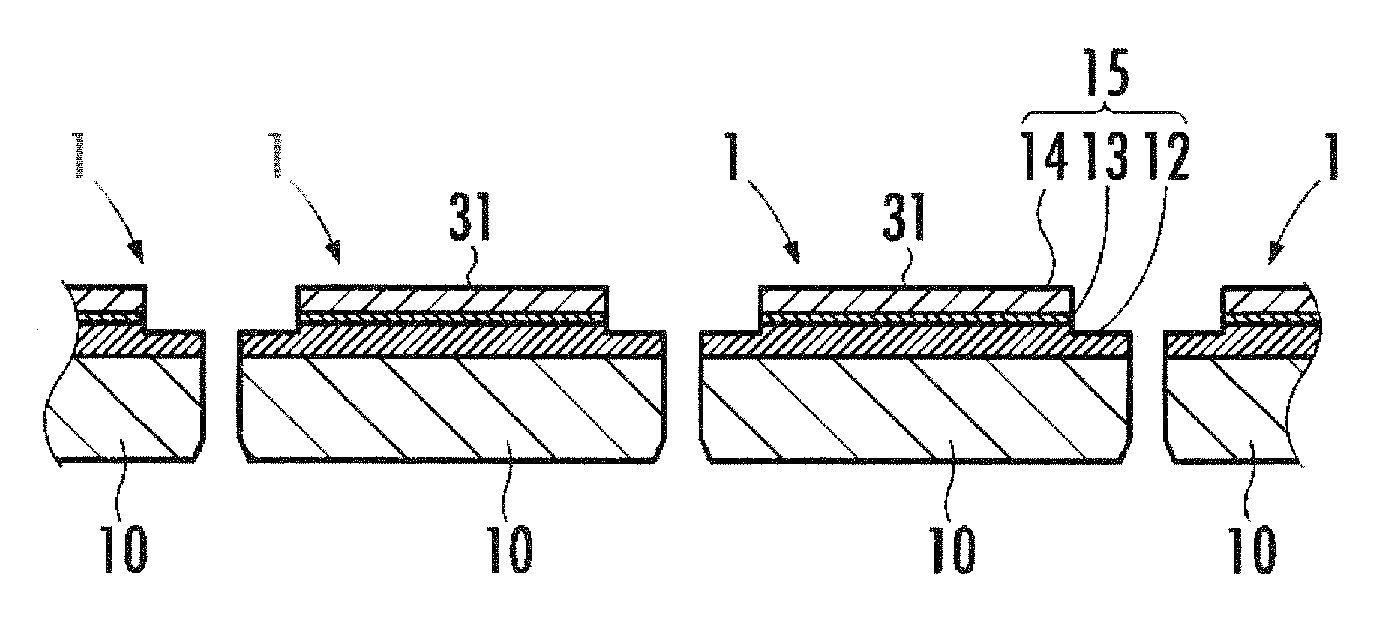

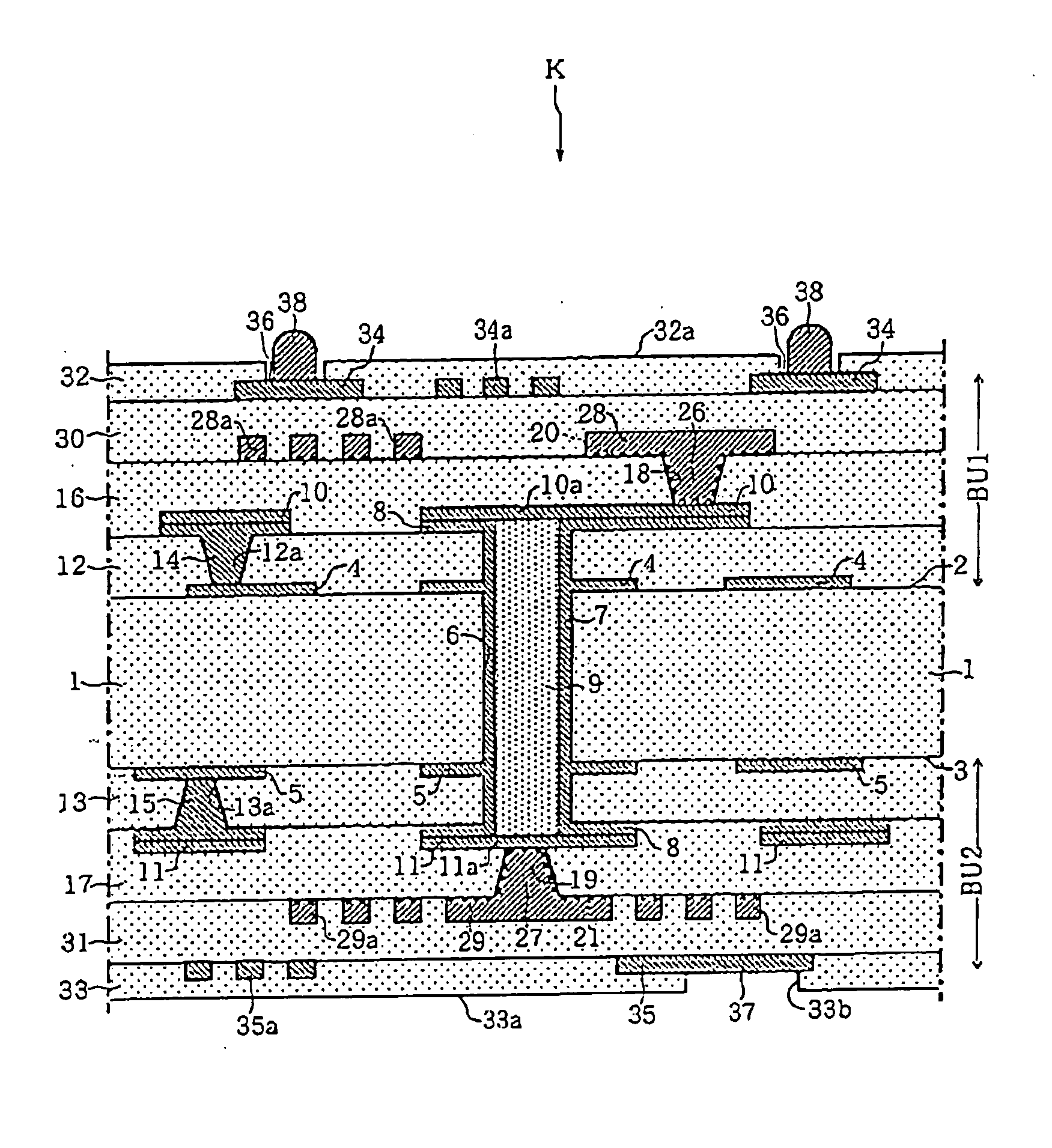

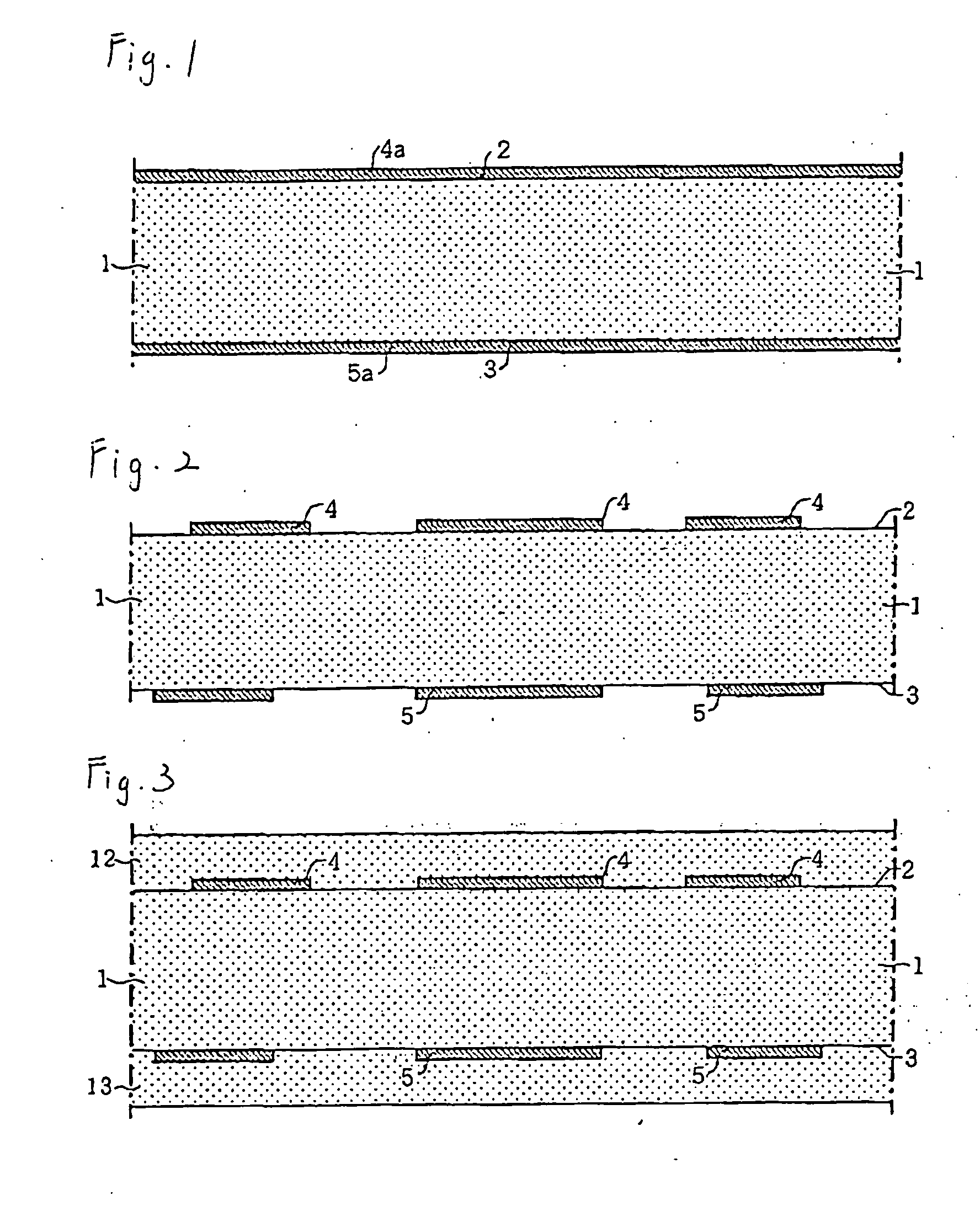

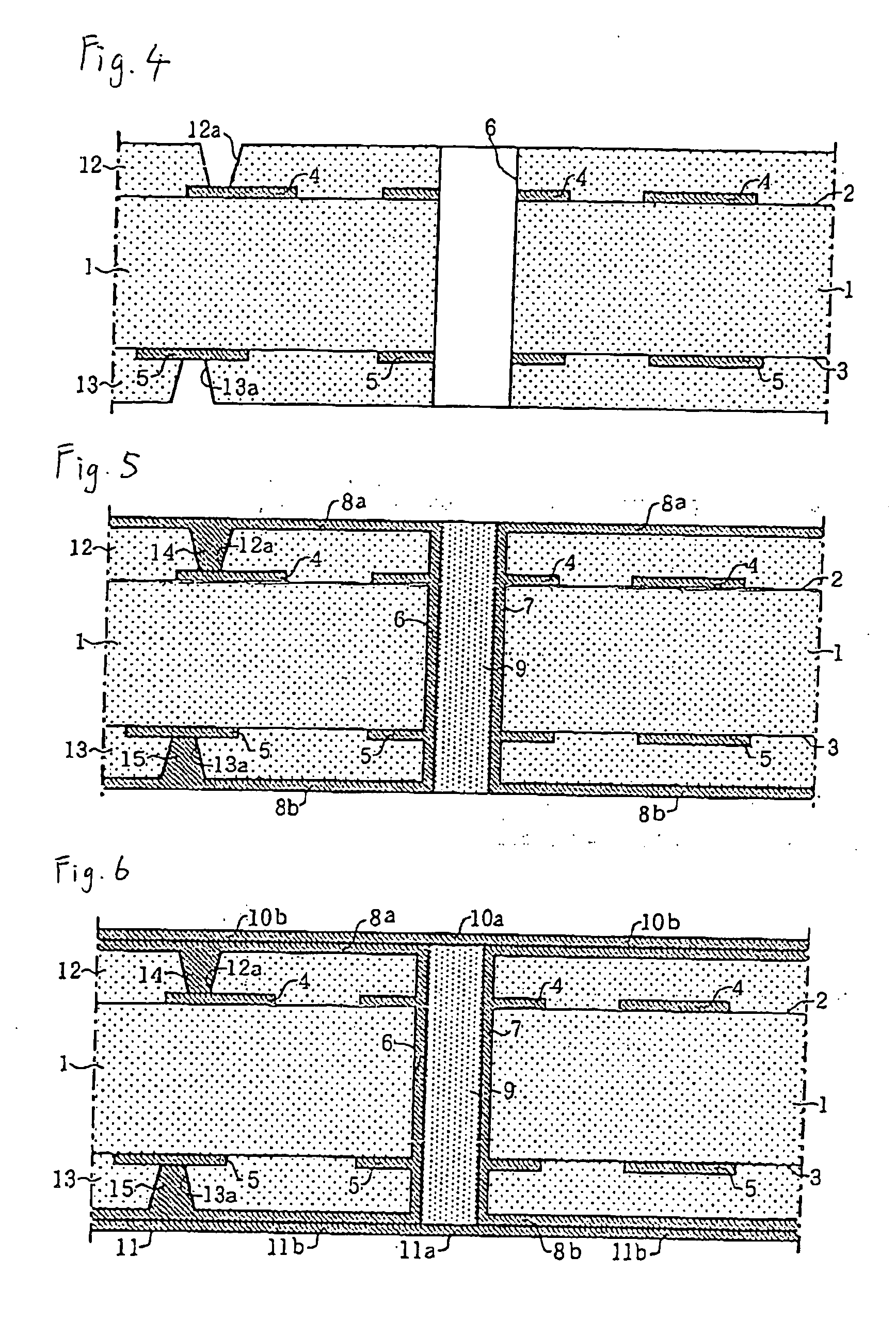

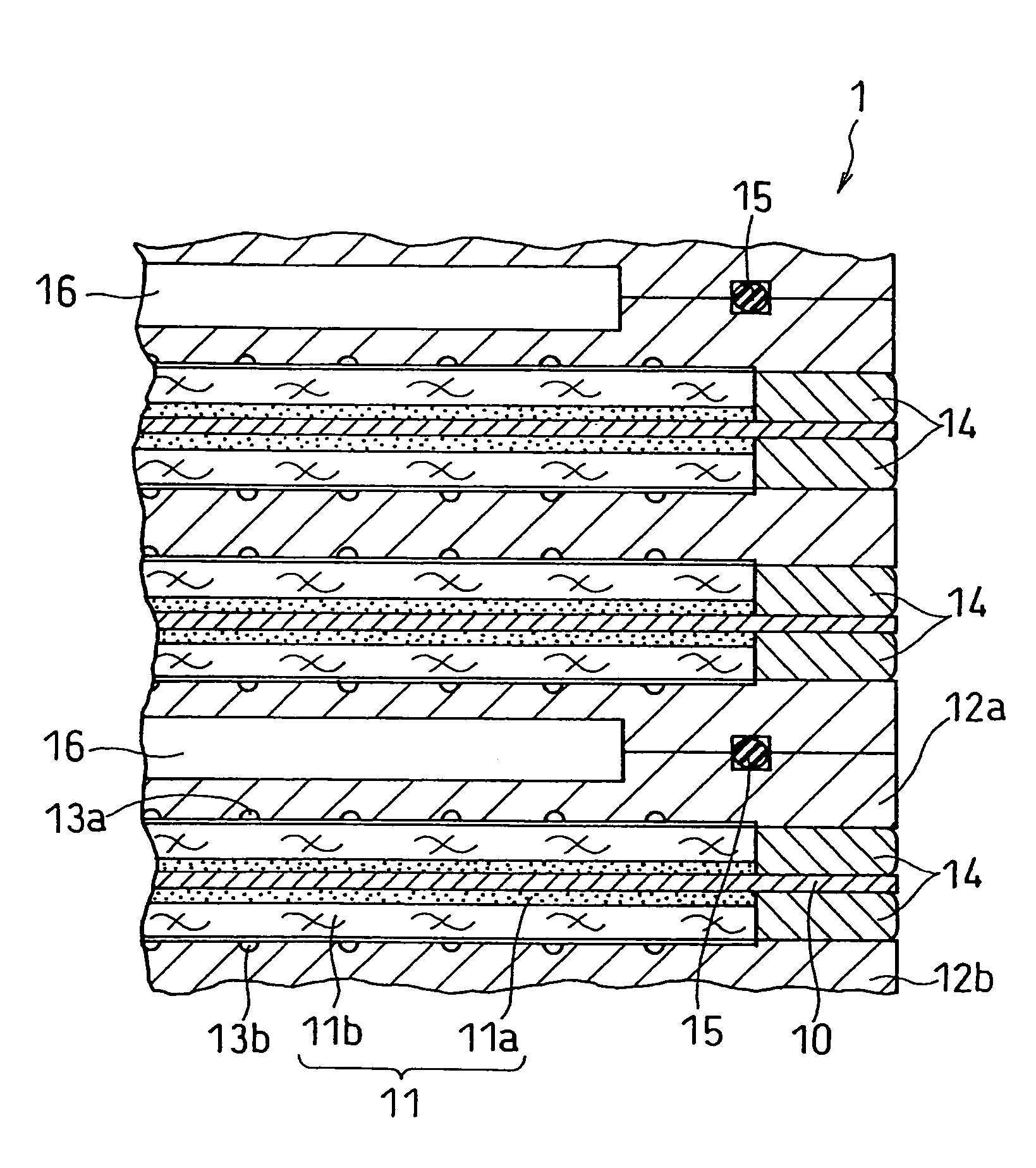

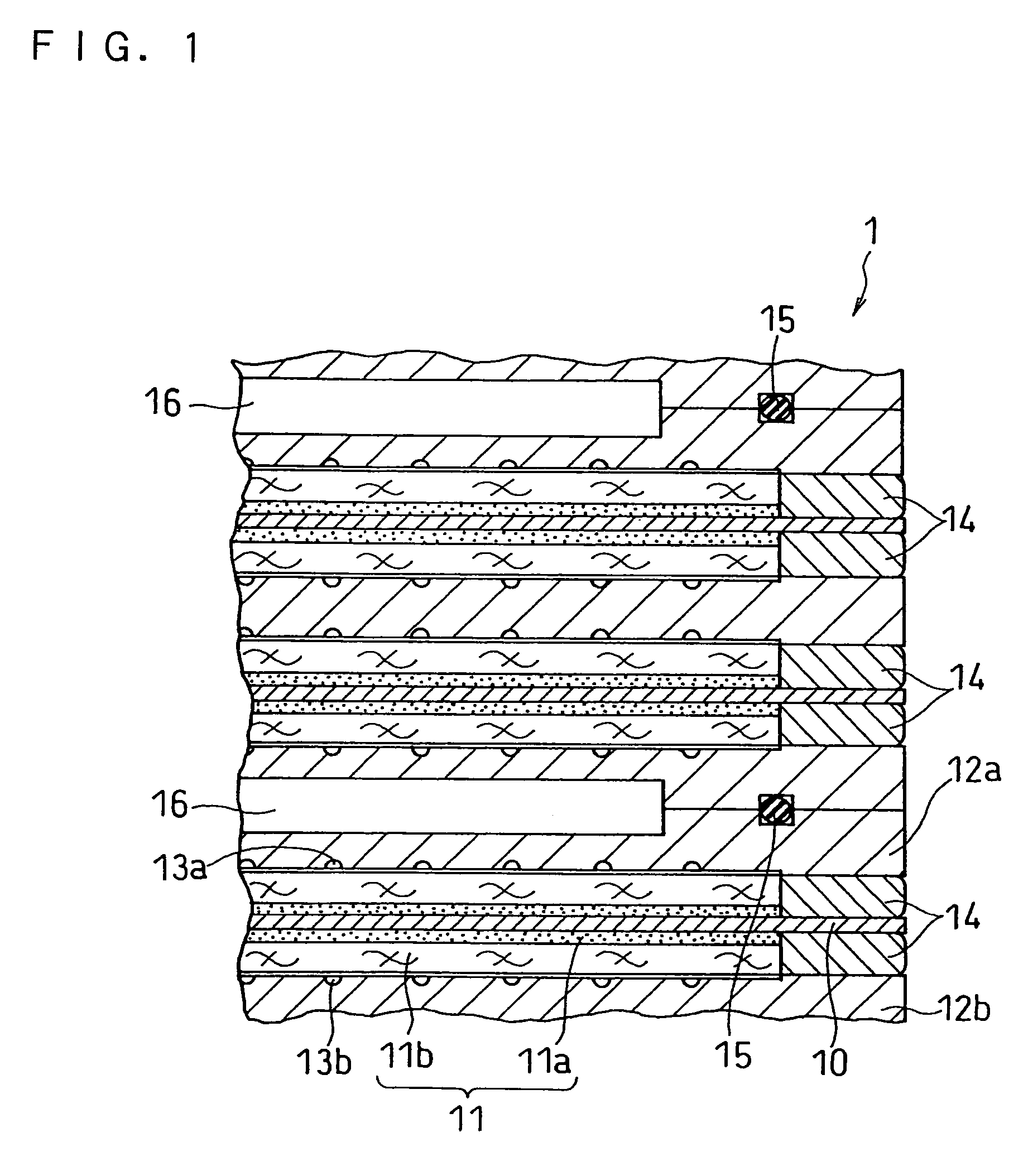

Method for forming crystalline semiconductor layers, a method for fabricating thin film transistors, and method for fabricating solar cells and active matrix liquid crystal devices

InactiveUS6066516AGreat fabricationImprove mobilityTransistorFinal product manufactureActive matrixSolar cell

PCT No. PCT / JP96 / 01775 Sec. 371 Date Jan. 31, 1997 Sec. 102(e) Date Jan. 31, 1997 PCT Filed Jun. 26, 1996 PCT Pub. No. WO97 / 01863 PCT Pub. Date Jan. 16, 1997A crystalline semiconductor layer can be formed by forming a semiconductor film on an inexpensive conventional substrate. Next, perform a first annealing process in which nearly the entire surface of the semiconductor film is exposed to laser irradiation or other forms of irradiation, and then perform a second annealing process consisting of rapid thermal annealing. This enables the formation of a high quality crystalline semiconductor film with high throughput but without subjecting the substrate to undue thermal stress. When this invention is applied to thin film transistors, good transistors having high performance are easily fabricated. When this invention is applied to solar cells, energy conversion efficiency is increased.

