Patents

Literature

206results about How to "Reduce surface hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

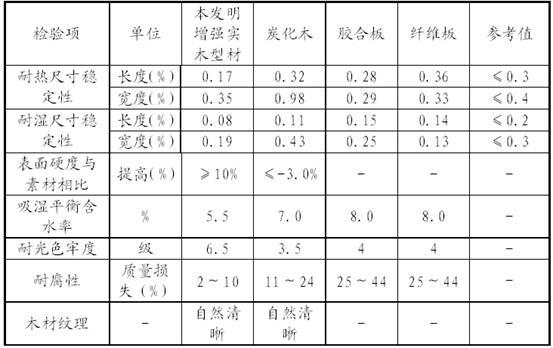

Stable enhanced type solid wood profile and production method thereof

ActiveCN101879736AReduce surface hardnessReduce surface strengthWood impregnation detailsSolid woodWeather resistance

The invention provides a production method of a stable enhanced type solid wood profile improved by a wood carbonization and acetylation process, which belongs woodwork production technique. The production method comprises the following steps of: a, drying treatment, wherein the wood moisture content is reduced to be as low as 5.0 to 8.0 percent, the moisture content deviation in the wood thickness is less than 2.0 percent, and the wood internal residual stress is less than 2.0 percent; b, carbonizing treatment; c, acetylation treatment; and d, equalization treatment. The invention also discloses a stable enhanced type solid wood profile prepared by the production method. The solid wood profile prepared by the method is stable, has high corrosion resistance and weathering resistance, high output, long product service life and wide utilization ways, is favorable for realizing flow line production, and is convenient for industrialization.

Owner:ZHEJIANG SHIYOU TIMBER

Acrylic film and moldings made using the same

InactiveUS6147162ALower glass transition temperatureReduced impact strengthSynthetic resin layered productsPolymer scienceAcrylic resin

PCT No. PCT / JP97 / 00382 Sec. 371 Date Aug. 12, 1998 Sec. 102(e) Date Aug. 12, 1998 PCT Filed Feb. 13, 1997 PCT Pub. No. WO97 / 30117 PCT Pub. Date Aug. 21, 1997An acrylic film or sheet made from a resin composition comprising 95 to 50 wt. % of an acrylic resin which comprises methyl methacrylate as a main component and has a glass transition temperature in the range of 40 to 105 DEG C., and 5 to 50 wt. % of a multilayer-structured acrylic polymer containing an elastomeric layer, wherein the polymer is dispersed in the acrylic resin, a molded article comprising a thermoplastic resin molded material and the above film or sheet which is adhered and unified with the surface of the molded material, and a method for the production of the above molded article are provided. This film or sheet is an excellent film for use in a simultaneous injection molding and lamination method.

