Co-extrusion formed wood-plastic composite plate and preparation method thereof

A wood-plastic composite material and co-extrusion molding technology, applied in the field of composite materials, can solve the problems of low anti-aging agents such as antioxidants, increase in the price of plastic-wood products, and poor aging resistance, so as to prevent thermal oxidation aging. , prolong the service life, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

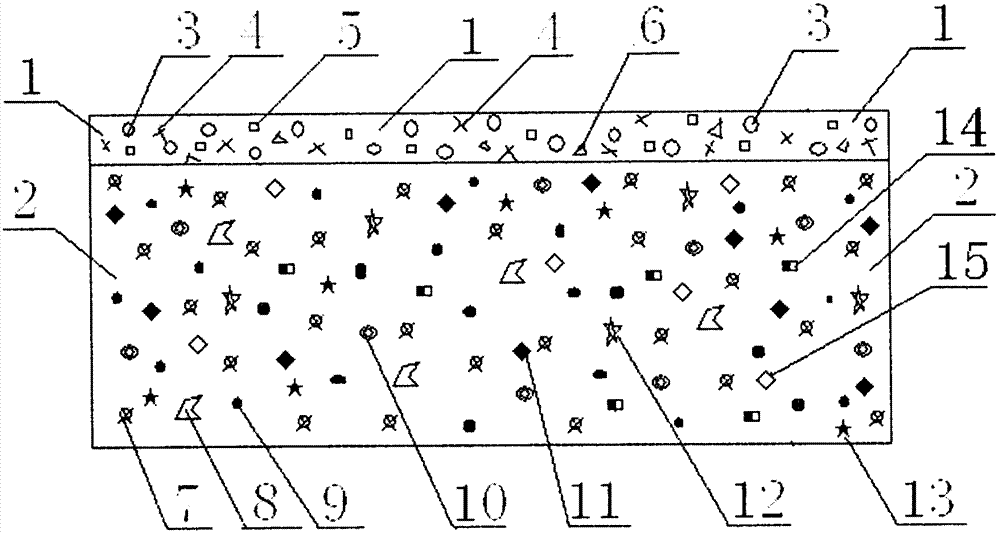

Image

Examples

Embodiment 1

[0031] Embodiment 1: A kind of co-extruded wood-plastic composite board and its preparation method, its preparation process is:

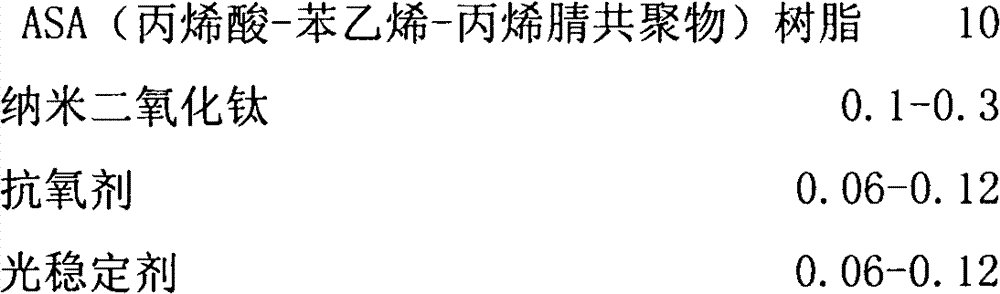

[0032] (1) ASA resin, nano-titanium dioxide, antioxidant, and light stabilizer are uniformly mixed according to the following parts by weight, and then extruded by an extruder to form a molten stream of an aging-resistant resin layer, and the extrusion temperature is 170°C:

[0033]