Owner:SEIKO EPSON CORP

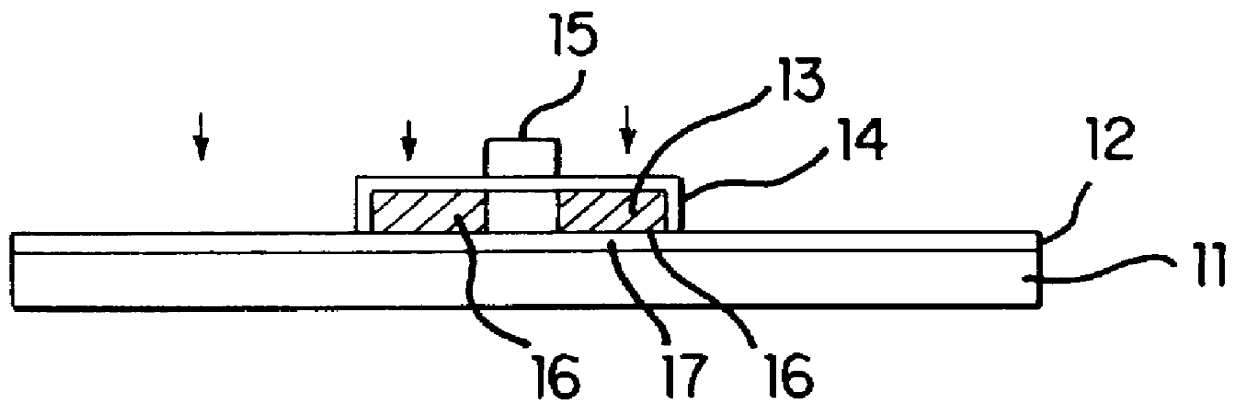

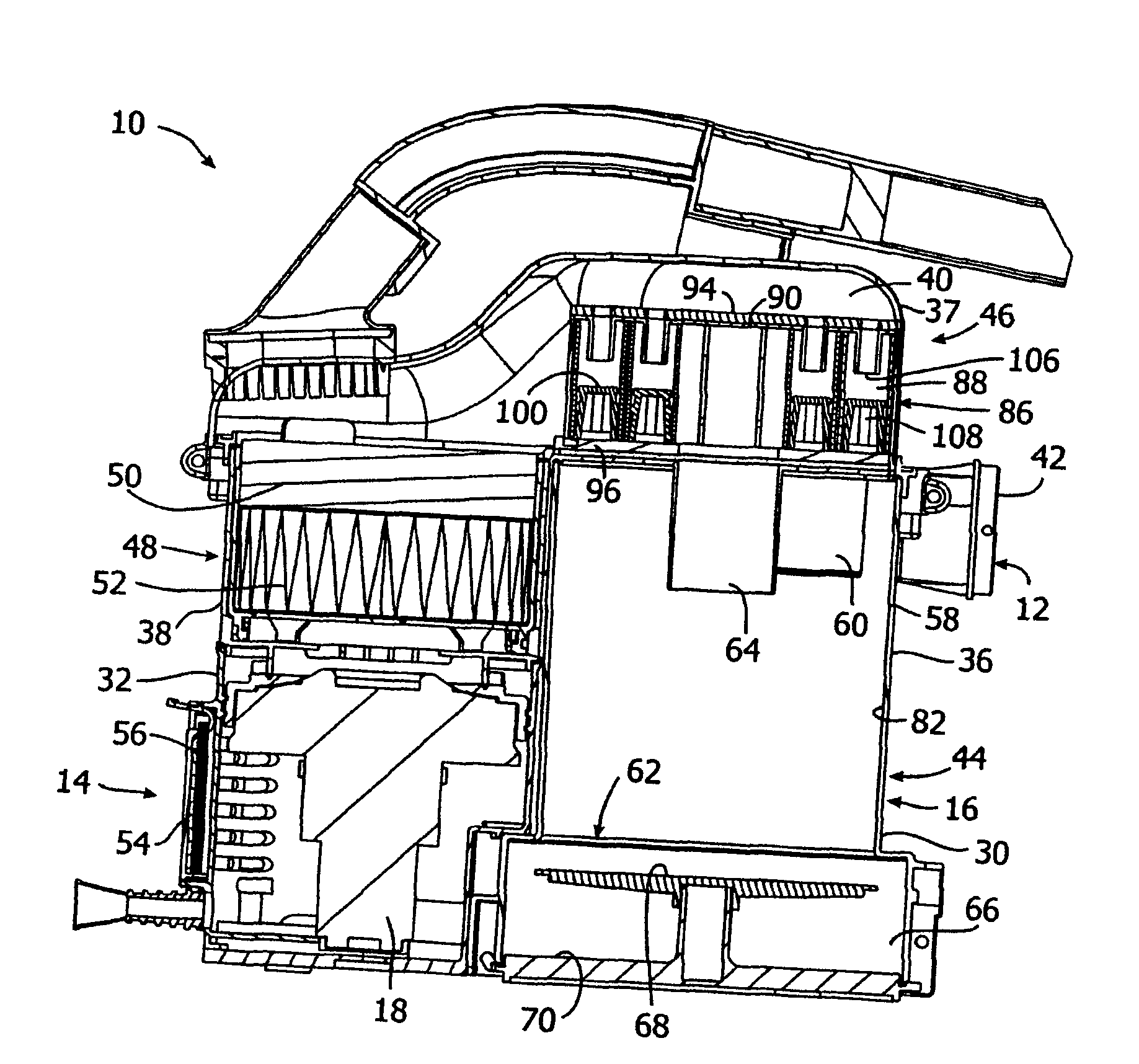

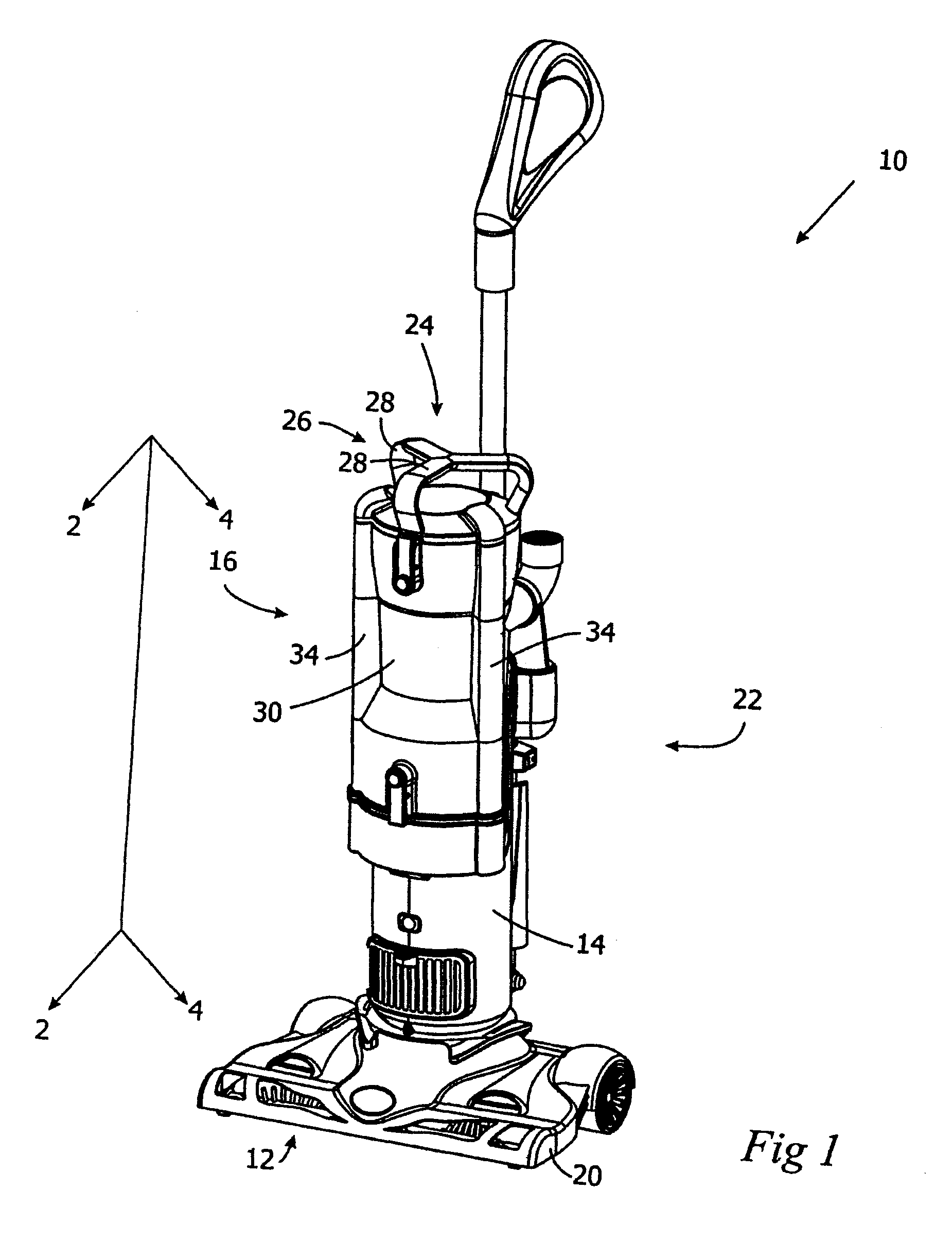

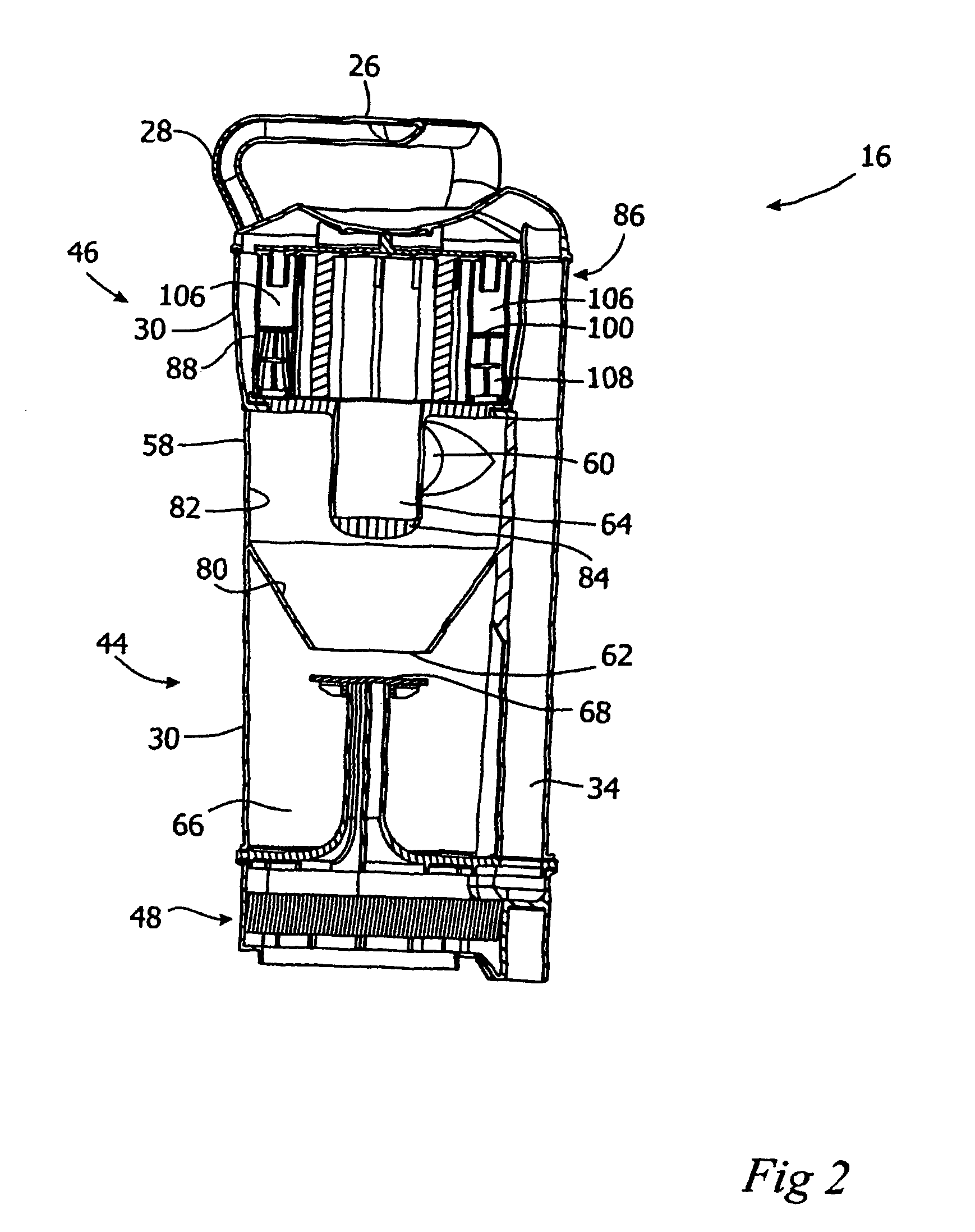

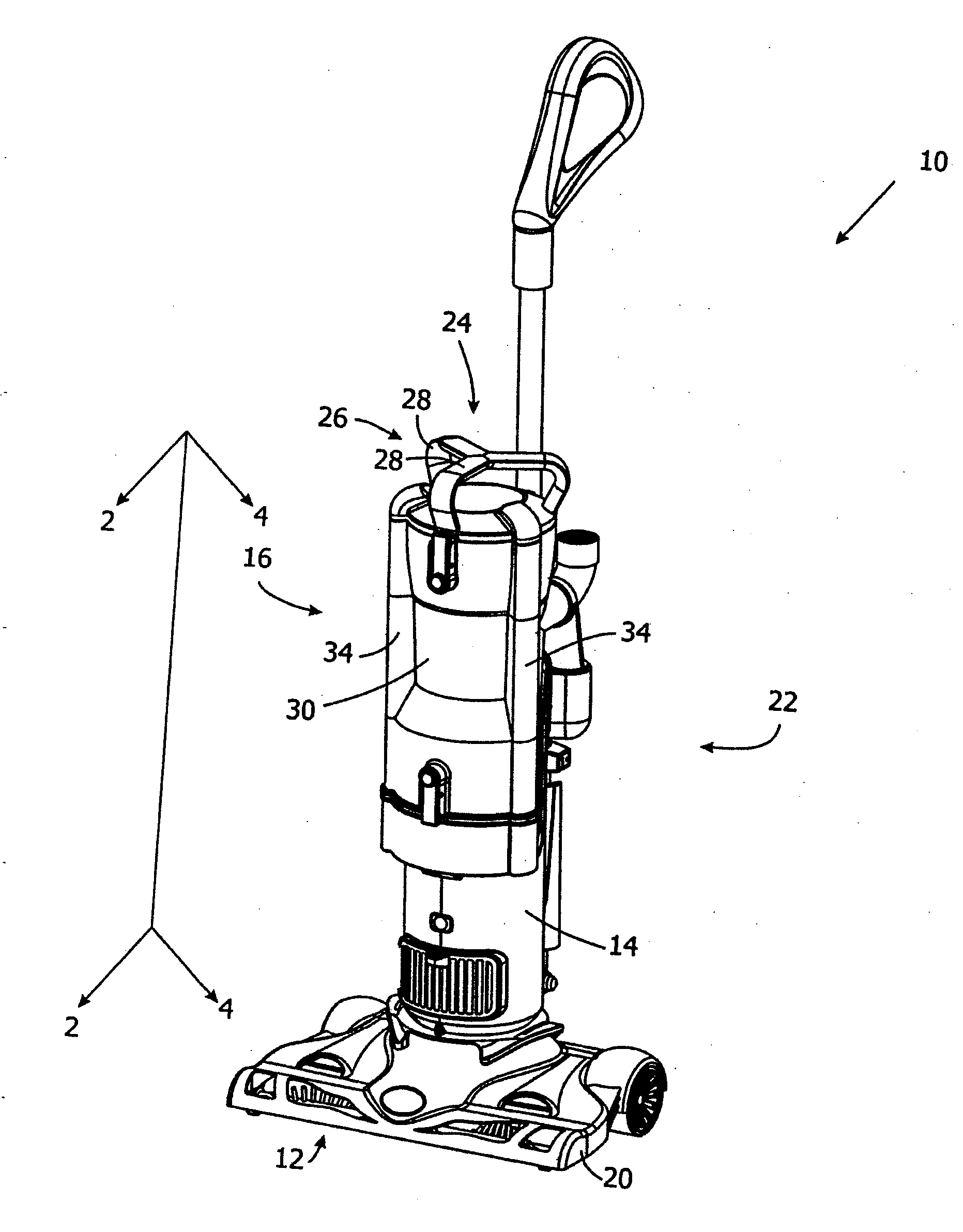

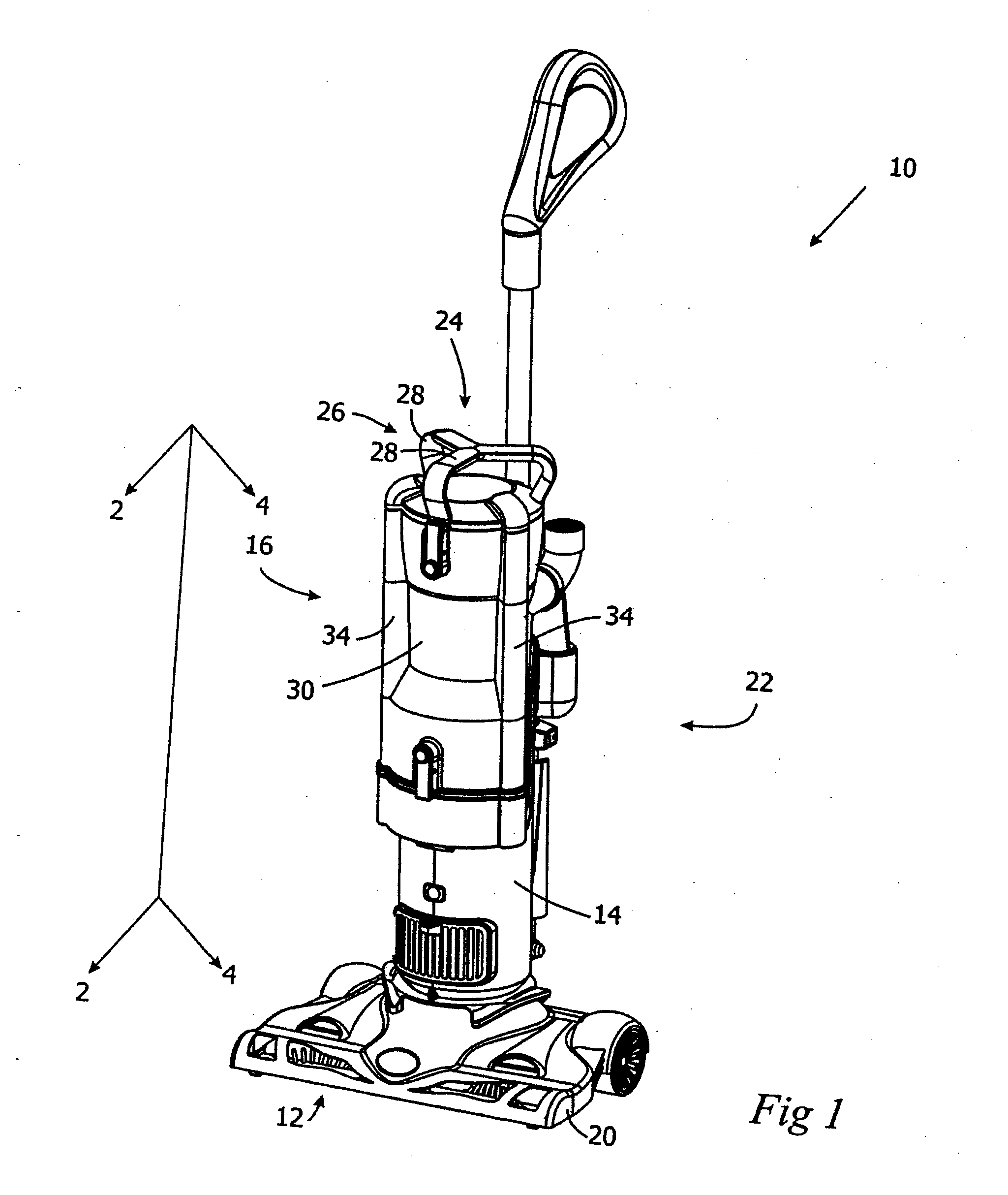

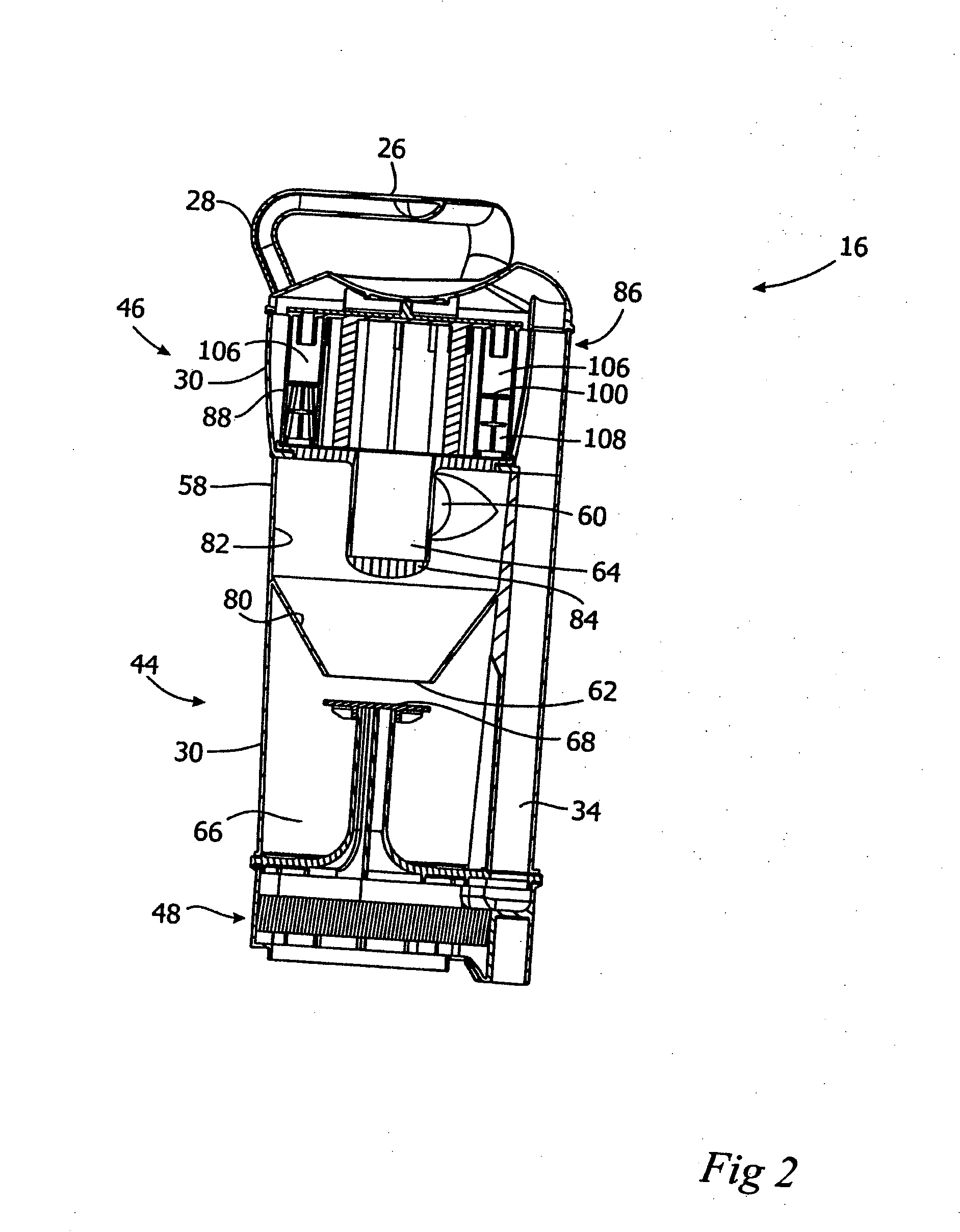

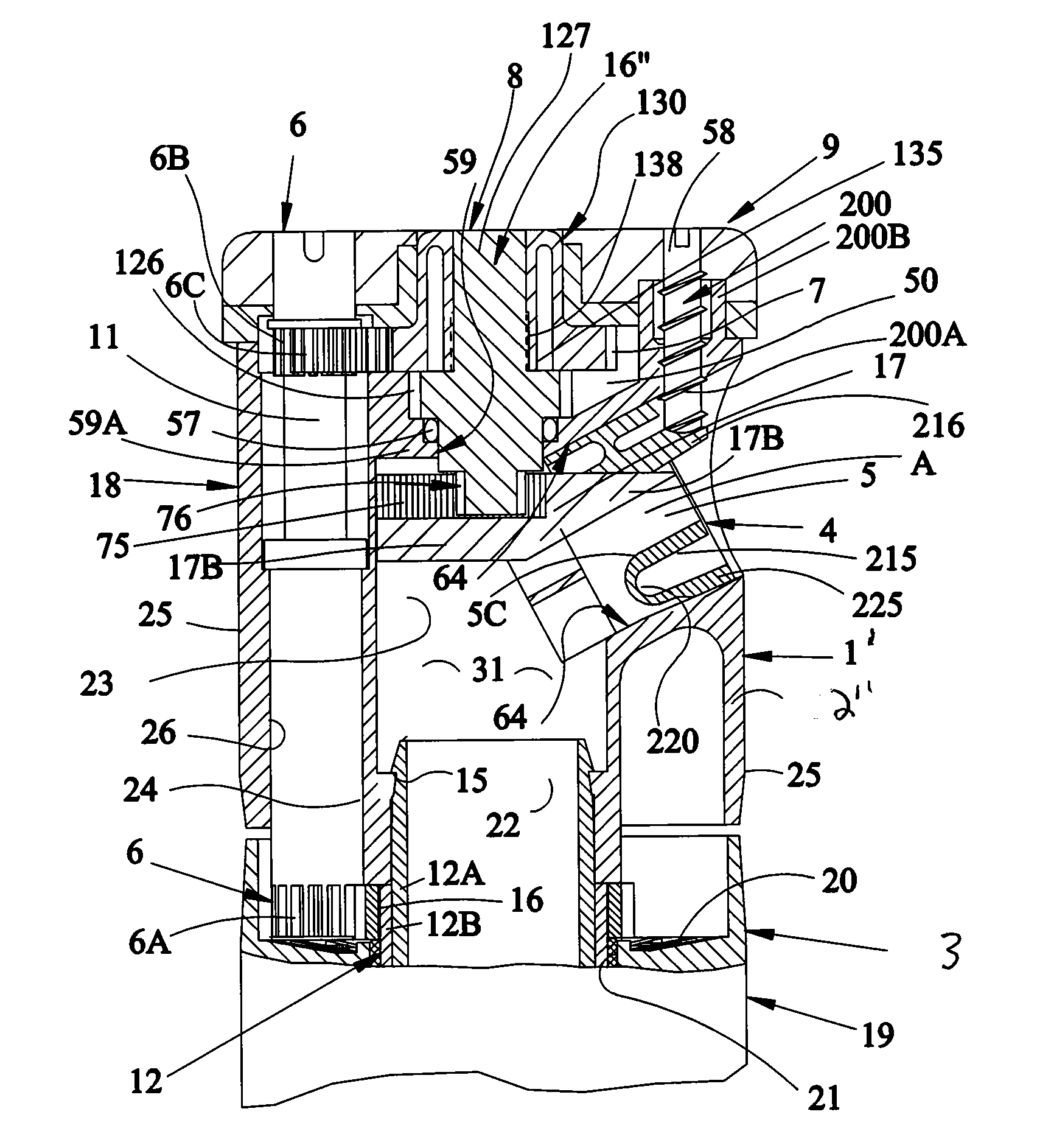

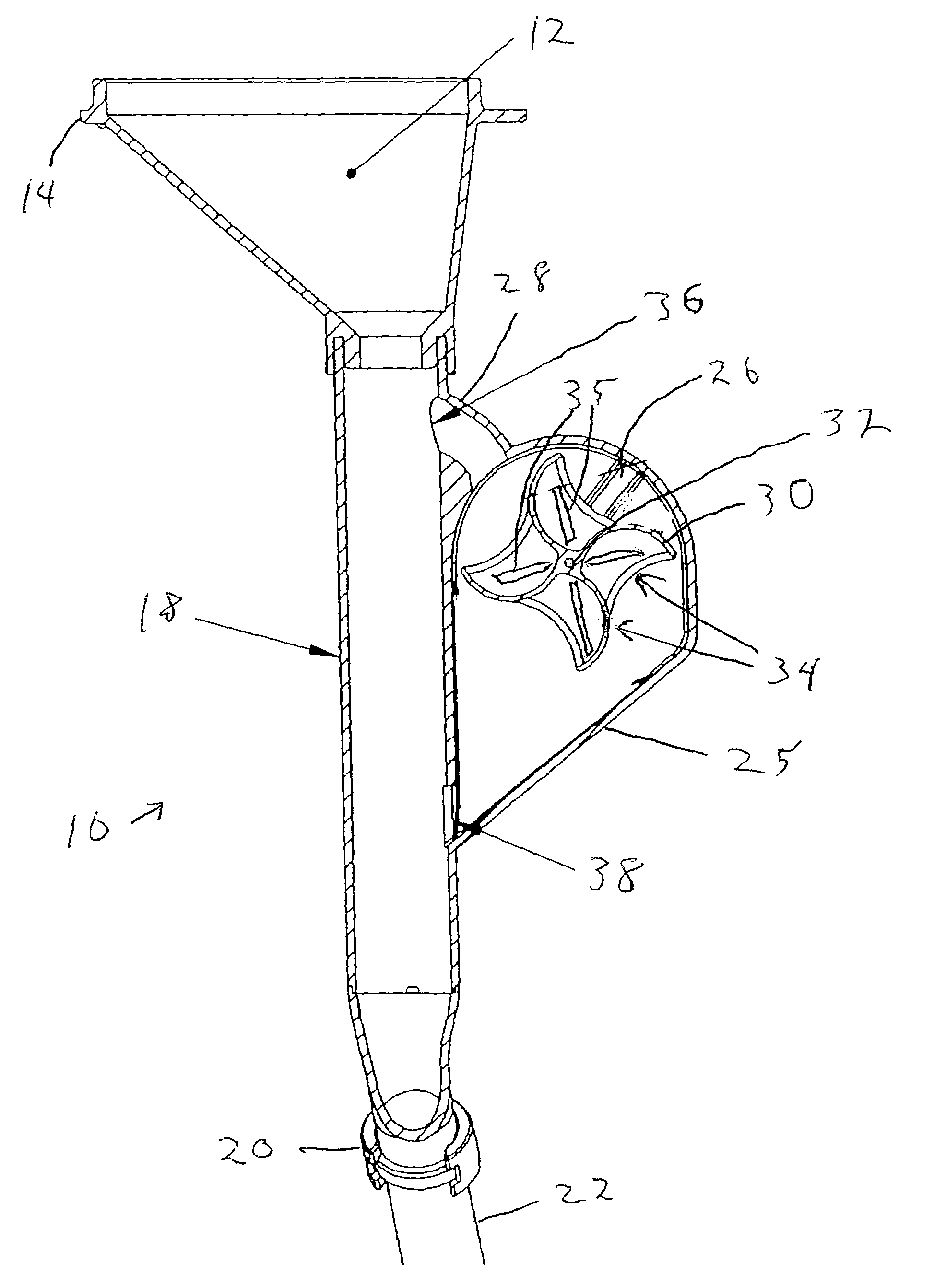

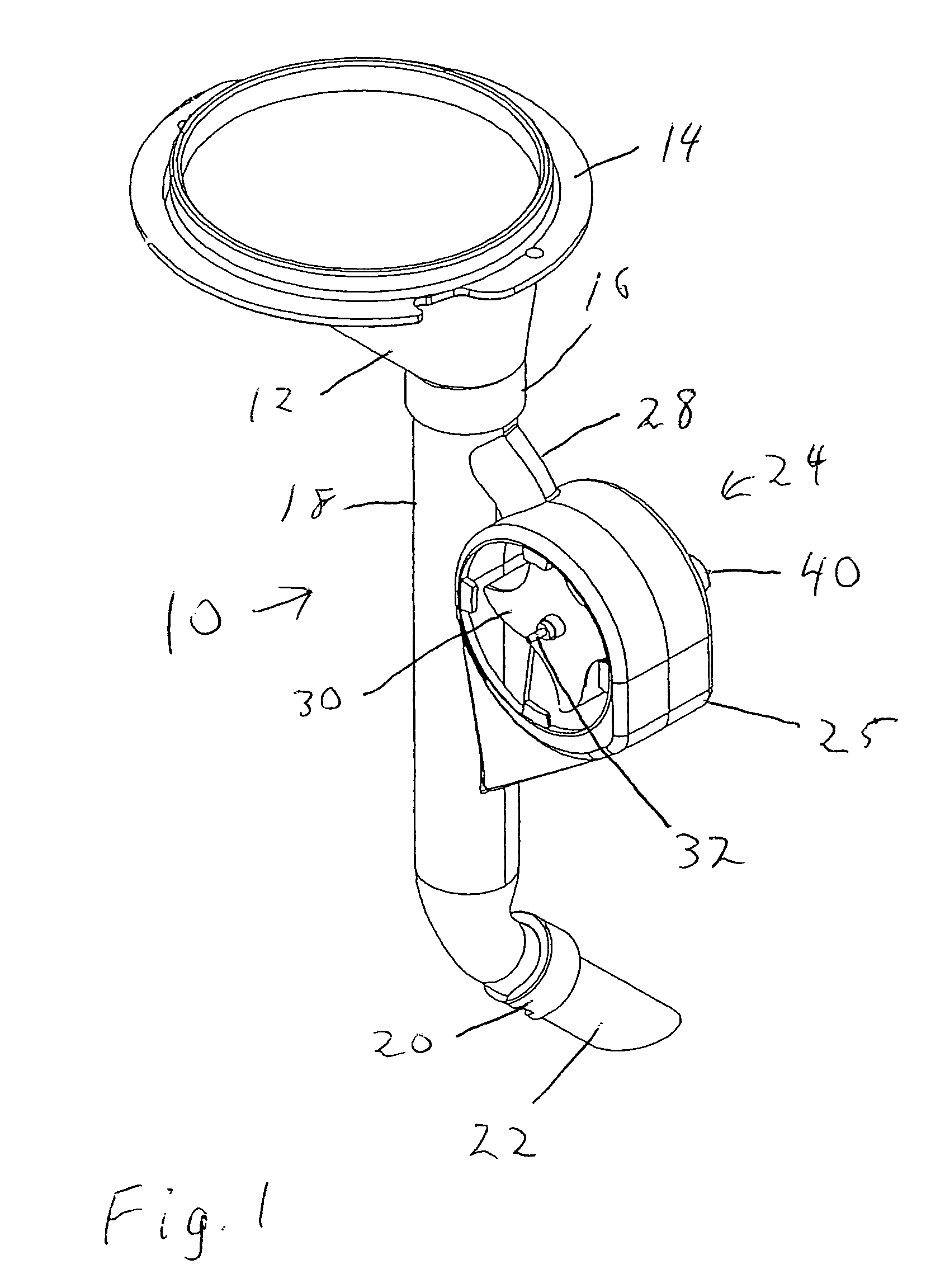

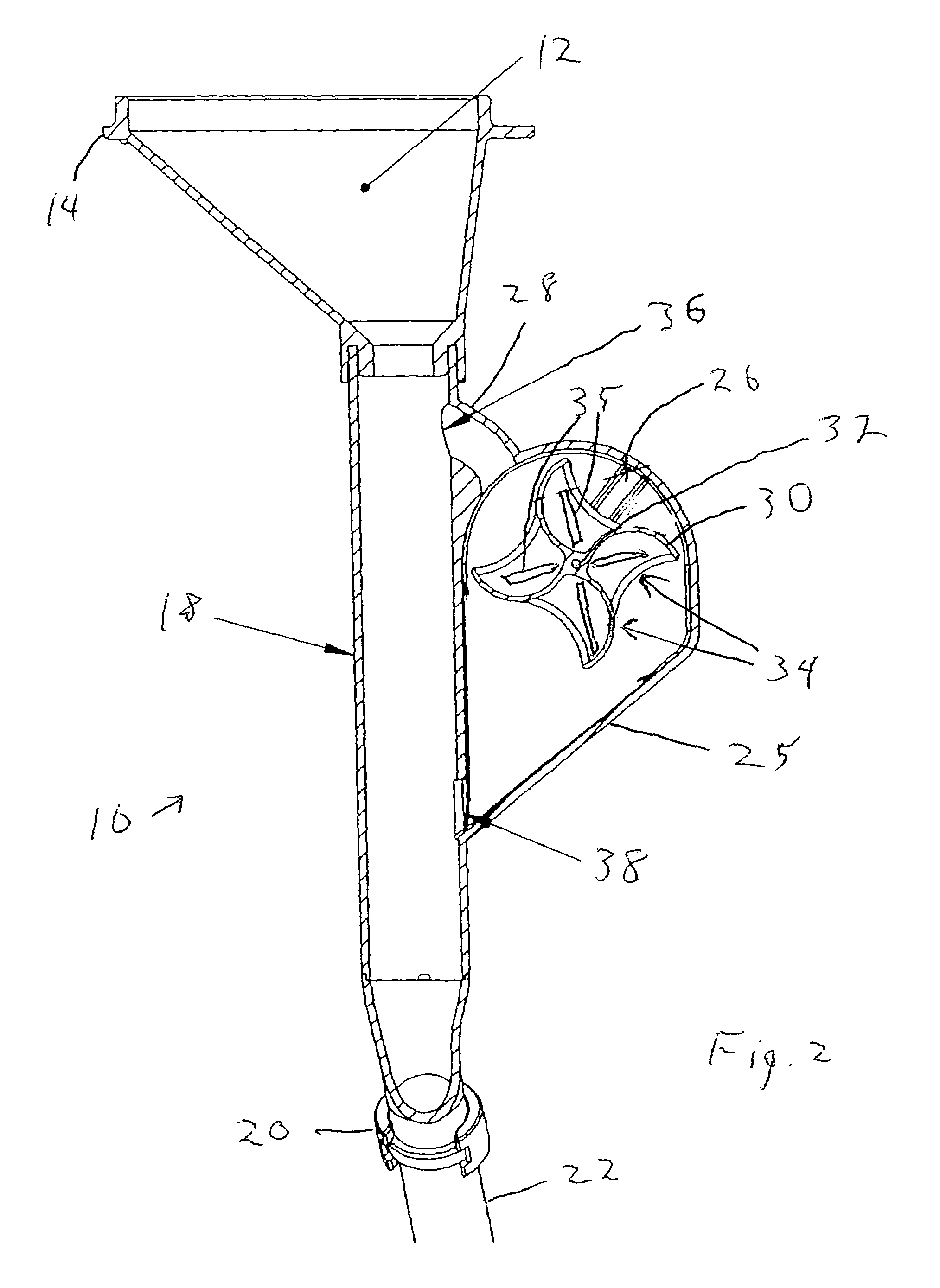

Cyclonic array such as for a vacuum cleaner

InactiveUS7867308B2Reliable and easy to manufactureEasy to disassembleCleaning filter meansCombination devicesCycloneSurface cleaning

A cyclonic cleaning stage for a, e.g., surface cleaning apparatus is provided. The cyclonic cleaning stage comprises a plurality of cyclones, which are integrally molded as a single body. Each cyclone has a cyclone body having an upper end, a lower end, a cyclone inlet, and a cyclone outlet. Each cyclone inlet has a top. A separately molded upper cover is mounted to the top of the single body at the upper ends. A separately molded lower cover is mounted on the single body at the lower ends of the cyclones.

Owner:OMACHRON INTPROP

Cyclonic array such as for a vacuum cleaner

InactiveUS20080172995A1Easy to disassembleEasy to cleanCleaning filter meansCombination devicesCycloneSurface cleaning

A cyclonic cleaning stage for a, e.g., surface cleaning apparatus is provided. The cyclonic cleaning stage comprises a plurality of cyclones, which are integrally molded as a single body. Each cyclone has a cyclone body having an upper end, a lower end, a cyclone inlet, and a cyclone outlet. Each cyclone inlet has a top. A separately molded upper cover is mounted to the top of the single body at the upper ends. A separately molded lower cover is mounted on the single body at the lower ends of the cyclones.

Owner:OMACHRON INTPROP

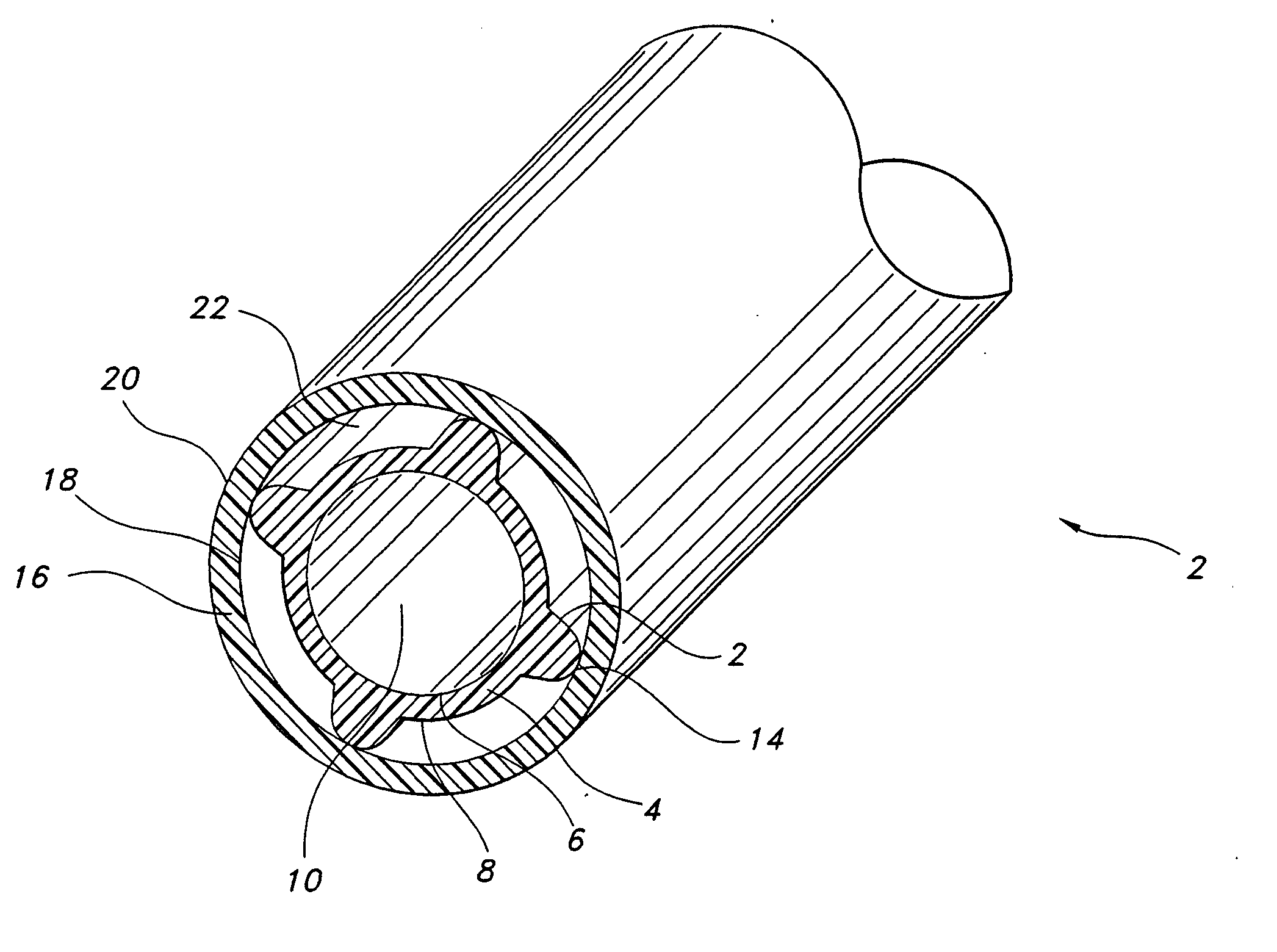

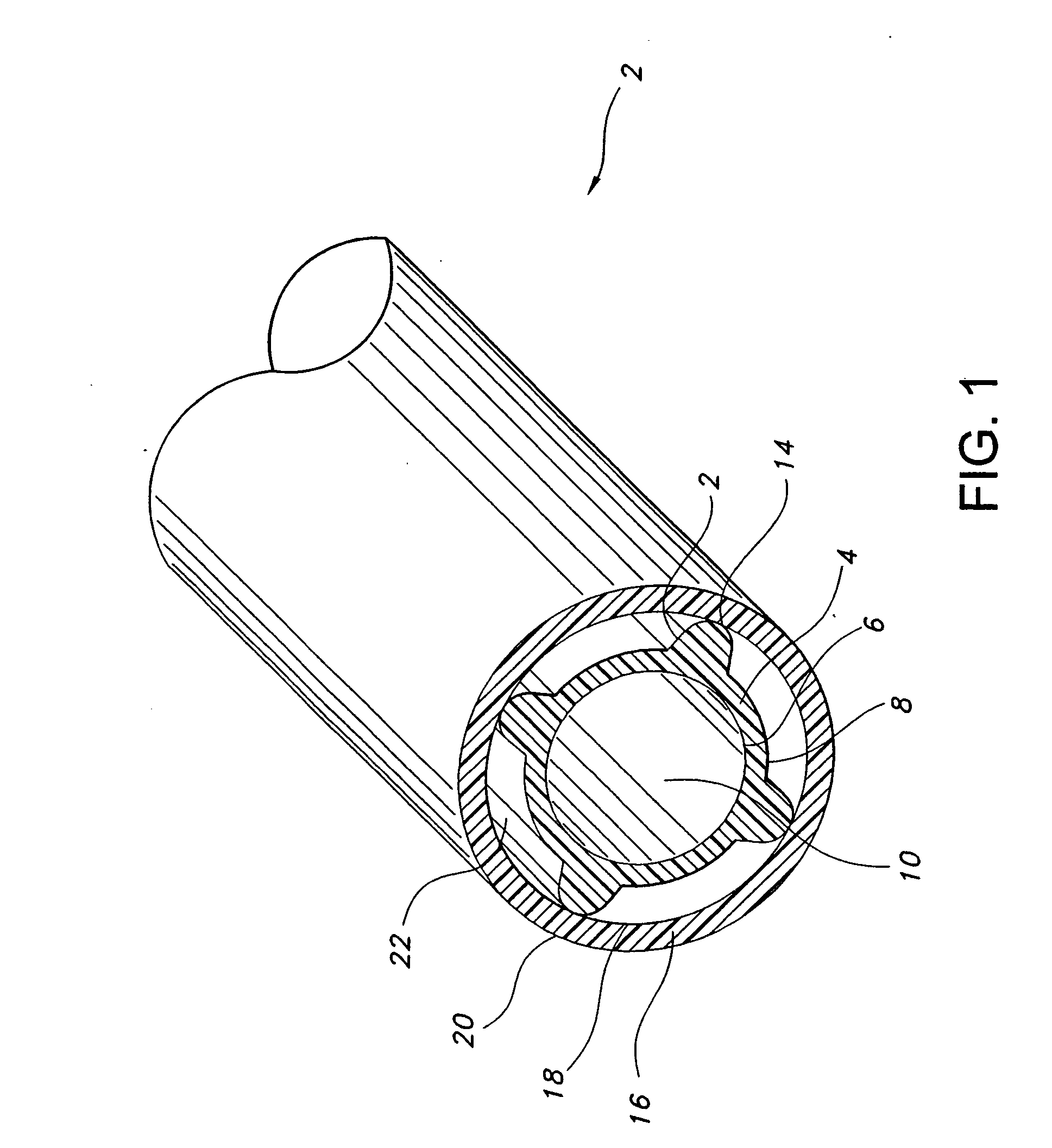

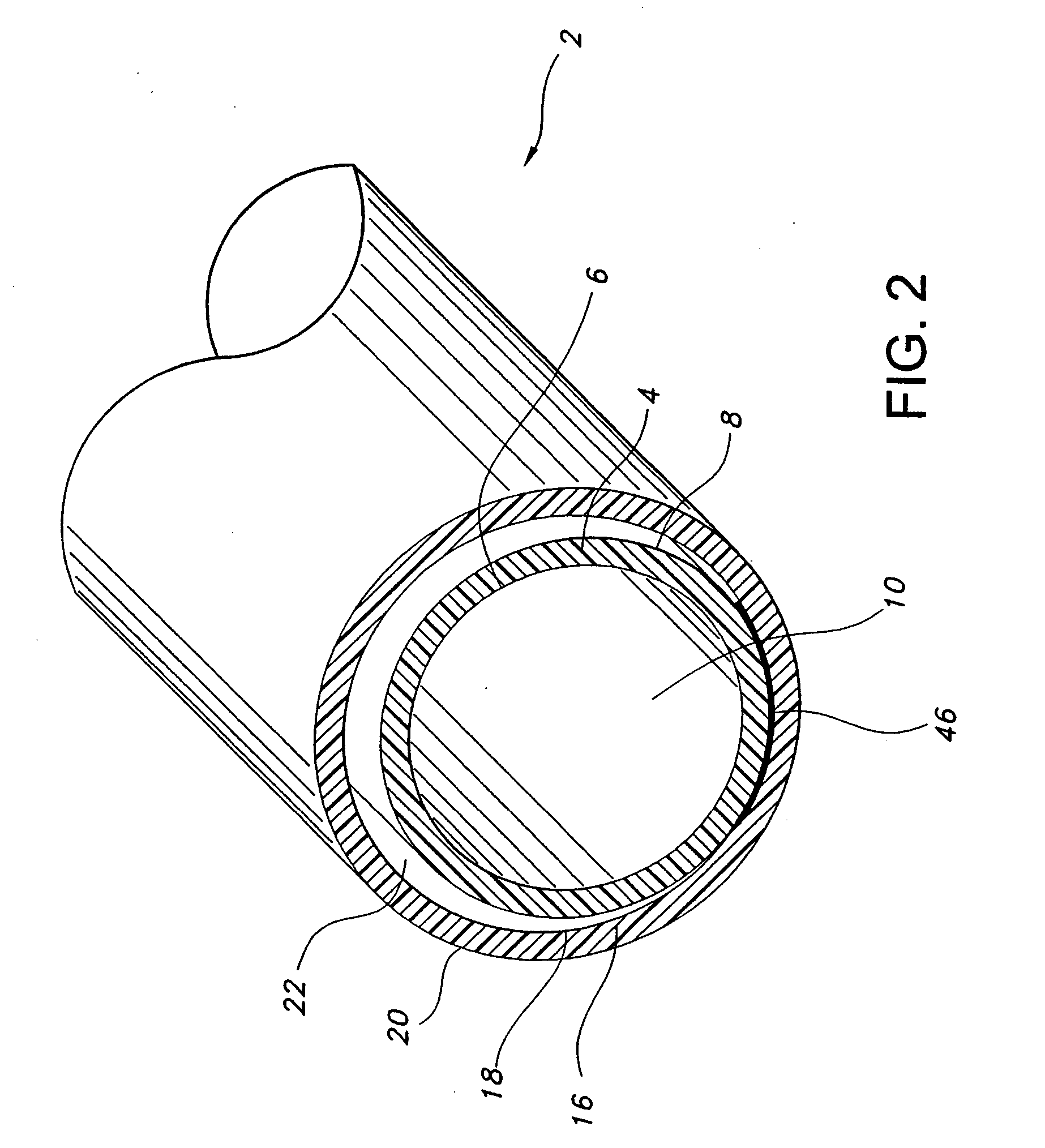

Multi-lumen vascular grafts having improved self-sealing properties

InactiveUS6926735B2Solve Porosity InsufficiencySolve the lack of flexibilityCoatingsBlood vesselsVascular graft

Owner:MAQUET CARDIOVASCULAR LLC

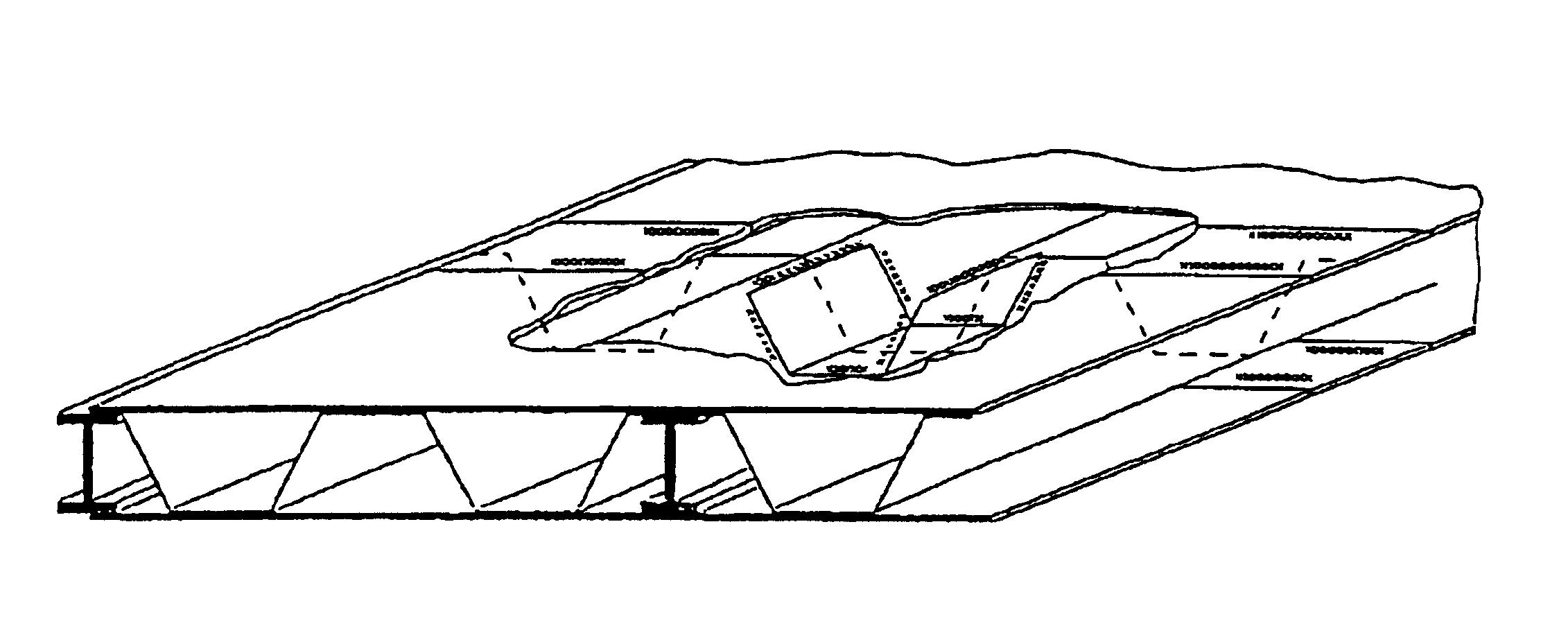

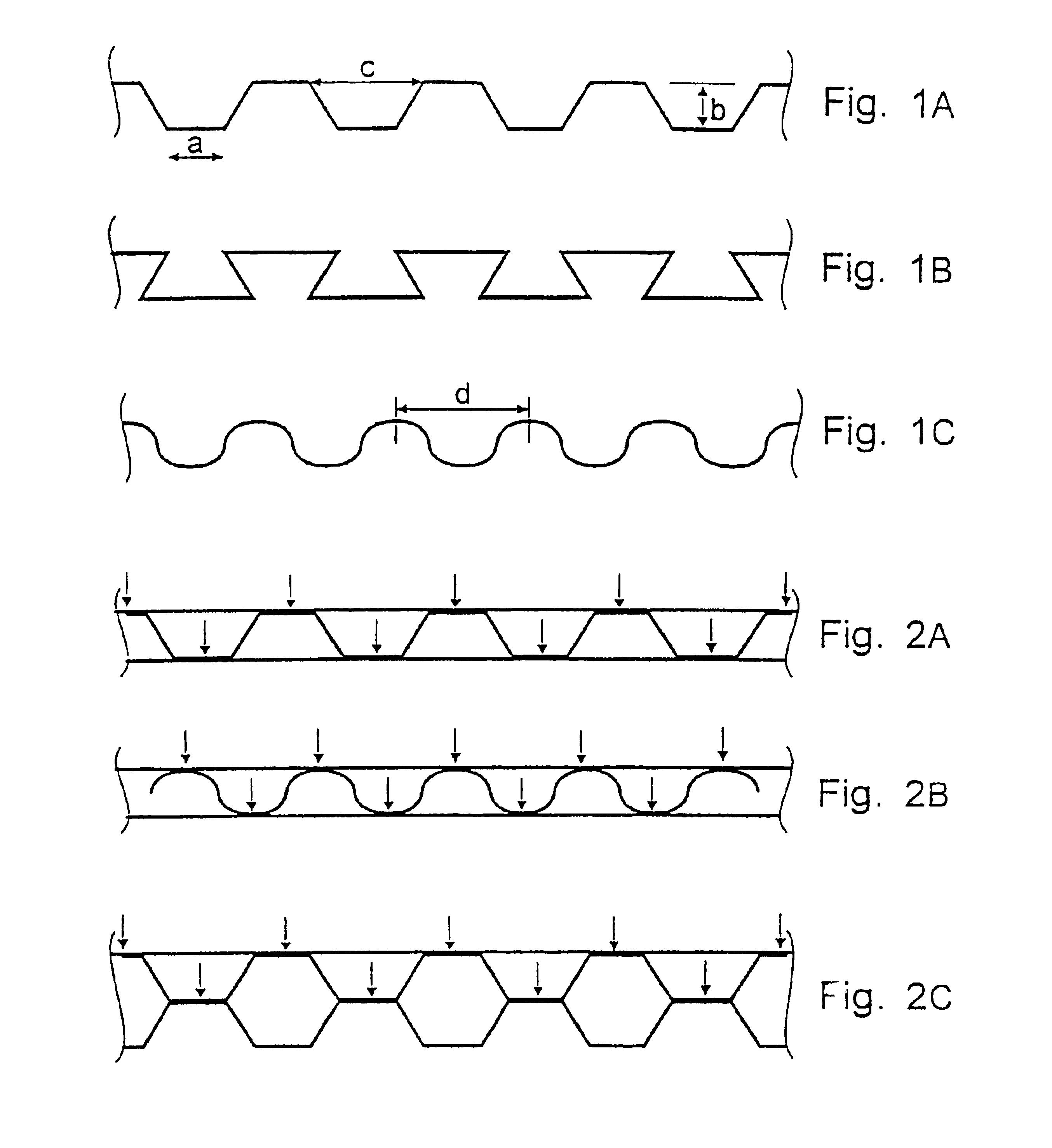

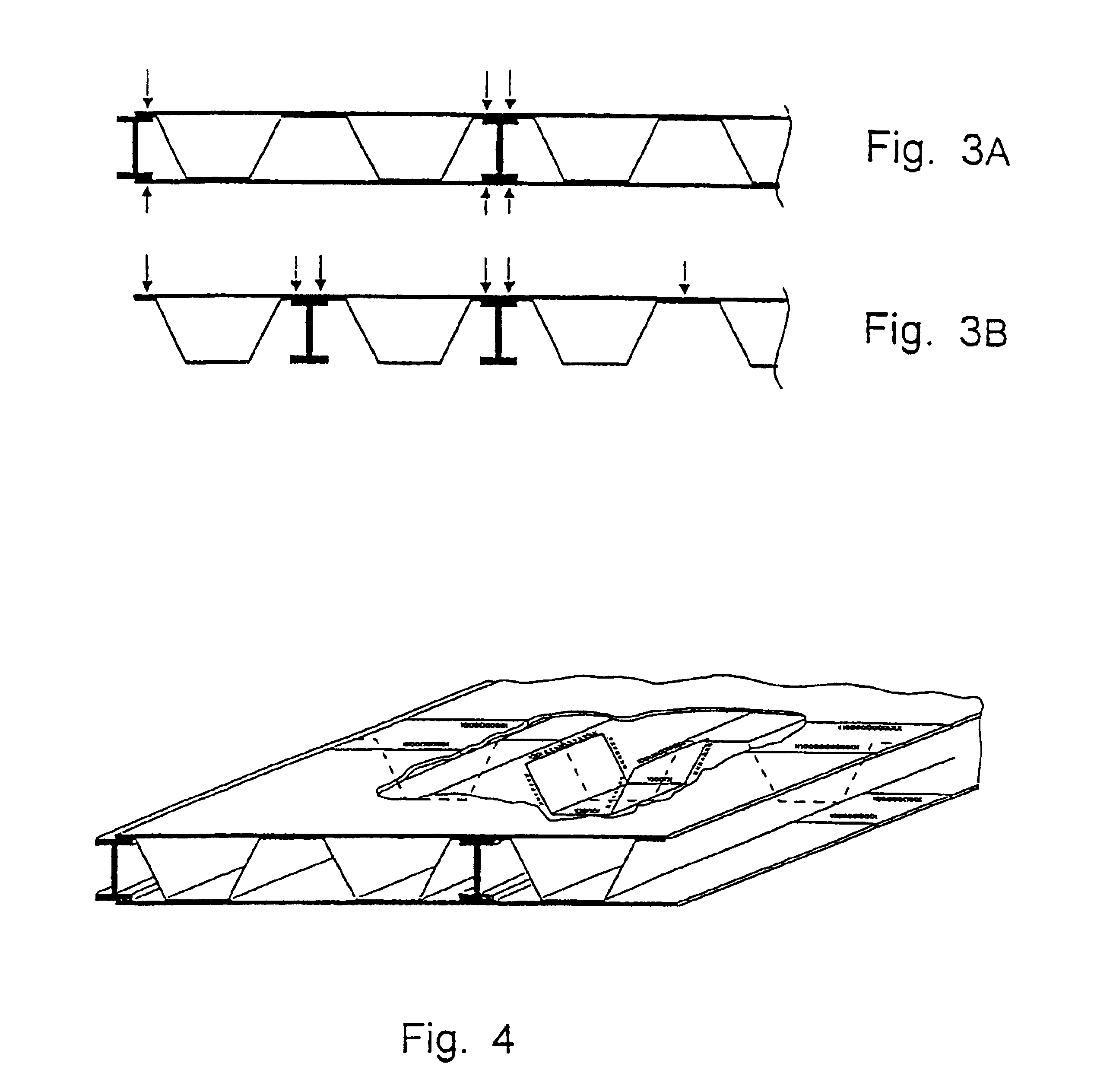

Composite aluminium panel

InactiveUS6848233B1Improve corrosion resistanceReliable and easy to manufactureNon-magnetic metal hullsLayered product treatmentParallel plateMaterials science

A composite aluminium panel comprising two parallel plates and / or sheets secured to the peaks and troughs of a corrugated aluminium stiffener sheet between the parallel plates and / or sheets, wherein the corrugated aluminium stiffener sheet is made from an aluminium alloy rolled sheet of composition (in weight percent): Mg 1.5-6.0, Mn 0.3-1.4, Zn 0.4-5.0, Fe up to 0.5, Si up to 0.5, Zr up to 0.30; optionally one or more of Cr 0.05-0.3, Ti 0.01-0.20, V 0.05-0.25, Ag 0.05-0.40, and Cu up to 0.40; and other elements up to 0.05 each, 0.15 total, with a balance of Al; and having in an H-condition or in an O-condition a ratio of PS / UTS in the range of 0.4 to 0.9 and having good roll formability.

