Preparation method of high temperature resistance ultrafine active calcium carbonate

A technology of activated calcium carbonate and ultra-fine calcium carbonate, which is applied in the direction of climate sustainability, sustainable manufacturing/processing, dyeing polymer organic compound treatment, etc., and can solve problems such as high surface energy, small particle size, and yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

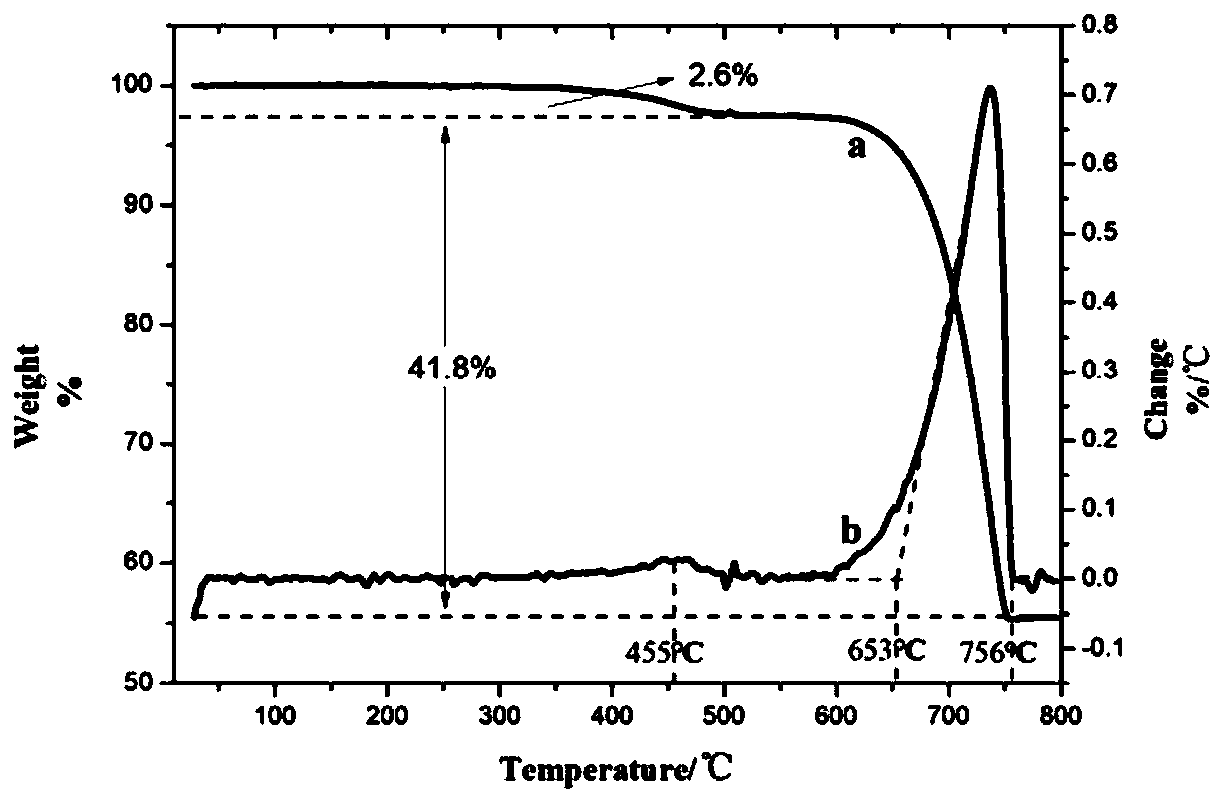

Embodiment 1

[0030] A preparation method of high temperature resistant ultrafine activated calcium carbonate, comprising the following steps:

[0031] S1. Preparation of ultrafine calcium carbonate slurry: using a carbonization method to obtain cooked nanometer calcium carbonate slurry as ultrafine calcium carbonate slurry;

[0032] S2. Put the ultrafine calcium carbonate slurry prepared in S1 in a sealed container, add 0.5-5% acrylic acid, and age for 24 hours at a temperature of 120° C. to obtain an aged slurry;

[0033] The amount of dispersant is calculated based on the mass of calcium carbonate on a dry basis;

[0034] S3. Add a surface treatment agent to the aged slurry prepared in S2, use a microwave with a power of 100W to carry out an auxiliary catalytic reaction, the temperature is 80°C, and the stirring and activation treatment time is 0.5h. After the surface treatment is completed, the slurry is dehydrated by pressure filtration , dried and pulverized to obtain the product;

...

