Patents

Literature

96results about How to "Not prone to agglomeration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

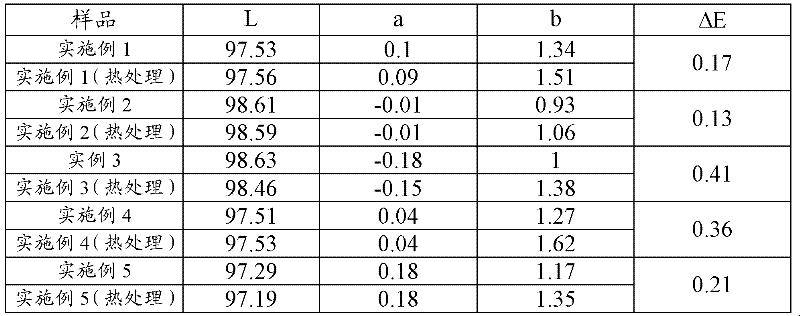

Method for preparing titanium dioxide pigment with high-temperature resistance

ActiveCN102199367AImprove temperature resistanceHigh whitenessPigment physical treatmentSlurryOperability

The invention discloses a method for preparing a titanium dioxide pigment with high-temperature resistance. The method comprises that: blending a primary titanium dioxide product into slurry by using distilled water or deionized water; regulating the slurry with pH value from 8 to 11 by using an alkaline solution; adding a dispersant, then performing a sand milling and filtering; heating the filtered slurry to the temperature of 50 DEG C to 75 DEG C and keeping the temperature unchanged in the whole process of coating; adding a sodium silicate aqueous solution, adding an acid solution for regulating the slurry with pH value of 8 to 11 and keeping the pH value unchanged; adding the acid solution to regulate the pH value of 2 to 7, then slaking; adding an aluminum salt aqueous solution, cocurrenting the acid solution or the alkaline solution for keeping the pH value unchanged, uniformly stirring after dropping; adding the alkaline solution to regulate the pH value of 6 to 8, then filtering, washing and drying after stirring, crushing by air flow and performing an organically treatment. According to the invention, the titanium dioxide pigment has the advantages of high temperature tolerance, good whiteness and good dispersibility. The method for preparing the titanium dioxide pigment with high-temperature resistance of the present invention has the advantages of good controllability, strong operability, low energy consumption and easy industrialization.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

Fluorine oxidized graphene/polyimide composite material, preparation method and application thereof

ActiveCN108484909AHigh tensile strengthReduce coefficient of frictionPolymer sciencePolymer composites

The invention discloses a fluorine oxidized graphene / polyimide composite material, a preparation method and application thereof. Active groups are contained in the surface of fluorine oxidized graphene, compared with graphene, an agglomeration phenomenon is unlikely to occur, the dispersibility inside a polymer is preferable, a relatively high mutual effect can be formed directly on the interfaceof the polymer, and the reinforced effect of the fluorine oxidized graphene inside the polymer composite material is realized; the fluorine oxidized graphene can be used for preparing the fluorine oxidized graphene / polyimide composite material; and the fluorine oxidized graphene / polyimide composite material has the characteristics of high tensile strength, low friction coefficient, low volume abrasion rate, corona resistance and the like. The fluorine oxidized graphene can be mixed with dianhydride monomers and diamine monomers, and through the steps of ultrasonic treatment, stirring, warmingand the like, the fluorine oxidized graphene / polyimide composite material is prepared and obtained. The fluorine oxidized graphene / polyimide composite material is simple and practical in preparation technology, convenient in operation and high in universality.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Treatment method for improving operating characteristics of nano-zinc oxide

ActiveCN107312362AOptimal treatment processImprove usage characteristicsPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsZno nanoparticlesNano zinc oxide

The invention discloses a treatment method for improving operating characteristics of nano-zinc oxide. The treatment method comprises the following steps of soaking modification treatment and deposition modification treatment. The prepared modified nano-zinc oxide has good dispersing characteristics, an agglomeration phenomenon is not likely to occur, the strength, corrosion resistance and temperature resistance of the nano-zinc oxide are very well improved, the compatibility with organic components are better, a filling usage effect is good, and the nano-zinc oxide has a popularization and usage value.

Owner:ANHUI JINHUA ZINC OXIDE CO LTD

Aerogel catalyst and preparation method thereof

ActiveCN102441370ANot prone to agglomerationHigh activityPhysical/chemical process catalystsCopolyesterBiodegradable polymer

The invention provides an aerogel catalyst. The aerogel catalyst is aerogel particles containing TiO2 and SiO2. The particle diameter of each aerogel particle is 10-200 nanometers, and the density of the aerogel particles is 30-600 mg / cm<3>. The invention also provides a preparation method of the aerogel catalyst. Biodegradable copolyester prepared by using the aerogel catalyst provided by the invention has higher polymerization degree, the distribution of molecular weights is more centralized, and the defect of yellow color of the biodegradable copolyester is relieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

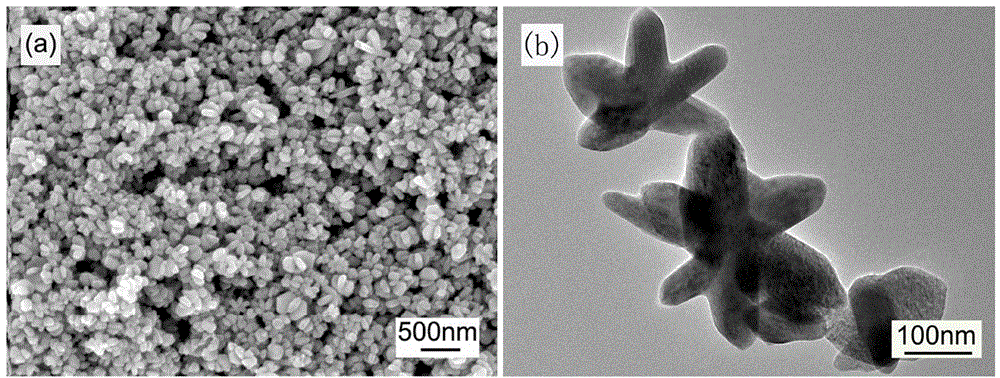

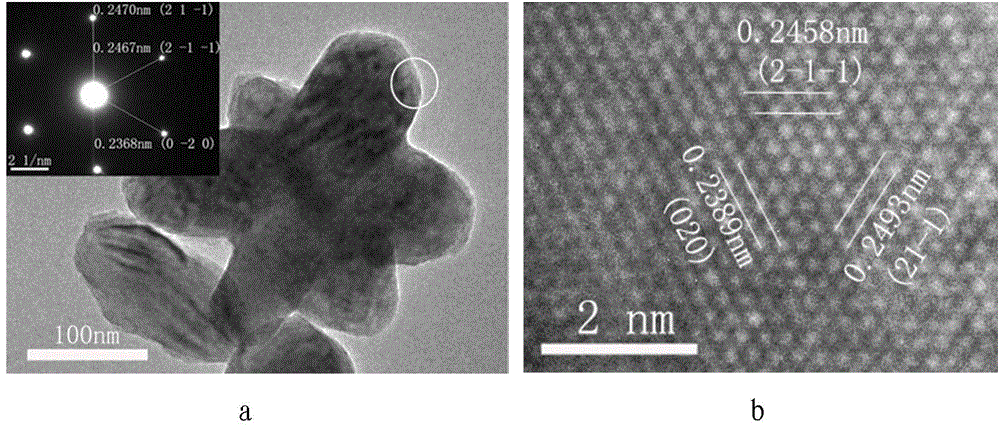

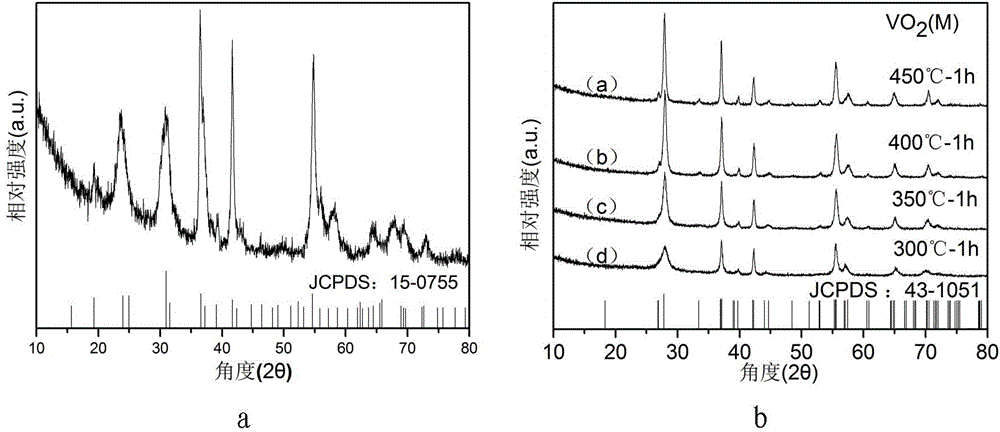

D-phase vanadium dioxide nano-star powder and preparation method thereof

ActiveCN104402050AImprove playbackGood dispersionMaterial nanotechnologyVanadium oxidesVanadium dioxideTemperature control

The invention relates to D-phase vanadium dioxide nano-star powder and a preparation method thereof. The powder is D-phase vanadium dioxide nano-star powder with a shape of pentagram or hexagram flat particles with the flat thickness of 30-60nm and the flat diameter of 60-100nm. Conical star point base thickness of the pentagram or hexagram particle is same with the flat thickness, conical star point base width is 30-60nm, and star point length is 70-100nm. The preparation method comprises the following steps: ammonium metavanadate is dissolved in deionized water, and the mixture is stirred, such that an ammonium metavanadate water solution is obtained; a formic acid solution is dropped into the ammonium metavanadate water solution being stirred, such that a mixed liquid with a pH value of 1-3 is obtained; the mixed liquid is set in a sealed state, and is allowed to react for 1-3d under a temperature of 180-220 DEG C, such that a reaction liquid is obtained; and the reaction liquid is sequentially subjected to solid-liquid separation, washing and drying, such that a target product is obtained. With subsequent heat treatment, obtained VO2(M) nano-star powder can be widely applied in the fields of intelligent temperature-control films, thermistor materials, photoelectric switch materials, infrared detection materials, gas sensors, storage materials, and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