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

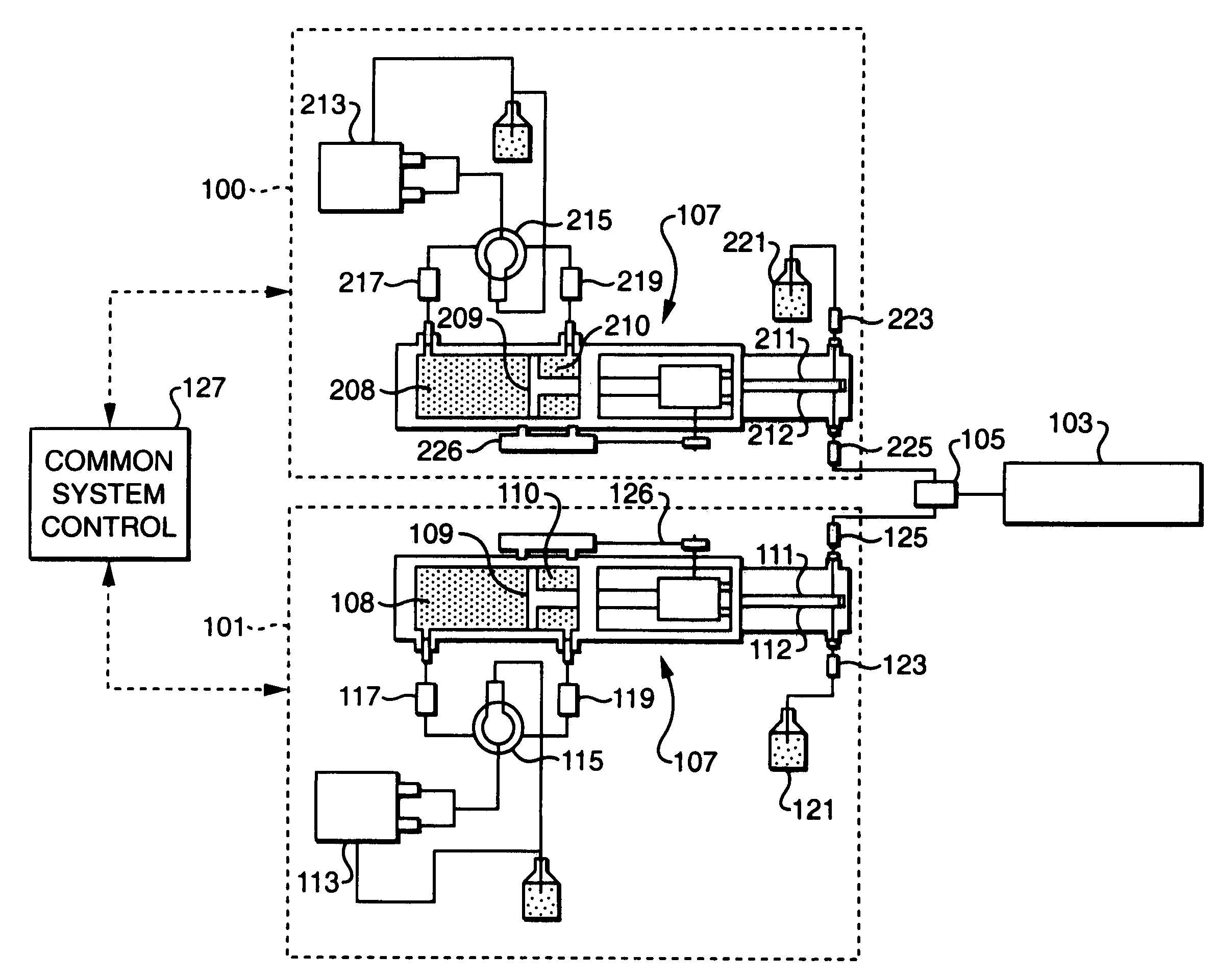

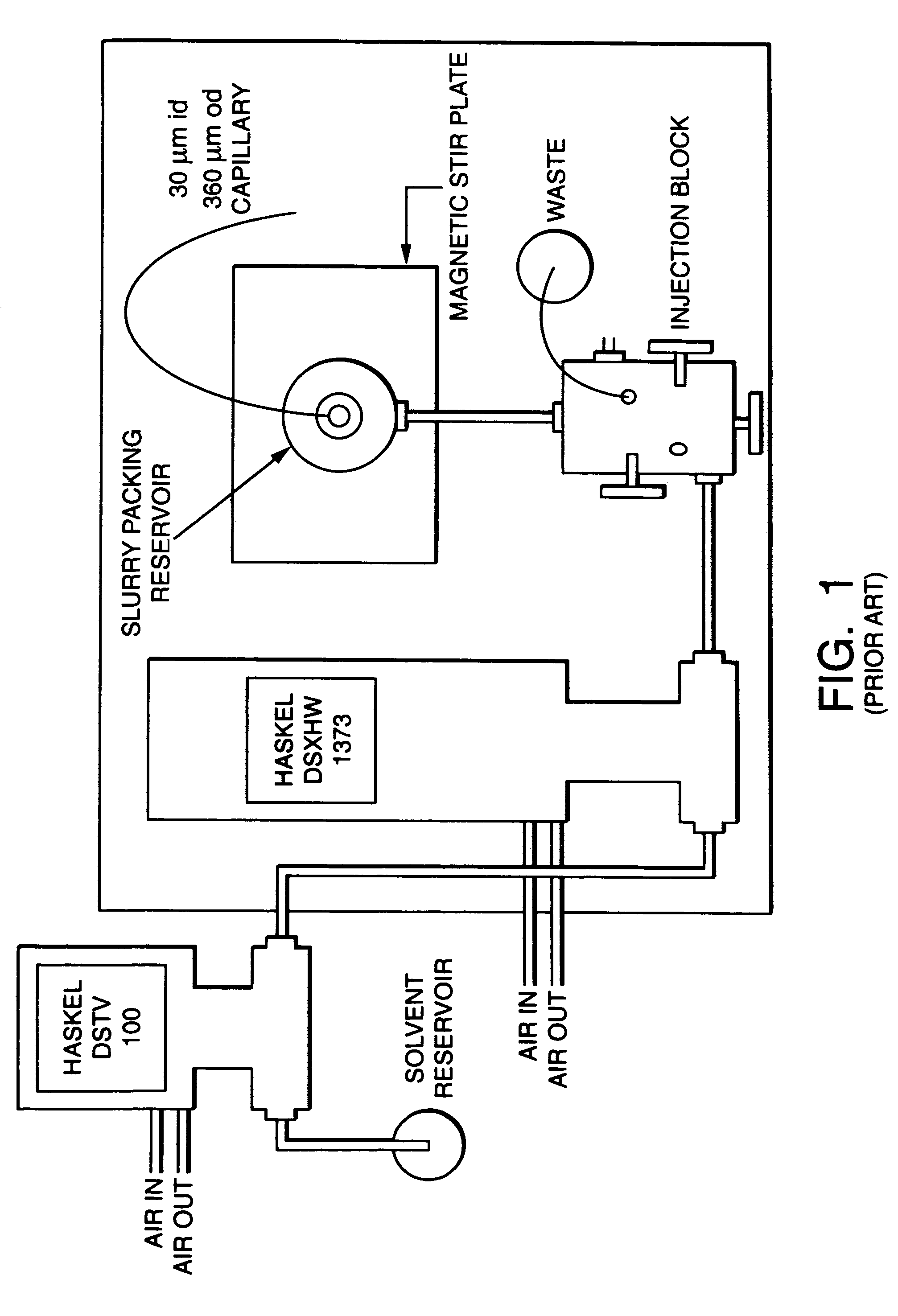

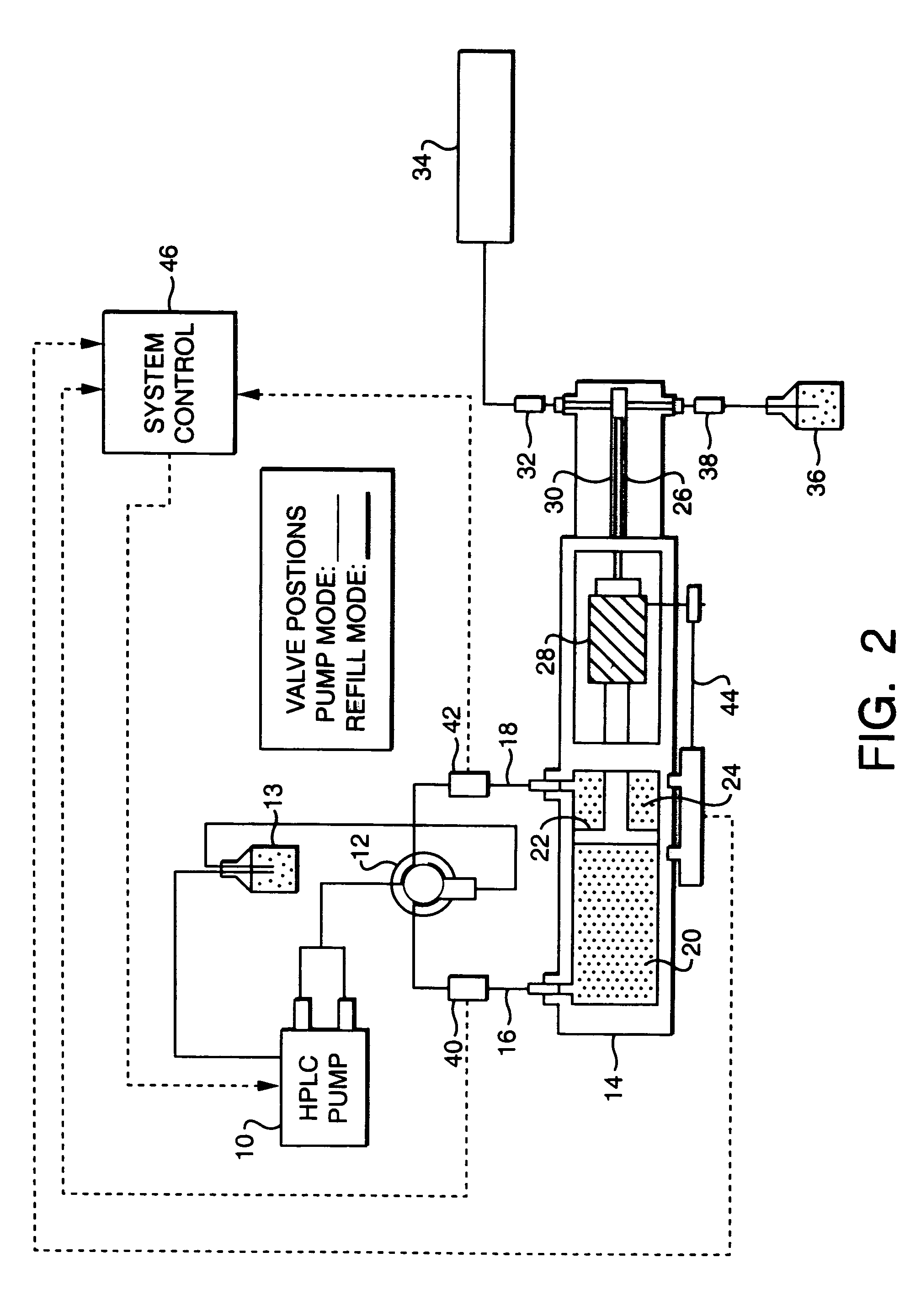

Method for using a hydraulic amplifier pump in ultrahigh pressure liquid chromatography

ActiveUS7311502B2Sufficient pressureConstant flowComponent separationPump controlHydraulic cylinderUltra high pressure

A method for supplying solvent to an ultra-high pressure liquid chromatography system using a hydraulic amplifier. The hydraulic amplifier system includes a hydraulic cylinder comprising a primary piston chamber in which a primary piston is disposed and a secondary piston chamber in which a secondary piston is disposed. The cross-sectional area of the primary piston is larger than the cross-sectional area of the secondary piston. The difference in the cross-sectional areas of the pistons creates an amplification of the pressure in the primary piston chamber and a reduction in flow rate.

