Patents

Literature

42results about How to "Good surface modification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface modification method for nano calcium carbonate

ActiveCN102174275AOvercome the disadvantage of being difficult to disperseGood dispersionPigment physical treatmentPigment treatment with non-polymer organic compoundsPolyvinyl chlorideSlurry

The invention discloses a surface modification method for nano calcium carbonate, which is characterized by comprising the following steps of: adding inorganic alkali into nano calcium carbonate slurry, uniformly stirring, heating the slurry, adding fatty acid and performing surface modification. The method comprises the following specific steps of: adding a certain amount of nano calcium carbonate slurry into a reaction kettle, adding 0.00004 to 0.00040mol of inorganic alkali into 1g of CaCO3, and uniformly stirring; heating to the temperature of between 75.0 and 90.0 DEG C, adding 0.00005 to 0.00035mol of fatty acid or fatty acid salt into 1g of nano calcium carbonate (CaCO3) slurry, reacting, and continuously stirring for 30 to 120 minutes; and after surface modification reaction is finished, cooling, filtering, washing, drying and grinding the slurry to obtain the nano calcium carbonate subjected to surface modification. The method is simple and practicable, a modifier can form a uniform and complete coating layer on the surface of the nano calcium carbonate, and the modified product has a good application effect in polymer such as silicone sealant, polyvinyl chloride (PVC) paste resin and the like.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

