Anti-corrosion, anti-wear and high-temperature-resistant electromagnetic shield powdery coating and preparation method of same

An electromagnetic shielding and powder coating technology, applied in powder coatings, anti-corrosion coatings, fire-proof coatings, etc., can solve the problems of high density, low strength, corrosion resistance, wear resistance and high temperature resistance, and achieve dielectric constant and The effect of small dielectric damage, high strength and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention also discloses a method for preparing an electromagnetic shielding powder coating resistant to corrosion, wear and high temperature, and the specific steps are as follows:

[0028] Step 1: Weighing the raw materials of each component according to the distribution ratio of the components, and mechanically mixing the raw materials of each component;

[0029] Step 2: Add the uniformly mixed raw materials of each component into a twin-screw extruder, extrude at 80°C-200°C, press into tablets, pulverize, and sieve to obtain an electromagnetic shielding powder coating that is corrosion-resistant, wear-resistant, and high-temperature resistant.

Embodiment 1

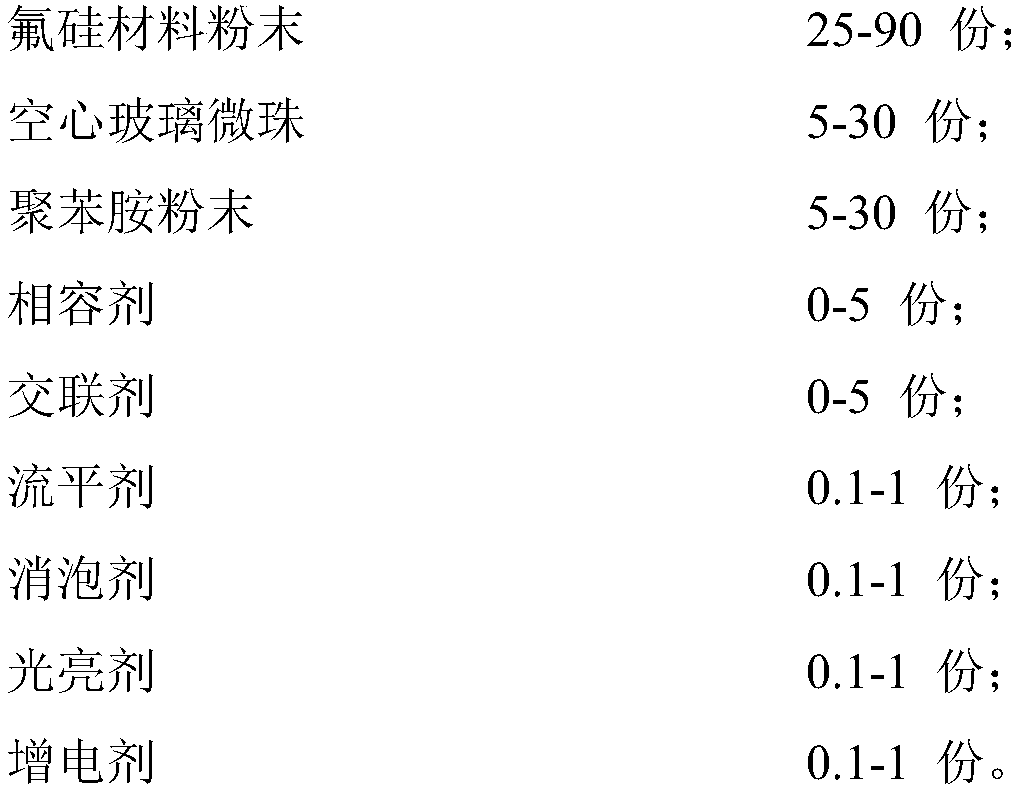

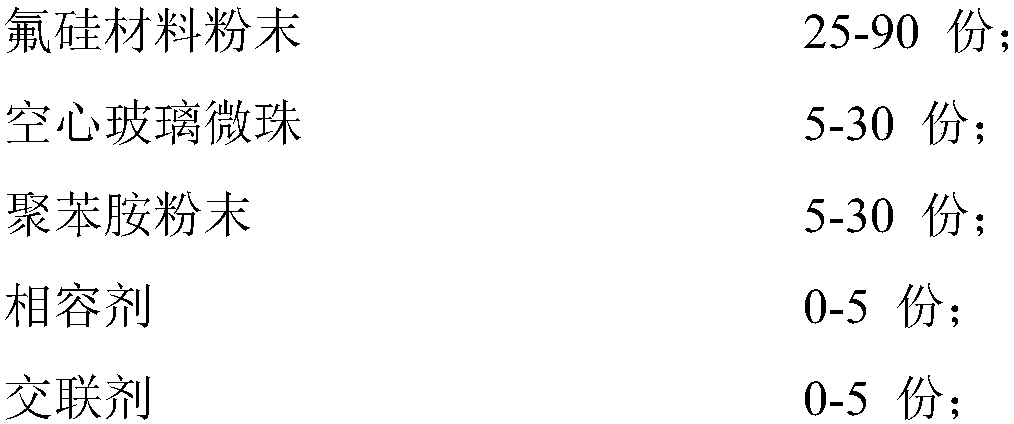

[0032]

[0033] Specific steps are as follows:

[0034] Step S11: weighing each component raw material according to the component distribution ratio, and mechanically mixing each component raw material;

[0035] Step S12: Put the uniformly mixed raw materials of each component into a twin-screw extruder, extrude at 80°C, press into tablets, pulverize, and sieve to obtain a corrosion-resistant, wear-resistant, and high-temperature resistant electromagnetic shielding powder coating.

Embodiment 2

[0037]

[0038] Step S21: weighing each component raw material according to the component distribution ratio, and mechanically mixing each component raw material;

[0039] Step S22: Add the homogeneously mixed raw materials of each component into a twin-screw extruder, extrude at 200°C, press into tablets, pulverize, and sieve to obtain a corrosion-resistant, wear-resistant, and high-temperature resistant electromagnetic shielding powder coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com