Patents

Literature

236results about How to "Has anti-rust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

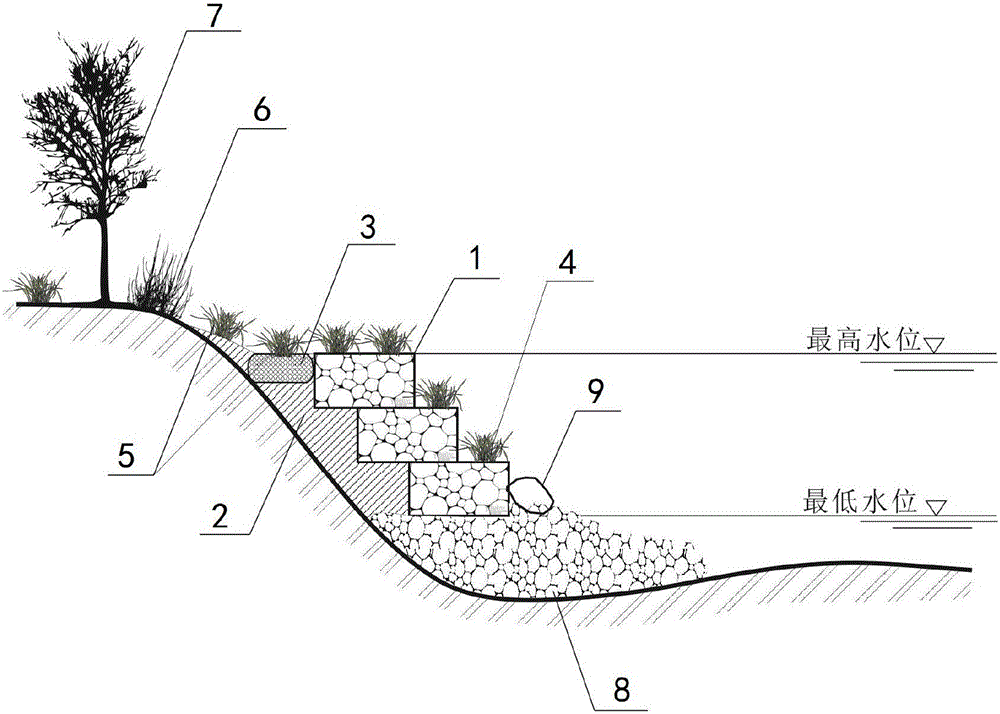

River bank ecological restoration device and method suitable for mountain river characteristics

InactiveCN106337394AStrong river erosionStrong water permeabilityWater resource protectionCoastlines protectionRiver waterFluvial

Owner:WATER ENG ECOLOGICAL INST CHINESE ACAD OF SCI

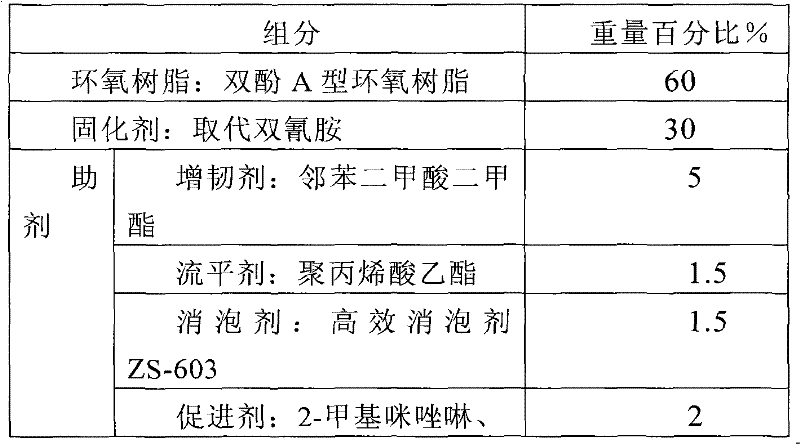

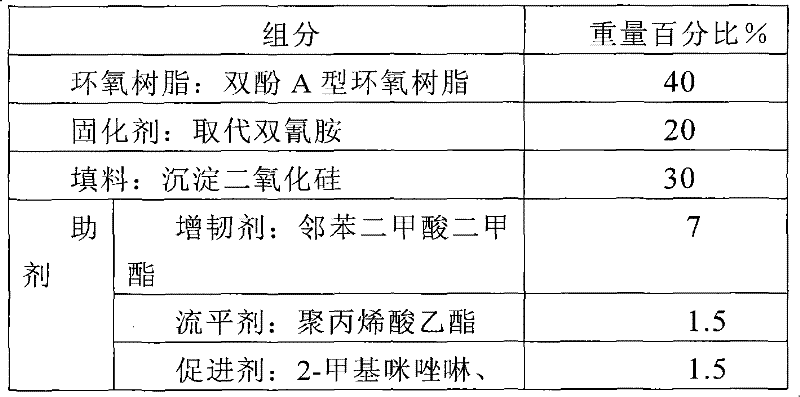

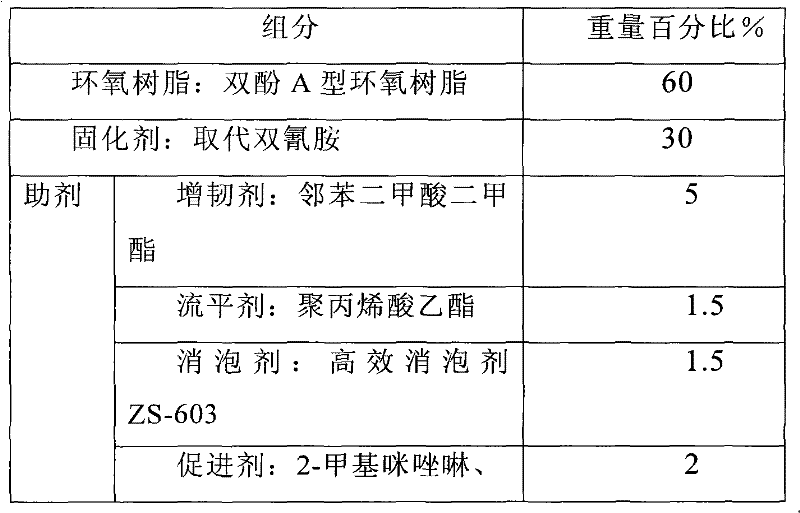

A kind of epoxy powder insulation anticorrosion coating

InactiveCN102294869AStrong adhesionImprove insulation performanceSynthetic resin layered productsAnti-corrosive paintsEpoxyMelt extrusion

The invention belongs to thermosetting epoxy powder insulation anticorrosion paint. It consists of a primer and a top coat, which together form an electrically insulating and anti-corrosion coating. The primer is composed of epoxy resin, curing agent and auxiliary agent; the surface coating is composed of epoxy resin, curing agent, filler and other auxiliary agents; both the primer and the surface coating are made by melt extrusion mixing method Powdered product. The primer coating does not contain or contains less filler, so the adhesion of the formed primer coating is not affected; the surface coating bears the main functions of electrical insulation and anti-corrosion, so the coating of the present invention has strong adhesion, excellent electrical insulation performance, and has Anti-corrosion, anti-rust, anti-mildew, heat-resistant, wear-resistant and other functions, and has the characteristics of low cost.

Owner:NINGBO KEXIN CORROSION CONTROL ENG

CO2 gas-shielded solid-core welding wire coateds graphite coating on its surface and its manufacturing method

InactiveCN1709637AConductiveHas anti-rustWelding/cutting media/materialsSoldering mediaElectricityElectrolysis

The invention relates to the solid solder which is protected by the carbon dioxide and the manufacture method. The exterior of the solder has the graphite dope. Its characteristic is that on the solid solder there is the dope of nm grade's graphite group. The production method is that it adopts the drawing way to execute the solder. Firstly, use the electrolyted alkali to wash the solder, then take turns as the water, the electrolysed acid and the water. As the above task steps, after eliminating the lube film which the solder adsorbed in the drawing process, make the solder smeared or sprinkled by the graphite group. Its technical flow is setting the line, washing with the electrolysed alkali, washing with the water, washing with the electrolysed acid, washing with the water, smearing or sprinkling with the graphite group, drying, receiving the line and tie by the layer. The graphite is provided with the function such as conducting the electricity, defending the rust, lubricating and so on. The above solder which can enhance the quality of the welding line is the solder of the environmental protection.

Owner:SHANXI WEIERDE IND

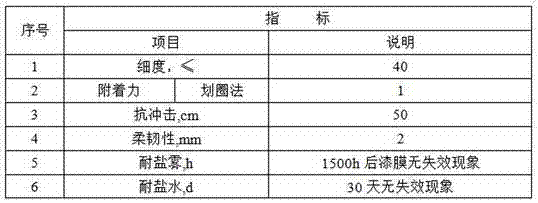

A preparing method of heavy-duty anticorrosion coating

InactiveCN107474683AGood dispersionPrevent floating color phenomenonAnti-corrosive paintsPowdery paintsEngineeringGraphene

A preparing method of heavy-duty anticorrosion coating is disclosed. The method includes (1) a material mixing step, namely a step of adding resin, a pigment filler, graphene, a solvent and an auxiliary agent into a dispersing machine according to a ratio, with a dispersing disc of the dispersing machine rotating at a speed of 400-500 r / min in a material adding process, adjusting the rotating speed of the dispersing disc after addition is finished to 1800-2000 r / min, maintaining the speed for 1 h, and shutting down the machine; and (2) a grinding step, namely a step of replacing the dispersing disc into a sand grinding disc, grinding the materials by the sand grinding disc at a speed of 2000-2800 r / min until the fineness is 40 [mu]m, shutting down the machine, discharging a product, and filtering the product to obtain a coating finished product. The method can improve anticorrosion performance defects of anticorrosion coating at present, and allows the coating to achieve a long-term anticorrosion objective. In addition, a coating preparing process is simplified and the production cost is reduced.

Owner:DEYANG CARBONENE TECH

Nano intelligent health powder coating

InactiveCN108610817AWith heat insulationWith sound insulationFireproof paintsAntifouling/underwater paintsFiberSlurry

The invention relates to a nano intelligent health powder coating. The nano intelligent health powder coating is prepared from the material components: dispersible film-forming materials, inorganic functional element materials, negative ion powder, sea-foam powder, diatomite, titanium dioxide, germanite powder, carbon fiber powder, nano titanium dioxide, nano-silica, nano-zinc oxide, microcapsules, cellulose, dispersan, antifoaming agents and the like; the nano intelligent health powder coating is prepared by the following steps of preparation of activated microporous materials, nano-slurry dispersion and powdering, mixing and stirring, melt extrusion, ball milling separation and sieving and the like; interior wall powder coating, exterior wall powder coating, thermosetting powder coating;in addition to fully complying with national standards, the coating also has new functions of temperature regulation, humidity control, sound insulation, heat preservation, air purification, anti-corrosion, antibacterial sterilization, anti-mold, anti-condensation, anti-radiation, anti-static, permanent release; negative ions, trace elements, far-infrared, bio-current, and permanent adsorption offormaldehyde, benzene, odor, smoke and harmful gases; the coating can be widely used for wall painting of habitable rooms, classrooms, offices, hospitals and the like.

