Patents

Literature

216results about How to "High temperature resistance has" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water high-temperature resistant flaming-proof anticorrosive paint

ActiveCN101165129AHigh temperature resistance hasPrevent rustFireproof paintsAnti-corrosive paintsEmulsionHeat resistance

The present invention relates to paint, and is especially one kind of water soluble high temperature fireproof antirust paint comprising silicone propylene emulsion 30-40 (in wt%, the same below), water 8-16, polysodium acrylate 0.3-0.5, sodium hexametaphosphate 0.1-0.3, moldproof fungicide 0.1-0.2, antirust agent 0.2-0.3, fire retardant 5-8, aluminum tripolyphosphate 3-5, titania powder 8-10, magnet powder 8-10, mica powder 3-5, barium metaborate 8-10, silica sol 3-5, potassium silicate 2-5, defoaming agent 0.1-0.3, and leveling agent 0.1-0.2. The water soluble high temperature fireproof antirust paint is prepared through mixing, stirring and depurating. It has heat resistance, fireproof effect and capacity of preventing metal from rusting.

Owner:青岛居芳环保技术有限公司

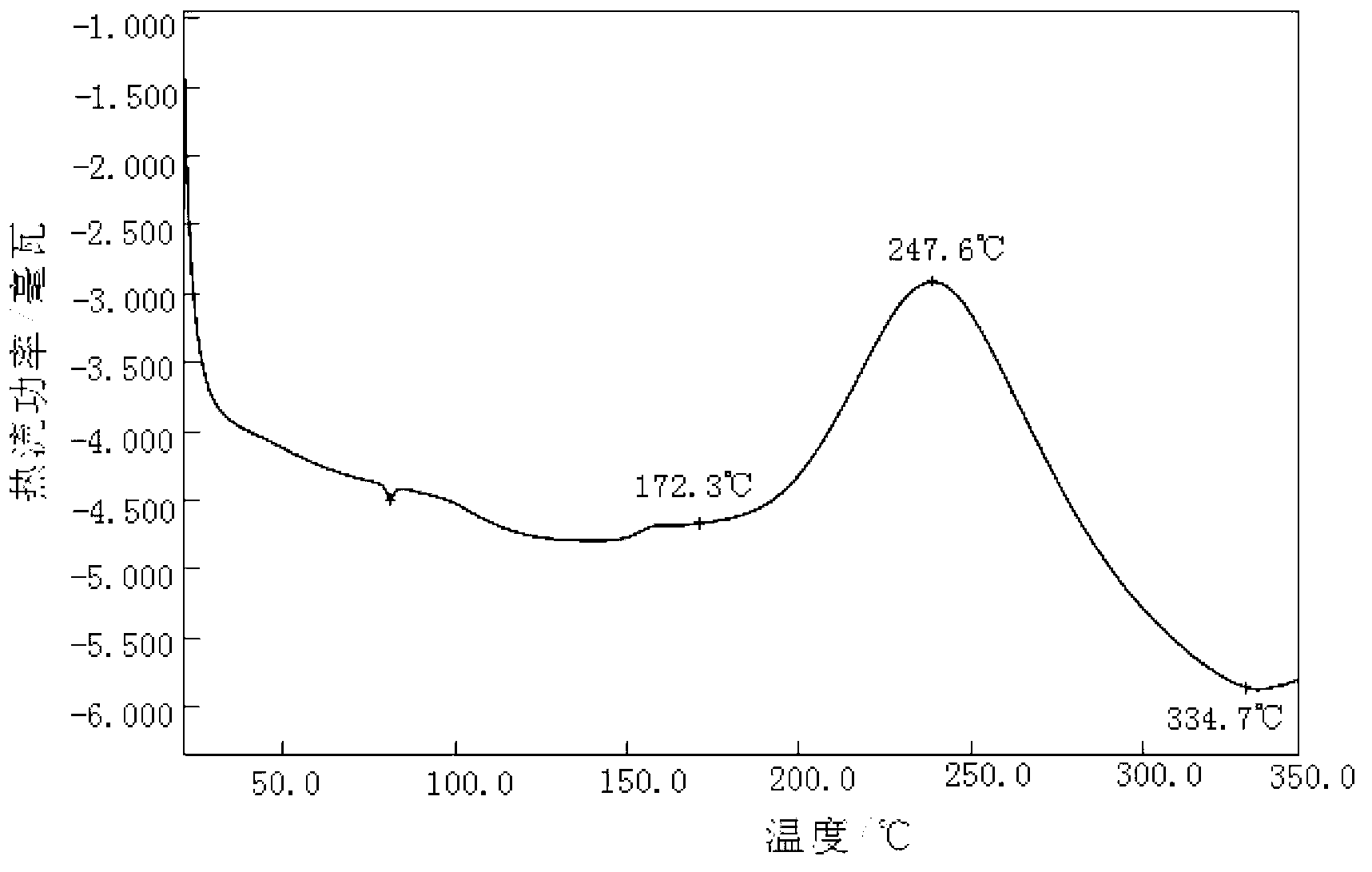

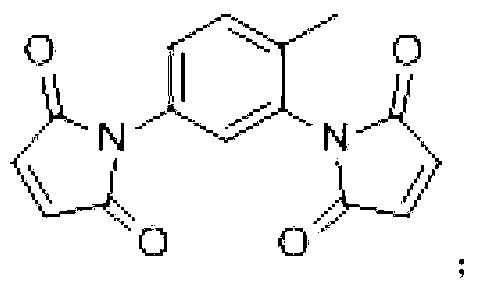

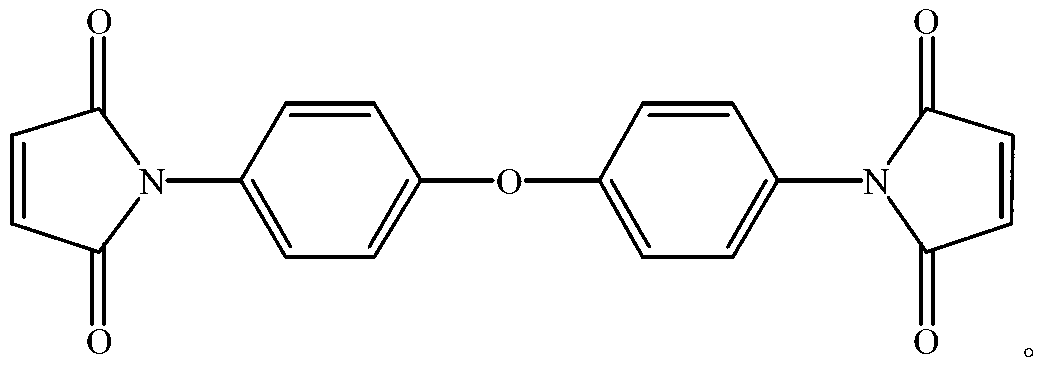

High-temperature-resistant bismaleimide resin carrier structure adhesive film and preparation method thereof

ActiveCN103242767AImprove bond reliabilityHigh temperature resistance hasNon-macromolecular adhesive additivesFilm/foil adhesivesTemperature resistanceGlass transition

The invention provides a high-temperature-resistant bismaleimide resin carrier structure adhesive film and a preparation method thereof, and relates to a high-temperature curing high-temperature-resistant structure adhesive. The invention aims to solve the problems that the conventional bismaleimide adhesive film does not have high temperature-resistant grade and high toughness. The adhesive film consists of bismaleimide resin, a technical modifier, a toughening modifier, a compatibilizer and a thixotropic agent. The preparation method comprises the following steps of: performing prepolymerization on the bismaleimide resin and the technical modifier to obtain a bismaleimide resin prepolymer; mixing the bismaleimide resin prepolymer, the toughening modifier, the compatibilizer and the thixotropic agent uniformly by a mechanical blending method to prepare an adhesive material; and preparing the adhesive by using a three-roller coating film-making machine under the film-forming assistance of the carrier. The adhesive has the characteristics of high-temperature resistance and high toughness, wherein the glass-transition temperature reaches above 280 DEG C and the honeycomb roller peeling strength reaches about 75.0 N.m / m. The adhesive is applied to adhesion of metal or composite material high-temperature-resistant structure members in the field of aerospace.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