Owner:SUMITOMO CHEM CO LTD

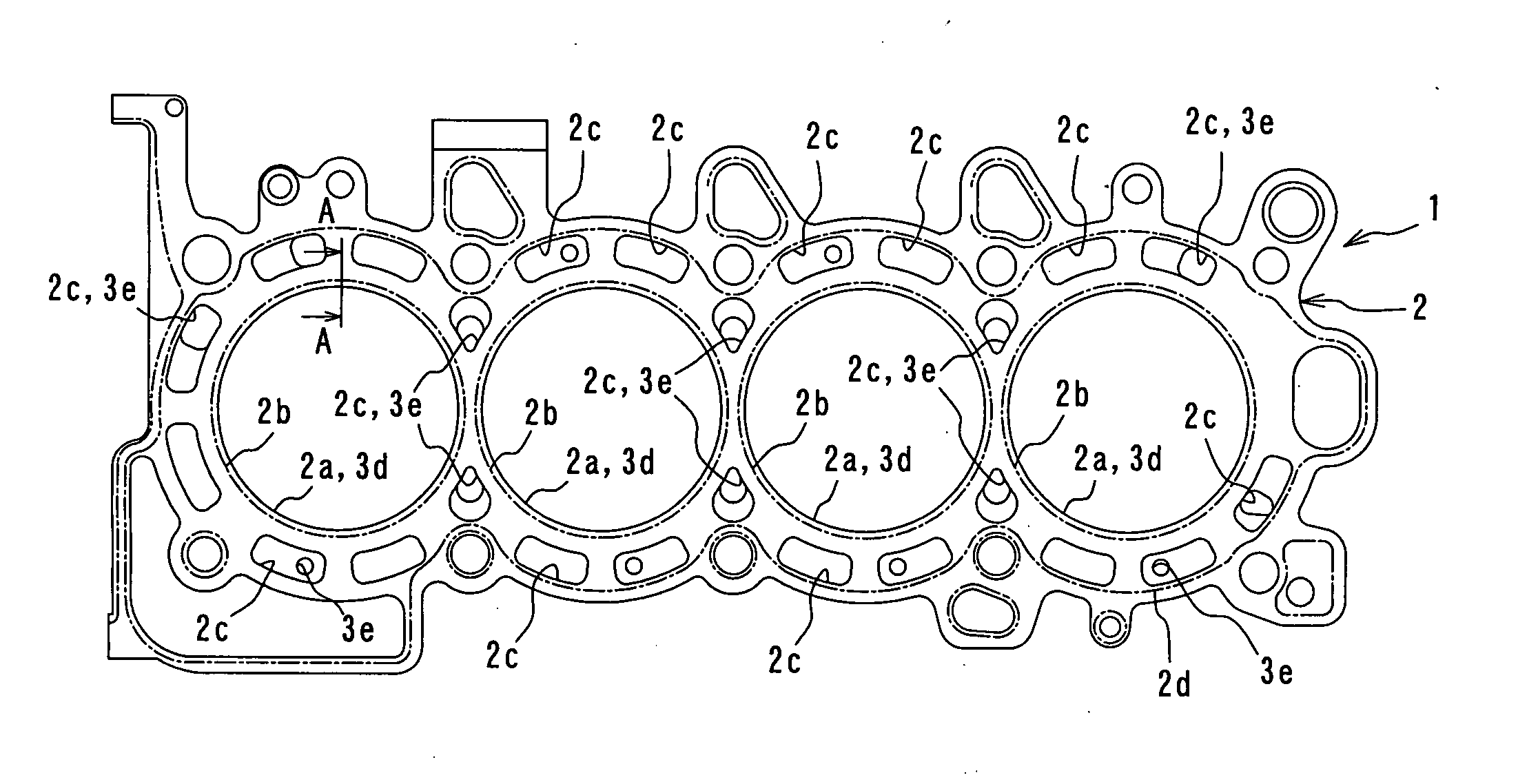

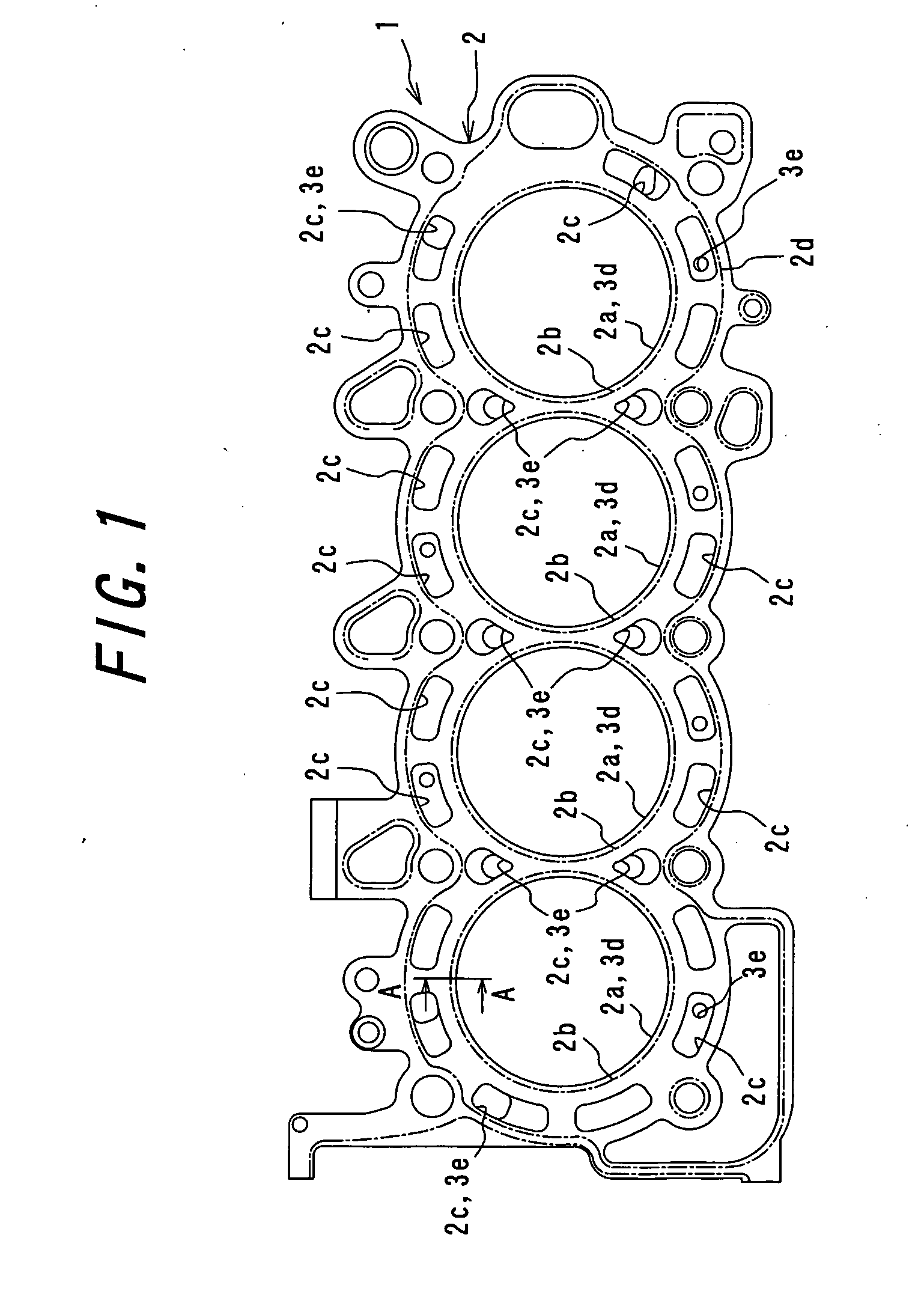

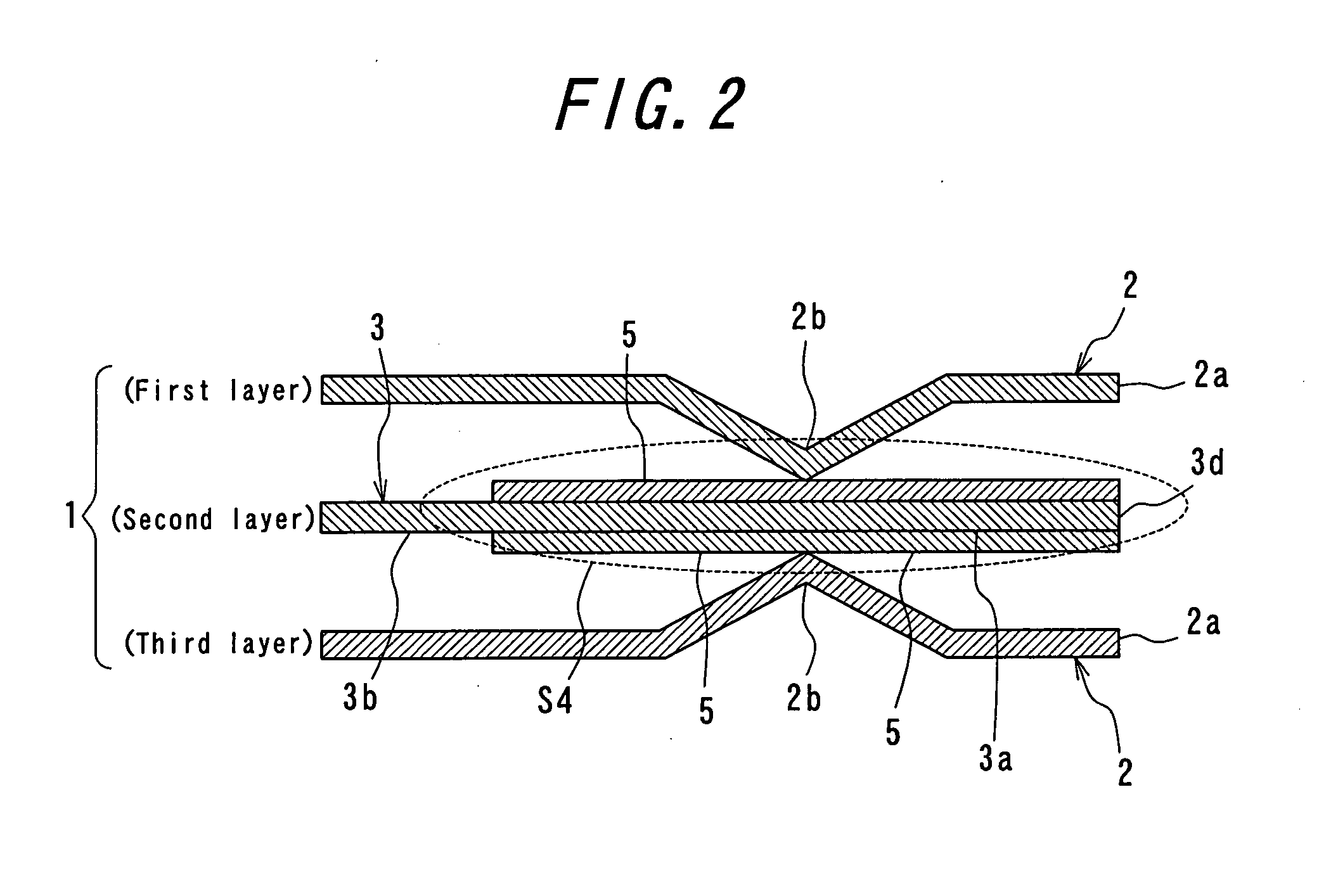

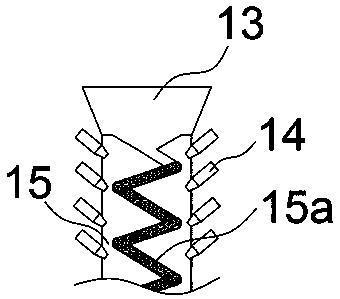

Metal gasket for cylinder head

InactiveUS20060232017A1Easy to adjustLine pressureEngine sealsSealing arrangements for enginesCylinder headHard metal

A metal gasket for a cylinder head has two base plates each constructed from a metal plate and layered over each other, an auxiliary plate constructed from a metal plate and interposed between the base plates, and hard metal-plated layers. The base plates each have cylinder holes, annular beads, coolant holes, and an outer peripheral bead. The cylinder holes correspond with the bore of each cylinder. The annular beads have an angled cross-sectional shape. The coolant holes correspond with a coolant jacket of the cylinder block and with a coolant hole of the cylinder head. The outer peripheral bead has a cross-sectional shape sloping on one side and surrounds the beads and the coolant holes. Each of the layers is extended from a position more radially inward than an annular bead of a base plate to a position radially outward.

Owner:NIPPON LEAKLESS IND CO LTD +1

Antibacterial Sol-Gel Coating Solution, Method for Preparing Antibacterial Sol-Gel Coating Solution, Antibacterial Articles, and Method and Equipments for Preparing Antibacterial Articles

InactiveUS20080305153A1Improve antibacterial propertiesReduce surface hardnessAntibacterial agentsPowder deliveryChemistryOrganic solvent

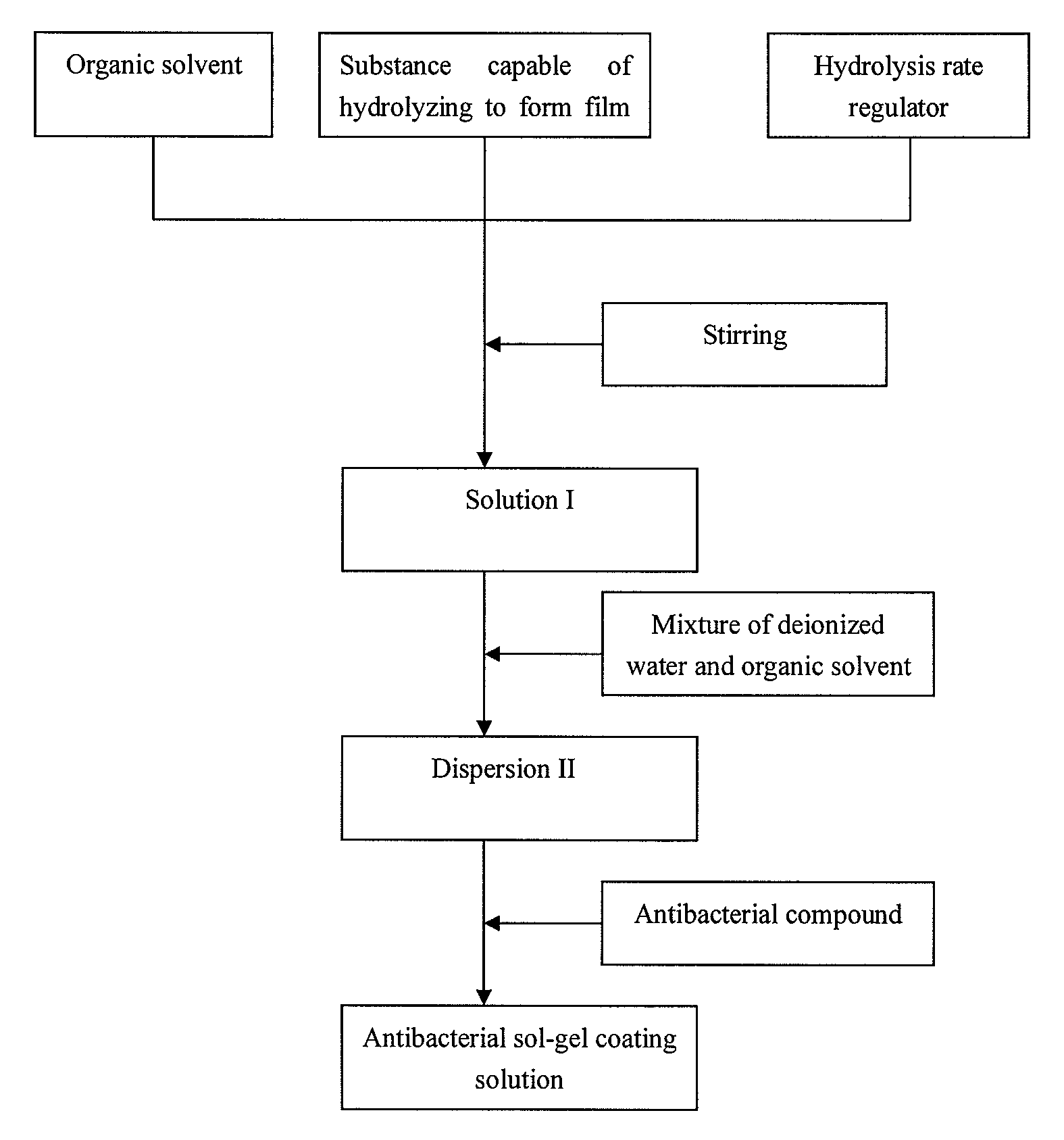

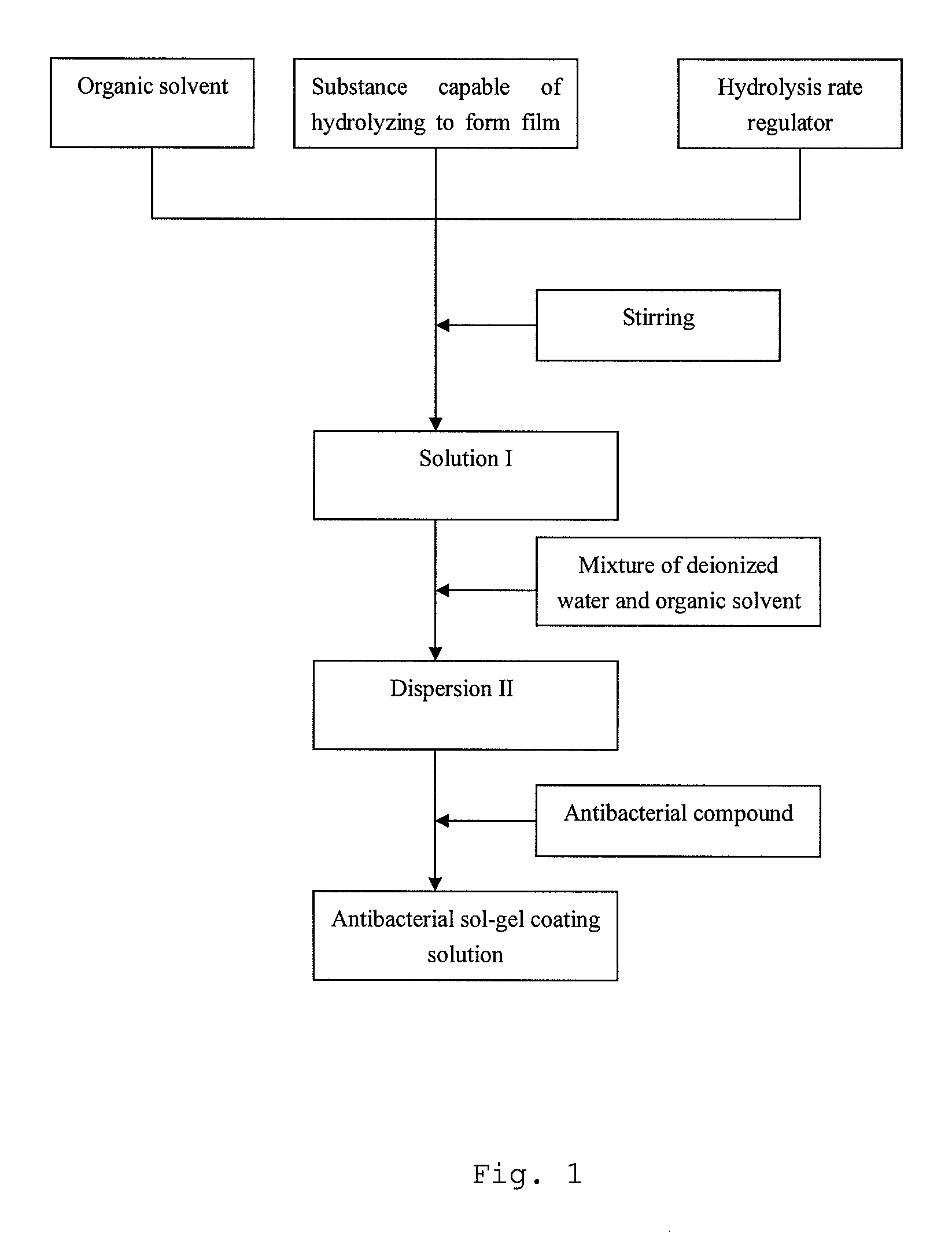

The invention relates to an antibacterial sol-gel coating solution, a process for preparing the antibacterial sol-gel coating solution, an antibacterial article, and a process and an apparatus for producing the antibacterial article. Said antibacterial sol-gel coating solution comprises a. at least one substance selected from the group consisting of Ti or Si-containing compounds capable of hydrolyzing to form a base film; b. a regulating agent capable of regulating the hydrolysis rate of the Ti or Si-containing compounds; c. an organic solvent; d. water; and e. at least one soluble compound of antibacterial metal selected from the group consisting of Ag, Cu, Mg, Zn, Sn, Fe, Co, Ni, and Ce; wherein a, b and a portion of c are first mixed to form a solution I, d and the rest of c are then mixed and added into solution I to form a dispersion II, and then e is added into dispersion II to form the antibacterial sol-gel coating solution.

