Electroplating method for aluminium product

A technology for aluminum products and electroplating nickel, applied in the field of electroplating of aluminum products, can solve the problems of poor adhesion, easy rust, and increased defect rate, and achieve the effects of good metallic luster, reduction of manufacturing costs, and improvement of electroplating quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

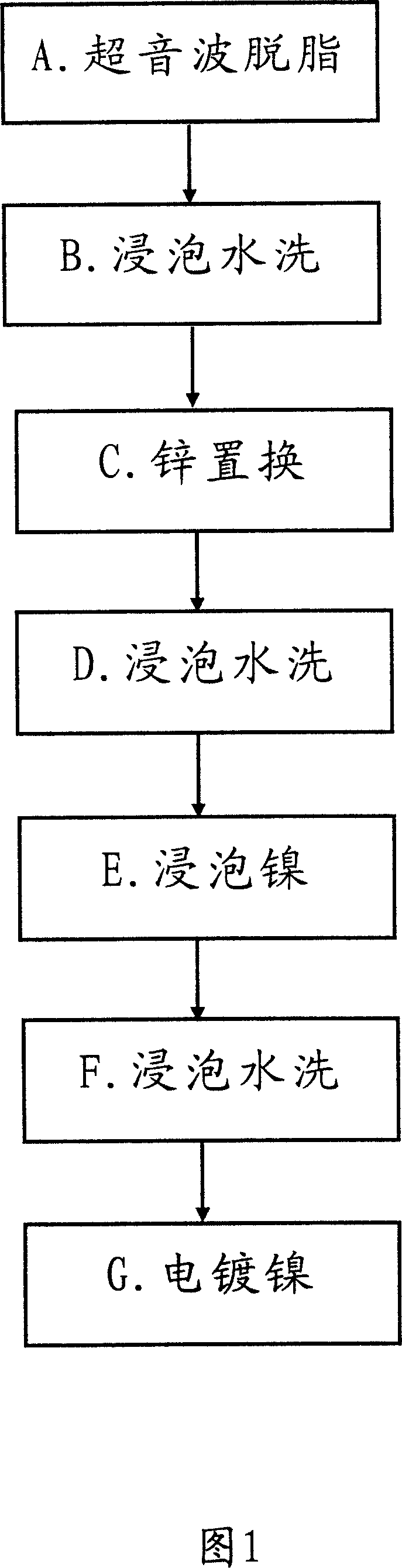

[0011] At first, referring to shown in Fig. 1, the present invention mainly comprises the following steps:

[0012] A. Ultrasonic degreasing: it puts aluminum products in an ultrasonic environment (the ultrasonic environment can be an ultrasonic vibration tank), immerses them in a degreasing agent, and uses ultrasonic vibration to degrease aluminum products. The dirt and grease on the surface are removed. The degreasing agent is mainly low-alkaline and will not corrode the surface of aluminum products. It has strong cleaning performance and less foam.

[0013] B. Soaking and washing: Put the aluminum product in a washing environment (the washing environment can be a washing tank), and use water to clean the surface of the aluminum product to remove degreaser and other liquid medicines.

[0014] C. Zinc replacement: put the aluminum product into the zinc agent again, so that the surface of the aluminum product is attached with a zinc alloy film, which can be soaked at room temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com