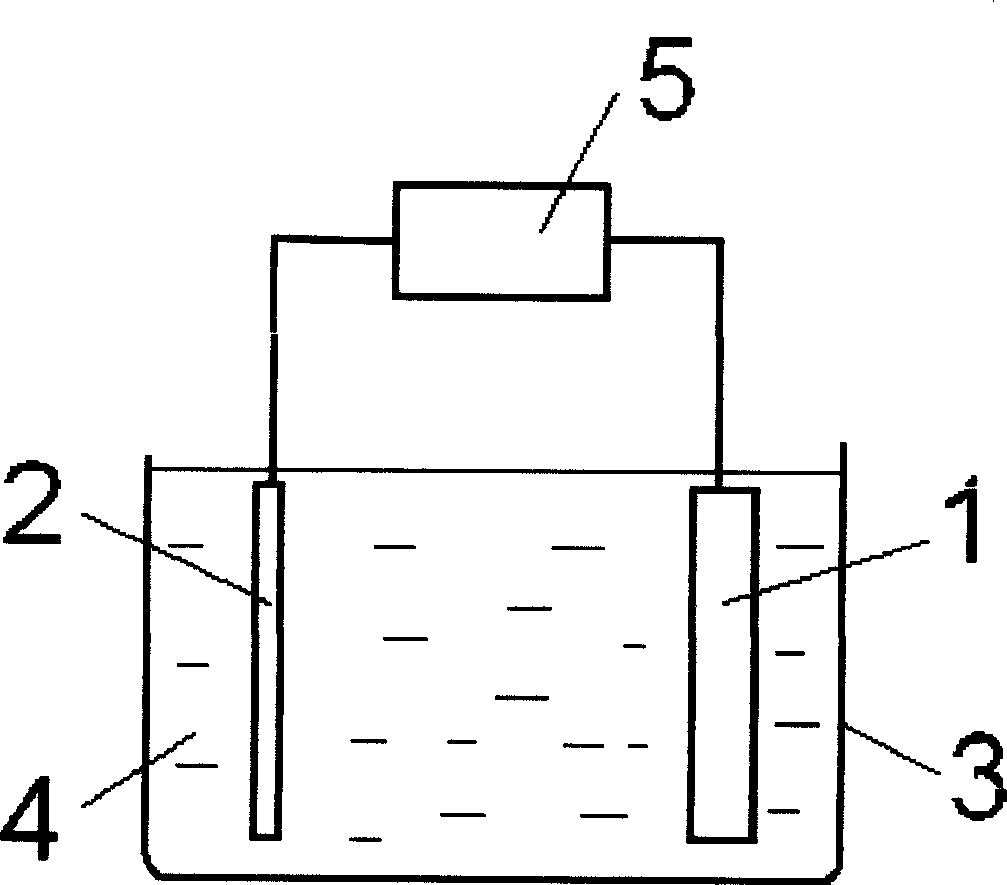

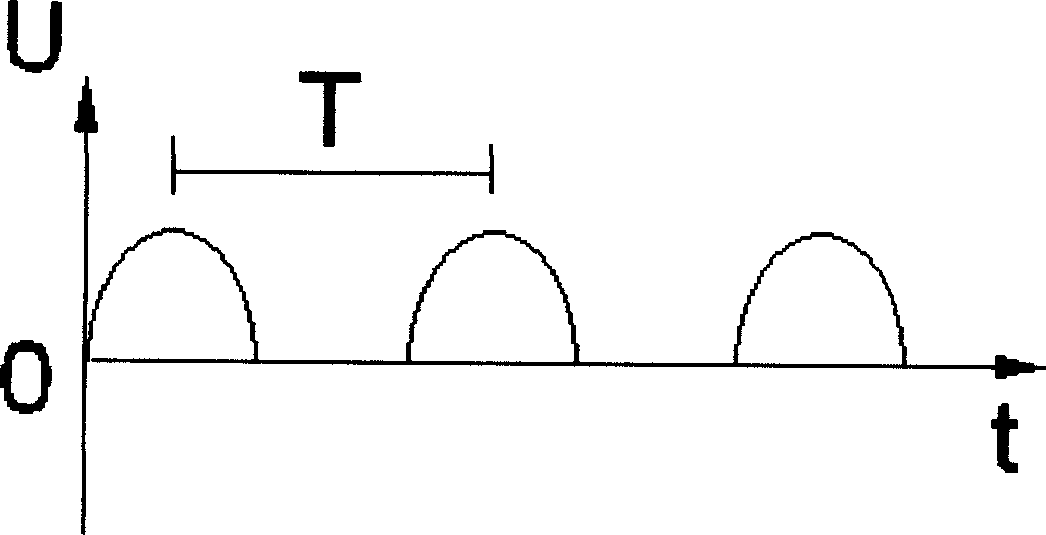

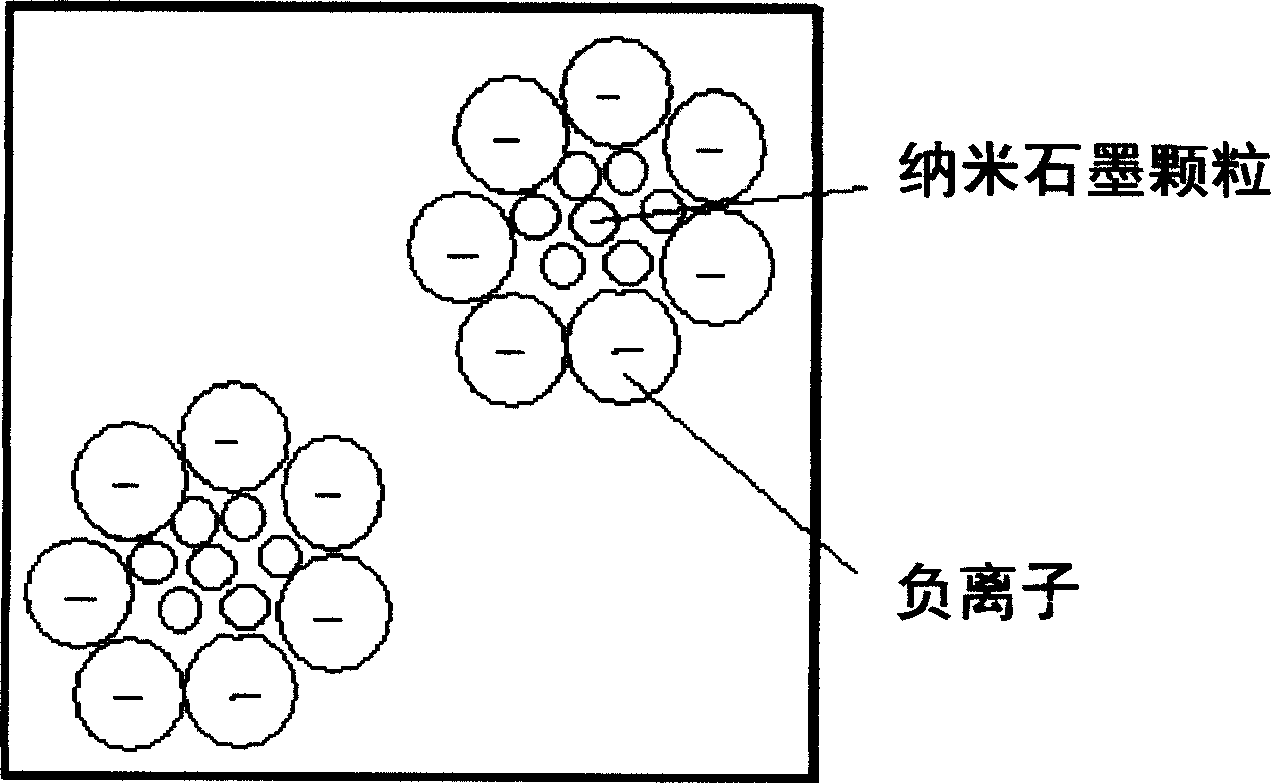

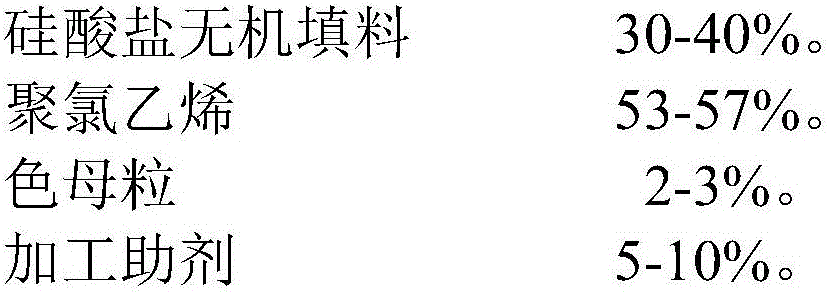

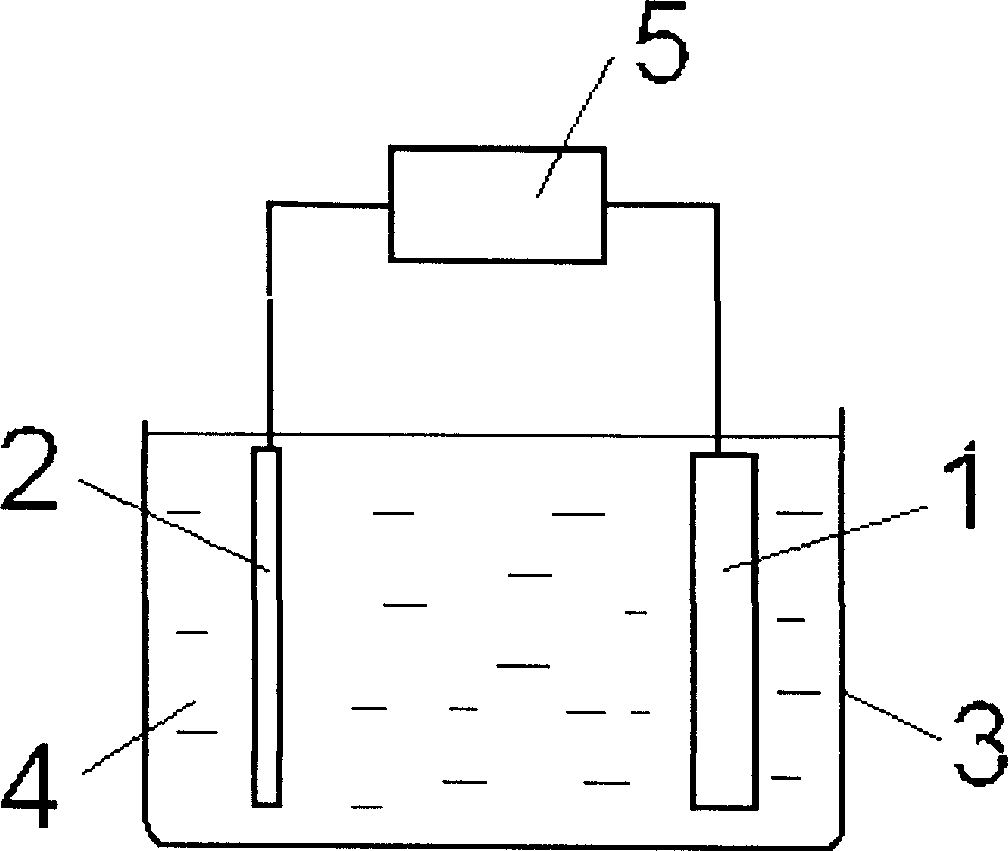

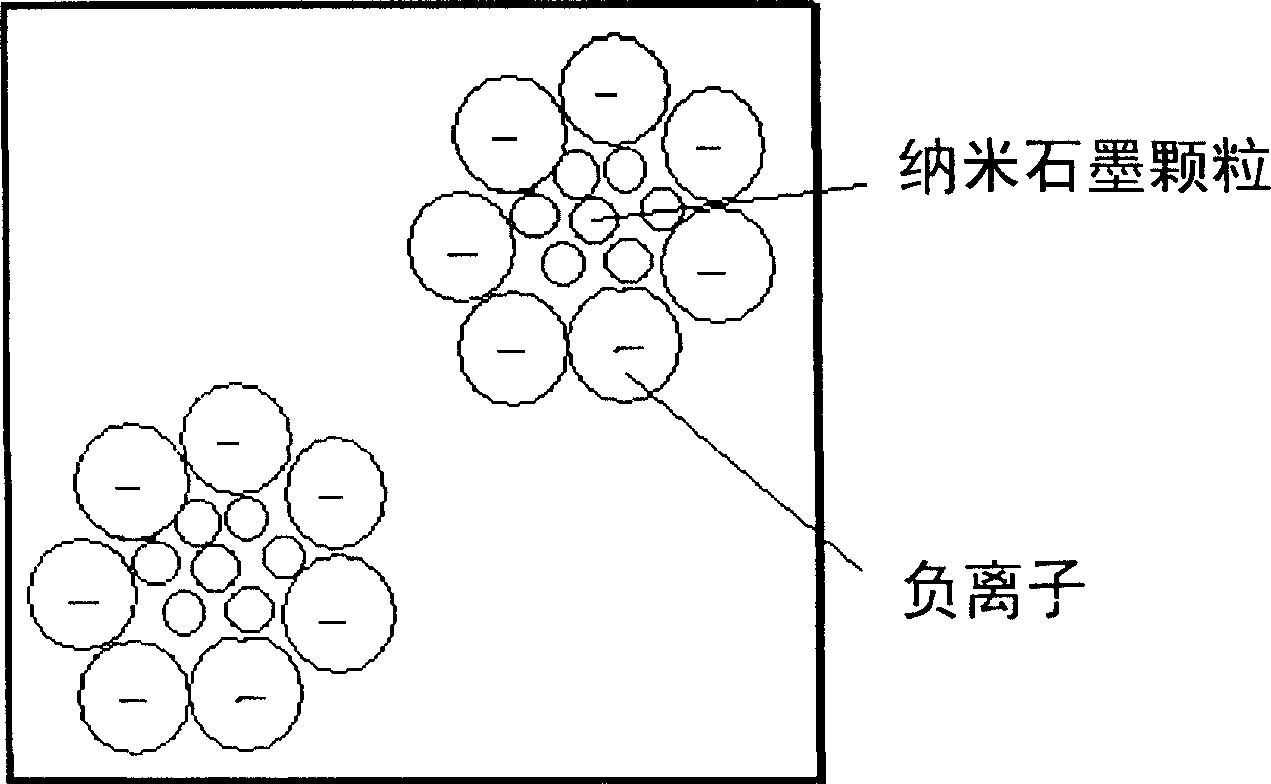

Preparation of nano graphite carbon colloidal SOL by pulse electrode process

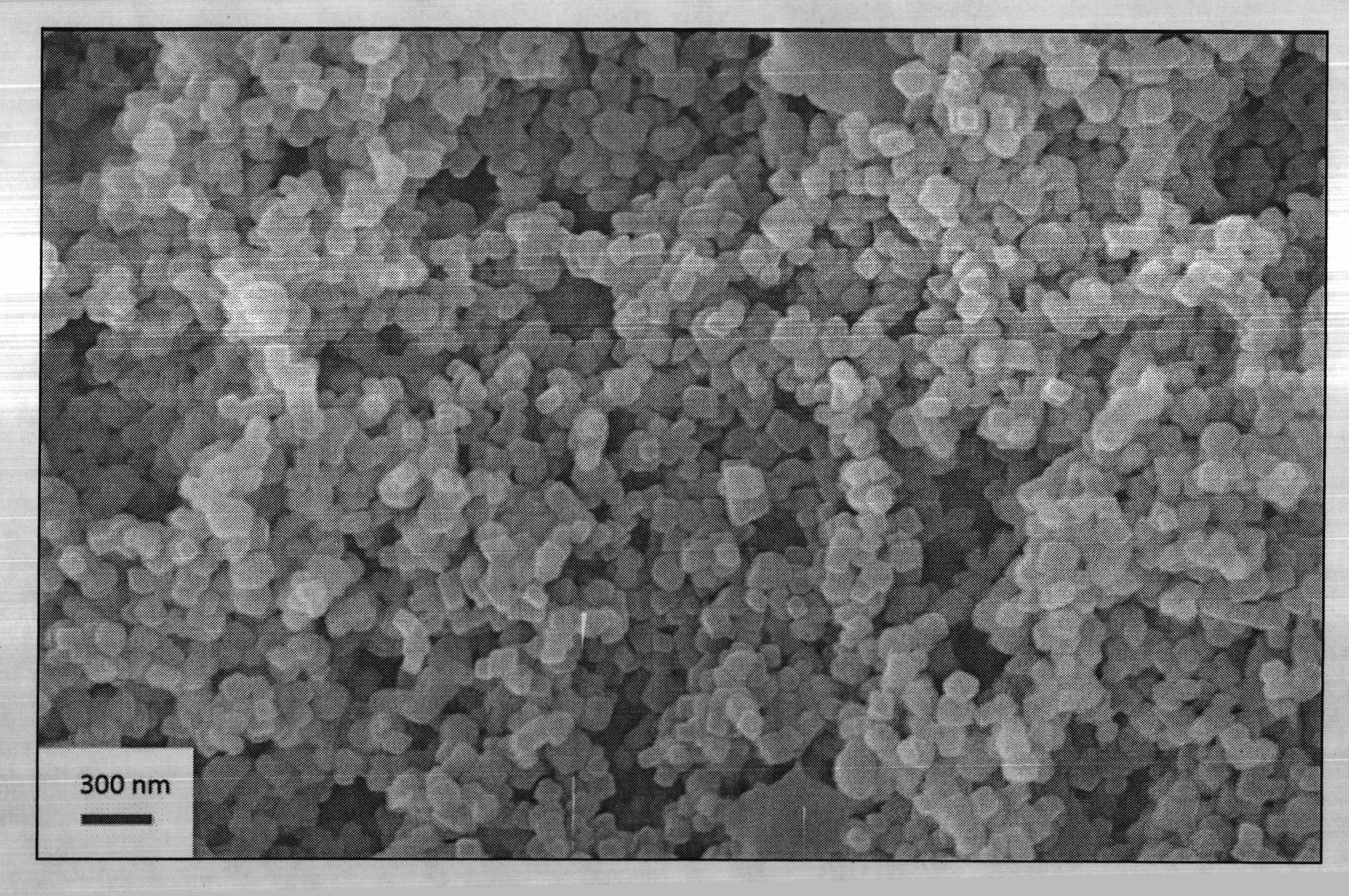

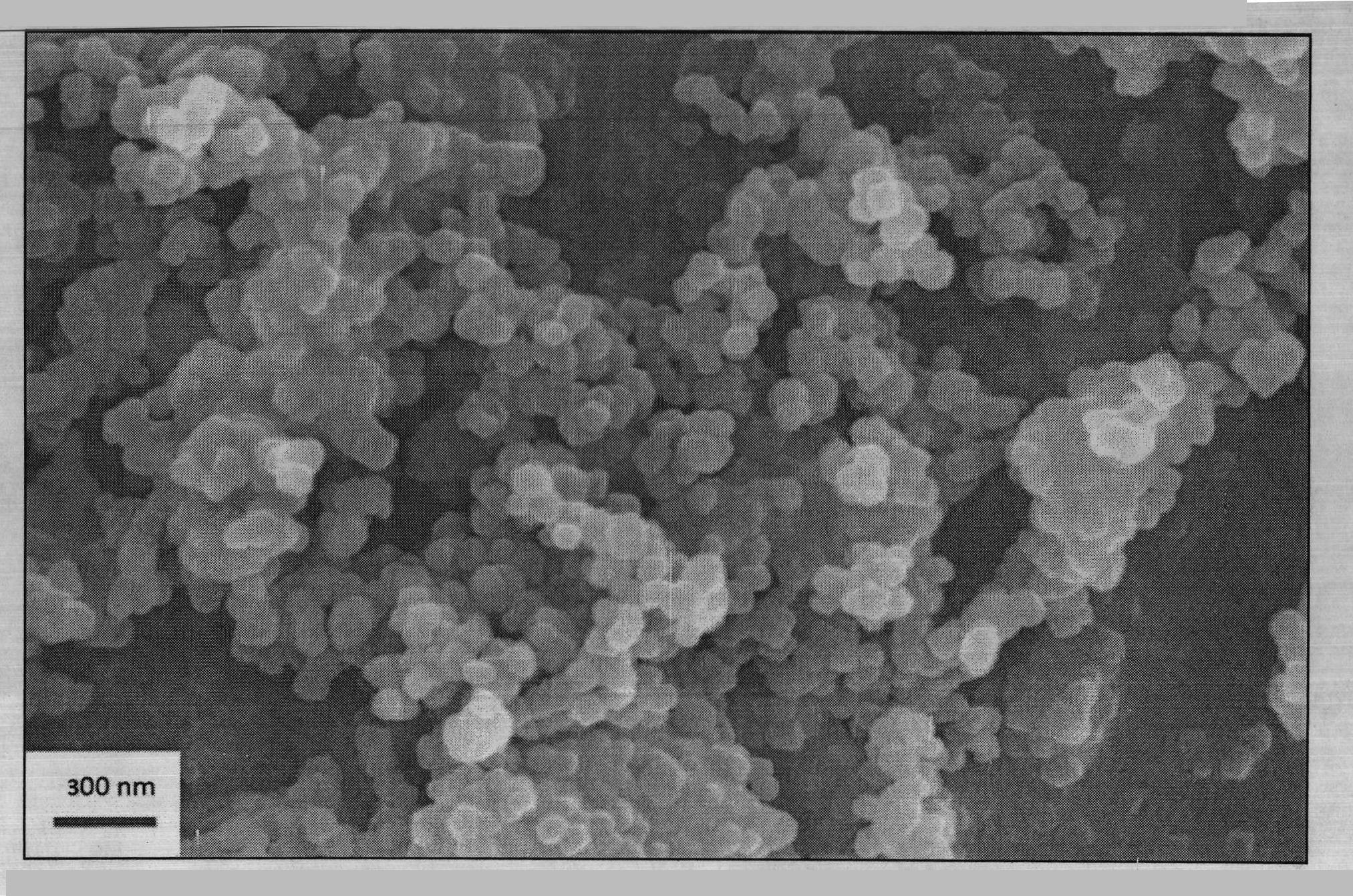

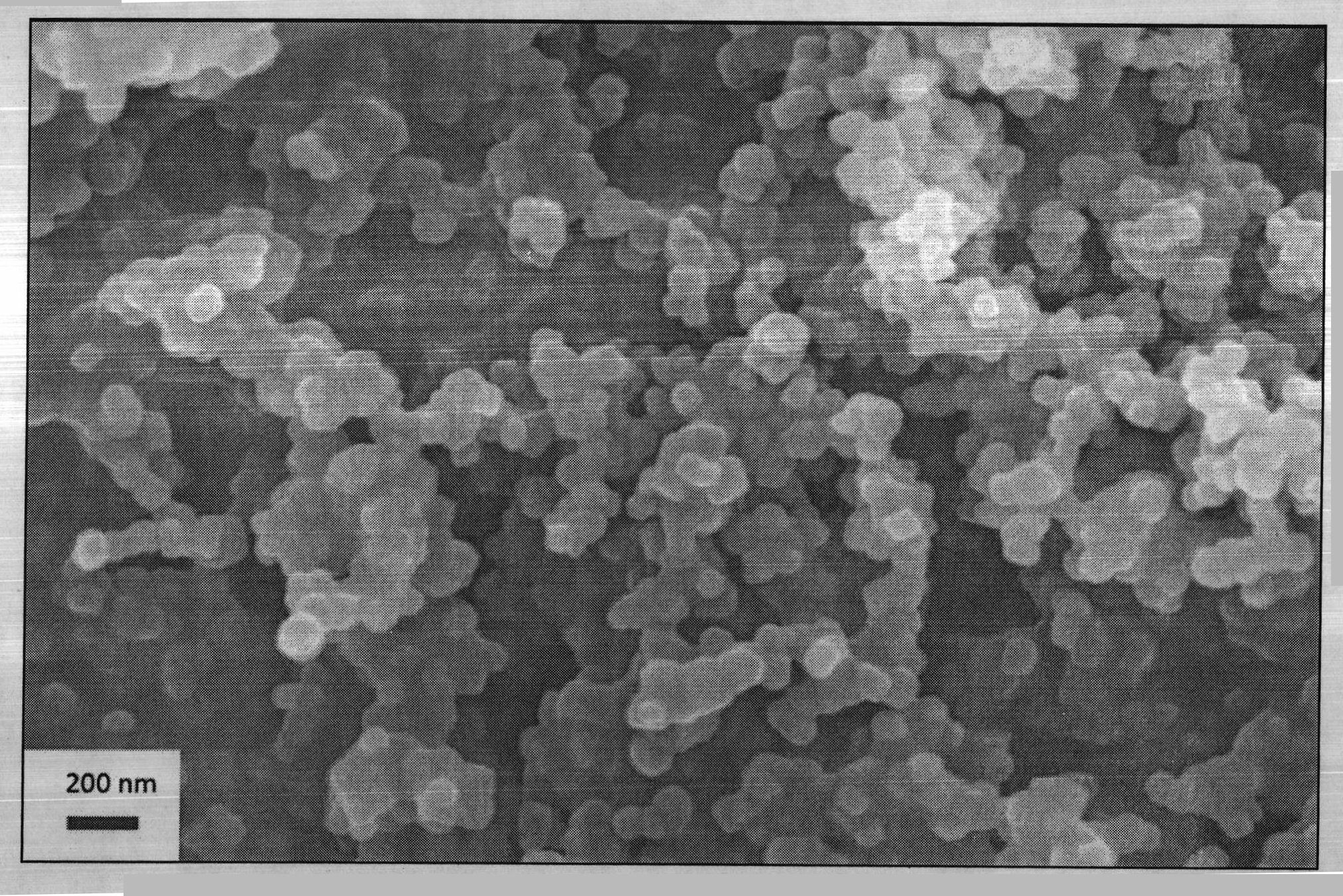

InactiveCN1579932ASimple processReduce manufacturing costElectrolysis componentsVolumetric Mass DensityPulse period

The invention discloses a method to produce nanometer graphite sol. It supplies a system which includes highly pure graphite as anode, inert materials as cathode and electrolytical aqueous solution. There is an impulsing power source to connect the anode and cathode. The pulse period of the power source is 0.05-0.5 second, effective voltage 2-10V (3-5V is prelatered) and effective amphere density 15-75A (25-35 is prelatered). The efficiency of this invention is higher than common direct-current electrode method. The produced nanometer graphite sol is stable and disperses so it can produce nanometer graphite powder whose diameter is under 15nm.

Owner:华农纳米科技(天津)有限公司

Surface treatment method of nano-calcium carbonate used for polyvinyl chloride plastisol

ActiveCN102492310AGood surface modificationRaw materials are cheap and easy to getPigment treatment with non-polymer organic compoundsPolyvinyl chlorideSlurry

The invention discloses a surface treatment method of nano-calcium carbonate used for polyvinyl chloride plastisol. The surface treatment method comprises the following steps: adding nano-calcium carbonate serous fluid into a reaction kettle, wherein the specific surface area (BET) of nano-calcium carbonate in the serous fluid is 18.0-60.0m<2> / g and the pH of the nano-calcium carbonate serous fluid is 8.5-9.5; heating to 70-95 DEG C, stirring, adding a mixed modifier accounting for 1.8-6.0% of the mass of the nano-calcium carbonate in the serous fluid, continuing stirring for 30-180 minutes, thus completing surface treatment. The mixed modifier is a mixture of stearic acid alkali metal saponified matter and calcium stearate, the mass ratio of fatty acid to calcium stearate in the complex modifier is 20-70%, and the proportion of the using quantity of the fatty acid to a saponifier is 1: 1. According to the method, the fatty acid is saponified by a strong base, so that the shortcoming that the fatty acid is difficult to react with the surface of calcium carbonate in water to generate the calcium stearate during wet process surface modification of the nano-calcium carbonate can be overcome; and the calcium stearate is directly introduced through fatty acid saponification liquor, so that a significant surface modification effect is obtained. The method has the advantages that raw materials are low in price and easy to obtain, the processes are simple and feasible, and the quality of a product is state. The method has significant economic benefits and social benefits.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

Method for preparing inorganic crystal whisker with SiO2-coated surface

InactiveCN1569746AThickness is easy to controlGood surface modificationPolycrystalline material growthAfter-treatment detailsAcetic acidCoated surface

Disclosed is a method for preparing inorganic crystal whisker with SiO2-coated surface which comprises, subjecting the inorganic crystal whisker to decentralized processing in precursor solution, carrying out inorganic coating by employing homogeneous precipitation method, thermal insulating and ageing, filtering, scouring, and drying to obtain the inorganic crystal whisker with SiO2-coated surface.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing Nano graphite sol by inputting pulsed dc bias to dual graphite electrodes

ActiveCN101092237ASimple processReduce manufacturing costElectrolysis componentsElectrolysisPulsed DC

This invention discloses a method for preparing graphite nanosol by pulse DC bias current with double graphite electrodes. The method comprises: placing two parallel graphite plates into an electrolytic tank filled with electrolyte aqueous solution, connecting to the anode and cathode of a pulse DC bias power source respectively, and applying pulse DC bias current (square wave, pulse frequency 20-50 Hz, pulse amplitude 8-12 V, bias voltage 2-5 V, bias current density 0.5-3 mA / cm2) to obtain graphite nanosol with particle sizes of 10-30 nm. The obtained graphite nanosol has such advantages as high dispersibility, high stability, low energy consumption and is suitable for mass production. The graphite nanosol has wide applications.

Owner:BEIJING NAIAISI NEW MATERIAL TECH

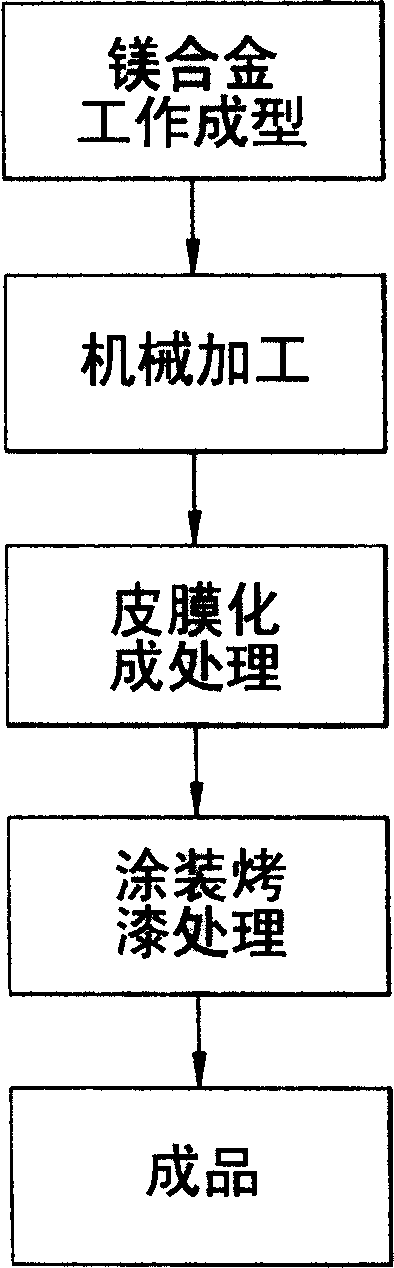

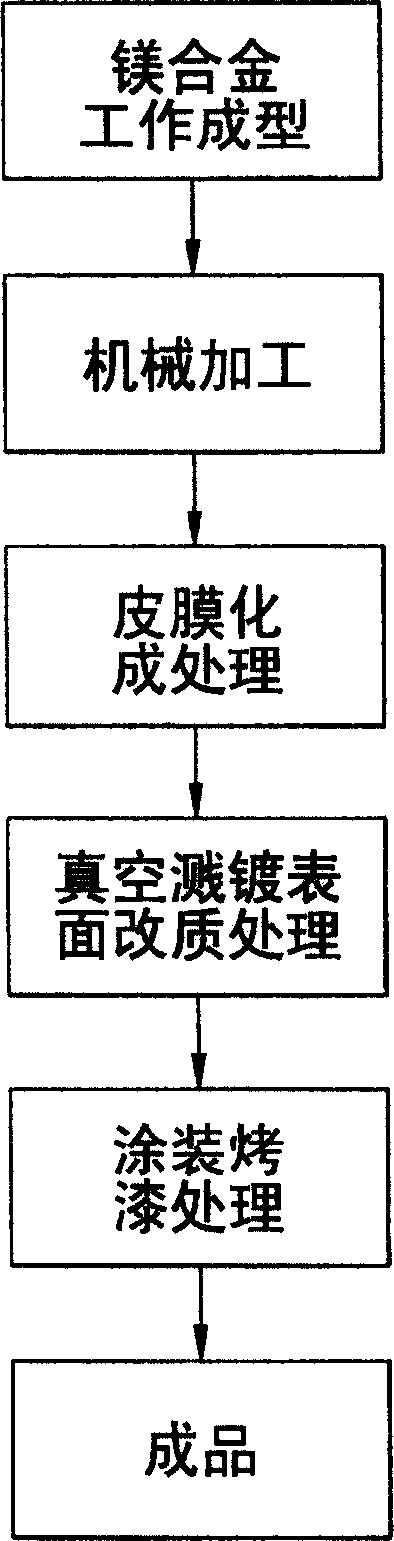

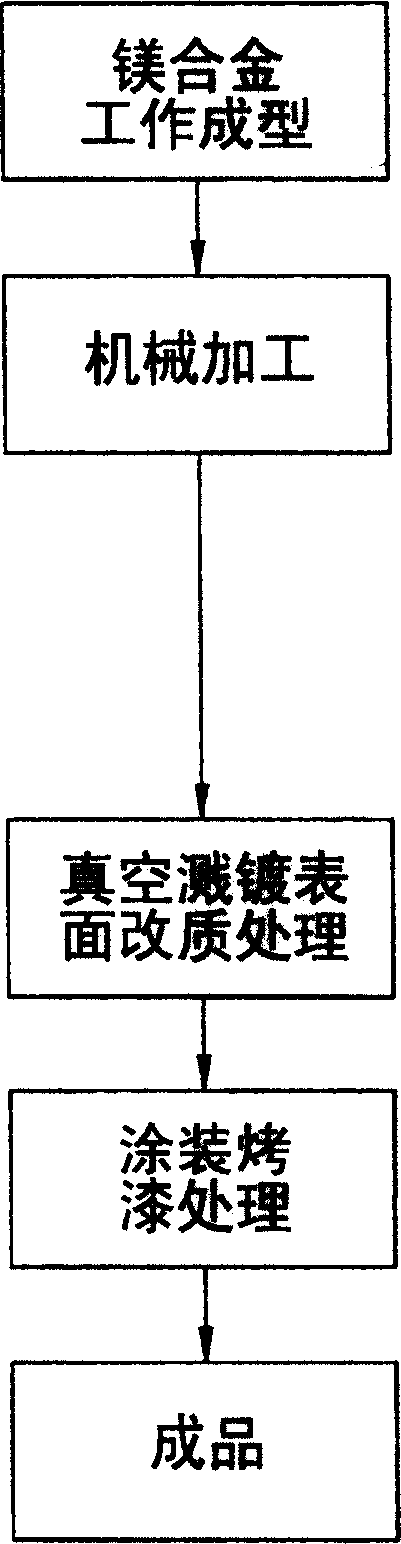

Method for manufacturing metallic products and production

InactiveCN1660510AReduced burst defectsImprove the excellent rateVacuum evaporation coatingPretreated surfacesSputteringMaterials science

A method for preparing the product of the soft metal difficult to machine, such as Mg-alloy or MgAl-alloy, features a vacuum sputtering method is used for modifying the surface of said product. Said Mg-alloy product has high surface quality.