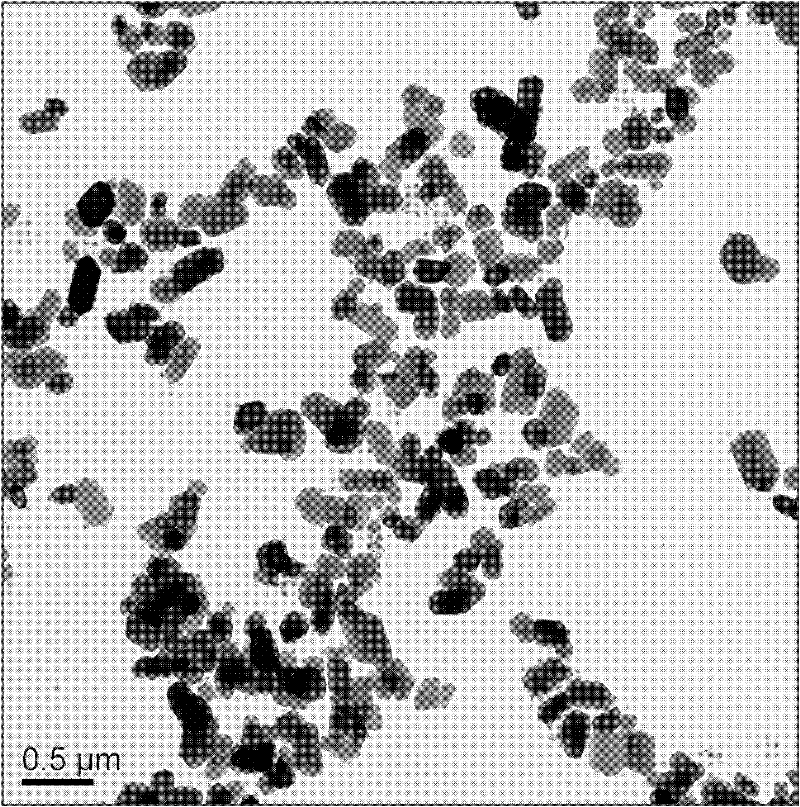

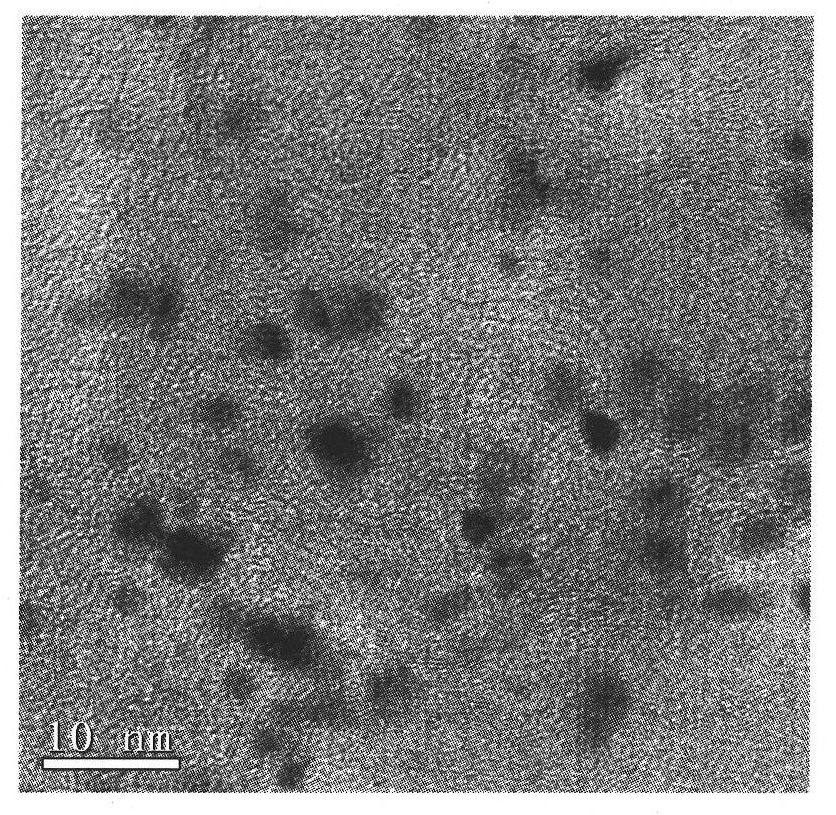

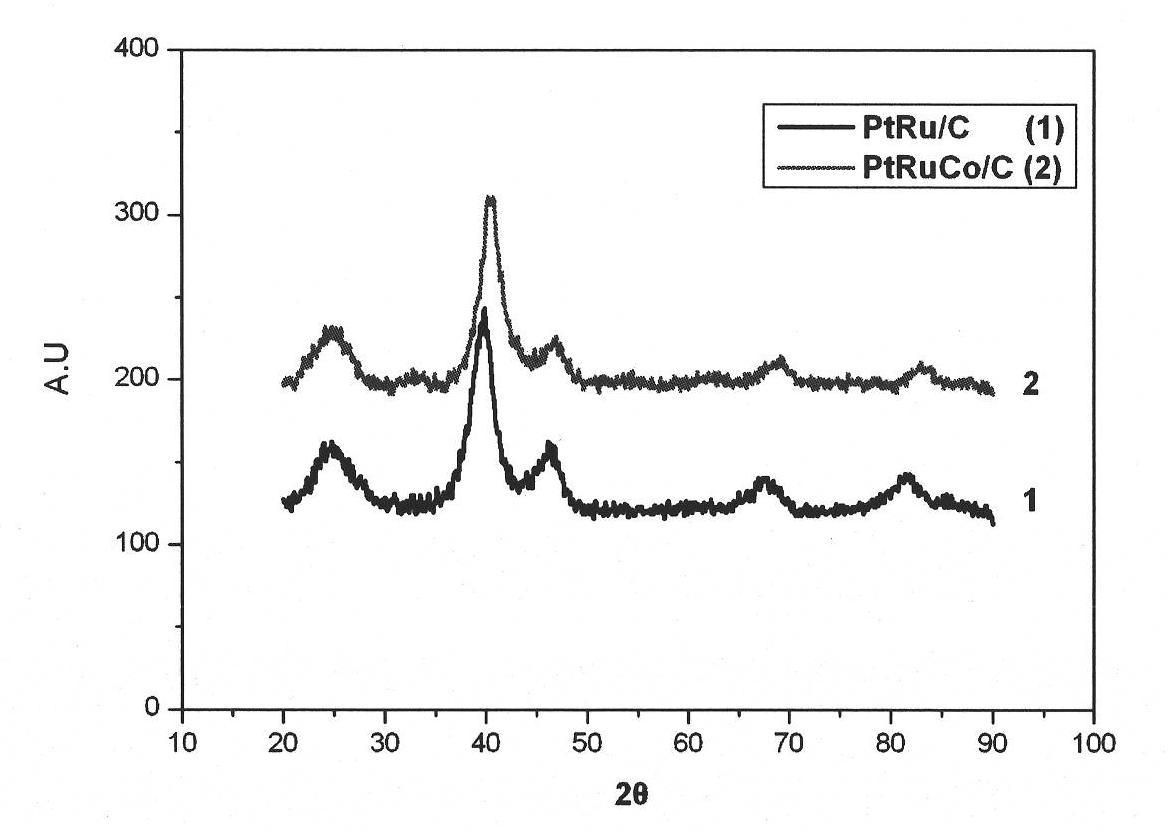

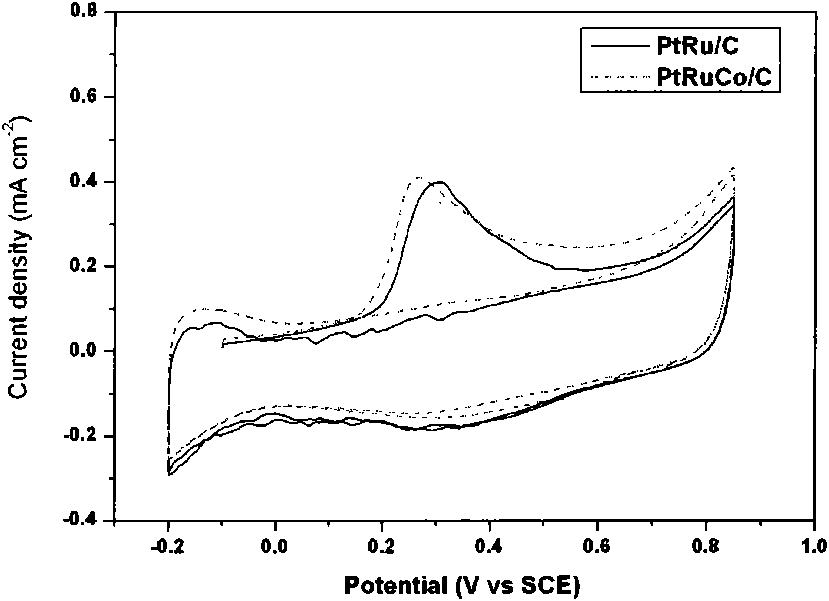

PtRuCo/C ternary alloy nano catalyst and preparation method thereof

ActiveCN101773839AEvenly dispersedNot prone to agglomerationCell electrodesMetal/metal-oxides/metal-hydroxide catalystsNano catalystIon

The invention discloses a PtRuCo / C ternary alloy nano catalyst and a preparation method thereof, and the method comprises the following steps: dissolving activated carbon in water, boosting the temperature to 40 DEG C, stirring by magnetic force, controlling the stirring velocity at 500r / min to form carbon slurry, dropwise adding H2PtCl6, RuCl3 and CoCl2 solution successively and slowly, adding trisodium citrate as a metal protective agent, carrying out ultrasound agitation, regulating the pH value of the solution to be 8 by NaOH, dropwise adding NaBH4 as a reducing agent slowly, reacting for 3h, vacuum filtering, rinsing until no chloride ion exists in the solution, and vacuum drying for 12h at the temperature of 70 DEG C to obtain the PtRuCo / C ternary alloy nano catalyst in the invention. The PtRuCo / C ternary alloy nano catalyst in the invention can greatly improve the ability of catalyzing methanol in fuel cells.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER +1

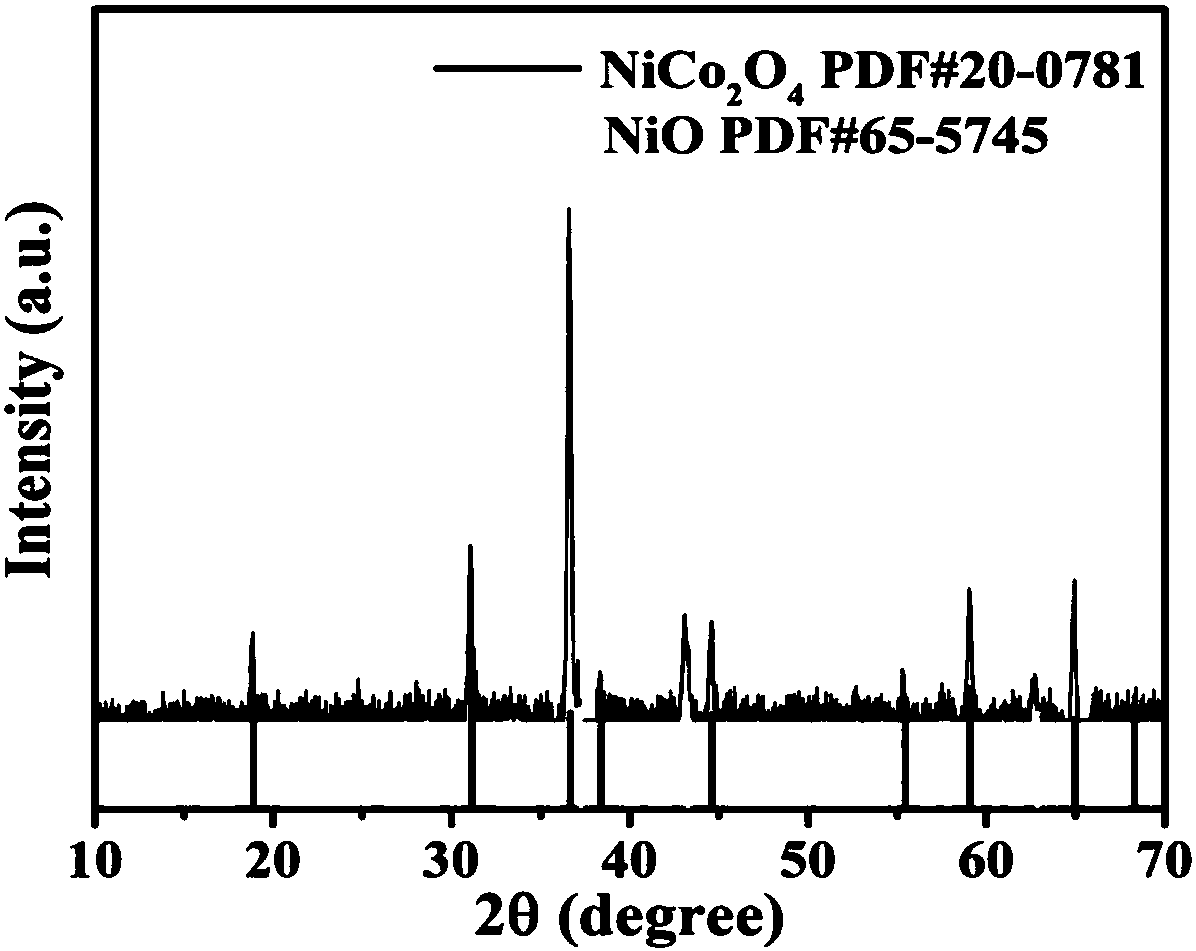

High performance urchin-like nickel oxide/nickel cobaltate microsphere lithium oxygen battery positive pole catalytic material and preparation method thereof

InactiveCN108493458AUniform particle sizeNot easy to reuniteFuel and secondary cellsCell electrodesNickel oxidesMicrometer

The invention provides a high performance urchin-like nickel oxide / nickel cobaltate microsphere lithium oxygen battery positive pole catalytic material and a preparation method thereof. The preparation material is sea urchin-like microspheres with uniform diameters of 3-10 micrometers, and nanoneedle structures are arranged neatly on the surface of the microspheres so that a high specific surfacearea is obtained. The catalytic material can be used for catalysis of a lithium oxygen battery. The urchin-like nickel oxide / nickel cobaltate microsphere material can be applied to the positive pole catalysis of a lithium oxygen battery, has a high specific capacity and excellent cycle stability, is prepared through simple processes of simple hydrothermal reaction and subsequent heat treatment andhas a great industrial production value and a practical application value.

Owner:SHANDONG UNIV

Hydrophilic anti-pollution polyether sulfone hollow fiber ultrafiltration membrane and preparation process thereof

InactiveCN103657455AGood dispersionNot prone to agglomerationSemi-permeable membranesDispersityFiber

The invention relates to a hydrophilic anti-pollution polyether sulfone hollow fiber ultrafiltration membrane and a preparation process thereof. The membrane is prepared from a polyether sulfone membrane casting liquid by using a nonsolvent phase separation method in a spinning mode, wherein the polyether sulfone membrane casting liquid comprises the following components by weight: a, an initial membrane casting liquid which comprises 10-30% of polyether sulfone resin, 40-60% of polar solvent and 5-20% of additive; b, aluminum silicon binary composite wrapping modified nanoscale titanium dioxide which accounts for 0.05-2% of the initial membrane casting liquid. The nano titanium dioxide which is subjected to surface modification is good in dispersity in the membrane casting liquid, agglomeration is not easy to happen, the prepared ultrafiltration membrane is high in water flux and high in pollution prevention performance, the operation pressure and the chemical washing frequency of the ultrafiltration membrane in an application condition are greatly reduced, and the membrane has a good application prospect.

Owner:JIANGSU MAYMUSE ENVIRONMENTAL TECH CO LTD

Aerogel catalyst and preparation method thereof

ActiveCN102443154ANot prone to agglomerationHigh activityBulk chemical productionPolymer scienceCopolyester

The invention provides an aerogel catalyst which is aerogel particle containing TIO2 and ZrO2, the particle diameter of the aerogel particle is 10-200mn, and the density is 30-600mg / cm<3>. The invention also provides a preparation method of the aerogel particle. Biodegradable copolyester prepared from the aerogel catalyst provided by the invention has high degree of polymerization and more intensive molecular weight distribution, and the detect that the color of the biodegradable copolyester is yellow color is alleviated.