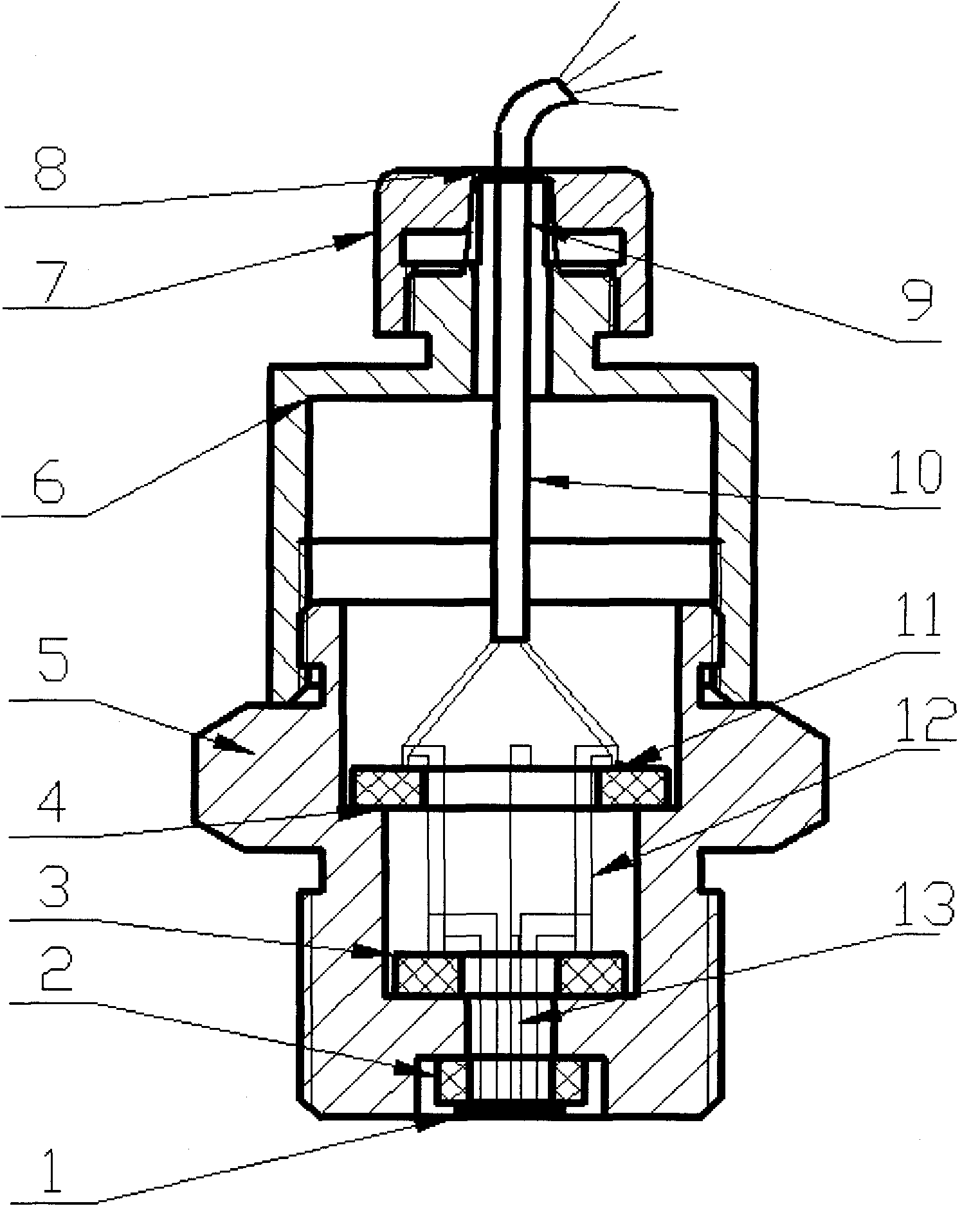

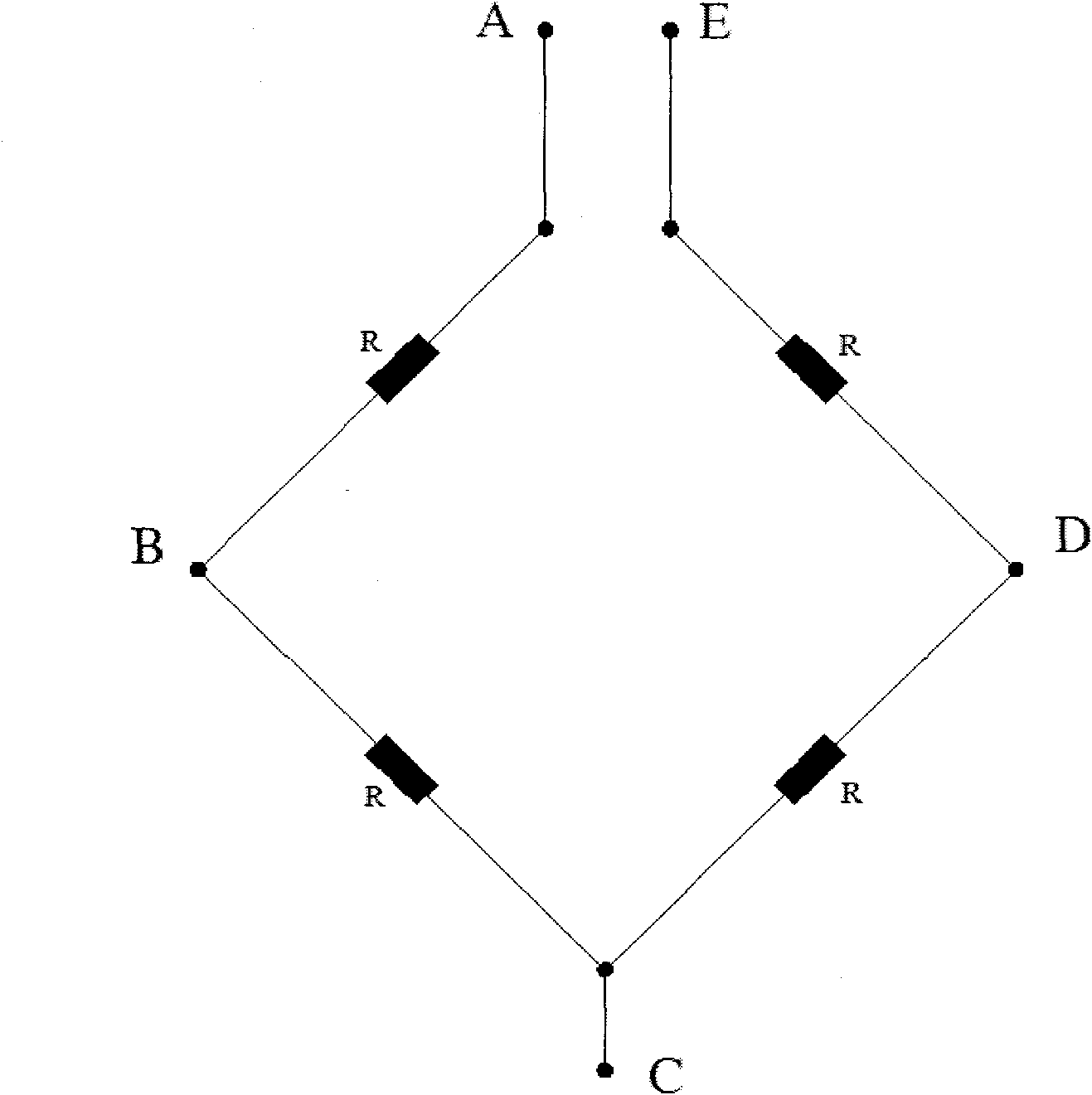

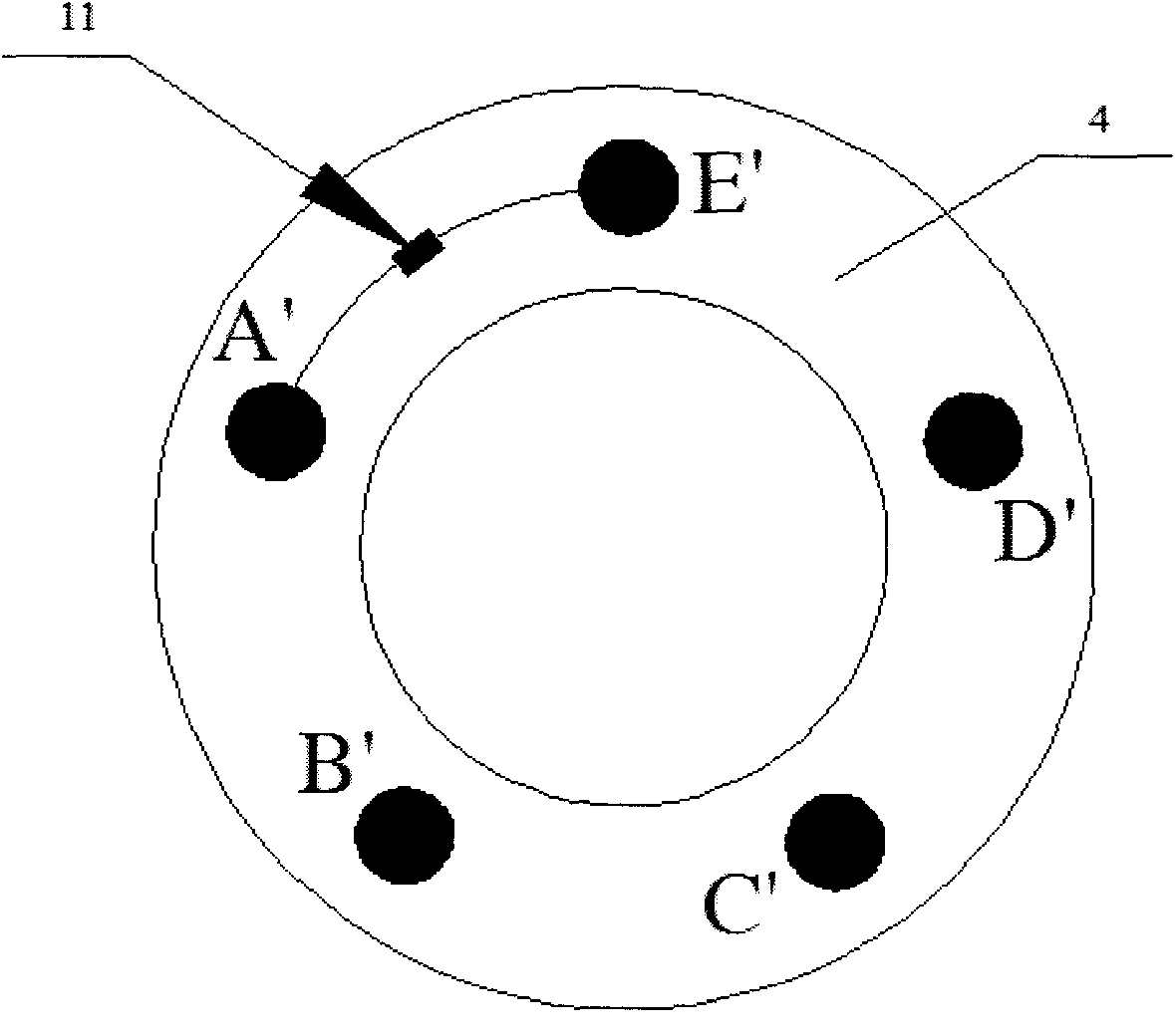

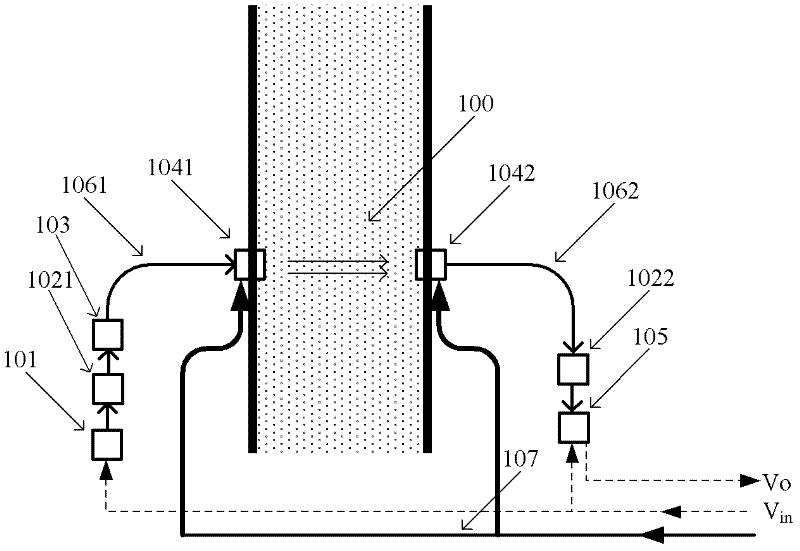

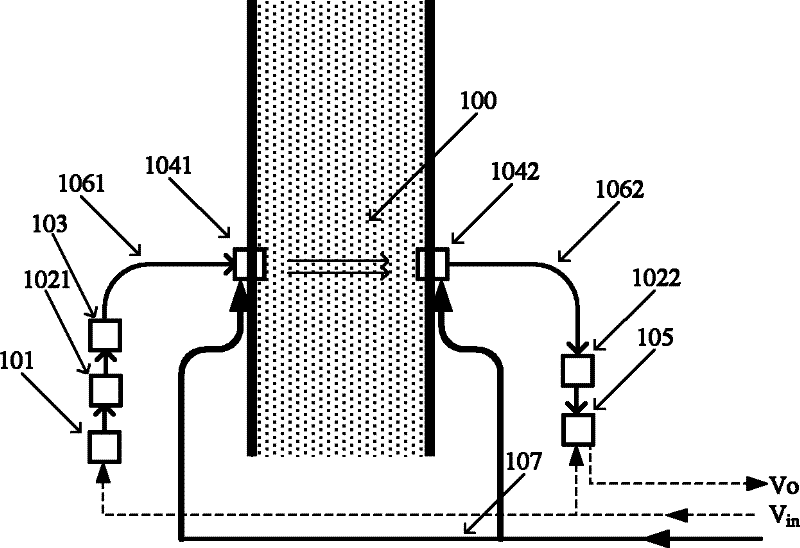

Flush packaged pressure sensor with high temperature resistance and high frequency response

InactiveCN101832830AHigh temperature resistance hasHigh temperature resistance and high frequency responseFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsEngineeringTemperature resistance

The invention relates to a flush packaged pressure sensor with high temperature resistance and high frequency response, which comprises a pressure chip. The pressure chip is combined with a glass ring; the glass ring is adhered to a metal substrate; a high-temperature switching plate and a high-temperature switching circuit compensation plate are respectively fixed in the metal substrate; the pressure chip is connected with the high-temperature switching circuit compensation plate through a gold wire lead; the high-temperature switching plate is connected with the high-temperature switching circuit compensation plate through a high-temperature lead; a four-core high-temperature lead is connected with the high-temperature switching circuit compensation plate; the metal substrate is connected with a metal shell; the metal shell is connected with a wire-fixing cap; the four-core high-temperature lead passes through the metal shell and a hole of the wire-fixing cap; the pressure chip senses pressure from an external medium and converts a pressure signal into a voltage signal; and the voltage signal passes through the gold wire lead, the high-temperature switching plate and the high-temperature lead, is transmitted to the high-temperature switching circuit compensation plate, and is output through the four-core high-temperature lead after being compensated. The pressure sensor has the advantages of high temperature resistance and high frequency response, and is used for measuring dynamic or static pressure signals.