Owner:WATERS TECH CORP

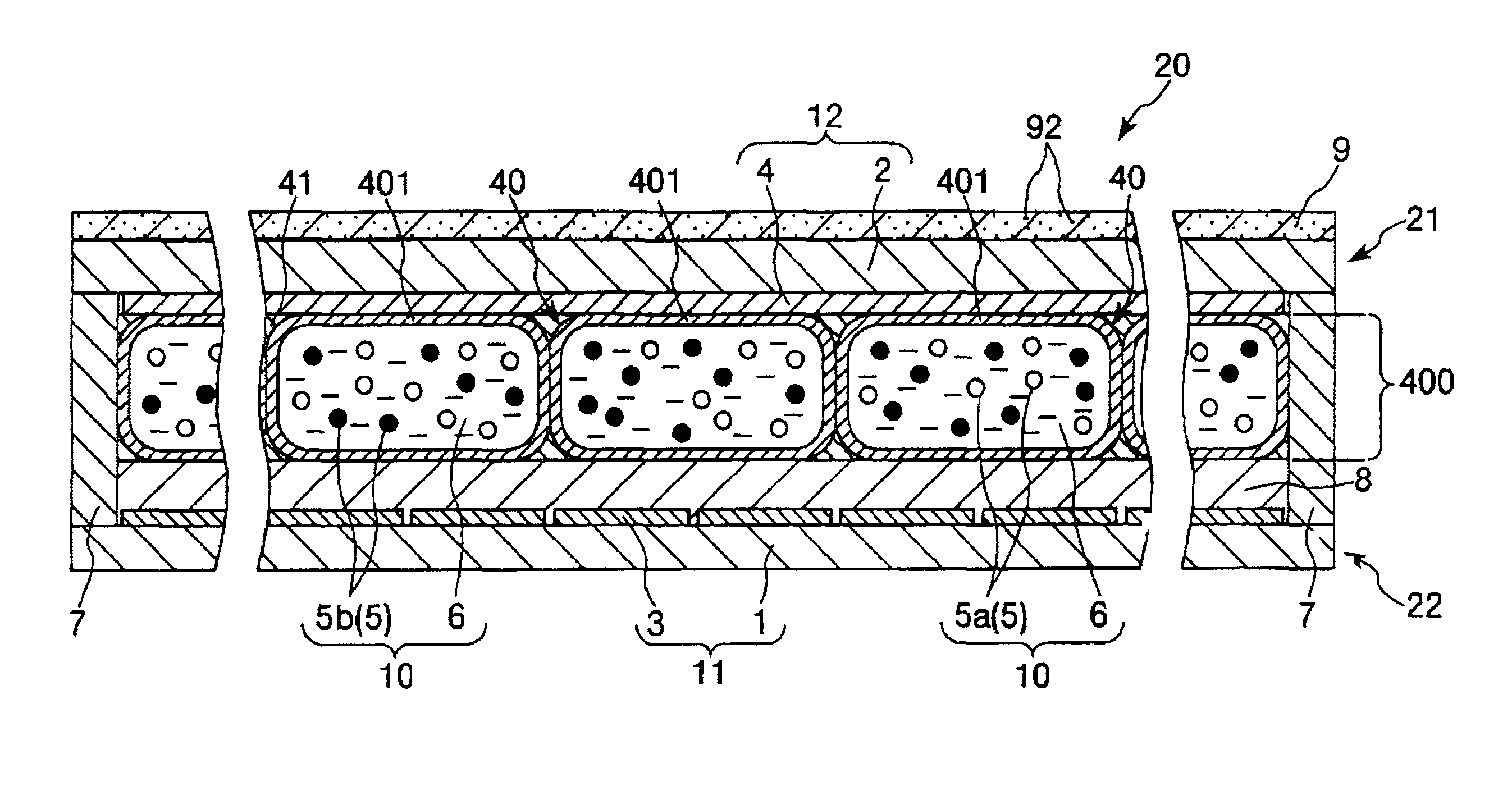

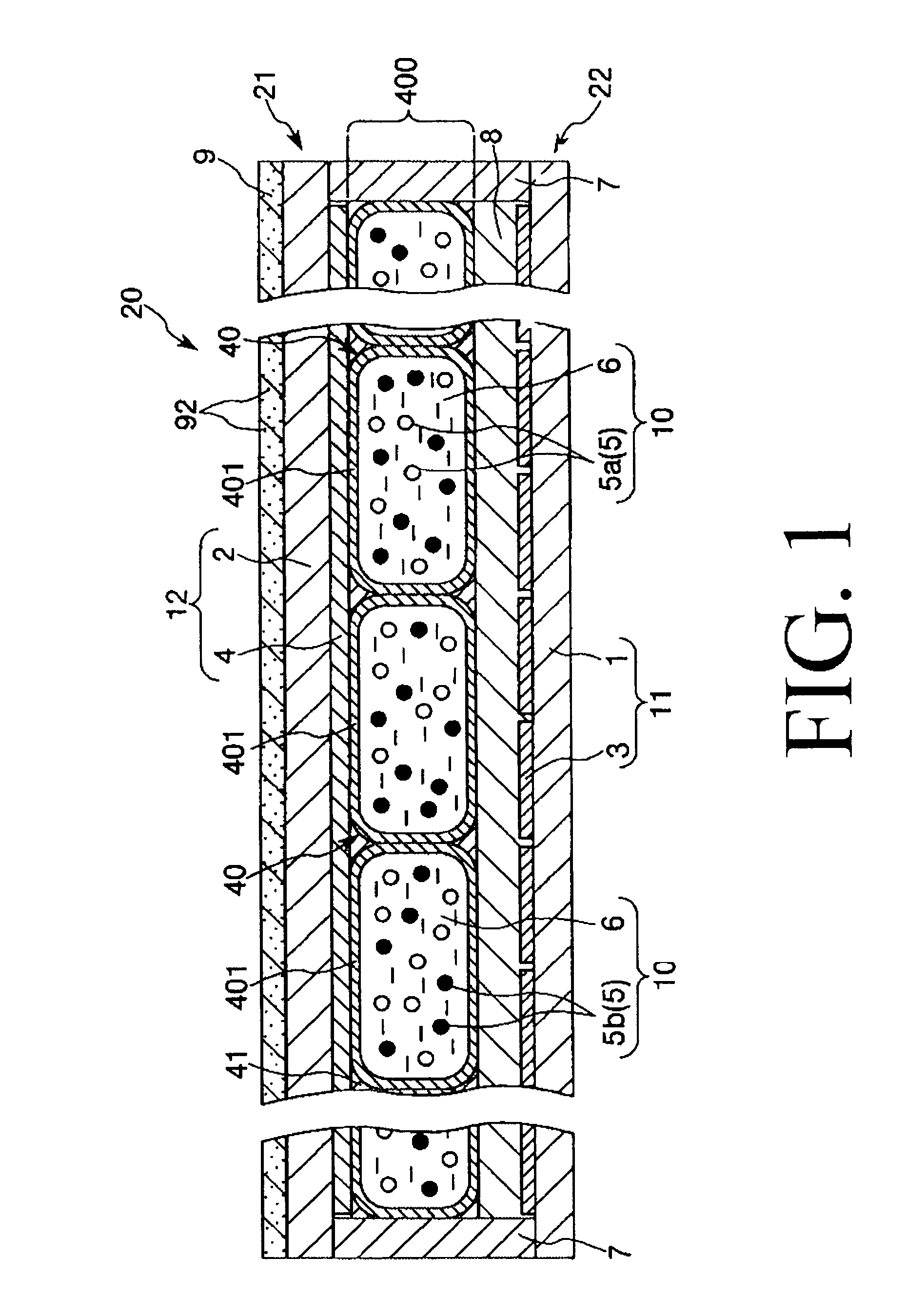

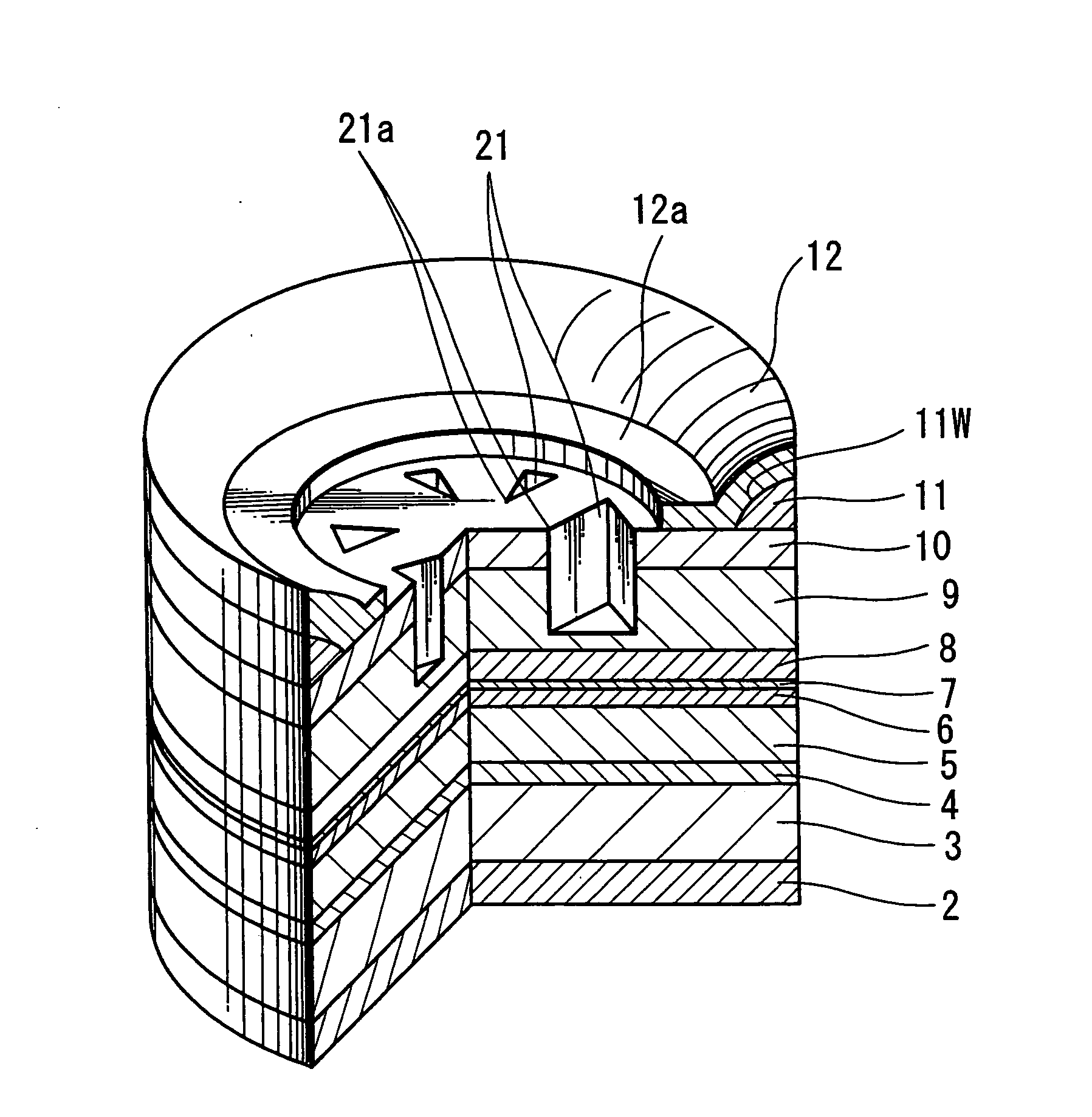

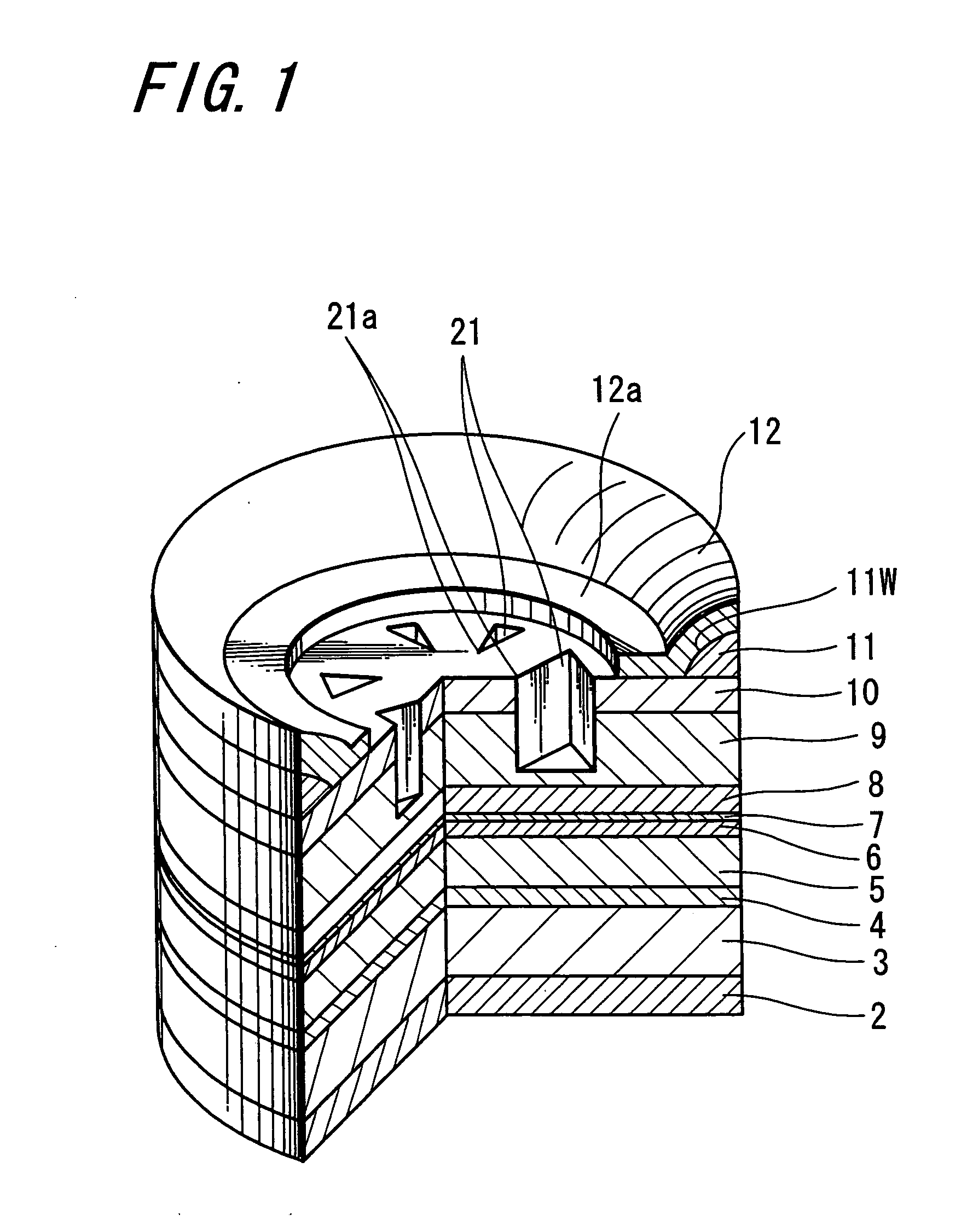

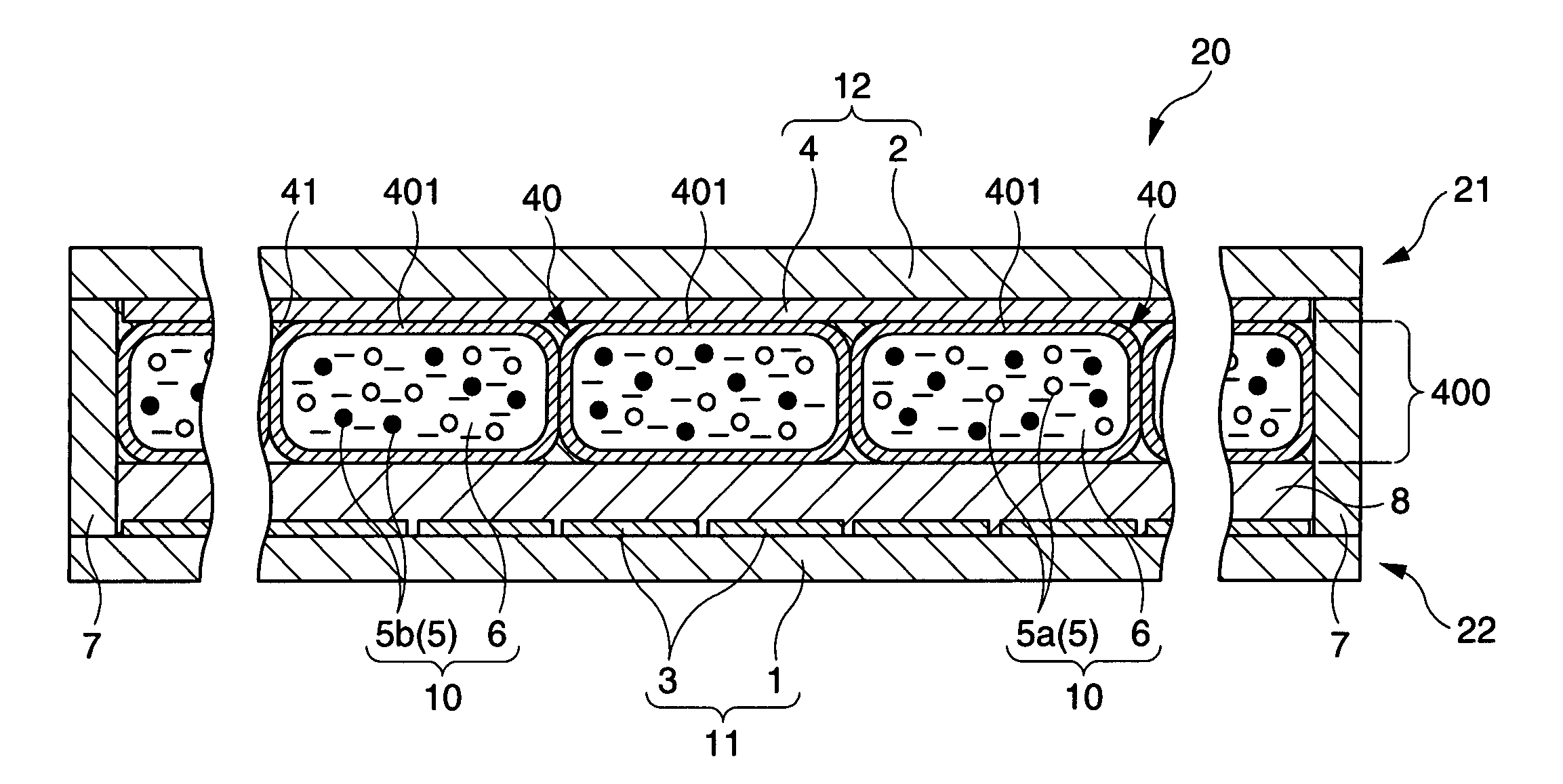

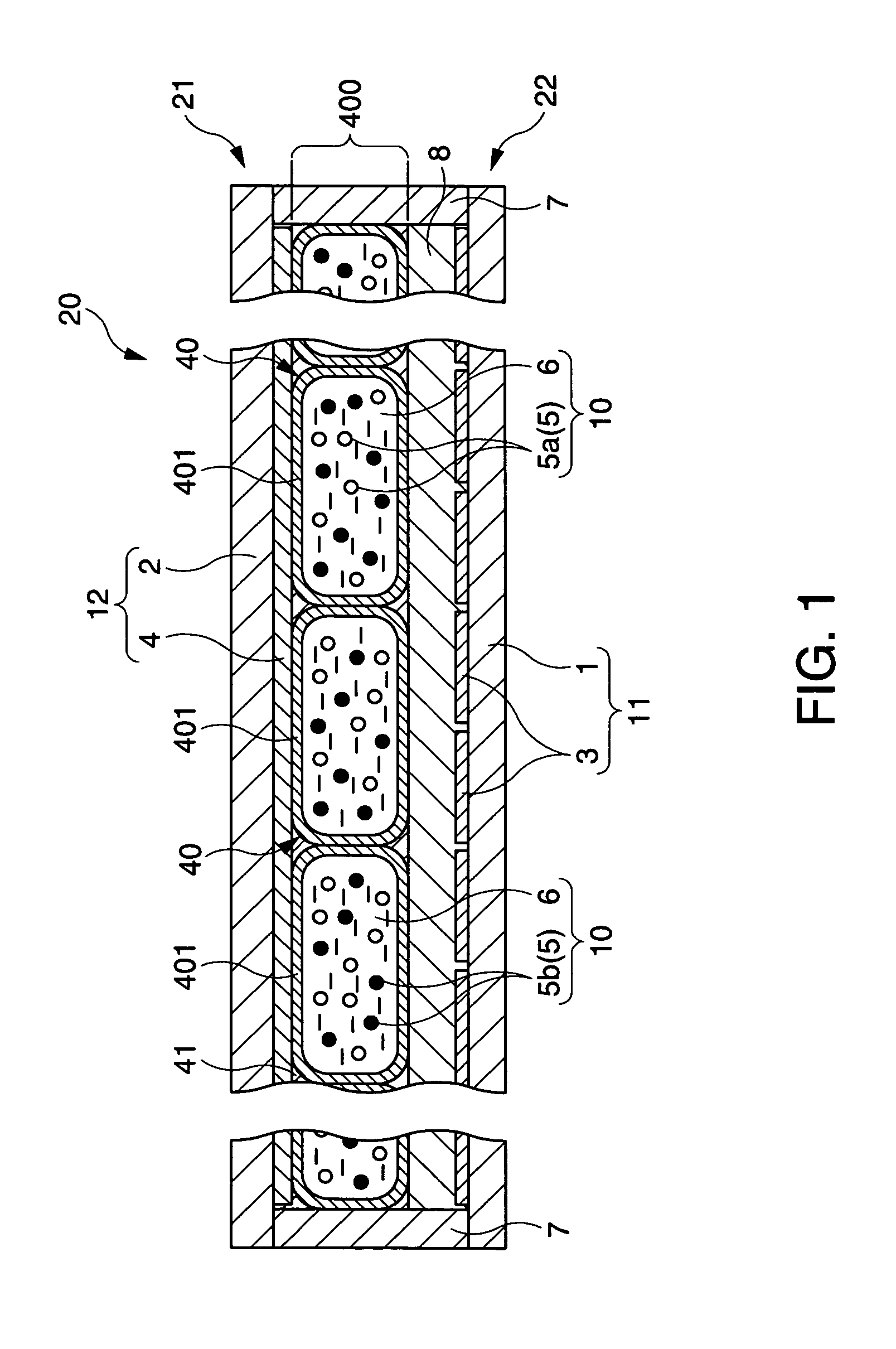

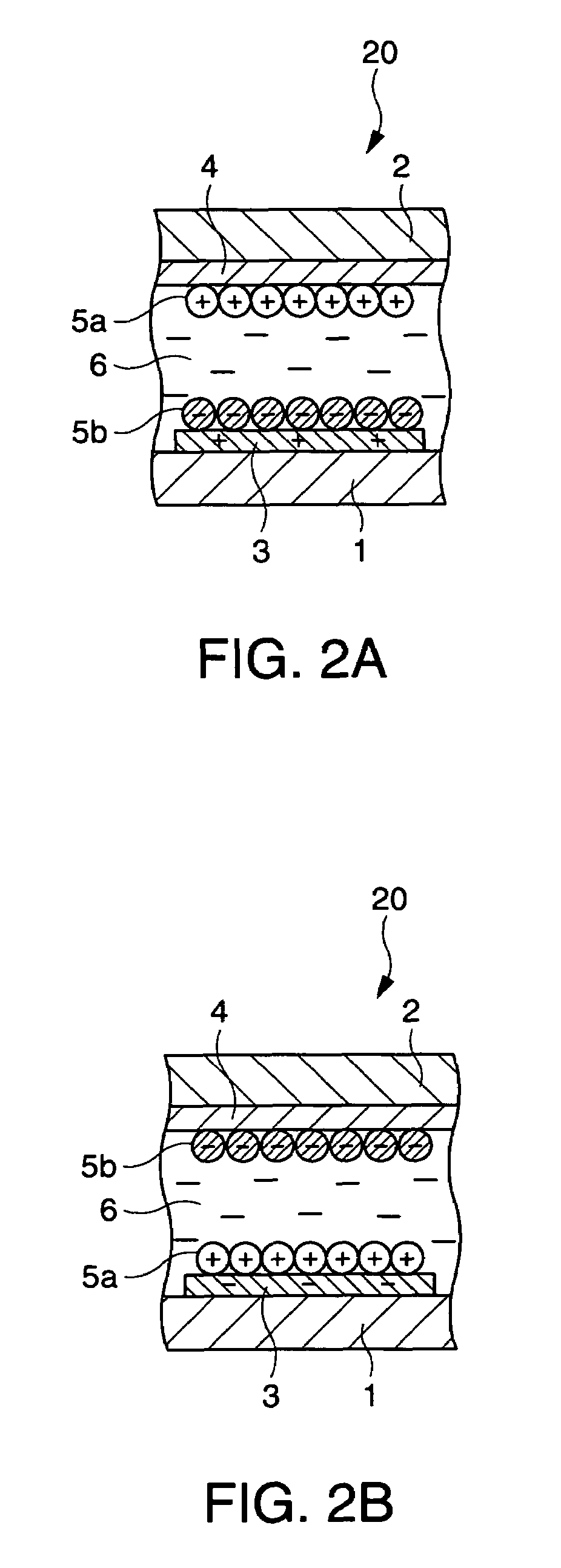

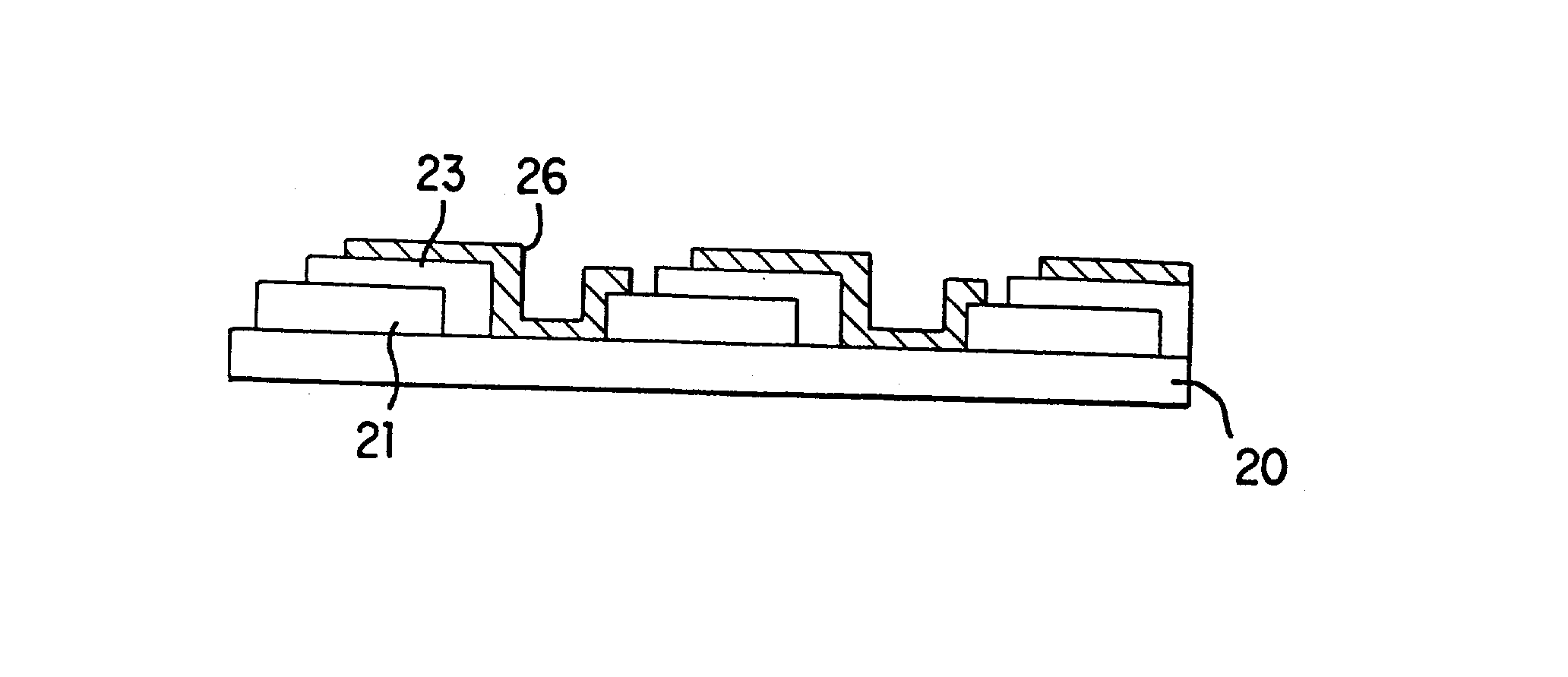

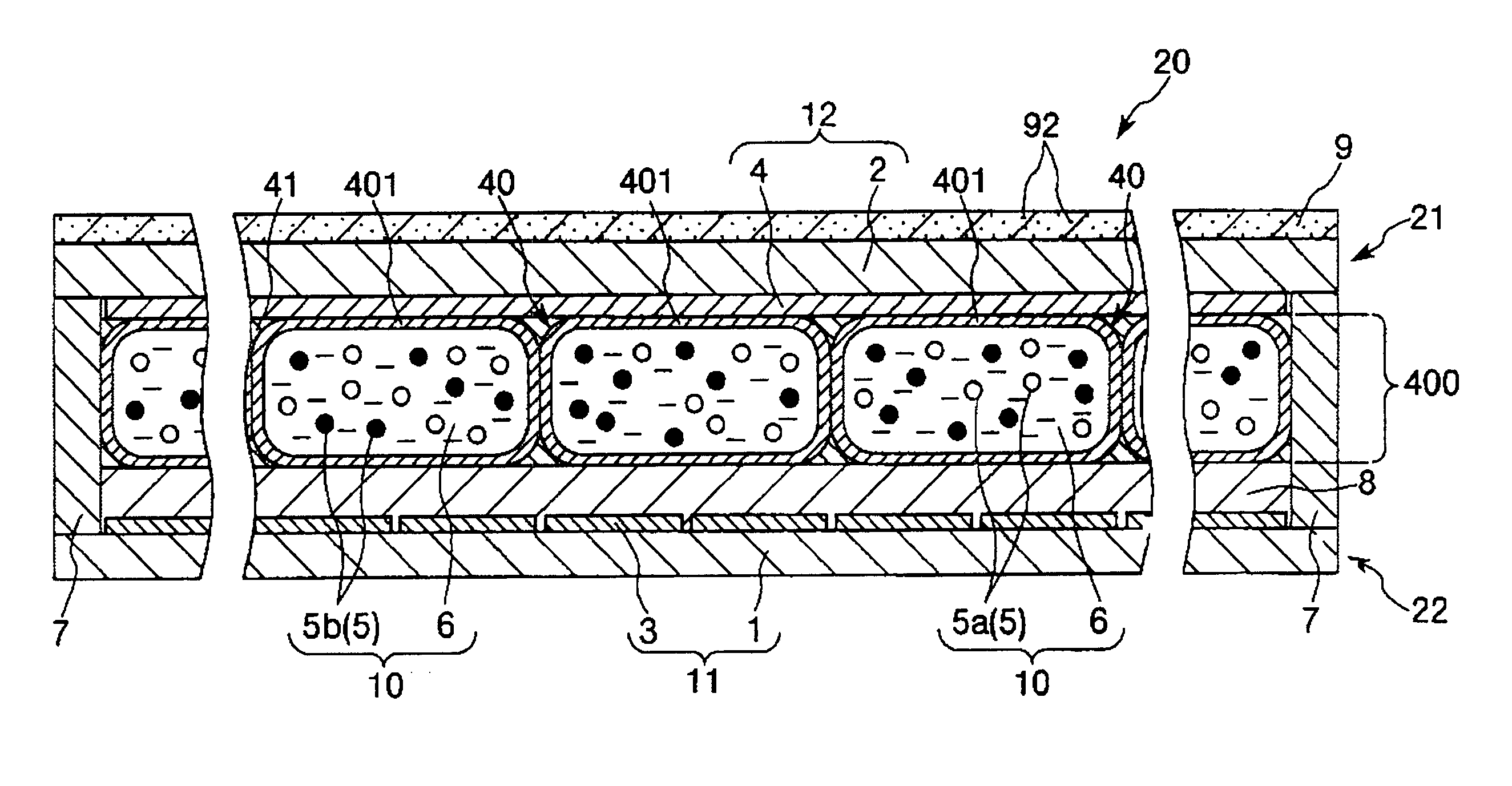

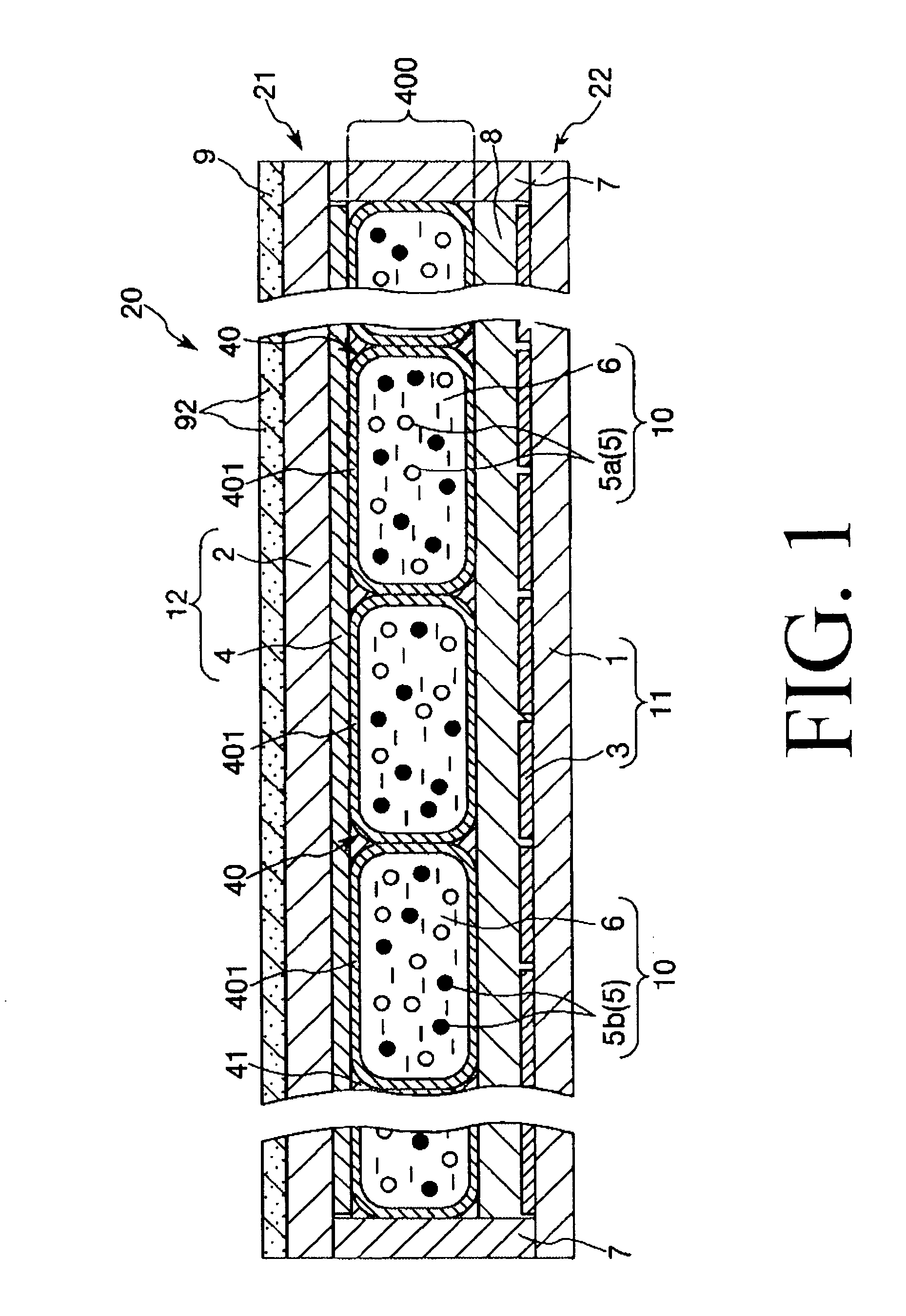

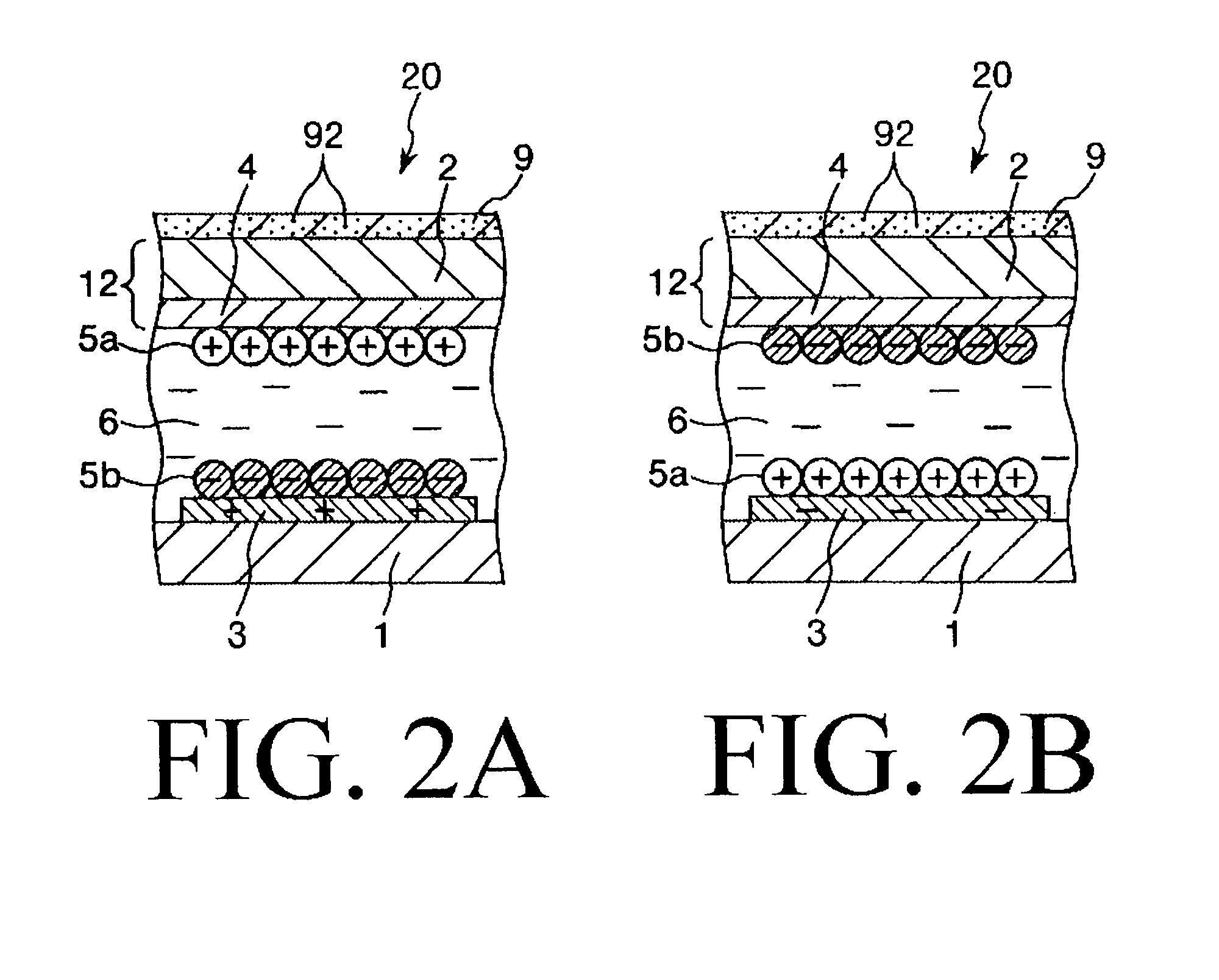

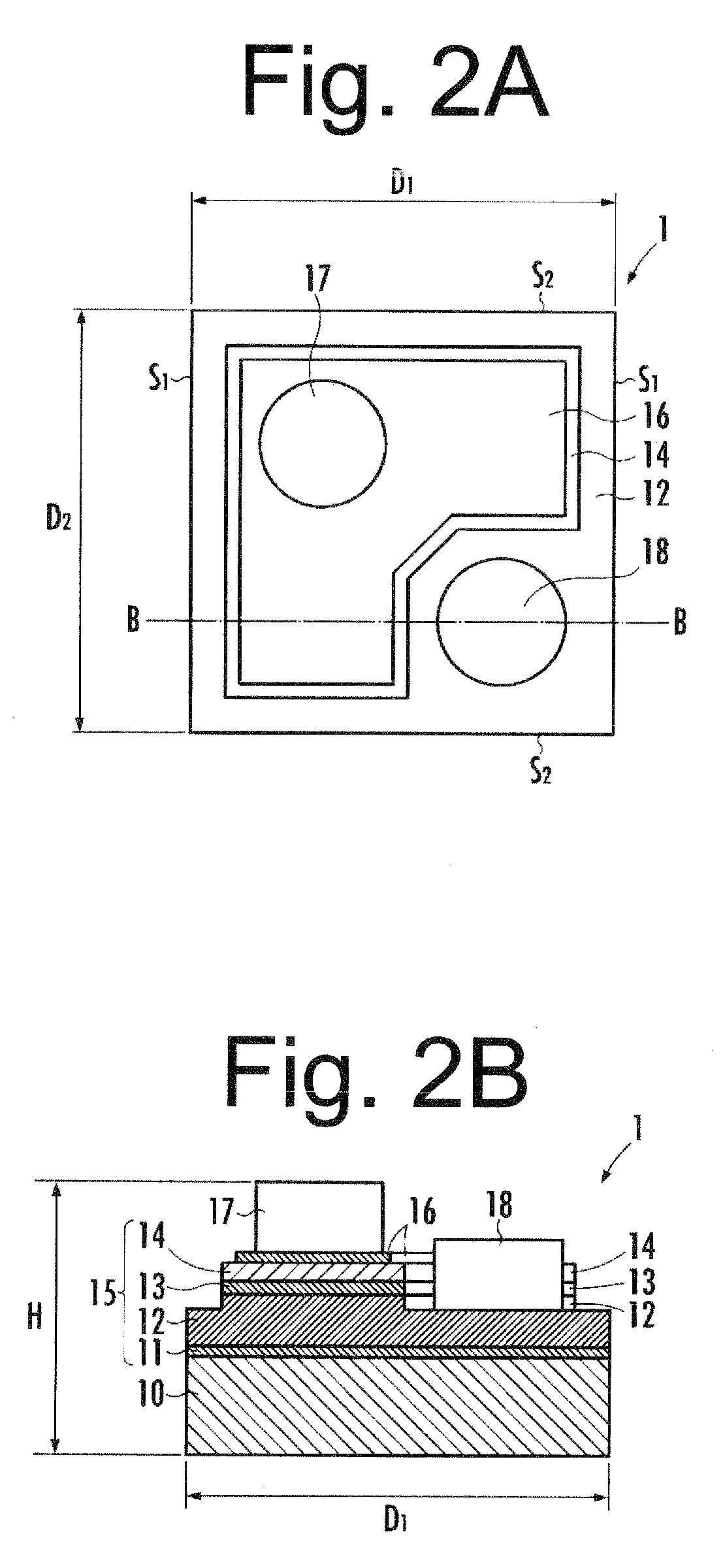

Electrophoretic sheet, electrophoresis apparatus, method for manufacturing an electrophoresis apparatus and electronic device

InactiveUS8081375B2High whitenessReliable and easy to manufacturePhotosensitive materialsStatic indicating devicesElectrophoresisBiomedical engineering

An electrophoretic sheet includes a substrate having one surface and the other surface, a microcapsule-containing layer comprised of a plurality of microcapsules, the microcapsule-containing layer provided on the other surface of the substrate, each of the plurality of microcapsules having a capsule body and an electrophoretic dispersion liquid contained in the capsule body, the electrophoretic dispersion liquid containing a plurality of electrophoretic particles of at least one color, and the capsule body having an inner circumferential surface and an outer circumferential surface, and at least one colored part provided on the external side of the inner circumferential surface of the capsule body of each of the plurality of microcapsules, and wherein each colored part has a color complementary to the color of the plurality of electrophoretic particles. By using the electrophoretic sheet mentioned above, it is possible to provide the increased whiteness in display of the electrophoretic particles. An electrophoresis apparatus provided with such an electrophoretic sheet is also provided. By using the electrophoresis apparatus, it is possible to provide a superior contrast ratio. It is also possible to obtain high reliability. A Method for manufacturing such an electrophoresis apparatus is also provided. An electronic device provided with such an electrophoresis apparatus is also provided.

Owner:E INK CORPORATION

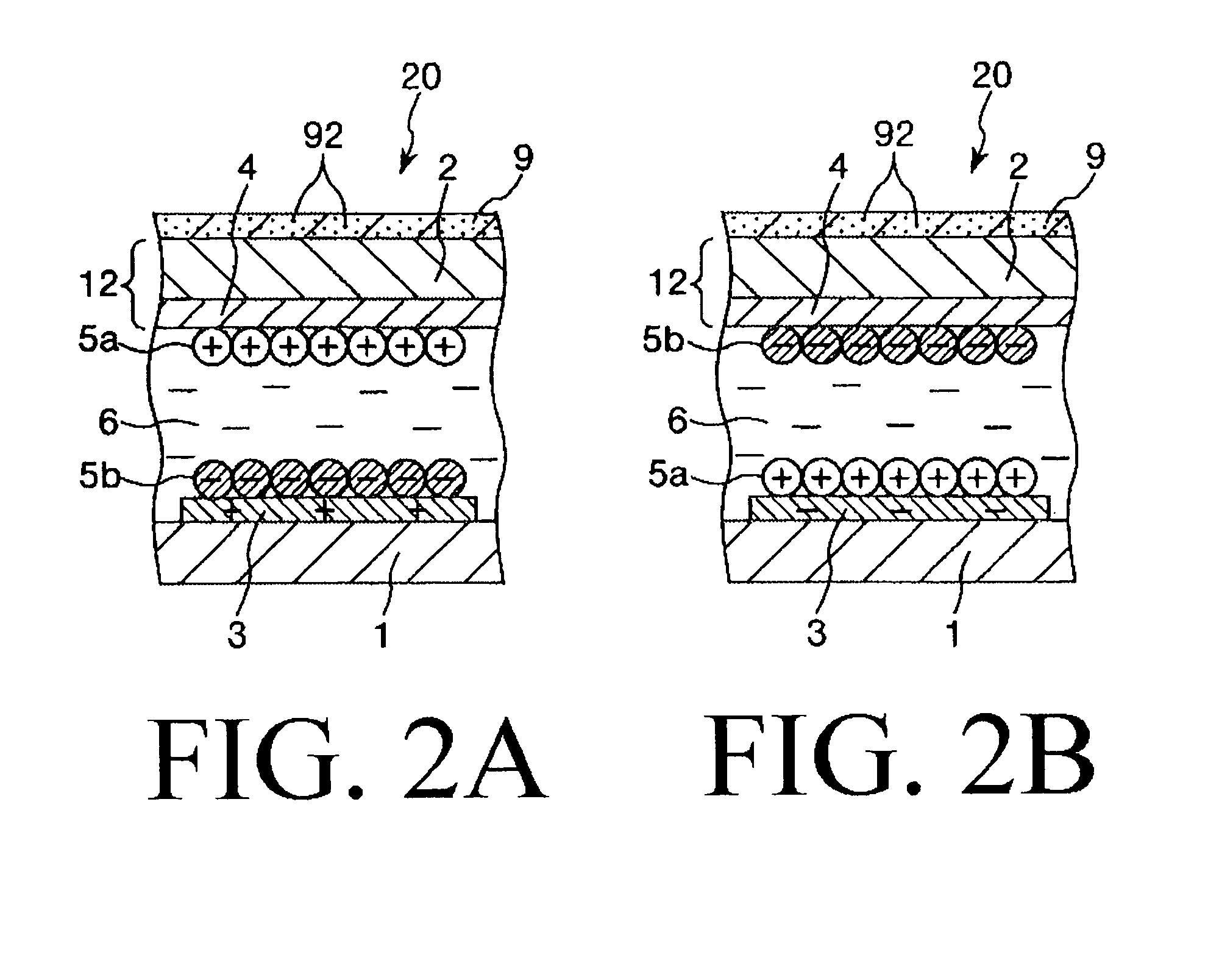

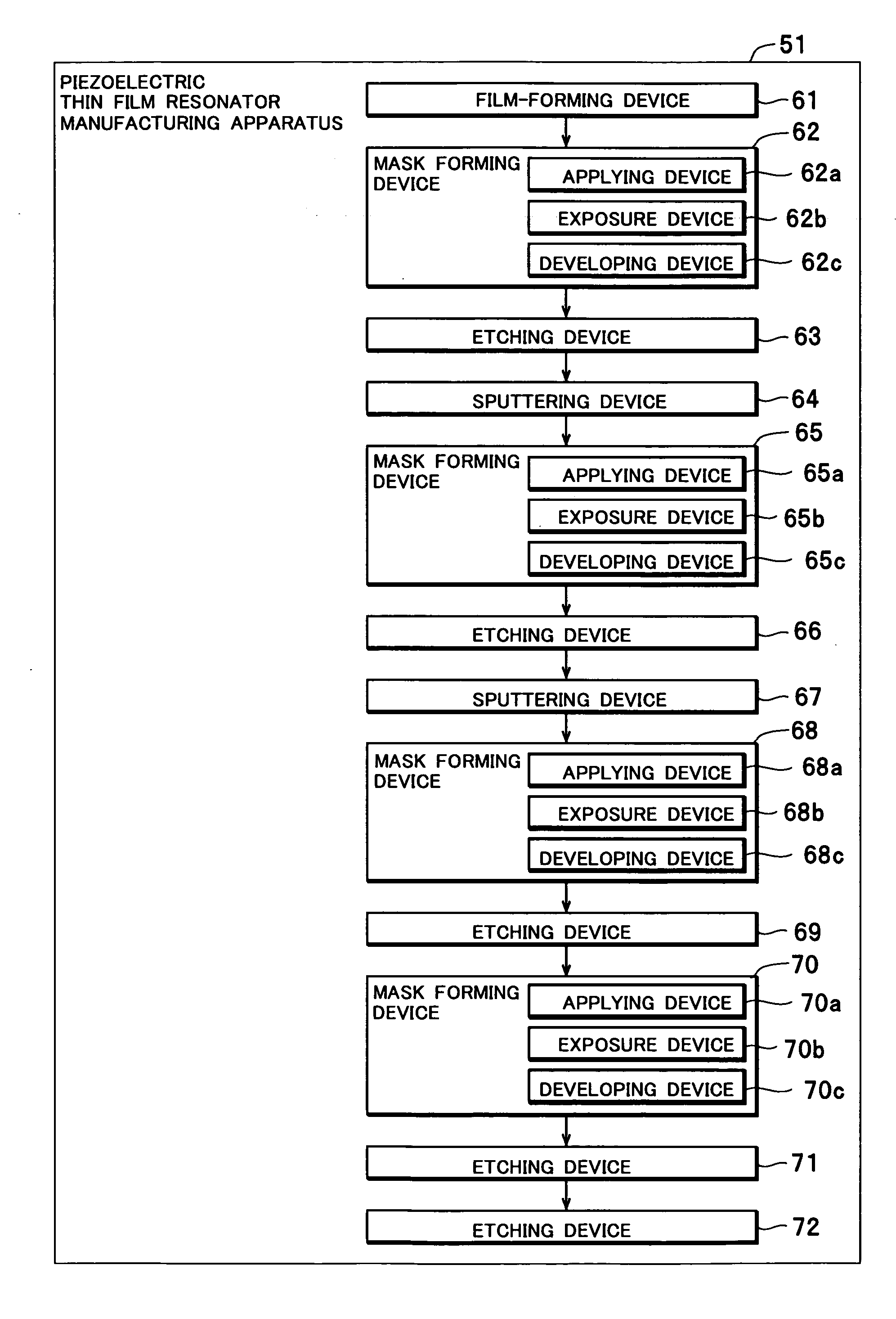

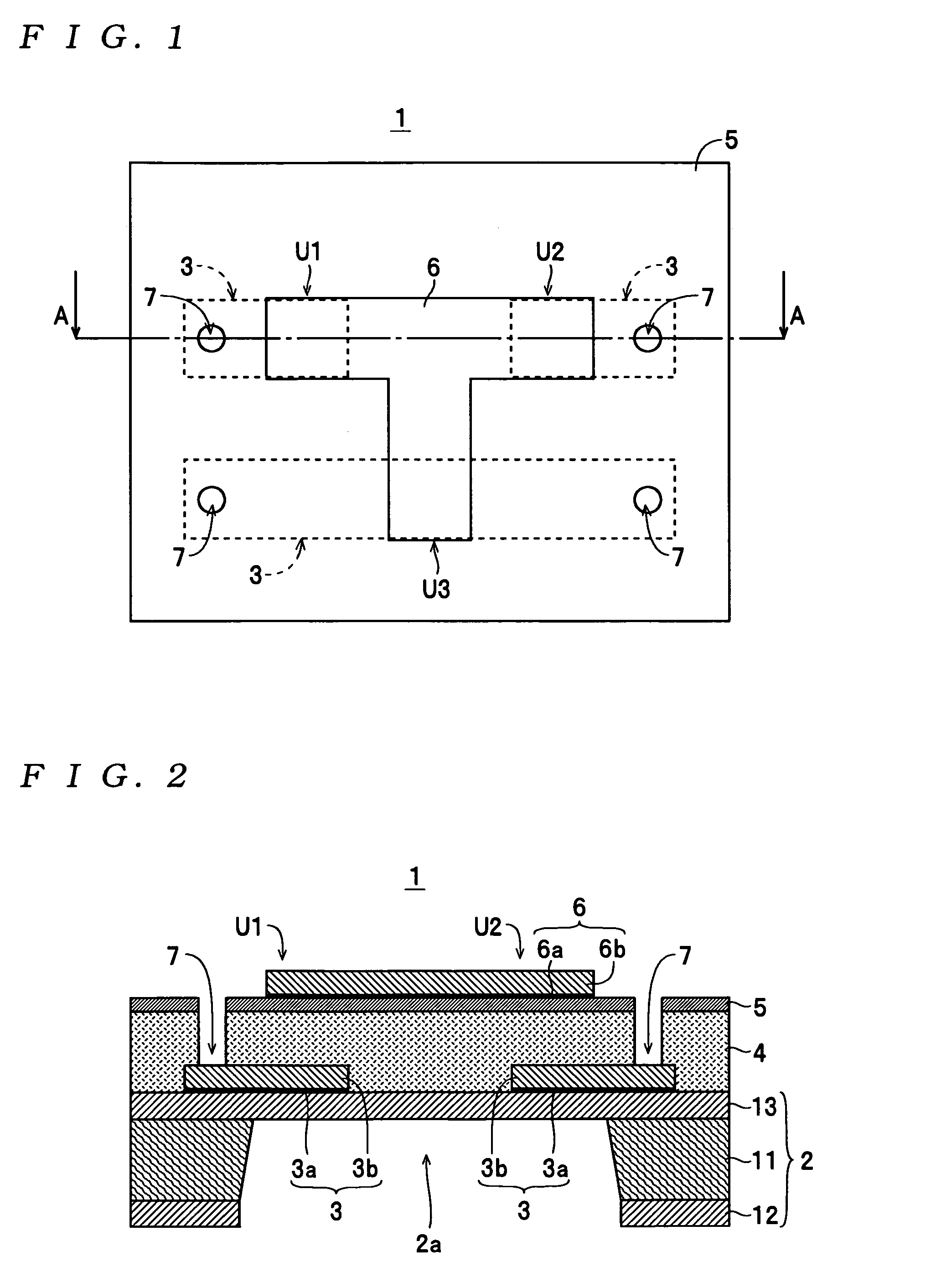

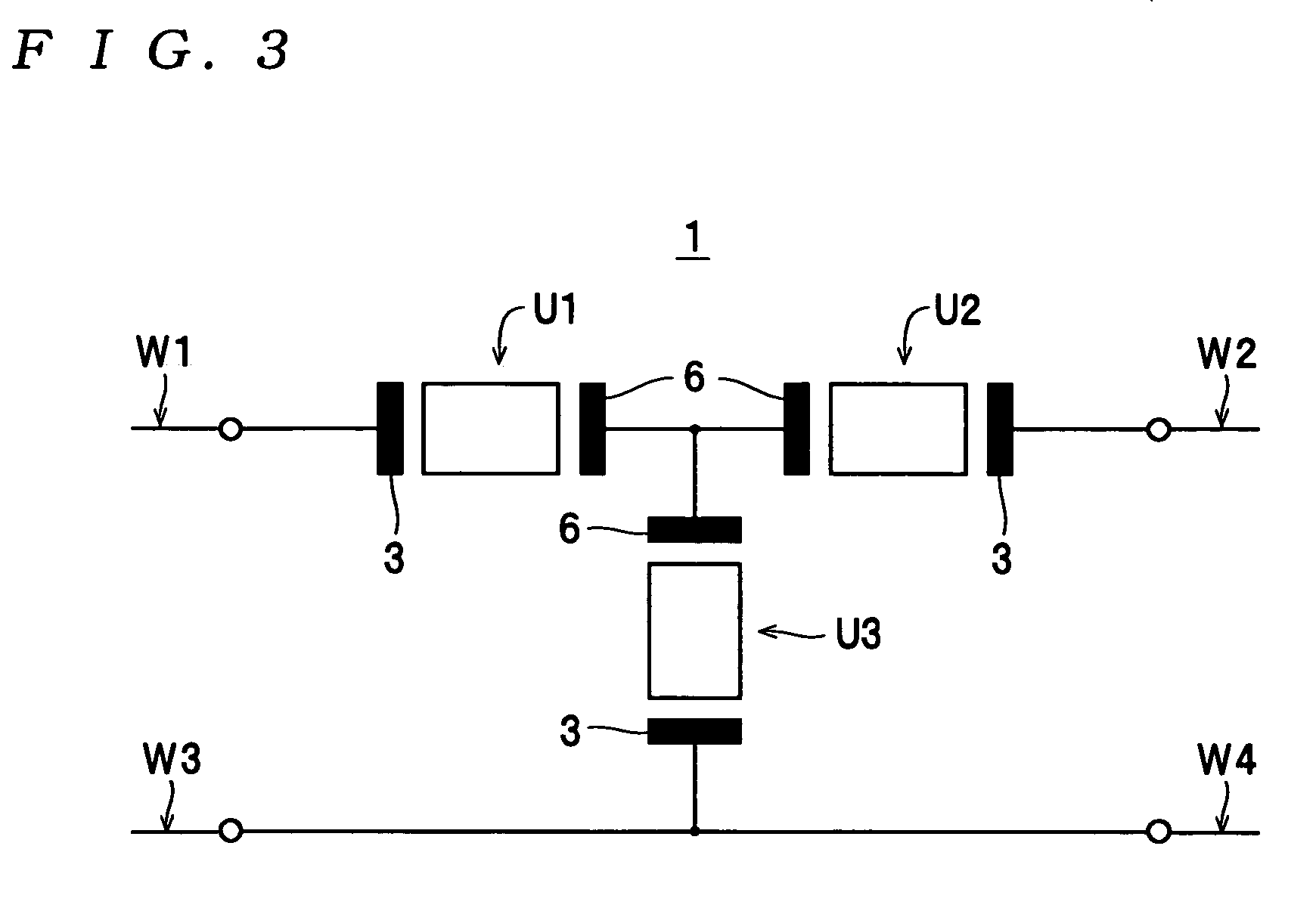

Method of manufacturing a piezoelectric thin film resonator, manufacturing apparatus for a piezoelectric thin film resonator, piezoelectric thin film resonator, and electronic component

ActiveUS7239067B2Avoid unnecessary etchingReliable and easy to manufacturePiezoelectric/electrostriction/magnetostriction machinesImpedence networksElectronic componentPiezoelectric thin films

A method of manufacturing a piezoelectric thin film resonator forms, after forming a piezoelectric film on a substrate so as to cover a lower electrode formed on the substrate, an electrode material layer for forming an upper electrode above the piezoelectric film, forms a mask of a predetermined form on the electrode material layer, and then etches the electrode material layer to form the upper electrode. Before a step of forming the electrode material layer, a protective layer for protecting the piezoelectric film during etching of the electrode material layer is formed so as to cover at least a part of the piezoelectric film where the upper electrode is not formed, and the electrode material layer is then formed so as to cover the protective layer.

Owner:SNAPTRACK

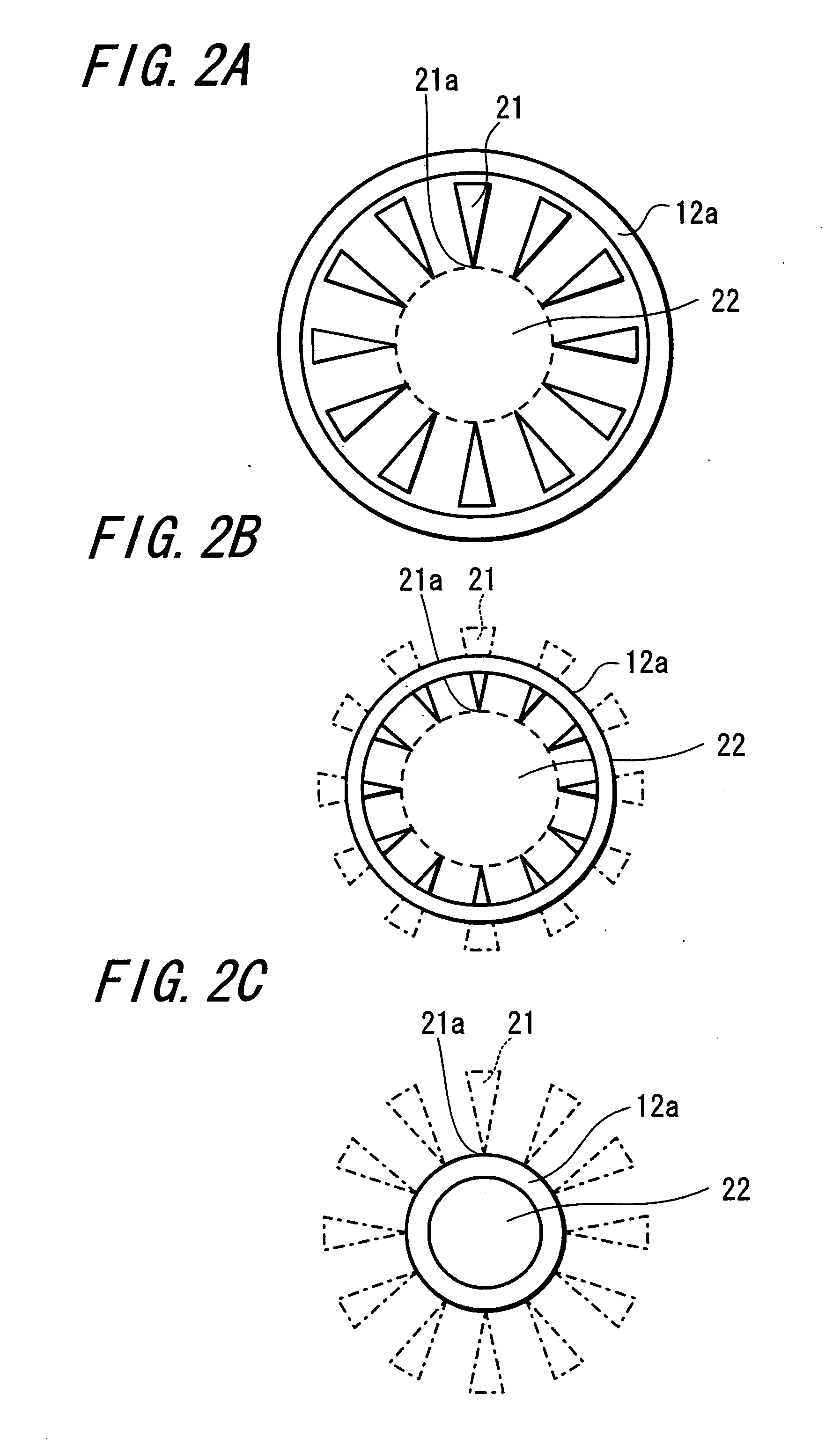

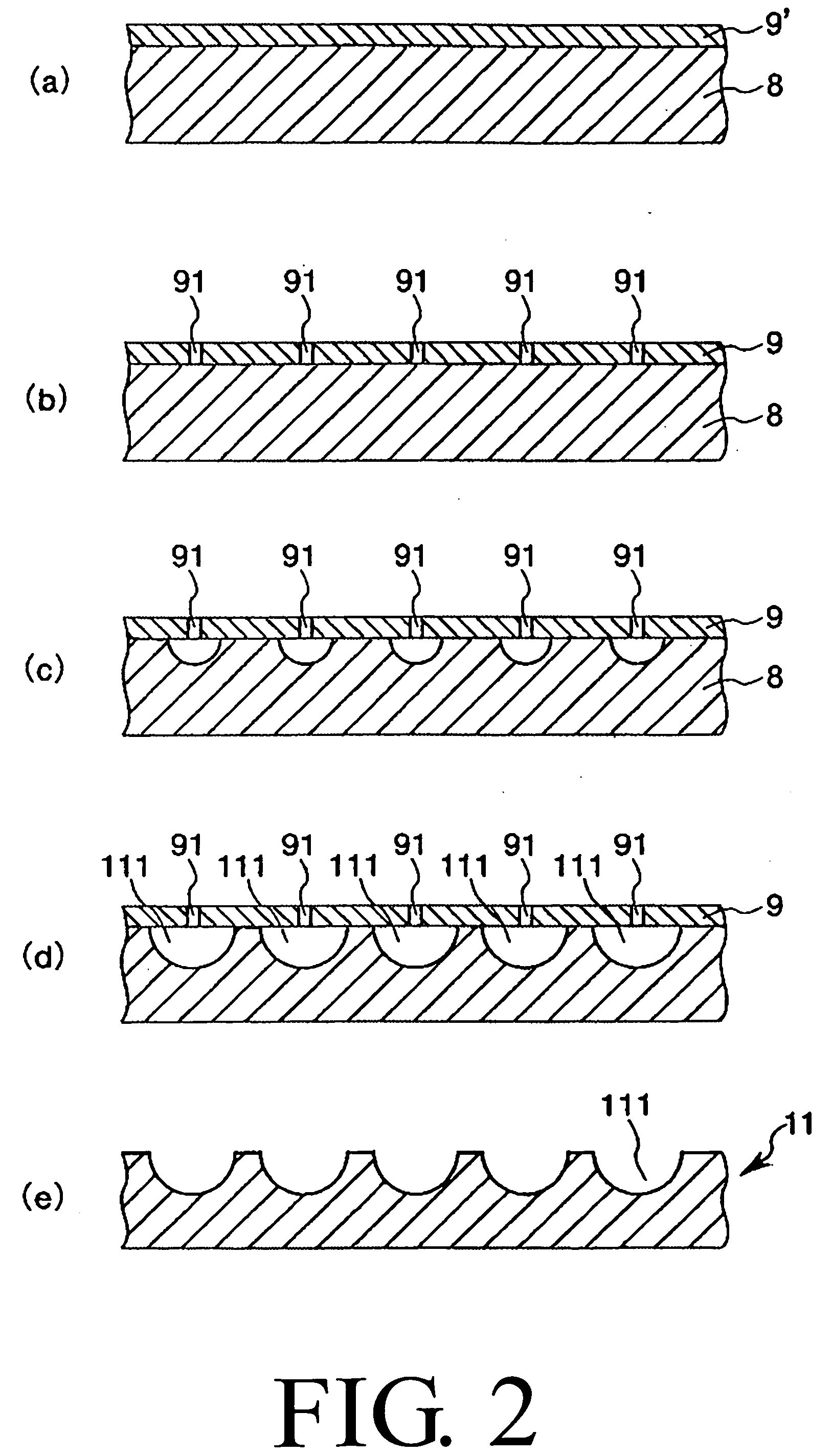

Surface-emitting semiconductor laser and method for manufacturing thereof as well as optical device

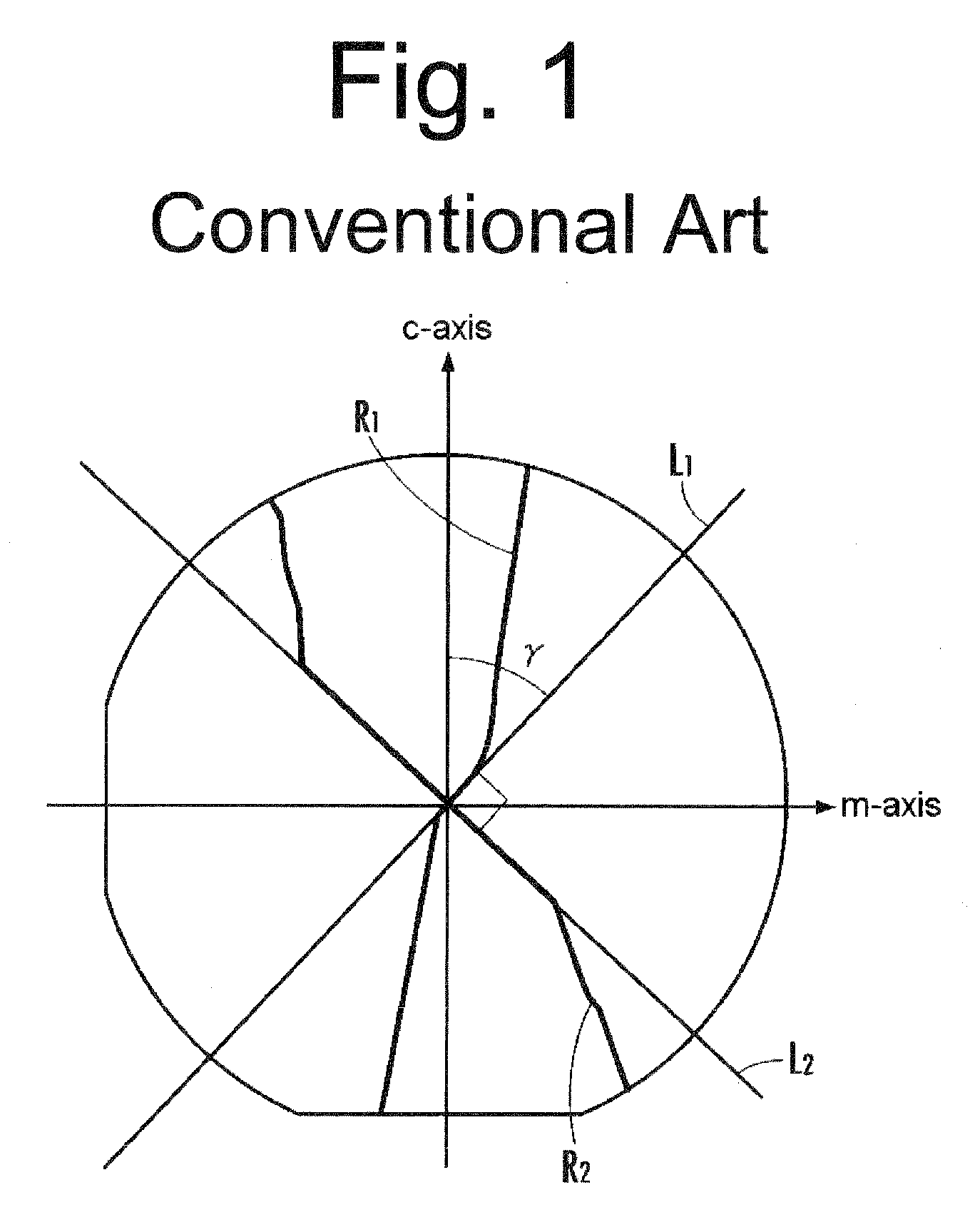

ActiveUS20050089075A1Improvement in singularityLower the thresholdLaser optical resonator constructionOptical resonator shape and constructionSingle mode laserAcute angle

A surface-emitting semiconductor laser (VCSEL) having a structure in which the single horizontal mode of high power is stably maintained, and an optical device including a light-source device having this surface-emitting semiconductor laser are provided. A scattering-loss-structure portion composed of a low refractive-index region is disposed around a main current path in a surface-emitting semiconductor laser, namely around a cavity structure portion; the low refractive-index region is disposed at intervals; and the shape of the tip portion opposing to the center portion is set to be a tapered shape, for example, at an acute angle. Accordingly, in the cavity structure portion, the loss of light-emitting laser of a high-order mode localized in the outer circumferential portion becomes large, so that a surface-emitting semiconductor laser that oscillates the single-mode laser with favorable performance is constructed.