Owner:SILITECH TECH CORP

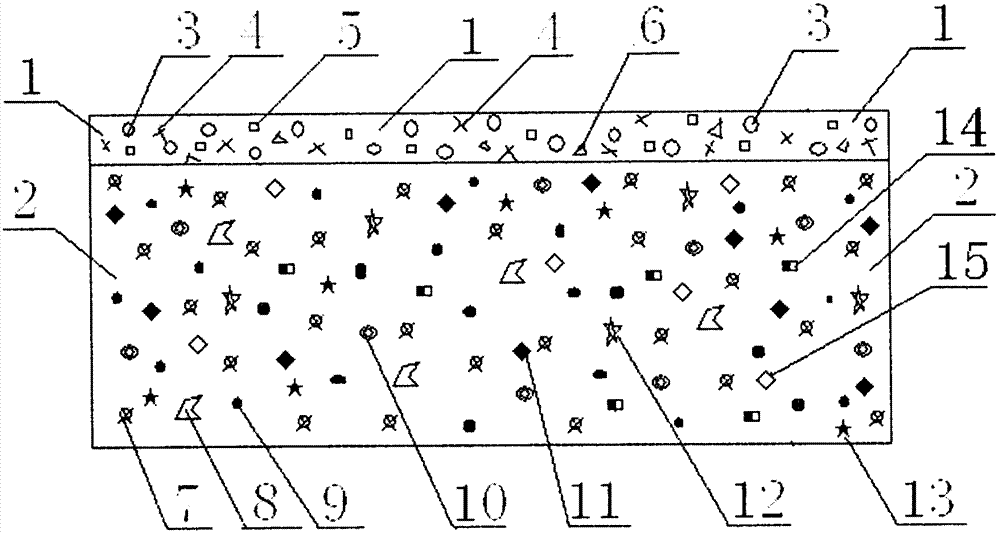

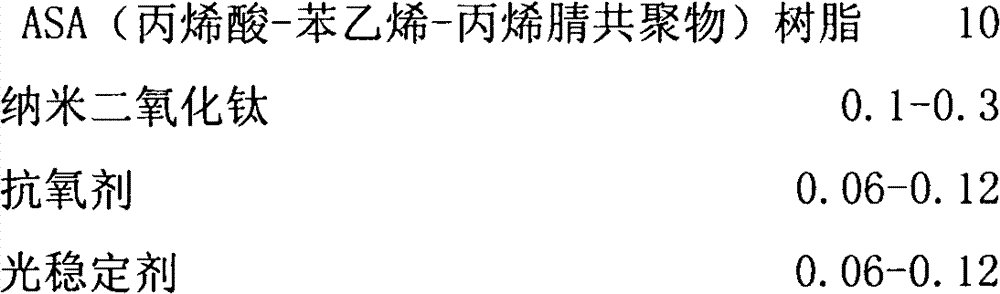

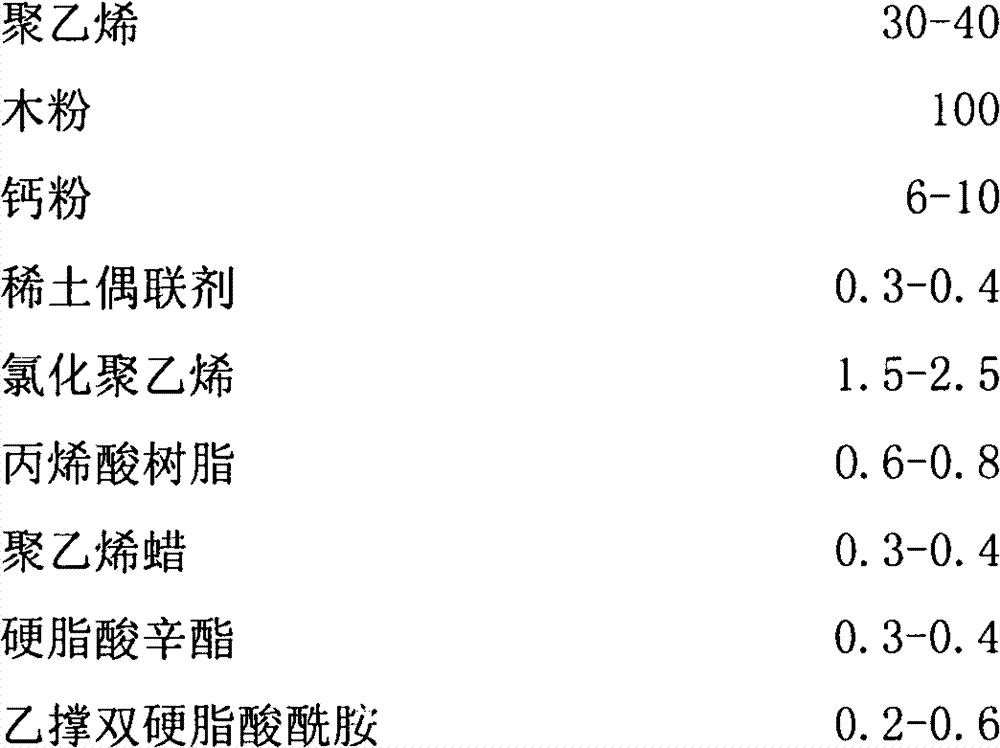

Co-extrusion formed wood-plastic composite plate and preparation method thereof

The invention discloses a co-extrusion formed wood-plastic composite plate and a preparation method thereof, which discloses a composite material, a structural material and the preparation method of the materials. The co-extrusion formed wood-plastic composite plate is composed of an anti-aging resin layer and a wood-plastic structural layer, wherein the anti-aging resin layer is located on the surface of the wood-plastic structural layer. The anti-aging resin layer is formed by melting, blending and extruding an ASA (Acrylonitile-Styrene-Acrylate) resin, titanium dioxide, an antioxidant and a light stabilizer; and the wood-plastic structural layer is formed by extruding polyethylene, wood power, calcium powder, a rare-earth coupling agent, chlorinated polyethylene, acrylic resin, polyethylene wax, octyl stearate and ethylene bis stearamide. Different molten material flows are formed by the anti-aging resin layer and the wood-plastic structural layer, and then the material flows are converged in a compound machine head and co-extruded by a neck mould, so that the co-extrusion formed wood-plastic composite plate is prepared. Besides the characteristics of multiple purposes of common wood-plastic plates, the wood-plastic plate has more excellent anti-aging property and does not age after a long use in the open air. The co-extrusion formed wood-plastic composite plate disclosed by the invention is suitable for preparing indoor and outdoor floors, guardrails, decorative sheets and the like.

Owner:NANJING FORESTRY UNIV

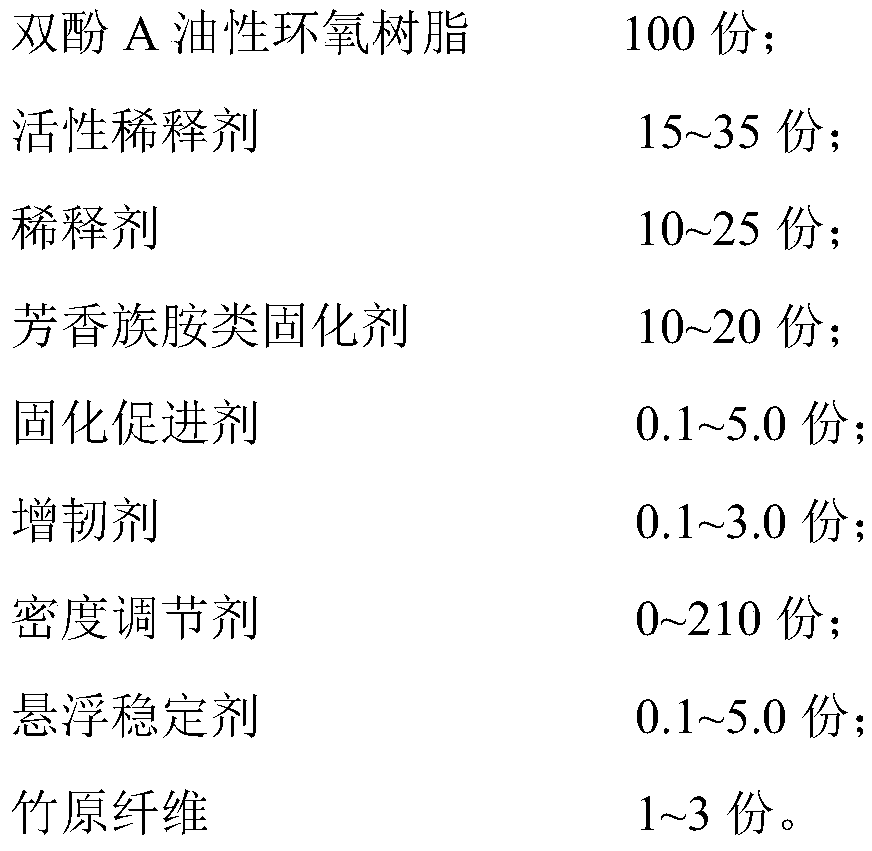

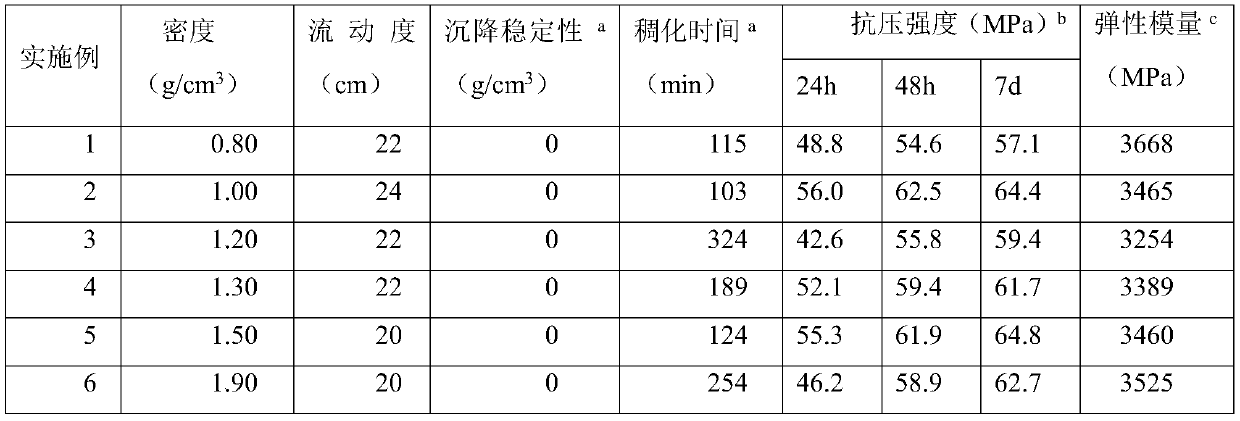

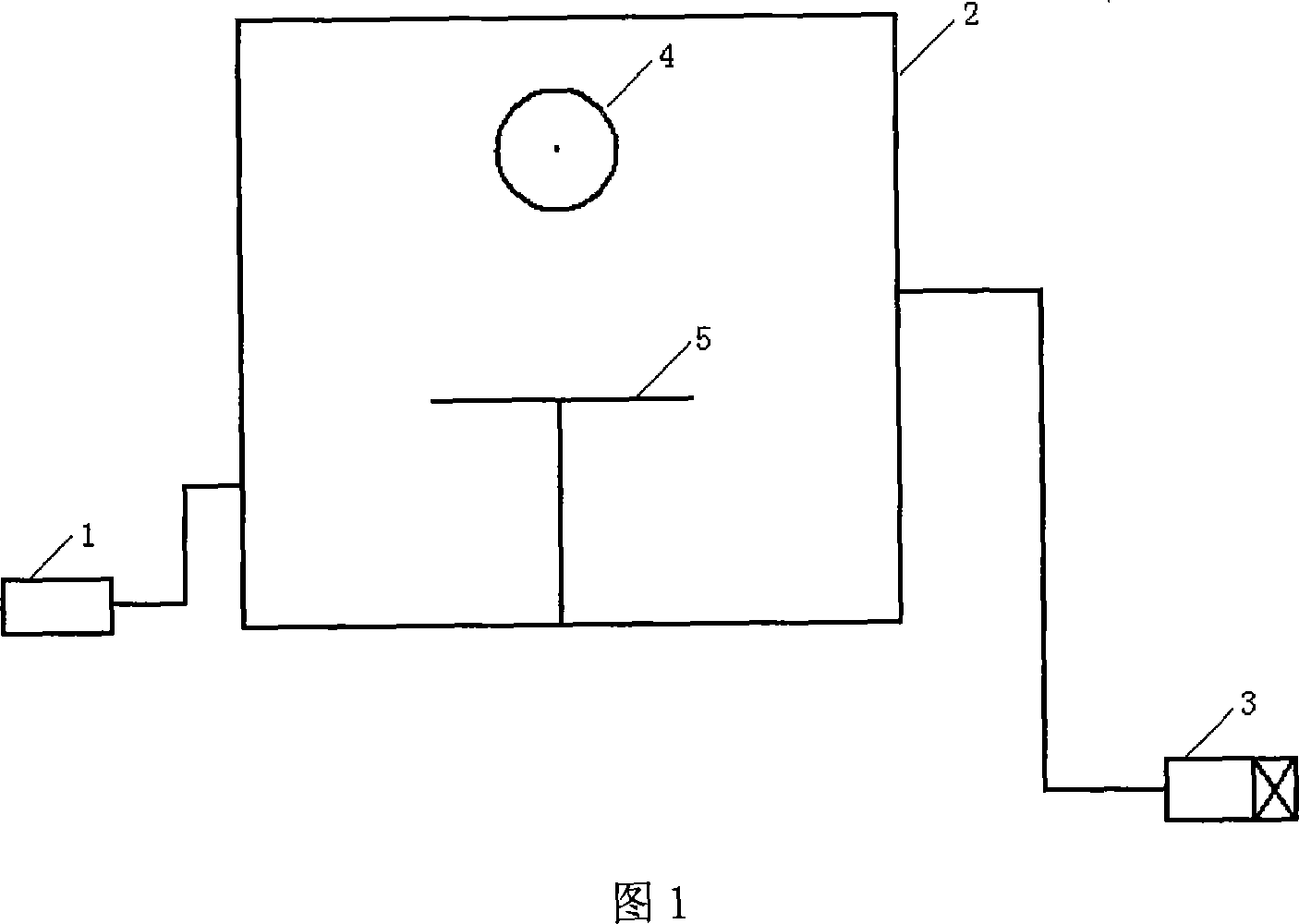

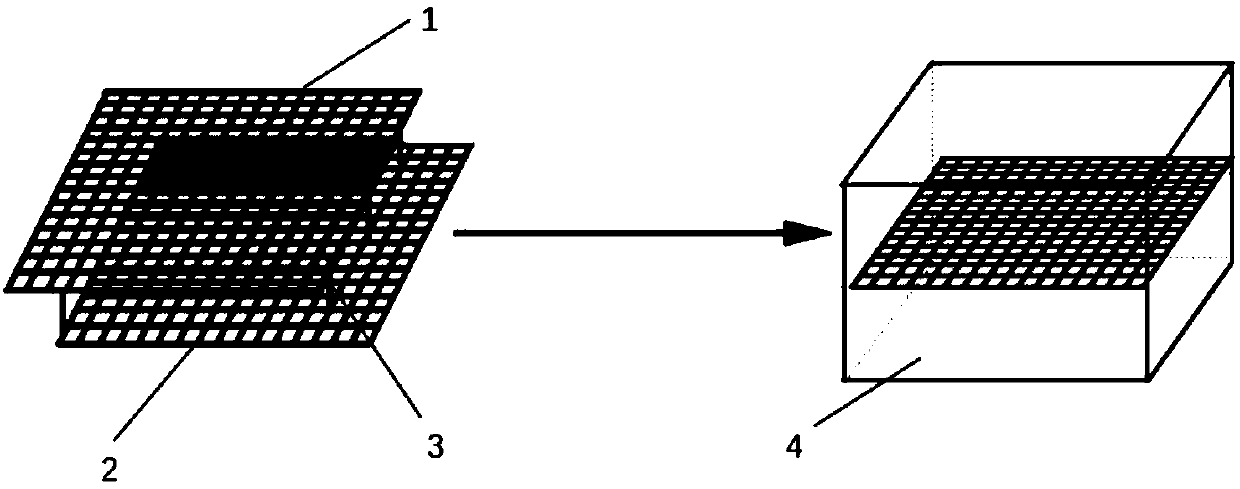

Epoxy resin-based well cementing fluid and preparation method thereof

The invention relates to an epoxy resin-based well cementing fluid and a preparation method thereof. The well cementing fluid includes, by weight, 100 parts of bisphenol A oily epoxy resin, 15-35 parts of an active diluent, 10-25 parts of a diluent, 10-20 parts of an aromatic amine curing agent, 0.1-5.0 parts of a curing accelerator, 0.1-3.0 parts of a flexibilizer, 0-210 parts of a density regulator, 0.1-5.0 parts of a suspension stabilizer and 1-3 parts of natural bamboo fibers. The flexibilizer is modified nano graphene oxide, and is prepared by the following steps: dissolving nano grapheneoxide powder into an ethanol solution; carrying out ultrasonic treatment to form a uniform dispersion liquid; adjusting the pH value of the system to 3-5; slowly dropwise adding an absolute ethyl alcohol mixed solution of gamma-aminopropyltriethoxysilane; putting the mixture into a microwave reactor for treatment; then performing washing, centrifugation, drying and grinding. The well cementing fluid is good in flowability, easy to pump, adjustable in thickening time, wide in density range and wide in applicable temperature, and the preparation method is reliable in principle, easy and convenient to operate and free of pollution to the environment and has wide market application prospects.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Quasi-molecule ultraviolet source treatment method and device for textile surface modifying