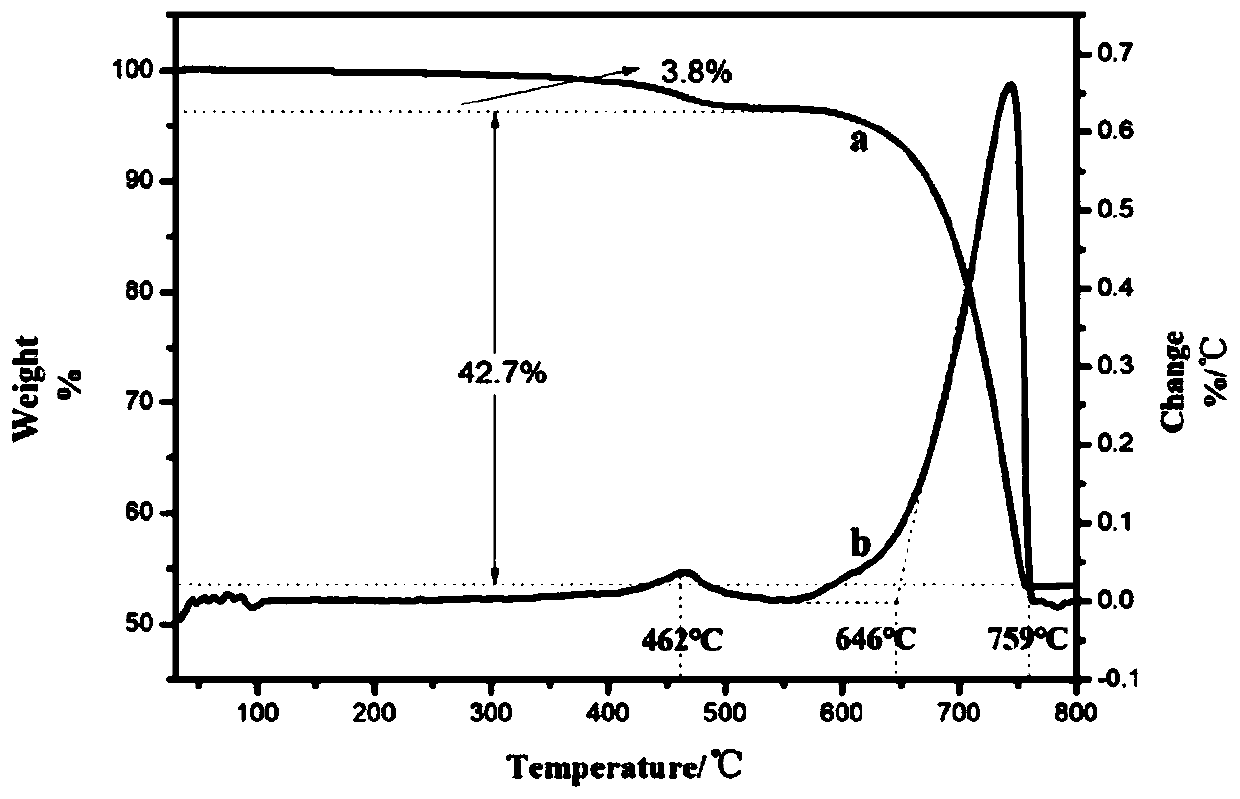

Embodiment 2

[0038] A preparation method of high temperature resistant ultrafine activated calcium carbonate, comprising the following steps:

[0039] S1. Preparation of ultrafine calcium carbonate slurry: using carbonization method to obtain light calcium carbonate cooked slurry as ultrafine calcium carbonate slurry;

[0040] S2. Put the ultrafine calcium carbonate slurry prepared in S1 in a sealed container, add 1% sodium hexametaphosphate, 1% citric acid, 1% silane coupling agent, and 2% sodium lauryl sulfate. , aged for 144h, and the aging temperature was 120° C. to obtain aged pulp; the amount of the dispersant was calculated based on the mass of calcium carbonate on a dry basis;

[0041] S3. Add a surface treatment agent to the aged slurry prepared in S2, and use a high pressure of 0.1 to 0.5 MPa to carry out an auxiliary catalytic reaction. The temperature of the reaction treatment is 130°C, and the stirring and activation treatment time is 2h. After the surface treatment is complet...