Owner:XI AN JIAOTONG UNIV

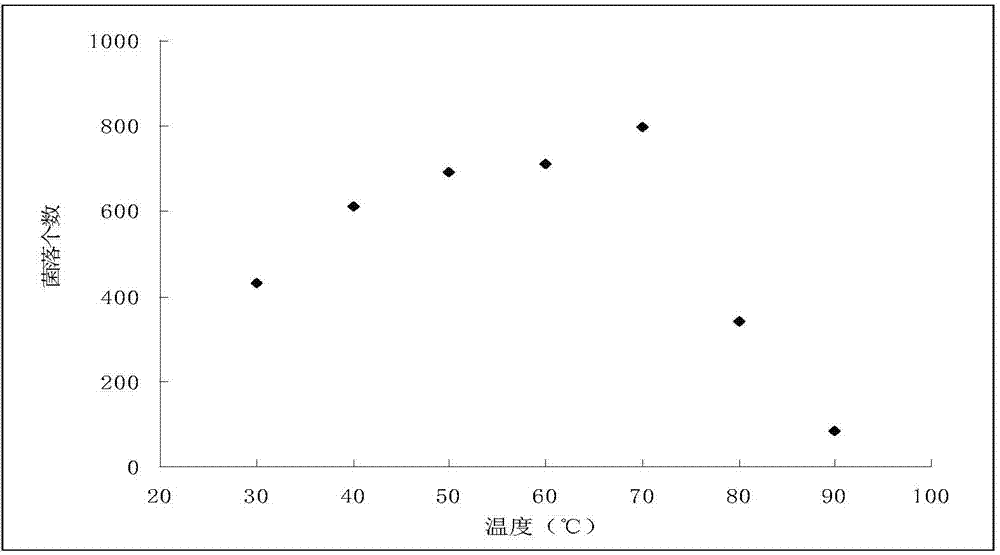

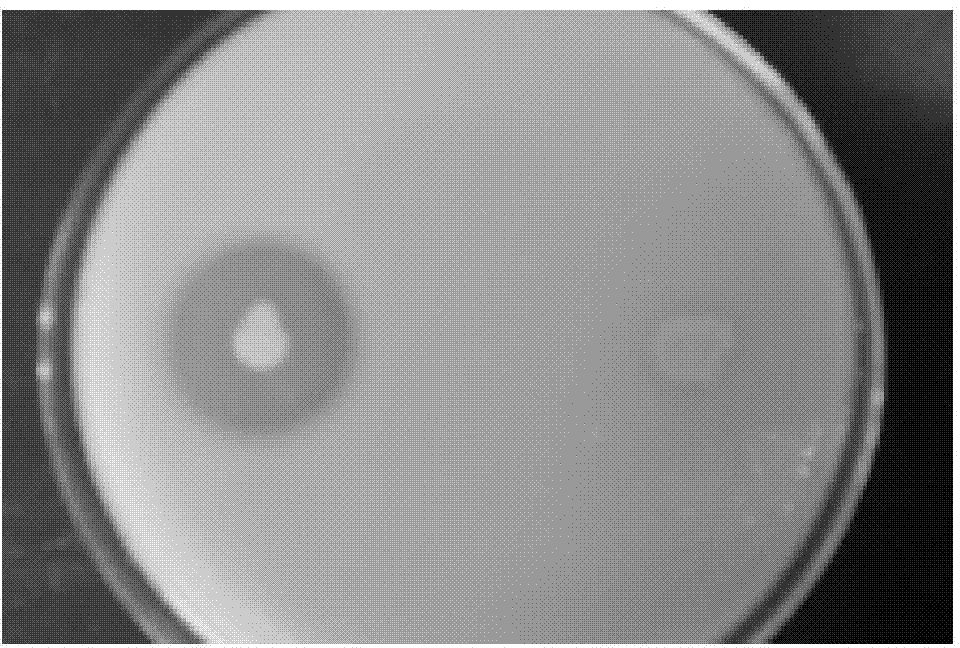

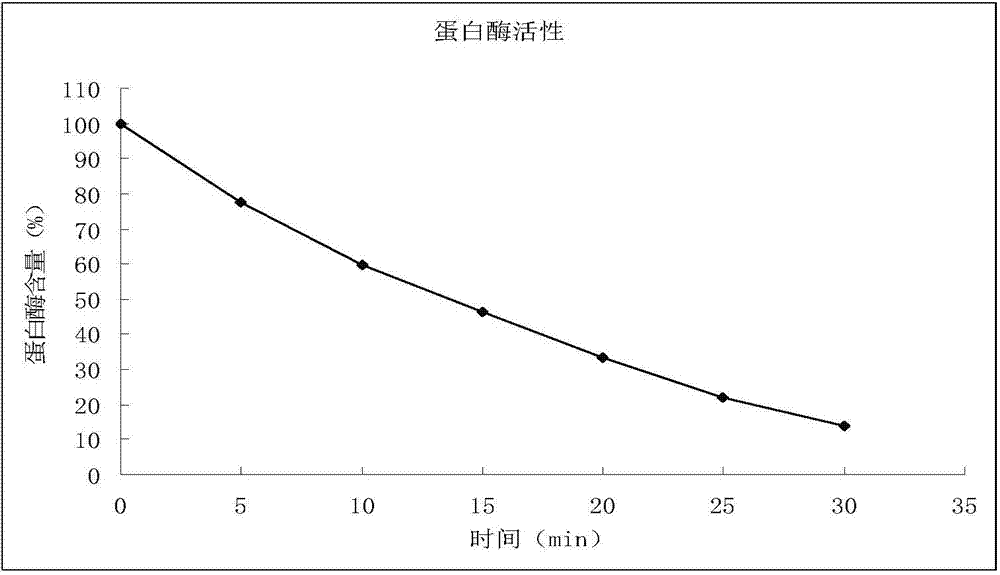

Bacillus subtilis H8-3 and application thereof

InactiveCN104328065AHigh temperature resistantIncrease protease activityBio-organic fraction processingBacteriaProteinase activityVirgibacillus species

The invention discloses a bacillus subtilis H8-3 and application thereof in preparation of a decomposed inoculant. The bacillus subtilis H8-3 is deposited with the CCTCC at Oct 21, 2013 in Hubei Wuhan university and is assigned the accession number CCTCC No:M 2013483. The bacillus subtilis H8-3 is high-temperature-resistant, can survive at 30-60 DEG C, is high in protease activity and is quick in growth. The decomposed inoculants prepared from the bacillus subtilis H8-3 is high-temperature-resistant and can secrete protease and lipase for high-efficiently fermenting animal wastes. Compost prepared through the decomposed inoculant is less in environmental pollution, is economical and is easy to use. When a product after compost treatment is subjected to subsequent treatment, the product can be employed as an organic fertilizer for achieving an object of turning waste into resources.

Owner:HANGZHOU FAMOXI BIOMEDICAL TECH

Preparation method of high-temperature resistant egg yolk essence and application thereof

The present invention belongs to technical field of essences for food, and discloses a preparation method of a high-temperature resistant egg yolk essence and an application thereof. Egg yolk liquid or egg yolk powder which has been subjected to spray drying is prepared into a solution of a certain concentration, the solution is subjected to enzymolysis through protease and flavourzyme, and reducing sugar, amino acid, yeast extract and edible flavor are added into the egg yolk enzymolysis product, so as to obtain the egg yolk essence. The combination method of biological enzymolysis effect and Maillard reaction is adopted, and subtle flavoring skills are used, so that the high-temperature resistant egg yolk essence is prepared. The essence has stronger natural feeling and thick taste, and meets the needs of the general public.

Owner:ZENGCHENG HANDYWARE SEASONING

High-temperature-resistant nylon yarn material for 3D printing, preparation method thereof and method for performing 3D printing by applying same

ActiveCN106433108AImprove mechanical propertiesIncrease temperatureAdditive manufacturing apparatus3D object support structuresYarnPolymer science

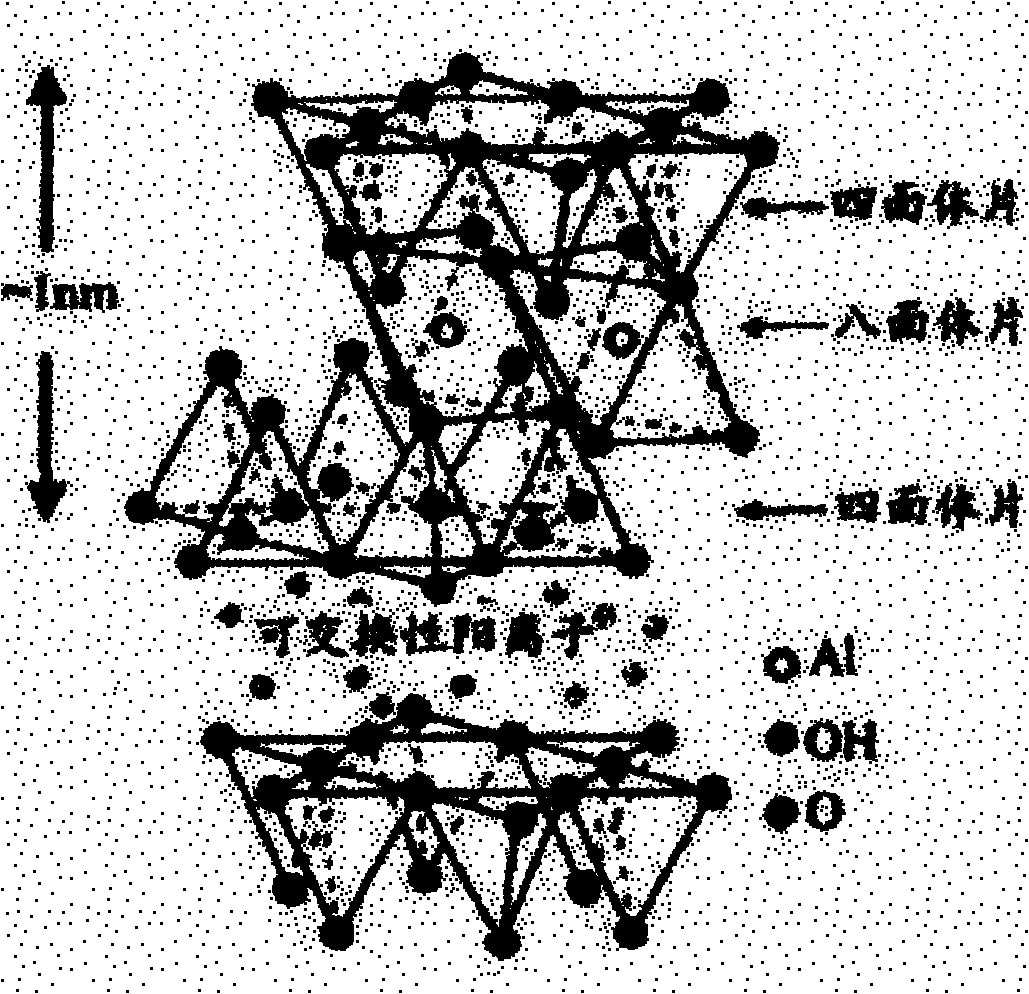

The invention relates to the technical field of 3D printing, in particular to a high-temperature-resistant nylon yarn material for 3D printing, a preparation method thereof and a method for performing 3D printing by applying the same. The high-temperature-resistant nylon yarn material contains the following raw materials in parts by weight: 90-100 parts of nylon resin, 1-10 parts of a reinforcing agent, 0.3-0.6 part of an antioxidant, and 0.1-0.3 part of a lubricant, wherein the reinforcing agent is organic modified montmorillonite. According to the invention, the high-strength nylon resin is used as a base material, the organic modified montmorillonite, the antioxidant and the lubricant are used for performing physical modification on the nylon resin, and the synergistic action among the components with different proportions is adjusted to improve the contractility and increase the thermal denaturation temperature of the nylon resin, so that the obtained high-temperature-resistant nylon yarn material for 3D printing is high in strength, low in shrinkage rate, low in warping deformation degree, and low in forming accuracy, and is high-temperature-resistant, and a support can be removed easily.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