InactiveCN101235589ASurface modification treatment is efficientGood surface modificationPhysical treatmentAnimal fibresBreaking strengthUltraviolet

The invention relates to a method for processing excimer laser irradiation, which is used for modifying textile surface, which comprises following steps: firstly, placing an object which will be processed, secondly, regulating the distance between the excimer laser irradiation and textile, thirdly, regulating the pressure strength in an excimer laser irradiation processing chamber, fourthly, processing by irradiating, and irradiating the object which will be processed for 0.1-0.5min. The method of the invention for modifying the surface of the textile is highly effective and convenient. The hydrophilicity of the textile surface which is modified is greatly increased, the appearance dying depth is also improved, and the influence for warp and weft breaking strength is not big.

Owner:DONGHUA UNIV

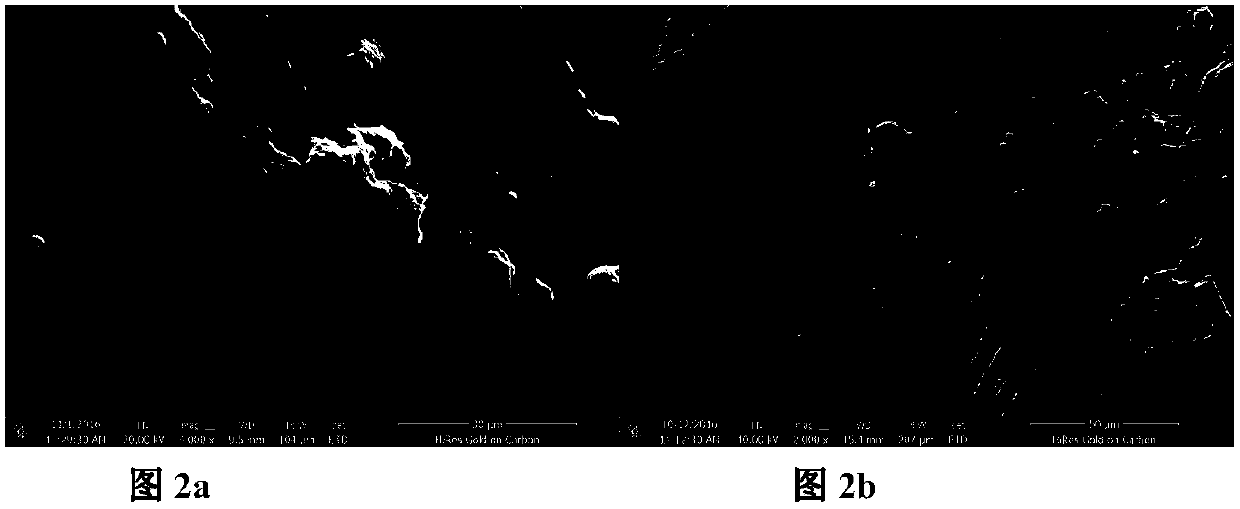

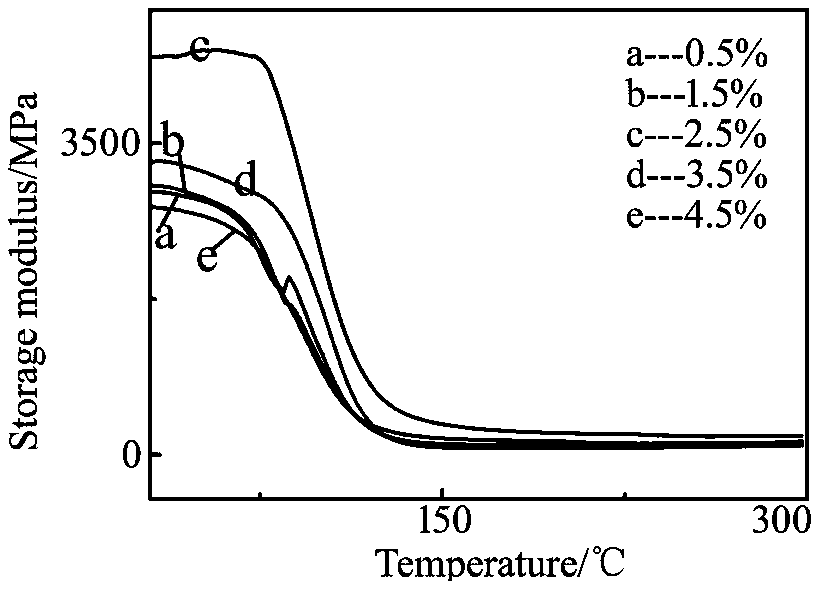

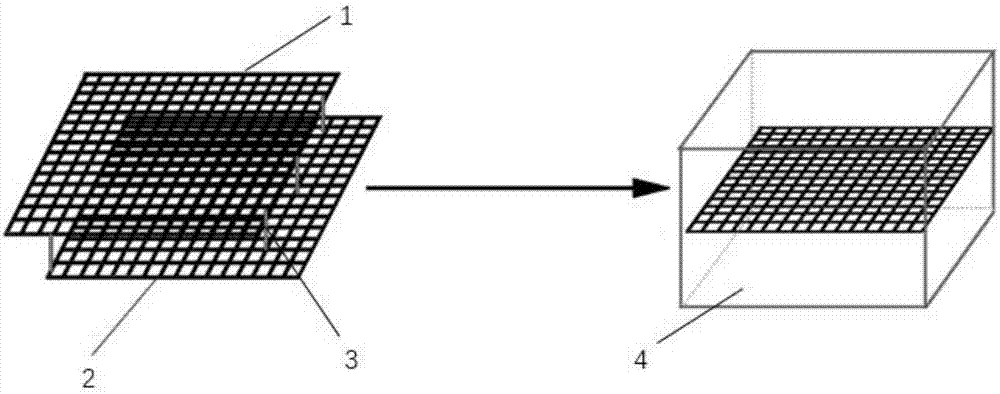

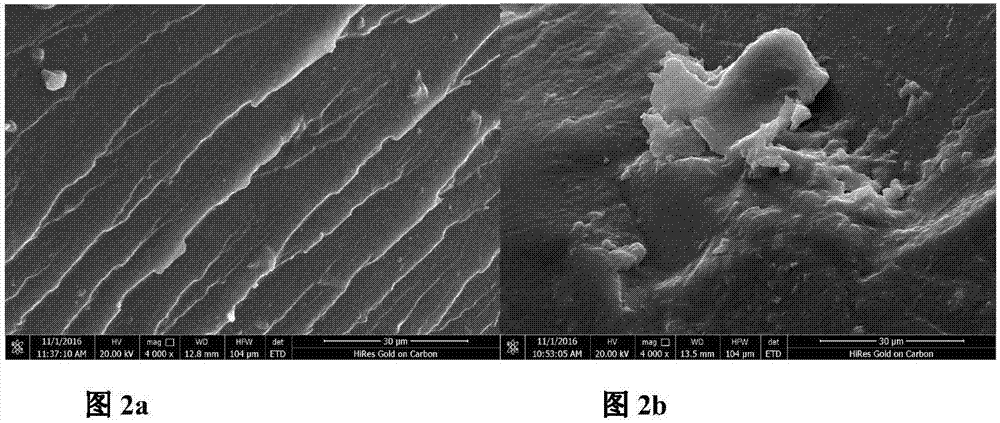

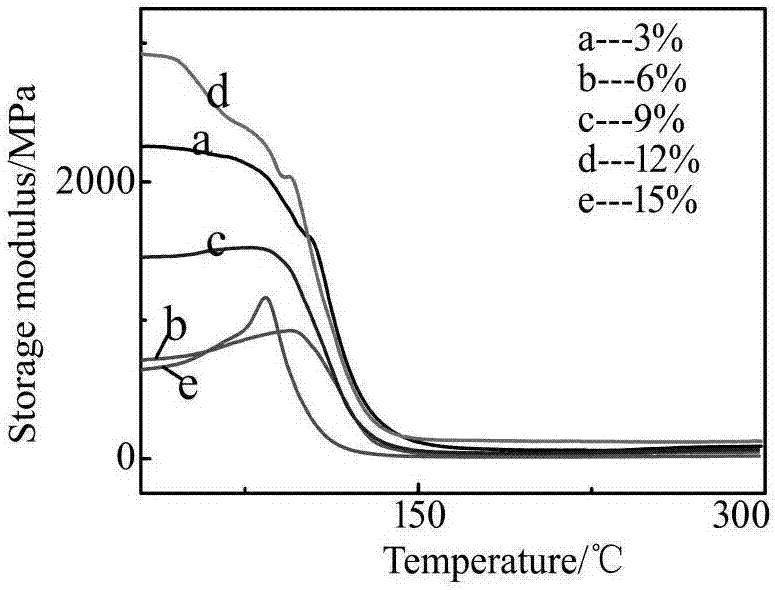

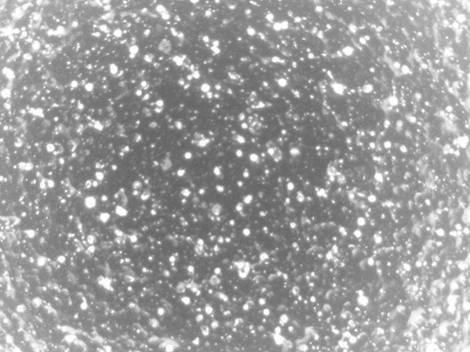

Preparation method for silane coupling agent modified CNTs/CFDSF/AG-80 epoxy resin composite material

InactiveCN107698739AEvenly distributedImprove conductivityCarbon fibresDry-cleaning apparatus for textilesEpoxyFiber

The invention relates to a preparation method for a silane coupling agent modified CNTs / CFDSF / AG-80 epoxy resin composite material. The preparation method mainly comprises the following steps: step 1,acidification of carbon nanotubes (CNTs) with a mixed acid solution of concentrated nitric acid and concentrated sulfuric acid; step 2, modification of O-CNTs obtained by acidification treatment through a silane coupling agent; step 3, surface cleaning and surface modification treatment of carbon fiber double-layer spaced fabric (CFDSF); and step 4, pouring and thermocuring of CFDSF with a prepared modified CNTs / AG-80 epoxy resin solution. According to the invention, the silane coupling agent modified CNTs / CFDSF / AG-80 epoxy resin composite material prepared through the above-mentioned preparation steps and concrete process parameters thereof and with advantages of good conductivity, thermodynamic properties and less usage amount of a conducting material has the following advantages: modified carbon nanotubes are uniformly distributed in a matrix; and the composite material has good conductive stability and can be extensively applied to the fields of electronics, electrostatic protection, electromagnetic shielding, microwave absorption, etc.

Owner:SHAANXI SCI TECH UNIV

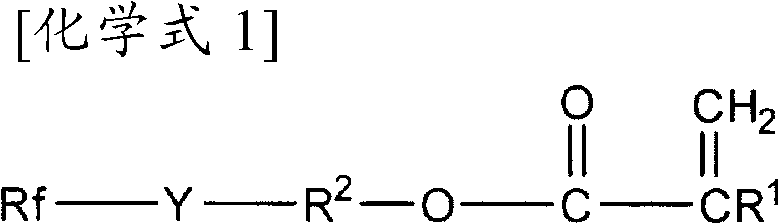

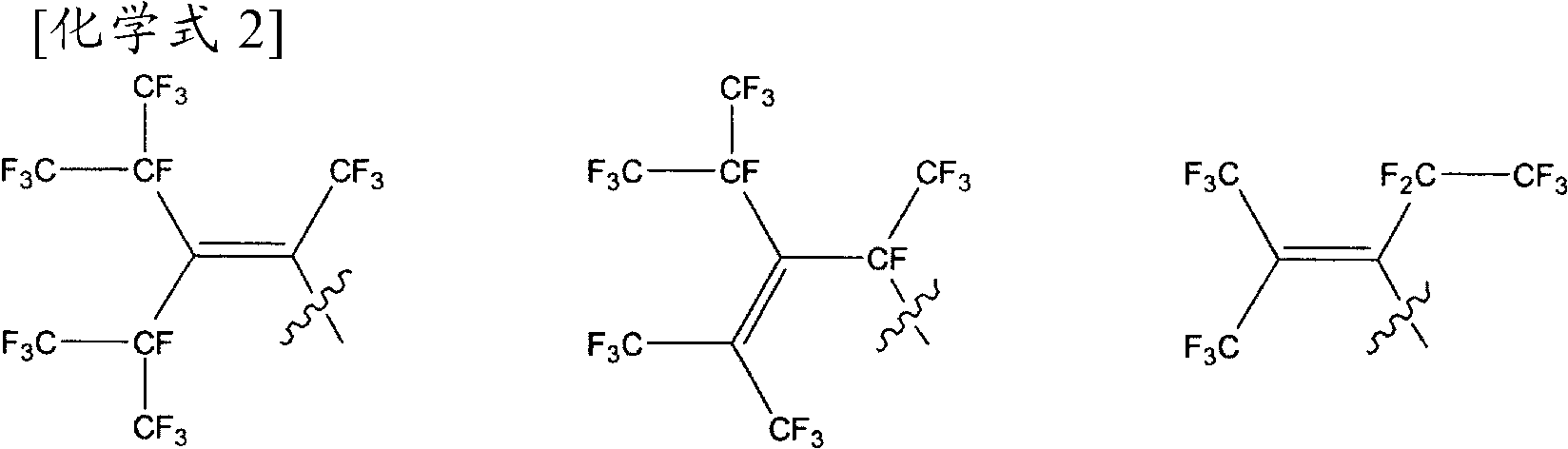

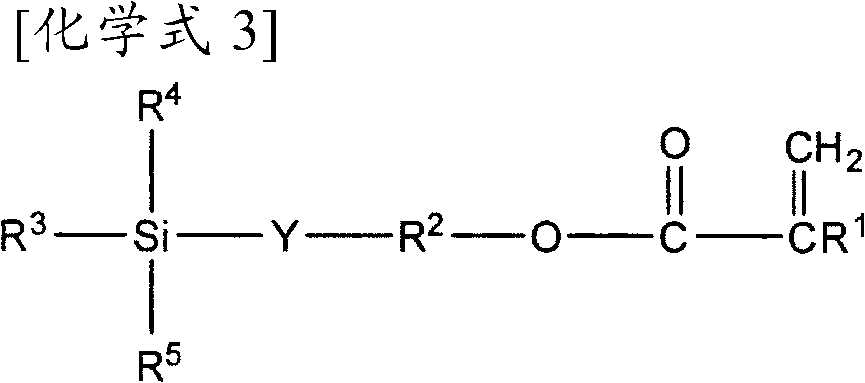

Agent for imparting antifouling properties

ActiveCN102834425AImprove solubilityGood surface modificationAntifouling/underwater paintsOther chemical processesFluorine containingPolymer chemistry

Disclosed is an agent for imparting antifouling properties, which is obtained by the copolymerization of a monomer (A), a monomer (B), and a monomer (C), wherein monomer (A) is a fluorine-containing (meth) acrylate, monomer (B) is a silicone-containing (meth) acrylate, and monomer (C) is a (meth) acrylate other than the aforementioned (meth) acrylates.