Owner:胡春宇

Glazing liquid for dry cleaning for automobile and its producing method

The automobile dry washing and polishing liquid is compounded with brightening agent, detergent, emulsifier, essence and other material. The present invention has the integrated decontaminating, polishing, antistatic, waterproof, rustproof and other functions, and may be used in keeping the automobile clean and prolonging the service life. The present invention is environment friendly.

Owner:于佰顺

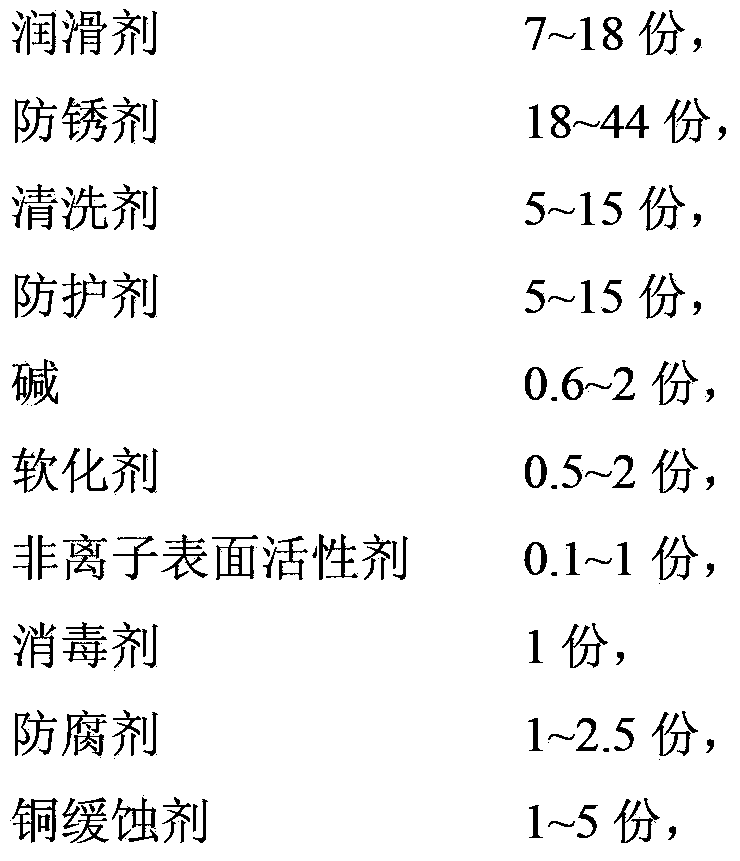

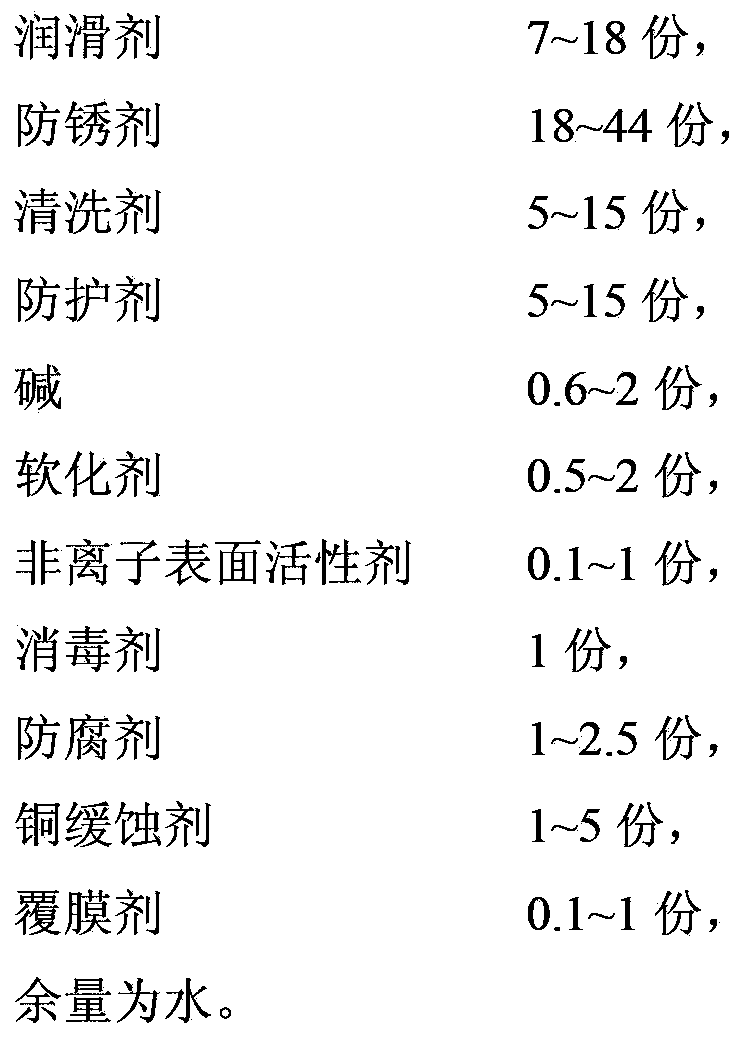

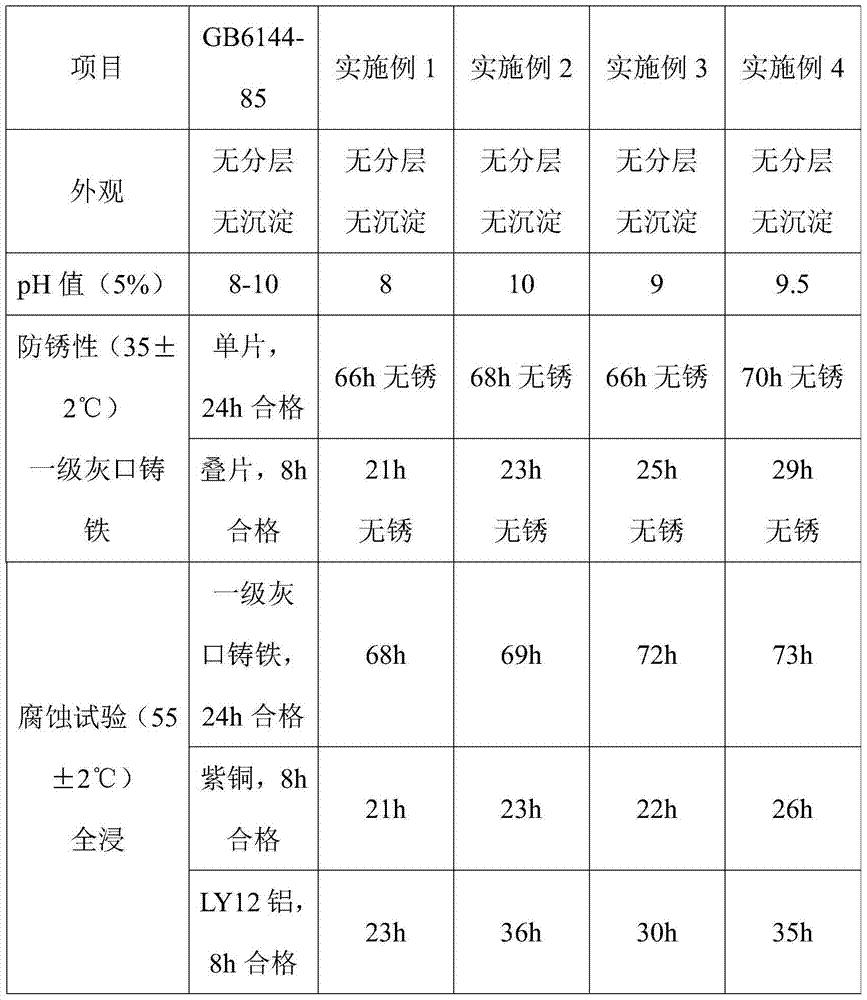

Noncorrosive water-based cutting fluid

The invention discloses a noncorrosive water-based cutting fluid. The cutting fluid comprises the following components in parts by weight: 7-18 parts of lubricating agent, 18-44 parts of antirust agent, 5-15 parts of cleaning agent, 5-15 parts of protective agent, 0.6-2 parts of alkali, 0.5-2 parts of softening agent, 0.1-1 parts of nonionic surfactant, 1 part of disinfectant, 1-2.5 parts of preservative, 1-5 parts of copper corrosion inhibitor, 0.1-1 part of filming agent, and the balance of water. The cutting fluid disclosed by the invention can be applied to machine tool processing, and has the functions of rust resistance, lubrication, cleaning and temperature reduction.

Owner:WEIFANG HENGYUAN CHEM PLANT

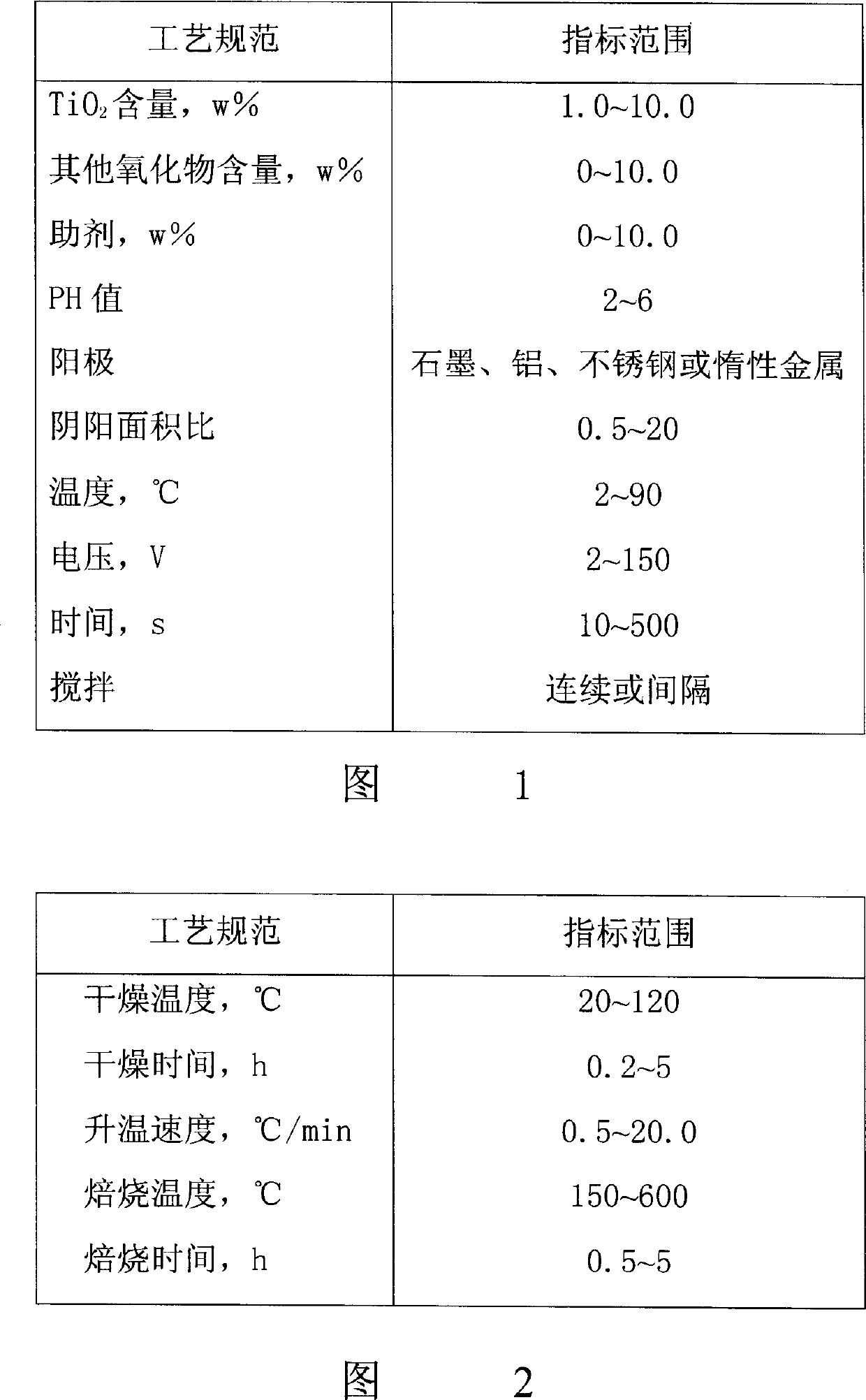

Electrophoresis preparation method for surface optical catalytic film of metal substrate