Owner:CHINA PETROLEUM & CHEM CORP +1

Anti-mosquito environment-friendly wallpaper

InactiveCN106283789AImprove moisture resistanceImprove anti-agingAgeing prevention agents additionCovering/liningsEnvironmental resistanceFiber

The invention discloses anti-mosquito environment-friendly wallpaper, made from, by weight, 20-30 parts of used clothes, 10-20 parts of waste wood, 10-20 parts of straws, 2-5 parts of nano zinc oxide, 1-2 parts of chitosan, 2-8 parts of sodium sulfate, 10-25 parts of sodium hydroxide, 5-10 parts of cassava starch, 2-5 parts of butyl acetate, 1-2 parts of titanate coupling agent, 1-3 parts of cationic polyacrylamide, 1-2 parts of sodium cocoyl glycinate, 1-2 parts of azodiisobutyronitrile, 60-100 parts of deionized water, 20-30 parts of ethyl acetate, and 5-10 parts of Chinese herbal powder; the anti-mosquito environment-friendly wallpaper employs the used clothes, waste wood and straws as fiber bases, resources are effectively utilized, resource waste is avoided, and environment protection is achieved; the anti-mosquito environment-friendly wallpaper using the Chinese herbal powder as a plant material can dispel mosquitoes but is harmless to human bodies, and can soothe body and mind and calm the mind since containing nerve-soothing ingredients.

Owner:南宁东印时代广告有限公司

Preparation method of novel environment-friendly wallpaper

InactiveCN107245911AHigh tensile strengthImprove breathabilityFibreboardSpecial paperFiberAcetic acid

A preparation method of a novel environment-friendly wallpaper, comprising the following preparation steps: a, soaking plant fibers under vacuum conditions, taking them out, adding fluorine-containing aromatic carboxylic acid ball mills to the plant fibers to obtain material 1; b, making chitosan Dissolve in acetic acid aqueous solution, add gelatin, synthetic vegetable ester, dioctyl ester, stir to obtain material 2; c, after material 1 is subjected to pulping treatment and material 2, modified nano-zinc oxide, corn starch-polyacrylamide copolymer Mix, stir, and adjust pH to obtain material 3; d, add preservative to material 3, heat and stir, and send it to a molding machine for compression molding. The wallpaper prepared by the invention has strong tensile strength, good air permeability, non-toxic, odorless, safe and environment-friendly.

Owner:HEFEI DAZHUO ELECTRIC POWER CO LTD

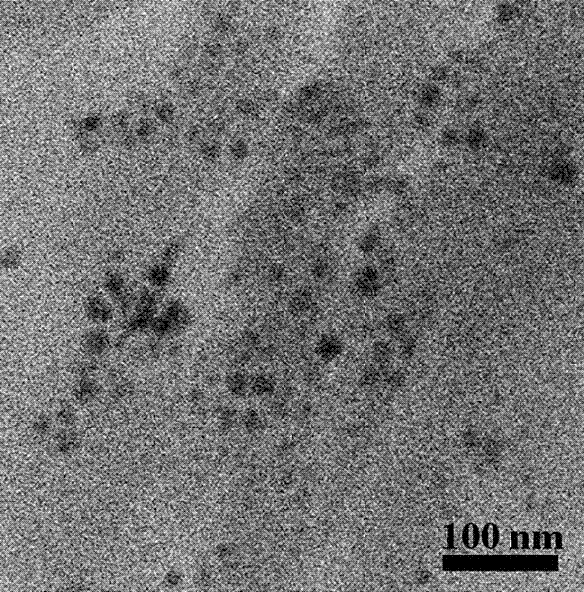

Preparation method of wear-resistant self-repairing sulfur-metal nanoparticles

The invention discloses a preparation method of wear-resistant self-repairing sulfur-metal nanoparticles. The preparation method comprises the following steps of: slowly adding a metal salt into a thiol compound of which the temperature is 60-150DEG C; vigorously stirring to obtain viscous fluid; and cooling the viscous fluid to obtain a solid namely the sulfur-metal nanoparticles. The sulfur-metal nanoparticles prepared by the method is small in diameter which is between 5 and 20 nm, has a good effect of repairing great abrasions including scratches and the like, can generate a full chemical reaction at a repaired part due to the small diameter, and also has a good effect of repairing fine abrasions including surface abrasions and the like; the surfaces of the sulfur-metal nanoparticles are provided with sulfur-bearing radicals, so that agglomeration of the nanoparticles cannot be generated easily, the metal nanoparticles can be kept in a monodisperse state in a short period or a long period of time, and the stability of the metal nanoparticles in oil phase media including lubricating oil and the like is lasting. The preparation method is simple and feasible, the purity of the product is high, and raw materials are easy to obtain and low in price.

Owner:SUZHOU FANGSHENG OPTOELECTRONICS CO LTD

Environmental-friendly wallpaper

InactiveCN106283791AImprove moisture resistanceImprove anti-agingAgeing prevention agents additionCovering/liningsFiberDimethyl siloxane

The invention discloses environmental-friendly wallpaper. The environmental-friendly wallpaper is prepared from the following materials in parts by weight: 20-30 parts of old clothes, 10-20 parts of cane trash, 10-20 parts of jute, 2-5 parts of nano zinc oxide, 1-2 parts of polydimethylsiloxane, 2-8 parts of sodium sulfide, 10-25 parts of sodium hydroxide, 5-10 parts of green bean starch, 2-5 parts of butyl acrylate, 1-2 parts of a silane coupling agent, 1-3 parts of cationic polyacrylamide, 1-2 parts of sodium dodecyl benzene sulfonate, 1-2 parts of ammonium persulfate, 60-100 parts of deionized water and 20-30 parts of ethanol. According to the environmental-friendly wallpaper disclosed by the invention, the old clothes, cane trash and jute serve as fiber base materials, the resources are effectively utilized, resource waste is avoided, and an environmental-friendly effect is achieved.

Owner:南宁东印时代广告有限公司

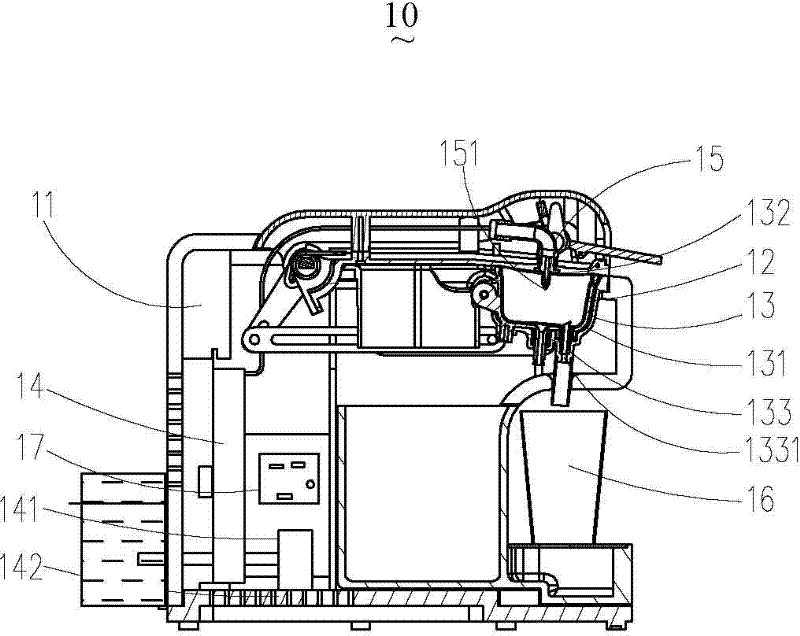

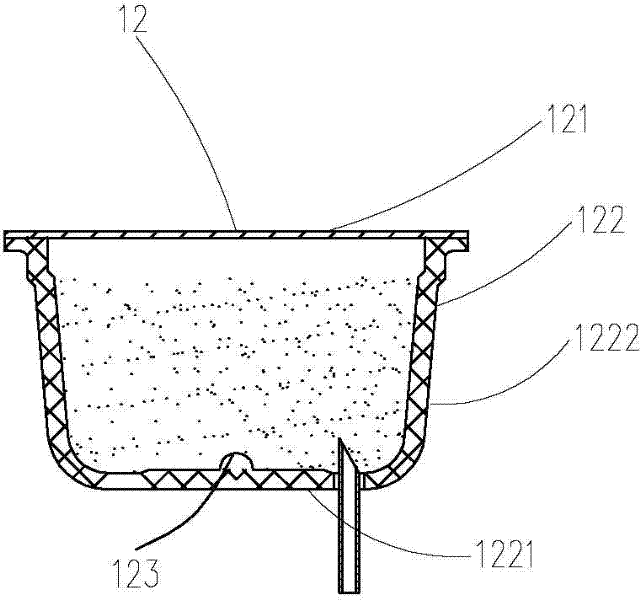

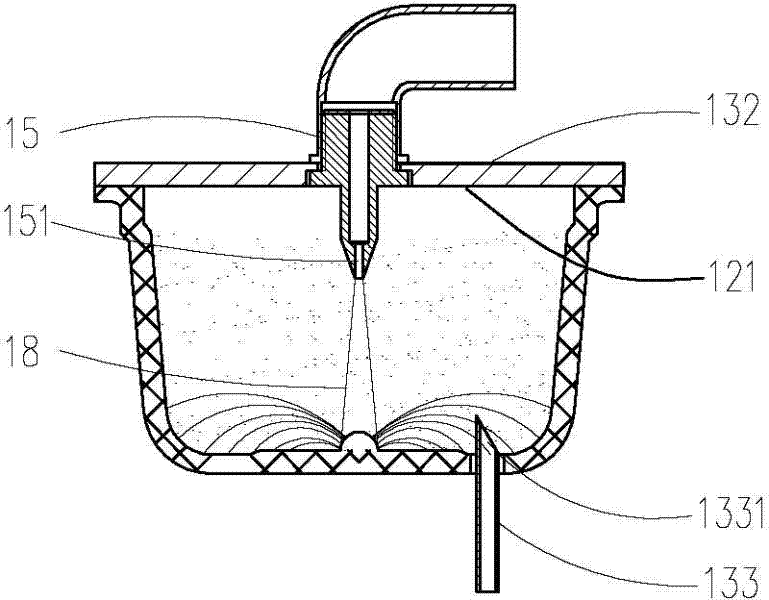

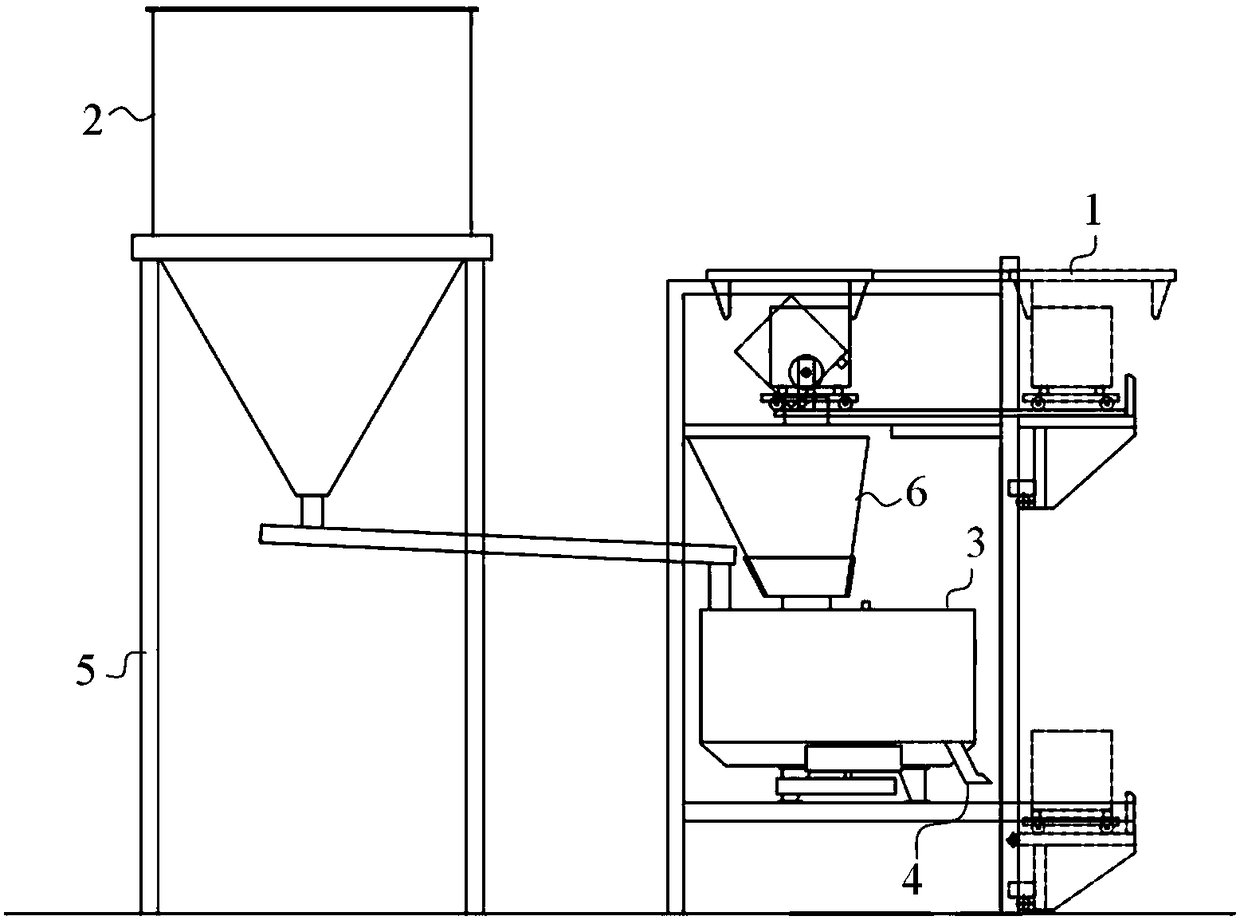

Bean flour refill bag, soybean milk manufacturing method and equipment for preparing soybean milk

ActiveCN102491006AIncrease the dissolution areaDissolve evenlyLiquid materialMilk substitutesMouthfeelSoybean oil

The invention relates to a bean flour refill bag, a soybean milk manufacturing method and equipment for preparing soybean milk. The bottom of the bean flour refill bag is provided with a backwash part; the soybean milk manufacturing method comprises the following steps of: (a) a pre-dissolution stage: providing an injection head, wherein the injection head passes through a diaphragm injection liquid so as to arrive in the refill bag, and the liquid penetrates through a bean flour layer so as to arrive at the bottom wall of the refill bag to form a fluid stream channel; and (b) a dissolution stage: leading the injection head to sequentially inject the fluid to the refill bag, wherein the liquid upward dissolves bean flour layer by layer from the bottom of the refill bag through the bottom wall backwash part of the refill bag until the refill bag is completely dissolved, providing an extraction hole which is deviated from an extended line of the injection head, and leading the soybean milk in the refill bag to eject through the extrusion of the extraction hole. According to the invention, the injection head is used for leading the injected liquid to penetrate through the bean flour layer so as to arrive at the bottom wall of the refill bag to form the fluid stream channel, the liquid is blocked through the backwash part and backwashes so as to form a 'spouting spring' effect, and the liquid can fully diffuse and increase the dissolution area; and the bean flour is not easy to have a conglomeration phenomenon in a dissolving process, thus the concentration of the prepared soybean milk is uniform, and the mouthfeel is better.