Owner:NEOS CO LTD

Preparation method of high temperature resistance ultrafine active calcium carbonate

ActiveCN109943101AStable chemical anchoringRapid responseChemical industryPigment treatment with macromolecular organic compoundsMicrowaveFiltration

The invention provides a preparation method of high temperature resistance ultrafine active calcium carbonate, and relates to the technical field of preparation and processing of calcium carbonate powder. The preparation method comprises the following steps of S1, preparing an ultrafine calcium carbonate slurry; S2, adding a dispersing agent into the ultrafine calcium carbonate slurry prepared byS1, and aging for 24-144 hours to obtain an aged slurry; S3, adding a surface treatment agent to the aged slurry prepared by S2, carrying out an auxiliary catalytic reaction by microwave or / and high pressure, after the surface treatment is finished, dehydrating the slurry by pressure filtration, drying, and pulverizing to obtain the calcium carbonate. The surface treatment agent is surface-hydrophilically-treated fatty acid, and the surface treatment agent accounts for 3-5% the mass of the dry basis of the calcium carbonate. The ultrafine active calcium carbonate can maintain the activation degree at 350 DEG C, and do not volatilize and turn yellow. The ultrafine active calcium carbonate can be widely applied to products having a processing temperature of 270 DEG C or higher such as BOPP and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

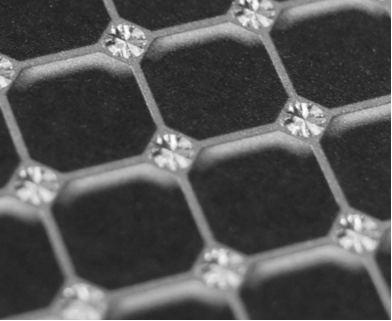

Preparation method of diamond-copper composite material with high diamond volume fraction

ActiveCN110317987AGood surface modificationProcess parameters are easy to controlThermal expansionElectron

The invention discloses an SPS (spark plasma sintering) preparation method of a diamond-copper composite material with a high diamond volume fraction. Firstly, diamond is subjected to surface modification, and tungsten carbide is generated from tungsten and a part of carbonized diamond under the function of thermal diffusion and is attached to the surface of the diamond; next, the diamond and copper powder are mixed uniformly with a wet-grinding and mixing method; finally, sintering is carried out with an SPS technique and the diamond-copper composite material is formed. Compared with a composite material obtained through direct sintering of diamond and copper, the composite material has the characteristics of high thermal conductivity and low thermal expansion coefficient and can be usedfor a new generation of electronic packaging materials.

Owner:安徽尚欣晶工新材料科技有限公司

Radiation curing transfer bright abrasive paper and preparation method thereof

PendingCN111235960AUnique sand effectGood effectSpecial visual effect coatingsFlexible coversVacuum evaporationMaterials science

The invention discloses a radiation curing transfer bright abrasive paper and a preparation method thereof. Organic frosted particles are added into a coating to replace existing inorganic frosted particles, the frosted effect is adjusted through the particle size and proportion of organic frosted particles, the particles are in an island-shaped dispersed state in a coating, gaps among the particles play a role in extinction after evaporation, the particles show a bright crystal effect after evaporation, and then the radiation curing transfer bright abrasive paper is prepared through a radiation curing coating process, a vacuum evaporation process and a transfer process. The obtained product is high in interlayer bonding fastness, high in surface smoothness, brightness and glossiness, highin bright crystal sand feeling, unique in sand feeling effect, large in visual impact force and good in re-modification performance. A radiation curing process is adopted for preparation, so that theproduction efficiency is high, the energy consumption is low, and zero emission of volatile organic compounds is realized in the process.

Owner:YANTAI BOYUAN TECH MATERIALS

Superfine powder cooling method

The invention provides a superfine powder cooling method. The method comprises the following steps of: atomizing a liquid phase protecting medium into particles with the diameter of 10 to 5,000 microns, spraying the particles into a cooler between a gas phase particle generator and a collector, coating the liquid phase protecting medium on the surface of superfine powder, cooling the superfine powder, and depositing the cooled superfine powder in the collector, wherein the tap volume ratio of the liquid phase protecting medium to the superfine powder is more than 50. The liquid phase protecting medium is water or an aqueous solution or organic liquid or an organic solution. By the superfine powder cooling method, material consumption and energy consumption are low, and the cooled superfine powder is strong in stability and good in dispersity.

Owner:JIANGSU BOQIAN NEW MATERIALS

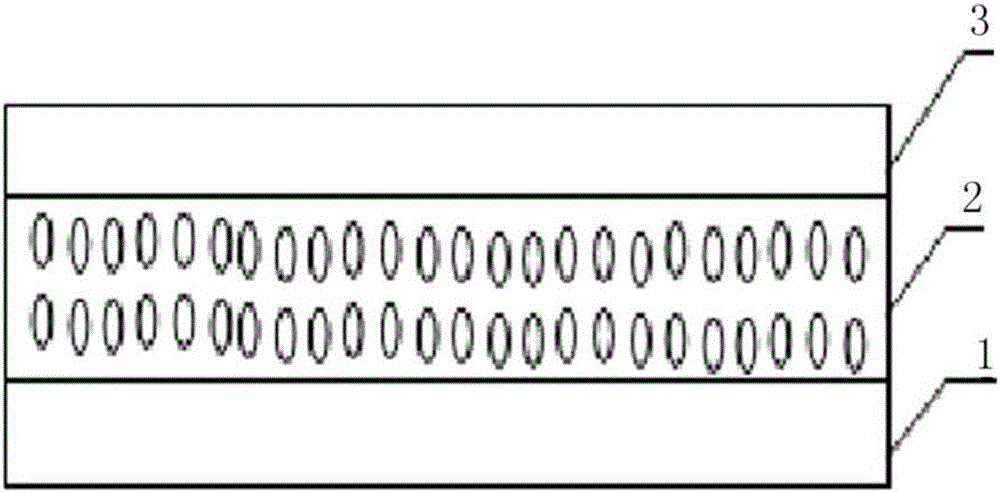

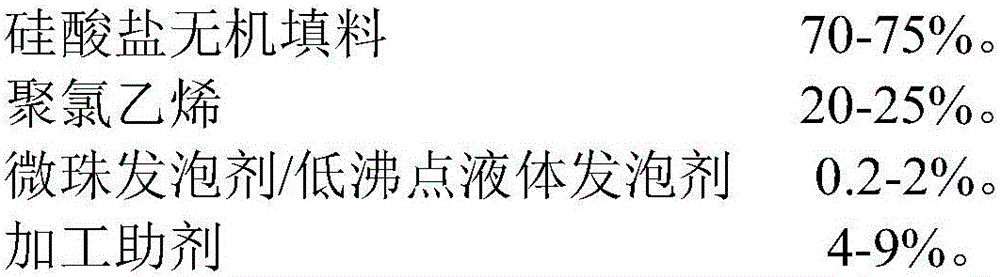

Silicate-modified PVC foamed composite decorative sheet and manufacturing method thereof

The invention discloses a silicate-modified PVC foamed composite decorative sheet and a manufacturing method thereof. The manufacturing method is mainly used for manufacturing a decorative sheet used in occasions such as a family, an office, a shopping mall and a meeting, and belongs to the technical field of composite materials. The silicate-modified PVC foamed composite decorative sheet mainly comprises three layers, namely a decorative layer, a foaming layer and a supporting layer, wherein the supporting layer is mainly prepared from silicate inorganic filler, polyvinyl chloride and a processing aid; the foaming layer is mainly prepared from silicate inorganic filler, polyvinyl chloride, a foaming agent and a processing aid; the decorative layer is mainly prepared from silicate inorganic filler, polyvinyl chloride, a color masterbatch and a processing aid. The decorative sheet has the advantages of being free of toxicity and odor as well as formaldehyde, being capable of preventing water, dampness, worm damage, light mass and high surface decoration property, being nailable, sawable and planeable, being capable of reducing the consumption of wood and macromolecular polymers, and being relatively high in strength and relatively long in service life.

Owner:SICHUAN MIANNING XICHENG TALC MINING

Preparation of nano graphite carbon colloidal SOL by pulse electrode process

InactiveCN1294078CGood surface modificationImprove stabilityElectrolysis componentsVolumetric Mass DensityPulse period

The invention discloses a method to produce nanometer graphite sol. It supplies a system which includes highly pure graphite as anode, inert materials as cathode and electrolytical aqueous solution. There is an impulsing power source to connect the anode and cathode. The pulse period of the power source is 0.05-0.5 second, effective voltage 2-10V (3-5V is prelatered) and effective amphere density 15-75A (25-35 is prelatered). The efficiency of this invention is higher than common direct-current electrode method. The produced nanometer graphite sol is stable and disperses so it can produce nanometer graphite powder whose diameter is under 15nm.

Owner:华农纳米科技(天津)有限公司

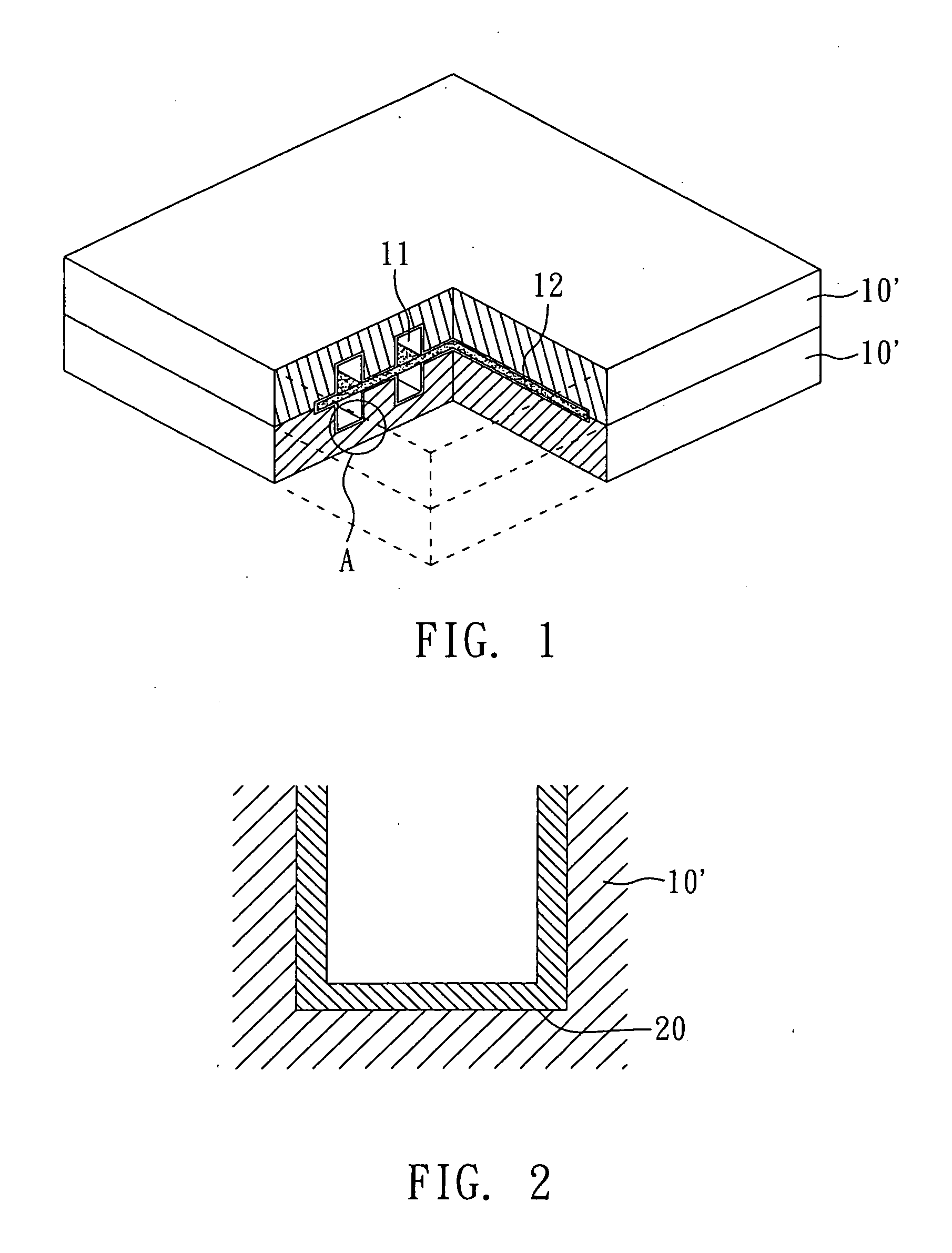

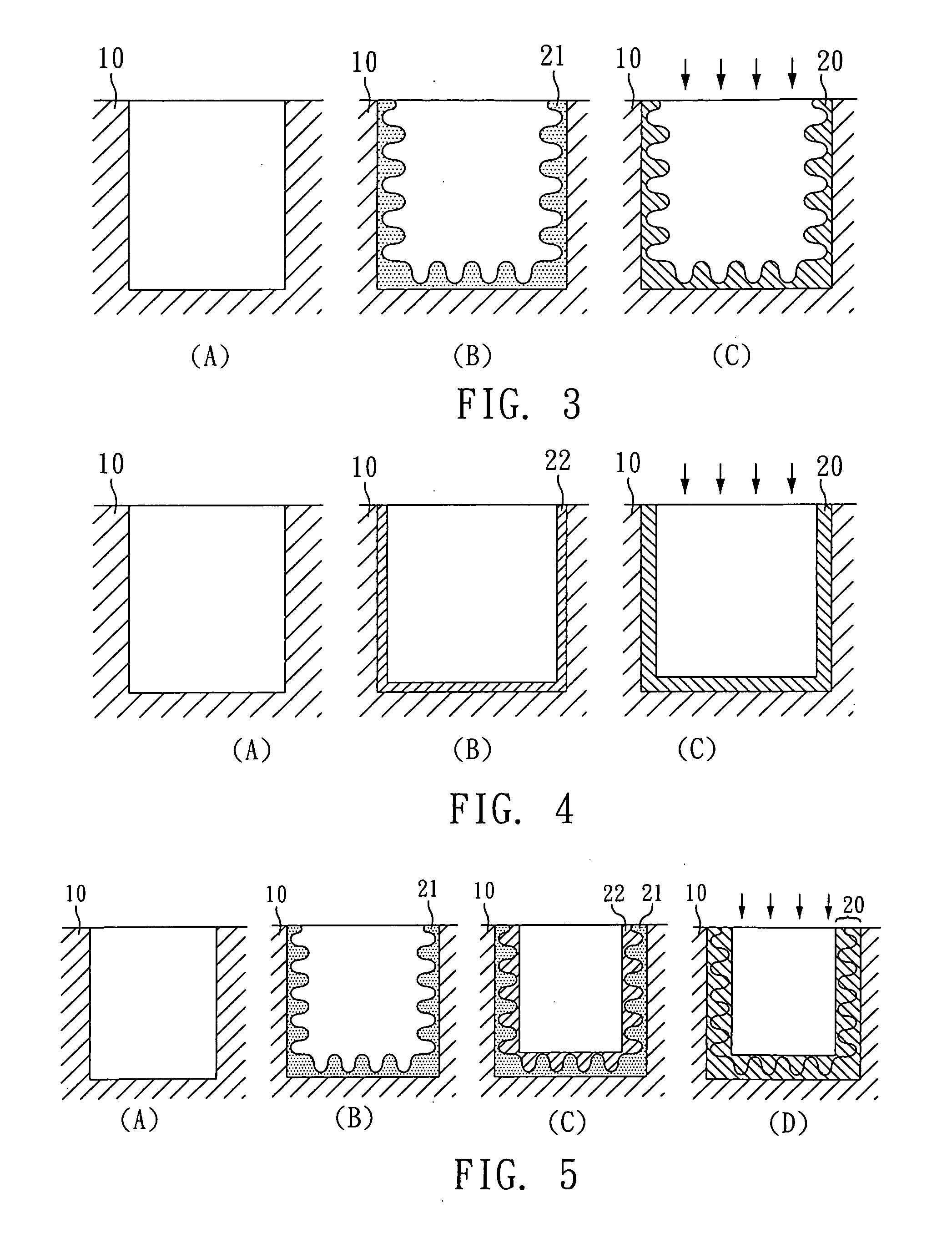

Method for preparing surface modification coating of metal bipolar plates

InactiveUS20100323101A1Increase coverageImprove adhesionElectrode manufacturing processesCoatingsPowder mixtureAlloy

A method for preparing a surface modification coating of metal bipolar plates is disclosed, which comprises the following steps: providing a metal substrate; pre-treating the metal substrate by substrate processing, depositing a Ni-based alloy layer on the metal substrate, or the combination thereof to form an activated layer on the surface of the metal substrate; packing the metal substrate in a powder mixture comprising permeated master metal, an activator, and filler powders; heat-treating the metal substrate in the powder mixture to allow the permeated master metal to diffuse into the activated layer and then to form a surface modification coating. The permeation rate of the permeated master metal can be increased due to high defect concentration of the activated layer. Hence, a corrosion-resistant surface modification coating is prepared at a low temperature, and it can decrease the interface contact resistance between the metal bipolar plates and gas diffusion layers.