InactiveCN1438069AImprove adhesion strengthThickness is easy to controlWater/sewage treatment by irradiationCatalyst activation/preparationMetallic materialsMetallic substrate

The present invention discloses a preparation method of titanium dioxide photocatalytic membrane loaged on metal surface, its main technological process includes: in the electrophoretic solution containing a certain content of titanium dioxide sol or containing binary or multi-component compounded oxide sol of titanium dioxide using the pretreated metal base body as cathode, using graphite, aluminium, stainless steel and inert metal as anode, utilizing electrophoretic mode to form a layer of titanium dioxide membrane on the metal surface under the condition of a certain voltage, drying and calcining to make the titanium dioxide membrane be fixed on the metal surface. Said membrane is high in adhesive strength, and has high photocatalytic activity.

Owner:FUZHOU UNIV

Method for processing wood grain on aluminium section bar

InactiveCN101486289ASolve the technical problem that the surface cannot have wood grainExquisite appearanceDecorative surface effectsPretreated surfacesLacquerSpray coating

The invention relates to a method for processing wood grains on an aluminum section, which comprises a step of preprocessing, a step of spray coating and a step of wood grain transfer printing sequentially, wherein in the step of preprocessing, the aluminum section is mounted to perform chemical degreasing and roll scale removal, then the aluminum section is washed in water and chromized by chromate, and is washed in the water again and dried; in the step of spray coating: the aluminum section is hung up to perform dust blowing, wiping, spraying a fluorocarbon prime lacquer and a fluorocarbon top coat, drying and solidification; and in the step of wood grain transfer printing, a transfer printing water tank and a soaking water tank is added with water and heated up first, a wood grain membrane is tiled on the water surface of the transfer printing water tank, and the surface of the aluminum section is contacted with the wood grain membrane so as to transfer the paint on wood grains to the surface of the aluminum section; then the aluminum section is transferred to the soaking water tank; after that the aluminum section is cleaned and wiped clean and dried, and is baked and solidified. The method coats the wood grains on the surface of an aluminum veneer or the aluminum section by a transfer printing method, and solves the technical problem that in the prior art, and the surface of the aluminum veneer or the aluminum section cannot be provided with the wood grains.

Owner:SHANGHAI HUAHUI CURTAIN WALL MFG

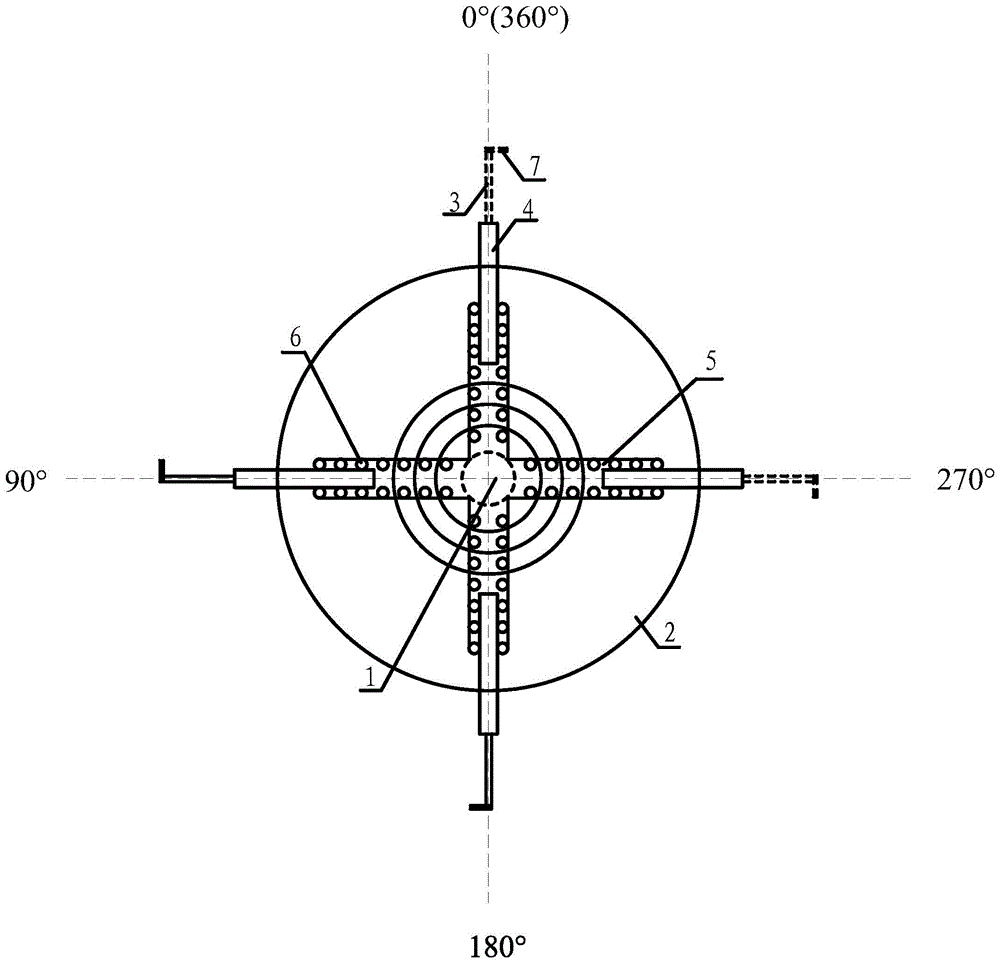

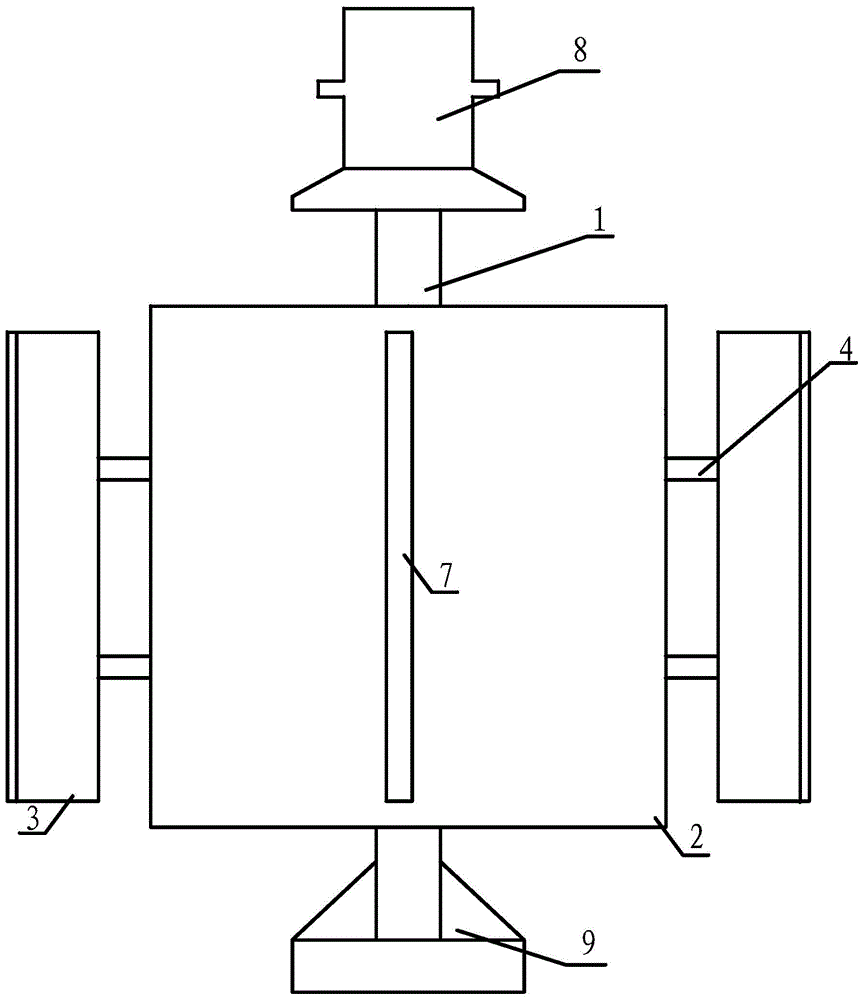

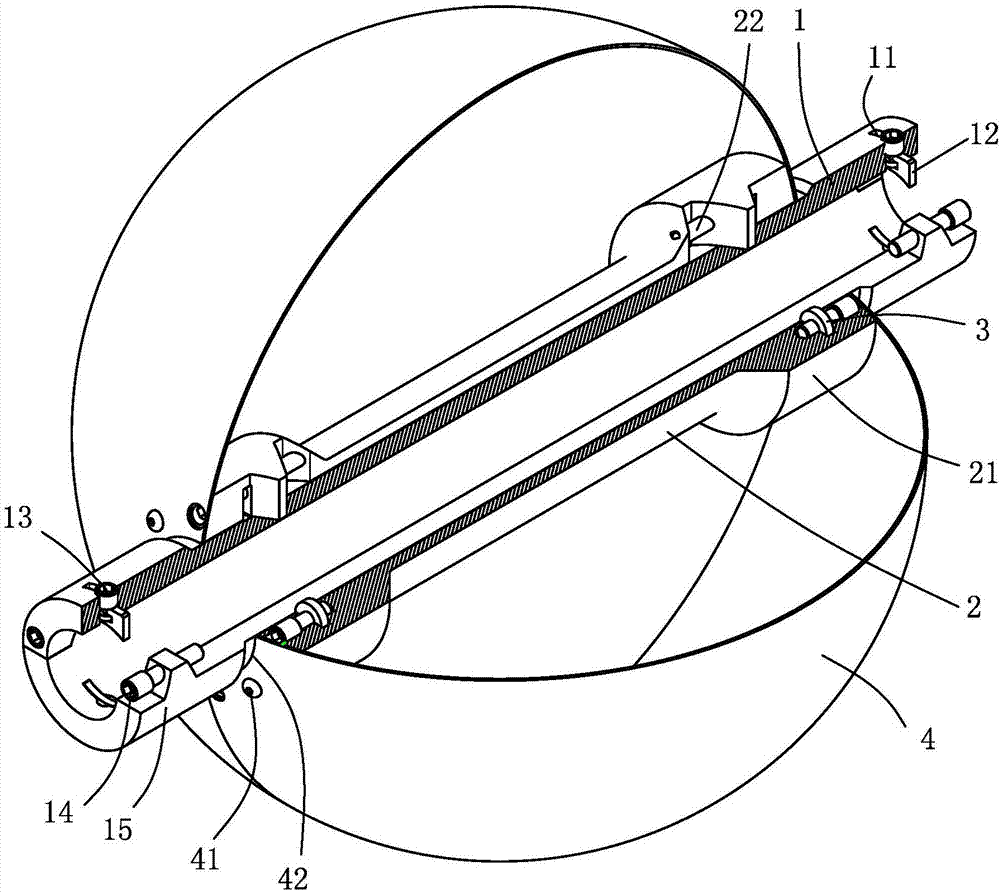

Retractable blade vertical-axis tidal turbine

InactiveCN104696139AGood energy gathering effectImprove energy harvesting efficiencyHydro energy generationReaction enginesSubmarineYield efficiency