Owner:杭州易杯食品科技有限公司

Insulating coating for electrical equipment and preparation method of insulating coating

InactiveCN108864794AGood adhesionImprove corrosion resistanceFireproof paintsAnti-corrosive paintsEmulsionPhosphate

The invention provides an insulating coating for electrical equipment and a preparation method of the insulating coating. The insulating coating is prepared from the following components: organic resin, an acrylate emulsion, calcium carbonate, silicon nitride, titanium dioxide, hollow glass microbeads, sepiolite, acetone, glycol, a phosphate modified acrylic leveling agent, a dispersant, a curingagent, a titanate coupling agent and water. The preparation method provided by the invention is simple and practicable, the preparation process is non-polluting, the prepared insulating coating has good adhesion and corrosion resistance, also has good flame retardancy and insulativity, and is environmentally-friendly, the safety is improved, and the service life of electrical equipment is prolonged.

Owner:HEFEI MINGYOU HIGH TEMPERATURE TECH CO LTD

Oral iron supplement for livestock and preparation method thereof

The invention provides an oral iron supplement for livestock and a preparation method. The oral iron supplement for the livestock adopts a dosage form of an oil-based suspension, and is prepared by mixing a compound iron supplement, liquid oil, a wetting agent, a flavoring agent, an antioxidant and a viscosity modifier according to a certain proportion and then grinding by using a bead mill. The oral iron supplement for the livestock is high in iron content and good in fluidity, uses the oil as a solvent, is good in palatability, is especially suitable for supplementing iron and zinc to newborn animals, and can effectively prevent iron deficiency anemia of piglets, cattle and sheep; the oral iron supplement for the livestock can be quantitatively administrated by using a hand-operated pump, with easy and convenient operation, and compared with an intramuscular iron supplementation, administration by using the hand-operated pump has the advantages as follows: animal stress can be reduced, the carcass quality is not affected, other nutrients needed by young livestock can be supplemented at the same time, the labor intensity of artificial injection can be reduced and the productivity is improved.

Owner:ANYOU BIOTECH GRP

Preparation method of modified fullerene material

The invention relates to a preparation method of a modified fullerene material. After nanometer TiO2 is processed with argon plasma, the surface energy of the nanometer TiO2 can be reduced, thus beingliable to uniform dispersionand not prone to clustering phenomenon; by utilizing the modified fullerene-loaded nanometer TiO2 and La<3+>, the antibacterial property of an ABS composite material can be well improved, and the anti-static performance function of PBT can be promoted, so that the antibacterial property and antistatic performance of the prepared polyolefin material can be greatly improved. The preparation method is very worthy of popularization.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Pure gum for emulsifying essence and its preparing process

A pure glue for emulsified essence is prepared from animal's protein pwoder and granular emulsifier through mixing. The animal's protein pwoder is prepared from animal protein through dissolving in water, adding enzyme for zymolysis, deactivating enzyme, filtering and drying. The granular emulsifier is prepared from tween-80, sucrose ester and monoglyceride through thermal fusing, cooling, granulating and drying. Its advantages are low cost, and better fusibility, emulsion stability, and thickening performance.

Owner:韦大文

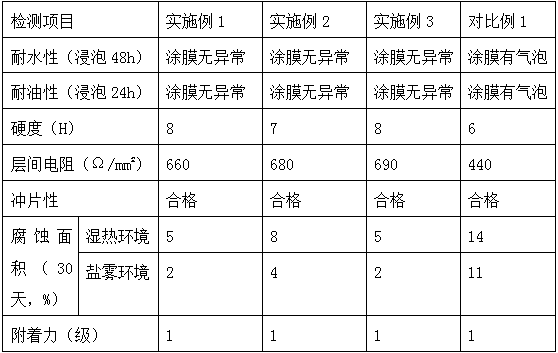

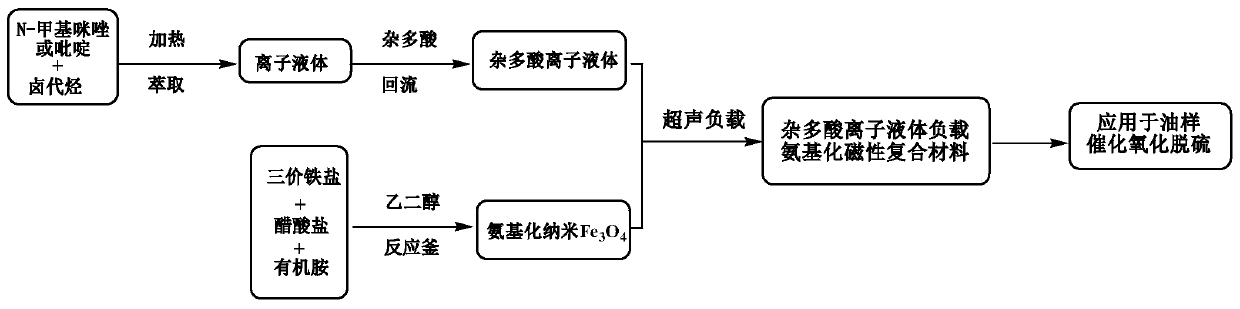

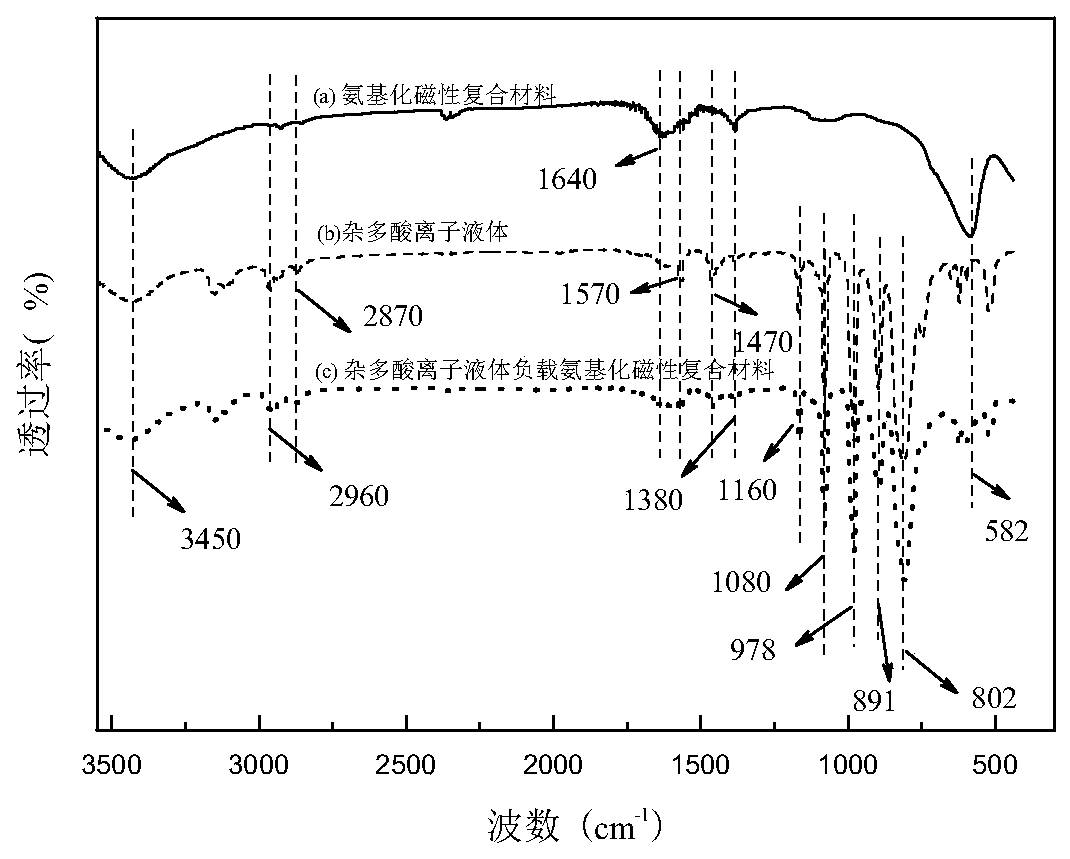

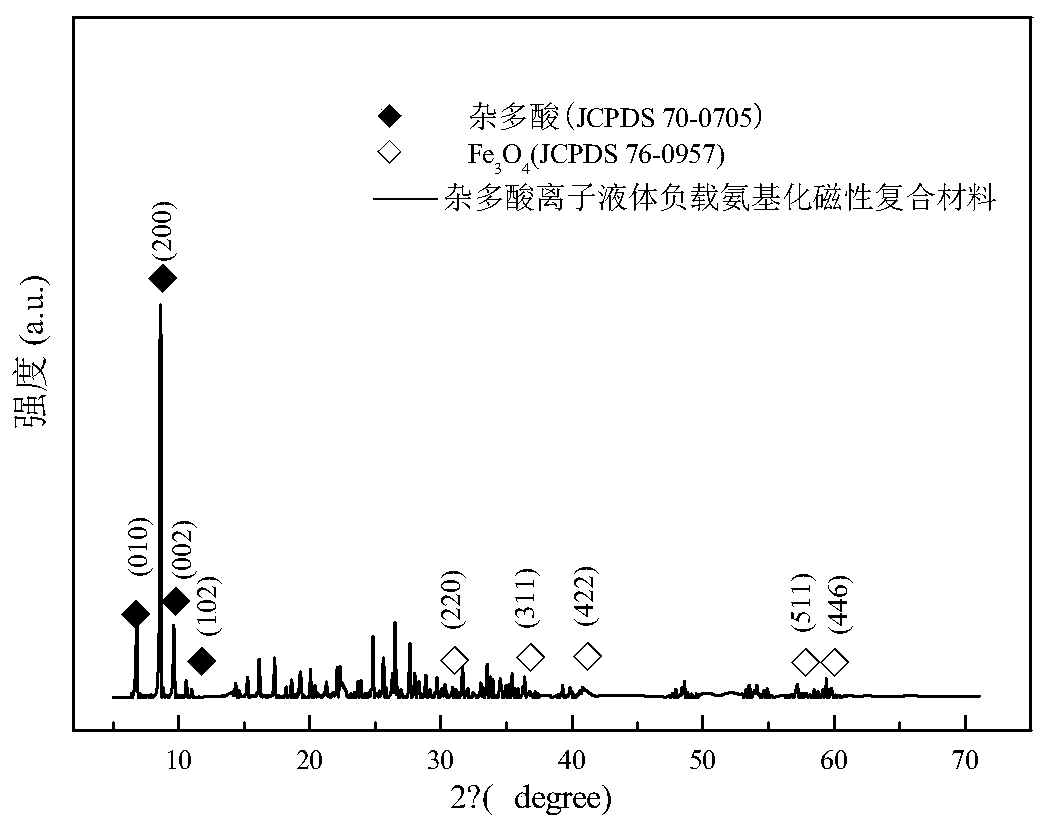

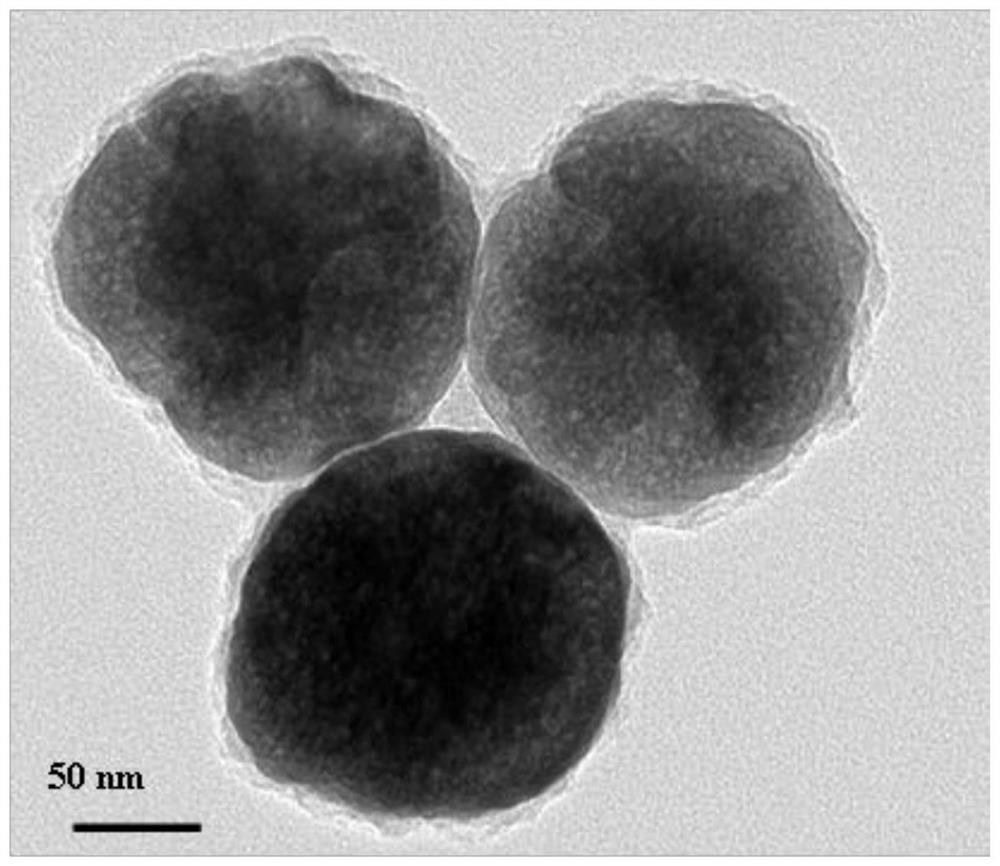

Heteropolyacid ionic liquid supported aminated magnetic composite of date cake structure, preparation method and application