Owner:NATIONAL DEFENSE UNIVERSITY

Real silk aluminum foil composite steel plate and manufacturing method thereof

InactiveCN104015435AGood metallic lusterGood surface modificationSynthetic resin layered productsLaminationEpoxyPolyurethane adhesive

The invention provides a real silk aluminum foil composite steel plate and a manufacturing method thereof. The composite steel plate comprises a PE (polyethylene) protection film, a PET (polyethylene glycol terephthalate) real silk film, a steel plate and a back coating layer which are arranged in sequence from top to bottom and are closely connected with one another. The manufacturing method comprises the following steps of pre-degreasing the steel plate, degreasing and washing by water, coating the back surface of the steel plate with an epoxy resin coating by rolling, solidifying and drying to form the back coating layer, coating the bottom coating layer of the steel plate with a polyurethane adhesive, solidifying to form a second adhesive layer, and compounding the second adhesive layer with a real silk aluminum foil film to obtain the real silk aluminum foil composite steel plate. Compared with a general composite steel plate, the real silk aluminum foil composite steel plate manufactured by adopting the method is better in metal luster and surface modification property, relatively low in relative cost, excellent in performance and environment-friendly in manufacturing process, and especially is very popular in consumers due to the characteristic of diversified appearances; the technical gap in the field of real silk aluminum foil composite steel plates in China is filled up.

Owner:合肥禾盛新型材料有限公司

Surface modification method for nano calcium carbonate

ActiveCN102174275BOvercome the disadvantage of being difficult to disperseGood dispersionPigment physical treatmentPigment treatment with non-polymer organic compoundsPolyvinyl chlorideSlurry

The invention discloses a surface modification method for nano calcium carbonate, which is characterized by comprising the following steps of: adding inorganic alkali into nano calcium carbonate slurry, uniformly stirring, heating the slurry, adding fatty acid and performing surface modification. The method comprises the following specific steps of: adding a certain amount of nano calcium carbonate slurry into a reaction kettle, adding 0.00004 to 0.00040mol of inorganic alkali into 1g of CaCO3, and uniformly stirring; heating to the temperature of between 75.0 and 90.0 DEG C, adding 0.00005 to 0.00035mol of fatty acid or fatty acid salt into 1g of nano calcium carbonate (CaCO3) slurry, reacting, and continuously stirring for 30 to 120 minutes; and after surface modification reaction is finished, cooling, filtering, washing, drying and grinding the slurry to obtain the nano calcium carbonate subjected to surface modification. The method is simple and practicable, a modifier can form a uniform and complete coating layer on the surface of the nano calcium carbonate, and the modified product has a good application effect in polymer such as silicone sealant, polyvinyl chloride (PVC) paste resin and the like.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

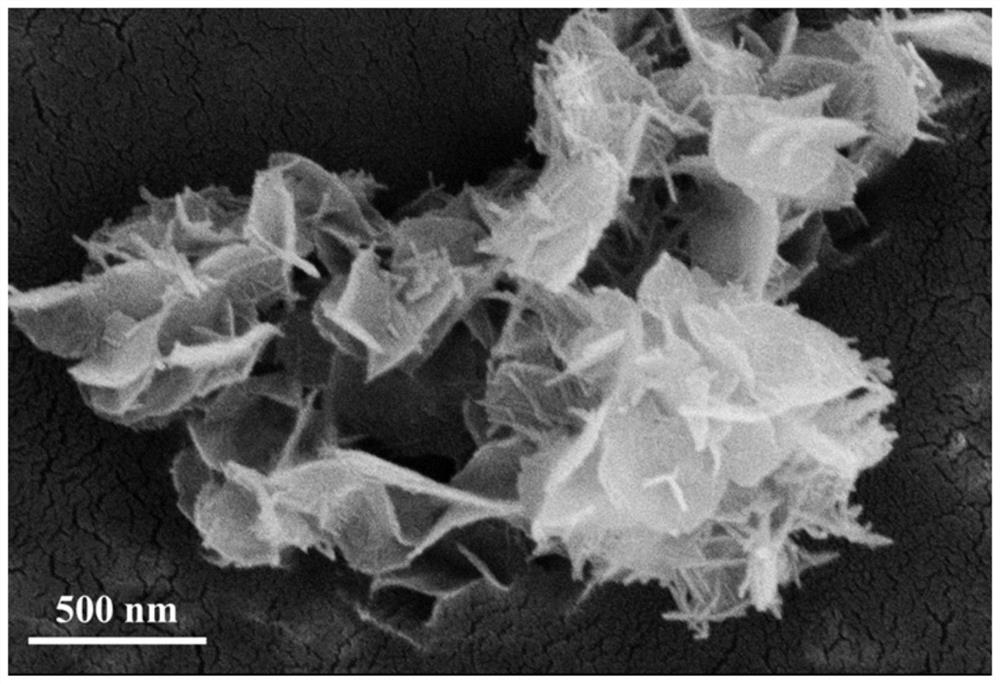

Low-cost composite surface modification method for lithium-ion battery negative electrode material

ActiveCN109935792ALow priceSolve the problems of poor rate performance and high current charge and discharge performanceCell electrodesLithium-ion batterySurface modification

The invention discloses a low-cost composite surface modification method for a lithium-ion battery negative electrode material, which comprises the steps of firstly crushing three raw materials such as petroleum asphalt, a modifier and a graphitization catalyst, mixing and batching, heating in stages and crushing, introducing a carbon source for graphitization, passivating to obtain graphene nanoplatelets, enabling the graphene nanoplatelets to be subjected to polyurethane oligomer modification and SBS modification to obtain composite modified graphite, finally coating the surface of natural graphene with the composite modified graphite to form a battery negative electrode material which takes the natural graphene as the core and is externally coated with the composite modified graphite. The surface modification method is low in cost, solves the defects of high cost and uneven coating and modification of the material surface of the existing negative electrode material, and can effectively improve the efficiency and uniformity of material surface modification.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

Preparation method for silane coupling agent modified CB/CFDSF/AG-80 epoxy resin composite material

The invention relates to a preparation method for a silane coupling agent modified CB / CFDSF / AG-80 epoxy resin composite material. The method mainly comprises the following steps: 1) adopting a silane coupling agent for modifying carbon black (CB); 2) performing surface cleaning and surface modification on carbon fiber double-layer spaced fiber (CFDSF); 3) preparing a modifying CB / AG-80 epoxy resin system solution for pouring and thermosetting CFDSF. The silane coupling agent modified CB / CFDSF / AG-80 epoxy resin composite material with excellent conductivity, thermodynamic property and less dosage of conductive material is prepared according to the preparation steps and the specific technical parameters of the invention; the composite material is capable of modifying the uniform distribution of carbon black in substrate; the composite material has high conductivity stability and can be widely applied to the fields, such as electronics, electrostatic protection, electromagnetic shielding and microwave absorption.

Owner:SHAANXI SCI TECH UNIV

Film-coated radiation-cured bright abrasive paper and preparation method thereof

PendingCN111270560AStrong combination fastnessHigh brightness and glossSpecial paperPaper/cardboardVolatile organic compoundPrepolymer

The invention discloses film-coated radiation-cured bright abrasive paper and a preparation method of the film-coated radiation-cured bright abrasive paper. The paper comprises a paper base material,an adhesive layer, an evaporation layer, a frosted layer, a film layer and a surface coating, wherein the frosted layer is prepared from a frosted coating added with organic frosted particles; the frosted coating is prepared from the following components in parts by weight: 20-70 parts of a prepolymer, 20-70 parts of an active diluent, 1.0-20.0 parts of organic frosted particles, 0-5.0 parts of aphotoinitiator and 1.0-5.0 parts of an auxiliary agent. By means of the technical scheme, the paper has bright bright crystal effect, strong visual impact effect, visual impression of frosted and gravel, smooth surface, low energy consumption, zero emission of volatile organic compounds in the technological process, and environmental protection.

Owner:YANTAI BOYUAN TECH MATERIALS

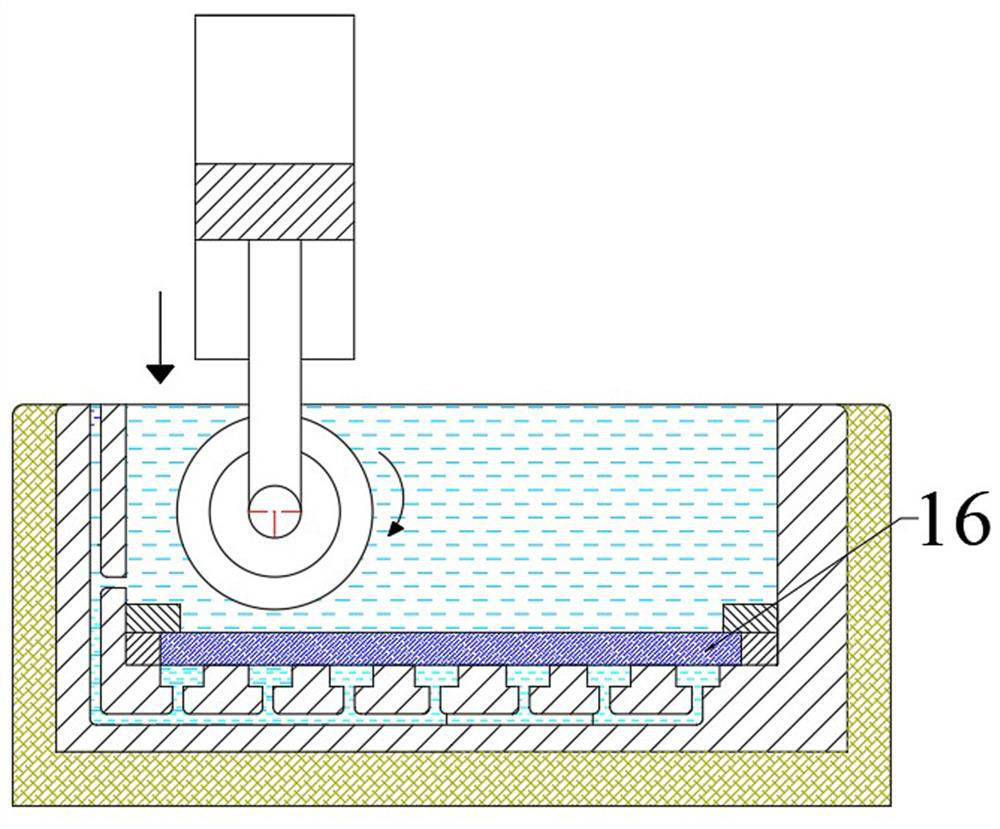

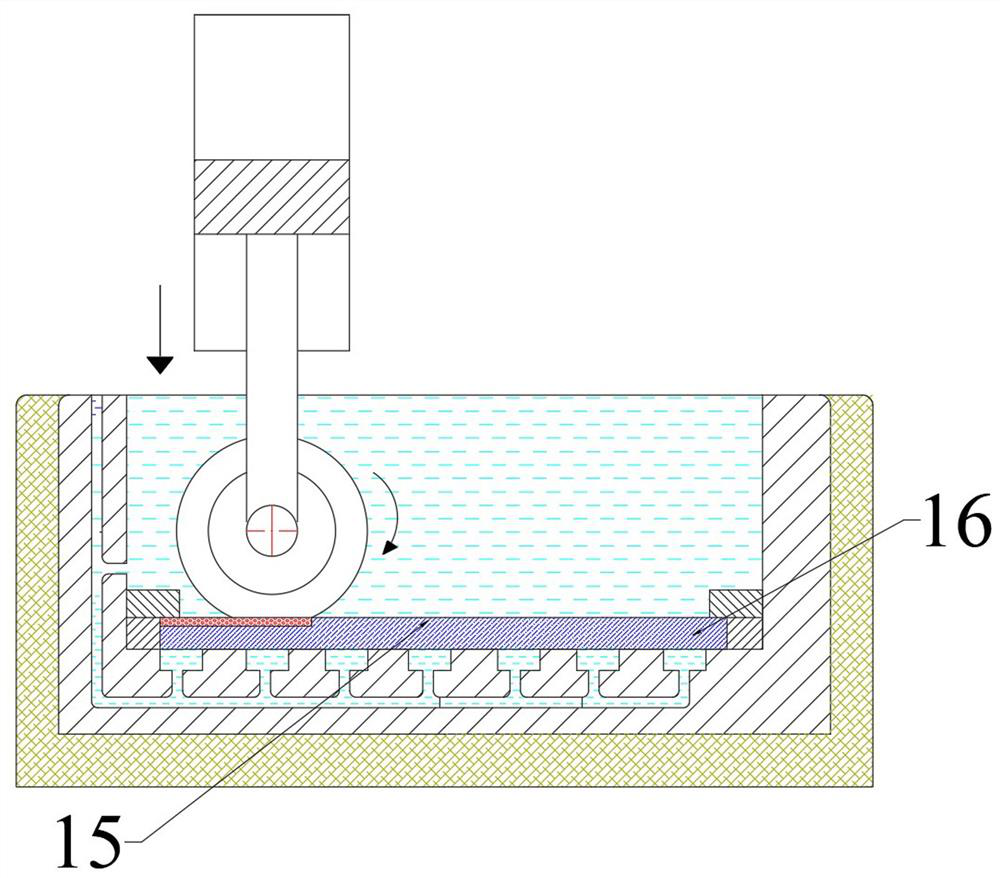

Ultralow-temperature rolling imprinting strengthening method and device for surface of austenitic stainless steel plate

The invention provides an austenitic stainless steel plate surface ultralow-temperature rolling imprinting strengthening method and device, and belongs to the technical field of special steel surface modification. The invention provides an austenitic stainless steel plate surface ultralow-temperature rolling impressing strengthening method and device aiming at the defects that when an austenitic stainless steel plate is in service, the surface hardness is low, scratching is prone to occurring, and attractiveness is affected. Firstly, a stainless steel plate is placed on a supporting plate in a cooling tank to be positioned, the positioned stainless steel plate and a corrugated roller are soaked and cooled at the same time through an ultralow-temperature medium filled in the cooling tank, and the temperature of the stainless steel plate is kept at the liquid nitrogen temperature. The cooled corrugated roller is driven by the servo hydraulic system to conduct rolling coining on the upper surface and the lower surface of the stainless steel plate in the liquid nitrogen environment, so that the surface strength and hardness of the stainless steel plate are remarkably improved. The austenitic stainless steel plate surface ultralow-temperature rolling imprinting strengthening method and device have the advantages of being rapid, efficient, environmentally friendly, remarkable in process integration level and strengthening effect and the like.

Owner:XINJIANG UNIVERSITY

Method for preparing Nano graphite sol by inputting pulsed dc bias to dual graphite electrodes

ActiveCN100513309CSimple processReduce manufacturing costElectrolysis componentsPulsed DCAqueous electrolyte

The method for preparing nano-graphite sol by passing a pulsed DC bias current through double graphite electrodes disclosed by the present invention is to put two graphite plates side by side in parallel into an electrolytic cell equipped with an aqueous electrolyte solution, and connect the positive and negative pulsed DC bias power supplies respectively. Negative electrode, at room temperature, apply a pulsed DC bias current with a square wave waveform, a pulse frequency of 20-50Hz, a pulse amplitude of 8-12V, a bias voltage of 2-5V, and a bias current density of 0.5-3mA / cm2 , to obtain a graphite sol with a graphite particle size of 10-30 nm. The nano-graphite sol obtained by the invention has good dispersibility and stability, saves energy, has low production cost, and is suitable for large-scale industrial production. The prepared nano-graphite sol has a wide range of applications.

Owner:BEIJING NAIAISI NEW MATERIAL TECH

Method for preparing novel packaging material with frosted effect

PendingCN111267535AStrong metal textureStrong three-dimensional senseDecorative surface effectsLight effect designsVisual perceptionMaterials science

The invention discloses a method for preparing a novel packaging material with a frosted effect. The method comprises the following steps of designing a pattern with the frosted effect, selecting an optical effect according to the pattern with the frosted effect, quantifying the optical effect, simulating the optical effect to determine the frosted effect and image units, assembling the image units, then photoengraving to prepare a mother set, and finally copying frosted information on the mother set to a substrate to obtain the novel packaging material with the frosted effect. The problems that a frosted or matte effect layer of the existing frosted material in the background art is uneven in surface, and is dim and dark and poor in metal texture visually, small in visual impact, and lowin gloss are solved, so that the novel packaging material with the frosted effect has a relatively strong metal texture, a relatively strong three-dimensional sense, a large visual impact, and high anti-counterfeiting performance, and is rich in variety, and high in selectivity.