The invention discloses a retractable blade vertical-axis tidal turbine, which comprises a rotating shaft, a turntable, blades, retractable support arms, eight guide rails, guide rail wheels, baffle plates, a controller and a support part, wherein the guide rails are positioned in the turntable, and are divided into two layers, and each layer comprises four guide rails; the guide rails are uniformly welded on the rotating shaft at intervals of 90 degrees; the guide rail wheels are mounted on the inner surfaces of the guide rails; a retractable support arm is mounted in each guide rail; the support arms are retractably and movably connected with the guide rails through the guide rail wheels; the blades are mounted at the ends, far away from the turntable, of the support arms; the blades are rectangular, and are positioned on the same planes as the upper and lower layers of retractable support arms; the baffle plates are fixedly mounted at the ends, far away from the turntable, of the blades, and are in right-angled connection with the blades; the blades slide in the guide rails through the retractable support arms, and are controlled by the controller to retractably move. According to the retractable blade vertical-axis tidal turbine with such a retractable design, the energy yielding efficiency of the vertical-axis turbine is improved, the size of the whole device is reduced, convenience in transportation and considerable market prospect are achieved, and the submarine mounting cost is reduced.

Owner:ZHEJIANG OCEAN UNIV

Heat-insulating powder for coating and preparation method thereof

InactiveCN101914314AGood heat insulationAnti-rustInorganic pigment treatmentPolyurea/polyurethane coatingsUltravioletVanadium oxide

The invention relates to heat-insulating powder for a heat-insulating coating in aspects of buildings, oil tanks, oil tubes and the like and a preparation method thereof. The heat-insulating powder is prepared by coating nano-titanium oxide, vanadium oxide, ferric oxide, rectorite powder and the like serving as a heat-insulating material with new nano-silicon oxide generated by reaction of sodiumsilicate and hydrochloric acid or sulfuric acid. The heat-insulating powder has the heat-insulating function of reflecting infrared rays and ultraviolet rays in sunlight, and the heat-insulating powder provided by the invention is a brand new heat-insulating material on the heat-insulating principle. In the heat-insulating powder, the nano-heat-insulating material is coated by the new nano-silicon oxide to enhance the heat-insulating effect of nanometer materials, avoid the agglomeration phenomenon and reduce the cost. In addition, the prepared heat-insulating material also has the multiple functions of rust prevention, corrosion prevention, sound insulation and the like.

Owner:SHANGHAI YUTANG INDAL

Spindling cleaning solution of cotton picker

InactiveCN101838593AWith coolingWith lubricationOrganic detergent compounding agentsSurface-active detergent compositionsAlcoholNitrite

The invention relates to a spindling cleaning solution of a cotton picker, which is prepared from the following components in percent by weight: 70-90 percent of mineral oil, 3-20 percent of non-ionic surfactant, 0-5.0 percent of rust inhibitor, 0-6 percent of alcohol antifreeze, 0-3.0 percent of inhibitor and 0-2 percent of alcohol amine alkaline agent. The cleaning solution can be used after being diluted with 150-300 times of water, has the functions of cleaning, cooling, lubricating, resisting rust, and the like, also has the advantages of low viscosity, good emulsibility and liquidity, low surface tension and favorable cleaning action on spindling and is environment-friendly and safe because contents, such as phosphate, nitrite and silicate are not contained in a formulation.

Owner:新疆五家渠现代石油化工有限公司

Manufacturing method for balance weight of compressor and balance weight manufactured by using manufacturing method

The invention relates to a manufacturing method for a balance weight of a compressor and a balance weight manufactured by using the manufacturing method. The balance weight of the compressor is manufactured by using alloy powder by a powder metallurgy method. The manufacturing method for the balance weight of the compressor is characterized by comprising the following steps of (a) placing raw materials comprising the alloy powder and adhesives in a blender mixer and uniformly mixing the raw materials; (b) feeding the mixed materials into a powder pressing machine, and performing compression moulding on the mixed materials to obtain a pressed blank of the balance weight; (c) covering copper plates on the outer surface of the pressed blank of the balance weight, placing the pressed blank of the balance weight in a sintering furnace, and sintering and solidifying the pressed blank of the balance weight to obtain a sintered blank of the balance weight; and (d) polishing the sintered blank of the balance weight and removing burs of the sintered blank of the balance weight. Compared with the prior art, the manufacturing method for the balance weight of the compressor and the balance weight manufactured by using the manufacturing method have the advantages that the density of the balance weight, which is manufactured by using the method, of the compressor is 7.5-8.0 grams per cubic centimeter, and the using range of the existing alloy for balance weights is greatly extended; and the balance weight has characteristics of zero magnetism, rust protection and the like, and can serve as a substitute product of various copper alloy balance weights and various stainless steel balance weight.

Owner:舒思雄

Anticorrosion primer paint for chimney of electric plant and its uses

InactiveCN101007923AHigh viscositySpeed up the flowAnti-corrosive paintsPolyester coatingsBenzeneAdhesion force

The invention relates to anticorrosion priming paint for power plant chimney, comprising unstaurated polyester base material and curing agent, and the proportion by weight between them is 100: 0.3-3. Said unstaurated polyester base material comprises: chemical-resisting unstaurated resin 20-70 (proportion by weight), cobaltic naphthenate 0.1- 1.0 (proportion by weight), alumina silicate 79.7- 28 (proportion by weight), and gas phase silica dioxide 0.2- 10 (proportion by weight). Said curing agent comprises: methyl-ethyl ketone peroxide 30- 70 (proportion by weight) and butyl benzene o-dicarboxylate 70- 30 (proportion by weight). The anticorrosion priming paint is characterized by fast curing, easy- polishing, little organic solvent discharging, strong adhesion force, simple process, convenient utilization and good corrosion resistance performance.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Multifunctional car water tank antifreeze fluid

The invention provides a multifunctional car water tank antifreeze fluid. The antifreeze fluid comprises the following components, by weight, 50-65 parts of alcohols, 30-45 parts of deionized water and 1-5 parts of an additive. The freezing point of the antifreeze fluid can reach -40DEG C or lower, so north cold weather demands can be satisfied; and the boiling point of the antifreeze fluid can reach 140DEG C or more, so an overheat case does not appear even in hot summer, thereby the car driving safety and the normal operation of a cooling system are guaranteed. The two used alcohols are nontoxic and harmless, so the damages of harmful substances to human bodies are eliminated, and environmental protection and safety are realized. The antifreeze fluid has the anticorrosion, antirust and antiscale effects, and can effectively protect the car cooling system, so the service life of the cooling system is prolonged.

Owner:马文俊

Medical apparatus fast-drying oil agent for bacteriostasis, lubrication and rust prevention

The invention relates to a medical apparatus fast-drying oil agent, and belongs to the technical field of the fine chemical industry. The medical apparatus fast-drying oil agent is characterized in that the medical apparatus fast-drying oil agent contains, by mass, 0.3-2% of a wetting component, 1-5% of an oily component, 1-5% of a surfactant component I, 0.4-2% of a surfactant component II, 0.05-0.25% of a bacteriostasis component, and the balance solvent component. The medical apparatus fast-drying oil agent can form a protection oil film on the surface of an apparatus to increase the glossiness of the apparatus and prevent the rust generation of the apparatus, has bacteriostasis, inflammation prevention and wound healing promotion effects, and is suitable for oiling medical apparatuses made of stainless steel, aluminum and plastics, and high-temperature and high-pressure steam and hydrogen peroxide plasma can easily penetrate the protection oil film. Additionally, the fast-drying oil agent has the advantages of easy drying, no silica gel, small viscosity, no residual oil marks on the surface of the apparatus, and the like.

Owner:BEI JING BAI XIANG NEW TECH

Novolac epoxy resin radiation protective paint and preparation method thereof

InactiveCN105694677AHigh transparencyHigh hardnessFireproof paintsAntifouling/underwater paintsEpoxyTemperature resistance

The invention provides a phenolic epoxy resin radiation protection coating, which comprises the following raw materials in parts by weight: 20-30 parts of phenolic epoxy resin, 10-15 parts of expanded graphite, 5-10 parts of carbon nanotubes, 1-30 parts of titanium dioxide 5 parts, 0.5-3 parts of hydroxypropyl methylcellulose, 8-14 parts of glass powder, 5-10 parts of talc powder, 8-12 parts of kaolin powder, 5-10 parts of perlite, 10-15 parts of wollastonite powder , 1-5 parts of dicyclopentenyloxyethyl acrylate and 20-30 parts of water. The present invention also provides a preparation method of the above-mentioned phenolic epoxy resin radiation protection coating. The components in the above-mentioned phenolic epoxy resin radiation-proof coating provided by the present invention cooperate with each other and complement each other, so that the coating has excellent anti-corrosion, radiation protection, antibacterial, flame-retardant, and anti-corrosion properties under the premise of maintaining good adhesion. High temperature, anti-cracking, anti-corrosion, resistance to alternating cold and heat, storage stability and other characteristics.

Owner:HUANGHE S & T COLLEGE

Metal polishing agent

The invention relates to a metal polishing agent which is characterized by comprising the following components in percentage by weight: 4%-8% of diethylene glycol butyl ether, 3%-6% of benzyl methanol, 2%-5% of disodium aminotriacetate, 1%-3% of sodium nitrite, 1%-3% of tallow fatty acid sodium, 1%-2.5% of a surfactant, 0.3%-0.8% of a corrosion inhibitor, 0.2%-0.5% of an anti-rust agent and the balance amount of water. The metal polishing agent has the characteristics of wide application range, stable polishing effect, convenience in use, high efficiency and the like.

