Real silk aluminum foil composite steel plate and manufacturing method thereof

A composite steel plate and manufacturing method technology, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problems that the technology of silk aluminum foil composite steel plate is not fully mastered, and achieve the production process of green environmental protection, superior performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

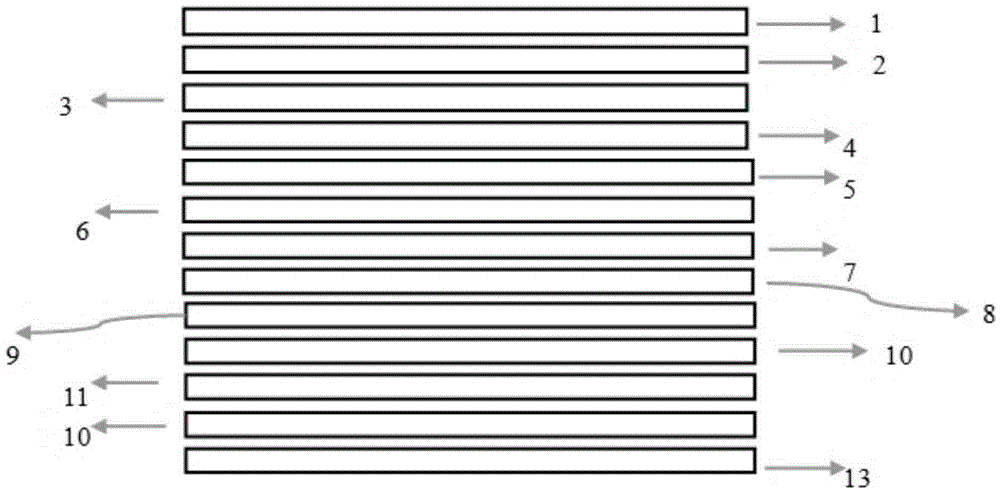

[0029] Such as figure 1 As shown, a silk aluminum foil composite steel plate and its manufacturing method, the composite steel plate is arranged in sequence from top to bottom and PE protective film 1, the first adhesive layer 2, hard coating 3, PET Silk film layer 4, first primer layer 5, silk aluminized layer 6, second primer layer 7, second adhesive layer 8, primer layer 9, chemical treatment layer 10, steel plate 11 and back paint layer 13.

[0030] In this embodiment, the preparation method of the silk aluminum foil film mainly includes the following two steps:

[0031] 1) Coat a layer of UV paint with a thickness of 5 μm on the front of a PET silk film with a thickness of 25um and a width of 800mm (that is, a UV curable adhesive with a viscosity of 500mPa.s), thereby forming a UV paint layer with a thickness of 5um on the front of the PET film .

[0032] 2) The PET silk film coated with UV paint passes through the force point of the mold roller and the rubber roller, ...

Embodiment 2

[0036] Such as figure 1 As shown, a silk aluminum foil composite steel plate and its manufacturing method, the composite steel plate is arranged in sequence from top to bottom and PE protective film 1, the first adhesive layer 2, hard coating 3, PET Silk film layer 4, first primer layer 5, silk aluminized layer 6, second primer layer 7, second adhesive layer 8, primer layer 9, chemical treatment layer 10, steel plate 11 and back paint layer 13.

[0037] In this embodiment, the preparation method of the silk aluminum foil film mainly includes the following two steps:

[0038] 1) Coat a layer of 10um thick UV paint (that is, UV curing glue with a viscosity of 1500mPa.s) on the front of a PET silk film with a thickness of 45um and a width of 1180mm, thereby forming a 10um thick UV paint layer on the front of the PET film .

[0039] 2) The PET silk film coated with UV paint passes through the force point of the mold roller and the rubber roller, so that the mold roller squeezes...

Embodiment 3

[0043] Such as figure 1As shown, a silk aluminum foil composite steel plate and its manufacturing method, the composite steel plate is arranged in sequence from top to bottom and PE protective film 1, the first adhesive layer 2, hard coating 3, PET Silk film layer 4, first primer layer 5, silk aluminized layer 6, second primer layer 7, second adhesive layer 8, primer layer 9, chemical treatment layer 10, steel plate 11 and back paint layer 13.

[0044] In this embodiment, the preparation method of the silk aluminum foil film mainly includes the following two steps:

[0045] 1) Coat a layer of UV paint with a thickness of 8 μm on the front of a PET silk film with a thickness of 30 um and a width of 900 mm (that is, a UV curable adhesive with a viscosity of 1000 mPa.s), thereby forming a UV paint layer with a thickness of 8 um on the front of the PET film .

[0046] 2) The PET silk film coated with UV paint passes through the force point of the mold roller and the rubber roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com