ActiveCN109908962AEasy reunionSimplify operation stepsOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsChemistryPetroleum

The invention discloses a heteropolyacid ionic liquid supported aminated magnetic composite of a date cake structure, a preparation method and an application. The composite is prepared from raw materials including a heteropolyacid ionic liquid and an aminated magnetic composite by supporting the heteropolyacid ionic liquid on an aminated nano magnetic material with an ultrasonic immersing method.The preparation steps are shown as follows: firstly, the heteropolyacid ionic liquid is prepared through a substitution reaction, the aminated magnetic composite is prepared with a solvothermal method, and the heteropolyacid ionic liquid supported aminated magnetic composite is prepared with an ultrasonic supporting method. The product obtained with the method is powdery and brown, has uniform particle size distribution and has the date cake structure and stable properties. The defect of high probability of agglomeration of the magnetic materials is overcome, and the obtained material has gooddispersity, high magnetism and high yield, and raw materials are easy to obtain; the composite has magnetism and catalytic activity and can be effectively used for a catalyst for desulfuration of petroleum samples, and the catalyst can be separately recycled.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

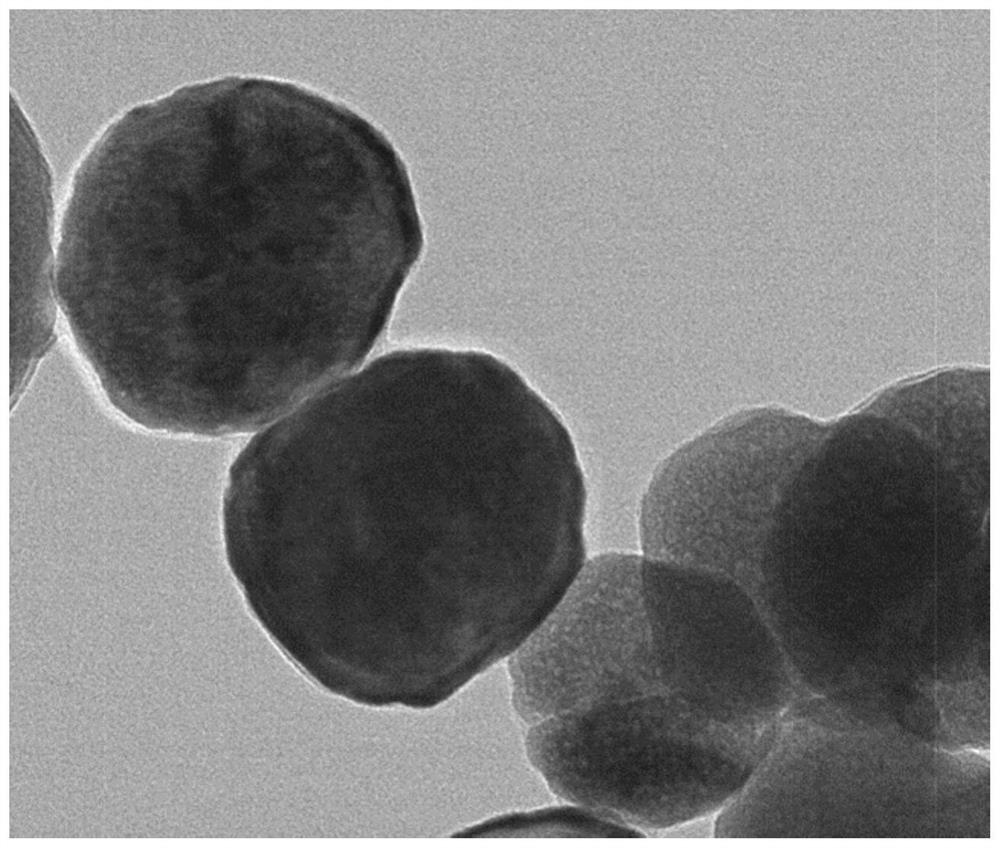

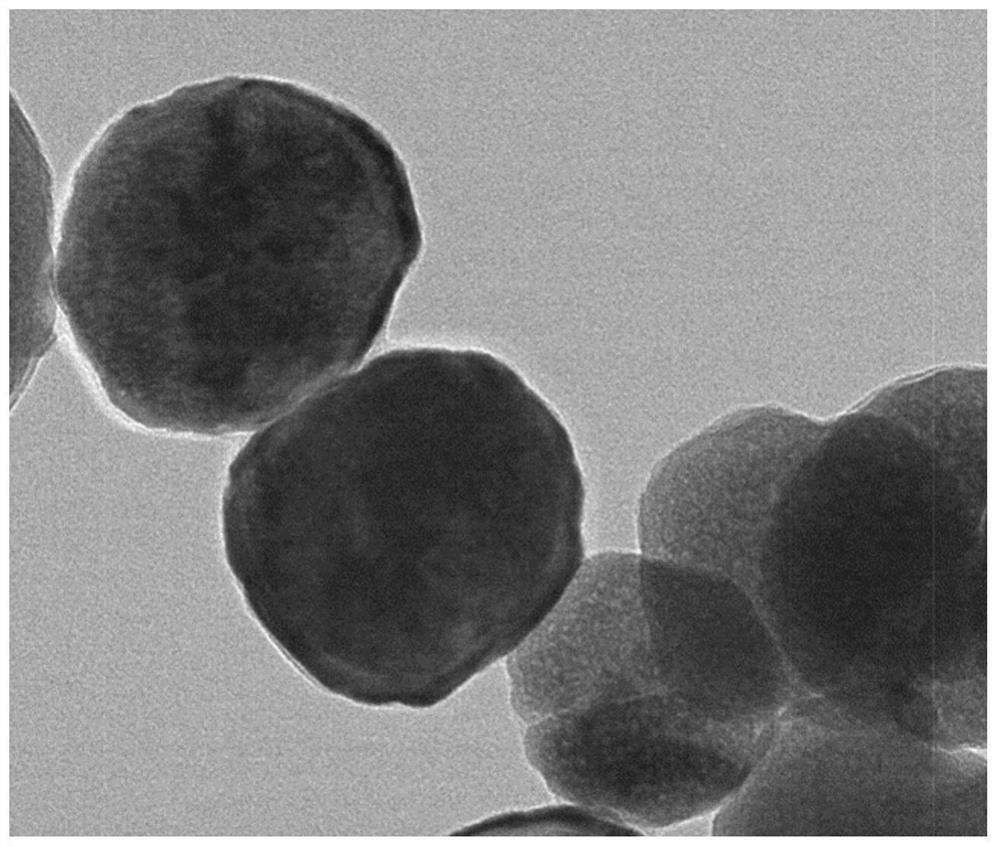

Magnetic core-shell nano-microsphere for adsorbing phenolic pollutants as well as preparation method and application

ActiveCN112791714AImprove compatibilityImprove adsorption efficiencyOther chemical processesWater contaminantsPollutantMagnetite Nanoparticles

The invention provides a magnetic core-shell nano-microsphere for adsorbing phenolic pollutants, a preparation method and application. The method comprises the following steps: preparing a nanoscale adsorption carrier; carrying out first modification on the nanoscale adsorption carrier to obtain a first modified adsorption carrier; performing secondary modification on the first modified adsorption carrier to obtain a second modified adsorption carrier; and carrying out polymerization reaction on the second modified adsorption carrier to obtain the magnetic core-shell nano-microsphere. The invention solves the problem that the adsorption operation of a magnetic adsorbent is influenced because the compatibility of magnetic nanoparticles and a polymer is destroyed if the magnetic adsorbent is subjected to adsorption operation in a high-temperature environment because only one-time modification is carried out on the magnetic nanoparticles in an existing preparation process of the magnetic porous adsorbent.

Owner:SHANDONG ACAD OF ENVIRONMENTAL SCI CO LTD +1

Waste emulsion sludge treatment method

ActiveCN109385321ALow costThe treatment method is economical and practicalBiofuelsSolid fuelsEmulsionPrill

The invention discloses a waste emulsion sludge treatment method, and belongs to the field of industrial waste treatment methods. The waste emulsion sludge treatment method comprises the following steps: 1, proportioning materials: quantitatively proportioning waste emulsion sludge and fly ash for next-step operation; 2, mixing: mixing materials proportioned in the proportioning step, namely repeatedly performing rolling, stirring and mixing operation thereon to obtain powdery particles; 3, discharging: outputting a finished product obtained in the mixing step, wherein the water content of thefly ash proportioned in the proportioning step is lower than or equal to 1%, the water content of the waste emulsion sludge is lower than or equal to 50%, and the content of particles with the particle size being smaller than or equal to 1mm in the proportioned fly ash is higher than or equal to 90%. According to the waste emulsion sludge treatment method, no chemical reaction occurs and no new pollutant is produced during treatment, two industrial wastes, namely the waste emulsion sludge and the fly ash, are treated, the obtained product can be fully burned as a fuel, the treatment cost is low, the treatment method is simple, the problem that the existing waste emulsion sludge is difficult to treat is solved, and industrialized application is easy.

Owner:马钢集团设计研究院有限责任公司

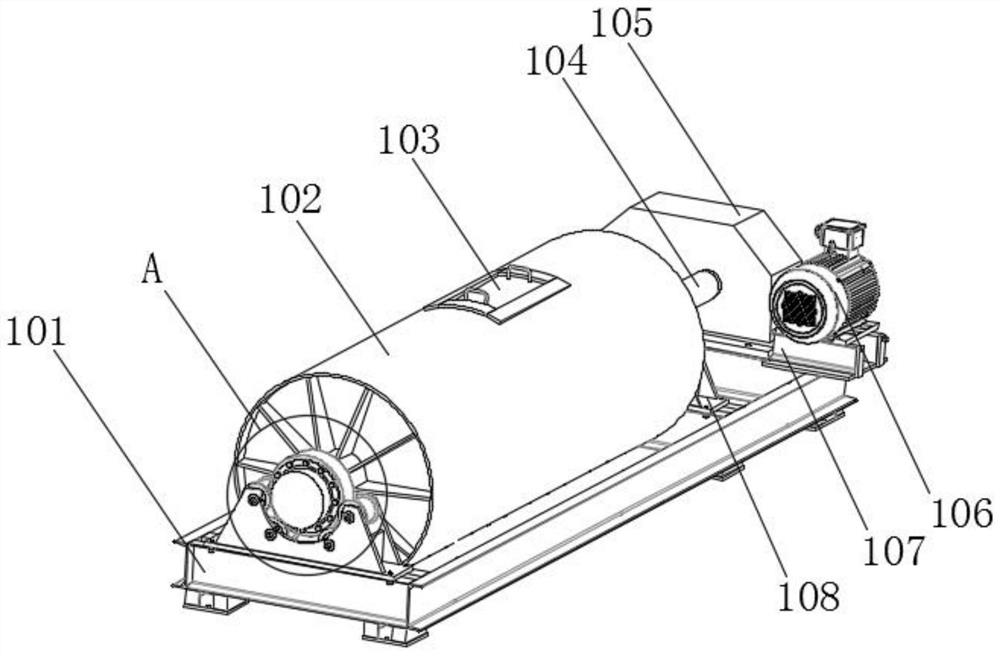

Biomass spiral-vibration electromagnetic induction pyrolysis reactor and pyrolysis treatment method thereof