Owner:黔东南州九黎苗妹工艺品有限公司

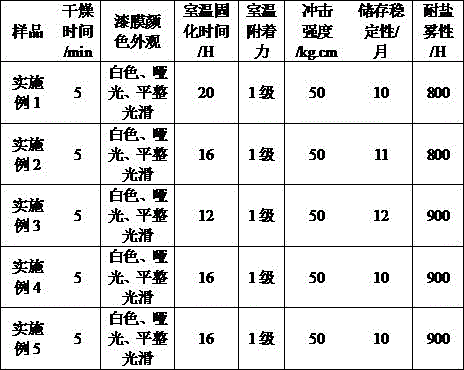

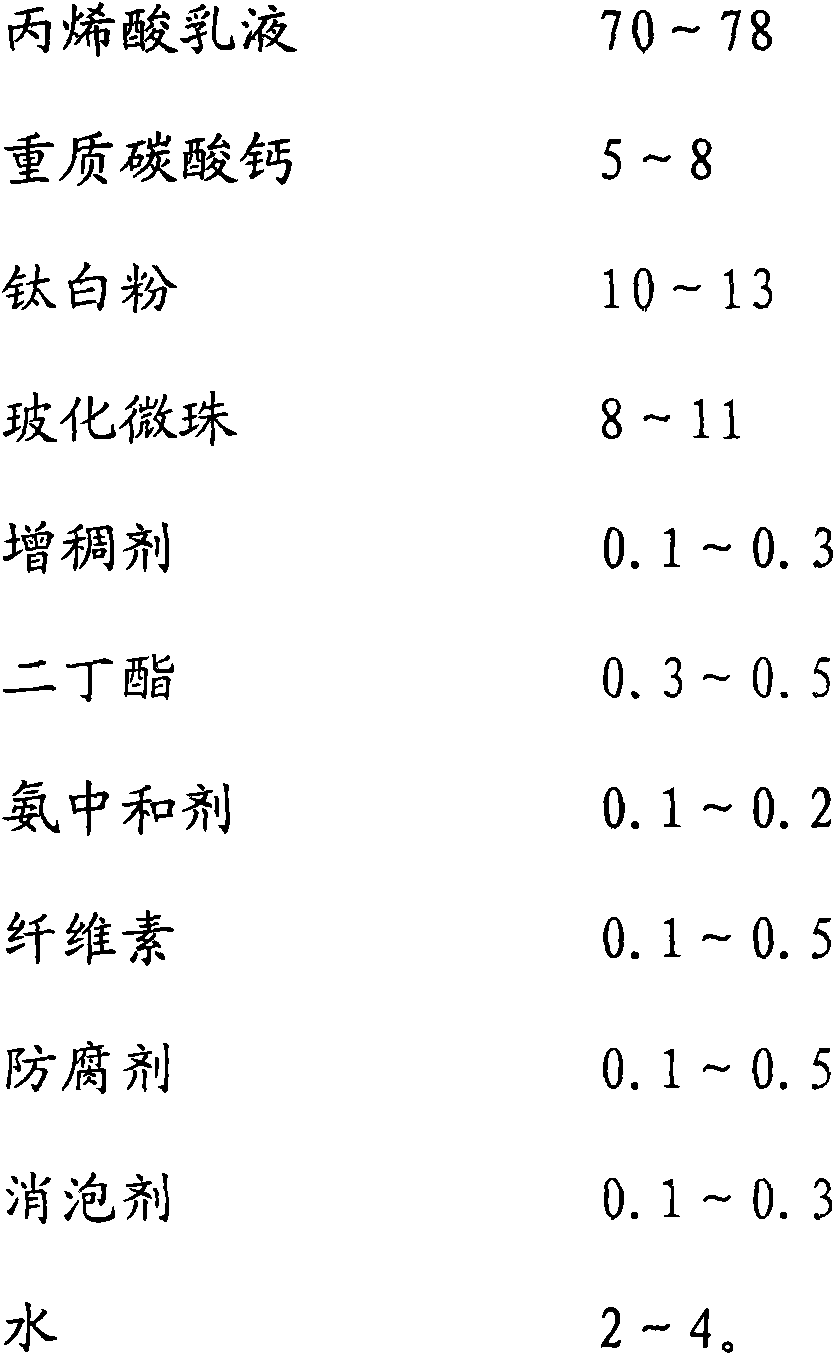

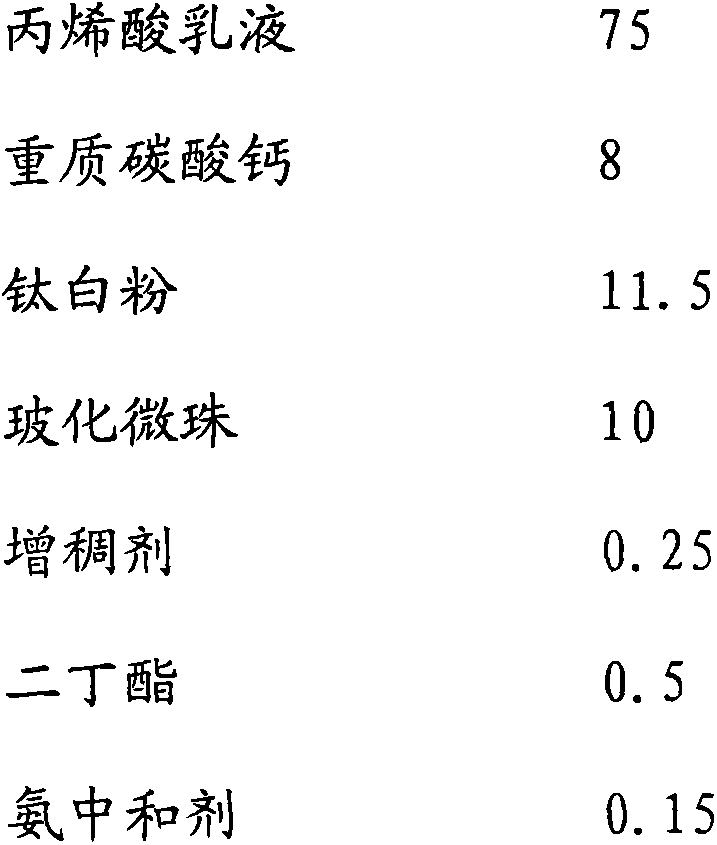

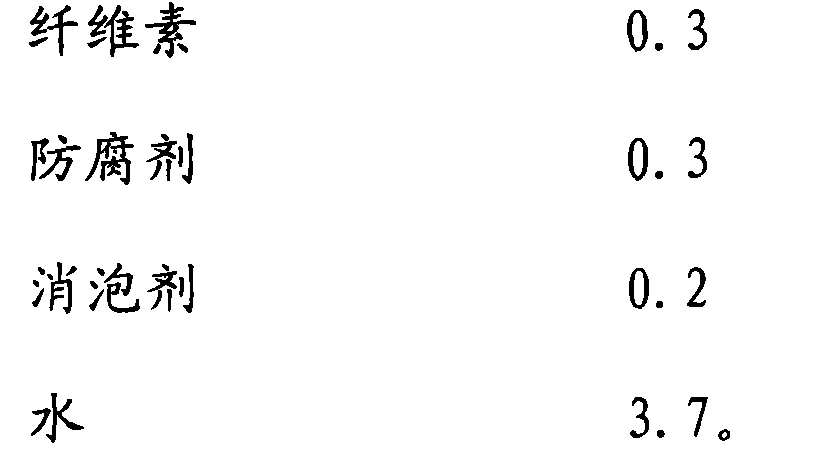

Water-resistant paint for steel structure color steel tile

ActiveCN103275582AAvoid sun and rainPrevent precipitationAnti-corrosive paintsCelluloseThermal insulation

The invention discloses a water-resistant paint for steel structure color steel tile. The water-resistant paint for steel structure color steel tile comprises the following ingredients in weight parts: 70-78 parts of propenoic acid latex, 5-8 parts of heavy calcium carbonate, 10-13 parts of titanium dioxide, 8-11 parts of glass beads, 0.1-0.3 part of thickener, 0.3-0.5 part of di-n-butyl phthalate, 0.1-0.2 part of ammonia neutralizer, 0.1-0.5 part of cellulose, 0.1-0.5 part of preservative agent, 0.1-0.3 part of foam killer, and 2-4 parts of water. The water-resistant paint has the benefits that the problems of high water seepage maintenance cost and short service life which are caused by the rusting of iron nails on the conventional metal color steel tile roof are solved; the structure performance of the water-resistant paint is improved; a waterproof layer with good overall performance is formed on a metal steel structure construction; and the water-resistant paint has the characteristics of good waterproof quality, high temperature resistance, no crack at 80 DEG C, good fire resistance, good thermal insulation, good corrosion prevention, good oxidation prevention, good rust prevention, good age resistance and long service life.

Owner:XIAMEN LIKASAM WATERPROOF ENG

Multifunctional phosphating solution, and preparation method and application thereof

InactiveCN103397324AHigh hardnessStrong impact resistanceMetallic material coating processesPhosphatePhosphoric acid

The invention relates to a multifunctional phosphating solution and a preparation method and application thereof. The multifunctional phosphating solution comprises liquid A and liquid B and is characterized in that a ratio of the liquid A to the liquid B in the multifunctional phosphating solution is 1: 0.1-1. The liquid A comprises the following substances, by mass, 26 to 48 parts of diammonium phosphate, 0.9 to 12 parts of phosphoric acid with a concentration of 85%, 0.8 to 1.8 parts of metal powder, 0.6 to 1.4 parts of animal glue, 0.4 to 10 parts of calcined gypsum powder and 0.3 to 0.8 part of alum, with the balance being water. The liquid B comprises the following substances, by mass, 20 to 46 parts of zinc dihydrogen phosphate, 38 to 55 parts of zinc nitrate, 2 to 3.8 parts of sodium fluoride, 2 to 4 parts of zinc oxide and 2 to 6 parts of phosphoric acid with a concentration of 85%, with the balance being water. The multifunctional phosphating solution provided by the invention is composed of the liquid A and the liquid B, can realize removal of oil and rust at the same time and has the efficacy of rust protection, heat insulation, high temperature resistance, heat preservation, flame retardation, noise abatement, shock prevention, isolation, pollution cleaning and resistance to fire. The multifunctional phosphating solution has the following beneficial effects: a fast rust removal speed, great thickness of a formed film, long antirust time, etc.

Owner:李春清

Water-based high-temperature-resistant antirust paint and preparation method thereof

InactiveCN104559670AHigh hardnessImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsPropanoic acidSodium phosphates

The invention discloses a water-based high-temperature-resistant antirust paint. The water-based high-temperature-resistant antirust paint is characterized by being prepared from the following raw materials in parts by weight: 1-2 parts of sodium propionate, 2-3 parts of sodium pyrophosphate, 4-6 parts of mica powder, 2-3 parts of propanediol butyl ether, 23-26 parts of styrene-acrylic emulsion, 1-2 parts of 18-alkyl primary amine acetate, 0.3-0.5 part of organic fluoride modified polysiloxane, 1-2 parts of zinc stearate, 2-3 parts of carbonate pickax, 0.3-0.5 part of sodium oleate, 2-3 parts of polyving akohol, 2-3 parts of a water-based curing agent D230, 0.1-0.3 part of polyxyethylated alkylphenol, 33-36 parts of epoxy resin emulsion, 3-4 parts of barite powder, 4-7 parts of talcum powder, 16-22 parts of deionized water and 4-7 parts of an additive. After the paint is solidified, a paint film is high in hardness, good in abrasive resistance, high in adhesive force and not easy to peel off and also has the functions of resisting high temperature and preventing rust. By utilizing the water-based high-temperature-resistant antirust paint, an out door device shell can withstand harsh environment, the service life is prolonged, the added additive has the effect of reducing noise through damping, outflow of noise is weakened, and harmonious living environment is built.