Owner:SONY CORP +1

Electrophoretic sheet, electrophoretic device, method for manufacturing electrophoretic device, and electronic apparatus

ActiveUS7365900B2Improve the display effectReliable and easy to manufactureStatic indicating devicesLayered productsElectrophoresisEngineering

Owner:E INK CORPORATION

Method for forming crystalline semiconductor layers, a method for fabricating thin film transistors, and a method for fabricating solar cells and active matrix liquid crystal devices

InactiveUS20020146868A1Great fabricationImprove mobilityTransistorFinal product manufactureActive matrixSolar cell

A crystalline semiconductor layer can be formed by forming a semiconductor film on an inexpensive conventional substrate. Next, perform a first annealing process in which nearly the entire surface of the semiconductor film is exposed to laser irradiation or other forms of irradiation, and then perform a second annealing process consisting of rapid thermal annealing. This enables the formation of a high quality crystalline semiconductor film with high throughput but without subjecting the substrate to undue thermal stress. When this invention is applied to thin film transistors, good transistors having high performance are easily fabricated. When this invention is applied to solar cells, energy conversion efficiency is increased.

Owner:SEIKO EPSON CORP

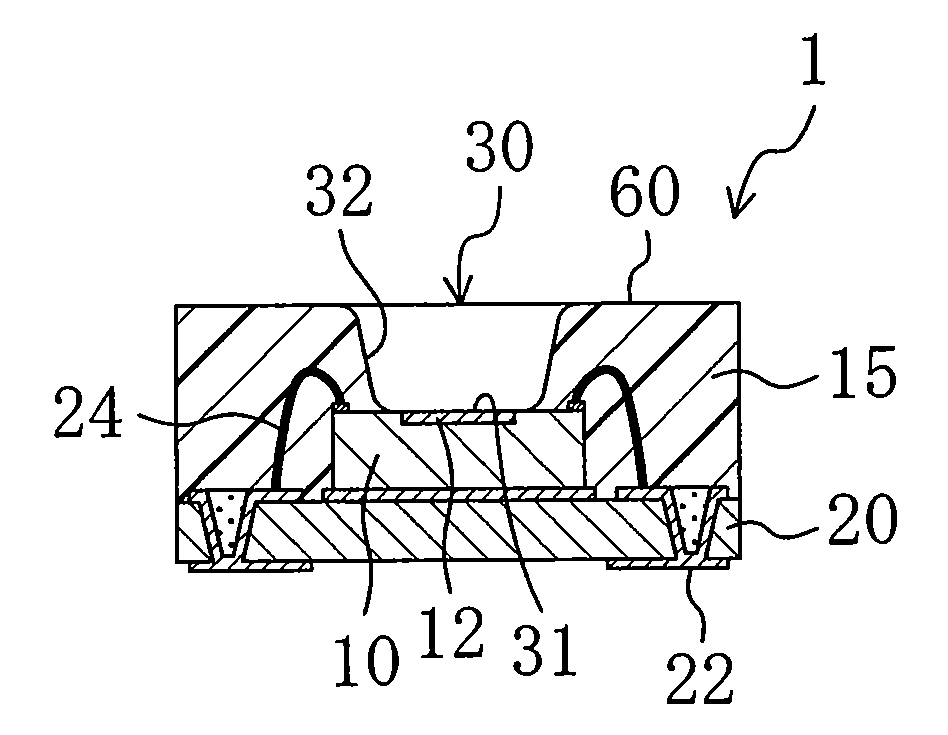

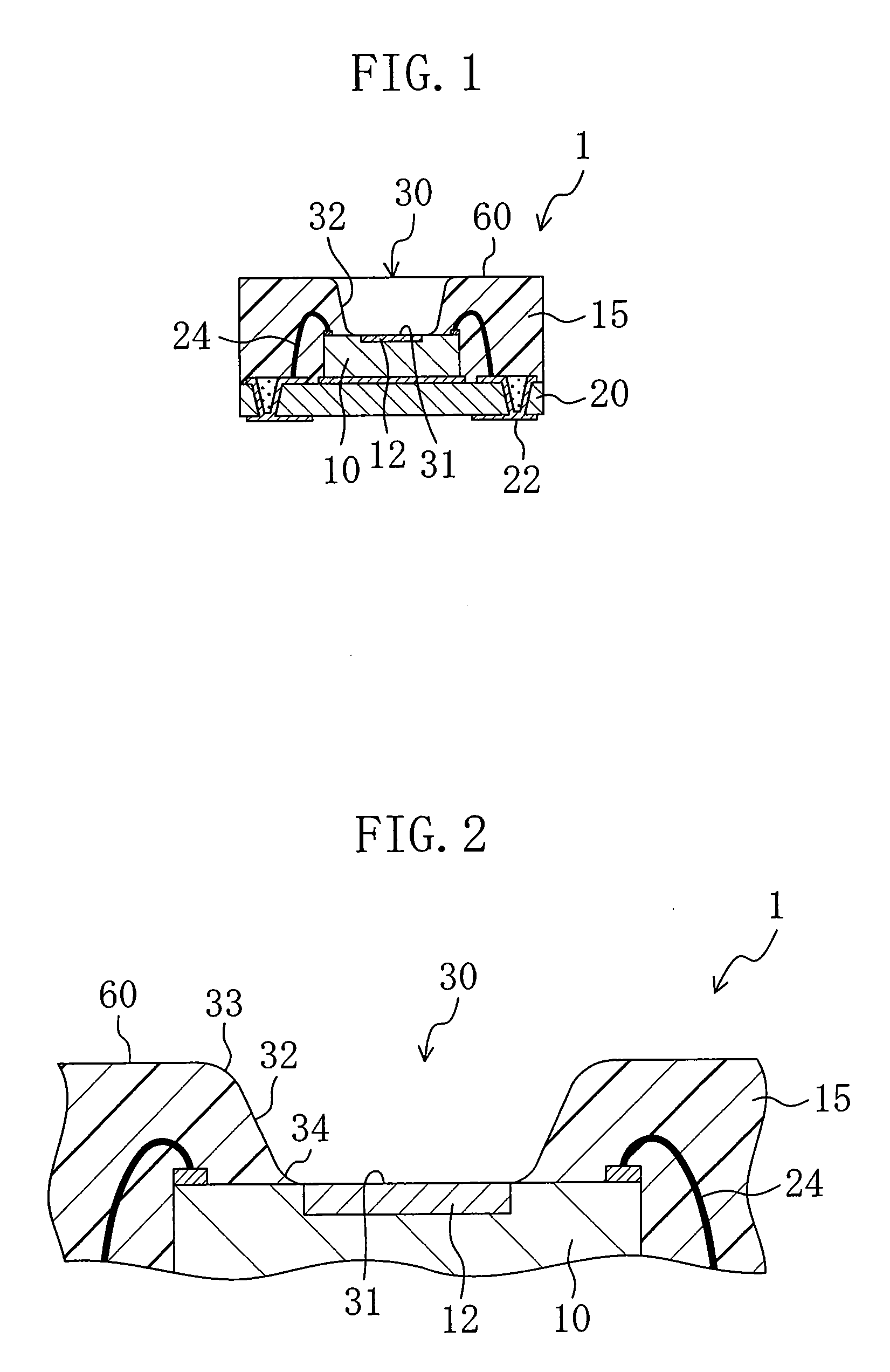

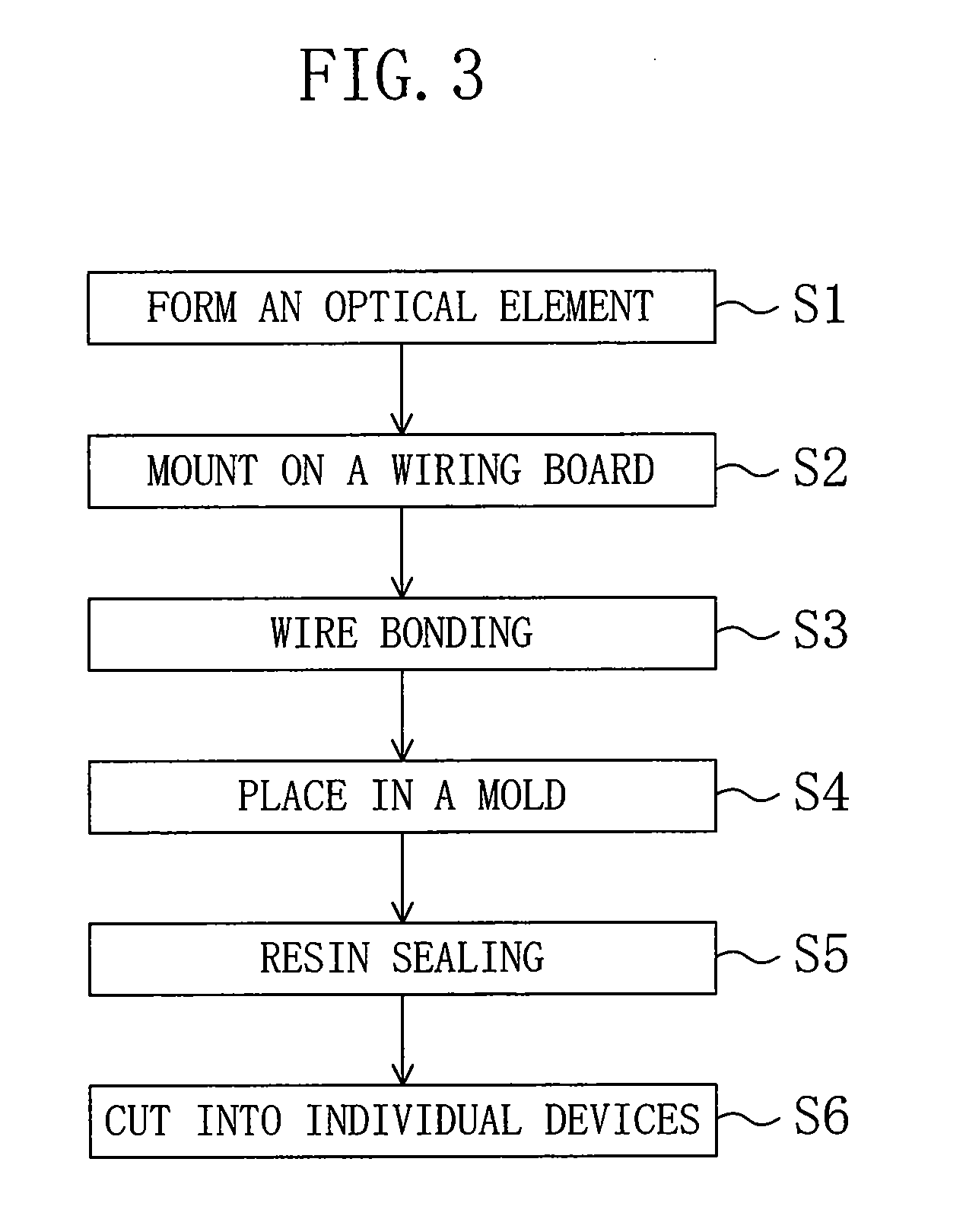

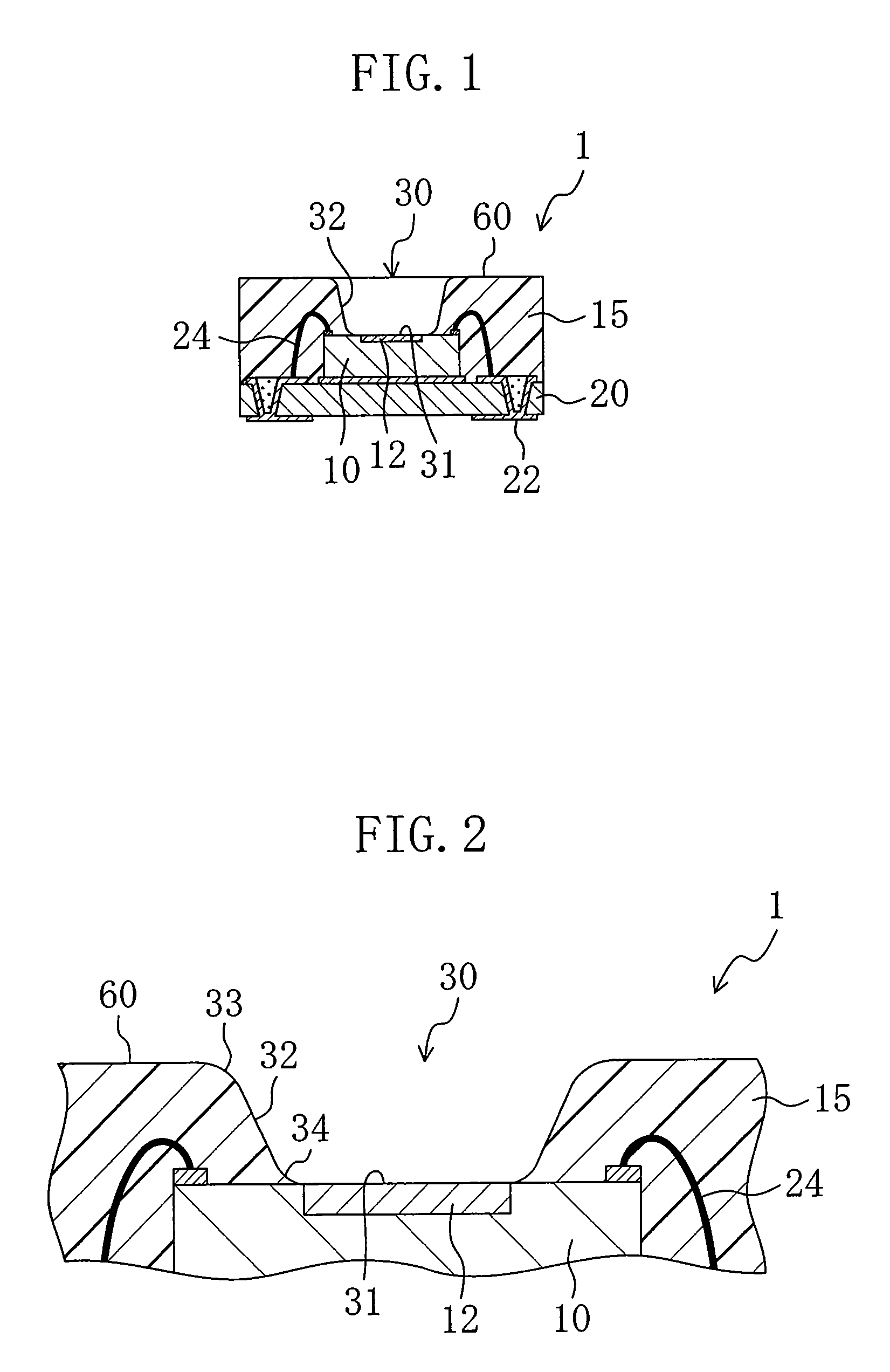

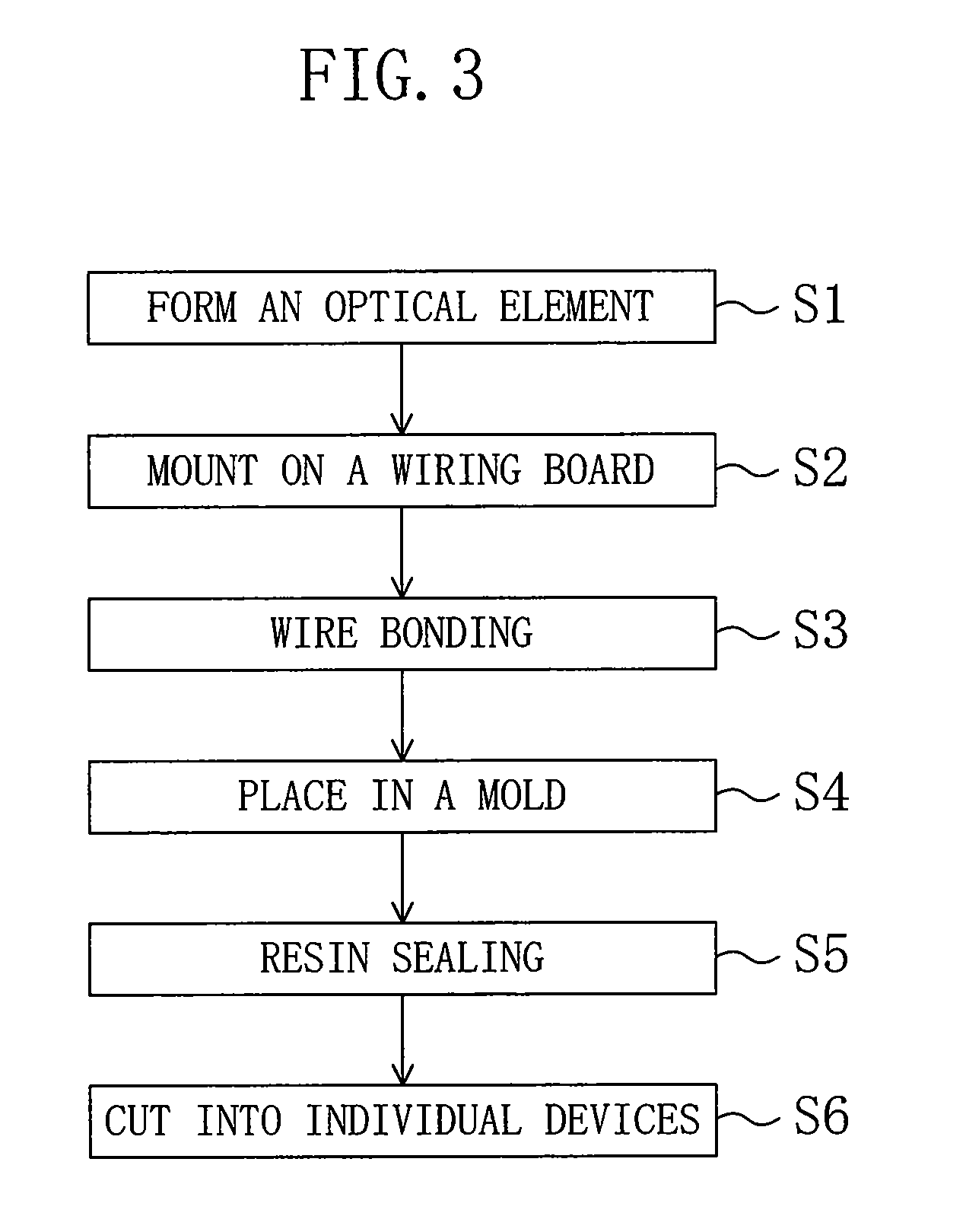

Optical device and manufacturing method thereof

ActiveUS20090097139A1Reliable and easy to manufactureSolid-state devicesOptical articlesEngineeringMechanical engineering

Owner:PANNOVA SEMIC

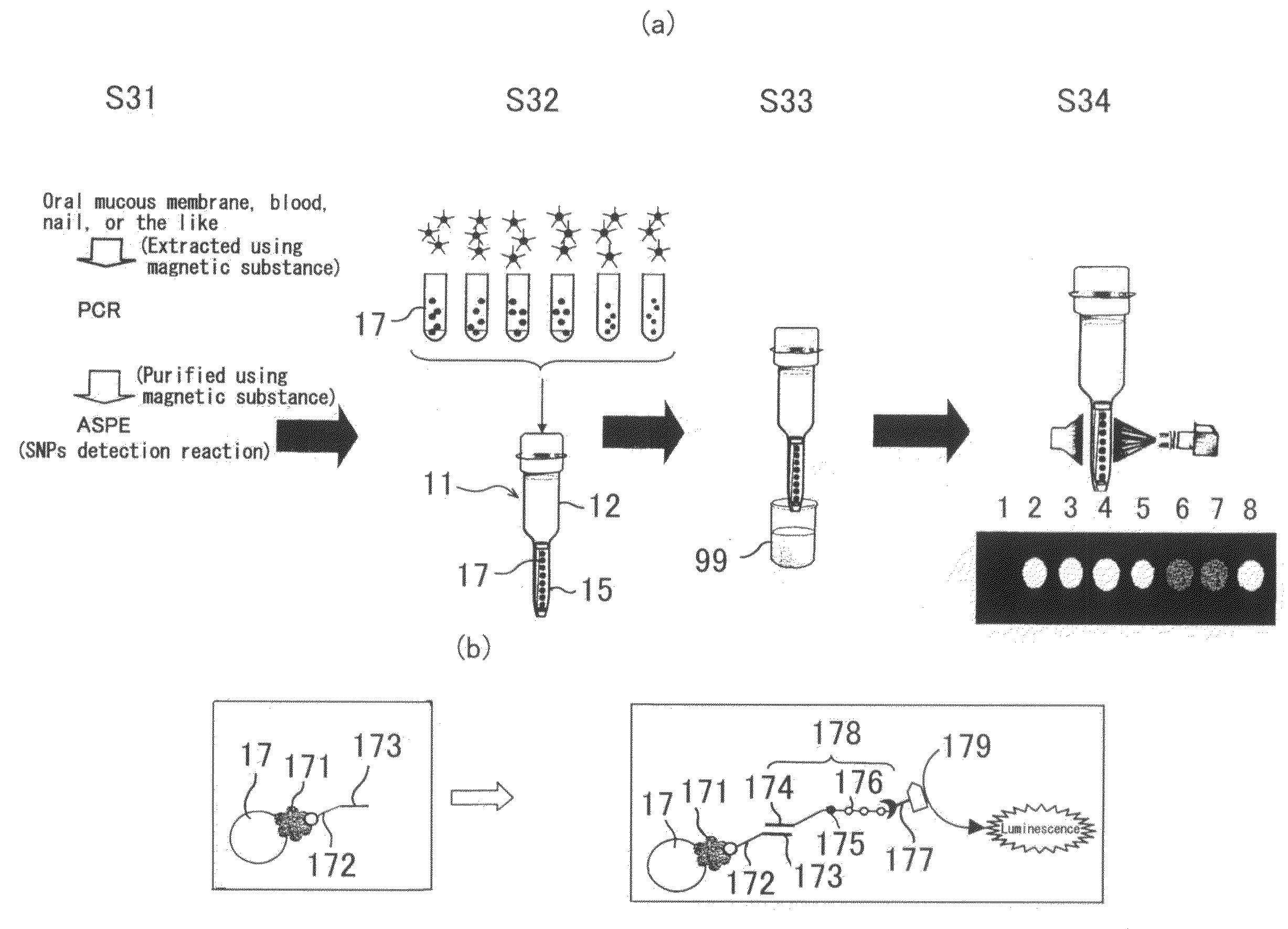

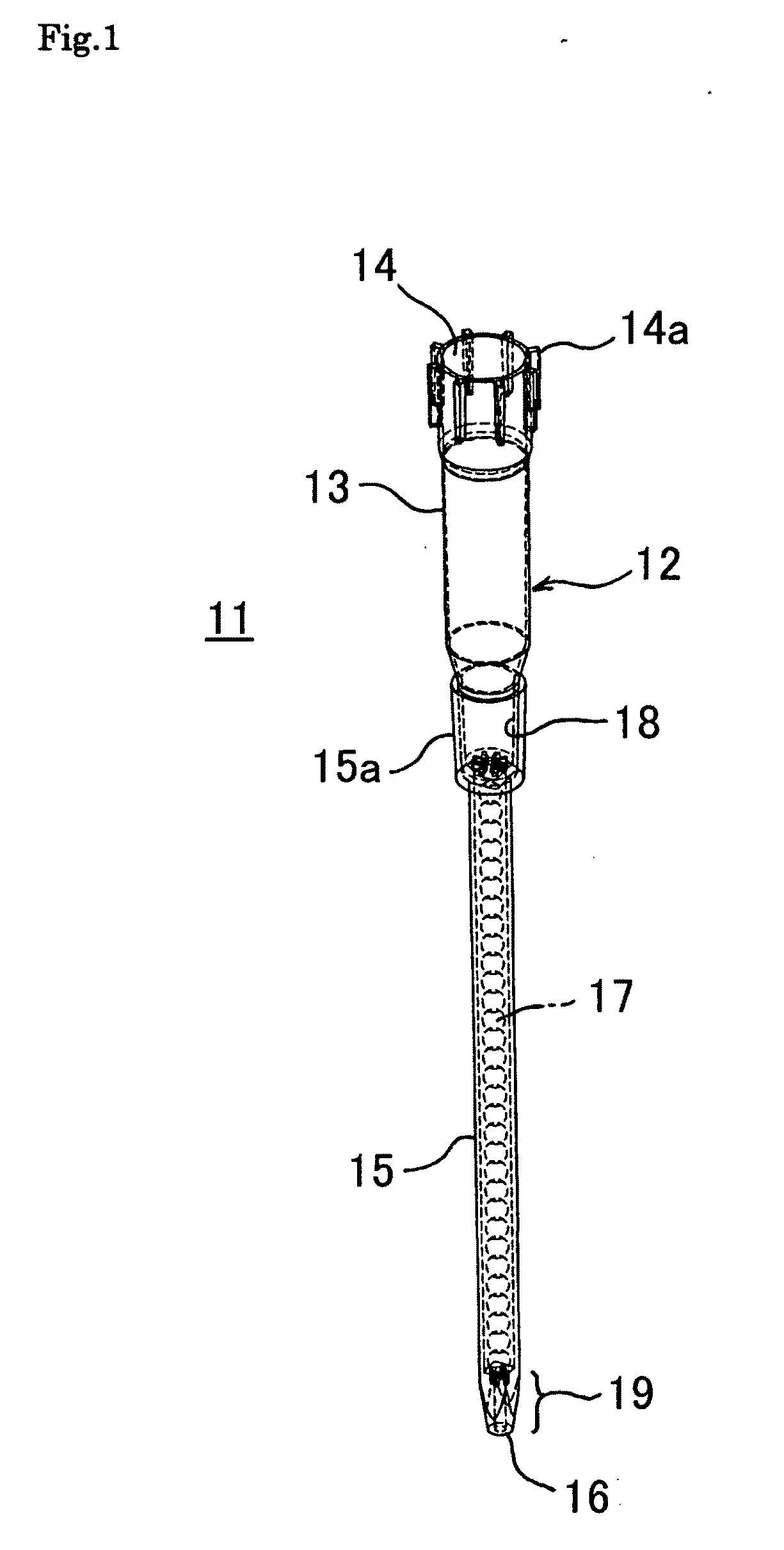

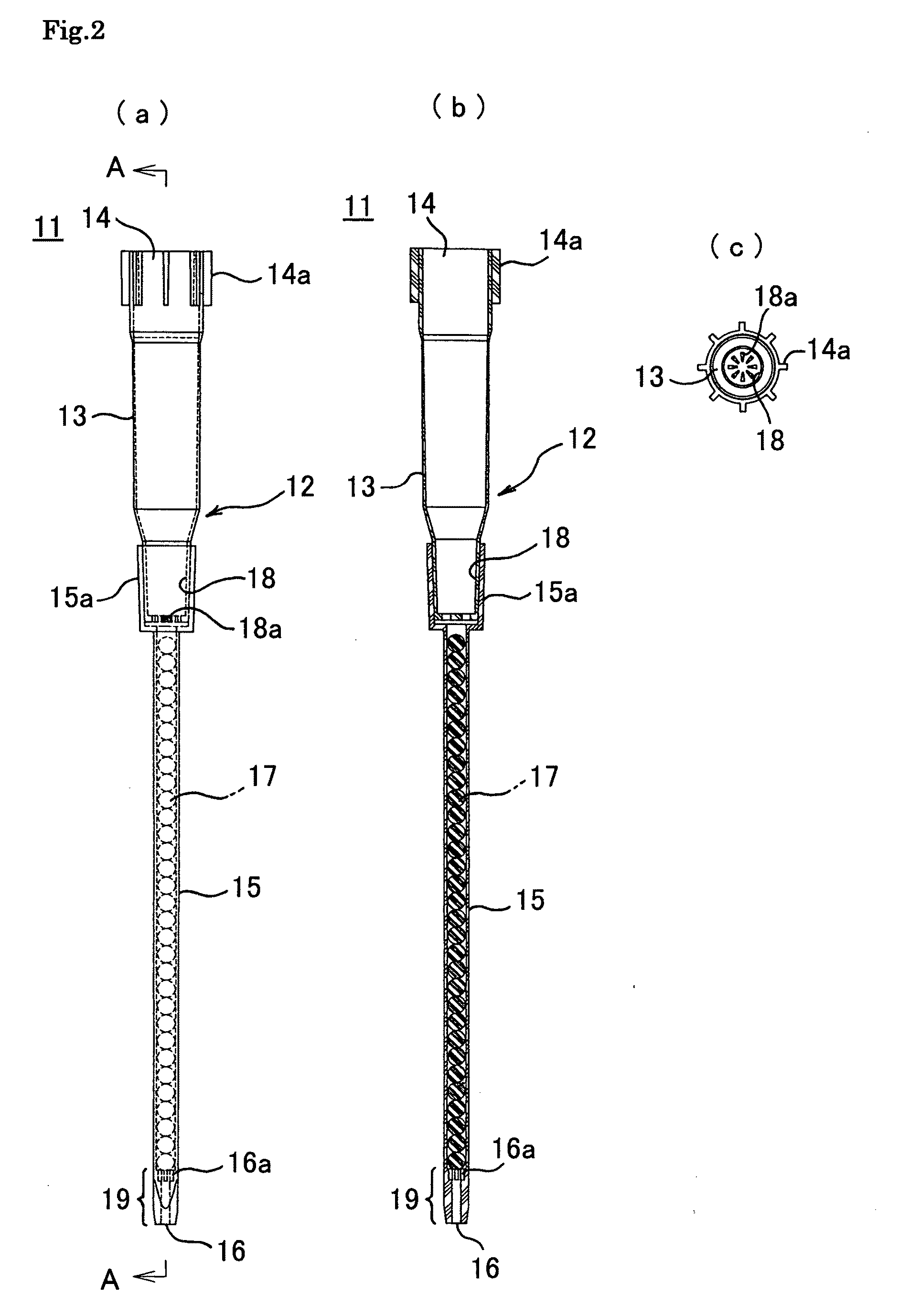

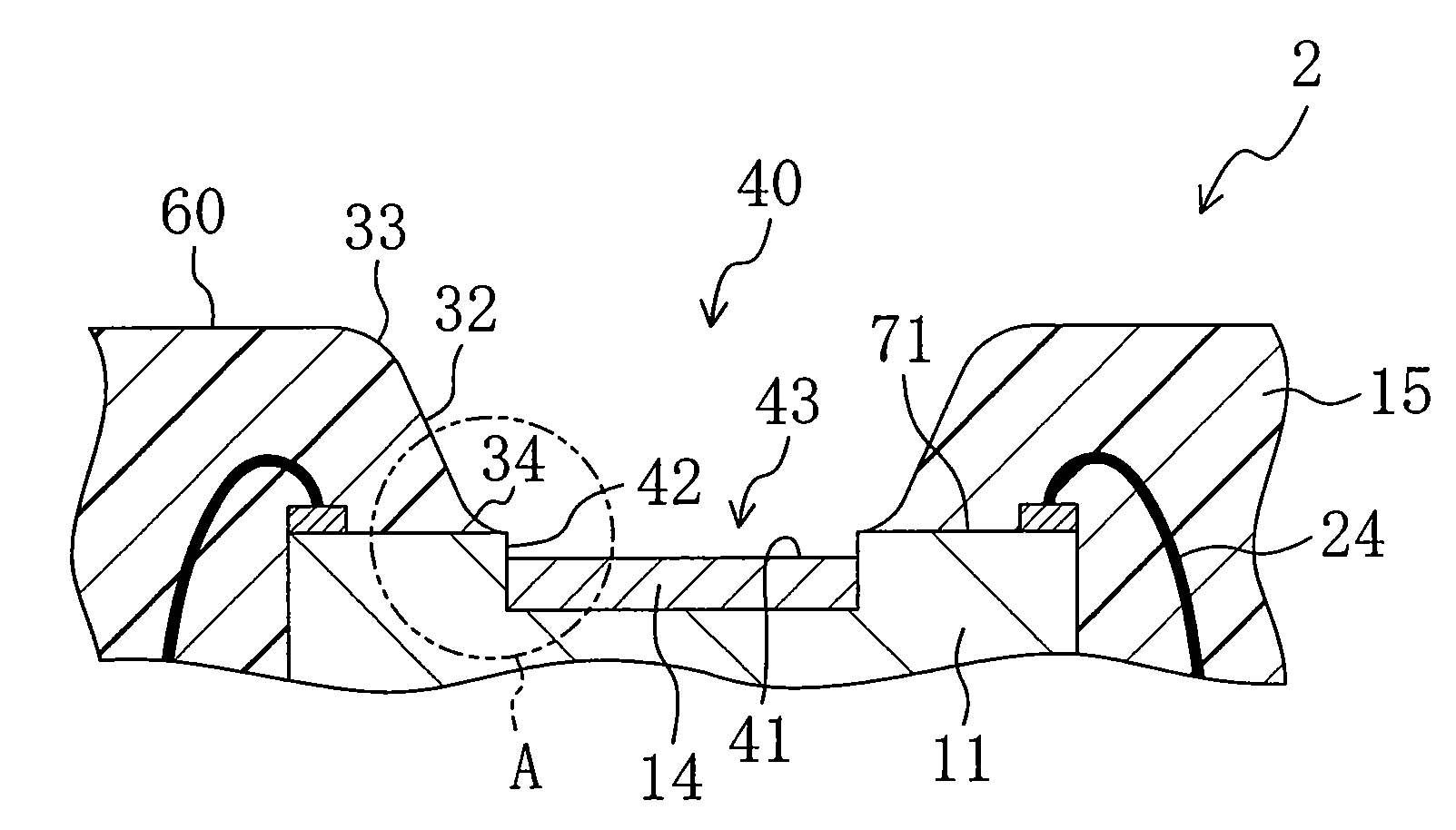

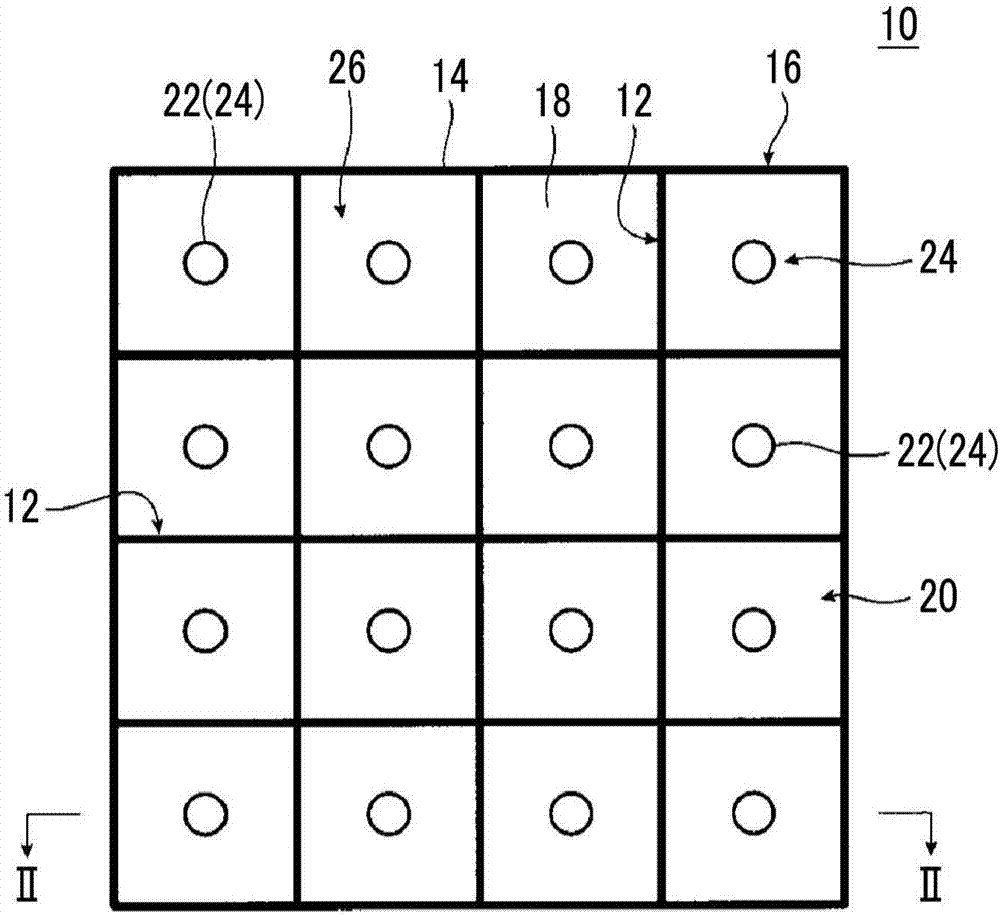

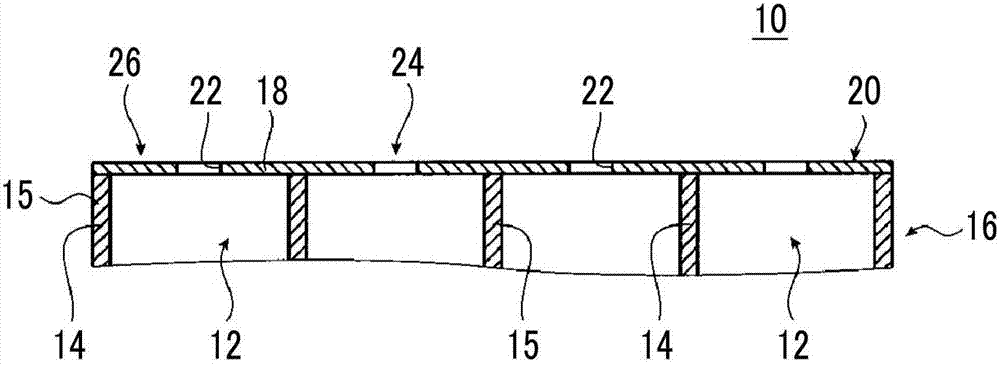

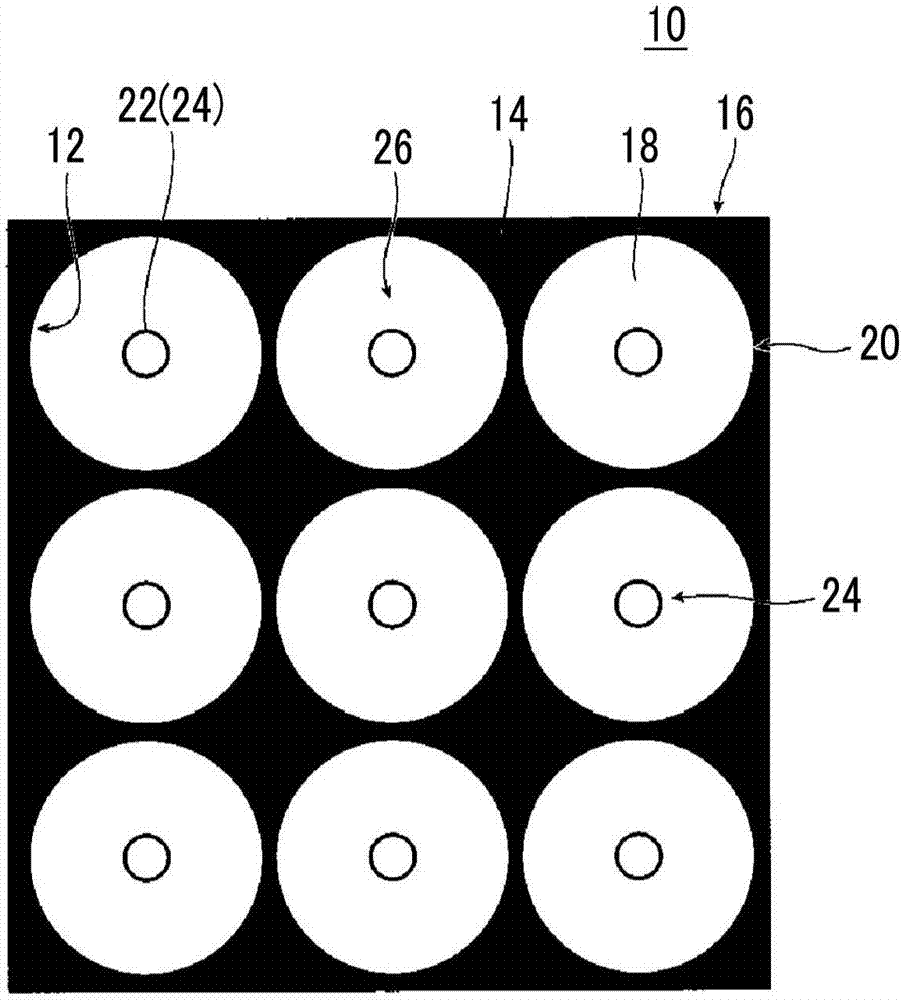

Various-Substance Holder, Various-Substance Holder Treating Apparatus, and Various-Substance Holder Treating Method