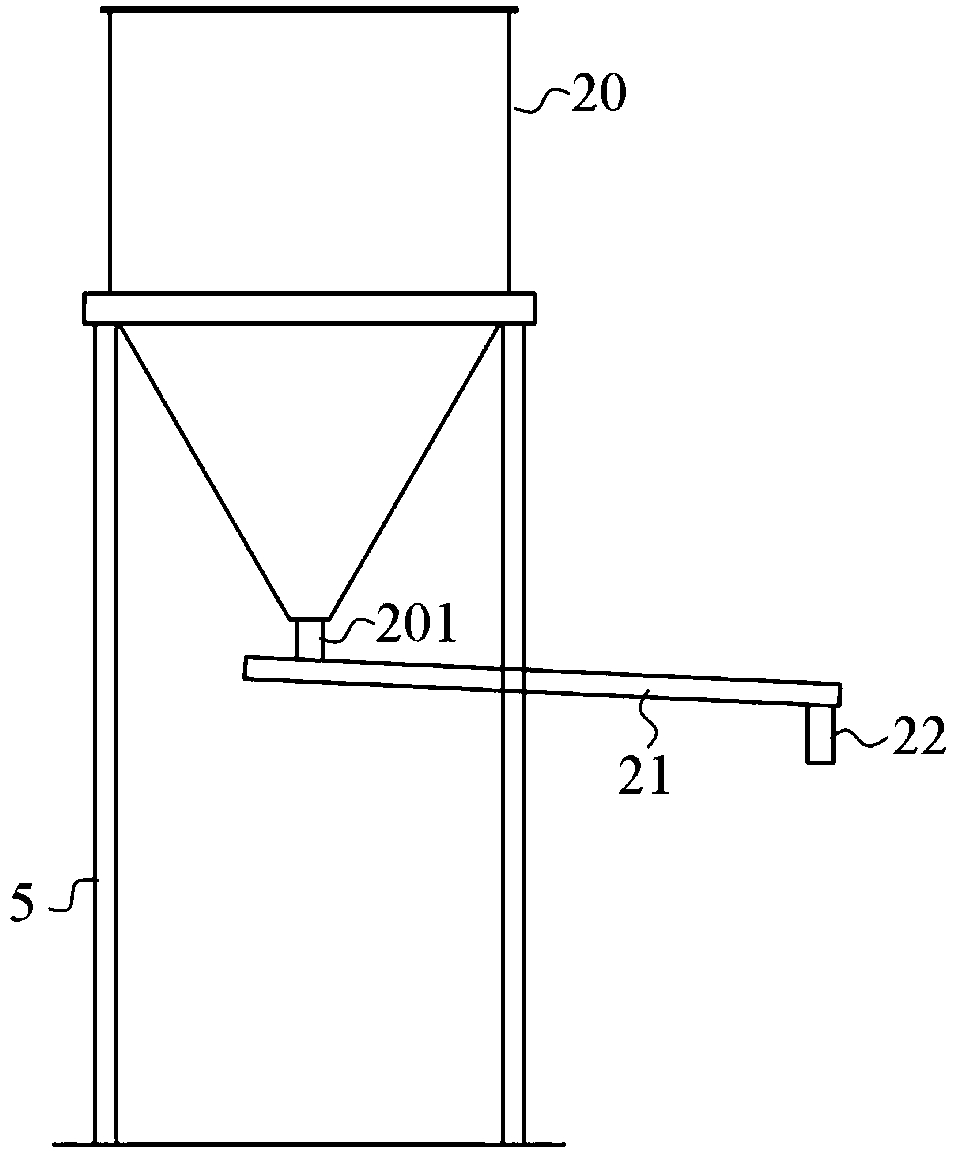

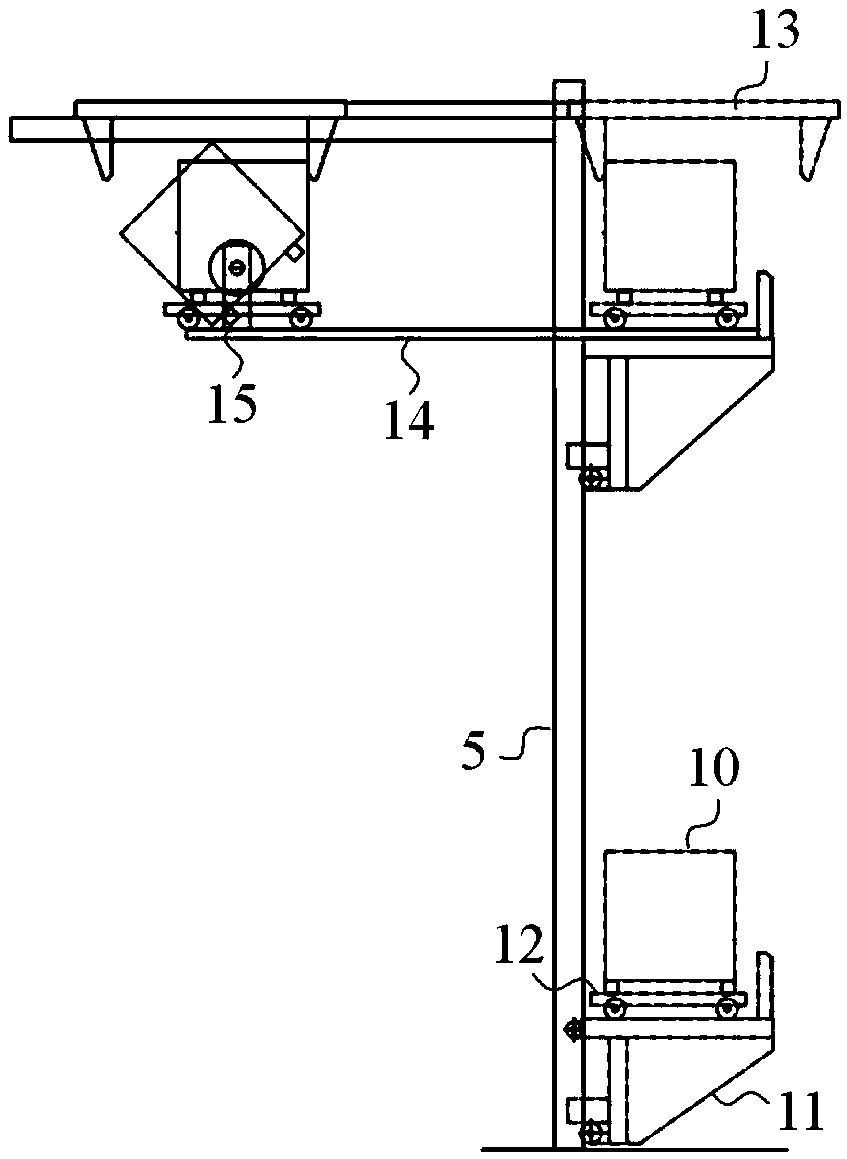

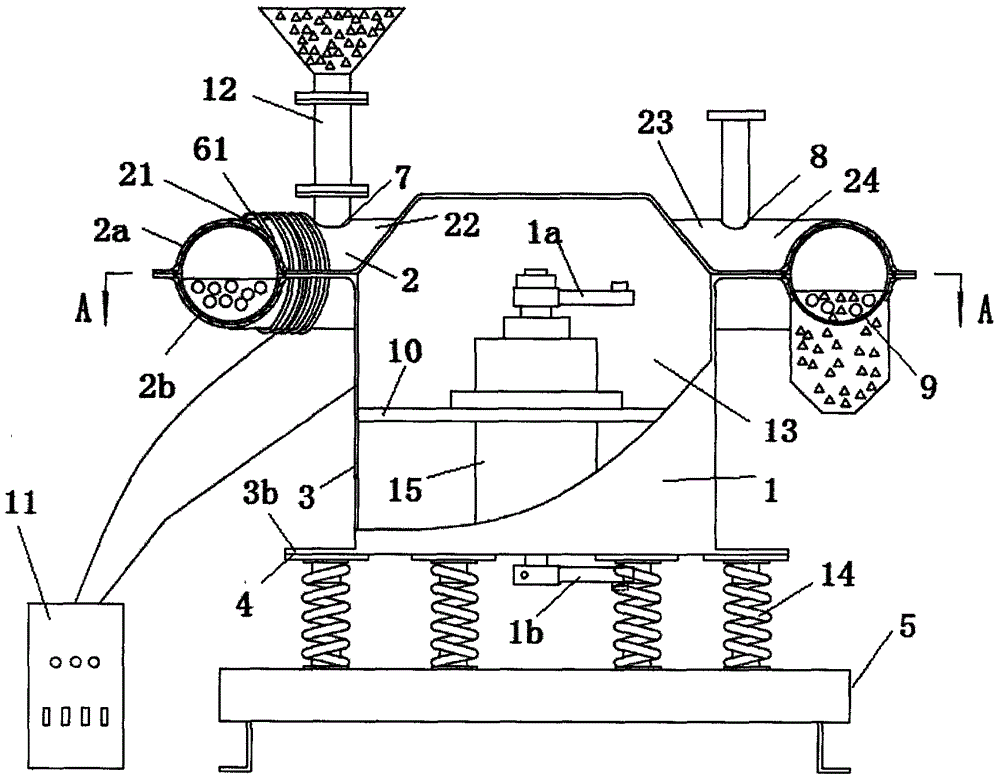

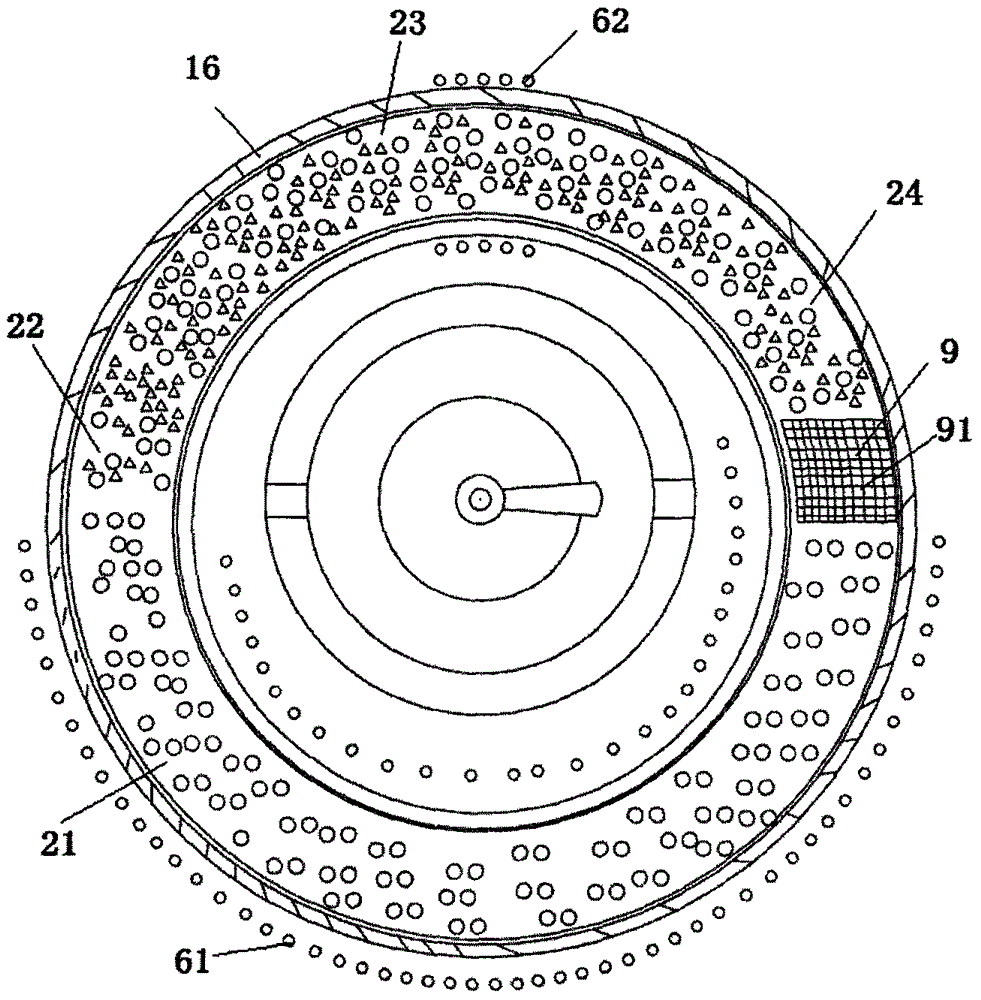

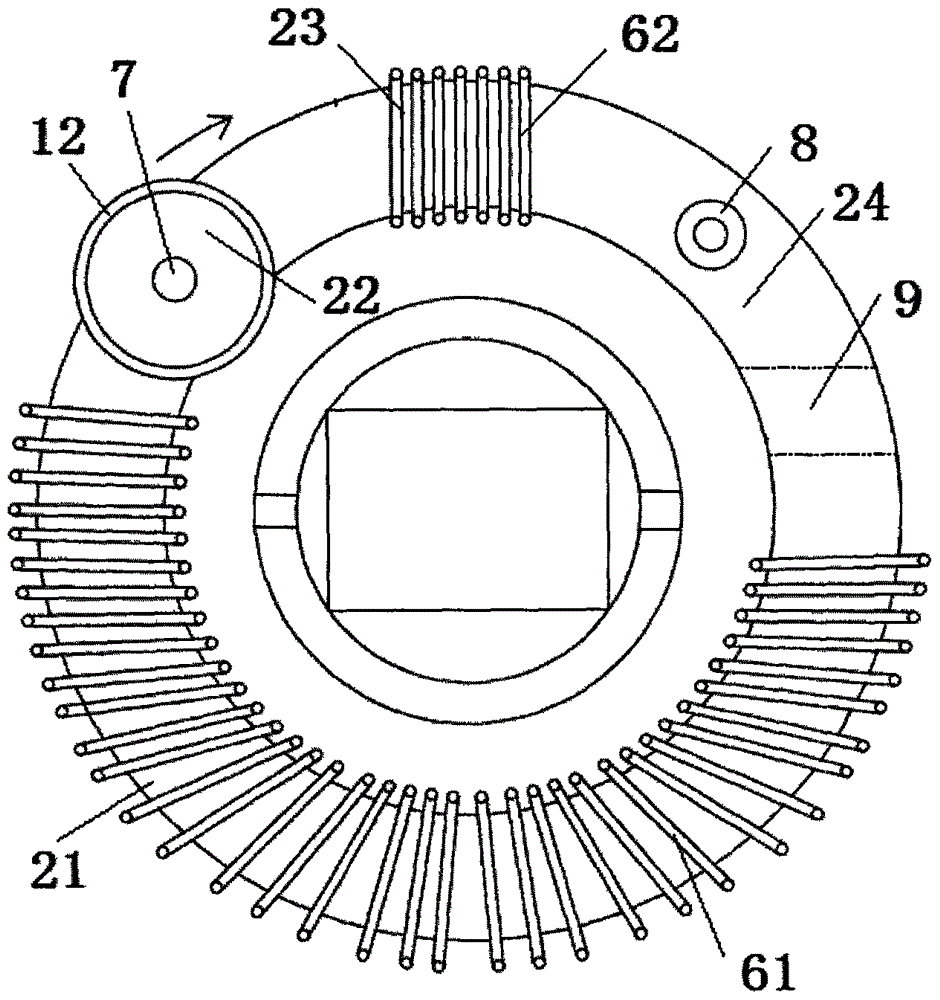

ActiveCN103333708AImprove general performanceIncrease temperatureDirect heating destructive distillationBiofuelsHeat carrierMotor drive

The invention relates to a biomass spiral-vibration electromagnetic induction pyrolysis reactor and a pyrolysis treatment method thereof. The pyrolysis reactor is composed of a casing and a heater, the casing comprises a feeding bin, a vibrating box, a support, a spring and a vibrating motor. The pyrolysis method is characterized in that a vibrating source generated by the vibrating motor drives the vibrating box to vibrate, the induction heater heats the hollow cylinder of the vibrating box in an induction heating manner, vibration and power-heat exchange of a heat carrier and biomass particles in the hollow cylinder are carried out in the vibrating and heating processes of the hollow cylinder, the pyrolysis treatment of the biomass particles is completed in the hollow cylinder, and the exciting force of the vibrating motor and the heating power and time of an induction heating coil are adjusted and controlled to control the realization of three different pyrolysis modes comprising pyrolysis liquefaction, pyrolysis gasification and pyrolysis charring of the biomass particles. The pyrolysis reactor and the pyrolysis method have the advantages of strong versatility, high pyrolysis efficiency, stable pyrolysis process and strong reliability.