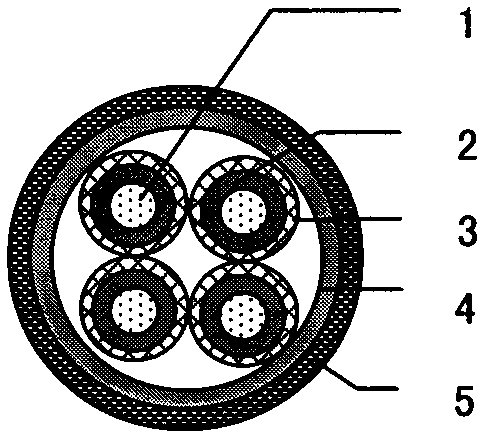

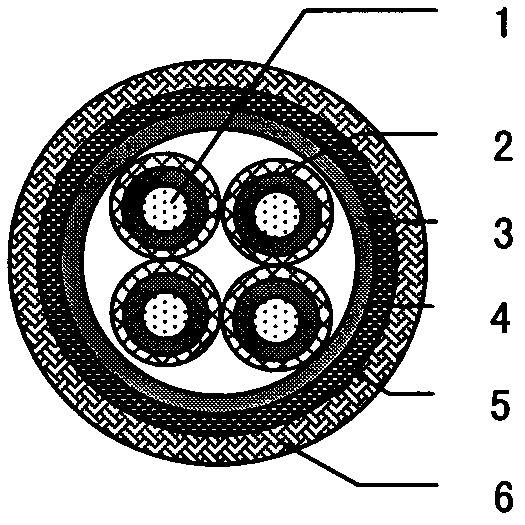

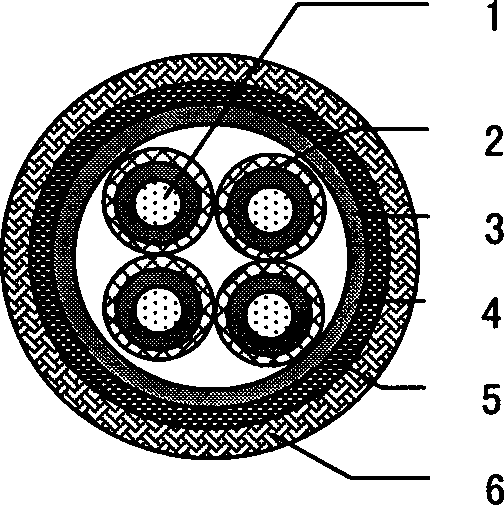

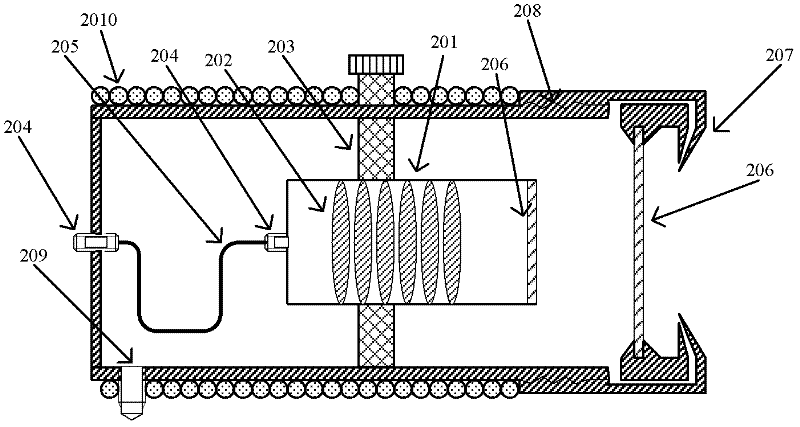

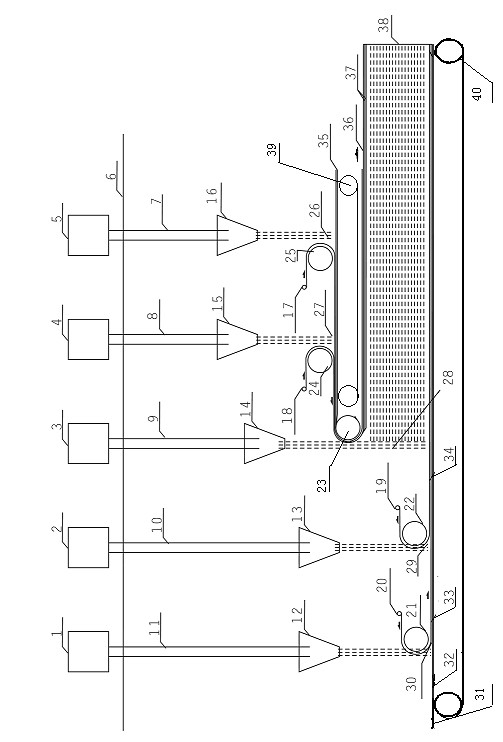

GWIB (general way interface bus) high-temperature-resistant cable and preparation process thereof

ActiveCN102360602ASmall outer diameterEasy to installFlexible cablesCable/conductor manufactureEnvironmental resistanceMica

The invention discloses a GWIB (general way interface bus) high-temperature-resistant cable and a preparation process thereof. The GWIB high-temperature-resistant cable and the preparation process thereof are characterized in that a nickel-clad copper alloy line conductor is twisted by a cable wire twisting machine, inner insulating layers of two polyimide composite belts (PTFE(polyterafluoroethylene) / PI(polyimide) / PTFE(polyterafluoroethylene)) which are lapped by a lapping machine are arranged on the periphery of the nickel-clad copper alloy line conductor, a high-temperature-resistant alkali-free glass fiber outer insulating layer which is woven by a weaving machine is disposed on the periphery of each inner insulating layer, a lapping layer which is lapped by a mica tape is disposed onthe periphery of each outer insulating layer, and a high-temperature-resistant alkali-free glass fiber woven protecting layer which is woven by the weaving machine is arranged on the periphery of each lapping layer. The GWIB high-temperature-resistant cable and the preparation process thereof have the advantages that lapping and sintering process is adopted to realize insulation, combined insulation is adopted, the cable has excellent electric performances, mechanical performances and environmental resistance, is resistant to high temperature of 400 DEG C, is high-temperature-resistant, low-temperature-resistant, mould-resistant, salt-air-resistant, moist-heat-resistant and flexible, and is small in outer diameter and light in weight, and the like.

Owner:NANJING QUANXIN CABLE TECH

High-temperature-resistant high-toughness photo-cured resin for photo-curing 3D printing

The invention discloses high-temperature-resistant high-toughness photo-cured resin for photo-curing 3D printing. The high-temperature-resistant high-toughness photo-cured resin is prepared from the following raw materials in percentage by mass: 20-50% of an epoxy prepolymer, 10-30% of an unsaturated prepolymer, 10-40% of an active dilution agent, 5-25% of a high-temperature-resistant cross-linking agent, 10-30% of silicone rubber acrylic ester and 2-6% of a photoinitiator. The substances are uniformly mixed and stirred to completely dissolve the photoinitiator, and thus a light yellow transparent liquid is prepared, that is, the high-temperature-resistant high-toughness photo-cured resin. The high-temperature-resistant high-toughness photo-cured resin disclosed by the invention has the characteristics of being high in temperature and high in toughness, and in addition, has the characteristics of being low in viscosity, low in shrinkage rate, high in curing speed and the like which meet photo-curing 3D printing molding processes.

Owner:SHAANXI HENGTONG INTELLIGENT MACHINE

High-temperature-resistant and antistatic coating

InactiveCN104877524AHigh temperature resistance hasImprove antistatic performanceAnti-corrosive paintsEpoxy resin coatingsFiberEpoxy

The invention discloses high-temperature-resistant and antistatic coating. The high-temperature-resistant and antistatic coating comprises, by weight, 37-40 parts of organic silicon resin, 15-18 parts of xylene, 12-14 parts of high aluminum fibers, 9-11 parts of magnesium chloride, 8-13 parts of polyisocyanate curing agents, 10-12 parts of nano silicon dioxide, 10-13 parts of cobaltous oxide, 9-13 parts of aluminium oxide, 43-45 parts of epoxy resin, 20-24 parts of conductive powder, 30-35 parts of styrene-acrylic emulsions, 3-4 parts of graphite powder, 2-3 parts of carbon black and 40-50 parts of diluents. The high temperature resisting, oil resisting and antistatic effects of the coating are good and effective in a long term. The surface of the coating is seamless and easy to clean, corrosion resistant performance is good, the preparation technology is simple, and cost is low.

Owner:任碧龙

Preparation method and application of high temperature solvent resistant acrylate pressure sensitive adhesive

ActiveCN104449486AImprove mechanical propertiesImprove high temperature resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesIsooctyl acrylateCarvacryl acetate

The invention relates to a high temperature solvent resistant acrylate pressure sensitive adhesive which comprises the following components in parts by weight: 150-250 parts of 2-ethylhexyl acrylate, 50-100 parts of butyl acrylate, 3-10 parts of acrylic acid, 3-10 parts of hydroxyethyl acrylate, 10-20 parts of vinyl acetate, 15-35 parts of bornyl isoacrylate, 0.5-3 parts of azobisisobutyronitrile, 0.3-2 parts of N-hydroxymethyl acrylamide and 400-600 parts of ethyl acetate. The mechanical property, high temperature resistance and weather resistance of the emulsion type acrylate pressure sensitive adhesive are improved, so that the application range of the emulsion type acrylate pressure sensitive adhesive is widened, and the pressure sensitive adhesive has the characteristics of high viscidity, high temperature resistance, damp-heat aging resistance and low cost.

Owner:新丰杰力电工材料有限公司

Halogen-free flame-retardant polyethylene foaming plastic and preparation method

InactiveCN102020801AImprove flame retardant performancePrevent volatilizationEnvironmental resistanceHigh pressure

The invention discloses halogen-free flame-retardant polyethylene foaming plastic and a preparation method. The halogen-free flame-retardant polyethylene foaming plastic comprises the following components in parts by weight: 15-40 parts of dicumyl peroxide and high pressure polyethylene fusion in the mass ratio of 1:15-25, 20-60 parts of fusion of ADC (Azobisformami-de) foaming agent and high pressure polyethylene in the mass ratio of 1:1.5-3.5, 3-20 parts of fusion of BDPI type P-N halogen-free flame retardant and high pressure polyethylene fusion in the mass ratio of 1:3-5, 5-25 parts of fusion of nano organic montmorillonite, KH-570 type organosilicon coupling agent and high pressure polyethylene fusion in the mass ratio of 1:0.05-0.15:3-5; 0.5-5 parts of ethylene vinylacetate copolymer and 0.5-5 parts of polyethylene color master batch. The halogen-free flame-retardant polyethylene foaming plastic is halogen-free and flame-retardant, meets the firefighting and environmentally-friendly requirements and has the characteristics of high oxygen index, favorable strength, strong strength, strong absorbing impact loading capability and the like.

Owner:安吉鼎烽塑料有限公司

Powder metallurgy wear-resistant corrosion-resistant bearing material and preparation method thereof

The invention discloses a powder metallurgy wear-resistant corrosion-resistant bearing material. The invention is characterized in that the material is prepared from the following raw materials in parts by weight: 0.4-0.6 part of vanadium carbide, 0.2-0.3 part of chromium carbide, 0.5-0.8 part of graphite, 2.0-3.2 parts of molybdenum powder, 9.4-9.6 parts of nickel powder, 0.15-0.25 part of silicon carbide, 0.2-0.3 part of tantalum carbide, 2-3 parts of polyethylene wax powder, 93-94 parts of iron powder and 1-2 parts of assistant. The corrosion-resistant high-temperature-resistant bearing material prepared from the titanium carbide, vanadium carbide, chromium carbide, nickel, molybdenum and graphite has the characteristics of high hardness, low deformation tendency, high wear resistance, high temperature resistance, corrosion resistance and the like, has favorable structural rigidity, hardness, fatigue resistance and tensile strength, and is suitable for a high-temperature wearing environment.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

Low shrinking unsaturated polyester resin glass fibre reinforced mould plastic and its use

The present invention relates to one kind of low shrinking glass fiber reinforced unsaturated polyester resin material (DMC, BMC and SMC) and its application in making fire-fighting equipment. The low shrinking glass fiber reinforced unsaturated polyester resin material consists of unsaturated polyester resin 28-32 weigh portions, low shrinking agent 11-15 weigh portions, 6-12 mm glass fiber 13-21 weigh portions, 3-5 mm ceramic fiber 7-11 weigh portions, filler 60-70 weigh portions, initiator 0.3-0.6 weigh portions, thickener 0.5-1 weigh portion, and flame retardant 11-15 weigh portions. The low shrinking glass fiber reinforced unsaturated polyester resin material is used in making fire-fighting water gun joint with high mechanical strength, high size precision, high impact resistance and other features.