ActiveUS20090221080A1Easy to manufactureReliable and easy to manufactureAnalysis using chemical indicatorsComponent separationChemical substanceEngineering

An object of the present invention is to provide a various-substance holder, a various-substance holder treating apparatus, and a various-substance holder treating method which enable the mutual identification of a plurality of particulate carriers to which various substances are or can be immobilized without the need to arrange the particulate carriers at predetermined positions or in a predetermined order, eliminating the need for time and effort to arrange the various substance at predetermined positions or in a predetermined order to allow treatments to be quickly and easily achieved. The various-substance holder according to the present invention has a plurality of particulate carriers or plural sets of particulate carriers to which plural types of chemical substances are or can be immobilized and a carrier holding portion holding the plurality of particulate carriers or the plural sets of particulate carriers in a substantially stationary state such that the plurality of particulate carriers or the plural sets of particulate carriers can be externally measured. The various-substance holder is configured so that each of the plurality of particulate carriers or at least one of the particulate carriers belonging to the plural sets of the particulate carriers are labeled according to types of the chemical substances or for each of the particulate carriers or each set of the particulate carriers so as to be mutually identifiable before the particulate carriers are introduced and held in the carrier holding portion.

Owner:UNIVERSAL BIO RESEARCH CO LTD

Optical device for reducing disturbance light and manufacturing method thereof

ActiveUS7939901B2Reliable and easy to manufactureSolid-state devicesOptical articlesEngineeringMechanical engineering

Owner:PANNOVA SEMIC

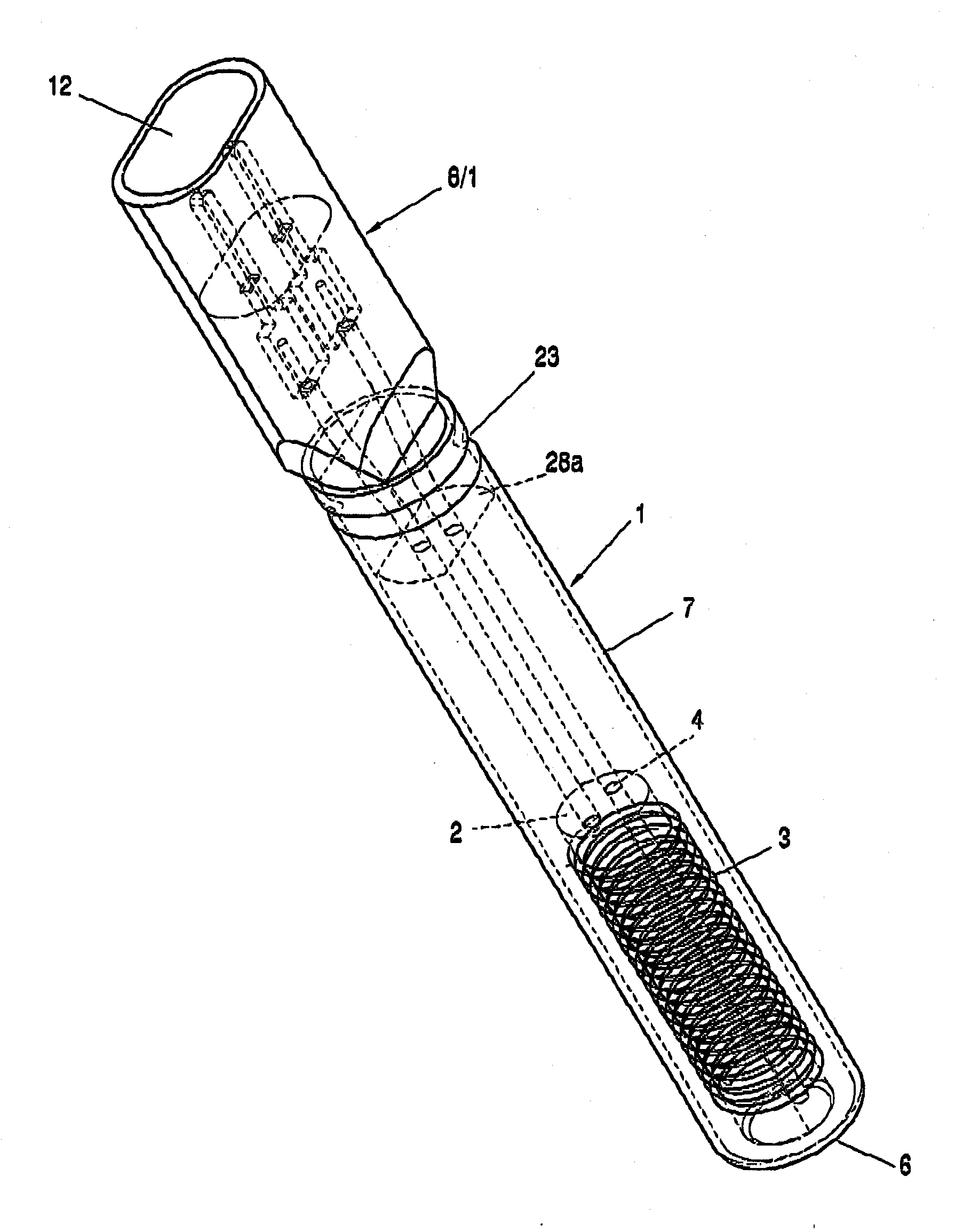

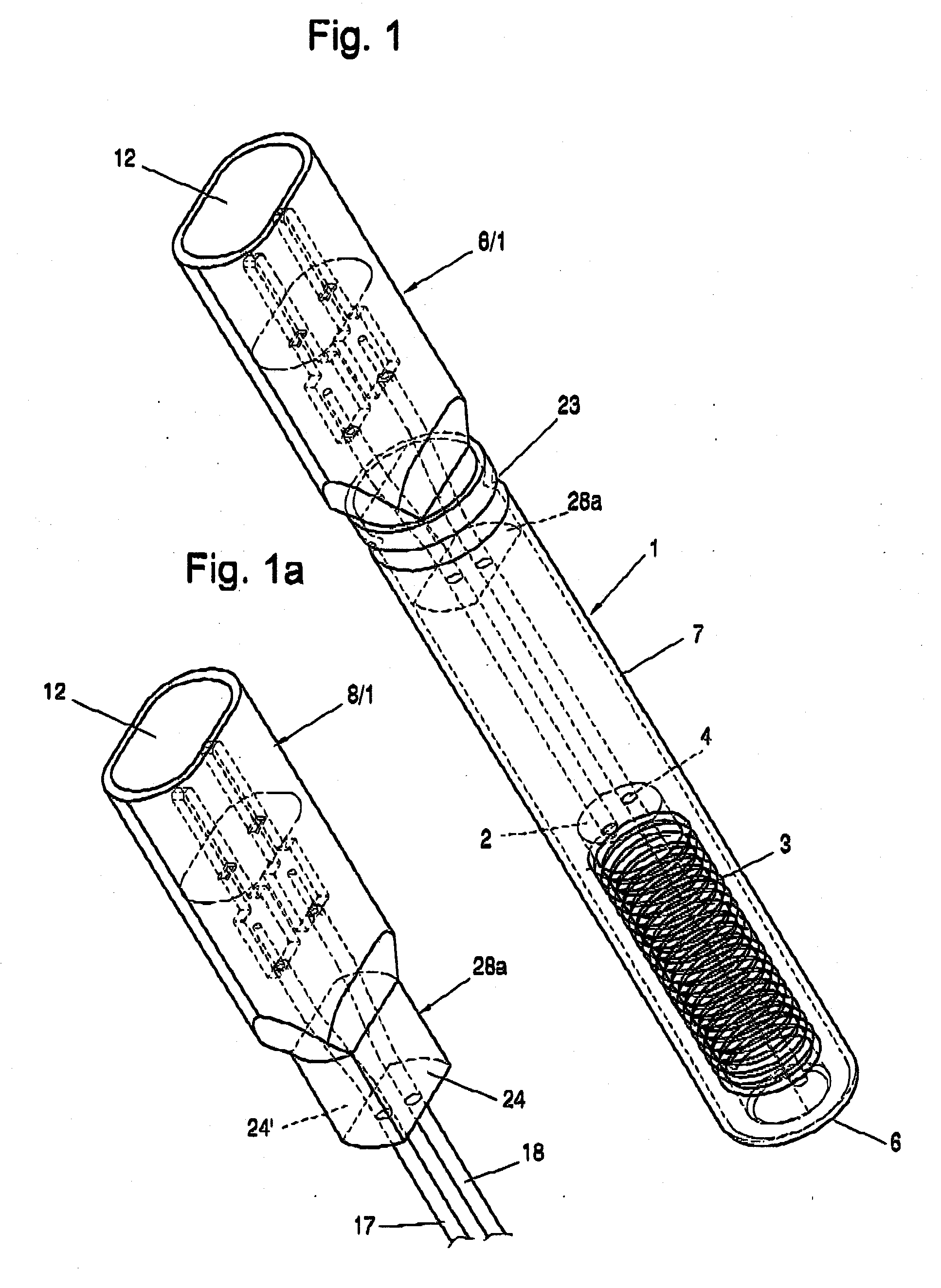

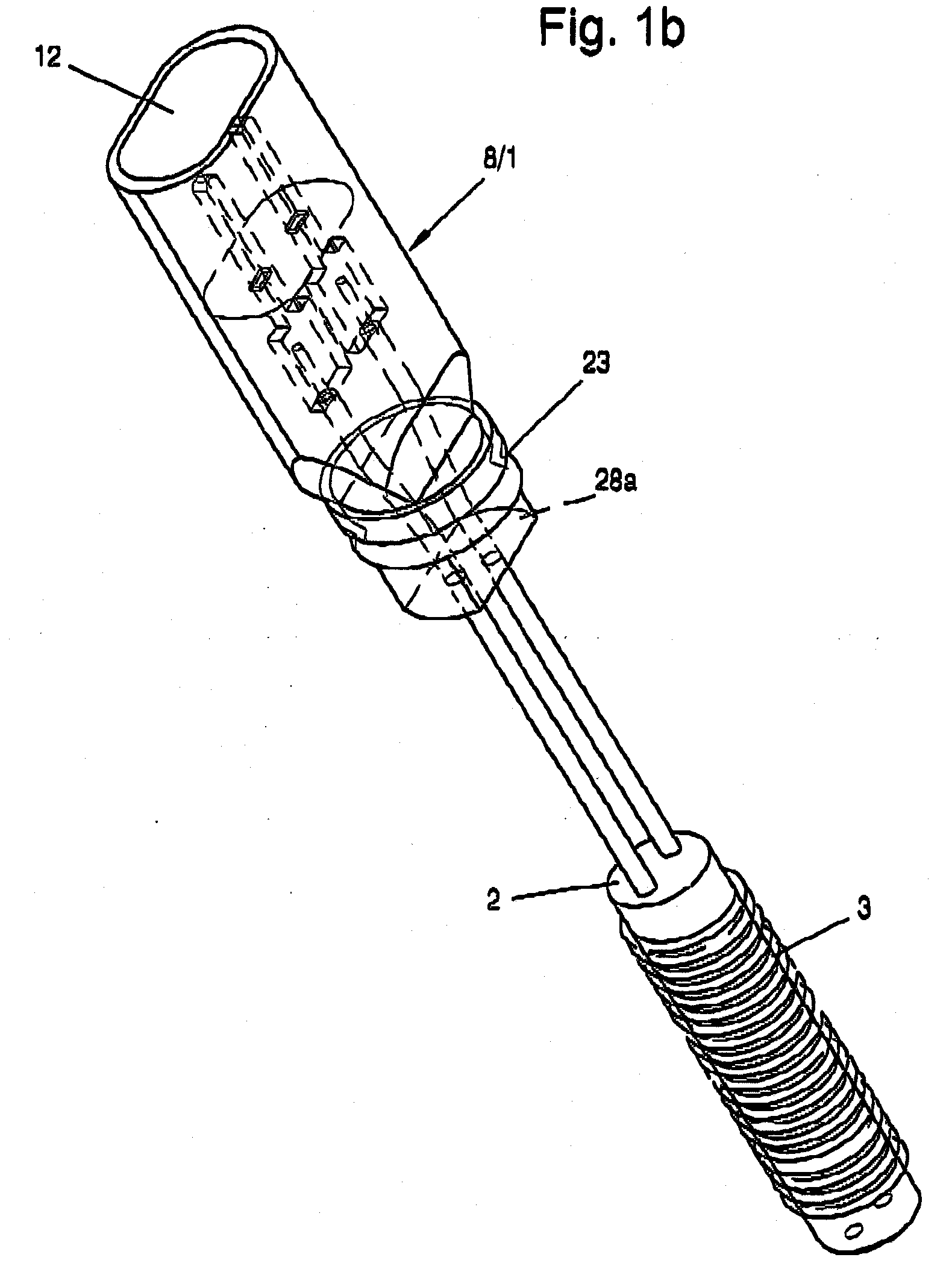

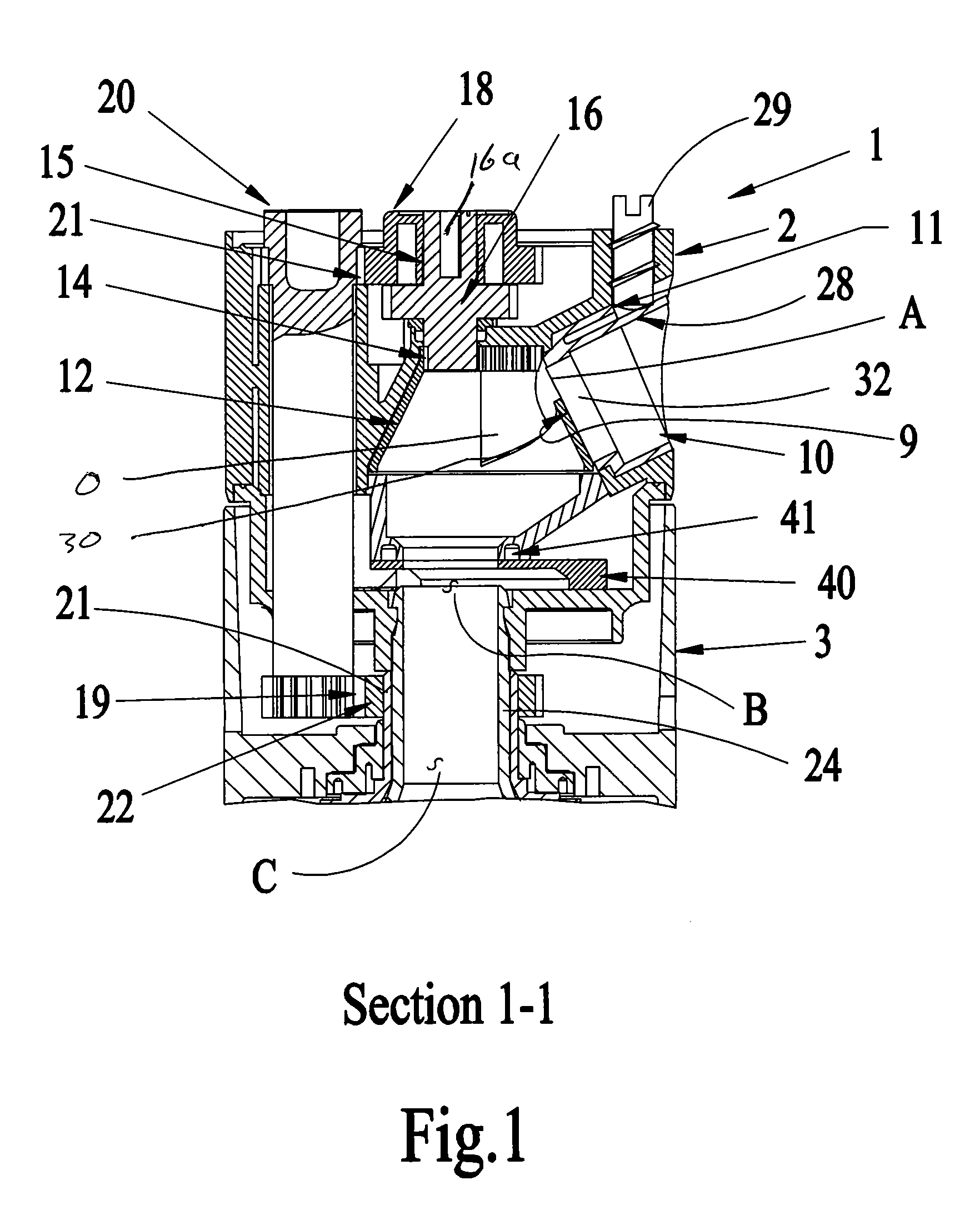

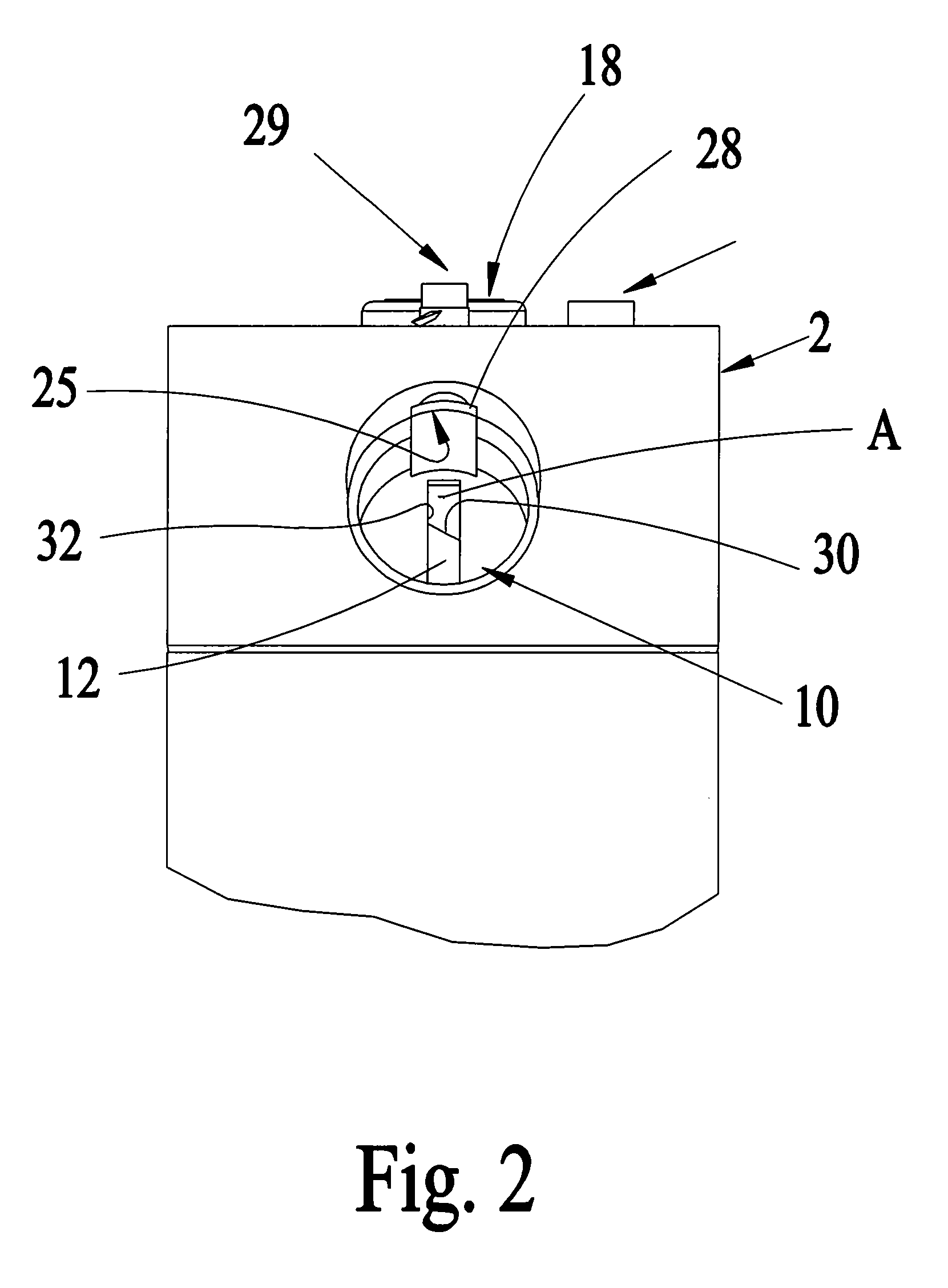

Heating cartridge with coupling element

ActiveUS20080290085A1Easy to operateSpace minimizationHeater elementsHeating element shapesCouplingEngineering

A heating cartridge is intended especially for a thermostatic working valve. The cartridge is provided with a resistance wire winding (3), which is wound on a winding support (2) and is embedded in an insulating material filling (5) in a metal sheathing (7). The metal sheathing (7) is provided at one end (6) with a dimensionally stable coupling element (8) manufactured from a plastic, in which connecting lines (17, 18) are arranged, which electrically connect pluggable contact elements, especially pins (9, 10) of a connector plug, to the ends of the resistance wire winding (3). To simplify the manufacture and to obtain a compact design, the connecting lines (17, 18) are rigidly seated in the coupling element (8). The coupling element (8) is designed as a connector plug (8 / 1) and / or holder (8 / 2) and it has a connection section (28a, 28b, 28c), which protrudes into the open end of the metal sheathing (7) and which is fastened in the metal sheathing (7) in a non-positive and / or positive-locking manner by preferably radial pressing and forms a dimensionally stable structural unit with same.

Owner:TUERK & HILLINGER

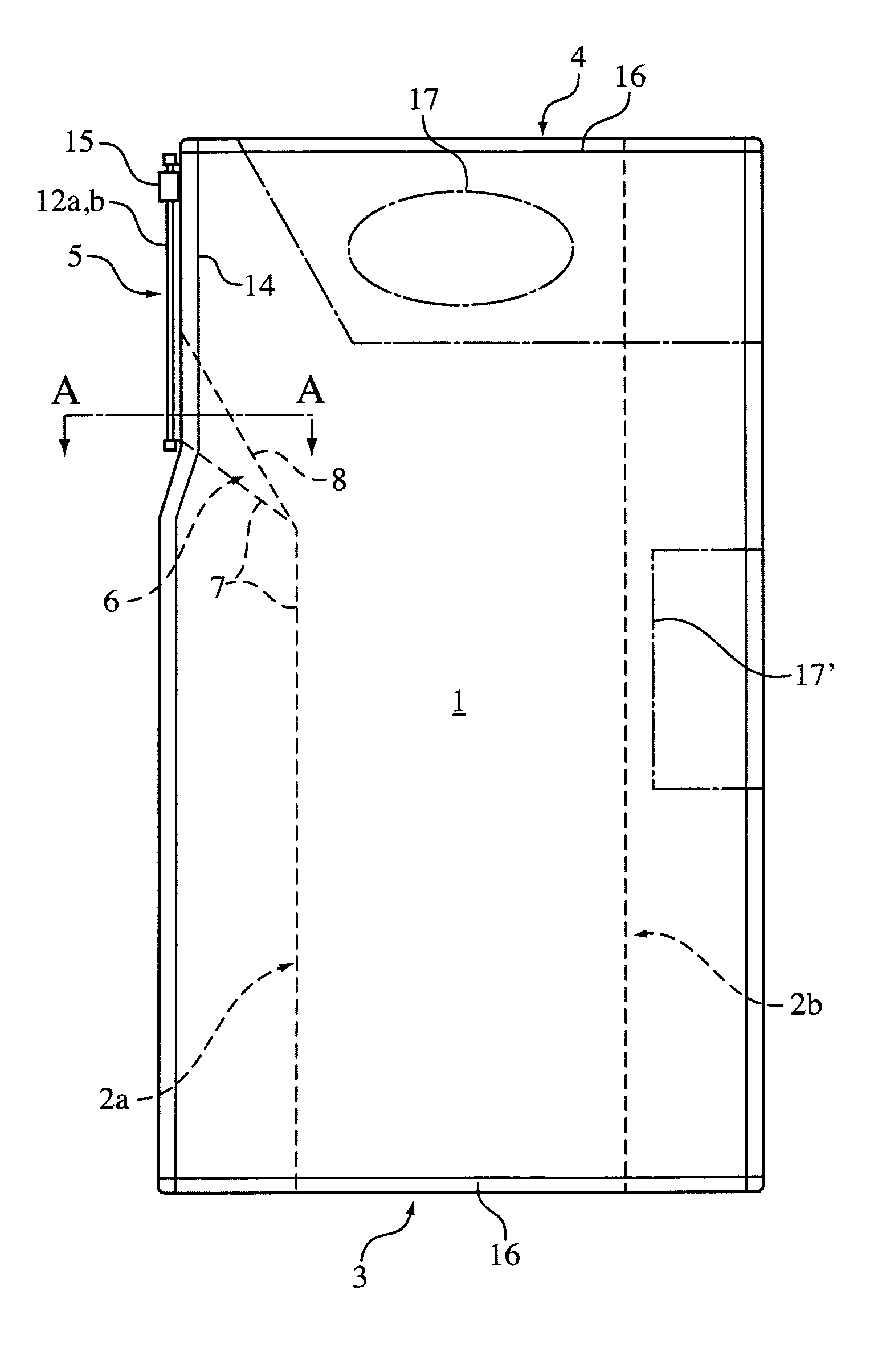

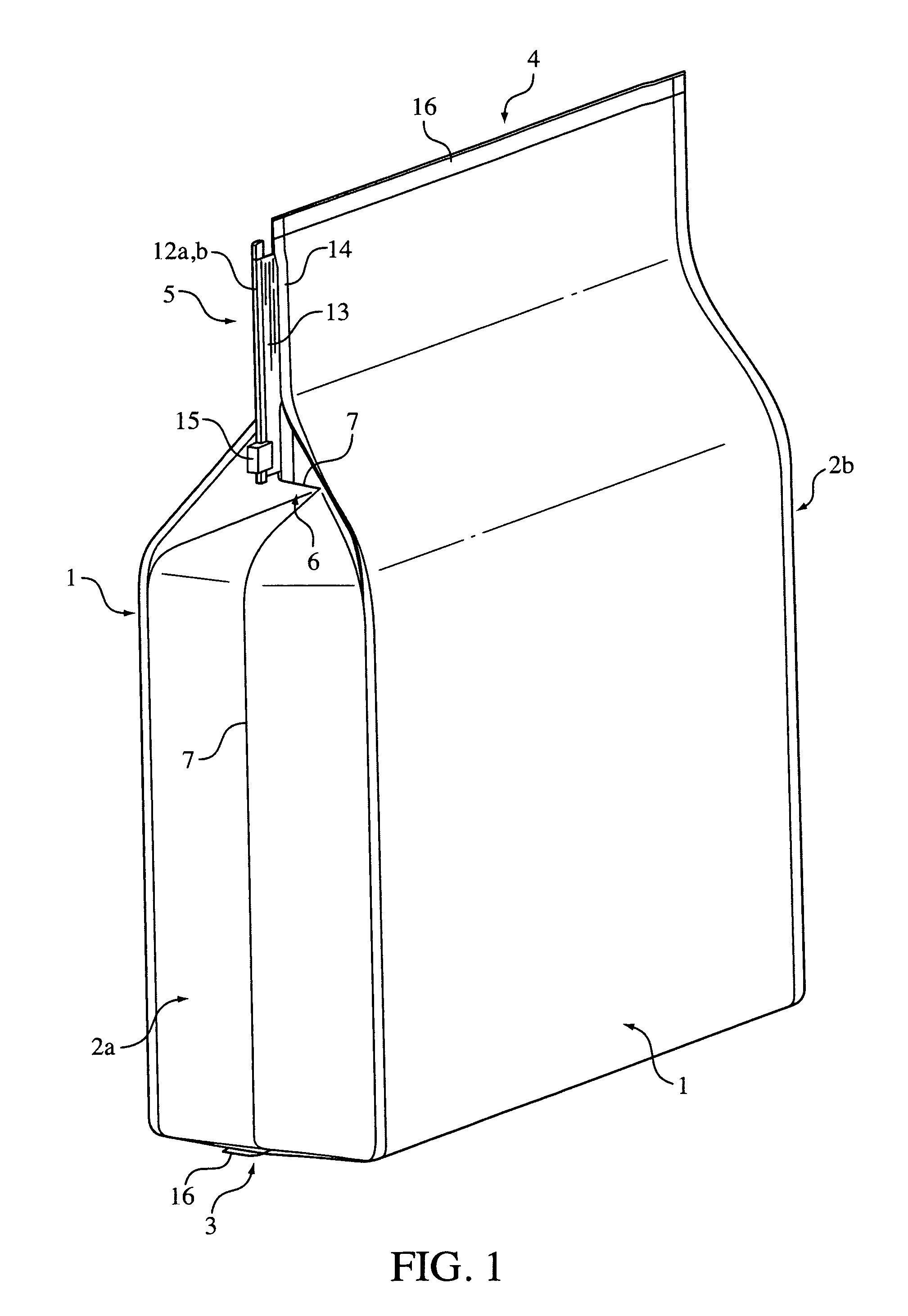

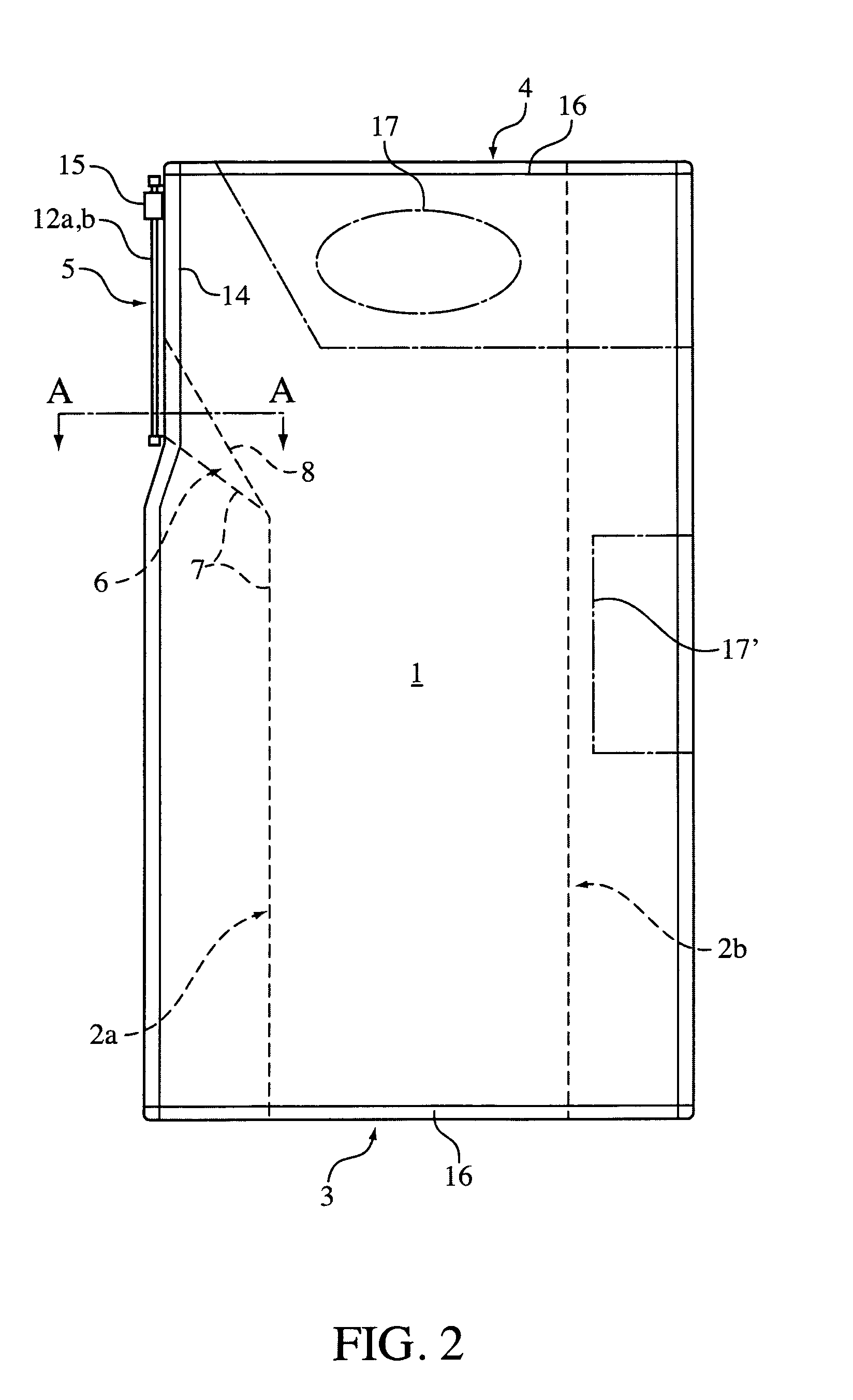

Side-gusseted bag and method for manufacturing same

ActiveUS8430566B2Reliable and easy to manufactureEnvelopes/bags making machineryFlexible coversGusset plateEngineering

Owner:MONDI JACKSON

Multi-lumen vascular grafts having improved self-sealing properties

InactiveUS20050246012A1Solve Porosity InsufficiencySolve the lack of flexibilityCoatingsBlood vesselsVascular graftAnatomy