Owner:QINHUANGDAO YIPENG SPECIAL GLASS

Surface-hardening treatment method of sealing pairs and friction pairs of titanium and titanium alloy ball valves

ActiveCN103334106AImprove reliabilityNo environmental pollutionVacuum evaporation coatingSputtering coatingCase hardeningBall valve

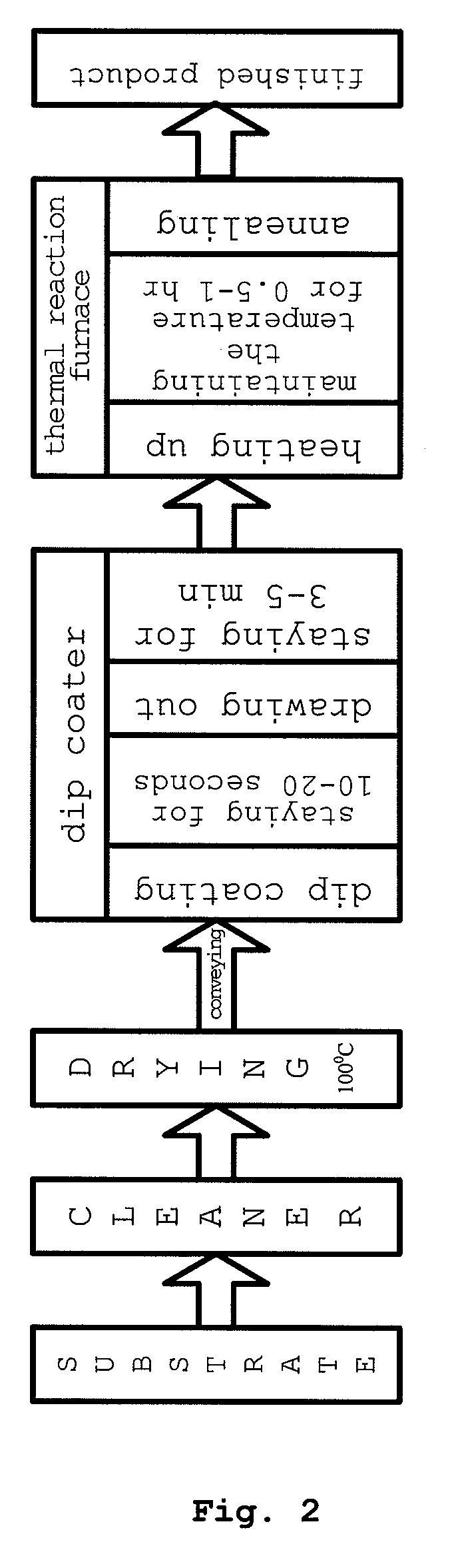

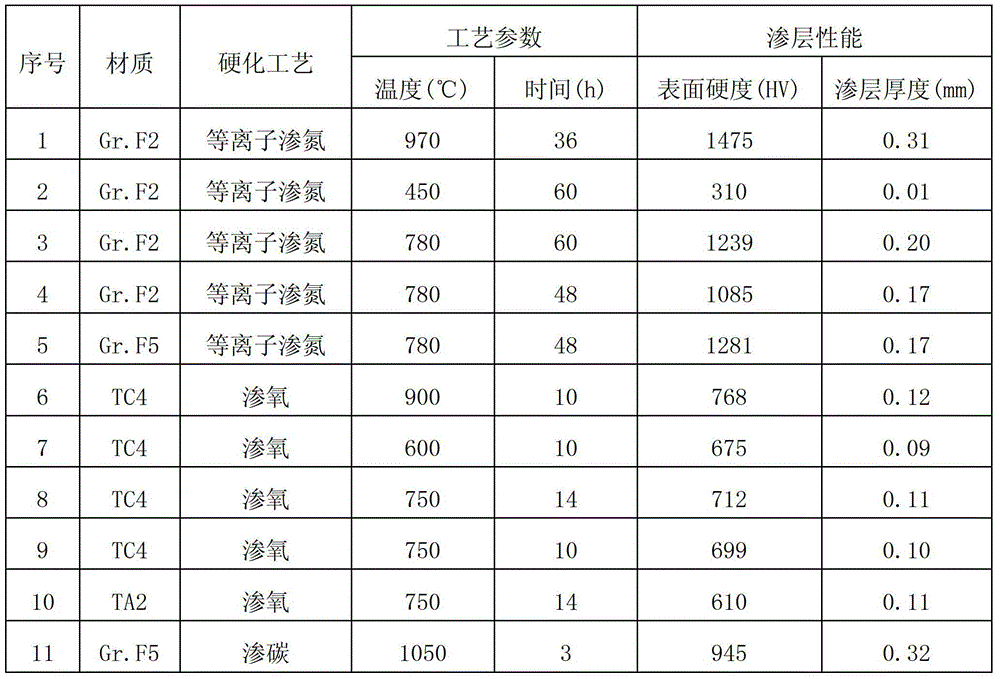

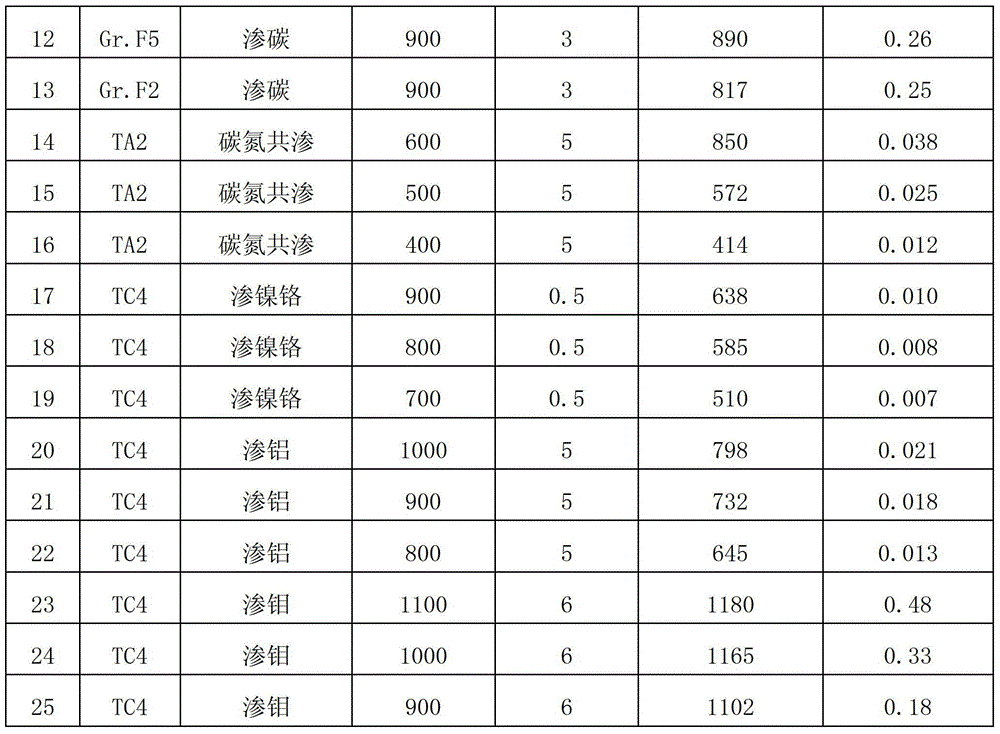

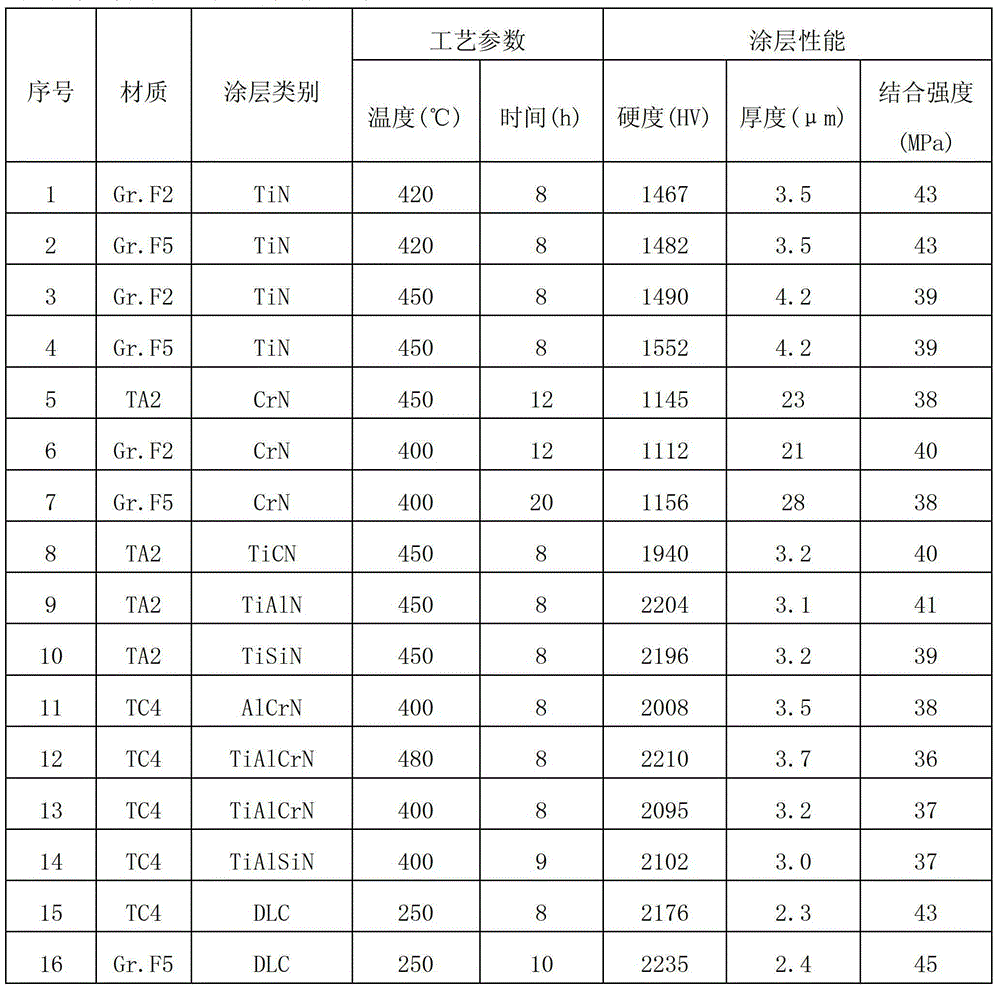

The invention discloses a surface-hardening treatment method of sealing pairs and friction pairs of titanium and titanium alloy ball valves. The sealing pairs are related sealing parts at all sealing positions in a valve, a ball and a valve base, and the friction pairs are related friction parts at all transmission connection positions in the valve, the ball and the valve base. The surface-hardening treatment method relates to chemical heat treatment and a vapor deposition hard coating. The chemical heat treatment and the vapor deposition hard coating are simultaneously used for the sealing pairs and the friction pairs of titanium and titanium alloy ball valves so that the problem that surface hardness of the titanium and titanium alloy ball valves treated by a single chemical heat treatment process is low. Based on the chemical heat treatment, the vapor deposition hard coating is adopted so that a hardness difference of a chemical heat treatment infiltrated layer is reduced. The vapor deposition hard coating further improves bonding strength of the chemical heat treatment infiltrated layer and improves surface hardness of the titanium and titanium alloy ball valves. Even if the vapor deposition hard coating is damaged in actual use, a hardened layer formed from the chemical heat treatment infiltrated layer still has a protection effect so that dual protection is realized.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

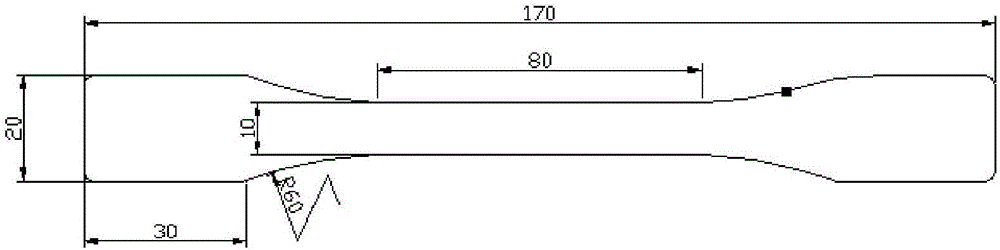

Asbestos-free clutch facing used in vehicle and manufacture method therefor

InactiveCN101033786AImprove performanceHigh strengthFriction liningHeat treatedTemperature and pressure

The invention discloses a kind of none asbestos clutch facing used in cars and its production technology. The recipe of the component is that: E-glass fiber 30~50%, fragrance fiber 1~4%, polyacrylonitrile fiber 0.6~1.2%, the oil of cashew shell friction-type mix 3~6%, oil coke blacking 3~5%, particle graphite 5~8%, zinc oxide 0.2~1%, calcium sulfate 5~15%, heavy calcium carbonate 10~20%, flour acrylonitrile butadiene rubber 15~25%, anti-aging protective TMQ 0.2~0.5%, curing accelerator MBTS 0.2~0.5%, the oil of cashew shell resin modified 6~12%. Banburying mix the component told above in proportions at the proper temperature then make up pellicle by smelting and at last rolls in with the E-glass fiber then forms different ordinance blanks by winding. The blanks confect by heat pressing at the proper temperature and pressure then make into production by grinding and drilling holes. It has the merits like that: high strength, good ductility and stabilize coefficient of friction and so on.