Owner:李刚

Waterproof plastering gypsum and preparation method thereof

InactiveCN107226672ASmaller specific heatGuaranteed performancePolyethylene terephtalateAntibacterial agent

The invention discloses a waterproof plastering gypsum, and belongs to the technical field of plastering gypsums. The plastering gypsum comprises the following raw materials in parts by weight: 60-70 parts of desulphurization gypsum, 25-30 parts of silica sand, 14-18 parts of calcium carbonate, 13-15 parts of cement, 8-10 parts of polytrimethylene terephthalate fiber, 10-12 parts of ceramic fiber, 7-9 parts of modified magnesium hydroxide, 6-8 parts of kieselguhr, 5-7 parts of starch, 1-3 parts of hydroxy propyl methyl cellulose, 3-5 parts of an organosilicone water repellent, 1-2 parts of a retarder, 2-4 parts of an antibacterial agent, 14-16 parts of an acrylic emulsion and 5-15 parts of water. The invention further discloses a preparation method of the waterproof plastering gypsum, the preparation is simple, and the waterproof plastering gypsum has excellent waterproof, fireproof and high temperature resistant capabilities after being solidified.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

Antistatic polyether-ether-ketone composite material and preparation method thereof

ActiveCN102660103AWide range of applicationsHigh tensile strengthPoly ether ether ketoneHigh polymer

The invention relates to an antistatic polyether-ether-ketone composite material and a preparation method thereof, and belongs to the fields of high polymer materials and the preparation thereof. The composite material of the invention is prepared by selecting polyether-ether-ketone, PAN carbon fiber, acetylene carbon black, and a coupling agent as raw materials, and the composite material is molded by adopting the method of compression molding. According to the invention, the preparation method is simple, the parameters are easy to control, the consistency is good, the stability is high, and no special device is needed. The composite material can be applied to vacuum suction cups and wafer trays used in semiconductor manufacturing industry, electronic components used in hostile environments such as high temperature and high pressure in oil field industry, and sealing-connecting electronic components used in electronic and electrical industries, and the like.

Owner:大连路阳科技开发有限公司

A through-beam type high temperature resistant smoke sensor and real-time detection method

InactiveCN102288555AHigh precisionHigh sensitivityColor/spectral properties measurementsPhotodetectorLaser probe

A through-beam high temperature resistant smoke sensor and a real-time detection method. The light radiated by the laser light source is in the visible light band. The core diameter of the pure silica fiber is 800 μm and has stainless steel armor. Each laser probe consists of a set of laser beam expander collimating mirror, a 5-dimensional adjustment frame, and a piece of pure quartz lens. , a pure silica fiber with a core diameter of 800μm, a gas input port, and three gas nozzles. The through-beam high temperature resistant smoke sensor of the present invention adopts the method of separating the laser probe from the laser light source and the photodetector. The method that the adopted devices such as lasers and photodetectors, which are easily affected by environmental conditions, are kept away from high temperature and high smoke concentration environments, and the self-cooling and self-cleaning capabilities of the laser probes enable the smoke sensor of the present invention to be used in various harsh smoke environments. It has the advantages of high temperature resistance, no cleaning, strong anti-interference, strong real-time performance, high precision, high sensitivity and low cost.

Owner:SHANXI WEILI TECH

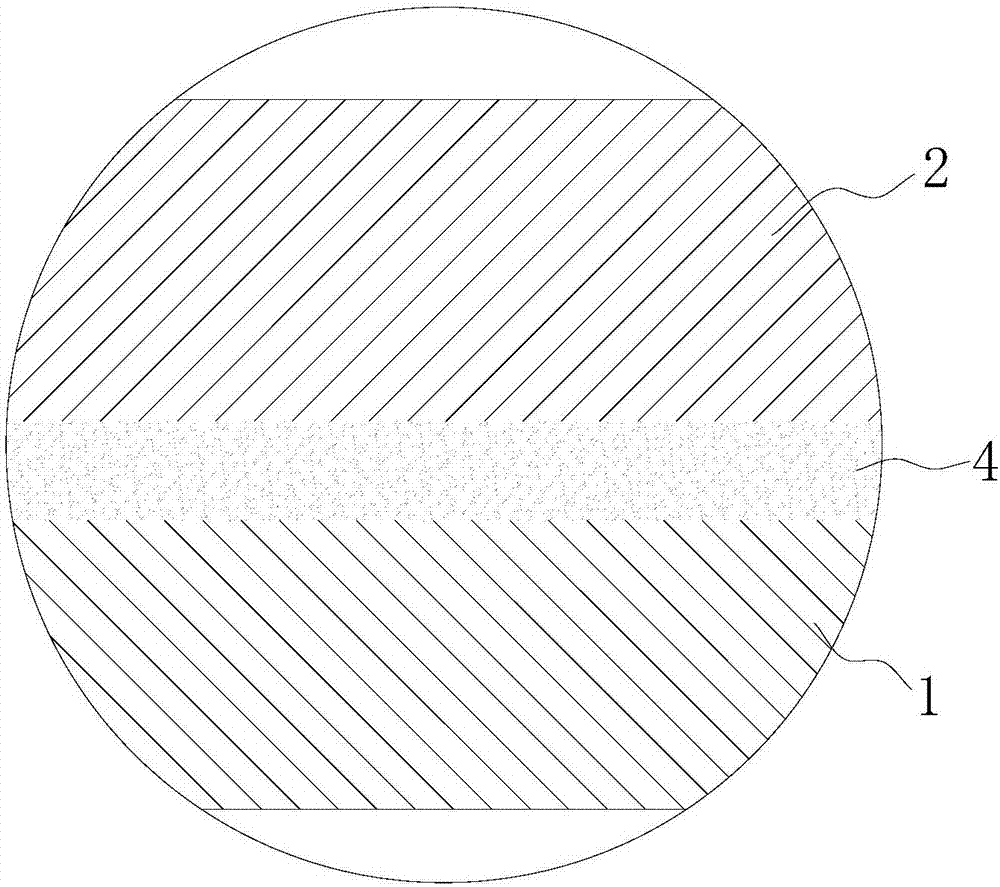

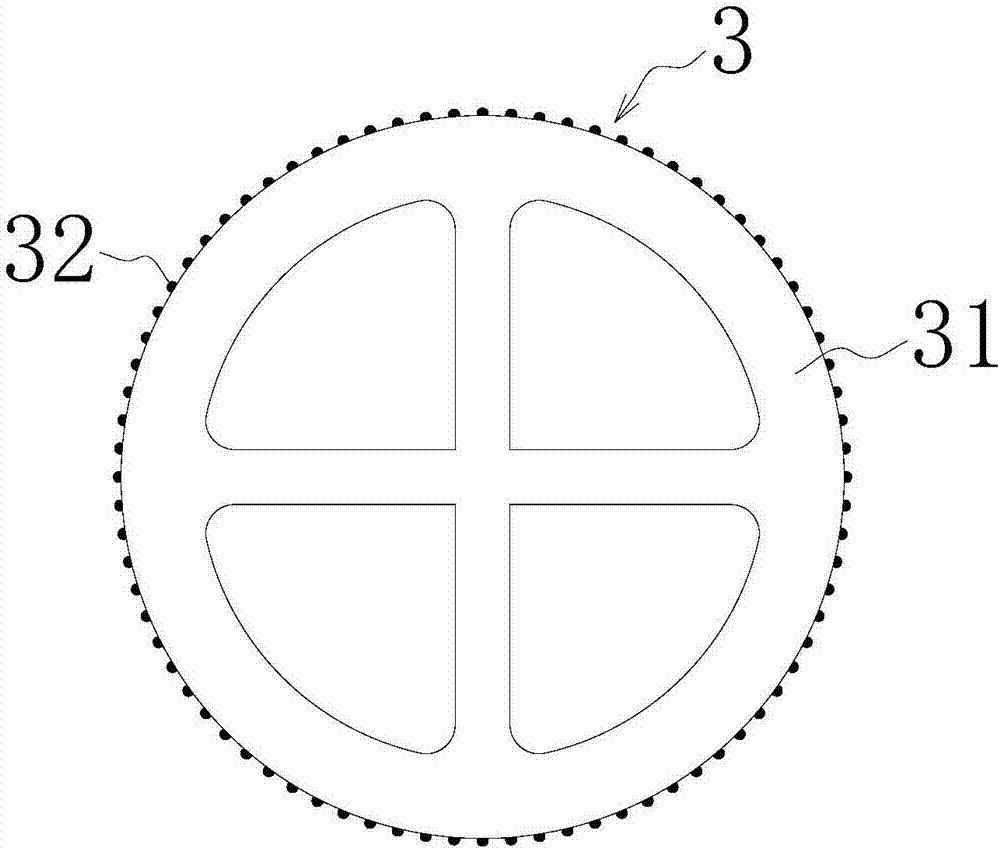

Molecular resonance plate

ActiveCN101898904AIncrease metabolic energyReduce the burden onWater/sewage treatmentResonanceHuman health

The invention discloses a molecular resonance plate which can achieve resonance with the surrounding environment. The molecular resonance plate comprises tile type ceramic materials at a middle layer and negative charged ion generating materials coated around the tile type ceramic materials. The molecular resonance plate provided by the invention can activate the purified water, can release a large amount of negative ions, has the advantages of high temperature resistance, no toxicity, no harm and no radioactivity, and is beneficial to the human health.

Owner:NEW SUN BIO SCI

Magnesium oxychloride cement foam light wallboard and preparation method as well as equipment

InactiveCN102322111AInsulation hasShock absorber hasBuilding componentsCeramicwareGlass fiberThermal insulation

The invention discloses a magnesium oxychloride cement foam light wallboard and a preparation method as well as equipment. The two surfaces of the wallboard are made of a mixture of glass fiber cloth and magnesium oxychloride cement; the middle part of the wallboard is made of a magnesium oxychloride cement foam material; and the magnesium oxychloride cement foam material is mainly prepared from MgO, MgCl2 and H2O. The magnesium oxychloride cement foam light wallboard has the advantages of water prevention, thermal insulation, heat preservation, shock absorption, high temperature resistance, light weight, high strength and convenience in mounting and construction. Through the magnesium oxychloride cement foam light wallboard, the problem of over high load of a high-rise building can be solved; and the volume weight of the wallboard can be controlled to be below 500kg / cu.m, so that the load is greatly reduced. Through the wallboard, the problem that the building is warm in winter and cool in summer can be solved; and the wallboard has thermal insulation, heat preservation and excellent water-proof performance. The wallboard has two extremely smooth surfaces and can be directly usedas a decorative material.