Owner:安徽省东瑞装饰材料有限公司

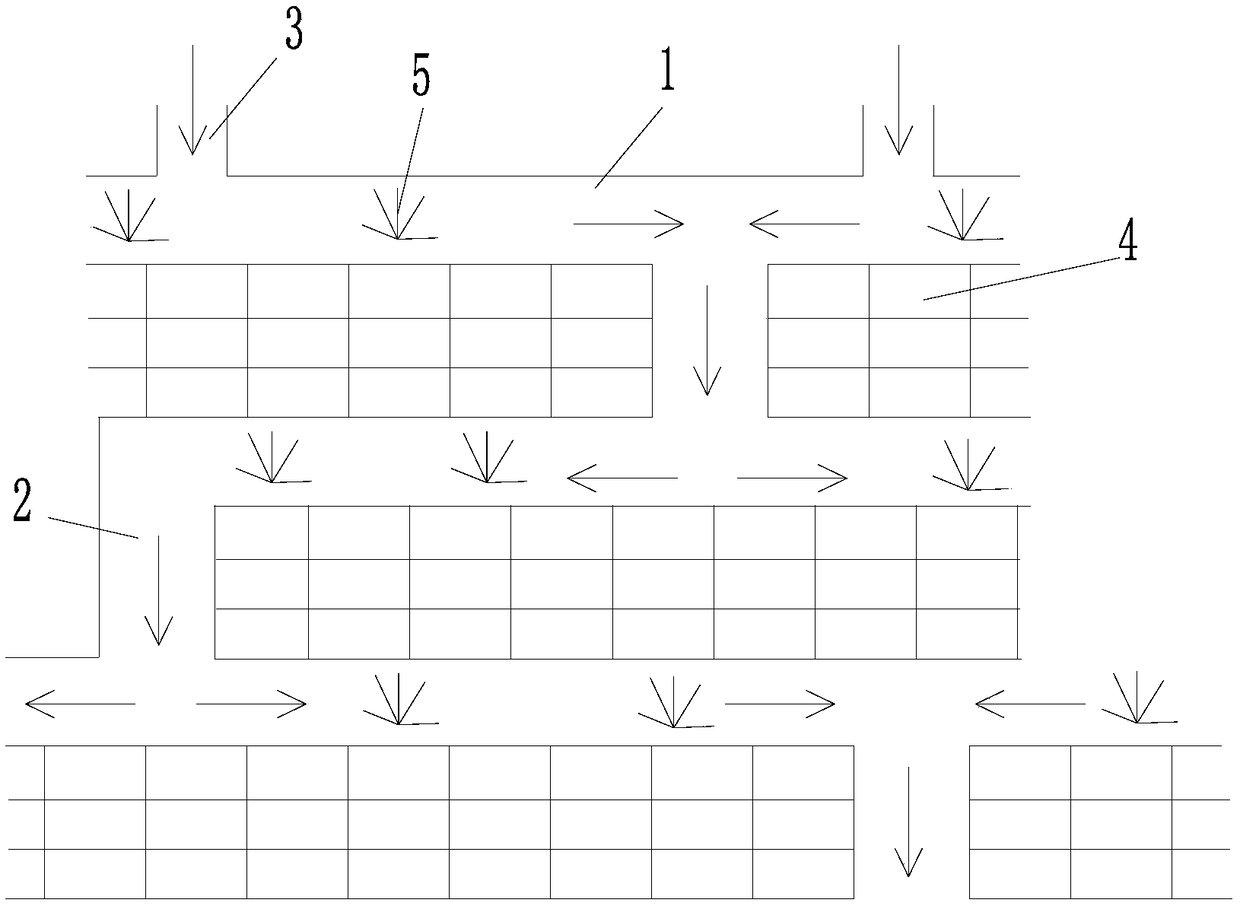

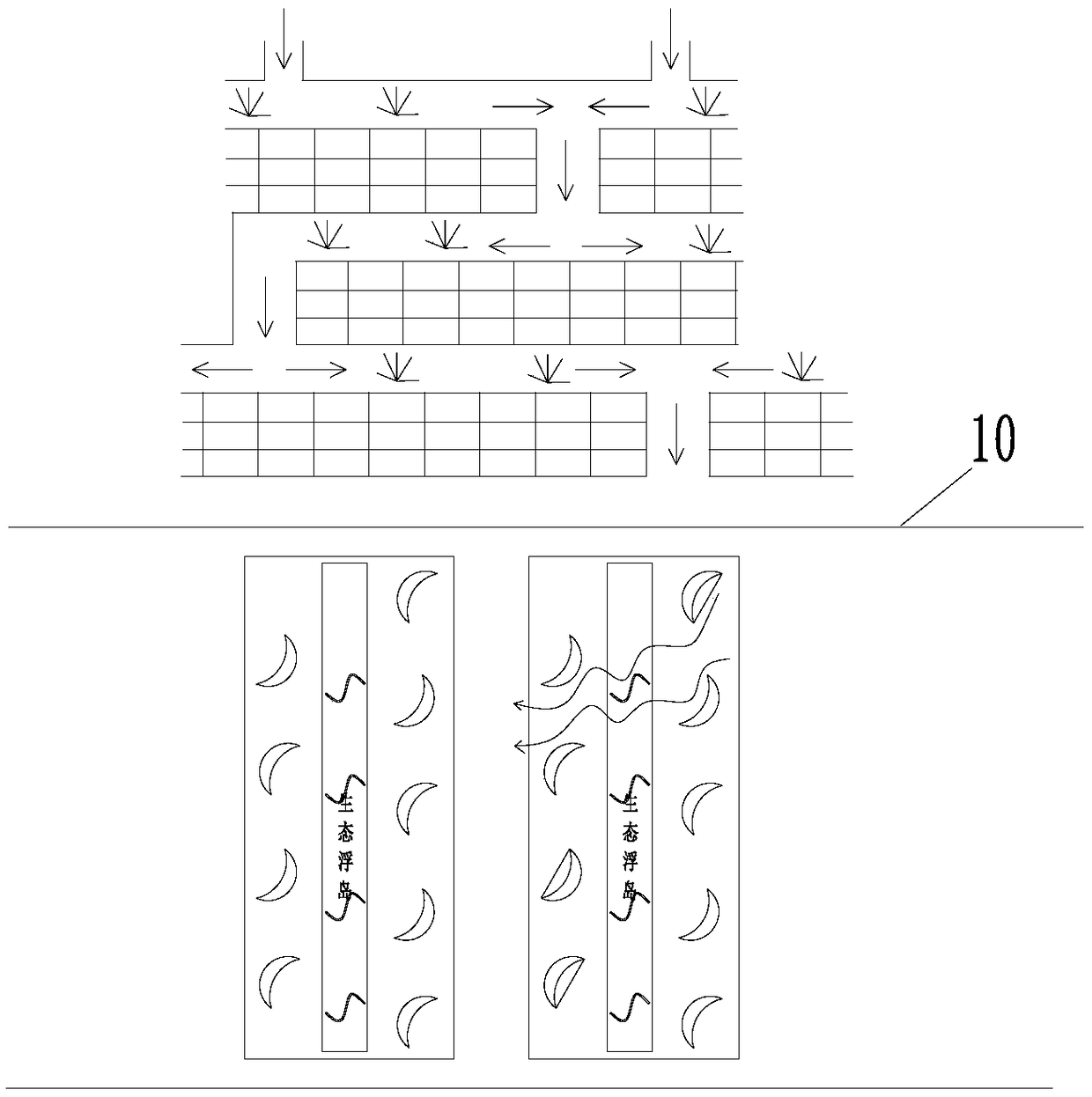

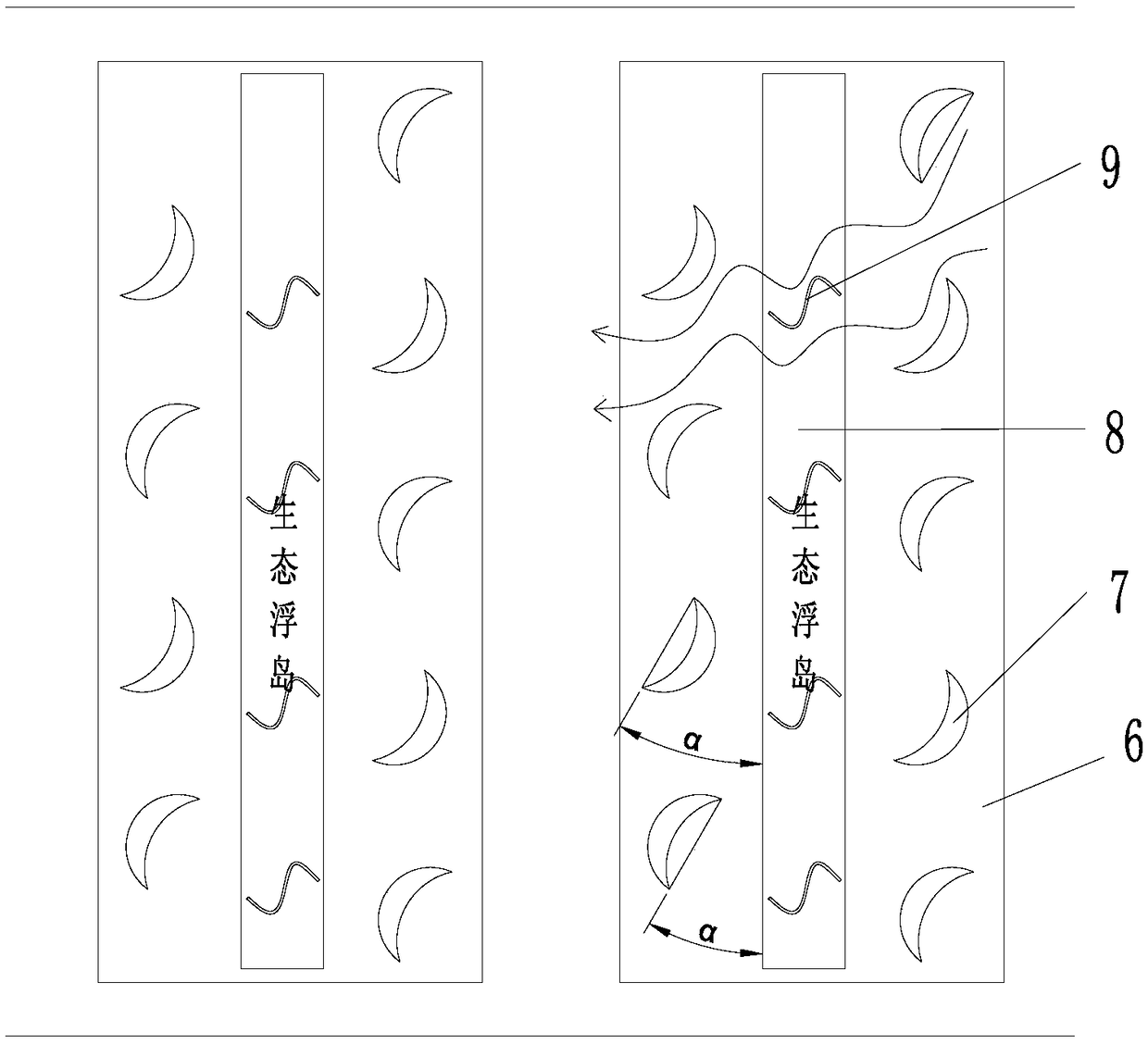

Slope protection structure and system with enhanced diversion, filtering and ecological sewage interception effects

ActiveCN109056648AEnhanced diversionImprove filtering effectCoastlines protectionBiological water/sewage treatmentRiver routingWater channel

The invention discloses a slope protection structure with enhanced diversion, filtering and ecological sewage interception effects. Multiple stages of diversion trenches are sequentially arranged at intervals along a river channel bank slope from top to bottom; the diversion trench of the previous stage and the diversion trench of the next stage are connected through a diversion channel; the diversion channels of the diversion trenches of the adjacent stages are horizontally staggered, and a staggered distance is at least 10 m; a rainwater inlet is arranged in the top of the diversion trench of the first stage; a mesh cage filled with cobblestones is laid on a part, which is not provided with the diversion trench and the diversion channel, on the river channel bank slope; biological ceramsite and gravel are placed in the diversion trenches of the upper half part of the river channel bank slope; biological ceramsite and coarse sand are placed in the diversion trenches of the lower halfpart of the river channel bank slope; green plants are planted in each stage of diversion trench; and meanwhile, the invention further discloses a slope protection system with the enhanced diversion,filtering and ecological sewage interception effects. The system comprises a plurality of crescent array diversion, sewage interception and purification groups which are arranged at intervals in a water channel along a water flow direction. The structure and the system have the enhanced diversion, filtering and ecological sewage interception effects.