Owner:福建冠良汽车配件工业有限公司

Dental restorative composition

InactiveUS6221931B1Improve surface activityImprove toughnessImpression capsSynthetic resin layered productsNatural toothMethacrylate

A dental restorative composition is disclosed, comprising: (a) a methacrylate or acrylate monomer, (b) an organic-inorganic composite filler prepared by curing a mixture of a particulate filler having a mean particle size of 20 nm or less with a methacrylate or acrylate monomer having a viscosity of 60 cP or more and pulverizing the cured mixture, (c) a particulate filler having a mean particle size of 20 nm or less, and (d) a polymerization initiator, and further, if desired, (e) a glass powder having a maximum particle size of 5 mum or less and having a mean particle size of from 0.5 to 2 mum. The dental restorative composition according to the invention gives restorations having surface smoothness and transparency similar to natural teeth, having superior esthetics and superior physical properties such as bending strength and bending strain energy characteristics, and being provided with easy polishing.

Owner:GC CORP

Automotive copper-based powder metallurgy composite friction material and manfuacturing method thereof

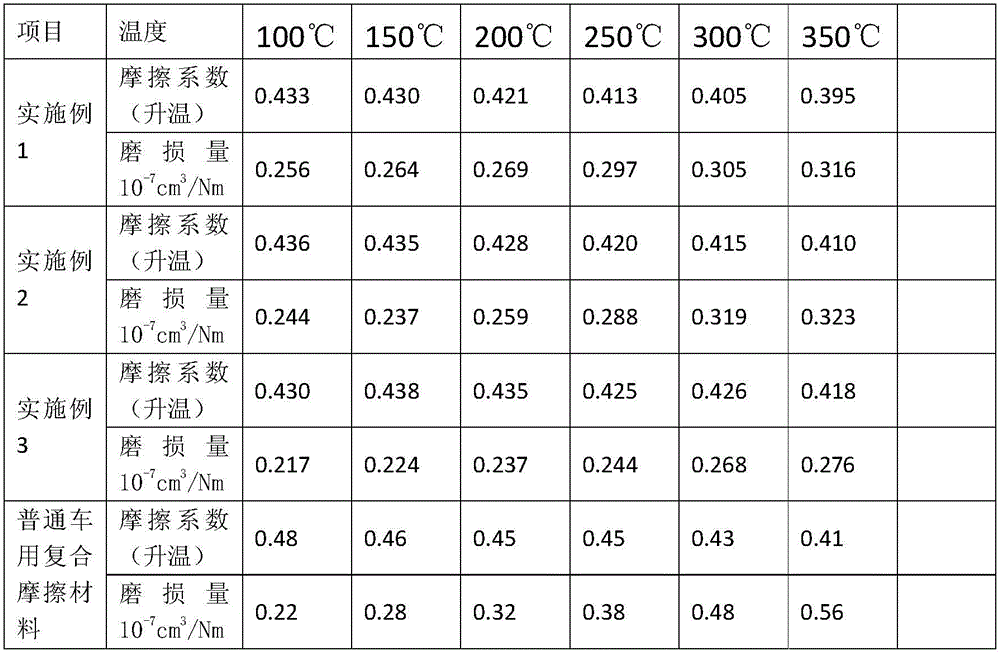

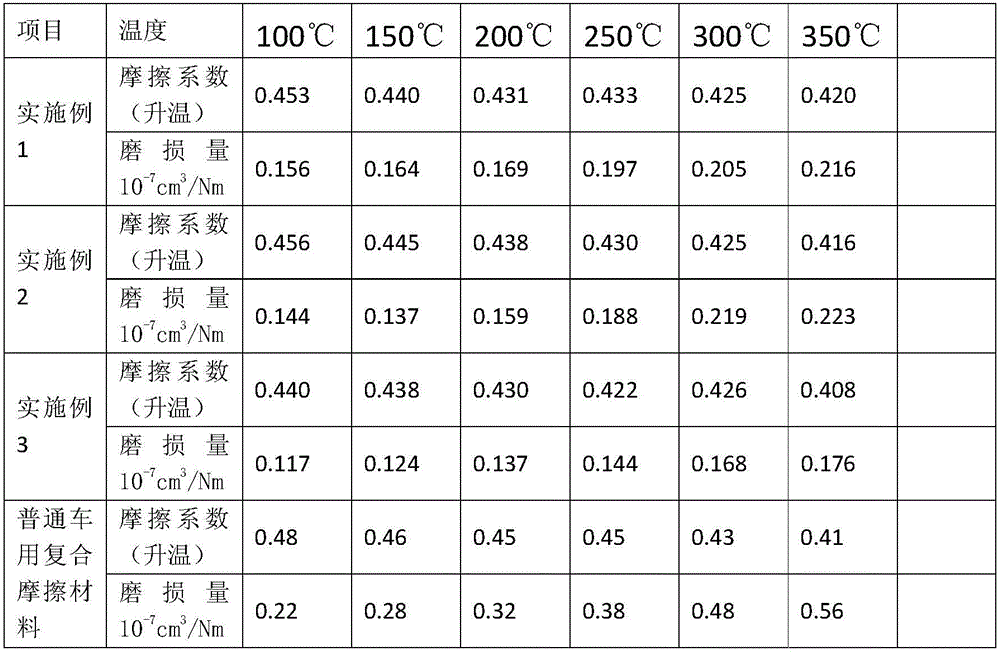

InactiveCN105778406AModerate modulus of elasticityStable coefficient of frictionPowder metallurgyPowder mixture

The invention discloses an automotive copper-based powder metallurgy composite friction material and a manufacturing method thereof. The manufacturing method includes that firstly, a basis powder material is mixed with a molding agent uniformly to obtain a mixture, the mixture is poured into a mold and is shaped into slender rods by pressing, the slender rods are compacted and separated and then charged into a sintering furnace, and the sintering furnace is heated up under protection of nitrogen gas or hydrogen gas so that a copper-based powder metallurgy friction material is obtained; secondly, the copper-based powder metallurgy friction material is subjected to processes of shearing, grinding and screening; thirdly, by mass percent, 10-20% of cashew nut oil modified phenolic resin, 30-60% of the copper-based powder metallurgy friction material, 10-20% of reinforced fibers, 5-15% of abrasives, 10-20% of lubricants and 5-20% of fillers are mixed uniformly to obtain a powder mixture, and the powder mixture is then subjected to hot press molding, is cooled to the room temperature and then is discharged from the furnace. The automotive copper-based powder metallurgy composite frictional material has both advantages of high temperature resistance and low abrasion as the copper-based powder metallurgy friction material and high ductility and low hardness as the resin-based composite friction material.

Owner:SOUTH CHINA UNIV OF TECH

Slag-based whole tailing gravity-flow filling cementing material and filling slurry preparation method thereof

The invention relates to a slag-based whole tailing gravity-flow filling cementing material and a filling slurry preparation method thereof. Blast furnace slag is used as a main cementing material, and water glass is used as a slag exciting agent, thereby significantly improving the early-stage strength. According to the invention, hemihydrate gypsum is also added, which shortens the cementing time; quicklime is added to realize volume expansion of the slurry after cementation is started, and thus to improve the tight-filling rate of the filling material. Since the solid concentration is increased, the rheological property of the filling material is reduced; the addition of a powdery water reducer can improve the fluidity and reduce the bleeding rate with the proviso that the solid concentration of the filling slurry is maintained to be high, thus the filling slurry is more uniform and gravity-flow filling is realized. With the addition of the high-efficient water reducer and the cooperative use of citric acid and glucose retarders, the pipe blocking phenomenon caused by fluidity loss during whole tailing filling is improved.

Owner:山东黄金矿业(莱州)有限公司焦家金矿

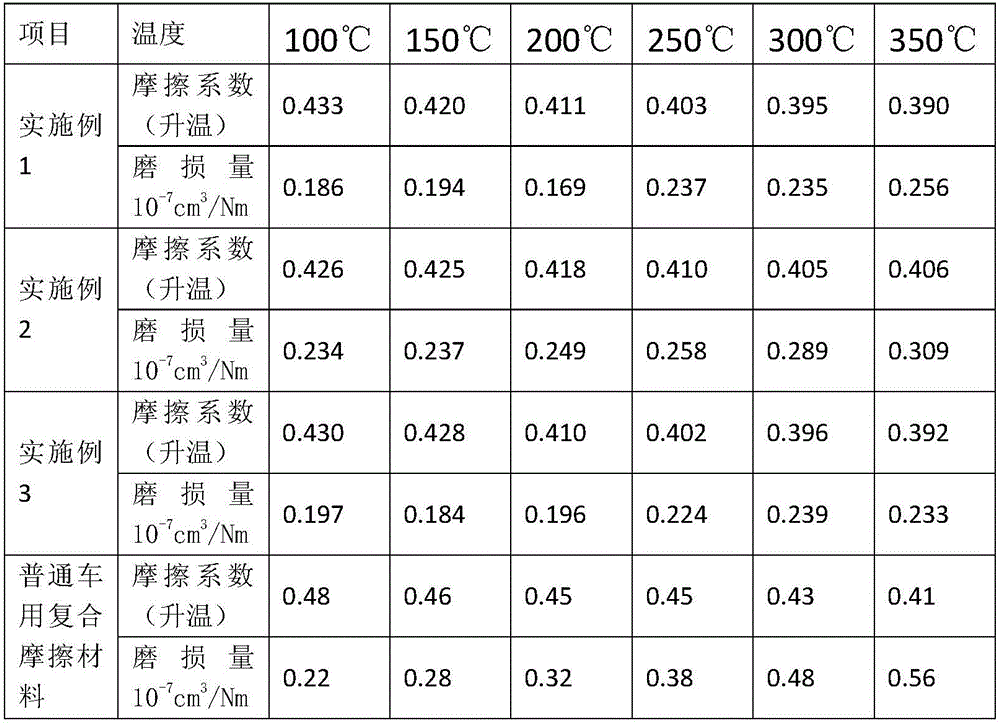

Automotive iron-based powder metallurgy composite frictional material and manufacturing method thereof

The invention discloses an automotive iron-based powder metallurgy composite frictional material and a manufacturing method thereof. The manufacturing method includes that firstly, a basis powder material is mixed with a molding agent uniformly to obtain a mixture, the mixture is poured into a mold and is shaped into slender rods by pressing, the slender rods are compacted and separated and then charged into a sintering furnace, and the sintering furnace is heated up under protection of nitrogen gas or hydrogen gas so that an iron-based powder metallurgy friction material is obtained; secondly, the iron-based powder metallurgy friction material is subjected to processes of shearing, grinding and screening; thirdly, by mass percent, 10-20% of cashew nut oil modified phenolic resin, 30-60% of the iron-based powder metallurgy friction material, 10-20% of reinforced fibers, 5-15% of abrasives, 10-20% of lubricants and 5-20% of fillers are mixed uniformly to obtain a powder mixture, and the powder mixture is then subjected to hot press molding, is preserved at the temperature of 150-180 DEG C, cooled to the room temperature and then discharged from the furnace. The automotive iron-based powder metallurgy composite frictional material remains the stable friction coefficient and good abrasive resistance of the conventional powder metallurgy friction material, service life of the friction material is prolonged and its high-temperature stability is also improved.