Owner:YANTAI BOYUAN TECH MATERIALS

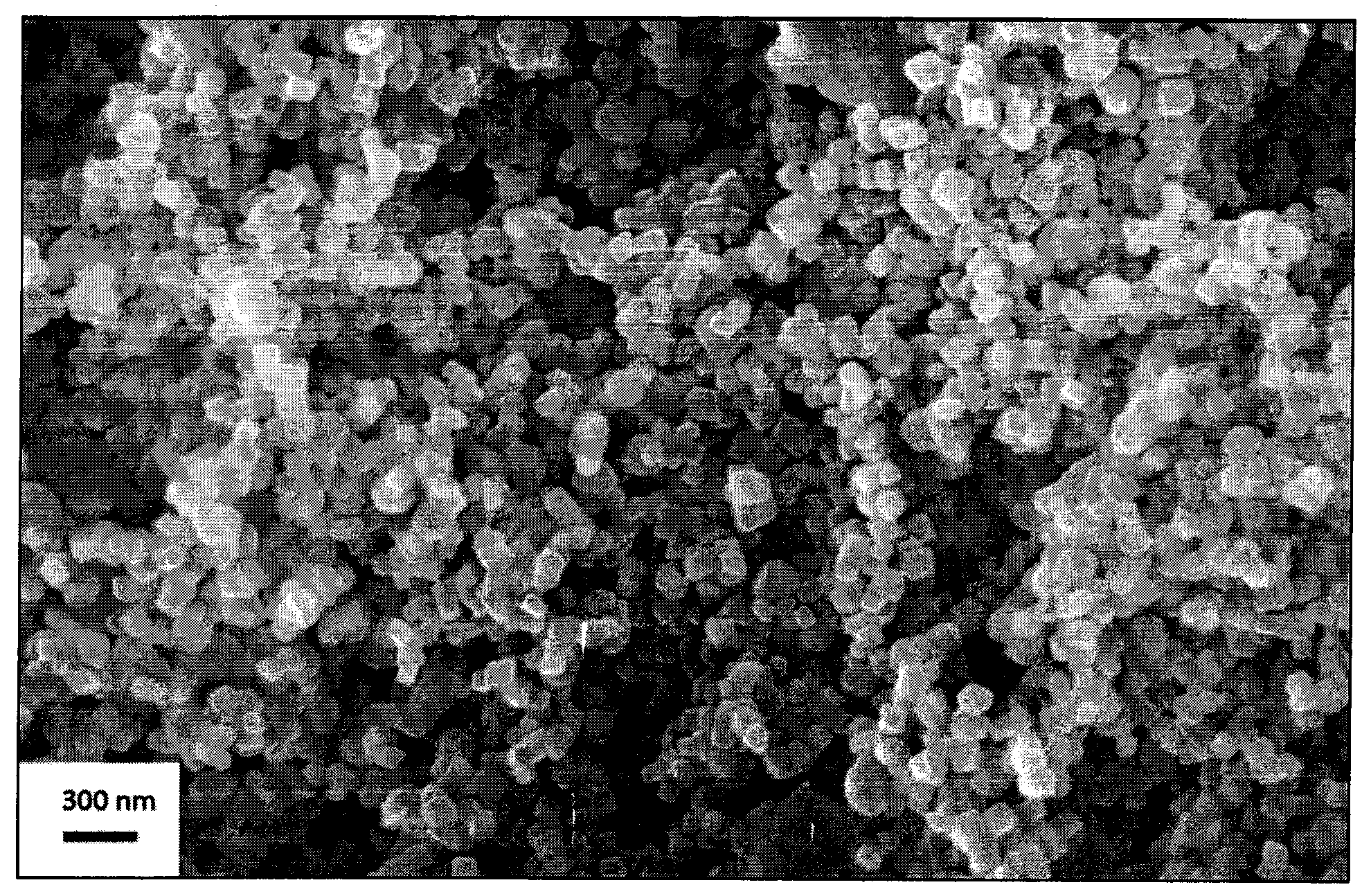

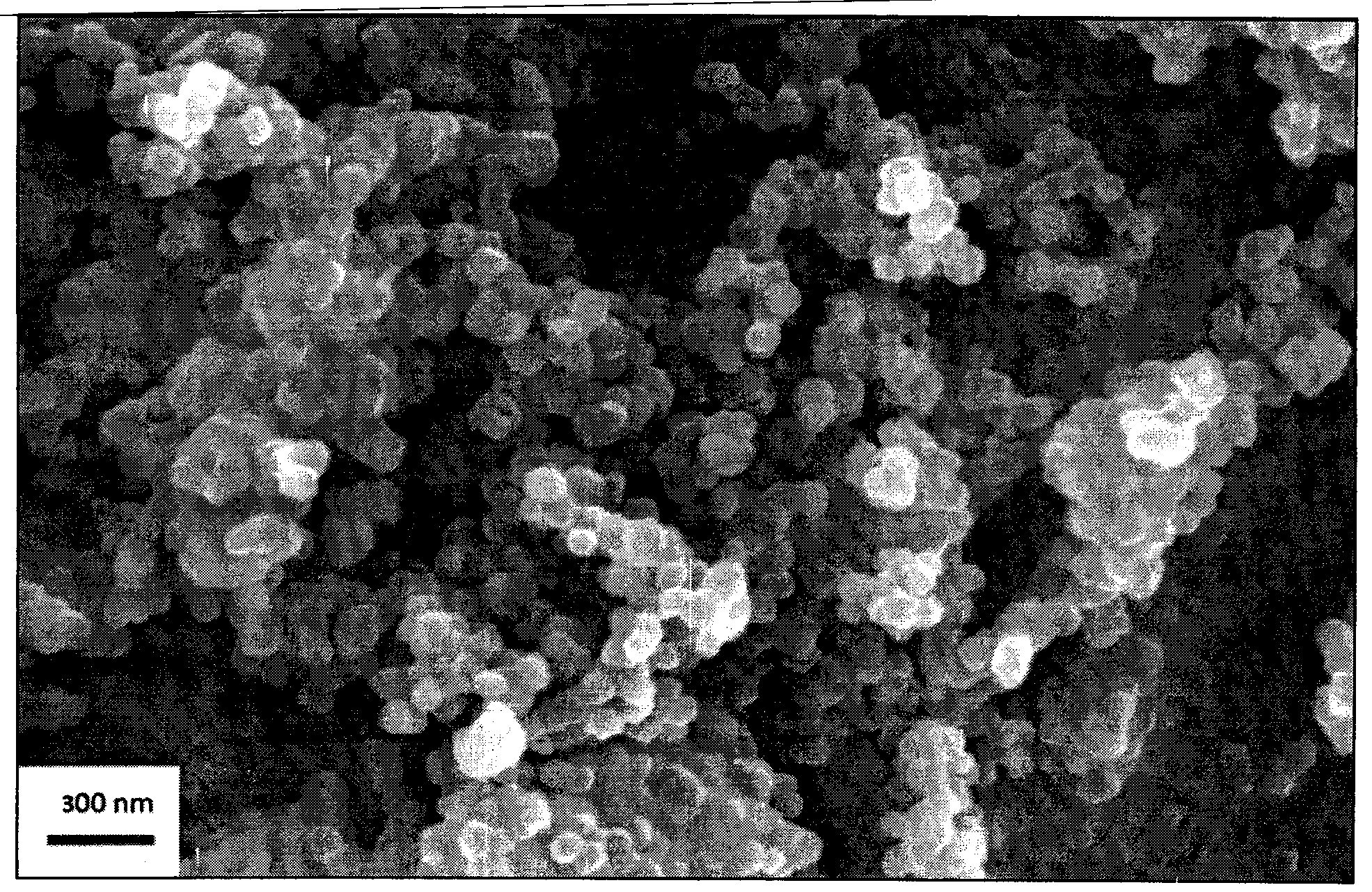

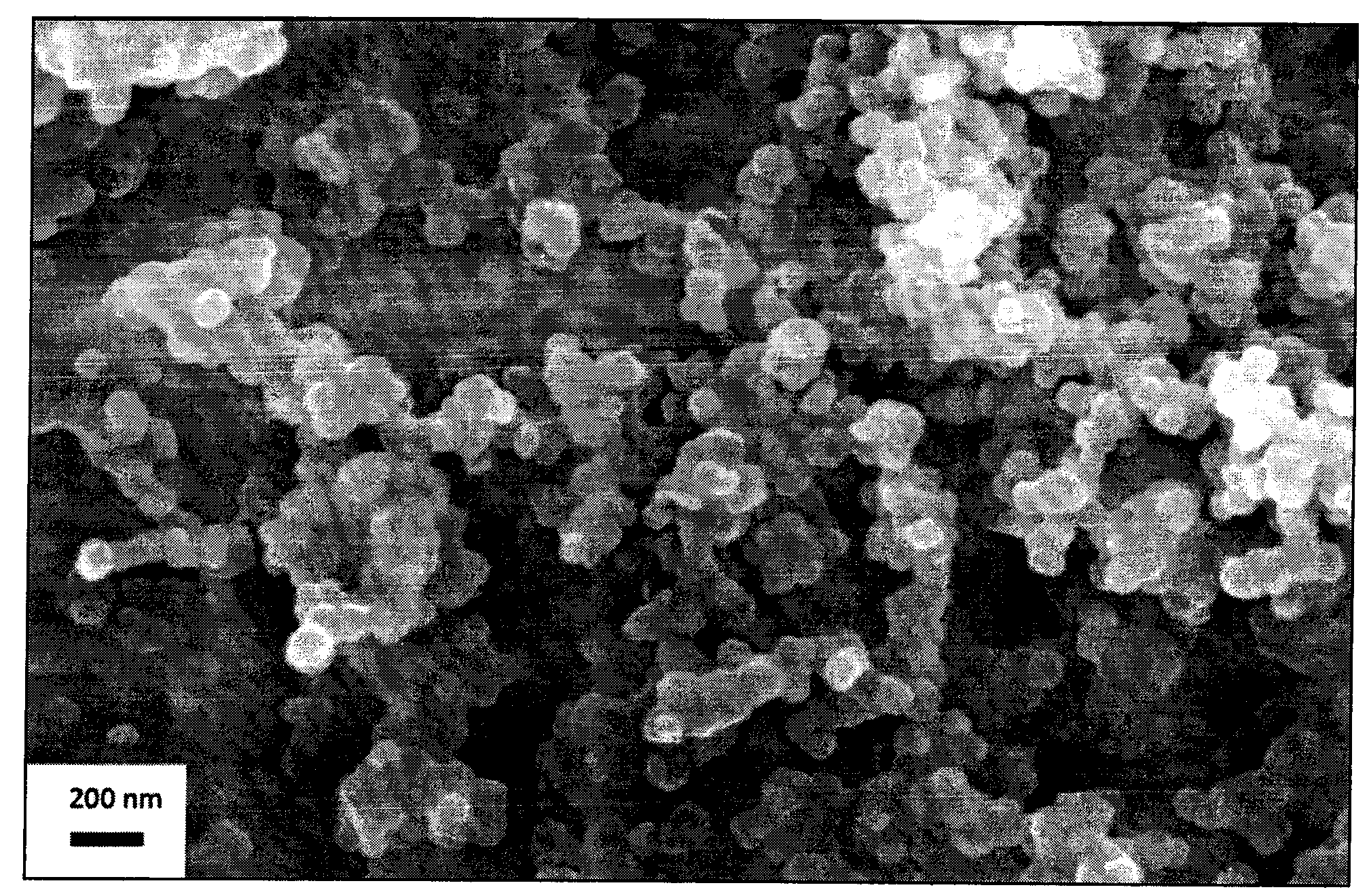

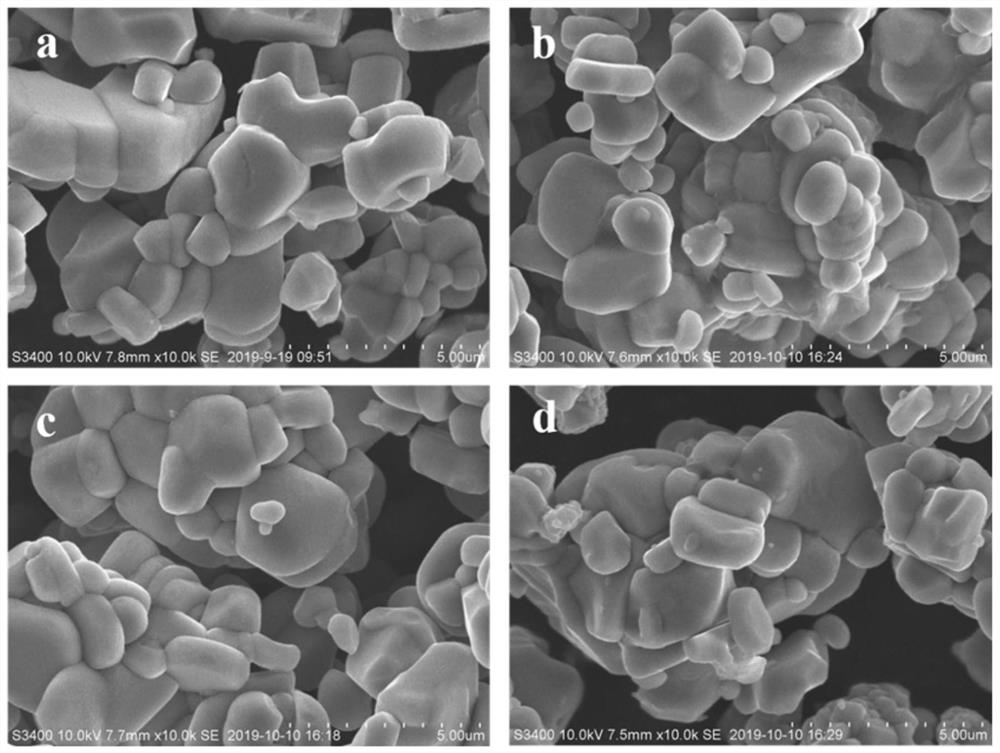

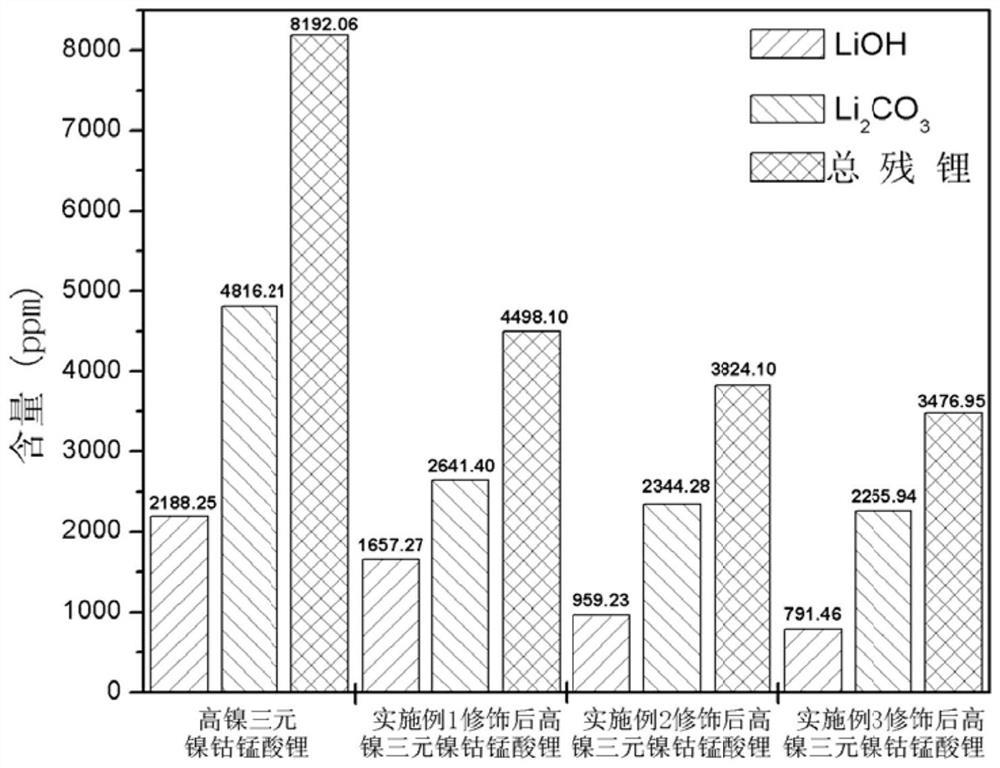

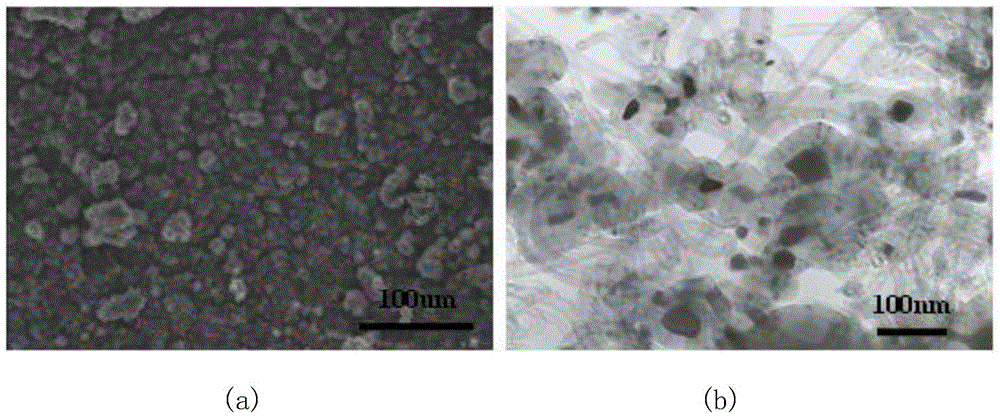

A kind of nickel cobalt manganese carbonate and its preparation method and application

ActiveCN111362318BSimple processReduce manufacturing costCell electrodesSecondary cellsPower batteryManganate

The invention discloses a method for preparing nickel-cobalt-manganese carbonate. The method is simple and convenient in process and low in preparation cost. Nano-scale nickel-cobalt-manganese carbonate with excellent surface modification effect. The invention also discloses a method for surface modification of high-nickel ternary nickel-cobalt manganese oxide lithium, specifically the nickel-cobalt-manganese carbonate prepared by the invention is used to modify the surface of high-nickel ternary nickel-cobalt lithium manganese oxide, the method It effectively improves the stability of the surface structure of the high-nickel ternary nickel-cobalt lithium manganese oxide, reduces the residual lithium on the surface, and improves the electrochemical performance and safety factor of the high-nickel ternary nickel-cobalt lithium manganese oxide. Using the modified high-nickel ternary nickel-cobalt lithium manganese oxide as the positive electrode material of the ternary lithium-ion battery can solve the problem of flatulence of the battery, greatly improve the safety performance of the battery, and provide help for its application in the field of power batteries .