Owner:HUZHOU TEACHERS COLLEGE

Environment-friendly noctilucent anti-mosquito wallpaper

InactiveCN106283792AImprove moisture resistanceImprove anti-agingAgeing prevention agents additionCovering/liningsFiberEthyl acetate

The invention discloses environment-friendly noctilucent anti-mosquito wallpaper. The environment-friendly noctilucent anti-mosquito wallpaper is prepared from, by weight, 20-30 parts of old clothes, 10-20 parts of waste wood, 10-20 parts of straw, 2-5 parts of nano-zinc oxide, 1-2 parts of chitosan, 2-8 parts of sodium sulfide, 10-25 parts of sodium hydroxide, 5-10 parts of cassava starch, 2-5 parts of butyl acrylate, 1-2 parts of a titanate coupling agent, 1-3 parts of cationic polyacrylamide, 1-2 parts of sodium N-cocoyl glycinate, 1-2 parts of azodiisobutyronitrile, 60-100 parts of deionized water, 20-30 parts of ethyl acetate, 3-6 parts of fluorescent powder and 5-10 parts of traditional Chinese medicine powder. According to the environment-friendly noctilucent anti-mosquito wallpaper, the old clothes, the waste wood and the straw are adopted as fiber base materials, resources are effectively utilized, resource waste is avoided, and the environment-friendly effect is achieved; the traditional Chinese medicine powder contained in the wallpaper achieve the killing effect, the fluorescent powder contained in the wallpaper can attract mosquitoes, and through mutual cooperation of the fluorescent powder and the traditional Chinese medicine powder, the mosquito dispelling effect is significant.

Owner:南宁东印时代广告有限公司

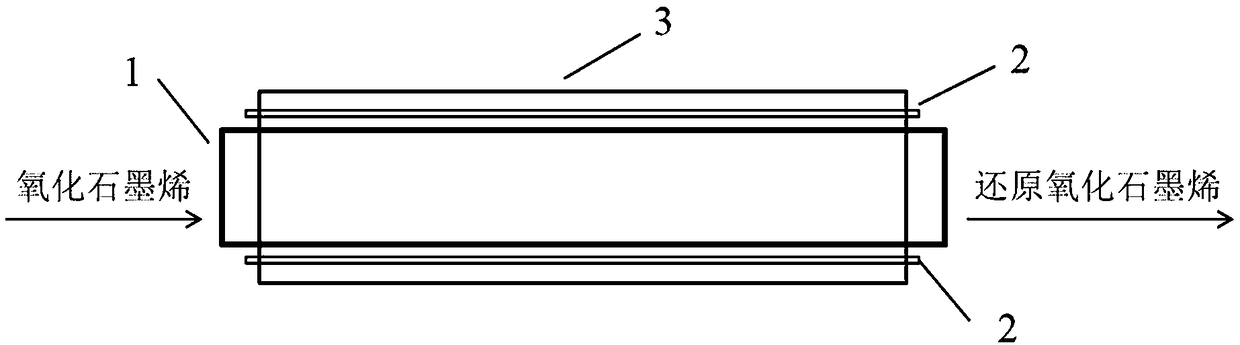

Preparation method of graphene oxide with small layer number and freeze-drying method of graphene oxide

The invention provides a preparation method of graphene oxide with a small layer number and a freeze-drying method of the graphene oxide. The preparation method comprises the following steps: dispersing graphene oxide having a first layer number in water and forming graphene oxide hydrogel; placing the graphene oxide hydrogel at a first temperature and a first pressure intensity to coagulate watermolecules in the graphene oxide hydrogel into ice molecules, and sublimating the ice molecules, so as to obtain graphene oxide having a second layer number, wherein the first layer number ranges fromten to tens of layers, and the second layer number is less than the first layer number. The preparation method has the beneficial effects that the freeze-drying process does not destroy the structureof a graphite oxide sheet layer, and functional groups are better preserved; the freeze-dried graphite oxide is less prone to agglomeration; the interlamellar spacing of the freeze-dried graphite oxide sheet layer is greater than that of a graphene oxide product dried by a conventional drying method; the graphene oxide is more excellent in dispersion property and has a smaller layer number and alarger specific surface area.

Owner:SICHUAN JUCHUANG SHIMOXI TECH CO LTD +1

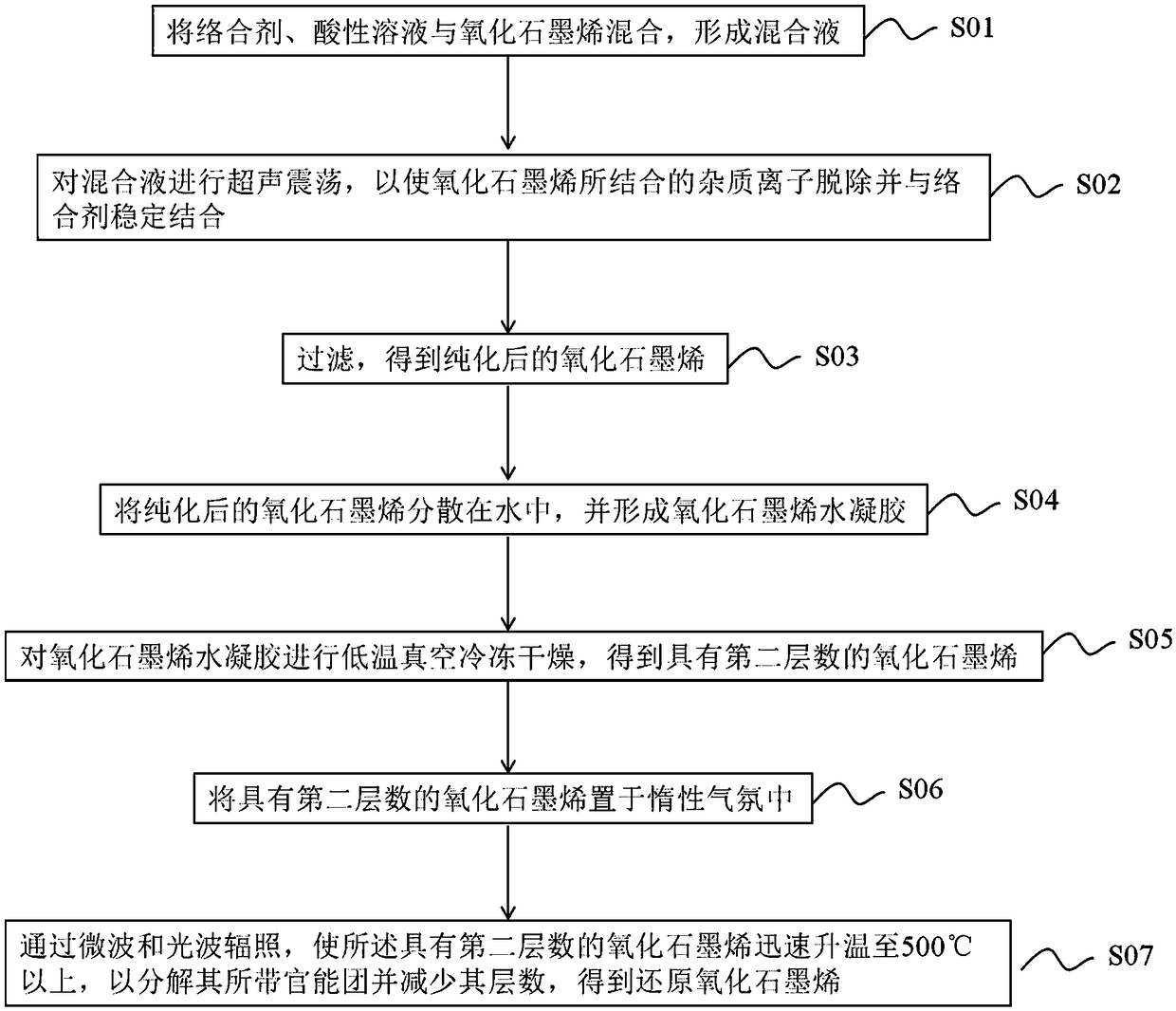

Method for producing reduced graphene oxide

The invention provides a method for producing reduced graphene oxide. The method comprises the following steps: mixing graphene oxide, a complexing agent and an acidic solution to obtain a mixed solution, wherein the graphene oxide has impurity ions combined on functional groups and has a first layer number; carrying out ultrasonic concussion to remove the impurity ions and combining the impurityions with the complexing agent; carrying out filtration to obtain purified graphene oxide; dispersing the purified graphene oxide in water to form a hydrogel; placing the hydrogel at a first temperature and a first pressure to obtain graphene oxide with a second layer number, wherein the second layer number is smaller than the first layer number; placing the obtained graphene oxide in an inert atmosphere; rapidly heating the graphene oxide to 500 DEG C or above by microwave and light wave irradiation to obtain reduced graphene oxide. The method provided by the invention has the following beneficial effects: the thoroughness of purification of graphene oxide can be effectively improved; the freeze-dried graphene oxide has a large interlayer spacing between sheet layers and few layers; in aphoto-microwave reduction process, the heating speed is high, the heating is uniform, and the reduction efficiency is high.

Owner:SICHUAN JUCHUANG SHIMOXI TECH CO LTD +1

Diamond composite material and preparation method thereof

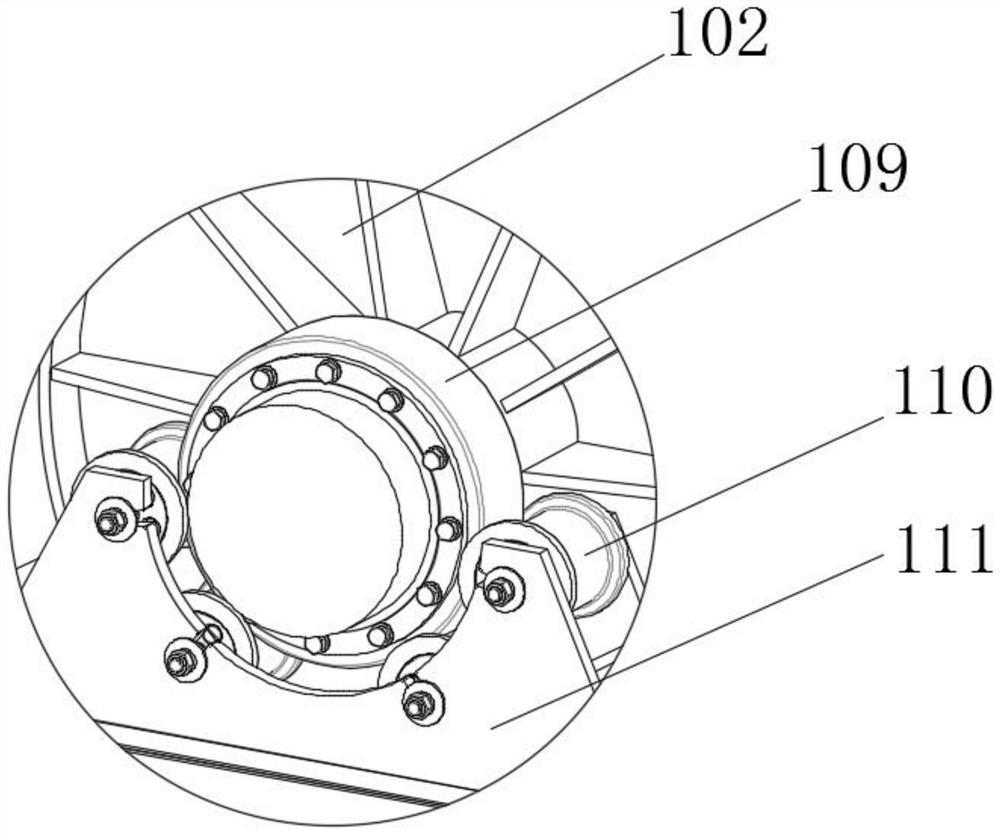

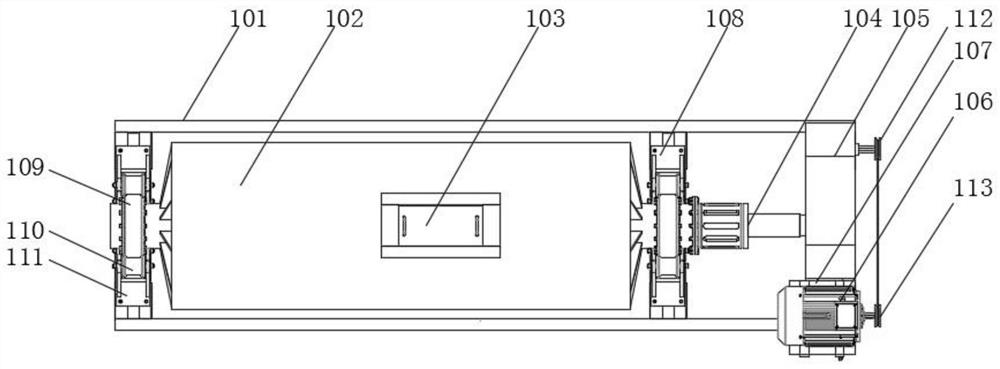

ActiveCN111676405AImprove the bonding strength of the interfaceHigh hardness valueOxidation resistantSteel ball