Owner:SOUTH CHINA UNIV OF TECH

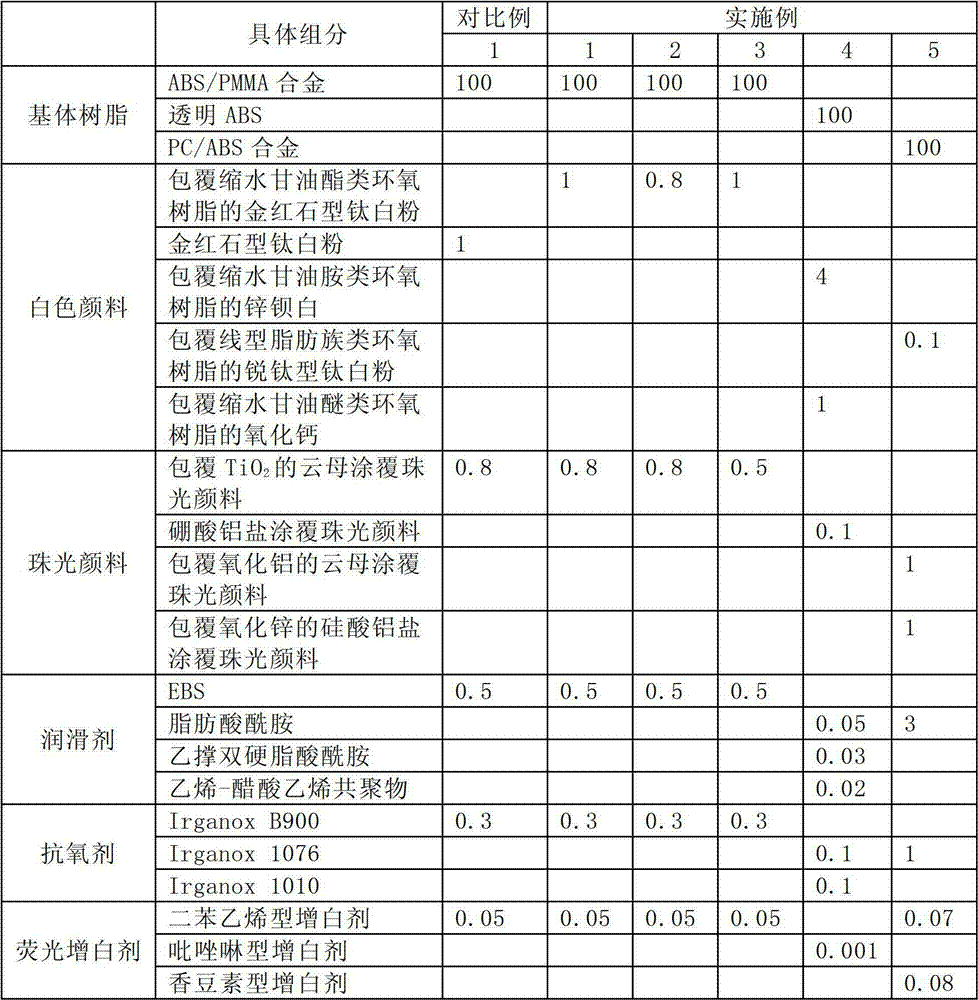

Aesthetic resin for improving whiteness and scintillation effect and preparation method thereof

InactiveCN102888071AReduce surface hardnessReduce surface friction coefficientFluorescenceAntioxidant

The invention relates to an aesthetic resin for improving whiteness and scintillation effect and a preparation method thereof. The resin comprises the following components in parts by weight: 100 parts of base resin, 0.1-5 parts of white pigment, 0.1-2.0 parts of pearlescent pigment, 0.1-3.0 parts of lubricant, 0.2-1.0 part of antioxidant and 0.001-0.15 part of fluorescent whitening agent. The preparation method of the resin comprises the following steps: stirring and mixing the components in a high-speed mixer, and then transferring into a double screw extruder; under the transferring, shearing and mixing effects of double screws, melting and compounding the materials; and then extruding, performing bar drawing, cooling, and pelleting to obtain the product. The invention overcomes the disadvantage that the existing white aesthetic resin can not simultaneously realize high whiteness and high scintillation effect, and ensures that the apparent effect of the white aesthetic resin is greatly enhanced, thereby ensuring that the white aesthetic resin meets the higher appearance application requirements in the fields of household appliances, automobiles, consumable electronics and the like and greatly widening the application range of the white aesthetic resin product.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Composite frictional material and preparation method thereof

The invention provides a preparation method of a composite frictional material. The preparation method comprises the following steps that 1, a ferrous-based powder metallurgical frictional material is prepared; 2, shearing, smashing and screening are performed; 3, material mixing is performed; 4, the composite frictional material is prepared; 5 posttreatment is performed; 6, the composite frictional material is machined. Compared with the prior art, the composite frictional material integrates the characteristics of high temperature resistance and low abrasion resistance of the ferrous-based powder metallurgical frictional material and the characteristics of good toughness and low hardness of a resin-based composite material and has the advantages of high temperature resistance, low abrasion resistance, good toughness and low hardness. The ferrous-based powder metallurgical frictional material is used for preparing an automobile braking accessory, scratching of an automobile brake disc or drum is effectively avoided based on good braking performance, and frictional noise is small.

Owner:CHONGQING AOSHUNTE MACHINERY MFG

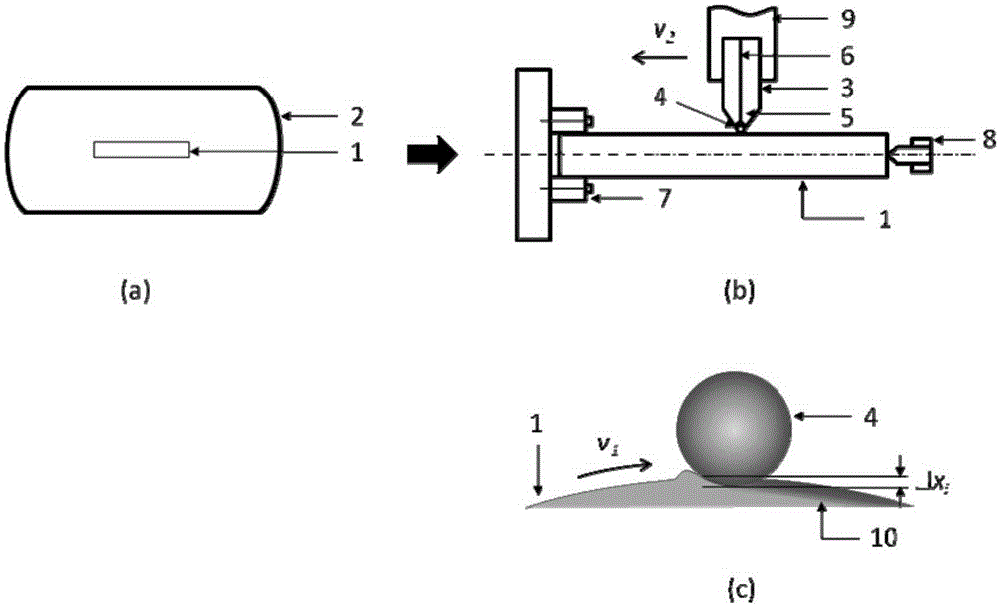

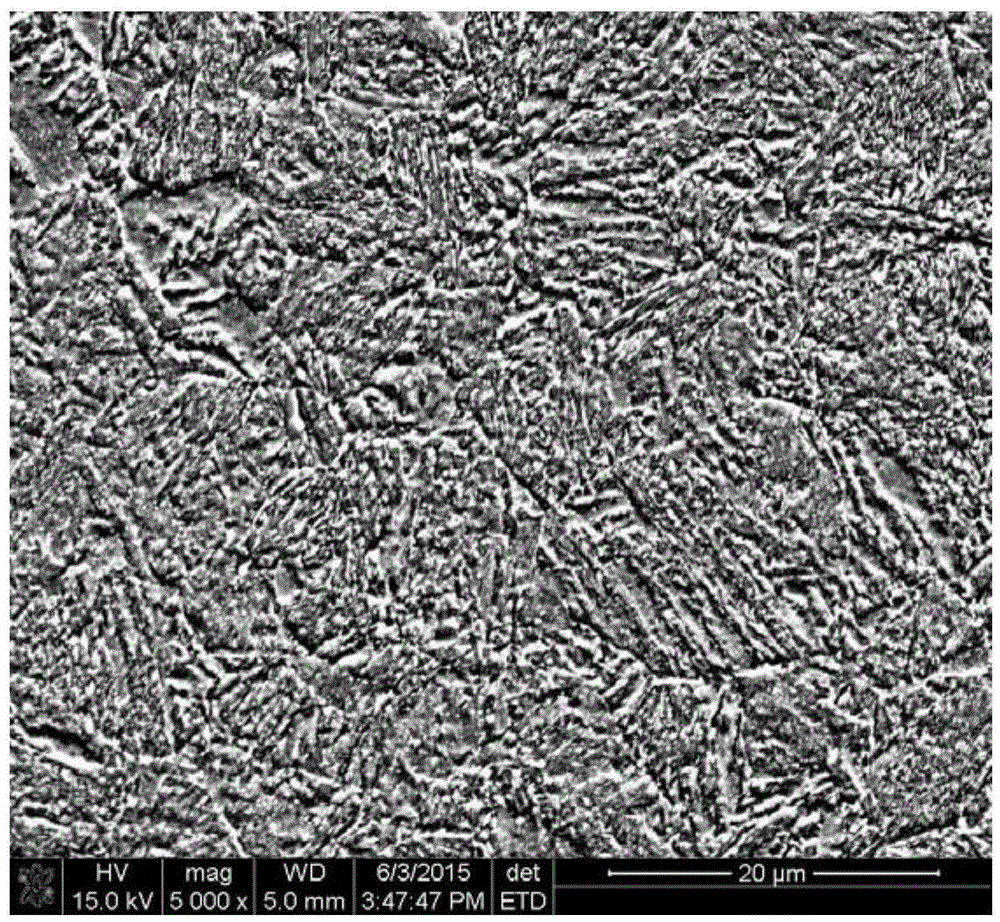

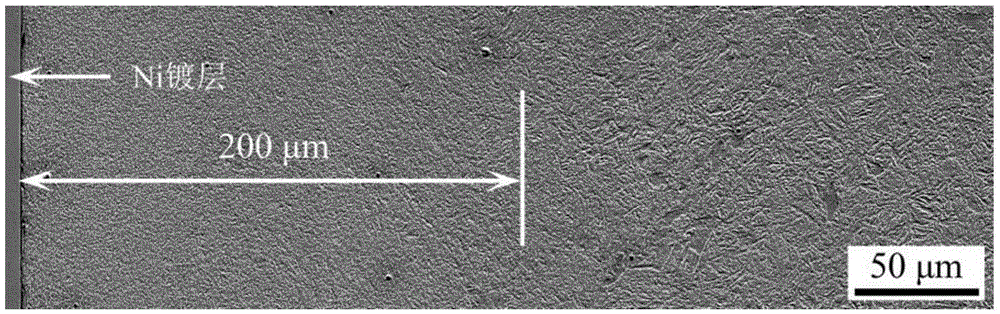

Surface-controllable composite strengthening method for forged steel crankshaft material

ActiveCN105385829AShorten the timeLow costFurnace typesHeat treatment furnacesMetallic materialsQuenching

The invention discloses a surface-controllable composite strengthening method for a forged steel crankshaft material, and belongs to the technical field of metal material surface strengthening. According to the method, heat treatment and surface mechanical rolling nanocrystallization treatment are combined, and surface-controllable composite strengthening treatment is carried out on a rotary piece of the forged steel crankshaft material. By means of the adjustment on a heat treatment technology (quenching and tempering treatment or medium-frequency quenching and low-temperature tempering treatment), the rotary piece can obtain organization structures different in hardness and high in plasticity; and then surface mechanical rolling nanocrystallization treatment is carried out on the rotary piece subjected to heat treatment, so that the surface grain size of the material is lowered, the surface hardness of the material is improved, the hardness distribution state of the material on the surface layer in the depth direction is adjusted, and meanwhile the surface smoothness of the material is improved. After surface-controllable composite strengthening treatment, controllable preparing of the structures, the grain size, surface smoothness and hardness distribution of the rotary piece of the forged steel crankshaft material is achieved, and a crankshaft can meet different use requirements.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