Owner:JIANGMEN KANHOO IND

Surface treatment method of nano-calcium carbonate used for polyvinyl chloride plastisol

ActiveCN102492310BGood surface modificationRaw materials are cheap and easy to getPigment treatment with non-polymer organic compoundsPolyvinyl chlorideSlurry

The invention discloses a surface treatment method of nano-calcium carbonate used for polyvinyl chloride plastisol. The surface treatment method comprises the following steps: adding nano-calcium carbonate serous fluid into a reaction kettle, wherein the specific surface area (BET) of nano-calcium carbonate in the serous fluid is 18.0-60.0m<2> / g and the pH of the nano-calcium carbonate serous fluid is 8.5-9.5; heating to 70-95 DEG C, stirring, adding a mixed modifier accounting for 1.8-6.0% of the mass of the nano-calcium carbonate in the serous fluid, continuing stirring for 30-180 minutes, thus completing surface treatment. The mixed modifier is a mixture of stearic acid alkali metal saponified matter and calcium stearate, the mass ratio of fatty acid to calcium stearate in the complex modifier is 20-70%, and the proportion of the using quantity of the fatty acid to a saponifier is 1: 1. According to the method, the fatty acid is saponified by a strong base, so that the shortcoming that the fatty acid is difficult to react with the surface of calcium carbonate in water to generate the calcium stearate during wet process surface modification of the nano-calcium carbonate can be overcome; and the calcium stearate is directly introduced through fatty acid saponification liquor, so that a significant surface modification effect is obtained. The method has the advantages that raw materials are low in price and easy to obtain, the processes are simple and feasible, and the quality of a product is state. The method has significant economic benefits and social benefits.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

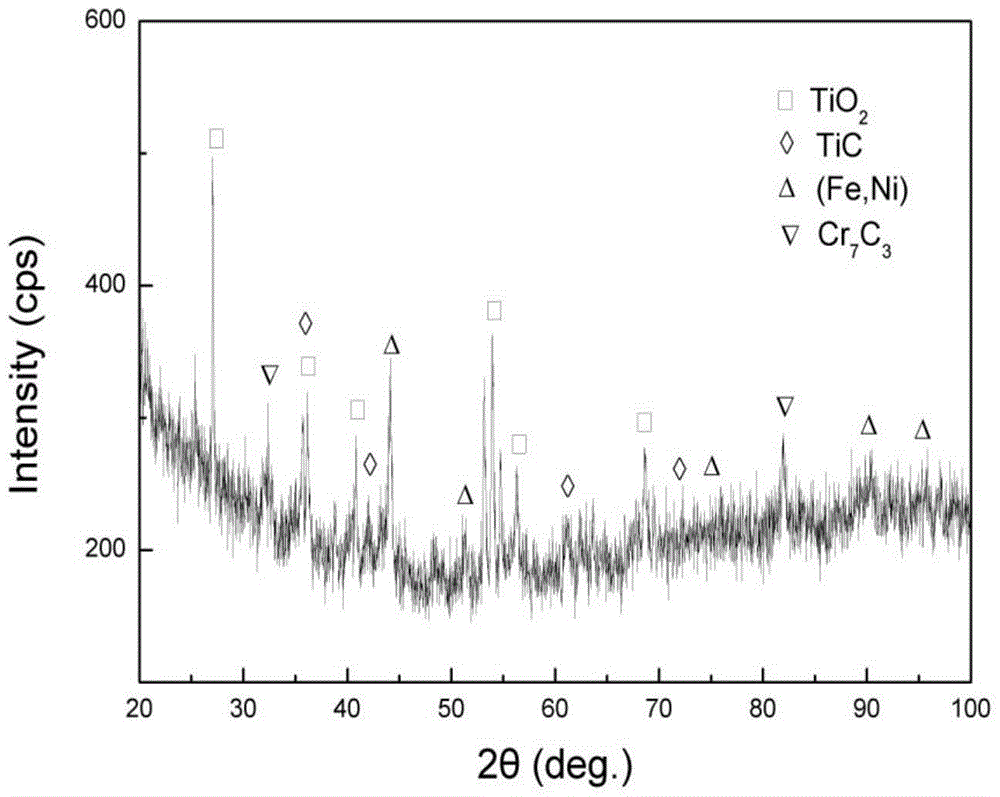

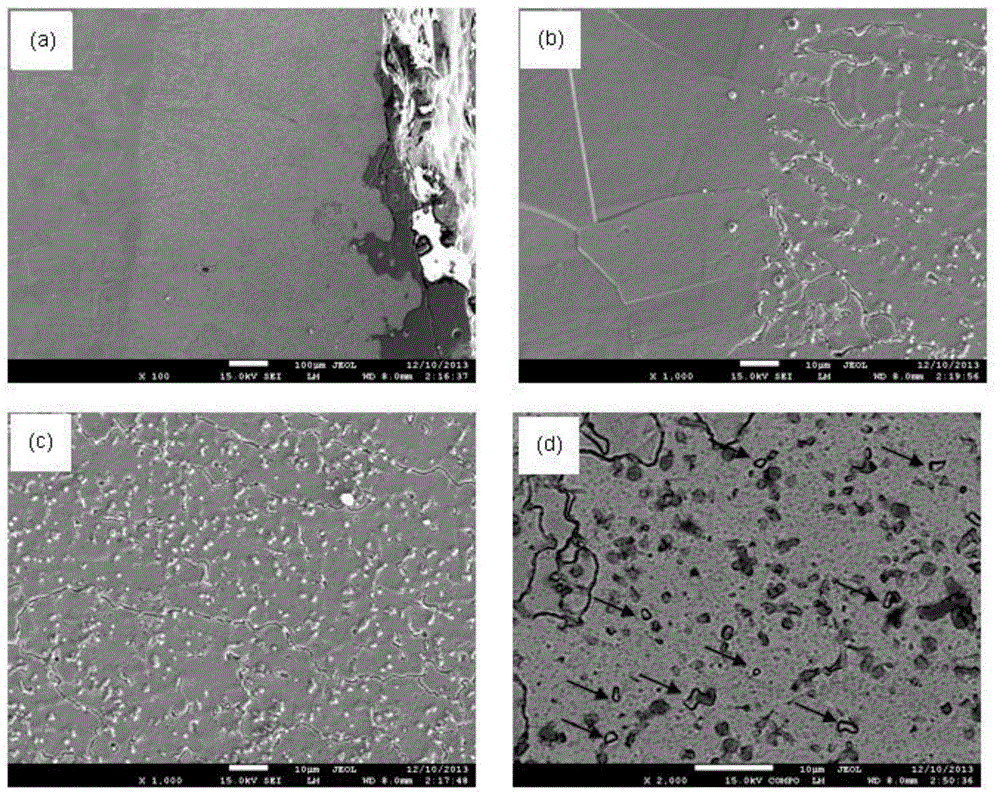

a tic-cr 7 c 3 -cnts/iron-based surface composite material and preparation method thereof

InactiveCN104388928BImprove adhesionNot easy to fall offMetallic material coating processesSurface engineeringAcid corrosion

The invention discloses a composite material belonging to the field of surface engineering, and in particular relates to a TiC-Cr7C3-CNTs / iron based surface composite material and a preparation method thereof. The preparation method comprises the following steps: pretreating an Fe-Cr-Ni stainless steel material, then reacting for 18-22 hours in a 680-700 DEG C supersaturated carbon atmosphere containing 68% of CO, 31% of H2 and 1% of H2O to obtain uniformly distributed CNTs on the surface of the stainless steel, and weighing the stainless steel before and after the reaction to obtain a difference value namely the weight of increased carbon; and according to the weight of the increased carbon, weighing Ti powder and Ni powder, mixing the Ti powder and Ni powder, and preparing the TiC-Cr7C3-CNTs / iron based surface composite material by adopting a laser cladding synchronous powder feeding technology. The composite material prepared by the method disclosed by the invention has strong cohesive force with the surface of a metal matrix, is difficult to fall off, and is high in hardness and excellent in acid corrosion resistance. The composite material disclosed by the invention has an extremely significant effect on modifying the surface of a steel and iron material, and expands the application field of steel and iron.

Owner:SHANGHAI MARITIME UNIVERSITY

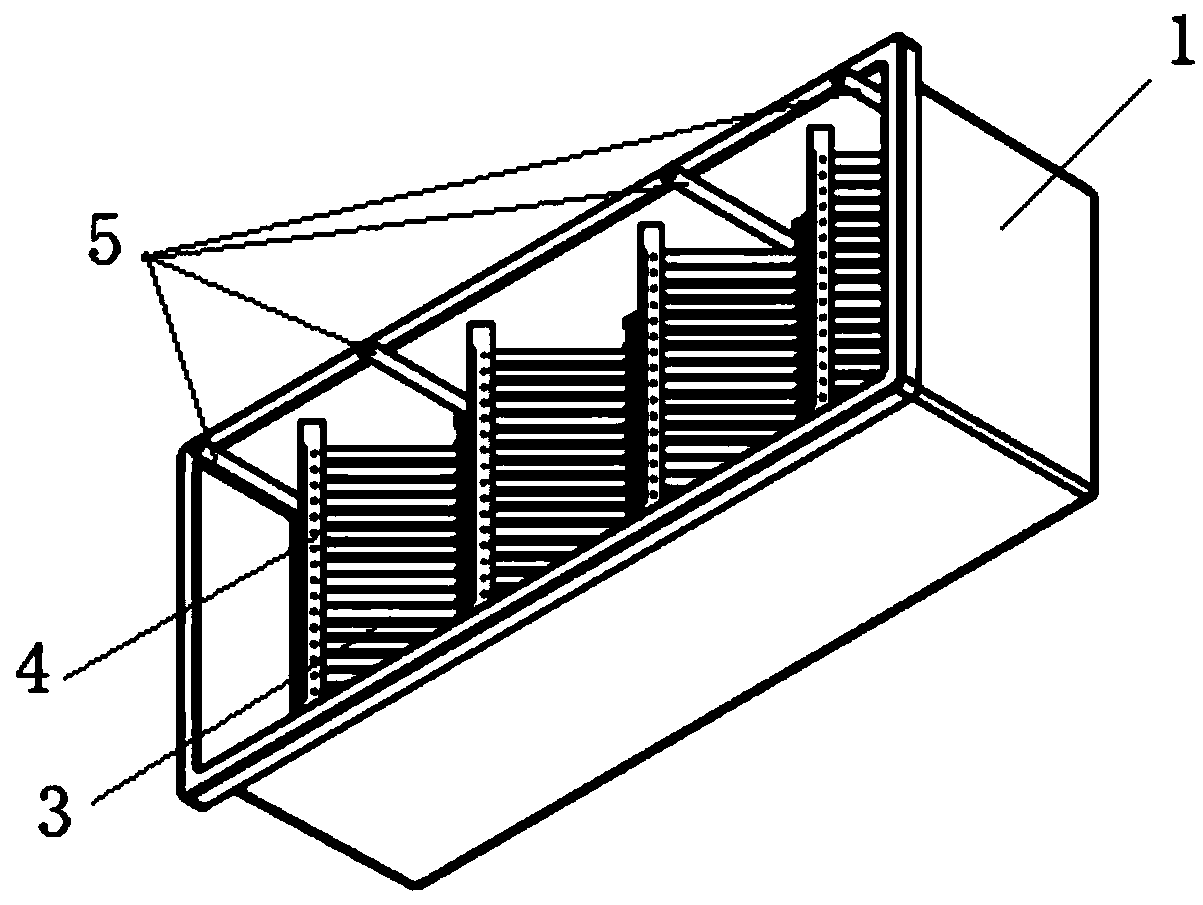

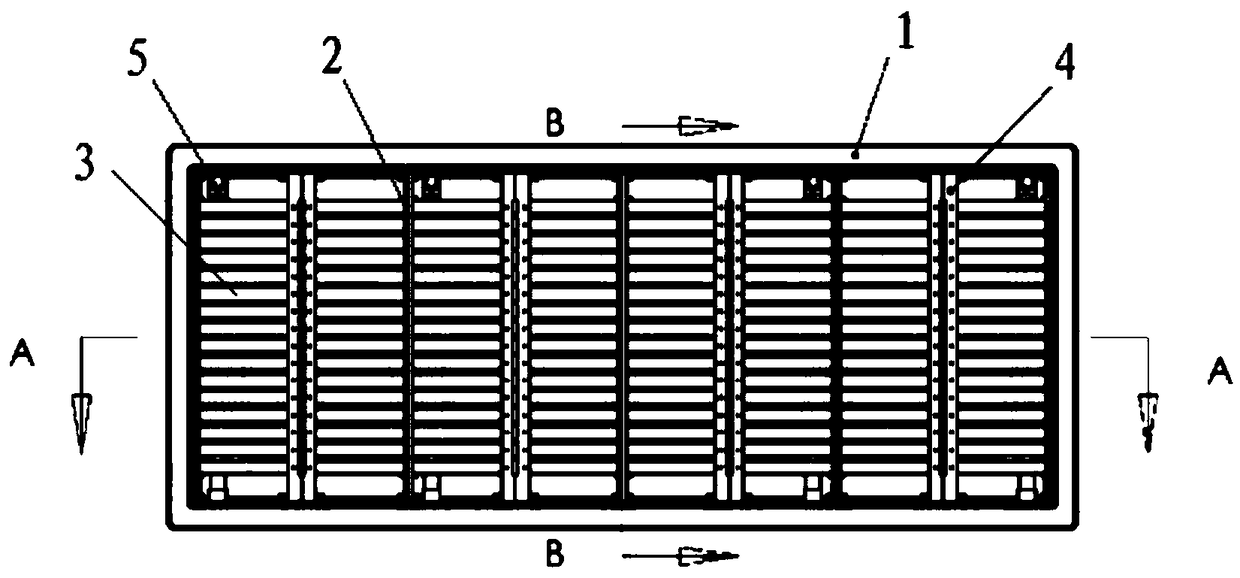

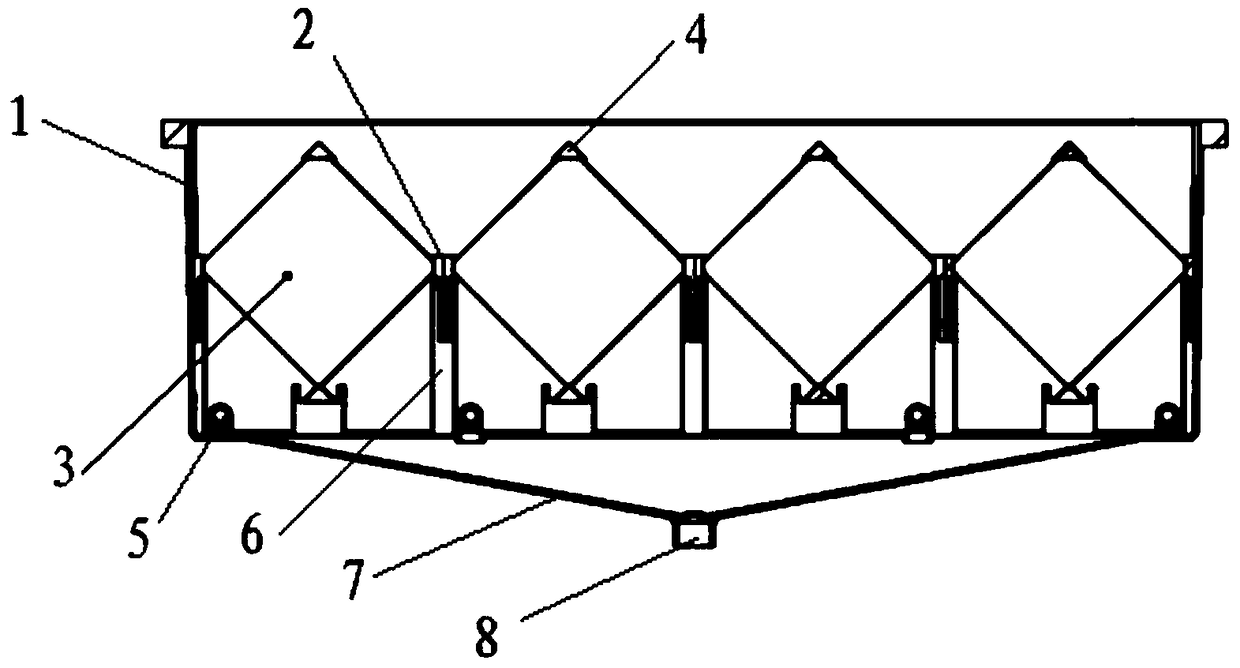

Nano-graphite sol preparation device and method

PendingCN109092218AIncrease profitAvoid short circuitSol preparationColloidal chemistry detailsHigh concentrationGraphite

The invention relates to the field of nano-graphite sol preparation and discloses a nano-graphite sol preparation device. The device comprises an electrolytic cell, flushing pipes and limiting cover plates, wherein the electrolytic cell comprises a cell body, a plurality of graphite supports are arranged at intervals in the width direction of the cell body, a plurality of groups of one-to-one corresponding support opening grooves are formed between every two adjacent graphite supports, a graphite plate is arranged between every group of support opening grooves, and one pair of diagonal cornersof each graphite plate are supported in the corresponding group of support opening grooves; the limiting cover plates are strip-shaped, a plurality of clamping grooves are formed in bottom surfaces of the limiting cover plates at intervals in the length direction, the limiting cover plates are arranged above the graphite plates, and the graphite plates are separated by the clamping grooves one byone; the flushing pipes are arranged along inner side walls of the cell body and extend along the bottom surface of the cell body. The invention further discloses a preparation method. The problem that the nano-graphite sol is easy to agglomerate in the preparation process can be solved, and the nano-graphite sol consumes short time during preparation and has few impurity ions, small particle size, high concentration and good stability.

Owner:曹明辉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com