The invention discloses a diamond composite material and a preparation method thereof. According to the preparation method, diamond particles can be subjected to a full metallurgical reaction with high manganese steel, and the diamond particles are well combined with surrounding iron atoms and alloy element atoms, so that the interface bonding strength of the diamond composite material is improved, and the diamond composite material has good impact resistance and oxidation resistance and also has the excellent characteristics of high hardness, high wear resistance, high corrosion resistance and the like of the reinforced particles. According to the preparation method, mixed powder is prepared by using ultra-micro grinding equipment, and the equipment enables the prepared mixed powder to besmaller in particle size and higher in uniformity and not to be prone to aggregation and agglomeration through the impact force of steel balls, the friction and collision between the steel balls andthe friction between raw materials and convex edges; and the equipment enables the friction force at the two ends to be effectively reduced when a rotating grinding bin rotates, and the equipment maintenance cost and the part replacement cost are reduced while the power loss is reduced.

Owner:ANHUI YAZHU DIAMOND

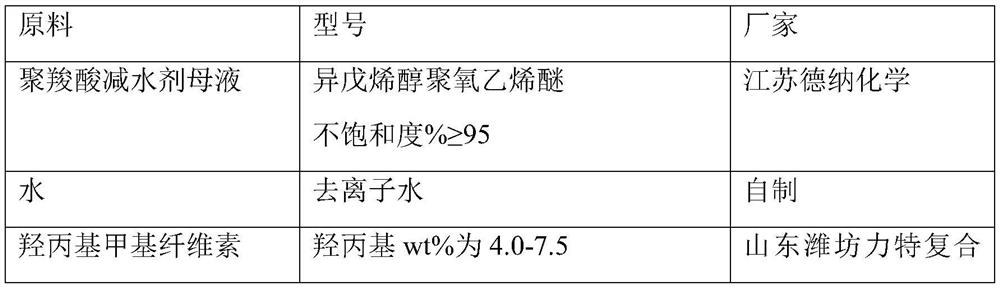

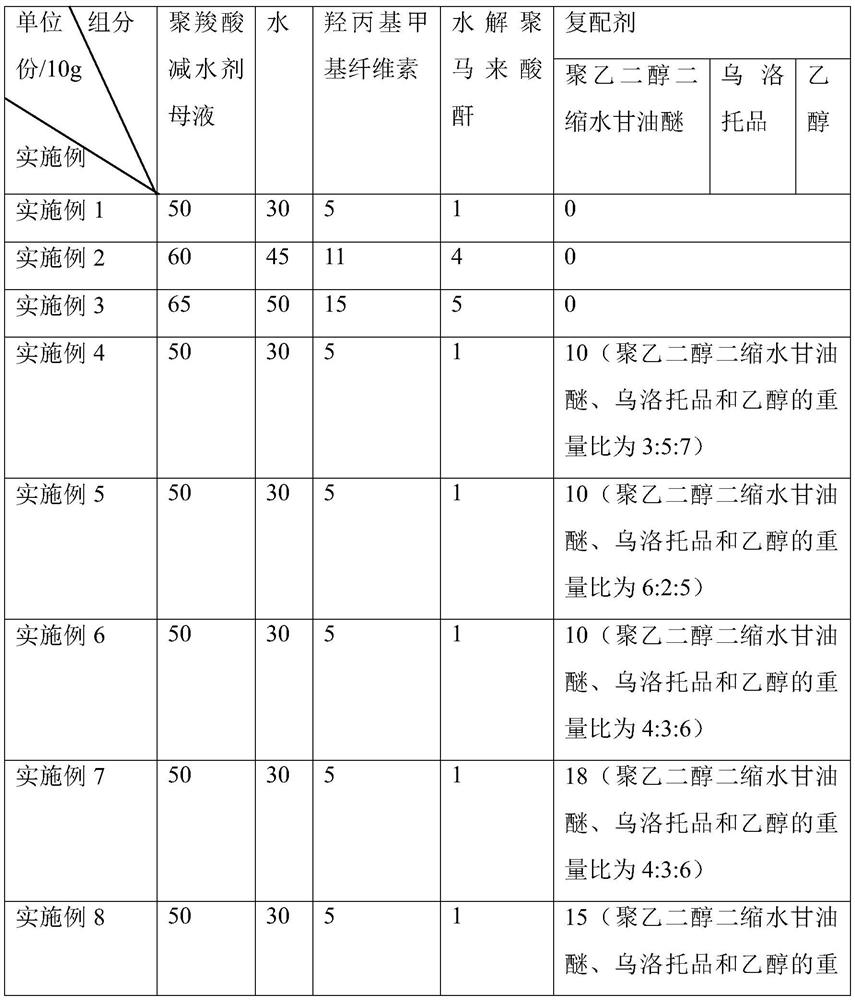

Water-retaining polycarboxylic acid water reducer and preparation method thereof

The invention relates to the technical field of concrete water reducing agents, and particularly discloses a water-retaining polycarboxylic acid water reducer and a preparation method thereof. The water-retaining polycarboxylic acid water reducer comprises, by weight, 50 to 65 parts of a polycarboxylic acid water reducer mother liquor; 5 to 15 parts of hydroxypropyl methyl cellulose; 1 to 5 parts of hydrolytic polymaleic anhydride; and 30 to 50 parts of water. The polycarboxylic acid water reducer mother liquor is an isopentenol type polycarboxylic acid water reducer mother liquor. The preparation method comprises the following steps: correspondingly weighing the raw materials in parts by weight, adding the raw materials into water, and stirring and dissolving to obtain the water-retaining polycarboxylic acid water reducer. The water-retaining polycarboxylic acid water reducer can be used in a concrete mixture, and has the advantages that the water-retaining property of concrete is enhanced, so that the bleeding phenomenon of the concrete is reduced.

Owner:唐山冀东水泥外加剂有限责任公司 +1

Forming process of hollow fiber membrane

InactiveCN106582309AGood dispersionImprove hydrophilicitySemi-permeable membranesFiberPolyvinyl chloride

The invention discloses a forming process of a hollow fiber membrane. The process includes the following steps that polyvinyl chloride resin is dissolved in a polar solvent, vinyl acetate, a dispersant and additives are added in sequence, stirring is conducted for dissolution for 15-20 h till nanoscale aluminum oxide and calcium carbonate particles are dispersed in the solution to form a uniform polyvinyl chloride casting membrane solution, and the obtained polyvinyl chloride casting membrane solution is defoamed; the prepared polyvinyl chloride casting membrane solution is put into a spinning kettle, the polyvinyl chloride casting membrane solution passes through an air layer through a spinning jet and then enters a coagulating bath for coagulating forming, and a nascent polyvinyl chloride hollow fiber membrane is obtained; the nascent polyvinyl chloride hollow fiber membrane is washed in flowing pure water; the washed nascent polyvinyl chloride hollow fiber membrane is spin-dried through a centrifugal device and then soaked in a mixed solution containing glycerol; finally, the nascent polyvinyl chloride hollow fiber membrane is spin-dried through the centrifugal device to remove part of mixture, taken out of the centrifugal device and then dried through a drying oven. The hollow fiber membrane is high in water flux, high in anti-fouling performance and high in strength, and the interception rate on particles with the average particle size of 0.15 micrometer is 98% or above.

Owner:广东嘉逸实业有限公司

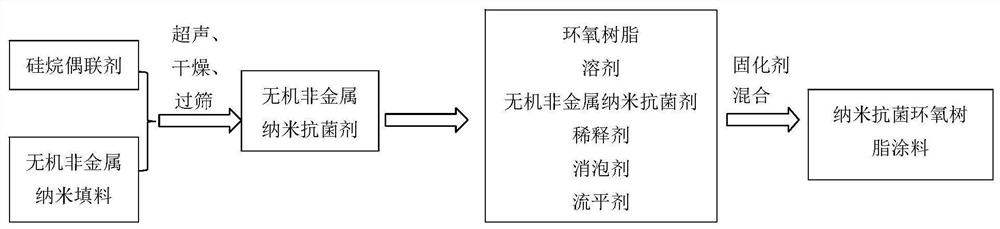

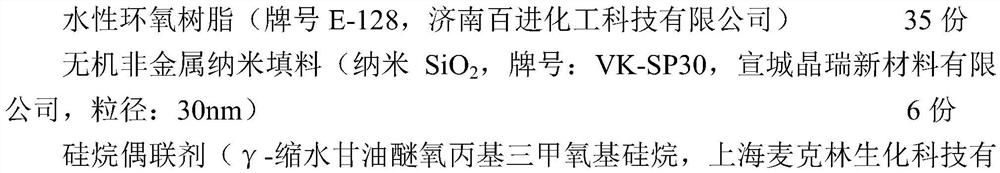

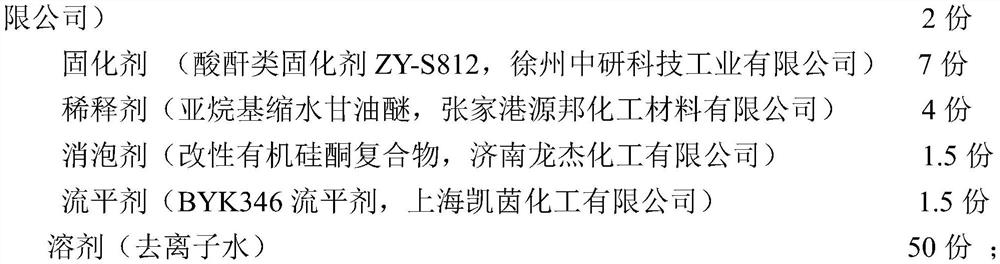

Nano-antibacterial epoxy resin coating for stainless steel water supply pipes as well as preparation method and application of nano-antibacterial epoxy resin coating

ActiveCN113736347AImprove the effect of surface modificationAvoid reunionAntifouling/underwater paintsPaints with biocidesEpoxyResin coating

The invention discloses a nano-antibacterial epoxy resin coating for a stainless steel water supply pipe and a preparation method and application thereof. According to the preparation method, an ultrasonic dispersion treatment method and an inorganic non-metal nano-filler surface modification method are combined, so inorganic non-metal nano-filler is always kept in a nano-size dispersion state, the agglomeration phenomenon of the inorganic non-metal nano-filler in the subsequent production process of preparing the nano-antibacterial epoxy resin coating is prevented, and the nano size effect and the corresponding antibacterial property of the nano-antibacterial epoxy resin coating are maintained. The nano-antibacterial epoxy resin coating prepared by the invention has the characteristics of high stability, good antibacterial effect, antibacterial durability, excellent broad-spectrum property, simplicity in production, convenience in use and the like; and the nano-antibacterial epoxy resin coating does not generate adverse effects on the performance of the stainless steel water supply pipe, and can also play a certain role in enhancing the corrosion resistance of the stainless steel water supply pipe.

Owner:SOUTH CHINA UNIV OF TECH

Antibacterial and mildew-proof material based on diatomite superfine powder and preparation method thereof

ActiveCN105111811BGood antibacterial and antifungal effectRelease negative ionsAntifouling/underwater paintsPaints with biocidesDispersion stabilityAnti bacteria

An anti-bacteria anti-mould material based on diatomite ultrafine powder and a preparation method therefor are provided by the present invention, and belong to the technical field of diatom nano materials so that the problems of higher costs, poor long-term dispersion stability, and poor anti-bacteria anti-mould effects of existing anti-bacteria anti-mould materials are solved. The anti-bacteria anti-mould material based on diatomite ultrafine powder comprises the following components in parts by weight: 5-15 parts of an anti-mold agent S89; 5-15 parts of diatomite ultrafine powder; and 2-6 parts of nano zinc oxide ZnO. The anti-bacteria anti-mould material provided by the present invention has an negative ion average increase of 127-131 / s.cm2 and an antibacterial rate of 94% - 97%. The anti-bacteria anti-mould material based on diatomite ultrafine powder has strong anti-bacteria anti-mould capabilities, and can further release negative ions and purify air. Compared with the prior art, the anti-bacteria anti-mould material greatly reduces the cost and has better long-term dispersion stability due to the fact that aggregation is unlikely to occur.

Owner:临江市绿苑环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com