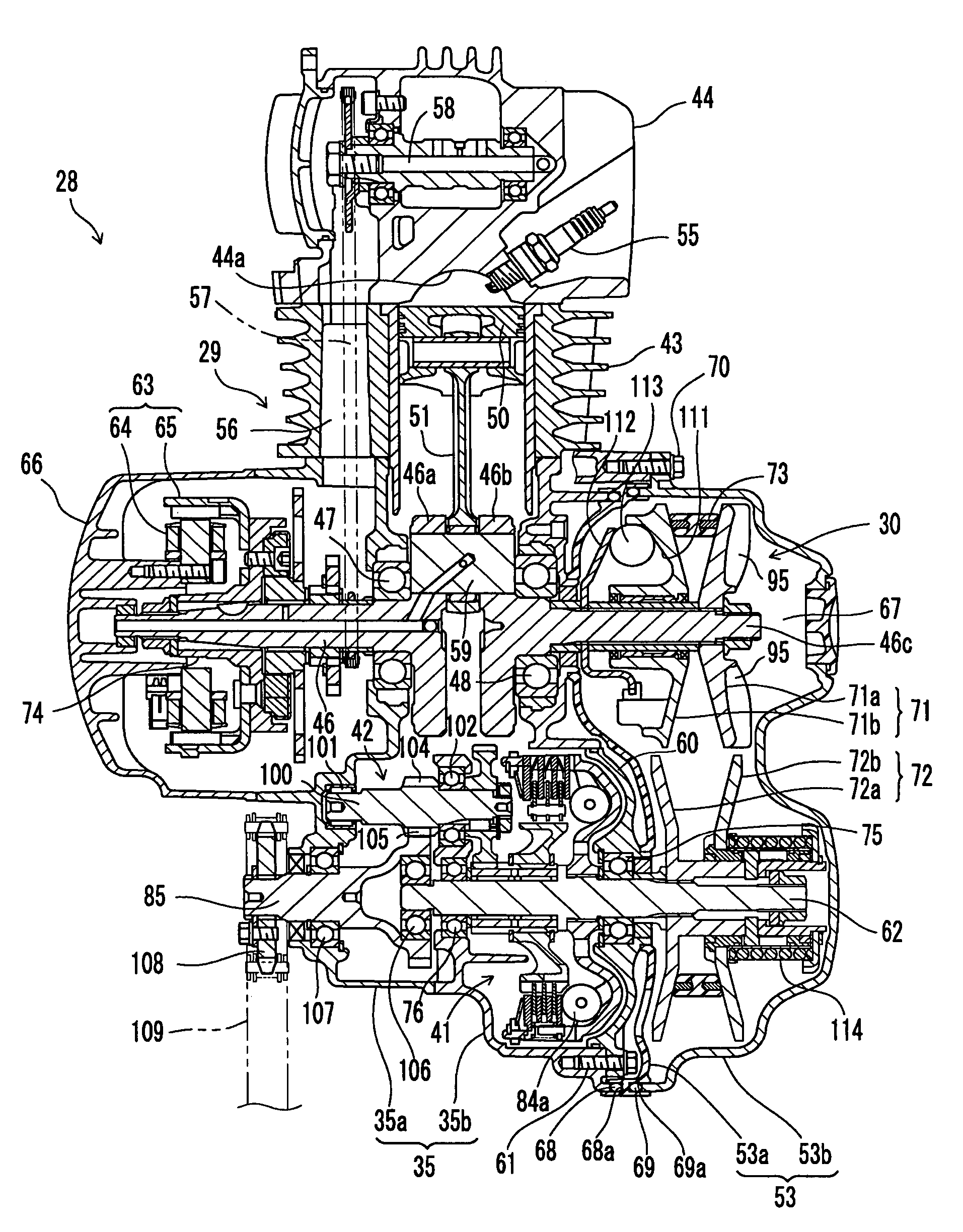

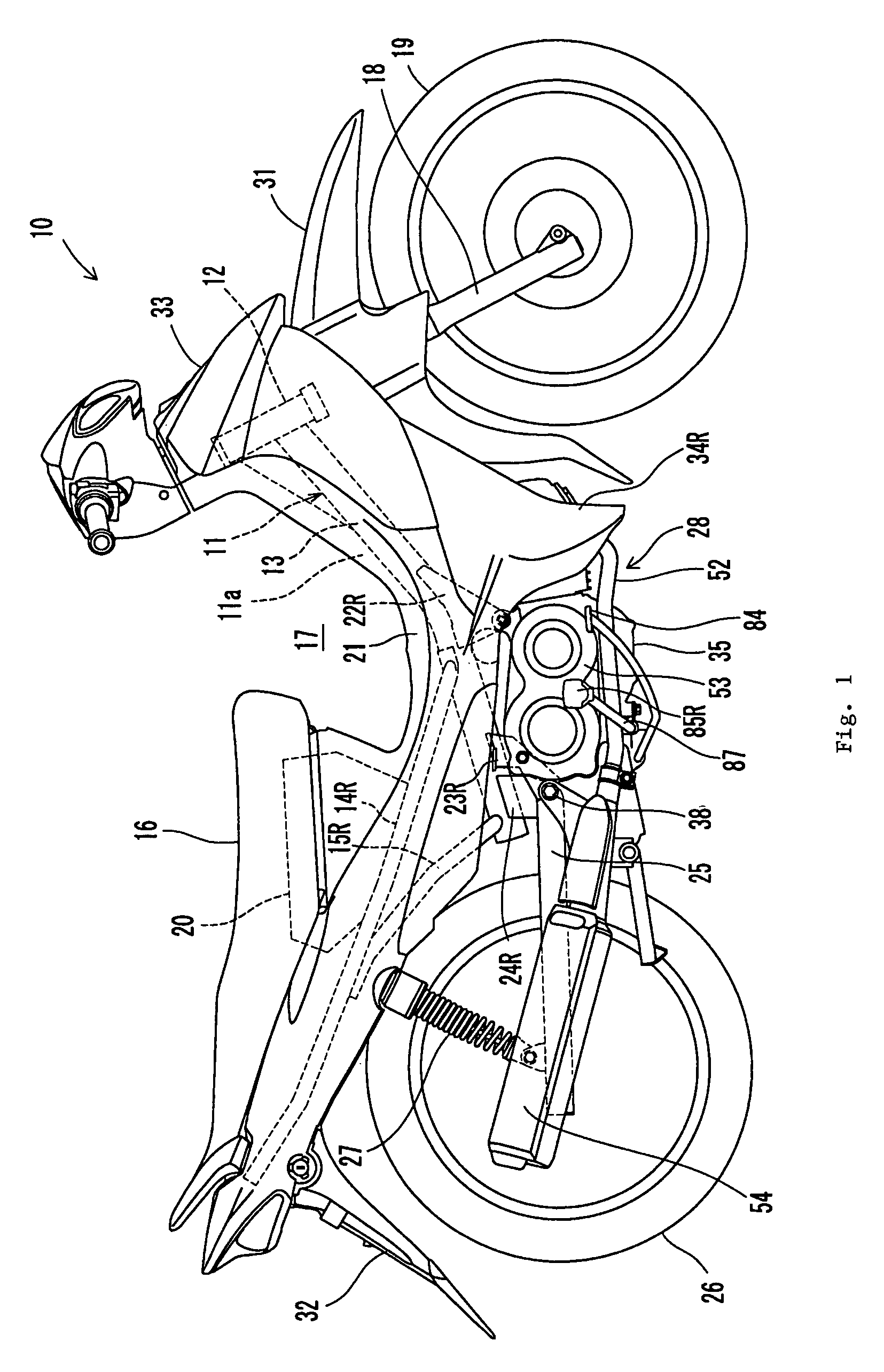

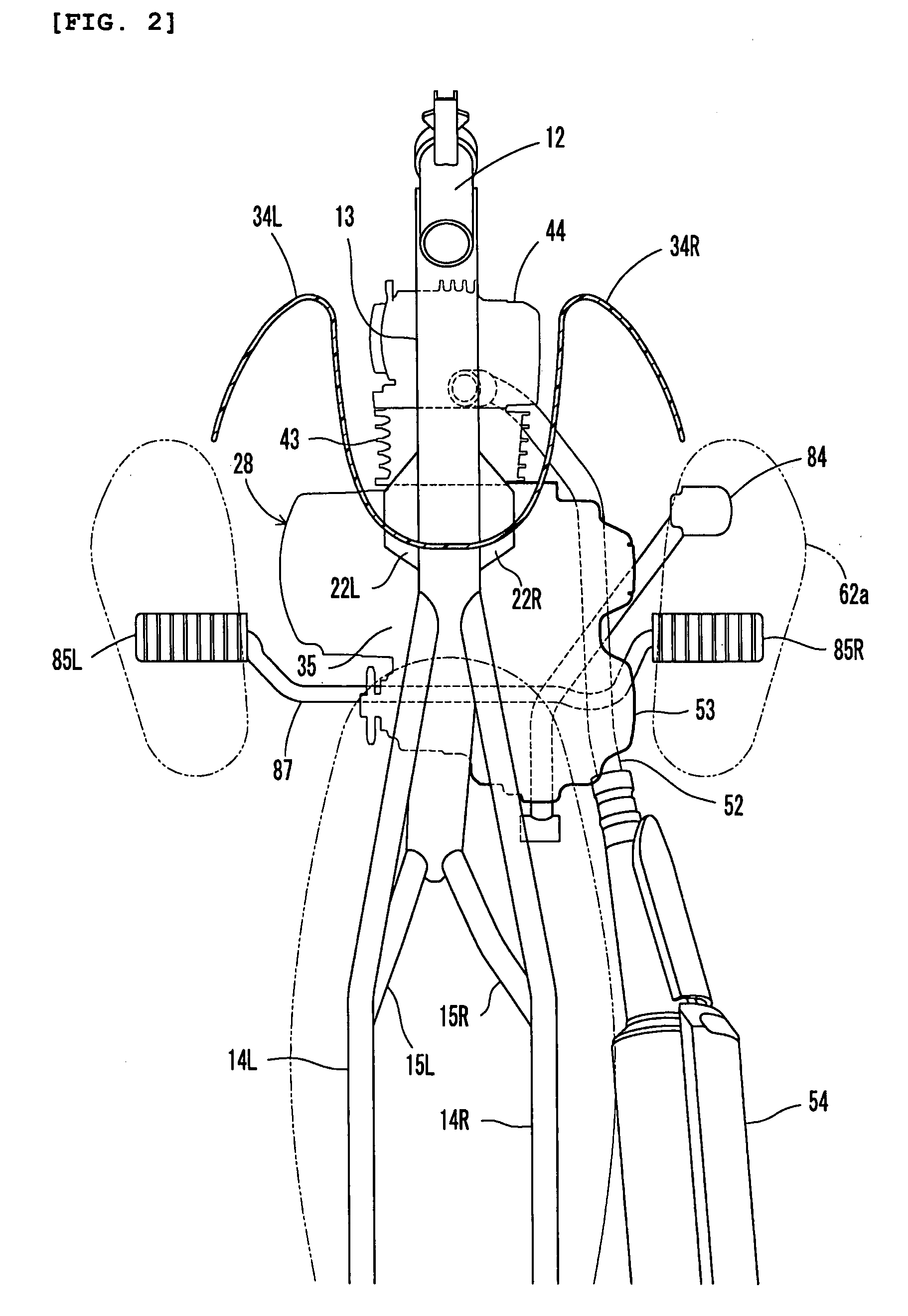

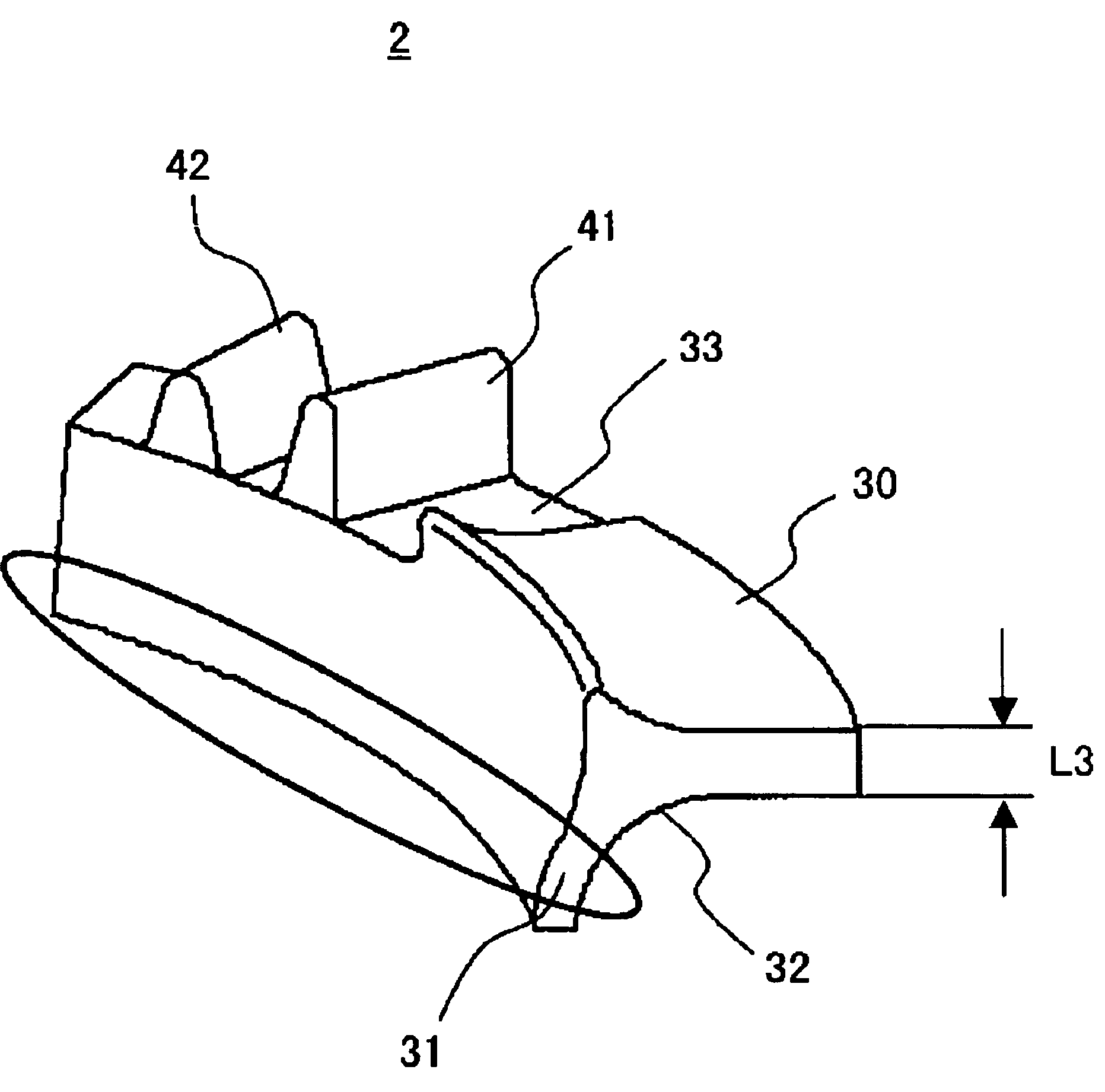

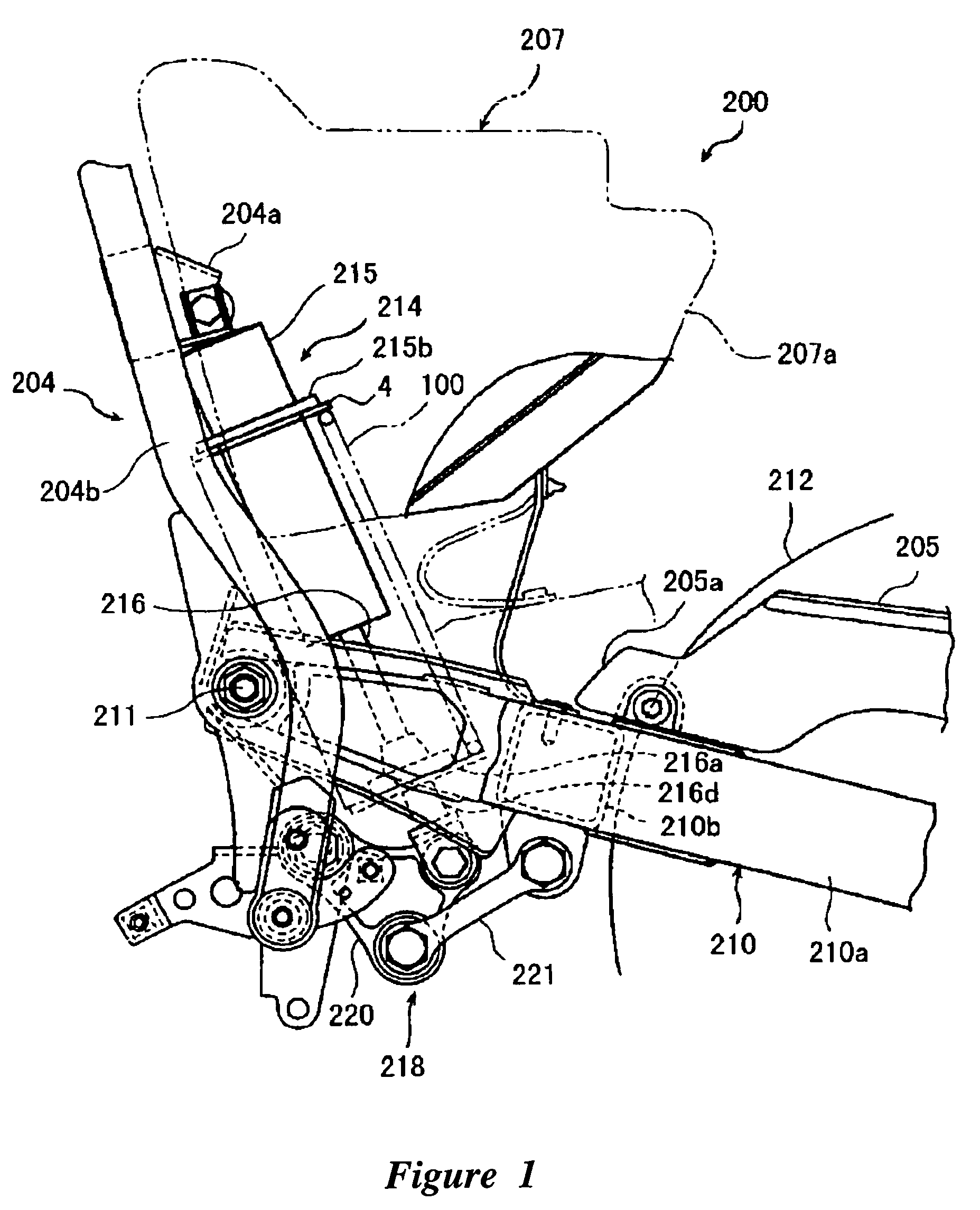

Belt-type continuously variable transmission and straddle-type vehicle

Wear of a V-belt and wear of sheaves in a belt type continuously variable transmission is compatibly prevented. A V-belt wound around a primary sheave \ and a secondary sheave is formed with a resin block belt. A sheave surface of the primary sheave is plated with chrome. The secondary sheave is made of stainless steel and is not plated with chrome. The sheave surface hardness of the secondary sheave is lower than the sheave surface hardness of the primary sheave.

Owner:YAMAHA MOTOR CO LTD

Abrasion resistant steel plate having excellent low-temperature toughness and excellent corrosive wear resistance

ActiveUS20150225822A1Excellent corrosive wear resistanceExcellent low-temperature toughnessFurnace typesHeat treatment furnacesSteel platesCrystallite

An abrasion resistant steel plate which possesses excellent abrasion resistance, excellent low-temperature toughness and excellent corrosive wear resistance. The abrasion resistant steel plate has the composition comprising by mass %: 0.10% to 0.20% C, 0.05% to 1.00% Si, 0.1% to 2.0% Mn, 0.020% or less P, 0.005% or less S, 0.005% to 0.100% Al, one or two kinds of components selected from a group consisting of 0.05% to 2.0% Cr and 0.05% to 1.0% Mo, and remaining Fe and unavoidable impurities as a balance. Content of solute Cr in steel (Crsol) and the content of solute Mo in steel (Mosol) satisfy the formula 0.05≧(Crsol+2.5Mosol)≧2.0. Steel plate has a structure where an as-quenched martensitic phase forms a main phase and a grain size of prior austenite grains is 30 μm or less, and surface hardness of the steel plate is 360 or more at Brinel hardness HBW10 / 3000.

Owner:JFE STEEL CORP

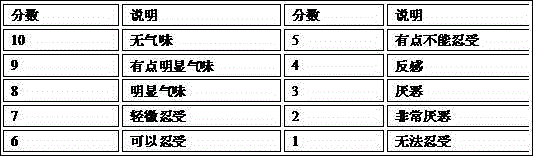

Low odor, scratch resistant and soft tactility polypropylene composition and preparation method thereof

