Nano-antibacterial epoxy resin coating for stainless steel water supply pipes as well as preparation method and application of nano-antibacterial epoxy resin coating

An epoxy resin coating, epoxy resin technology, applied in epoxy resin coatings, antifouling/underwater coatings, coatings, etc., can solve the problem of losing nano-size effect antibacterial function, etc., to improve the surface modification effect, The effect of improving uniform dispersion and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

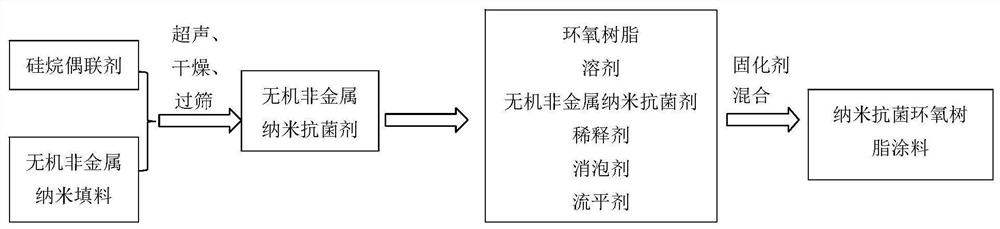

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: the preparation of the nanometer antibacterial epoxy resin coating that is used for stainless steel water supply pipe

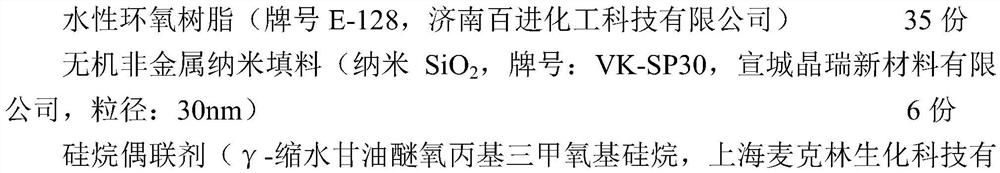

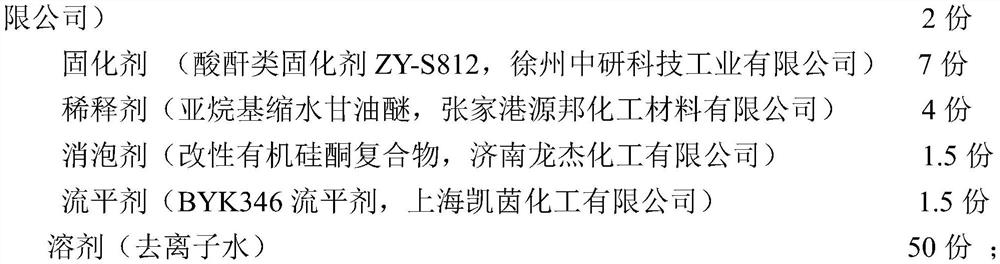

[0041] (1) Prepare raw materials according to the following parts by mass:

[0042]

[0043]

[0044] (2) While stirring and dispersing, nano-SiO 2 Added to ethanol aqueous solution, nano-SiO 2 Stir for 1 minute after addition to obtain nano-SiO 2 / ethanol aqueous suspension; use ultrasonic nanomaterial disperser (model: JH, Hangzhou Jinghao Machinery Co., Ltd.) to the nano-SiO 2 / Ethanol aqueous suspension is processed and added γ-glycidyl etheroxypropyl trimethoxysilane coupling agent through the automatic quantitative feeding system (model: LS series, Jiangsu Lisheng Measurement and Control Instrument Co., Ltd.), the specific method is: ultrasonic oscillation 30s, pause for 30s, cycle 10 times, divide the γ-glycidyl etheroxypropyl trimethoxysilane coupling agent evenly into 10 parts according to the number of cycles, before ul...

Embodiment 2

[0047] Embodiment 2: the preparation of the nanometer antibacterial epoxy resin coating that is used for stainless steel water supply pipe

[0048] (1) Prepare raw materials according to the following parts by mass:

[0049]

[0050]

[0051] (2) While stirring and dispersing, the nano-TiO 2 Added to ethanol aqueous solution, nano-TiO 2 Stir for 1 minute after addition to obtain nano-TiO 2 / ethanol aqueous suspension; use an ultrasonic nanometer material disperser (model: JH, Hangzhou Jinghao Machinery Co., Ltd.) to the nano TiO 2 / Ethanol aqueous suspension is processed and 3-aminopropyltriethoxysilane coupling agent is added through the automatic quantitative feeding system (model: LS series, Jiangsu Lisheng Measurement and Control Instrument Co., Ltd.), the specific method is: ultrasonic oscillation for 30s, Pause for 30s, cycle 8 times, divide 3-aminopropyltriethoxysilane coupling agent evenly into 8 parts according to the number of cycles, add 1 part every time y...

Embodiment 3

[0054] Embodiment 3: the preparation of the nano antibacterial epoxy resin coating that is used for stainless steel water supply pipe

[0055] (1) Prepare raw materials according to the following parts by mass:

[0056]

[0057]

[0058](2) Add nano-ZnO to the aqueous ethanol solution while stirring and dispersing, and then stir for 1 minute after adding the nano-ZnO to obtain a nano-ZnO / ethanol aqueous suspension; use an ultrasonic nanomaterial disperser (model: JH, Hangzhou Jinghao Machinery) Co., Ltd.) to process the nano-ZnO / ethanol aqueous suspension and add γ-(methacryloyloxy)propyltrimethoxysilane through the automatic quantitative feeding system (model: LS series, Jiangsu Lisheng Measurement and Control Instrument Co., Ltd.) Coupling agent, the specific method is: ultrasonic oscillation for 30s, pause for 30s, cycle operation 12 times, divide the γ-(methacryloyloxy)propyltrimethoxysilane coupling agent evenly into 12 parts according to the number of cycle operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com