Owner:王翔

Yield 345 MPa grade fire-resistant steel plate and production method thereof

ActiveCN106282800AImprove high temperature tempering stabilityImprove high temperature strengthAlloy elementBainite

The present invention discloses a yield 345 MPa grade fire-resistant steel plate and a production method thereof. The production method comprises the steps of heating, rolling, and tempering. In the step of rolling, a recrystallization zone plus non-recrystallization zone two-stage conditioned rolling process is adopted. The steel plate is composed of the following chemical components in percentage by weight: 0.10-0.12% of C, 0.20-0.40% of Si, 1.43-1.53% of Mn, less than or equal to 0.008% of P, less than or equal to 0.003% of S, 0.15-0.25% of Mo, 0.020-0.030% of Nb, 0.020-0.50% of Al, 0.020-0.030% of V, and the balance of Fe and inevitable impurities. Low C is determined in the chemical component design of the steel plate in the method to ensure favorable weldability of the steel plate; the microalloying design of Nb and V, accompanied with such alloy elements as Mo, is adopted to ensure matching of strength and toughness and high temperature resistance of the steel plate; and a TMCP plus tempering process is adopted to obtain a composite structure of bainite and ferrite. The method provided by the present invention is used to produce the steel plate through the thermo mechanical control processing plus tempering process; the obtained yield 345 MPa grade TMCP plus tempering type fire-resistant steel plate has the characteristics of low carbon equivalent and crack sensitivity index, low yield ratio, favorable low temperature impact strength, good weldability, and the like.

Owner:WUYANG IRON & STEEL

Method and device for preparing gradient metal ceramic composite coating on surface of bias current plate

ActiveCN105755422AAdhesive hasThermal conductivity hasMolten spray coatingEfficient propulsion technologiesSurface layerHigh-temperature corrosion

The invention discloses a method for preparing a gradient metal ceramic composite coating on the surface of a bias current plate.The method comprises the steps that bottom layer raw material powder is introduced into a supersonic plasma spraying system, and under the effect of spraying current, the bottom layer raw material powder is sprayed to a matrix through primary airflow; middle layer raw material powder is introduced into the supersonic plasma spraying system, and under the effect of the spraying current, the middle layer raw material powder is sprayed to the matrix through the primary airflow; surface layer raw material powder is introduced into the supersonic plasma spraying system, and under the effect of the spraying current, the surface raw material powder is sprayed to the matrix through the primary airflow.The invention further discloses a device for preparing the gradient metal ceramic composite coating on the surface of the bias current plate.The method and device have the properties such as high temperature corrosion resistance, thermal shock resistance, high temperature erosion resistance, normal temperature salt-spray corrosion resistance and abrasion resistance, and have the advantages that the bonding strength of a bottom layer in the coating is high, and the heat conductivity is good.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

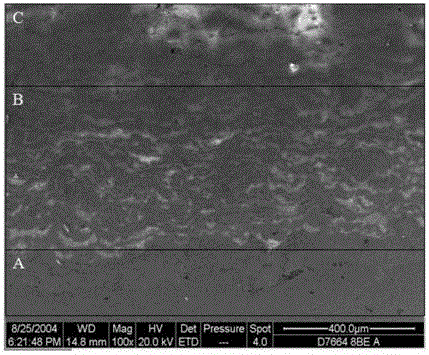

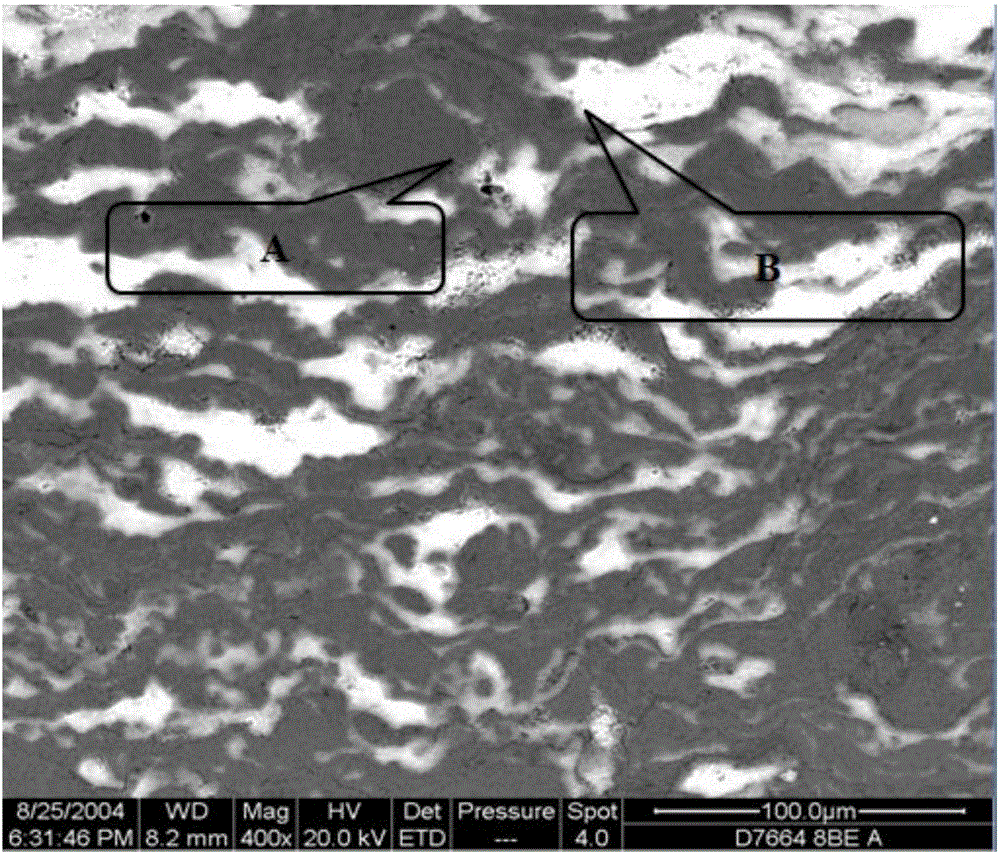

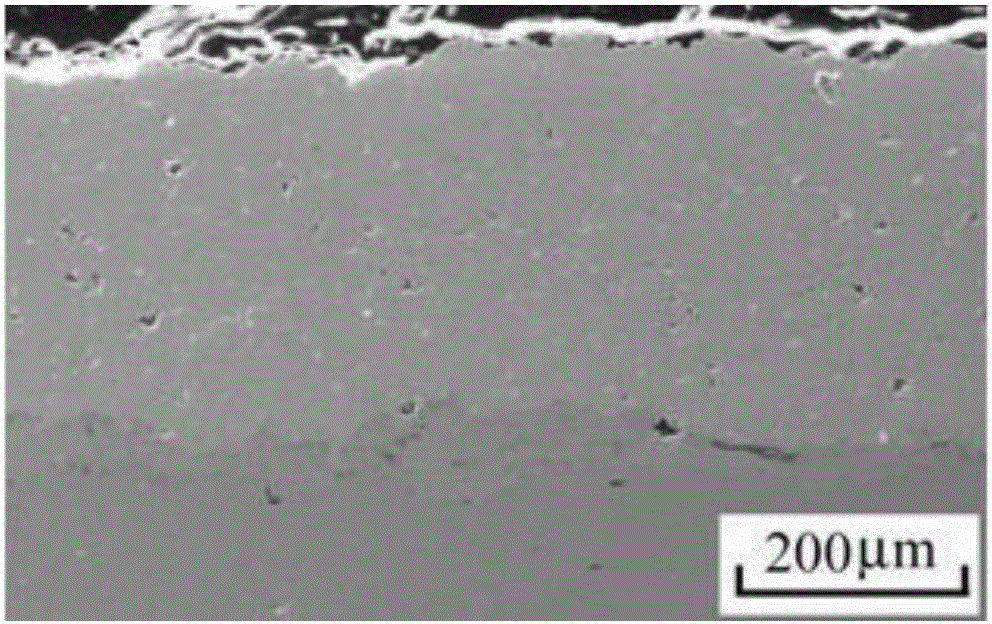

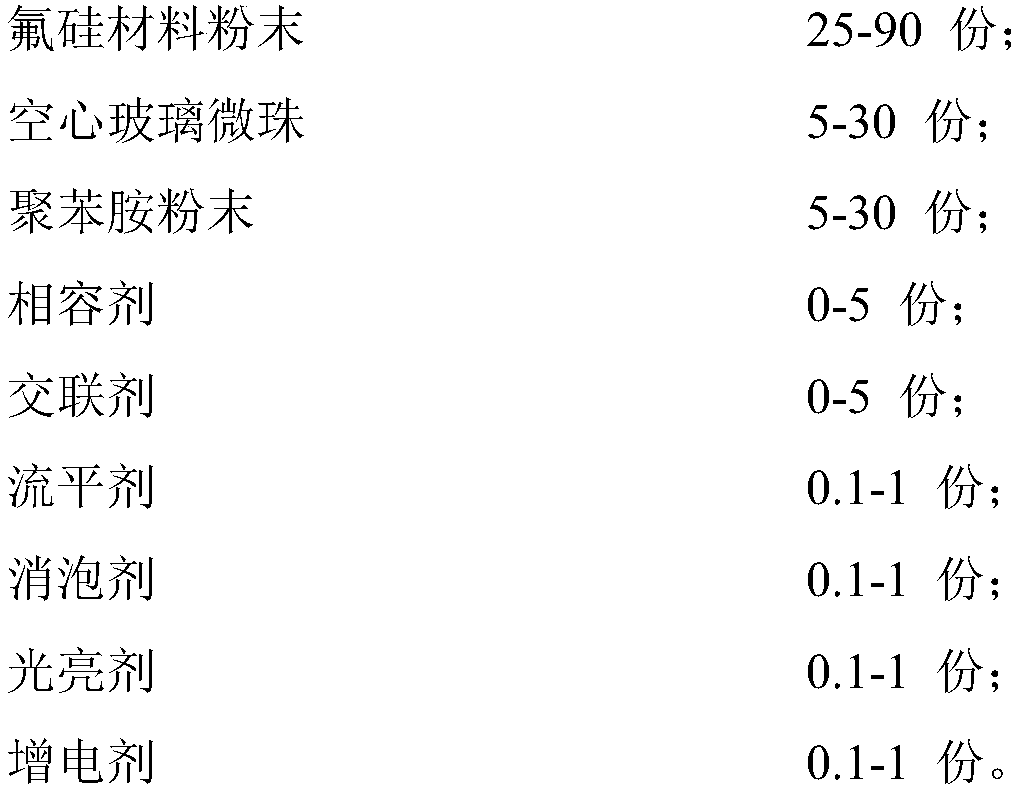

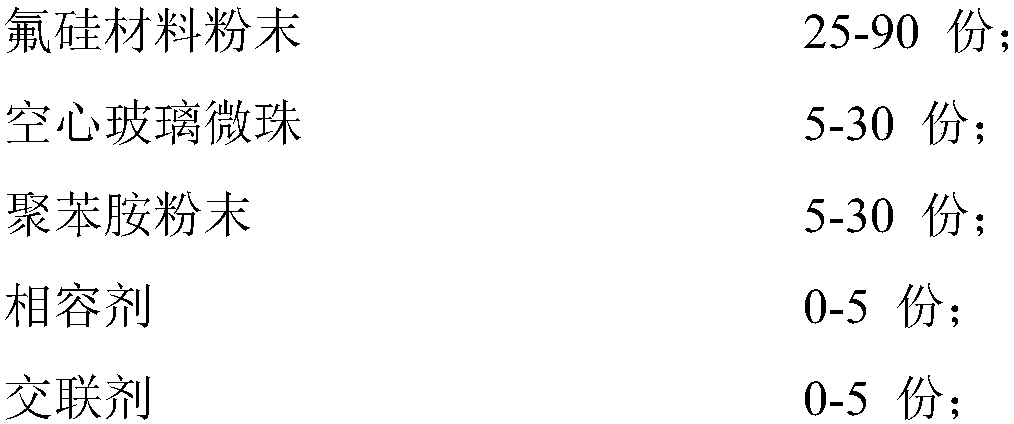

Anti-corrosion, anti-wear and high-temperature-resistant electromagnetic shield powdery coating and preparation method of same

InactiveCN108034338AHigh strengthHigh temperature resistance hasFireproof paintsAnti-corrosive paintsCorrosion resistantDefoaming Agents

The invention relates to an anti-corrosion, anti-wear and high-temperature-resistant electromagnetic shield powdery coating and a preparation method of same, wherein the powdery coating is prepared from: 25-90 parts of a fluorosilicon material powder, 5-30 parts of hollow glass microbeads, 5-30 parts of polyaniline powder, 0-5 parts of a compatibilizer, 0-5 parts of a crosslinker, 0.1-1 part of aflatting agent, 0.1-1 part of a defoaming agent, 0.1-1 part of a brightening agent, and 0.1-1 part of a charging additive. The preparation method includes the steps of: according to the ratio, weighing the raw materials and uniformly mechanically mixing the raw materials, feeding the mixed raw materials into a twin-screw extruder to extrude the raw materials at 80-200 DEG C; and tabletting, pulverizing and sieving the product to obtain the anti-corrosion, anti-wear and high-temperature-resistant electromagnetic shield powdery coating. The material is good in anti-corrosion and anti-wear performances, is high-temperature-resistant, is high in strength and low in density, is low in dielectric constant and dielectric damage, can be extensively applied to the industrial fields such as weaponry, information technology and others requiring the anti-corrosion, anti-wear and high-temperature-resistant properties and electromagnetic shield.