Owner:CHONGQING UNIV IND TECH RES INST +1

Special high temperature-resistant coating on outer wall of tobacco-curing furnace and preparation method thereof

InactiveCN102153947AMeet the needs of useHigh temperature resistance hasCoatingsMicrosphereTemperature resistance

The invention discloses a special high temperature-resistant coating on an outer wall of a tobacco-curing furnace, which consists of the following components according to parts by weight: 30-40 parts of organic silicon resin, 5-10 parts of aluminium paste, 8-12 parts of titanium white, 30-40 parts of mixed stuffing, 0.5-1.5 parts of organic bentonite, 2-4 parts of PM, 1-3 parts of PMA (Propylene Glycol Monomethyl Acetate), and 4-6 parts of absolute ethyl alcohol, wherein the mixed stuffing consists of the following components according to parts by weight: 35-45 parts of low-melting point glass powder, 10-20 parts of hollow ceramic microspheres, 10-20 parts of zinc phosphate, 5-15 parts of aluminum tripolyphosphate and 18-22 parts of talcum powder. The special high temperature-resistant coating on the outer wall of the tobacco-curing furnace mainly has the advantages that a viscosity number reaches 85s, the percentage of solid reaches 65%, surface dry only needs 16 minutes, hard dry only needs 6 hours, the thermal endurance is strong, and the coating is not stripped for 6h at 500 DEG C. The coating has the advantages of high temperature resistance, rust prevention, quick drying, heat insulation, environmental protection and the like, can satisfy the use requirements on the outer wall of the tobacco-curing furnace, and is especially applicable for the tobacco-curing furnace.

Owner:无锡市南雅化工有限公司

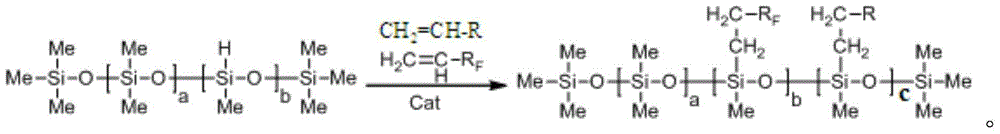

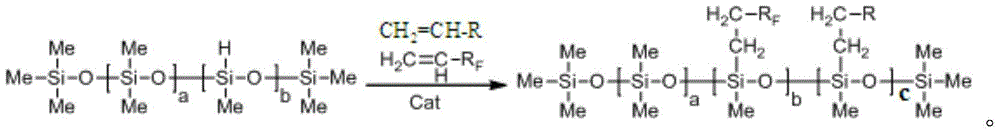

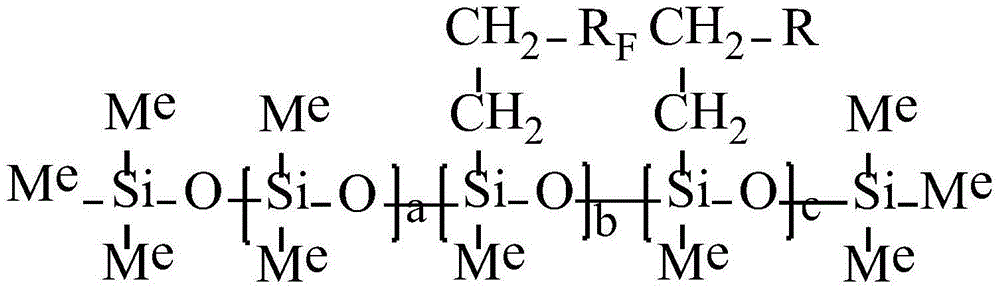

Novel functional group-containing fluorine-modified silicone oils and preparation method thereof

The invention discloses novel functional group-containing fluorine-modified silicone oils and a preparation method thereof, and belongs to the technical field of organosilicon high molecular material. Perfluorobutyl ethylene, perfluorohexyl ethylene, perfluorooctyl ethylene and perfluoroalkyl ethylenes as initial fluorine-containing materials are subjected to a hydrosilylation reaction with a methyl hydrogen-containing silicone oil under the action of a platinum catalyst, and fluorine-containing hydrogen-containing alkyl silicone oils are comprehensively prepared. The obtained fluorine-containing hydrogen-containing alkyl silicone oils further are subjected to a hydrosilylation reaction with allyl alcohol, hydroxyethyl acrylate and other functional group-containing monomers, and the fluorine-containing silicone oils with functional groups are prepared and have good mold release persistence, heat resistance and stability when used as mold release agents. According to principles, a series of fluorine-containing silicone oils with the functional groups can be synthesized by different fluorine-containing olefins; and the preparation process is simple and has wide application fields.

Owner:JUHUA GROUP TECH CENT

Environmental-friendly antirust cutting fluid and preparation method thereof

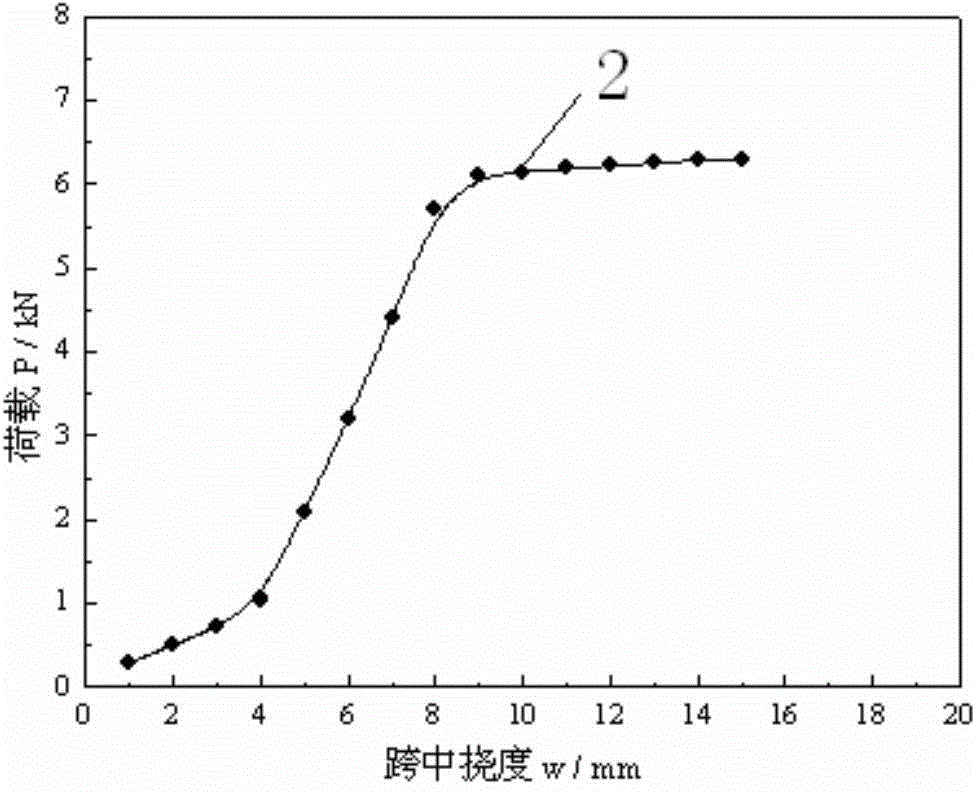

The invention discloses antirust cutting fluid and a preparation method thereof. The antirust cutting fluid comprises the ingredients in percentage by mass: 0.5-2.5% of boric acid, 4.9-30.2% of triethanolamine, 1-5% of oleic acid, 0.5-2% of dodecyl dimethyl betaine, 0.1-2% of rosin, 0.1-0.5% of defoamer, 1-5% of lubricant and the balance of water. The preparation method comprises the steps of firstly enabling boric acid, oleic acid and rosin, which are in the formula ratio, to respectively react with triethanolamine, then, mixing three solutions which are obtained through reaction, then, adding a proper amount of dodecyl dimethyl betaine, a proper amount of defoamer, a proper amount of lubricant and the balance of water, heating and uniformly stirring. The antirust cutting fluid disclosed by the invention has good rust resistance and lubricating property to first-level cast iron; both original cutting fluid and diluted liquid thereof are stable in performance and low in cost and are harmless to environment and human.

Owner:HUBEI UNIV OF EDUCATION

High-temperature-resistant paint for hydraulic cylinder and preparation method thereof

ActiveCN104789116AStrong adhesionNot easy to fall offRubber derivative coatingsAnti-corrosive paintsPhosphorous acidPolymer science

The invention discloses a high-temperature-resistant paint for a hydraulic cylinder and a preparation method thereof. The high-temperature-resistant paint for the hydraulic cylinder is prepared from the following constituents in parts by weight: 58-60 parts of modified epoxy organic silicon resin, 22-24 parts of hydrogenated acrylonitrile butadiene rubber, 27-29 parts of bisphenol A epoxy resin, 12-14 parts of mica powder, 10-13 parts of butyl rubber, 5-7 parts of polydimethylsiloxane, 12-14 parts of phenylmethylsilane resin, 3-5 parts of dioctyl phthalate, 2-4 parts of copper powder, 2-4 parts of rutile type titanium dioxide, 1-3 parts of ceramic powder, 20-25 parts of deionized water, 2-4 parts of triethylene tetramine, 5-7 parts of triphenyl phosphite, and 1-3 parts of an auxiliary.

Owner:SUZHOU TONGMING MACHINERY

Thermal insulating sterilization type coating for glass doors and preparation method of thermal insulating sterilization type coating

InactiveCN104449206AImprove self-cleaning abilityEnhanced stain and mildew resistanceAntifouling/underwater paintsPaints with biocidesPolymer scienceAluminum silicate

The invention discloses a thermal insulating sterilization type coating for glass doors. The thermal insulating sterilization type coating is characterized by being prepared from the following raw materials in parts by weight: 38-42 parts of aqueous epoxy resin, 12-15 parts of aqueous alkyd resin, 11-14 parts of acrylic resin emulsion, 0.3-0.5 part of a leveling agent BYK-307, 0.2-0.4 part of gas phase nanosilicon dioxide, 1-2 parts of butyl stearate, 0.3-0.5 part of methyl glycidyl acrylate, 0.2-0.3 part of cashew nut oil, 1-3 parts of zinc powder, 0.2-0.3 part of octadecanamide, 1-3 parts of dipropylene glycol butyl ether, 0.5-1.0 part of a silane coupling agent KH, 0.2-0.4 part of a polysiloxane defoaming agent, 0.2-0.4 part of a dispersing agent BYK-415, 0.3-0.5 part of fatty alcohol sodium succinate, 1-2 parts of a polymercaptan curing agent, 1-2 parts of aluminum silicate powder, 0.4-0.8 part of sodium phytate, 3-5 parts of a modified nano titania photocatalyst, 1-2 parts of pigment and 12-15 parts of deionized water. By adopting the thermal insulating sterilization type coating disclosed by the invention, a coated film is smooth and flat, hard in hardness, free of peeling or dropping, resistant to brushing and washing and good in water resistance after being cured, the added aluminum silicate powder has a function of reflection thermal insulation, the added zinc powder has the functions of corrosion resistance, rusting resistance and aging resistance, and due to addition of the modified aluminum silicate powder, the self-cleaning property, the antifouling property, the anti-mildew property, the air purification property and the like of the coating are improved.

