A kind of nickel cobalt manganese carbonate and its preparation method and application

A technology of nickel-cobalt lithium manganese oxide and carbonate, applied in chemical instruments and methods, nickel compounds, structural parts, etc., can solve the problems of destroying the surface structure and affecting the electrochemical performance of materials, so as to achieve good electrochemical performance and reduce The effect of battery flatulence problem and improvement of surface structure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

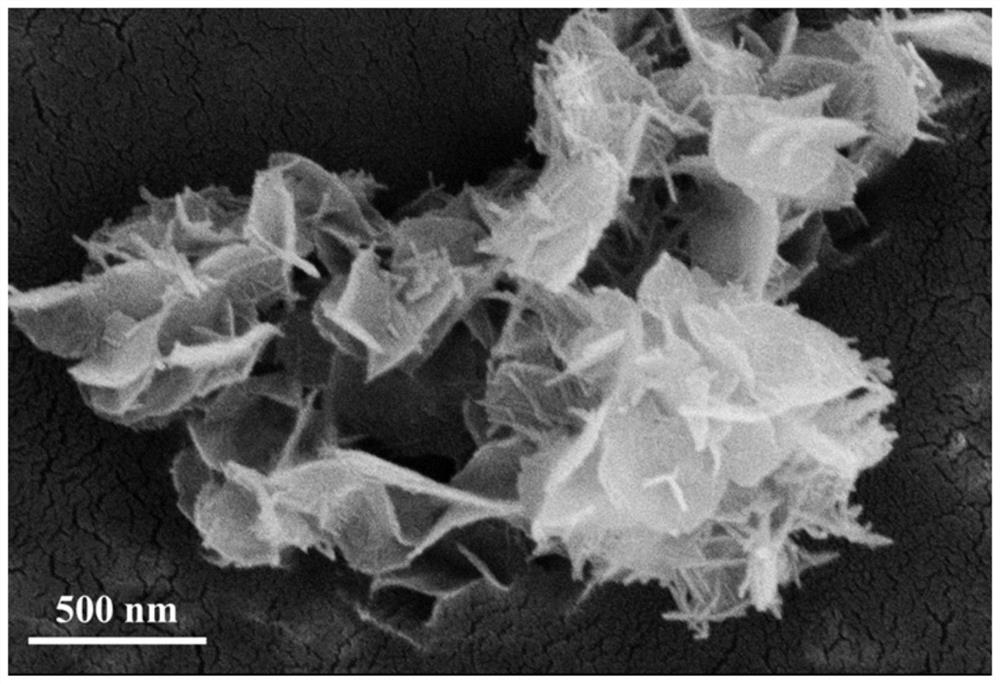

[0036] 1) Add 1.69g NiSO 4 ·7H 2 O, 0.17g CoSO 4 ·7H 2 O and 0.1 g MnSO 4 ·H 2 O was dissolved in 100mL deionized water, 0.43g urea was added, stirred for 10 minutes to completely dissolve each solute, and a mixed aqueous solution was obtained;

[0037] 2) Add 10 mL of tetrahydrofuran into the mixed aqueous solution prepared above, and ultrasonically treat it for 30 minutes while stirring, then pour it into a high-pressure reaction kettle while stirring, seal it and place it in a constant temperature blast drying oven, and conduct a hydrothermal reaction at 120°C for 10 minutes. hours, take it out after cooling to room temperature, centrifuge the mixture after the hydrothermal reaction, remove the solid phase of the lower layer, wash with water and ethanol respectively, and then vacuum-dry at 80°C for 3 hours to obtain nickel-cobalt-manganese carbonate;