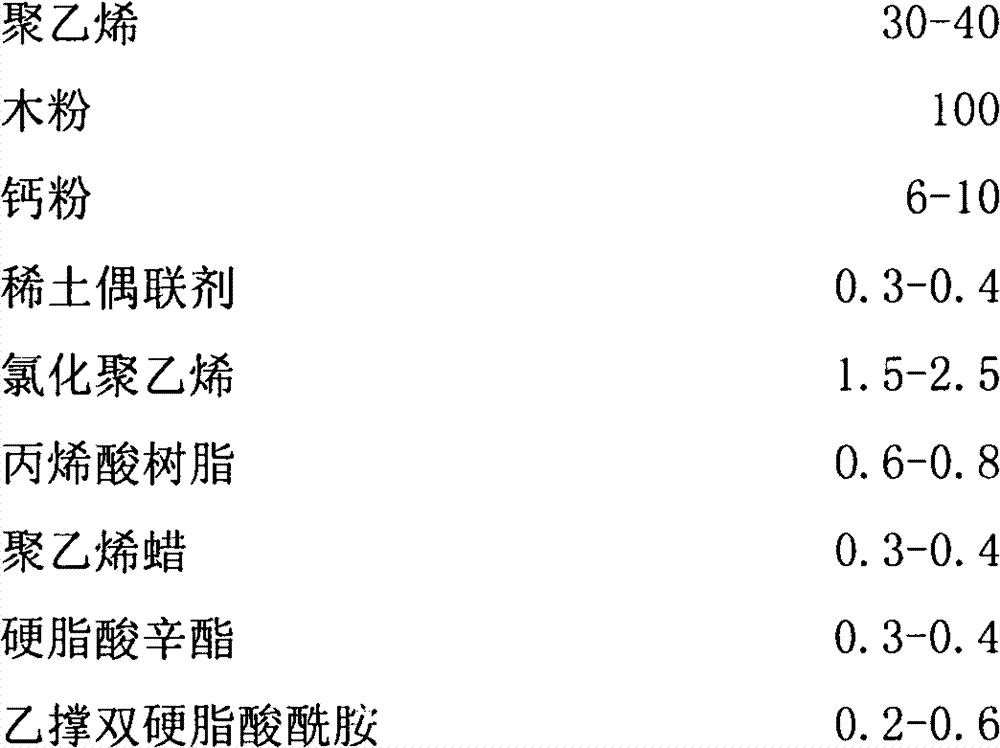

[0034] (2) After mixing polyethylene, wood powder, calcium powder, rare earth coupling agent, chlorinated polyethylene, acrylic resin, polyethylene wax, octyl stearate, and ethylene bis stearic acid amide according to the following parts by weight Use the second extruder to extrude the molten material flow of the plastic-wood composite material structure layer, and the extrusion temperature is 180°C:

[0035]

[0036] (3) The aging-resistant resin layer and the wood-plastic composite material structure layer are formed into different molten streams and superimpos...

Embodiment 2

[0037] Embodiment 2: A kind of co-extruded plastic-wood composite board and its preparation method, its preparation process is:

[0038] (1) ASA resin, nano-titanium dioxide, antioxidant, and light stabilizer are uniformly mixed according to the following parts by weight, and then extruded by an extruder to form an aging-resistant resin layer molten stream, and the extrusion temperature is 160°C:

[0039]

[0040] (2) After mixing polyethylene, wood powder, calcium powder, rare earth coupling agent, chlorinated polyethylene, acrylic resin, polyethylene wax, octyl stearate, and ethylene bis stearic acid amide according to the following parts by weight Use the second extruder to extrude the molten material flow of the plastic-wood composite material structure layer, and the extrusion temperature is 170°C:

[0041]

[0042]

[0043] (3) The aging-resistant resin layer and the wood-plastic composite material structure layer are formed into different molten streams and sup...

Embodiment 3

[0044]Embodiment 3: A kind of co-extruded plastic-wood composite material board and its preparation method, its preparation process is:

[0045] (1) ASA resin, nano-titanium dioxide, antioxidant, and light stabilizer are uniformly mixed according to the following parts by weight, and then extruded by an extruder to form an aging-resistant resin layer molten stream, and the extrusion temperature is 180°C:

[0046]

[0047] (2) After mixing polyethylene, wood powder, calcium powder, rare earth coupling agent, chlorinated polyethylene, acrylic resin, polyethylene wax, octyl stearate, and ethylene bis stearic acid amide according to the following parts by weight Use the second extruder to extrude the molten material flow of the plastic-wood composite material structure layer, and the extrusion temperature is 190°C:

[0048]

[0049] (3) The aging-resistant resin layer and the wood-plastic composite material structure layer are formed into different molten streams and superim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com