Owner:成英

Special high temperature-resistant coating on outer wall of tobacco-curing furnace and preparation method thereof

InactiveCN102153947AMeet the needs of useHigh temperature resistance hasCoatingsMicrosphereTemperature resistance

The invention discloses a special high temperature-resistant coating on an outer wall of a tobacco-curing furnace, which consists of the following components according to parts by weight: 30-40 parts of organic silicon resin, 5-10 parts of aluminium paste, 8-12 parts of titanium white, 30-40 parts of mixed stuffing, 0.5-1.5 parts of organic bentonite, 2-4 parts of PM, 1-3 parts of PMA (Propylene Glycol Monomethyl Acetate), and 4-6 parts of absolute ethyl alcohol, wherein the mixed stuffing consists of the following components according to parts by weight: 35-45 parts of low-melting point glass powder, 10-20 parts of hollow ceramic microspheres, 10-20 parts of zinc phosphate, 5-15 parts of aluminum tripolyphosphate and 18-22 parts of talcum powder. The special high temperature-resistant coating on the outer wall of the tobacco-curing furnace mainly has the advantages that a viscosity number reaches 85s, the percentage of solid reaches 65%, surface dry only needs 16 minutes, hard dry only needs 6 hours, the thermal endurance is strong, and the coating is not stripped for 6h at 500 DEG C. The coating has the advantages of high temperature resistance, rust prevention, quick drying, heat insulation, environmental protection and the like, can satisfy the use requirements on the outer wall of the tobacco-curing furnace, and is especially applicable for the tobacco-curing furnace.

Owner:无锡市南雅化工有限公司

Anti-heat wear-resisting lubricating reducing wear alloy casting steel material

InactiveCN100999801AHigh strengthHigh temperature resistance hasHeat treatment process controlProcess efficiency improvementRare earthAlloy

The present invention relates to one kind of self-lubricating casting steel material and its preparation process. The self-lubricating casting steel material is prepared through smelting with the raw materials including waste steel, ferrochromium, ferrotungsten, ferrovanadium, selenium alloy, heavy RE, etc and casting. The chemical components include Fe, C, Si, Mn, Cr, W, Se, V, Dr, Si, Ba and P. The added Se forms selenide with other metal elements as solid lubricant, and this makes the self-lubricating casting steel material possess excellent self lubricating performance. The self-lubricating casting steel material may be used in producing different castings with excellent antifriction performance, high strength, high toughness and other features.

Owner:侯贵敏

High-strength mica powder modified polypropylene plastic

The invention discloses a high-strength mica powder modified polypropylene plastic which is prepared from, by weight, 50-70 parts of polypropylene resin, 20-50 parts of mica powder, 5-10 parts of titanium dioxide, 5-15 parts of brominated epoxy resin, 4-12 parts of silicone oil, 2-8 parts of polyvinyl alcohol, 5-15 parts of tertiary butylhydroquinone, 10-18 parts of dicapryl phthalate, 4-12 parts of heat stabilizer, 10-15 parts of antifreezing agent, 3-9 parts of light stabilizer and 6-10 parts of ferric oxide. According to the high-strength mica powder modified polypropylene plastic, the original characteristics of being resistant to high temperature, nontoxic and odorless of polypropylene plastic are reserved, the added mica powder has insulation, high temperature resistance, acid-base resistance and corrosion resistance, the low-temperature resistance of the plastic is enhanced through the antifreezing agent, the raw materials are easy to obtain, the cost is low, operation is simple, and wide application can be achieved.

Owner:安徽格锐新材料科技有限公司

High-temperature-resisting heating composite fabric and preparation method thereof

ActiveCN107263947AReasonable structureHigh temperature resistance hasLamination ancillary operationsSynthetic resin layered productsFiberCarbon fibers

The invention discloses a high-temperature-resisting heating composite fabric. The high-temperature-resisting heating composite fabric comprises a moisture-absorption heating layer and a high-temperature-resisting protection layer, wherein the moisture-absorption heating layer and the high-temperature-resisting protection layer are compounded to form an integrated structure through a double-point coating; the moisture-absorption heating layer is made of moisture-absorption heating fibers; the moisture-absorption heating fibers are composite fibers formed by loading heating nanoparticles on surfaces of hollow moisture-absorption fibers; a nano heating layer is further loading on one face, which is compounded with the high-temperature-resisting protection layer, of the moisture-absorption heating layer; the high-temperature-resisting protection layer is formed by blending carbon fibers and Kevlar fibers. The invention further provides a preparation method of the high-temperature-resisting heating composite fabric; the high-temperature-resisting heating composite fabric is prepared through preparing the nanoparticles, preparing nano gel, preparing the moisture-absorption heating fibers, preparing a fabric layer, loading the nano heating layer, preparing the composite fabric and metering and packaging; the high-temperature-resisting heating composite fabric has excellent far infrared heat accumulation and temperature raising performance and high-temperature-resisting performance and has relatively good heat absorption and heating effect and protection effect.

Owner:平湖市新保纺织科技有限公司

High temperature and high pressure resistant alkali-free aluminosilicate glass for high pressure liquidometer

InactiveCN106800370AImprove uniformityReduce cooling areaGlass furnace apparatusGlass drawing apparatusTemperature resistancePetrochemical

The invention discloses high temperature and high pressure resistant alkali-free aluminosilicate glass for a high pressure liquidometer, and is characterized in that the high temperature and high pressure resistant alkali-free aluminosilicate glass for the high pressure liquidometer comprises the oxide components by the mass percentage: (55-65)% of SiO2, (14-25)% of Al2O3, (3-8)% of B2O3, (5-12)% of CaO, (4-10)% of MgO, (3-8)% of BaO, (0.2-0.5)% of As2O3, (0.2-0.5)% of Sb2O3, (0.1-0.3)% of NaNO3, and (0.2-0.5)% of ZrO2. The glass contains no alkali metal oxides in the composition, has the advantages of high temperature resistance, high pressure resistance, high tenacity, high Young modulus, good chemical stability, suitable expansion coefficient of physical tempering, high transparency and the like, and is applied in requirements of high temperature and high pressure resistant glass view windows for harsh work condition environments of high temperature and high pressure steam liquidometer observation windows, high pressure pipeline view mirrors, deep-sea exploration equipment observation windows and the like in steel metallurgy, petrochemical engineering, thermal power plants and other industries.

Owner:南京神童特种玻璃技术有限公司

Inorganic coated sand and preparation process thereof

ActiveCN108296412AHigh hardnessImprove wear resistanceFoundry mouldsFoundry coresFiberPowder mixture

The invention discloses inorganic coated sand. The inorganic coated sand comprises raw materials of, by weight, 70-100 parts of raw sand, 20-40 parts of resin binders, 20-30 parts of dolomite powder,5-10 parts of sulfonation lignin fibers, 10-20 parts of thermoplastic phenolic resins, and 7-42 parts of high temperature resistance additives. The invention further discloses a preparation process for the inorganic coated sand. The preparation process comprises the steps that the high temperature resistance additives is mixed and then poured into a grinding machine, and the high temperature resistance additives are grinded into a powder mixture; the dolomite powder, the sulfonation lignin fibers, and the thermoplastic phenolic resins are added into the powder mixture A to be mixed, and then poured into a stirring tank to be stirred at a high speed; the resin binders are added into a mixture B, mixed and fully stirred; the raw sand is added into a mixture C, and the mixture C after being mixed is poured into a mixing mill to be mixed; and the inorganic coated sand is obtained after a mixture D is sieved. The preparation process is simple in operation and low in cost, and it is guaranteed that compositions of the raw materials can be fully mixed. The inorganic coated sand has high temperature resistance and high strength, and the stability of the inorganic coated sand is effectivelyimproved.

Owner:柳州柳晶环保科技有限公司

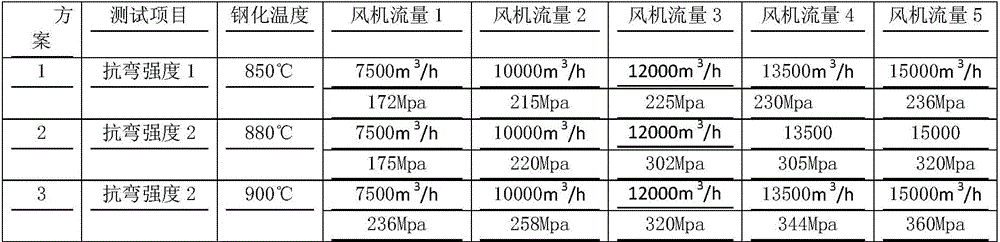

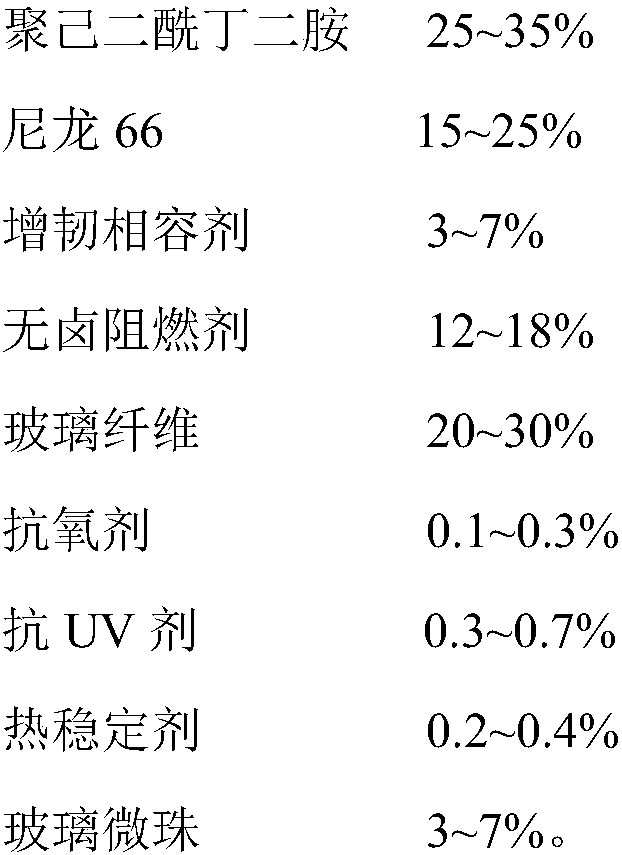

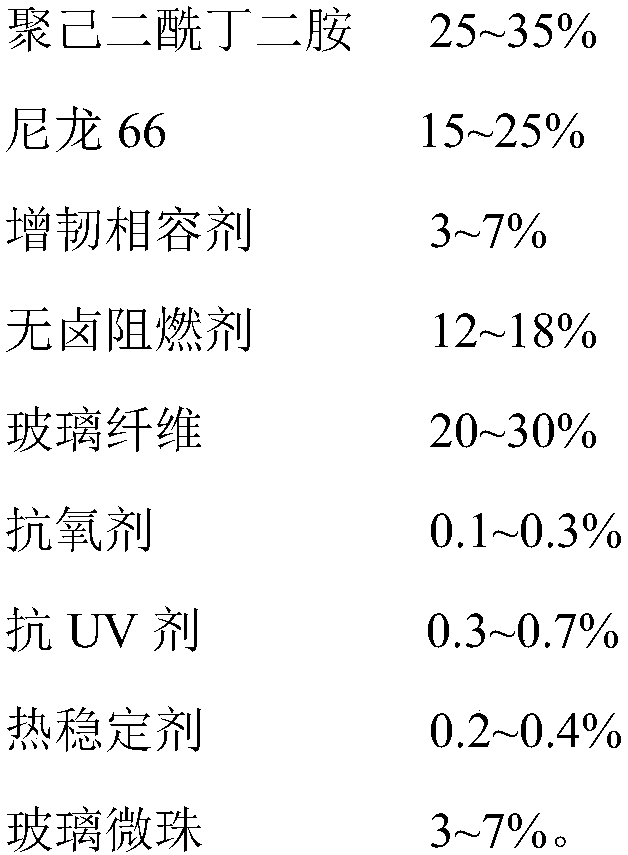

Halogen-free flame-retardant highly-temperature-resistant polytetramethylene adipamide composite material and preparation method thereof