The invention relates to a polypropylene composition, in particular to a low odor, scratch resistant and soft tactility polypropylene composition and a preparation method thereof. The polypropylene composition comprises the following raw materials in percent by weight: 30 to 60 percent of polypropylene, 20 to 35 percent of copolymer of ethylene and propylene, 10 to 30 percent of glass fiber, 5 to 10 percent of hyperbranched (ethylene and methyl acrylate) copolymer, 0.2 to 1 percent of an antioxydant, 0.2 to 1 percent of a light stabilizer, and 0.3 to 3 percent of an additive, wherein the total amount of the raw materials is 100 percent. The invention further provides the production method of the polypropylene composition. The polypropylene composition has the characteristics of high mechanical performance, strong impact resistance, scratch resistance, low odor, soft tactility, low linear expansion coefficient and the like.

Owner:SILVER AGE ENG PLASTICS DONGGUAN +2

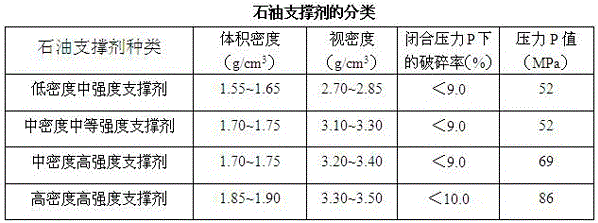

Low-density and moderate-strength oil fracturing propping agent and preparing method thereof

ActiveCN104479667AGood appearanceImprove the ability to resist crushingFluid removalDrilling compositionSlagManganese oxide

The invention relates to a low-density and moderate-strength oil fracturing propping agent and a preparing method thereof, and belongs to the technical field of oil-gas well fracturing in oil production. The low-density and moderate-strength oil fracturing propping agent is made of powder and a silica solution accounting for four percent of the weight of the oil fracturing propping agent. The powder is formed by mixing, by weight, 85-90 parts of raw bauxite, 5-8 parts of molybdenum ore gangue, 2-3 parts of bentonite and 2-5 parts of composite additive. The molybdenum ore gangue and the composite additive composed of manganese oxide powder and ferronickel slag powder are added, good balance is obtained between obvious propping agent density reduction and certain strength keeping, the developed oil propping agent has good comprehensive performance, it is ensured that the propping agent has considerable strength, the firing temperature of the propping agent is reduced, the purposes of saving energy and reducing consumption are achieved, the wasted mineral is fully utilized, and waste resources are repeatedly utilized.