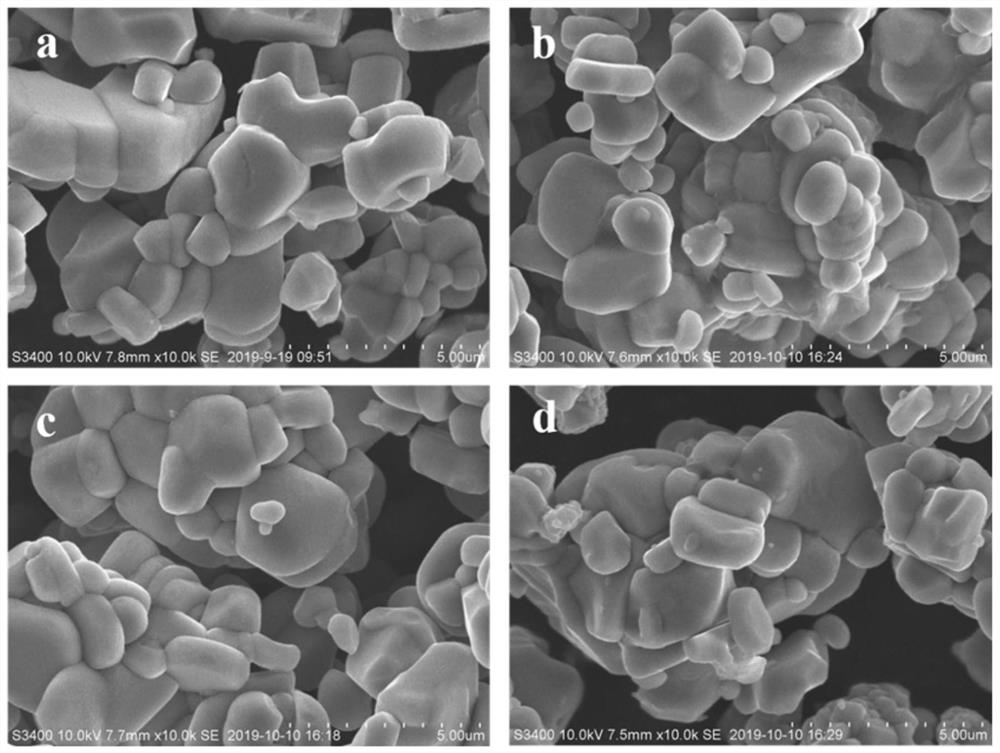

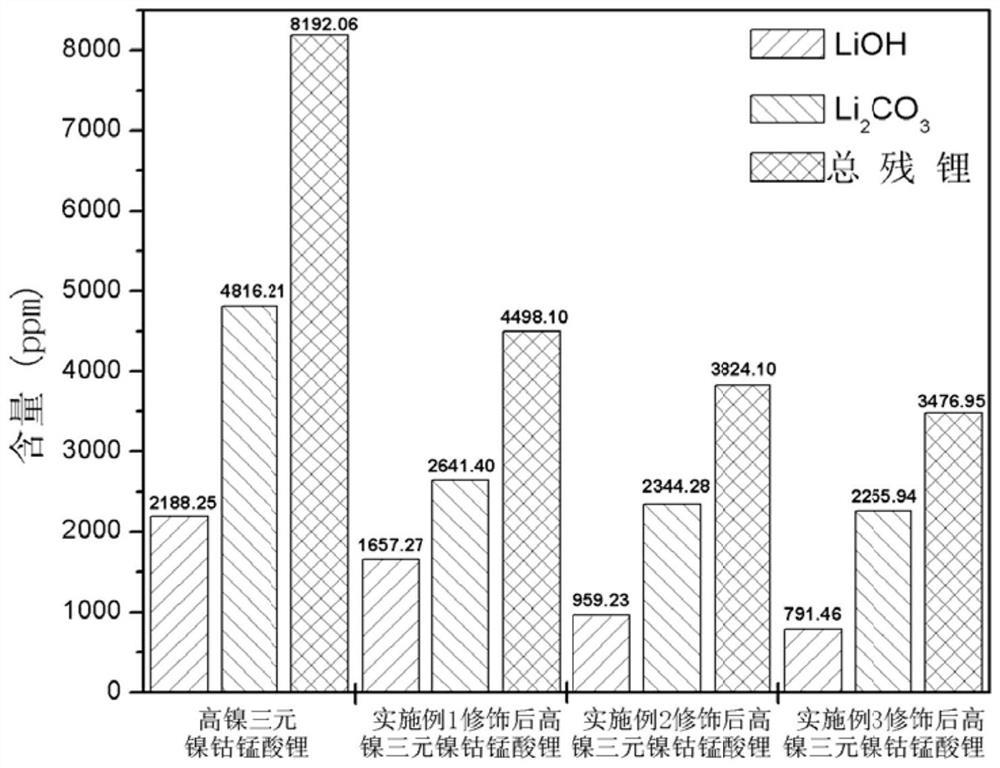

[0038] 3) Weigh 100g of high-nickel ternary nickel-cobalt-manganese lithium and 0.4g of the above-mentioned nickel-cob...

Embodiment 2

[0040] 1) Add 2.25g NiSO 4 ·7H 2 O, 0.28g CoSO 4 ·7H 2 O and 0.17g MnSO 4 ·H 2 O was dissolved in 100mL deionized water, 0.43g urea was added, stirred for 10 minutes to completely dissolve each solute, and a mixed aqueous solution was obtained;

[0041] 2) Add 12 mL of tetrahydrofuran into the mixed aqueous solution prepared above, and ultrasonically treat it for 30 minutes while stirring, then pour it into a high-pressure reaction kettle while stirring, place it in a constant temperature blast drying oven after sealing, and conduct a hydrothermal reaction at 120°C for 10 minutes. hours, take it out after cooling to room temperature, centrifuge the mixture after the hydrothermal reaction, remove the solid phase of the lower layer, wash with water and ethanol respectively, and then vacuum-dry at 80°C for 3 hours to obtain nickel-cobalt-manganese carbonate;

[0042] 3) Weigh 100g of high-nickel ternary nickel-cobalt-manganese lithium and 0.86g of the above-mentioned nickel-...

Embodiment 3

[0044] 1) 2.81g NiSO 4 ·7H 2 O, 0.42g CoSO 4 ·7H 2 O and 0.25g MnSO 4 ·H 2 O was dissolved in 100mL deionized water, 0.43g urea was added, stirred for 10 minutes to completely dissolve each solute, and a mixed aqueous solution was obtained;

[0045] 2) Add 16 mL of tetrahydrofuran into the mixed aqueous solution prepared above, and ultrasonically treat it for 30 minutes while stirring, then pour it into a high-pressure reaction kettle while stirring, seal it and place it in a constant temperature blast drying oven, and conduct a hydrothermal reaction at 120°C for 10 minutes. hours, take it out after cooling to room temperature, centrifuge the mixture after the hydrothermal reaction, remove the solid phase of the lower layer, wash with water and ethanol respectively, and then vacuum-dry at 80°C for 3 hours to obtain nickel-cobalt-manganese carbonate;

[0046] 3) Weigh 100g of high-nickel ternary nickel-cobalt-manganese lithium and 1.5g of the above-mentioned nickel-cobalt-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com