Owner:MAQUET CARDIOVASCULAR LLC

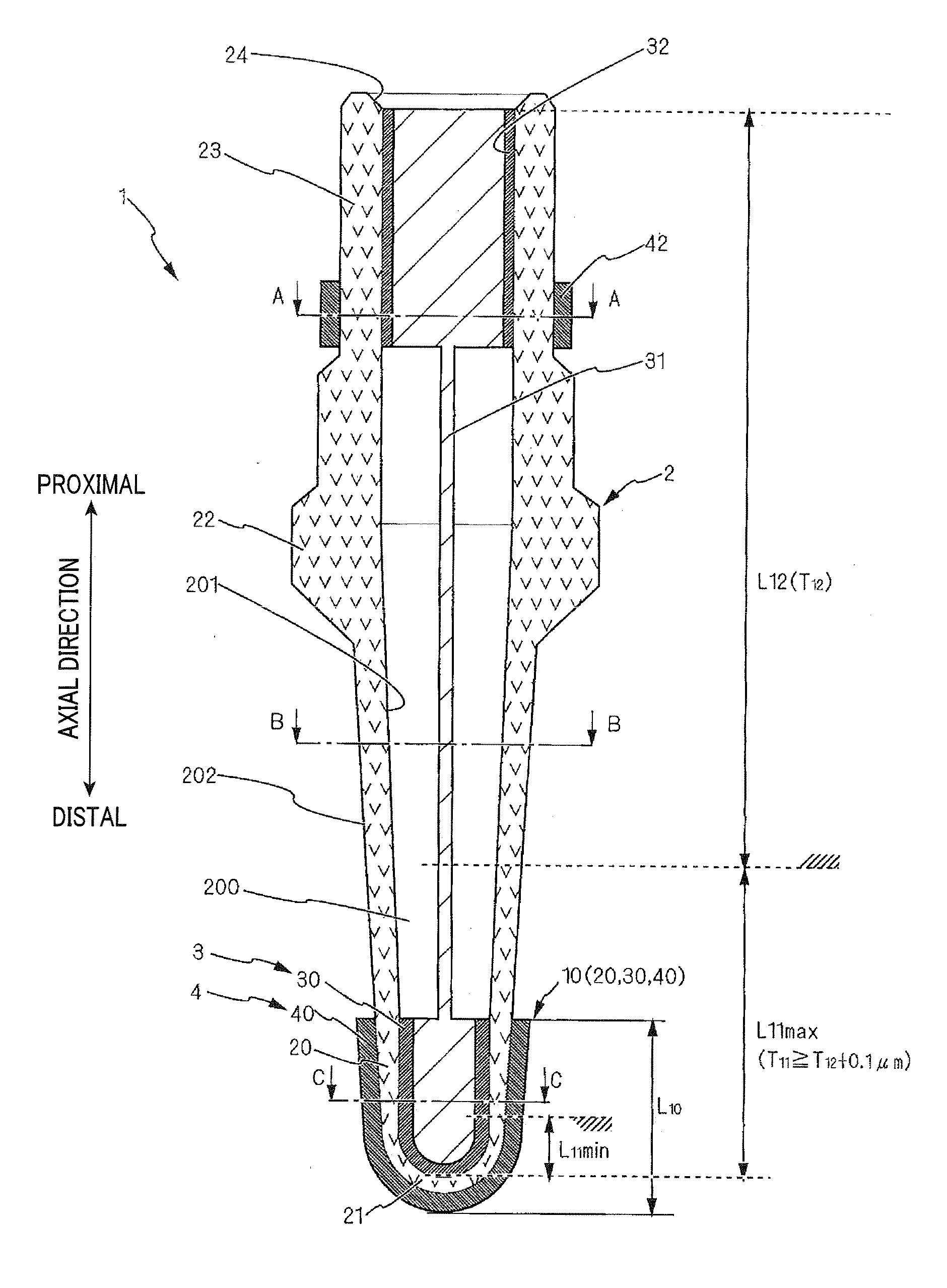

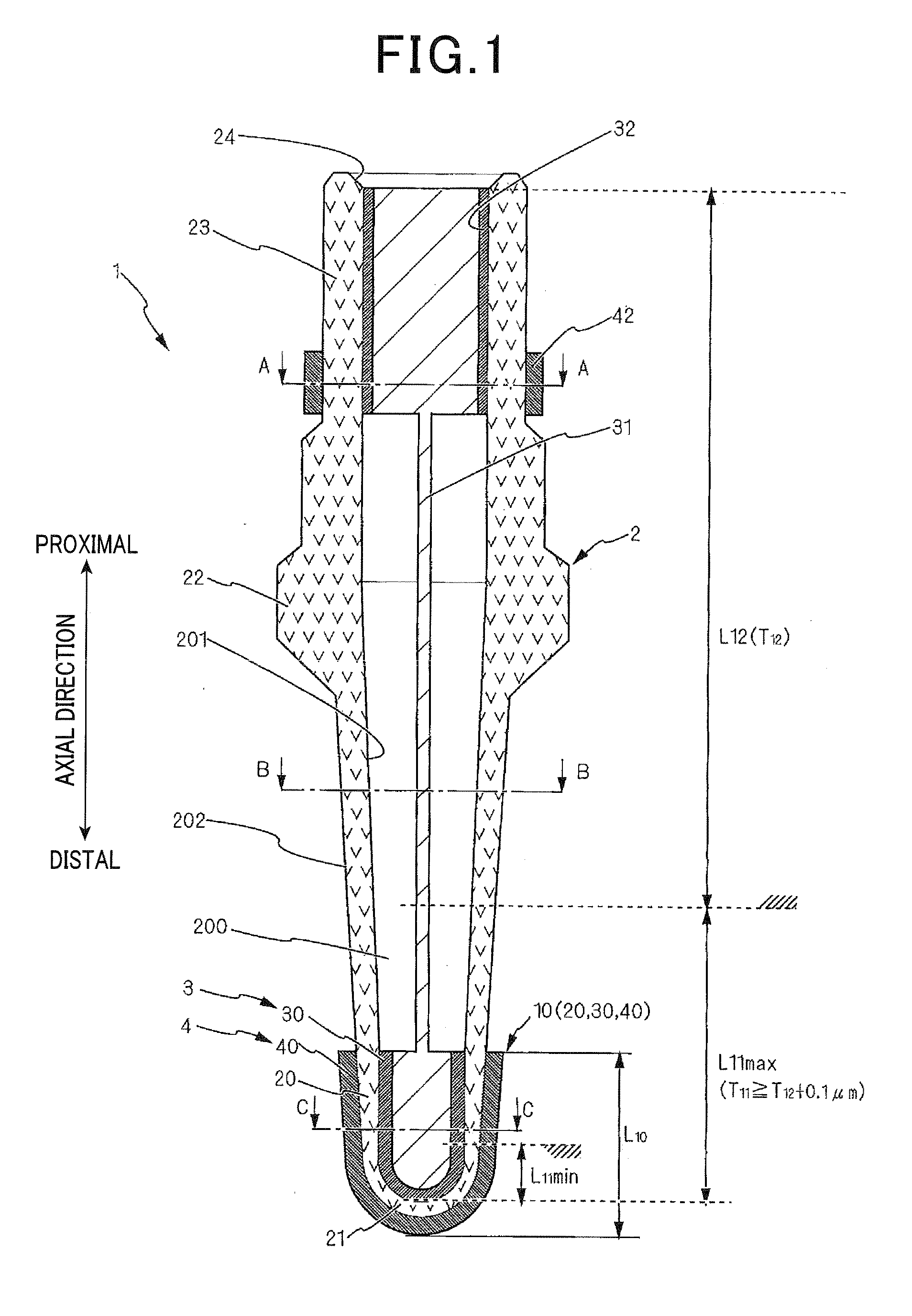

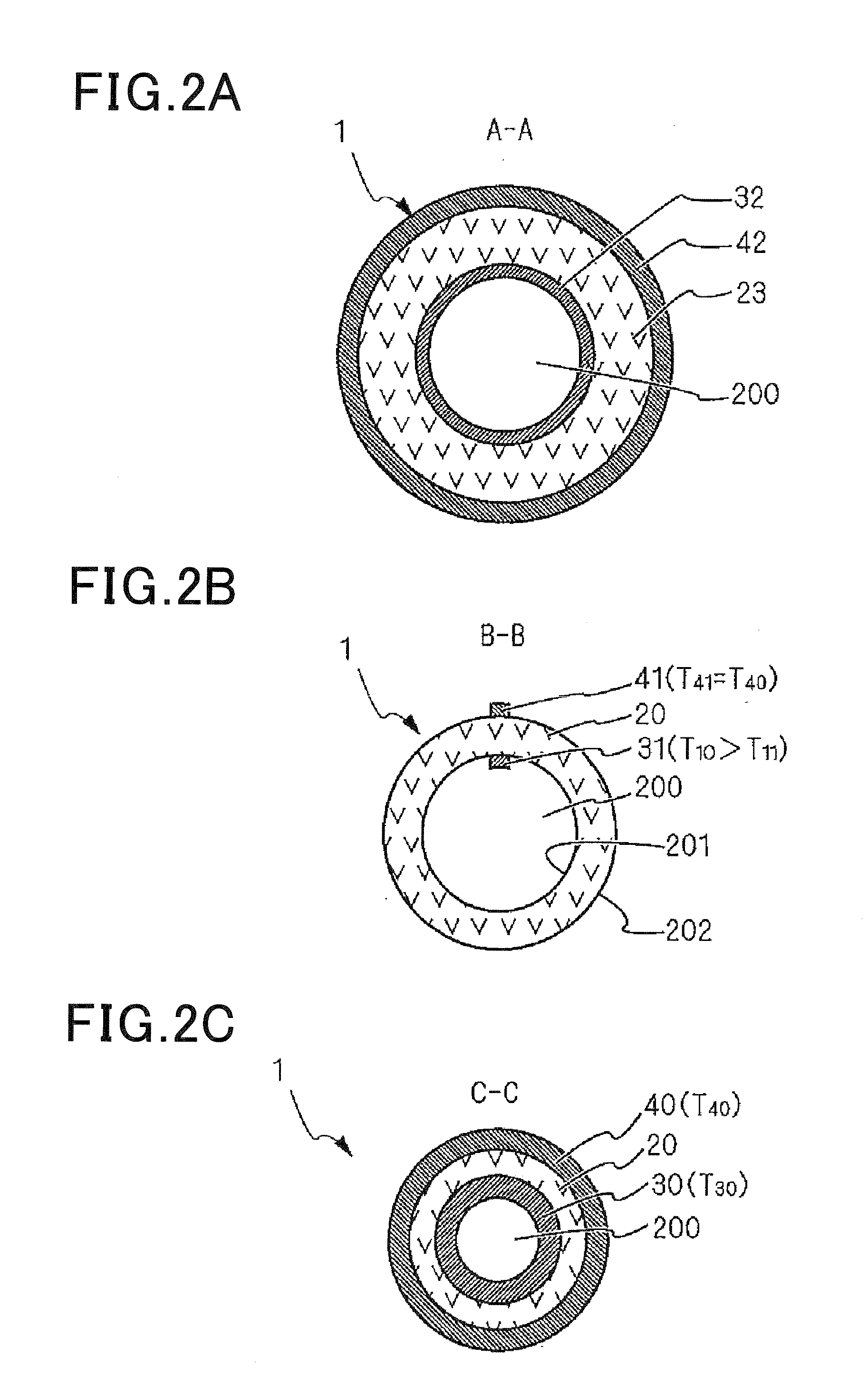

Gas sensor element, its manufacturing method and gas sensor including the gas sensor element

ActiveUS20150253282A1Suppression of impedance changesHigh temperature control accuracyMaterial analysis by electric/magnetic meansCoatingsEngineeringReference electrode

A gas sensor element includes a cup-shaped solid electrolyte body having closed and open ends, a reference electrode provided on an inner surface of the solid electrolyte body, and a measurement electrode provided on an outer surface of the solid electrolyte body. The reference electrode has a detection portion located closer to the closed end than to the open end of the solid electrolyte body, a terminal portion located closer to the open end than to the closed end of the solid electrode body, and a lead portion connecting the detection and terminal portions. Moreover, the reference electrode has a first thickness in a large-thickness region and a second thickness smaller than the first thickness in a small-thickness region. The large-thickness region includes at least part of the detection portion of the reference electrode, and the small-thickness region includes at least the lead and terminal portions of the reference electrode.

Owner:DENSO CORP

Sound insulation structure and method for manufacturing sound insulation structure

ActiveCN107408378ALight and thinImprove sturdinessSound proofingSound producing devicesNatural resonanceEngineering

A sound insulation structure having one or more sound insulation cells, wherein: each of the one or more sound insulation cells is provided with a frame having through holes, a film affixed to the frame, and an opening part formed from one or more holes penetrating the film; both end parts of the through holes in the frame are not closed; and the sound insulation structure has, on the low-frequency side of a first natural resonance frequency for the film of the one or more sound insulation cells, a masking peak frequency that is determined due to the opening parts of the one or more sound insulation cells and for which transmission loss is maximum, and selectively insulates sound of a fixed frequency band centered on the peak masking frequency. Thus, it is possible to provide a sound insulating structure that is lightweight and thin, is not dependent on the position and shape of holes, has high robustness as an acoustic insulator, has stability, has air permeability, does not retain heat, and has excellent manufacturing suitability, and a manufacturing method for the sound insulating structure.

Owner:FUJIFILM CORP

Oscillating nozzle sprinkler assembly with matched precipitation and adjustable arc of coverage

ActiveUS8628027B2Reliable and easy to manufactureMovable spraying apparatusSpray nozzlesWater flowPrecipitation

An oscillating nozzle sprinkler with adjustable arc of coverage in accordance with an embodiment of the present application includes a nozzle, a nozzle drive mechanism operable to drive the nozzle through a set arc of coverage, an arc set mechanism coupled to the nozzle drive mechanism and operable to adjust the set arc of coverage for the nozzle drive mechanism; and a flow control mechanism operable to vary a nozzle flow area through which water flows through the nozzle and out of the sprinkler, the flow control mechanism coupled to the arc set mechanism such that the flow area is adjusted with the arc of coverage.

Owner:KAH JR CARL L C +2

Electrophoretic sheet, electrophoresis apparatus, method for manufacturing an electrophoresis apparatus and electronic device

InactiveUS20100097686A1High reliabilityHigh whitenessSynthetic resin layered productsLaminationBiomedical engineeringElectrophoresis

An electrophoretic sheet includes a substrate having one surface and the other surface, a microcapsule-containing layer comprised of a plurality of microcapsules, the microcapsule-containing layer provided on the other surface of the substrate, each of the plurality of microcapsules having a capsule body and an electrophoretic dispersion liquid contained in the capsule body, the electrophoretic dispersion liquid containing a plurality of electrophoretic particles of at least one color, and the capsule body having an inner circumferential surface and an outer circumferential surface, and at least one colored part provided on the external side of the inner circumferential surface of the capsule body of each of the plurality of microcapsules, and wherein each colored part has a color complementary to the color of the plurality of electrophoretic particles. By using the electrophoretic sheet mentioned above, it is possible to provide the increased whiteness in display of the electrophoretic particles. An electrophoresis apparatus provided with such an electophoretic sheet is also provided. By using the electrophoresis apparatus, it is possible to provide a superior contrast ratio. It is also possible to obtain high reliability. A Method for manufacturing such an electrophoresis apparatus is also provided. An electronic device provided with such an electrophoresis apparatus is also provided.

Owner:E INK CORPORATION

Semiconductor light emitting element and method for manufacturing the same

InactiveUS20090267065A1Reliable and easy to manufactureHigh yieldSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorSapphire

A ZnO-based semiconductor light emitting element includes a ZnO-based semiconductor layer formed on a rectangular sapphire A-plane substrate having a principal surface lying in the A-plane {11-20}. The substrate has a thickness of 50 to 200 μm and is surrounded by two parallel first side edges forming an angle in a range of 52.7° to 54.7° with respect to the m-axis orthogonal to the c-axis and two parallel second side edges orthogonal to the first side edges. The light emitting element is obtained by: forming, on a surface of the sapphire A-plane substrate opposite to the surface on which the ZnO-based semiconductor layer is formed, first scribed grooves forming an angle in a range of 52.7° to 54.7° with respect to the m-axis and second scribed grooves orthogonal to the first scribed grooves; and breaking the substrate along the first scribed grooves and then along the second scribed grooves.

Owner:STANLEY ELECTRIC CO LTD

High sensitivity mechanical fluid level sensing device and method of use

InactiveUS7588169B1Accurately determineSlight frictionOpening closed containersBottle/container closureLevel sensorEngineering

A mechanical level sensor detects when a fluid material added to a chamber has reached a predetermined level and therefore comprises a predetermined particular volume. Material is added to a chamber until it has reached the predetermined level. Once this level is reached, additional material overflows into a level sensor. The overflow material causes a wheel having a plurality of wells to rotate. This rotation is detected by a control circuit that signals the cessation of addition of material to the chamber and the dispensing of the material present in the chamber. The sensor is highly sensitive due to the almost frictionless rotation of the wheel about its axle.

Owner:GREEN SCOTT DAVID +1

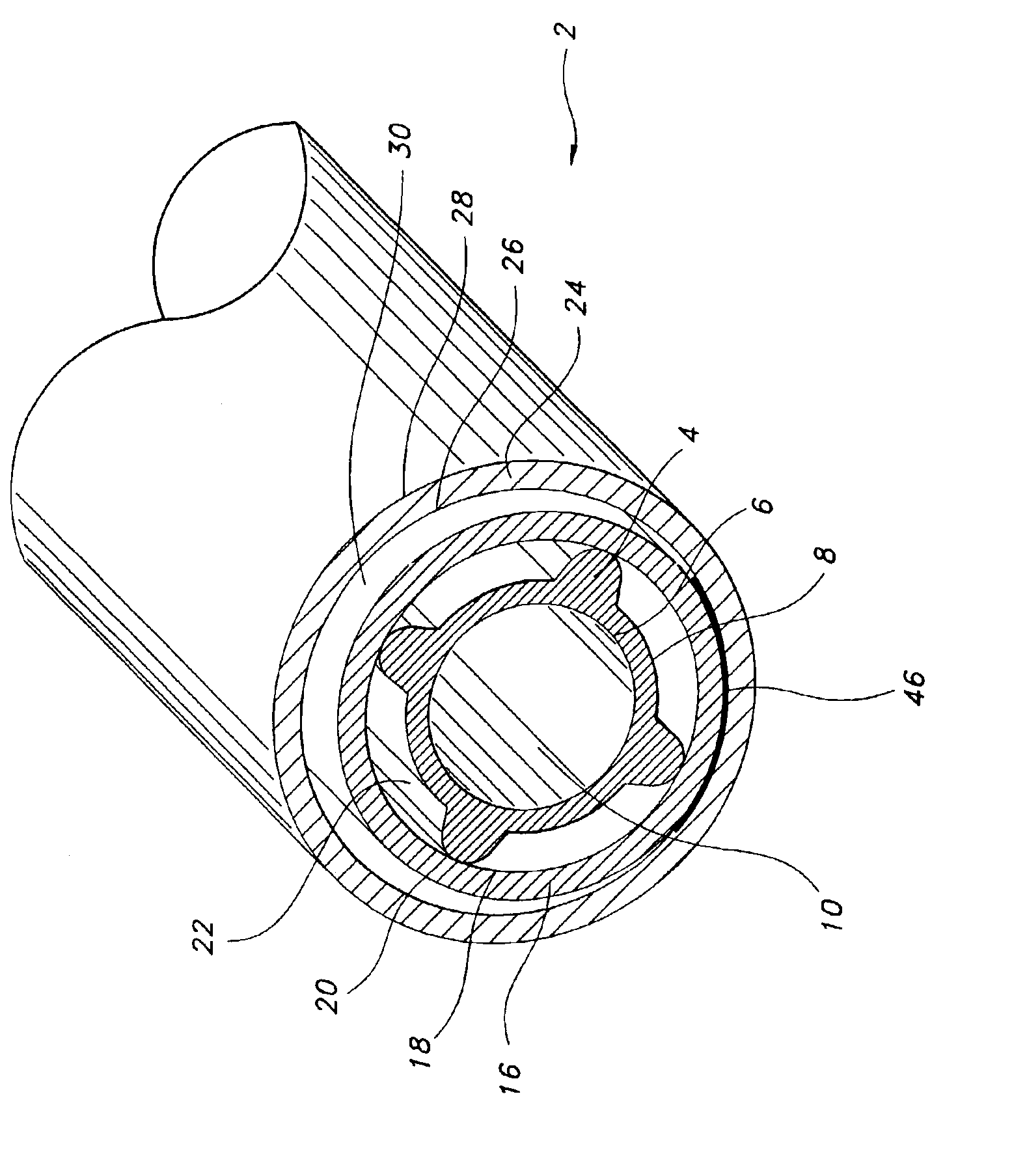

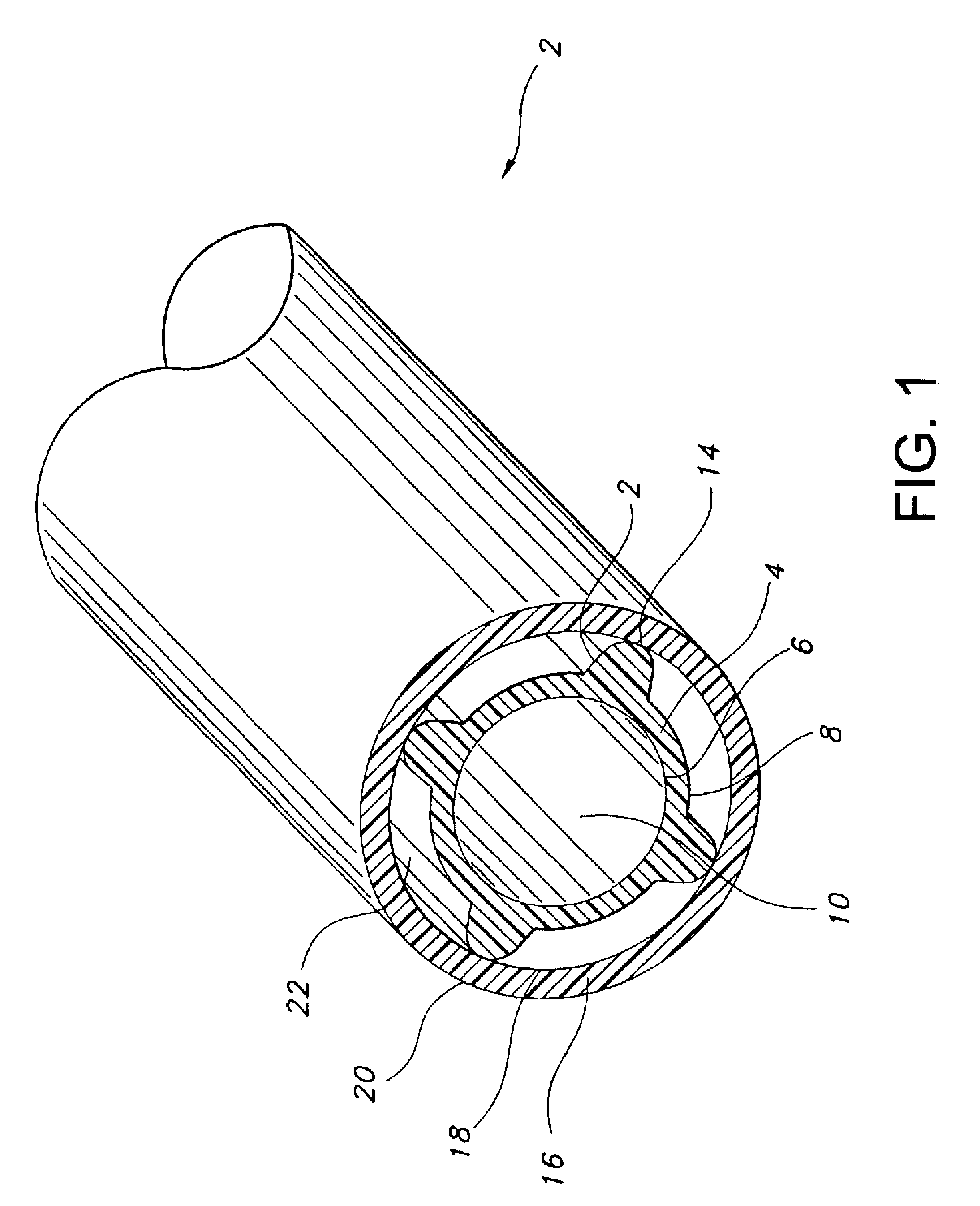

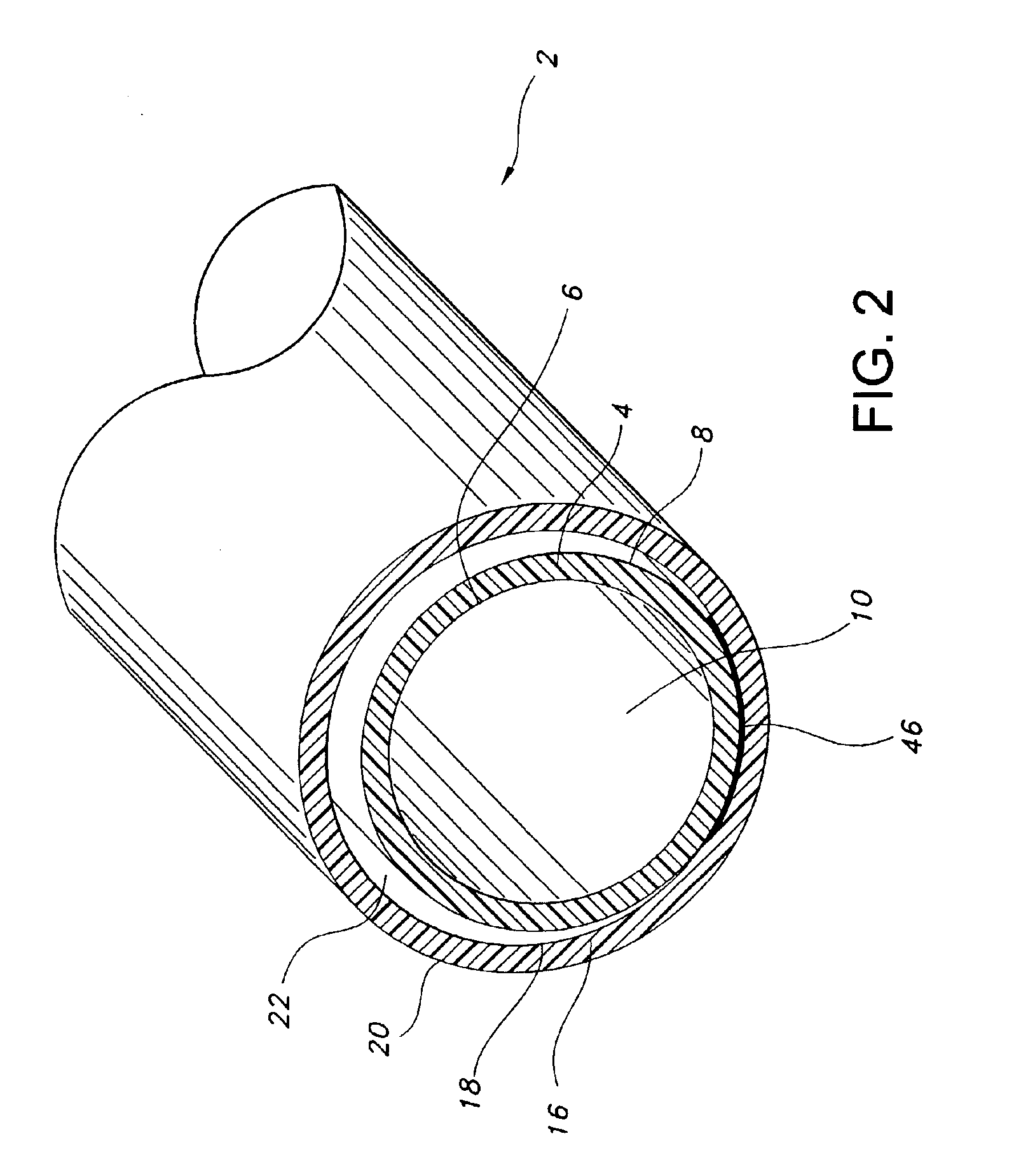

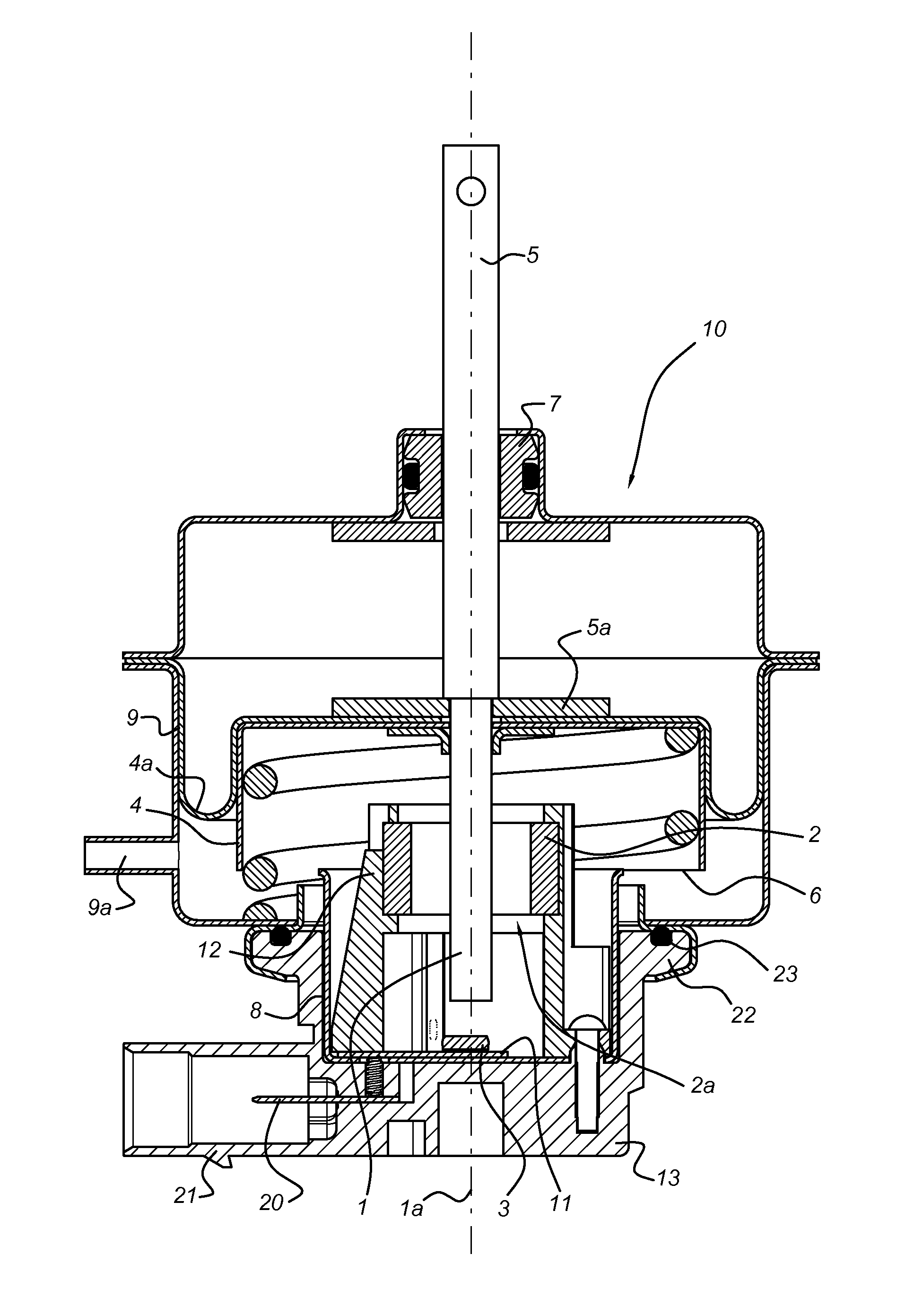

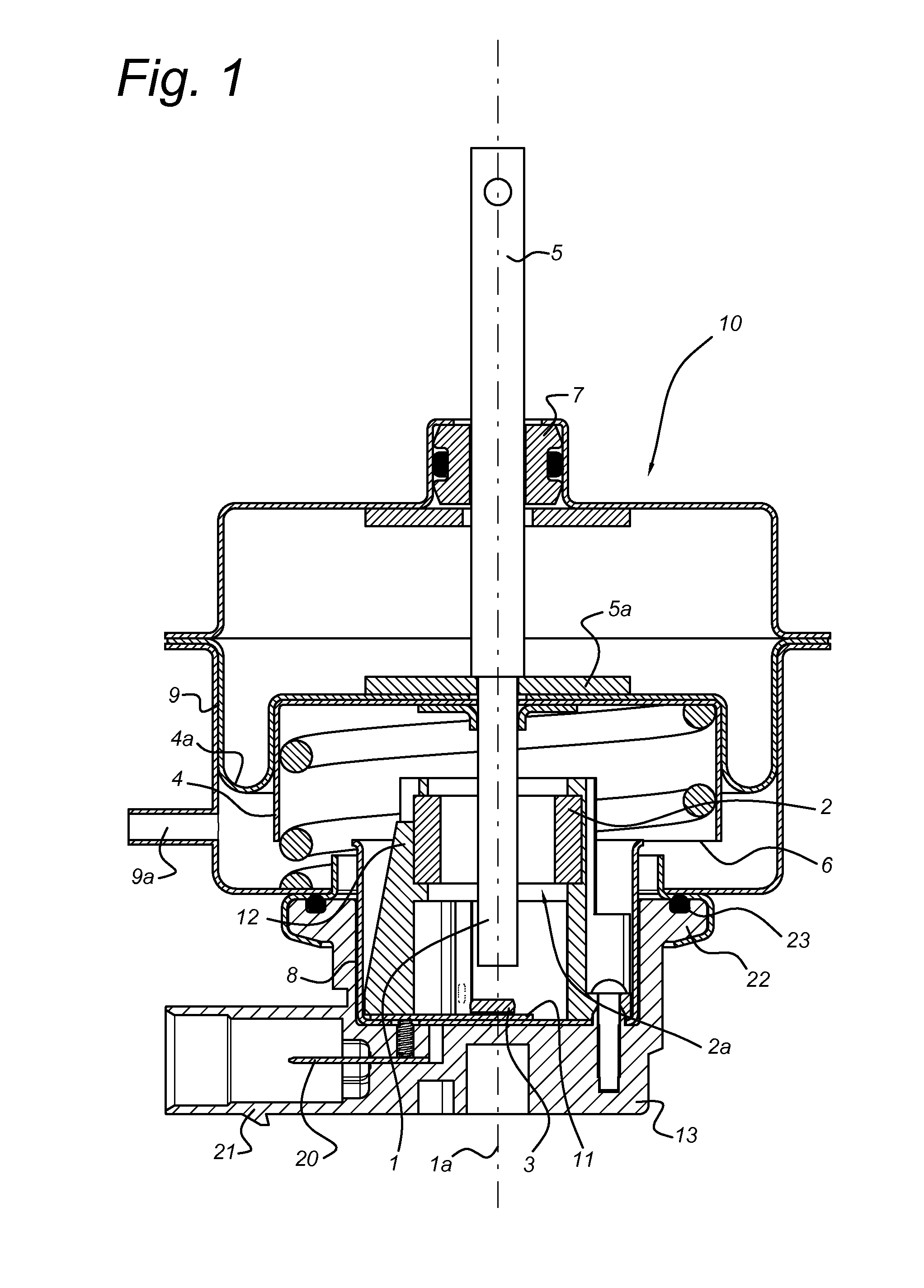

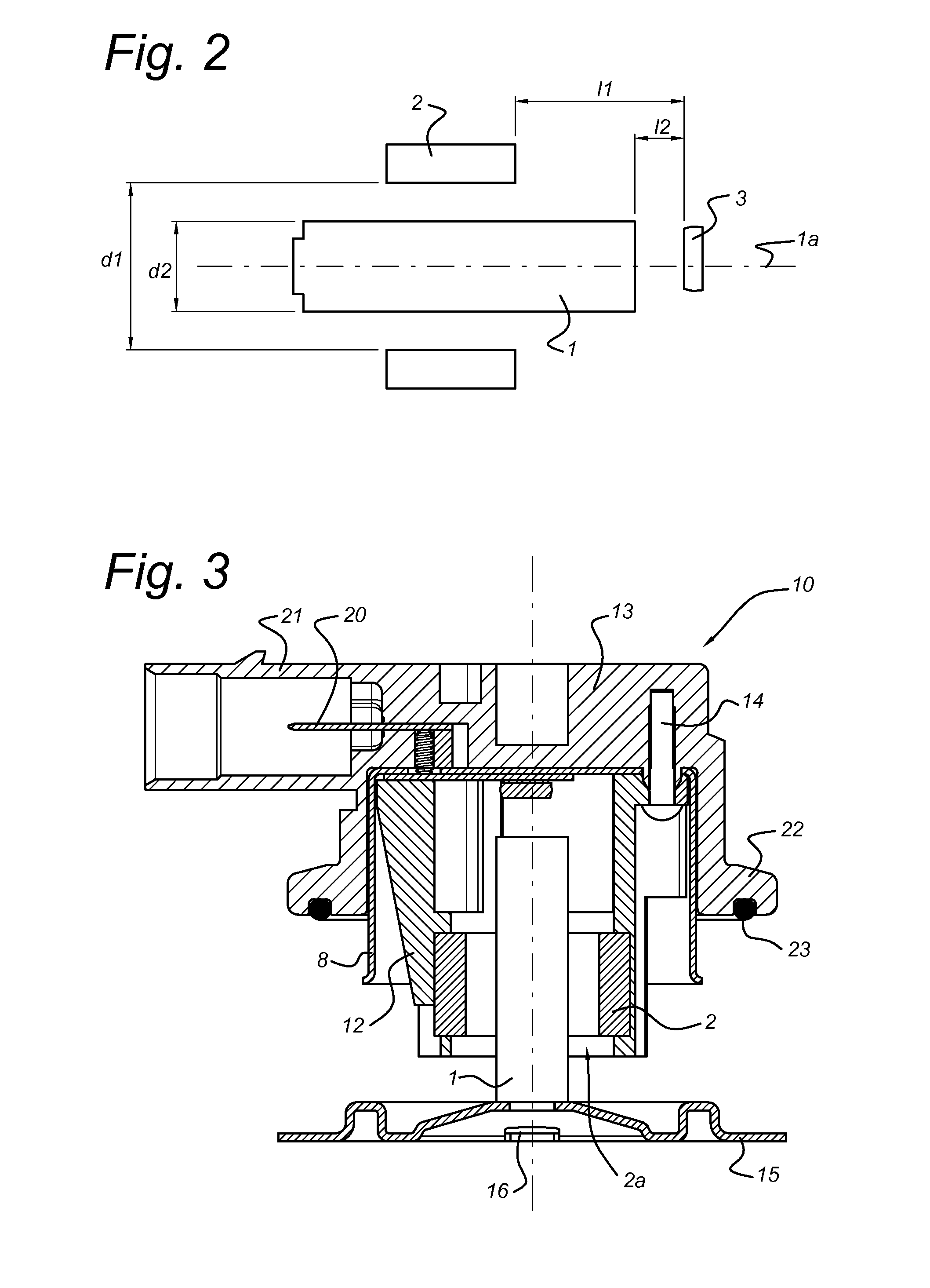

Position sensor

ActiveUS20130285649A1Reliable and easy to manufactureLow costUsing electrical meansConverting sensor outputActuatorPosition sensor

Position sensor (10) for determining a linear position in a sensing direction, e.g. for application in a vacuum actuator. The position sensor (10) has a first sensor part and a second sensor part moveable with respect to each other. The first sensor part comprises an annular magnet (2) and a magnetic field sensor (3) positioned at a first distance (l1) from the annular magnet on the magnet axis (1a). The second sensor part comprises a flux shaper (1) moveable through the annular magnet (2) along the sensing direction between a first and a second position, in the first position the flux shaper being substantially at the first distance (l1) from the magnetic field sensor (3). The flux shaper is arranged to influence the magnetic field in a space between the annular magnet (2) and the magnetic field sensor (3).