Owner:安徽省实防新型玻璃科技有限公司

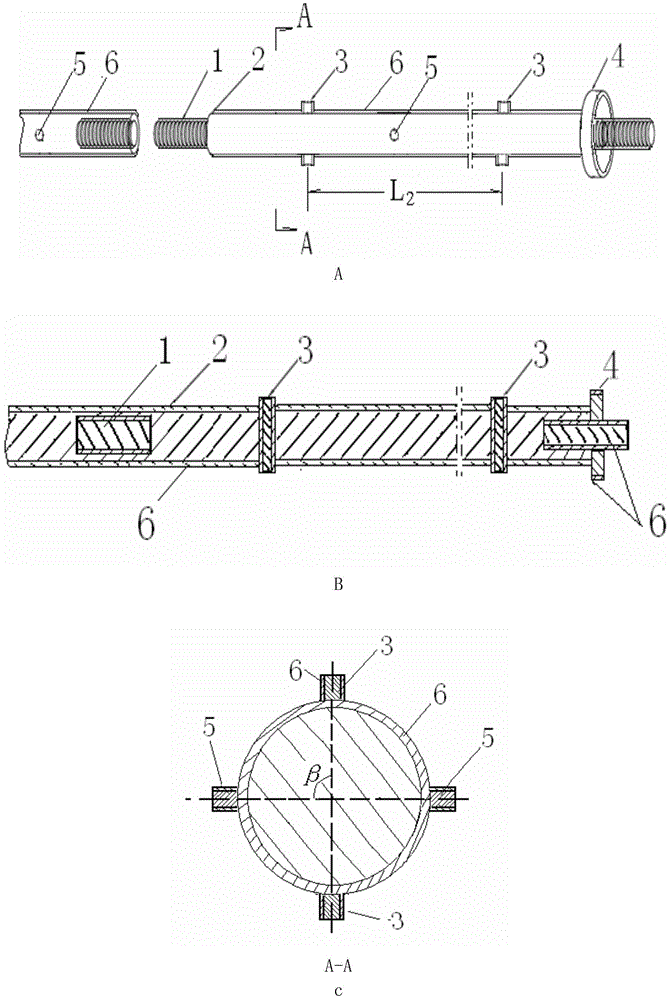

Earthen ruin reinforcing anchor rod and design method thereof

ActiveCN104088277AAvoid a single stick design philosophyIncrease anchoring forceBulkheads/pilesEngineeringStructural engineering

The invention discloses an earthen ruin reinforcing anchor rod and a design method of the earthen ruin reinforcing anchor rod. According to the structure, the anchor rod comprises multiple connecting threaded rods, multiple sections of bakelite rods, multiple resistance bars and multiple bakelite nuts, and a traditional single bar-shaped design concept is abandoned. The resistance bars intersect by 90 degrees and are evenly distributed on the bakelite rods, so that the formed resistance structure is more beneficial to reinforcement of anchoring force. According to the anchoring length, the bakelite rods are connected into the anchor rod through the connecting threaded rods, so that the anchor rod is suitable for anchoring operation of ruin soil bodies of various lengths. The bakelite rods are selected as an anchor rod material so that the anchor rod can be applied to arid, semi-arid and damp earthen ruin reinforcing environments. Structure parameters of the anchor rod are determined according to the conditions of earthen ruins and different earth conditions determine the anchor rods with different parameters. By the adoption of the method, the proper anchor rod can be designed according to the specific conditions of different earthen ruins.

Owner:SHAANXI NORMAL UNIV

Environmental-protection lubricating water-based cutting fluid

InactiveCN104327933AGood emulsification and dispersionGood dispersionLubricant compositionSolubilityWater based

The present invention discloses an environmental-protection lubricating water-based cutting fluid, which comprises the following raw materials by weight: 8-20 parts of sodium abietate, 15-25 parts of a rosin amine glucose ester surfactant, 5-10 parts of rosin amine polyoxyethylene ether, 12-18 parts of a polyaniline aqueous anti-corrosion agent, 5-15 parts of triethanolamine oleate, 3-8 parts of triethanolamine, 3-10 parts of diisopropanolamine, 10-15 parts of sodium carbonate, 5-15 parts of hydrophilic alcohol, 3-6 parts of a sterilization agent, 2-5 parts of a foaming agent, 3-10 parts of a stabilizer, and 80-100 parts of water. The environmental-protection lubricating water-based cutting fluid has functions of excellent cleaning, excellent lubrication, excellent corrosion resistance and excellent cooling, and further has characteristics of environmental protection, long service life, good water solubility, low cost, and high stability.

Owner:CHAOHU GUANGFENG METAL PROD

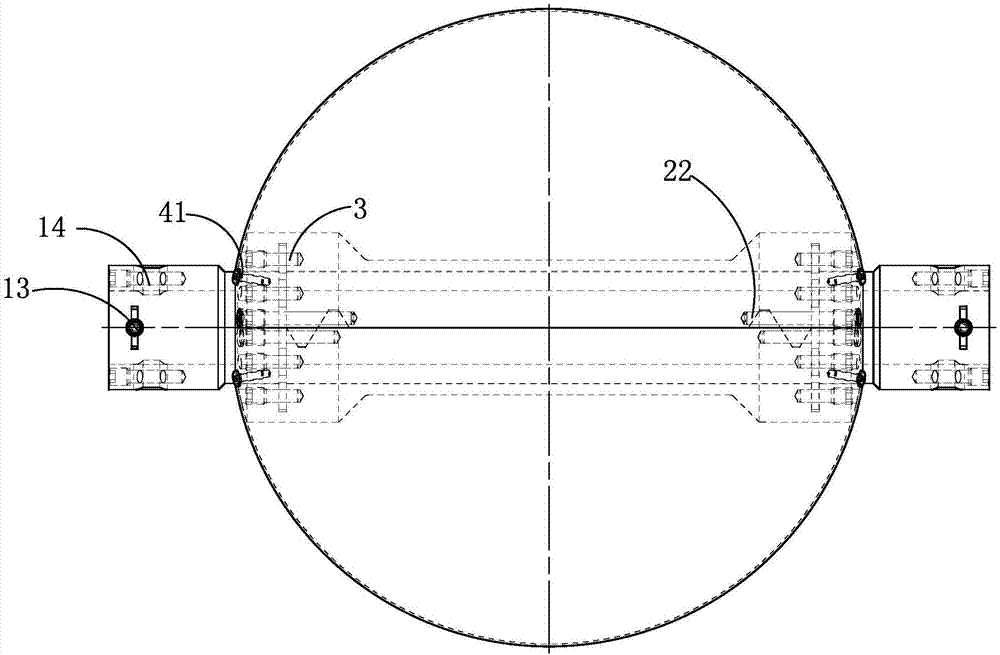

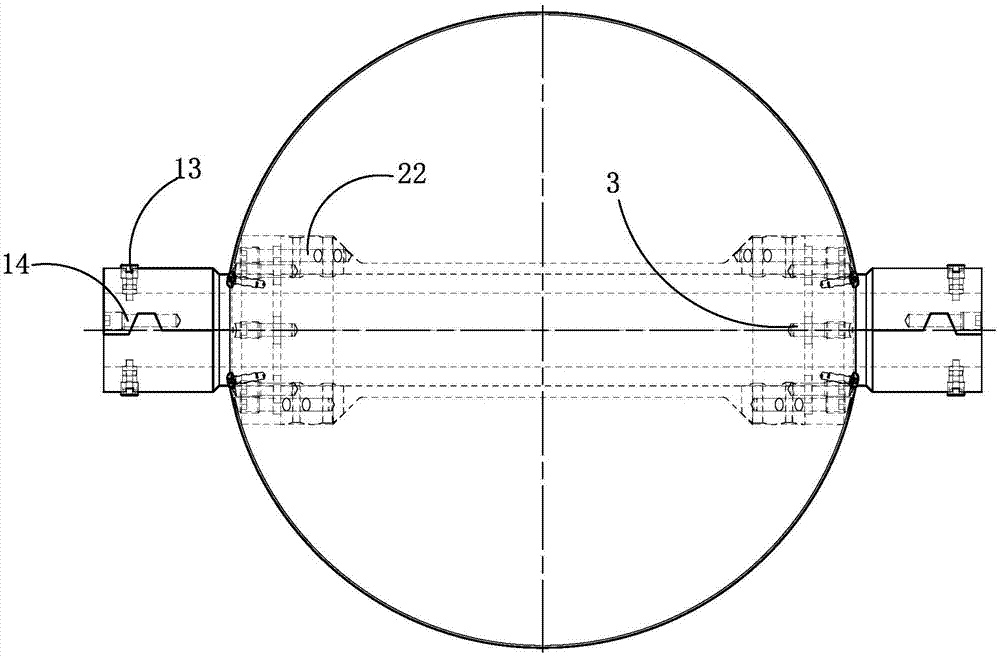

Split rotary rat-proof sphere

The invention discloses a split rotary rat-proof sphere which comprises a fixed shaft sleeve, a rotary shaft sleeve, bearings and a sphere shell. The fixed shaft sleeve and the rotary shaft sleeve are in the shapes of hollow ring columns, a pair of circumferential clamp plate grooves which are symmetric with each other around the axis of the fixed shaft sleeve is formed in two ends of the fixed shaft sleeve, and clamp plates are connected into the clamp plate grooves by adjusting bolts; the fixed shaft sleeve and the rotary shaft sleeve are provided with two symmetric half fixed shaft sleeves and two symmetric half rotary shaft sleeves, and the axial end surfaces of the two half fixed shaft sleeves and the two half rotary shaft sleeves are butted to one another, are connected with one another by mortises and tenons and are fixed by the aid of bolts; the rotary shaft sleeve is connected to the outer surface of the fixed shaft sleeve by the bearings arranged in bearing blocks at two ends of the rotary shaft sleeve; the sphere shell is a spherical shell, circular through holes are symmetrically formed in two ends of the sphere shell along the axis of the sphere shell, the sphere shell comprises two symmetrical half sphere shells and sleeves the outer surface of the rotary shaft sleeve, the through holes sleeve the outer surface of the fixed shaft sleeve in a movable fit manner, and the two ends of the sphere shell are connected onto two end surfaces of the bearing blocks by mounting screws. The split rotary rat-proof sphere has the advantage that the purpose of preventing rats from passing through places between wharves and ship hulls can be achieved by the aid of the split rotary rat-proof sphere.

Owner:中国人民解放军62040部队

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com