The invention discloses a halogen-free flame-retardant highly-temperature-resistant polytetramethylene adipamide composite material and a preparation method thereof. The composite material is preparedfrom the following components in percentage by weight: 25-35% of polytetramethylene adipamide, 15-25% of nylon 66, 3-7% of a toughening compatibilizer, 12-18% of a halogen-free flame retardant, 20-30% of glass fibers, 0.1-0.3% of an antioxidant, 0.3-0.7% of a UV resistant agent, 0.2-0.4% of a heat stabilizer and 3-7% of glass beads. The preparation method comprises the following steps: weighing the various raw materials in percentage by weight, and mixing the various weighed raw materials; and adding the mixed materials into a twin-screw extruder, and performing extruded granulation. The polytetramethylene adipamide is modified, so that the prepared polytetramethylene adipamide composite material has the characteristic of high temperature resistance.

Owner:江门市荣龙新材料科技有限公司

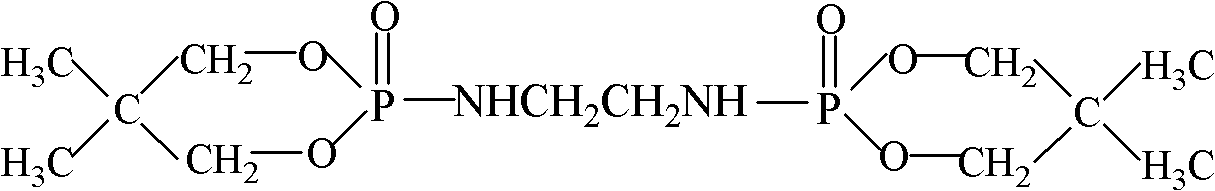

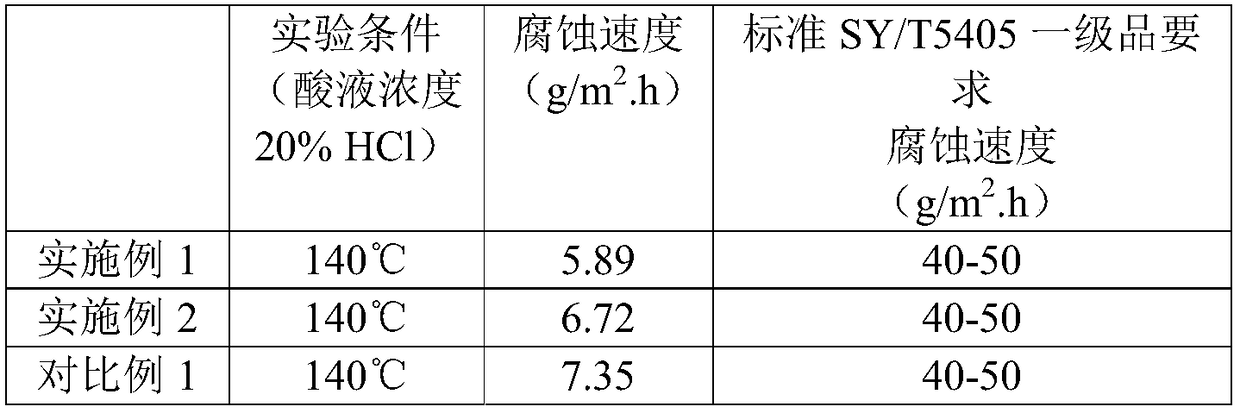

Environment-friendly high-temperature acidizing resistant corrosion inhibitor and preparation method thereof

The invention provides an environment-friendly high-temperature acidizing resistant corrosion inhibitor and a preparation method thereof. The environment-friendly high-temperature acidizing resistantcorrosion inhibitor comprises the components of, by weight, 10-50 parts of corrosion inhibitor primary agents, 1-10 parts of synergists, 0.5-1.5 parts of surfactants, 40-60 parts of solvents and 5-10parts of mercaptan acid; the corrosion inhibitor primary agent comprises 5-15 parts of polyquinoline quaternary ammonium salt, 5-10 parts of imidazolium quaternary ammonium salt, 10-25 parts of Mannich base; and the synergist comprises 1-5 parts of organic alkynol and 1-10 parts of plant extracts, wherein plant extract comprises one or more of a stephania tetrandra extract, a rhizoma corydalis extract, a sophora flower bud extract and a roxburgh rose extract. The environment-friendly high-temperature acidizing resistant corrosion inhibitor has the excellent performance of environmental protection, high temperature resistance, low damage and the like.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

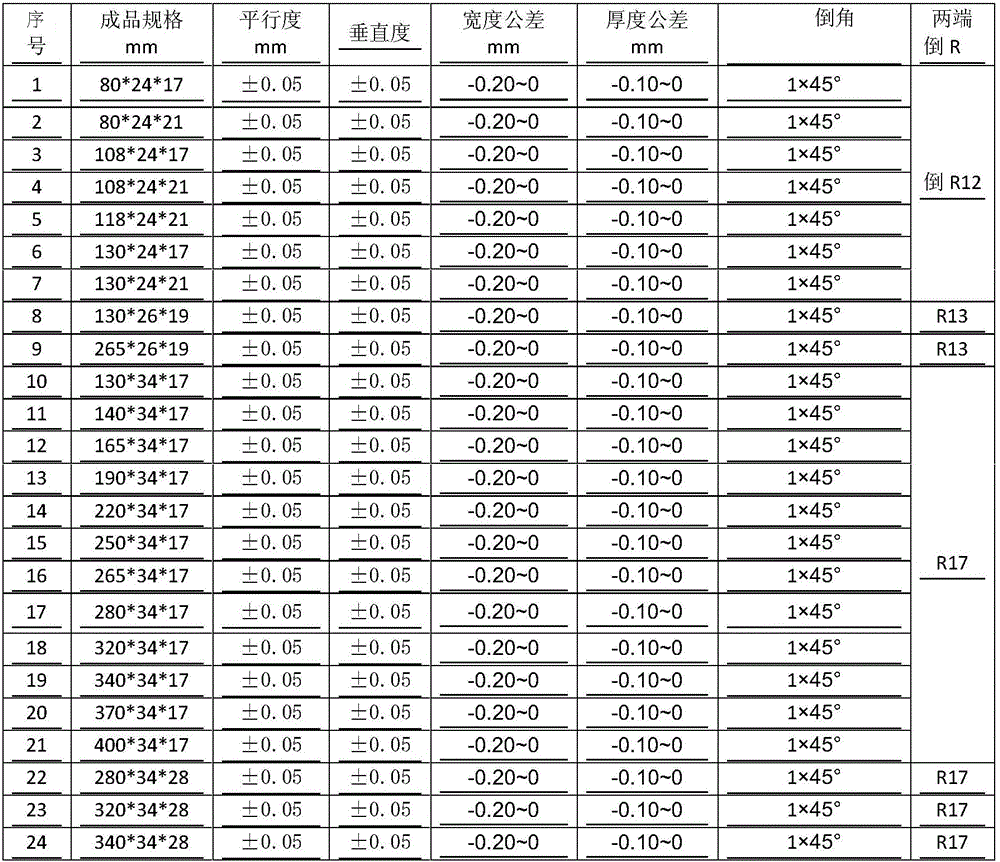

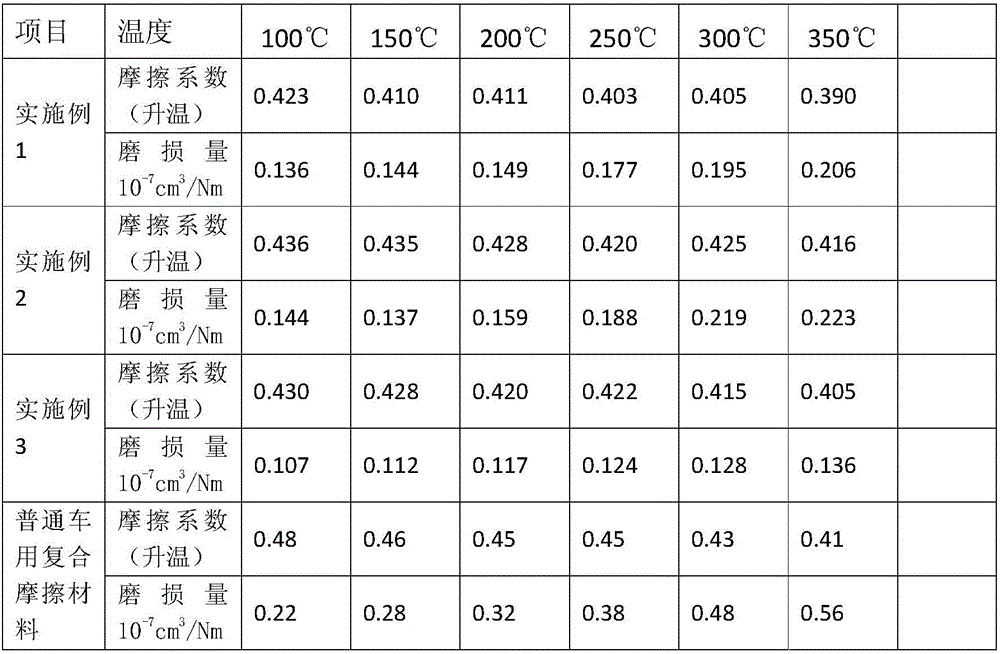

Resin-based powder metallurgy steel fiber friction material used for vehicle and production method thereof

InactiveCN106084645AReduce surface hardnessModerate modulus of elasticityTransportation and packagingMetal-working apparatusNitrile rubberHydrogen

The invention discloses a method for producing a resin-based powder metallurgy steel fiber friction material used for vehicle. The method comprises the following steps: uniformly mixing a matrix powder material and a forming agent, dumping a mixture in a die for compacting the mixture to obtain several elongated rods, compacting the elongated rods, separating the rods, putting the rods in a sintering furnace, heating the material under condition of introduction of nitrogen or hydrogen to obtain a copper-based powder metallurgy friction material; shearing the material, crushing the material, and sieving the material; uniformly mixing 10-20% of nitrile rubber-modified phenolic resin, 20-40% of the copper-based powder metallurgy friction material, 15-30% of steel fiber, 5-15% of an abrasive, 10-20% of a lubrication material, and 5-20% of a filling material; performing hot press molding, cooling the material, and discharging. According to the enhancement effect of the steel fiber, by combining the characteristics of high temperature resistance, low abrasion of the copper-based powder metallurgy friction material as well as good toughness and low hardness of the resin-based composite friction material, the obtained material has the characteristics of high temperature resistance, low abrasion, good flexible performance and low hardness.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com