Owner:SENSATA TECHNOLOGIES INC

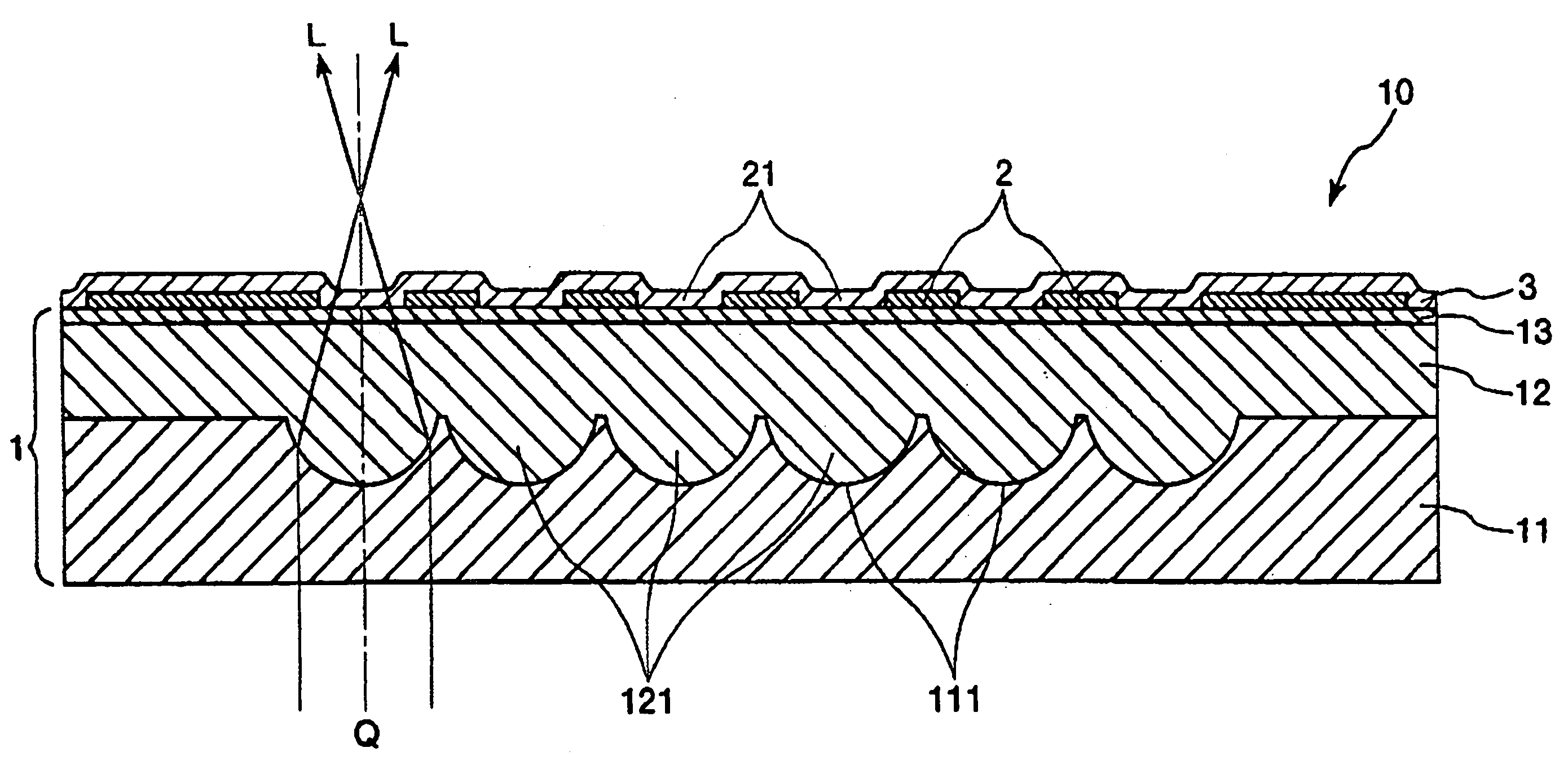

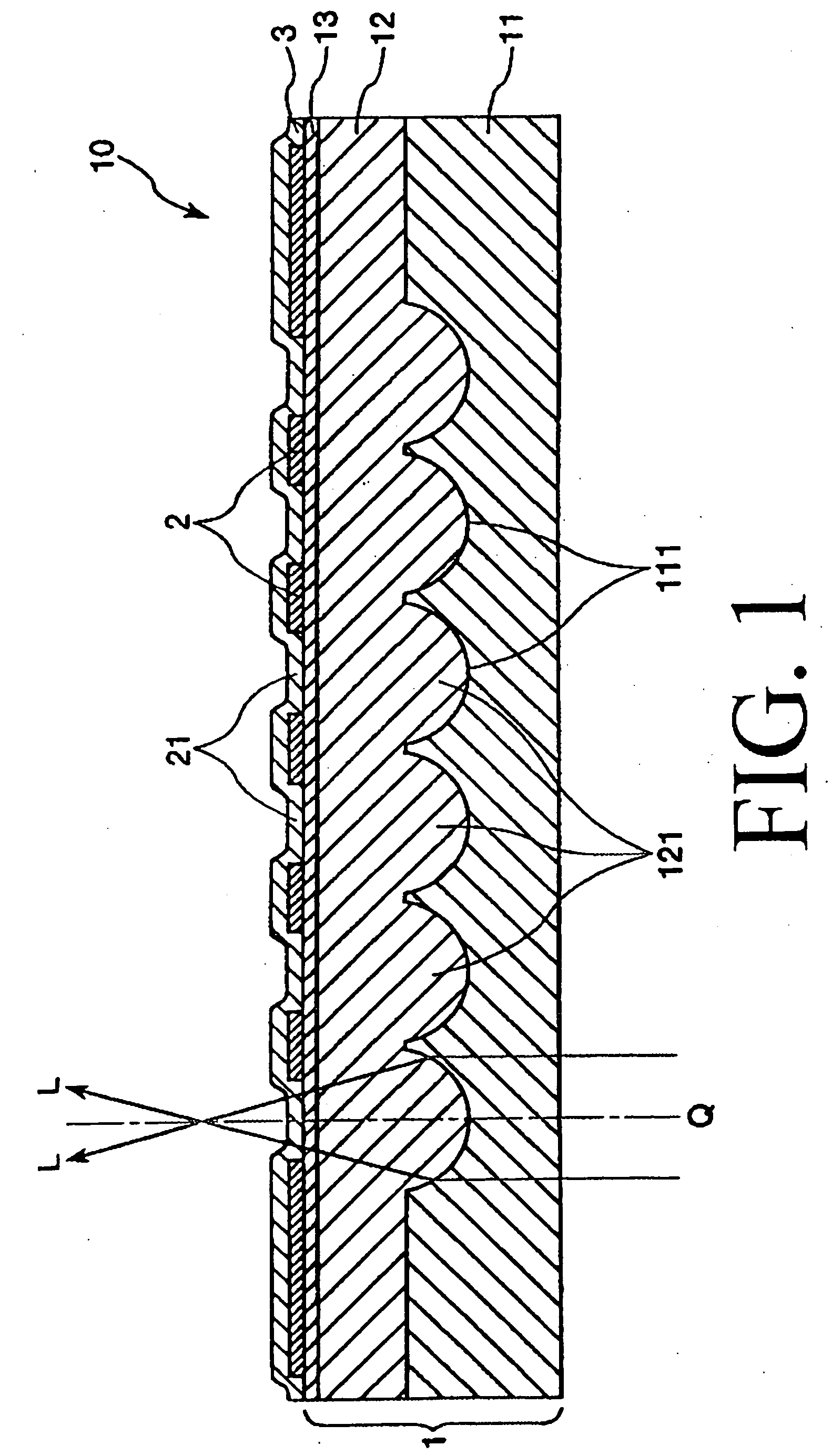

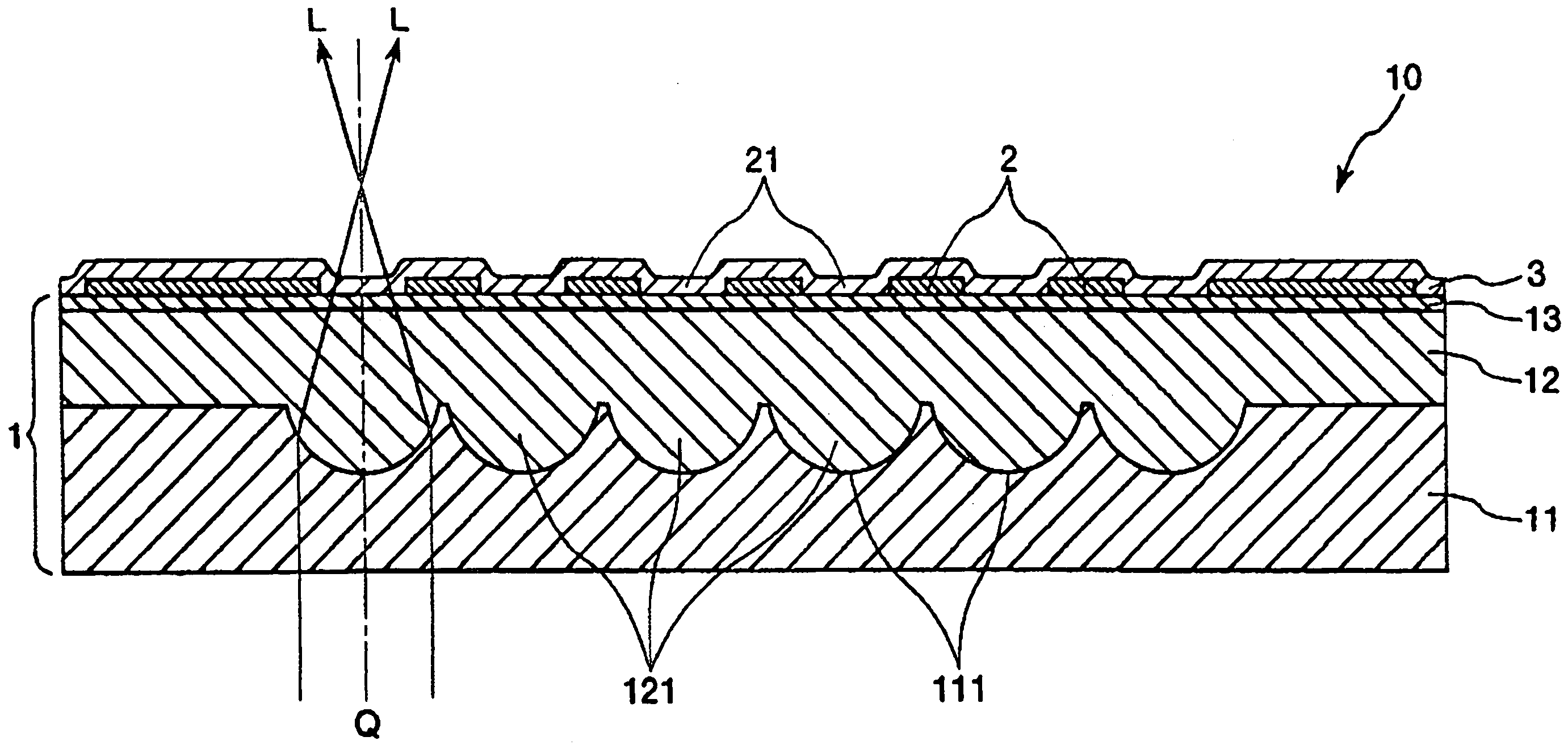

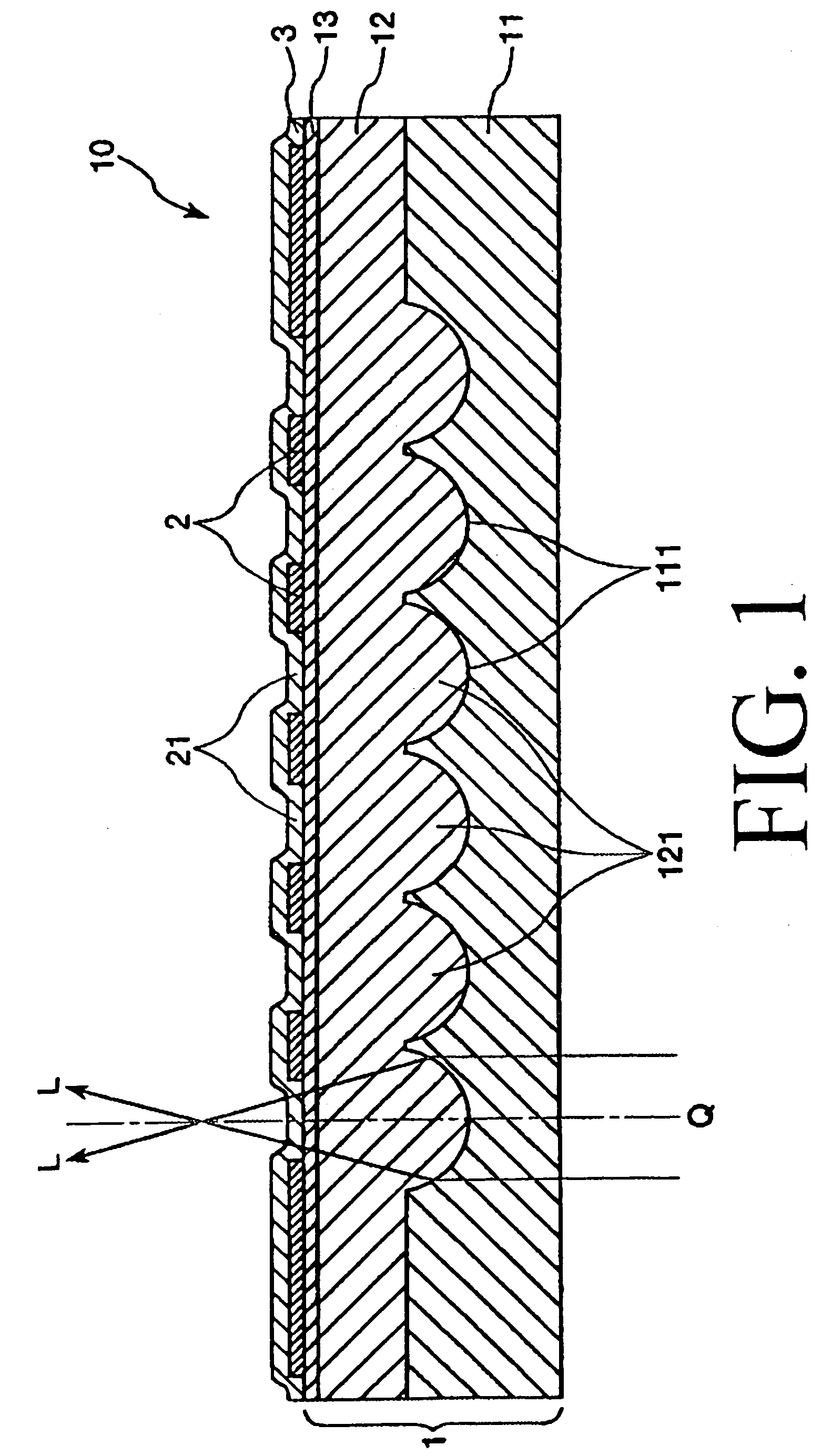

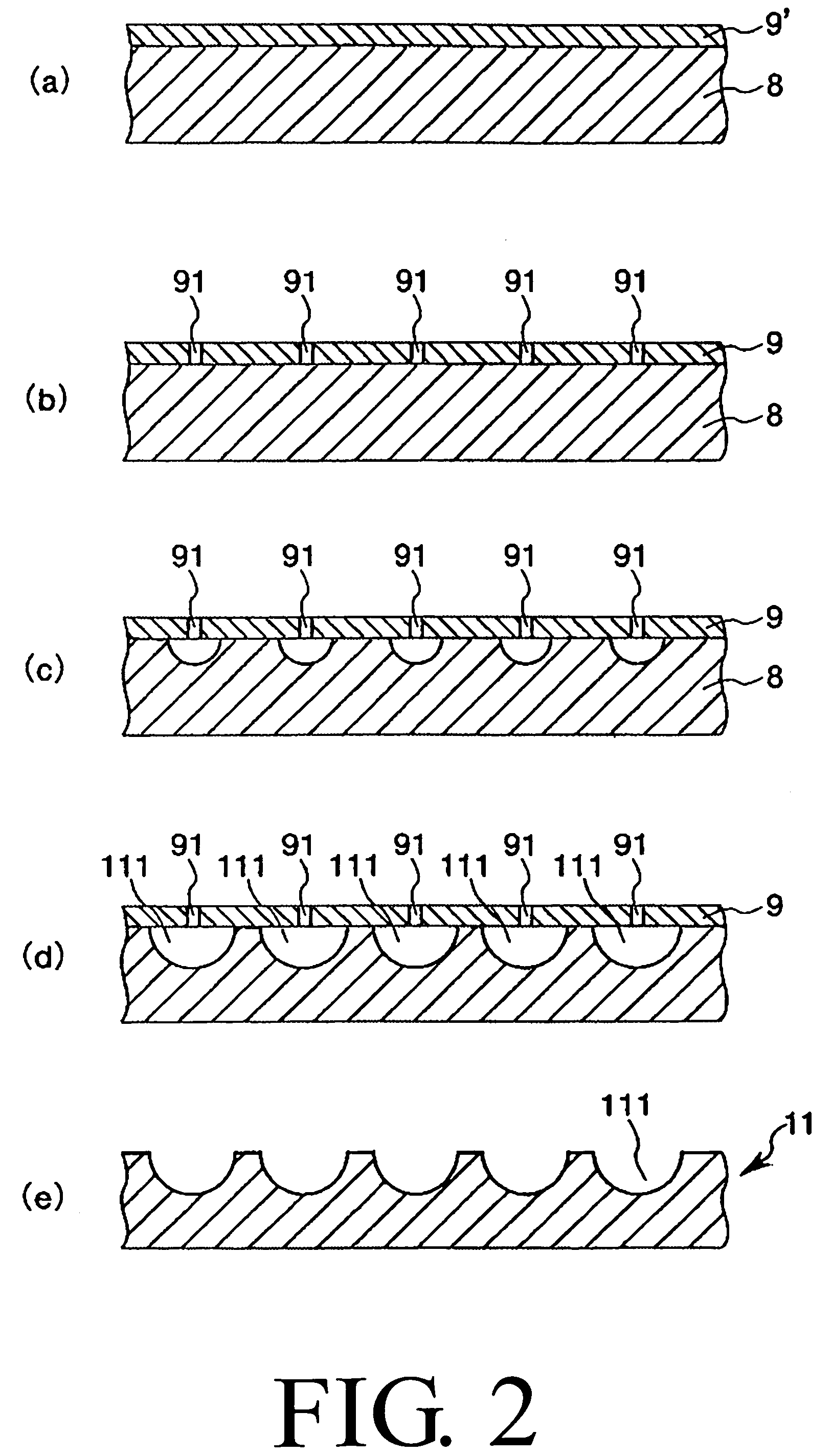

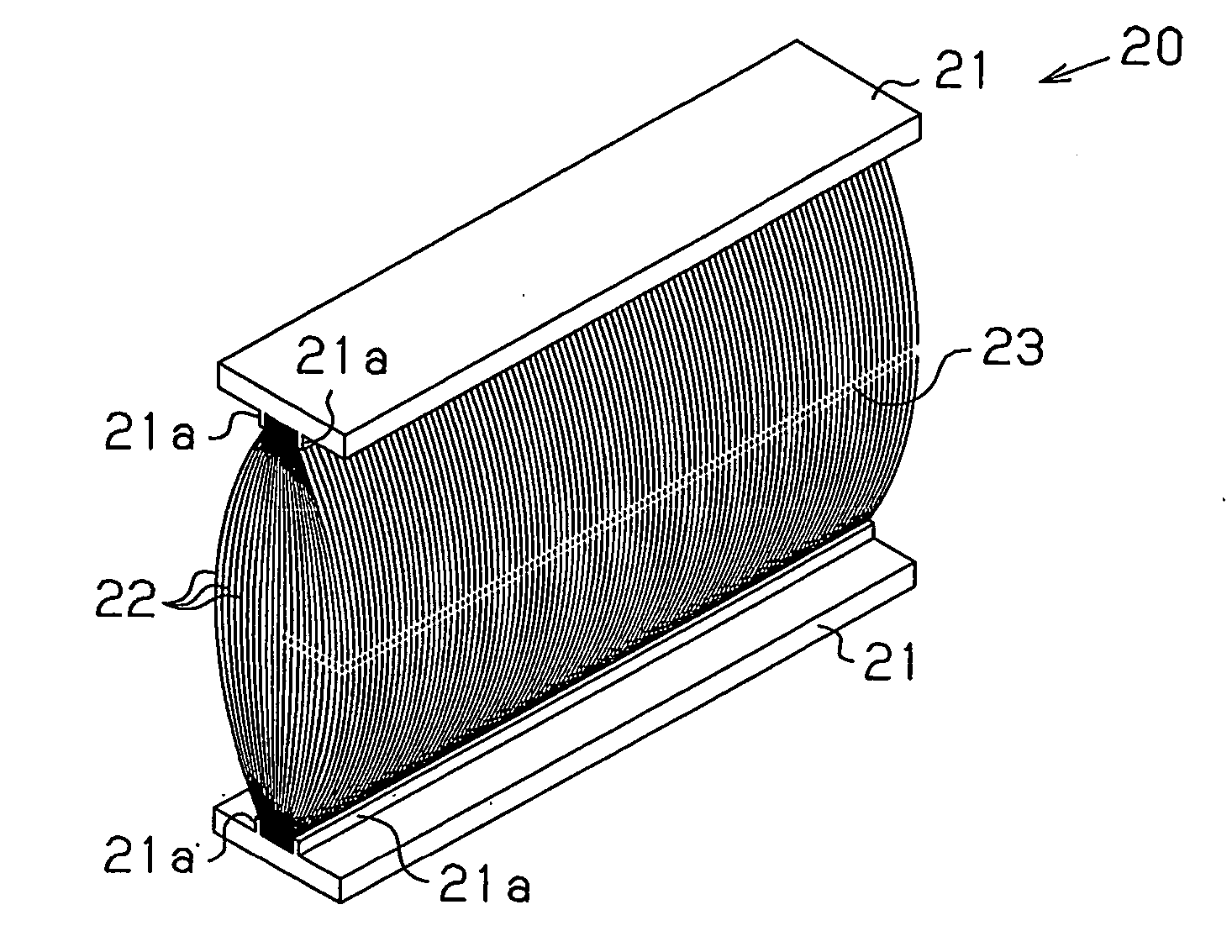

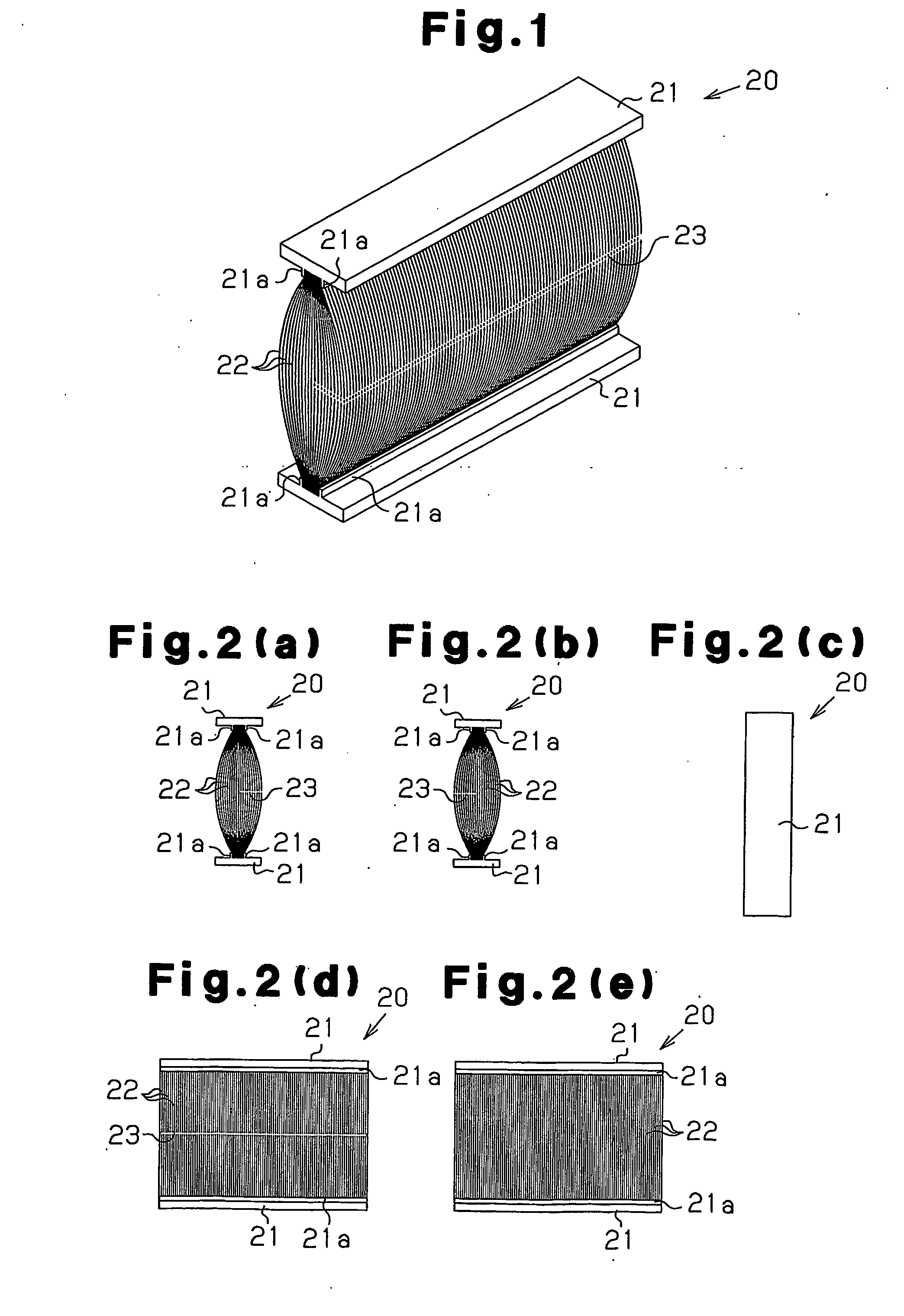

Microlens substrate, a method for manufacturing the microlens substrate, a liquid crystal panel, and a projection type display apparatus

InactiveUS20070047090A1Excellent optical characteristicIncreased durabilityProjectorsNon-linear opticsCompound (substance)Liquid crystal

A microlens substrate for an opposed substrate for use in a liquid crystal panel is provided. The microlens substrate includes: a substrate with concave portions having a plurality of concave portions; a convex lens substrate having convex lenses, each of the convex lenses having a shape corresponding to each of the concave portions, and the convex lens substrate being provided with respect to the substrate with concave portions so that the convex lenses are opposed to the corresponding concave portions, respectively; and a coating layer provided on the surface of the convex lens substrate which does not face the substrate with concave portions, the coating layer being mainly constituted of a product material produced by a reaction of a polysilazane compound with water, wherein the polysilazane compound is represented by the following formula (I): SiH2NHn (I) A method of manufacturing the microlens substrate, a liquid crystal panel provided with the microlens substrate, and a projection type display apparatus provided with the liquid crystal panel are also provided.

Owner:138 EAST LCD ADVANCEMENTS LTD

Process for manufacturing a wiring substrate

InactiveUS20050102830A1Accurate and reliableProvide reliablyInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentResistCopper plating

A process for manufacturing a wiring substrate, comprising: a step of forming thin copper film layers on surfaces of insulating resin layers by plating the same electrolessly with copper; a step of forming plated resists of a pattern over the thin copper film layers; a step of forming wiring pattern layers in clearances of the plated resists by plating the same electrolytically with copper; a step of removing the plated resists and the thin copper film layers just below the plated resists; a step of etching surfaces of the wiring pattern layers to remove a thickness of 1 μm or less from the wiring pattern layers; and a step of forming another insulating resin layers over the insulating resin layers and the wiring pattern layers etched.

Owner:NGK SPARK PLUG CO LTD

Microlens substrate, a method for manufacturing the microlens substrate, a liquid crystal panel, and a projection type display apparatus

InactiveUS7345821B2Excellent optical characteristic and durabilitySuitable for useProjectorsNon-linear opticsLiquid-crystal displayLiquid crystal

A microlens substrate for an opposed substrate for use in a liquid crystal panel is provided. The microlens substrate includes: a substrate with concave portions having a plurality of concave portions; a convex lens substrate having convex lenses, each of the convex lenses having a shape corresponding to each of the concave portions, and the convex lens substrate being provided with respect to the substrate with concave portions so that the convex lenses are opposed to the corresponding concave portions, respectively; and a coating layer provided on the surface of the convex lens substrate which does not face the substrate with concave portions, the coating layer being mainly constituted of a product material produced by a reaction of a polysilazane compound with water, wherein the polysilazane compound is represented by the following formula (I):A method of manufacturing the microlens substrate, a liquid crystal panel provided with the microlens substrate, and a projection type display apparatus provided with the liquid crystal panel are also provided.

Owner:138 EAST LCD ADVANCEMENTS LTD

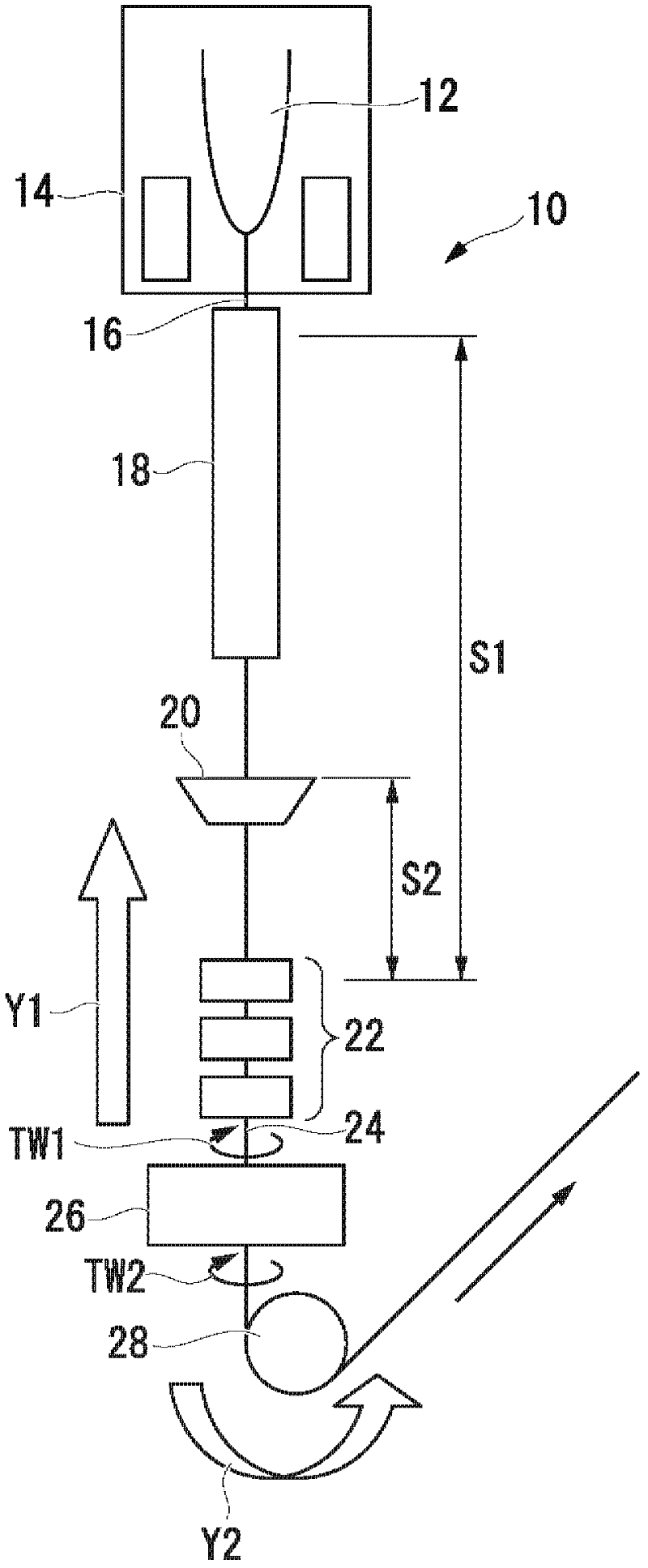

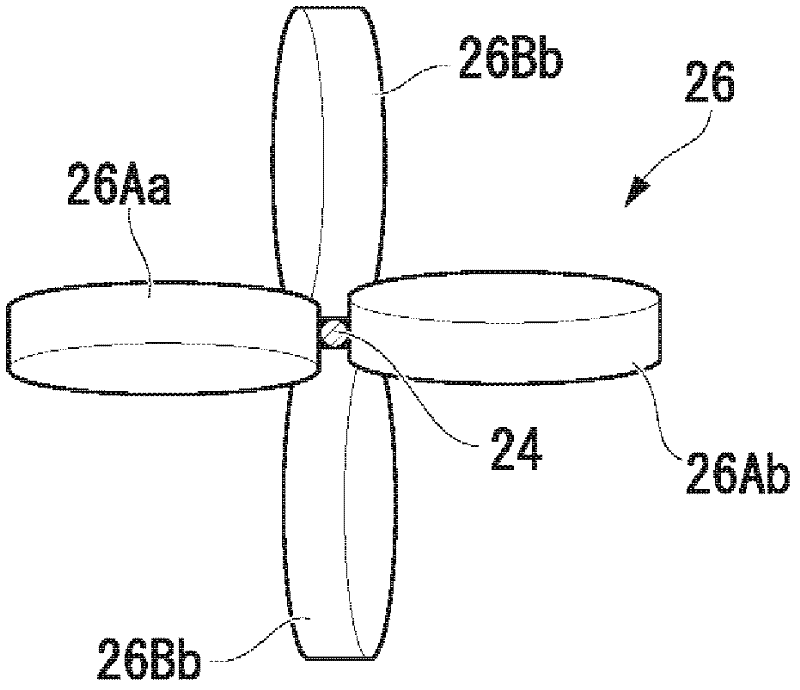

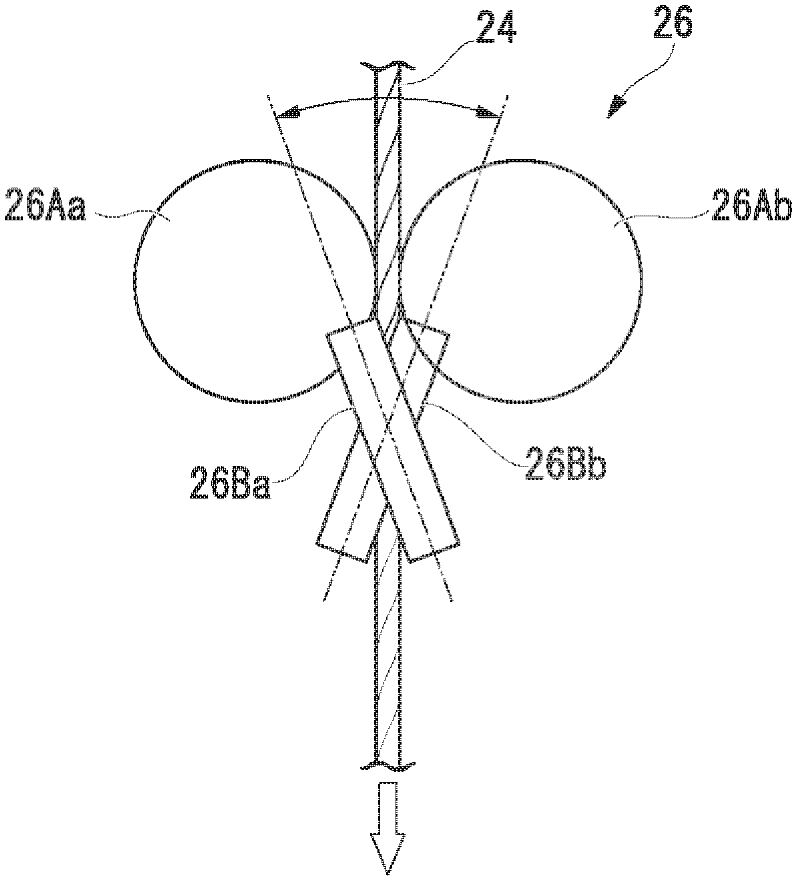

Optical fiber and method and apparatus for manufacturing optical fiber

ActiveCN102636837AElastic twist holdReliable and stable elastic twistCladded optical fibreGlass fibre drawing apparatusEngineeringOptical fiber cable

An optical fiber includes a bare optical fiber portion, to which elastic torsion is applied, and a coating layer, which coats the bare optical fiber portion, is formed of curable resin, and causes elastic repulsion against resilience occurring in the bare optical fiber portion so that the elastic torsion applied to the bare optical fiber portion is held.

Owner:FUJIKURA LTD

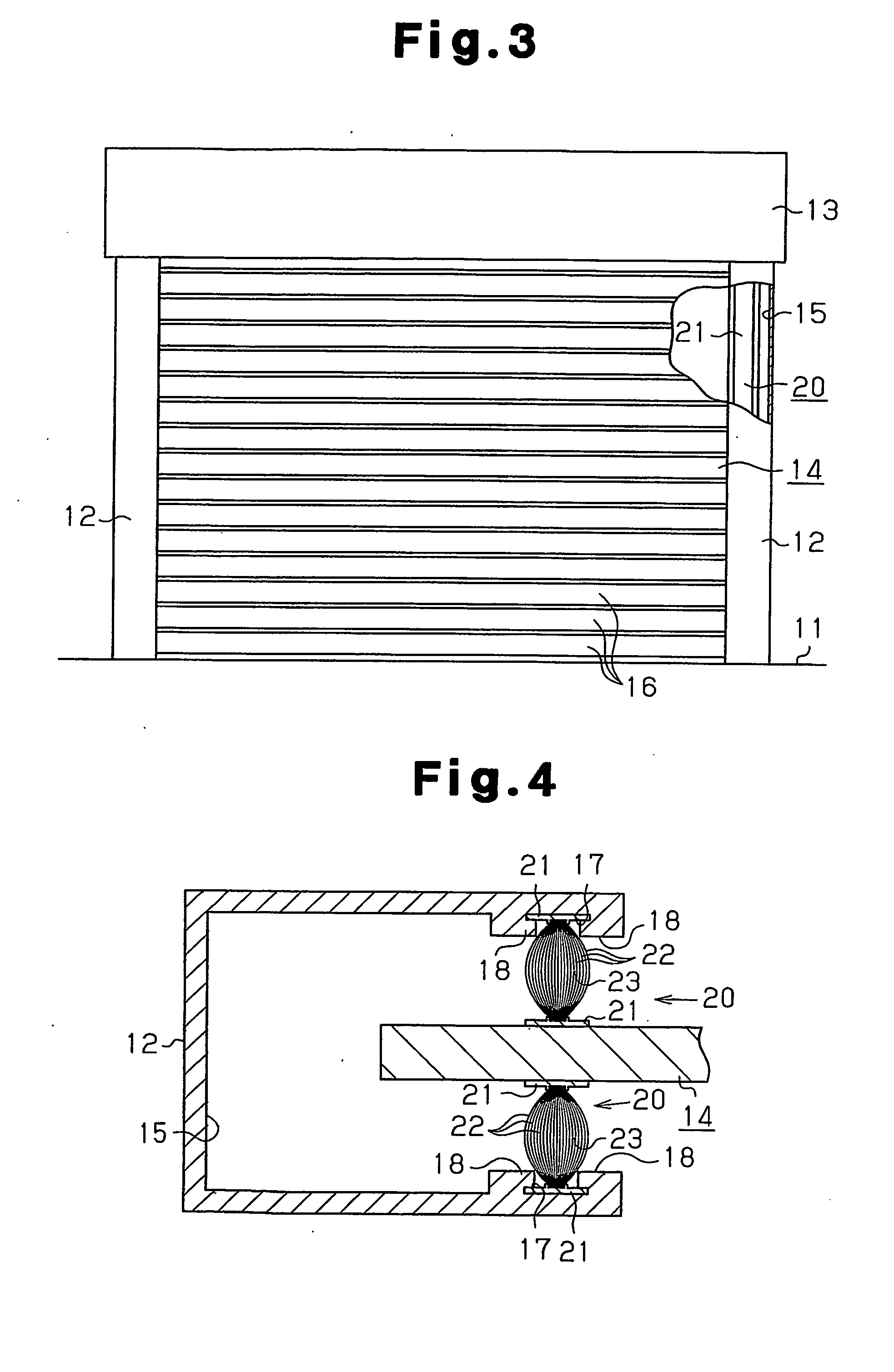

Cushioning member and method of manufacturing the same

InactiveUS20060049559A1Satisfactory cushioning functionSatisfy functionDoor/window protective devicesRubber-like material springsYarnEngineering

A cushioning member is located between each support frame and the corresponding side of the shutter. The cushioning member includes a pair of belt-shaped base members and pile yarns bridging between the base members. Some of the pile yarns are cut at intermediate portion between the base members, which forms opposing first and second cut pile yarns with a cut in between. One of the base members is attached to each support frame, and the other base member contacts the shutter. The cut permits the cushioning member to flexibly respond to movements of the shutter and satisfactorily exerts a cushioning function to suppress swaying of the shutter.

Owner:TSUCHIYA TSCO CO LTD +1

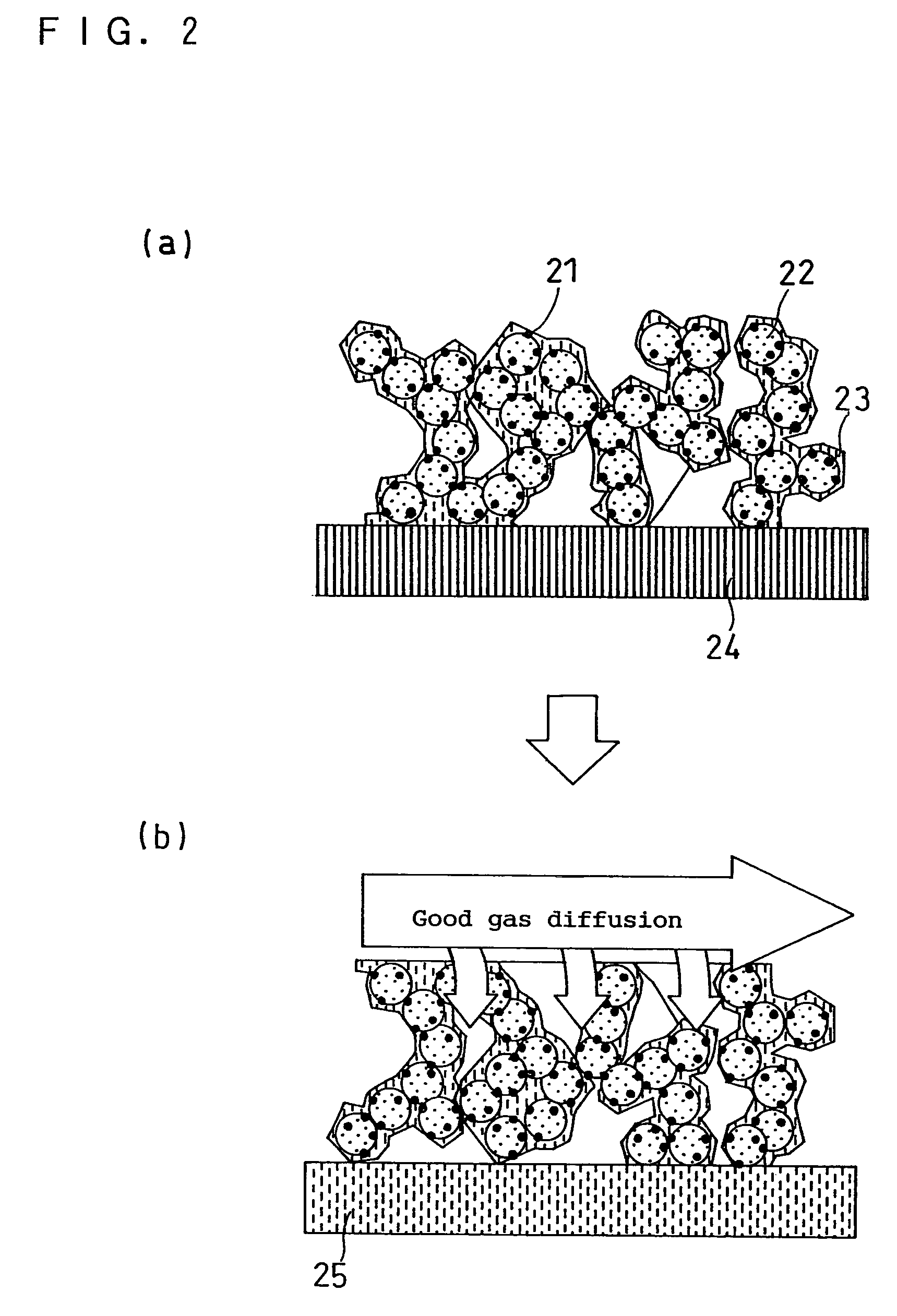

Ink for forming catalyst layer, and electrode and membrane-electrode assembly using the same

ActiveUS7364813B2Reliable and easy to manufacturePrevent floodingOrganic-compounds/hydrides/coordination-complexes catalystsFuel cell auxillariesHigh cellPolymer electrolytes

The present invention provides ink for forming a catalyst layer containing at least a cation conductive polymer electrolyte, catalyst-supporting particles including conductive carbon particles and an electrode catalyst supported thereon, and a dispersion medium, wherein the polymer electrolyte has a mean inertia radius of 150 to 300 nm. A catalyst layer made of the catalyst layer ink improves in gas diffusion property and increases cell voltage, which allows providing a proton conductive polymer electrolyte fuel cell capable of maintaining the high cell voltage for a long time.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com