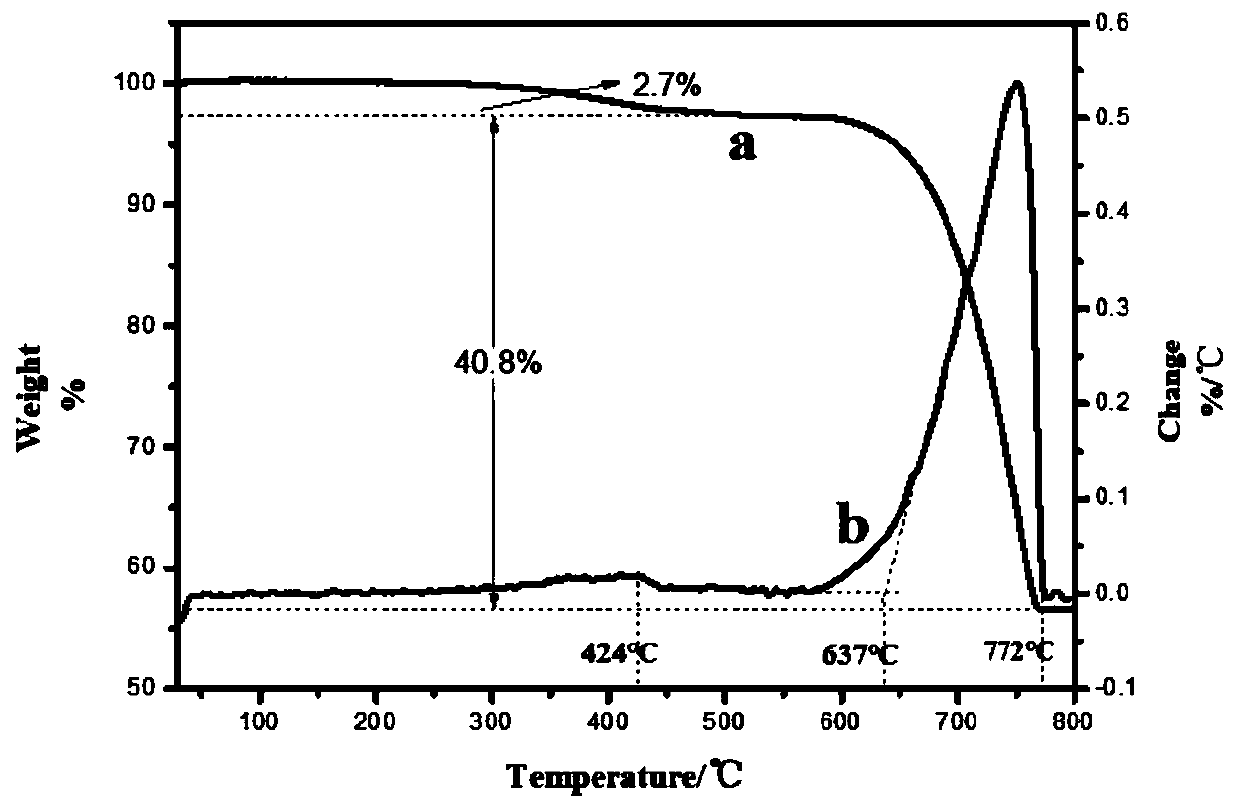

Embodiment 3

[0045] A preparation method of high temperature resistant ultrafine activated calcium carbonate, comprising the following steps:

[0046] S1. Preparation of ultrafine calcium carbonate slurry: using a carbonization method to obtain cooked nanometer calcium carbonate slurry as ultrafine calcium carbonate slurry;

[0047] S2. Place the superfine calcium carbonate slurry prepared in S1 in a sealed container, add 0.5% sodium lauryl sulfate, 0.8% ethylenediaminetetraacetic acid, 0.4% cetyltrimethylammonium bromide, 0.2 A dispersant composed of % polyvinylpyrrolidone was aged for 45h, and the aging temperature was 100°C to obtain aged pulp; the amount of the dispersant was calculated as the mass of calcium carbonate on a dry basis;

[0048] S3. Add a surface treatment agent to the aged slurry prepared in S2, use a microwave with a power of 300W and a high pressure with a pressure of 0.7-0.9MPa to carry out an auxiliary catalytic reaction, the temperature of the reaction treatment is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com