Owner:LUOYANG INST OF SCI & TECH +1

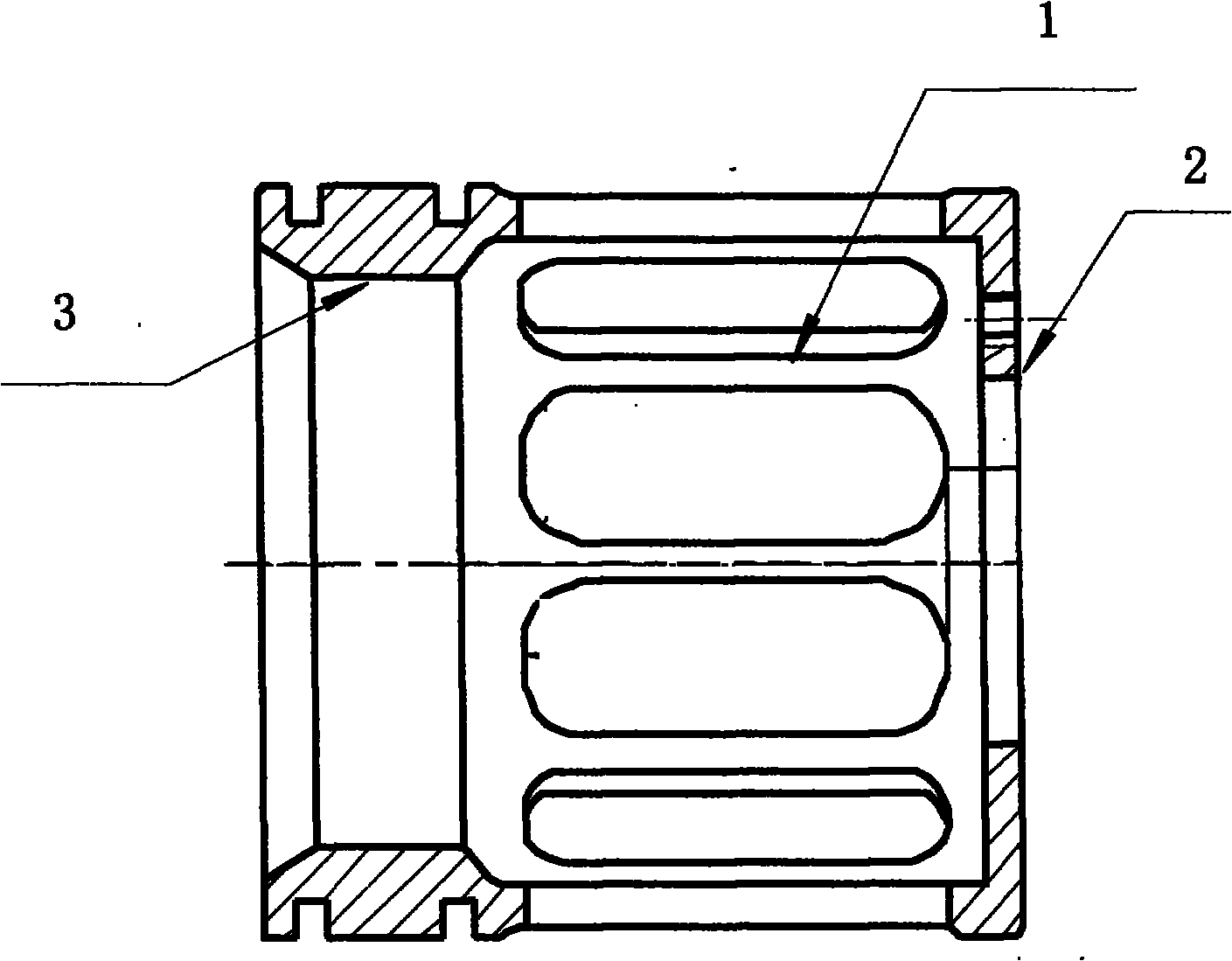

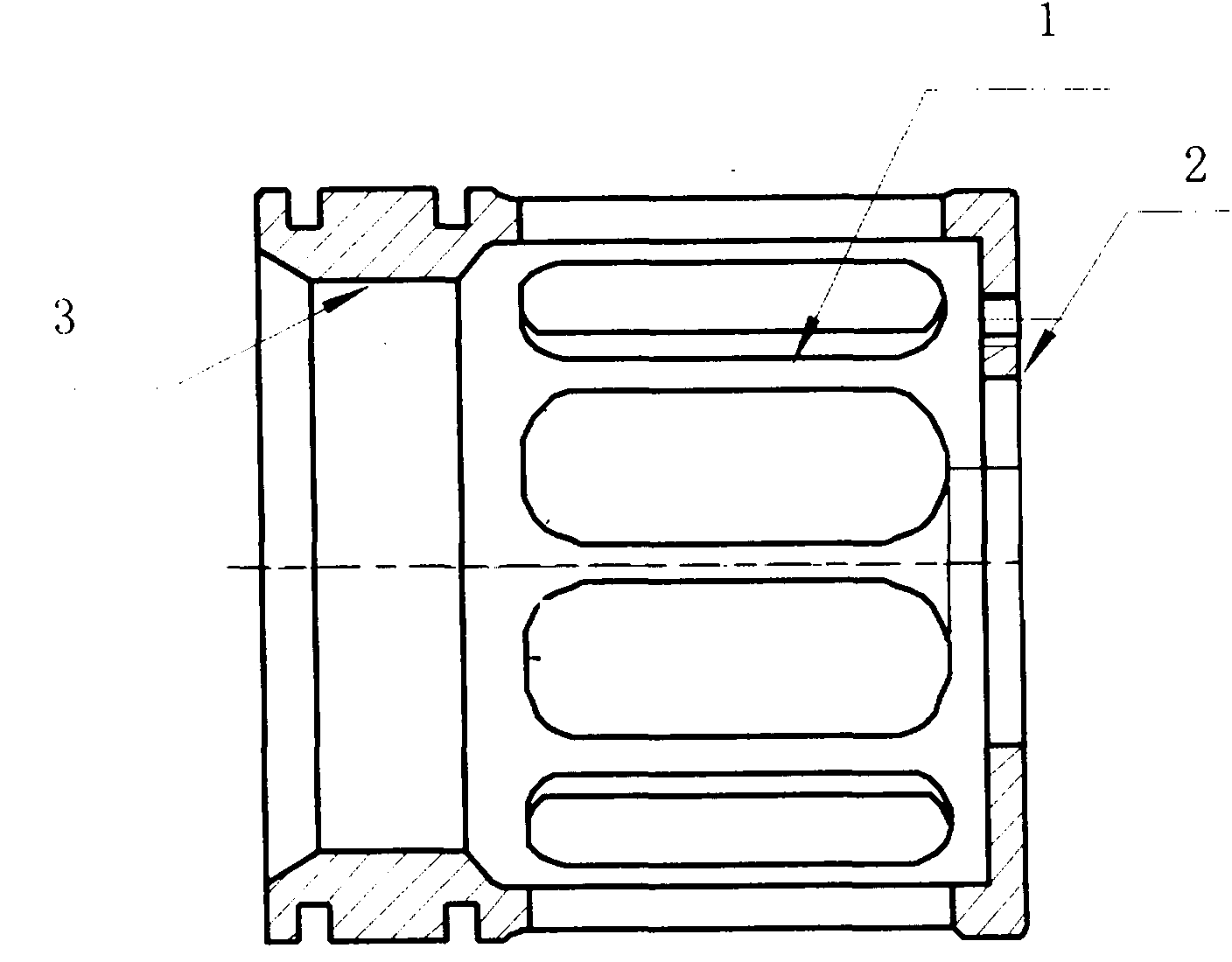

Double carburization protecting process in manufacture of bearing outer ring of squirrel-cage elasticity support

InactiveCN101812658AReduce internal stressAvoid deformationBearing componentsSolid state diffusion coatingCopper platingEngineering

The invention belongs to the technical field of bearing manufacture, and mainly relates to a double carburization protecting process in manufacture of a bearing outer ring of a squirrel-cage elasticity support. The process comprises the following steps: 1) adding allowance on a non-raceway surface and a raceway surface to protect reserved allowance in machining; performing whole copper-plating protection on the bearing outer ring of the squirrel-cage elasticity support; 2) lathing a bearing copper plating layer with a carburized surface before carburizing process to ensure that the bearing raceway achieves the required size of a lathing finished product; 3) integrally carburizing the bearing outer ring of the squirrel-cage elasticity support to ensure that the raceway surface has the surface hardness in accordance with the technical requirement; and 4) lathing the carburized protective layer on the non-raceway surface, manufacturing the non-raceway surface to be in accordance with the finishing size requirement, and turning to the next process subsequently for manufacture according to the normal process. The invention adopts double carburization protection means, namely copper plating and allowance addition for complementation, has the advantages of high utilization rate of materials, low machining cost, stability and reliability, and ensures position accuracy in raceway manufacturing. The process is safer and more reliable, and can completely meet the requirement of products.

Owner:LUOYANG LYC BEARING

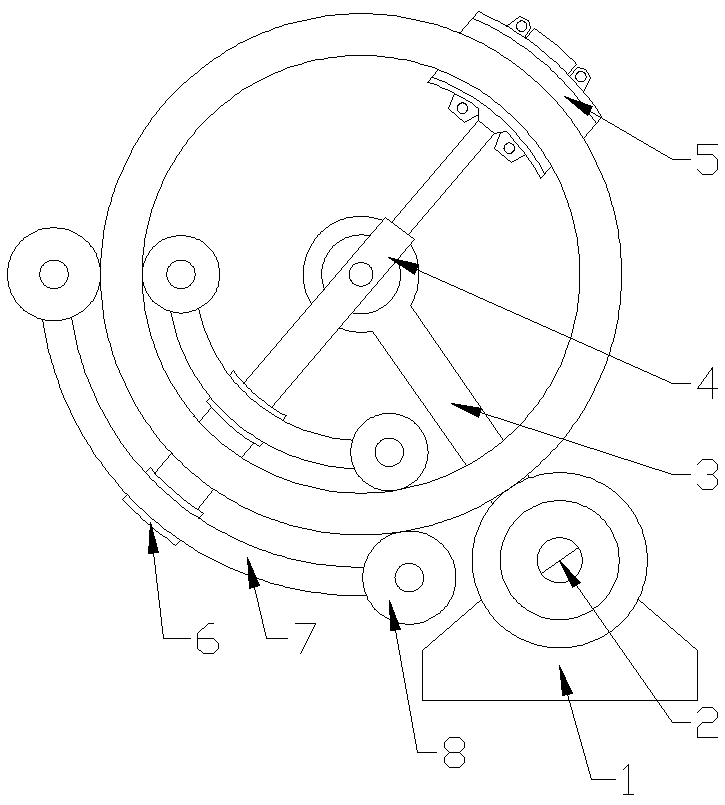

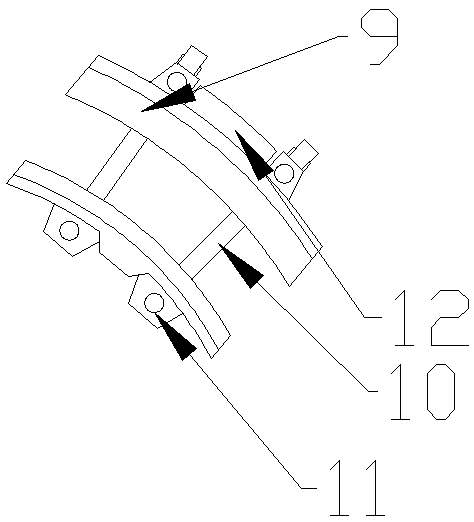

Polishing mechanism for bearing inner frame and outer frame

InactiveCN107685258ASimple structureLow costGrinding carriagesRevolution surface grinding machinesAxial compressionEngineering

The invention relates to a grinding mechanism for the inner frame and outer frame of a bearing, which comprises a support arm, on which a sliding arm is arranged, and the middle part of the sliding arm is fixedly connected with the supporting arm; A group of pressing members, the pressing member includes a sliding sleeve that is slidably connected with the sliding arm, an arc-shaped pressing sheet is fixed on the sliding sleeve, and pressing wheels are respectively arranged at both axial ends of the pressing sheet; A sliding rod is provided on the other end of the sliding rod, and a clamping inner plate and a clamping outer plate are arranged on the sliding rod, and the clamping inner plate and the clamping outer plate are connected by a tensioning mechanism, including a support fixedly connected with the sliding rod Two screw rods are rotated and connected on the support block, and two clamping blocks are symmetrically arranged on the clamping inner plate and the clamping outer plate, and one end of the screw rod is rotatably connected with the clamping block clamping the inner plate. The other end and the clamping block of the clamping inner plate are threadedly connected; a grinding layer is arranged on the clamping inner plate and the clamping outer plate.

Owner:WUXI SIBORUI ELECTROMECHANICAL CO LTD

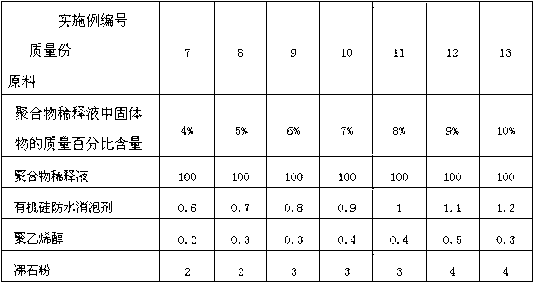

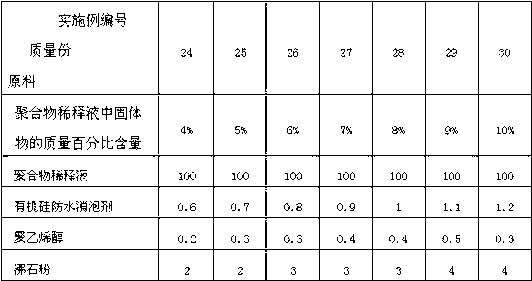

Modified high carbon ferro-chrome slag aggregate for road concrete and preparation method of modified high carbon ferro-chrome slag aggregate

ActiveCN103073210AFix bugsSolve hidden dangersSolid waste managementPolyethylene vinyl acetatePolyvinyl alcohol

The invention discloses a modified high carbon ferro-chrome slag aggregate for road concrete and a preparation method of the modified high carbon ferro-chrome slag aggregate. The modified high carbon ferro-chrome slag aggregate is characterized by being prepared from a high carbon ferro-chrome alloy slag aggregate and a chemical modifying agent accounting for 2-6 percent of the mass of the high carbon ferro-chrome alloy slag aggregate through mixing, wherein the chemical modifying agent is prepared from 100 parts by mass of polymer diluting solution, 0.5-1.2 parts by mass of organic silicon waterproof defoaming agent, 0.2-0.5 part by mass of polyvinyl alcohol and 2-4 parts by mass of zeolite powder through uniform mixing; the polymer diluting solution is prepared by diluting a polymer emulsion stock solution through adding water; and the polymer emulsion stock solution is any one of a butylbenzene emulsion, a polyacrylate emulsion, a polyethylene-vinyl acetate emulsion and a styrene-acrylic emulsion. By adopting the invention, waste alloy waste is used as a raw material, and thus building materials of carbon chromic slag can be recycled and efficiently utilized, and the defects and the hidden dangers of the carbon chromic slag as the concrete aggregate are solved; and the preparation method is simple and easy to realize and is strong in practicability.

Owner:李素娥

Ultralow-density cordierite petroleum fracturing propping agent and preparation method thereof

ActiveCN106431349AHigh hardnessHigh mechanical strengthFluid removalDrilling compositionCordieriteManganese oxide

The invention provides an ultralow-density cordierite petroleum fracturing propping agent and a preparation method thereof. A principal crystalline phase of the popping agent is of a cordierite structure and is formed by firing coal ash, caustic-burned magnesia powder, Jiaozuo clay and a composite mineralizer, and the composite mineralizer is formed by mixing manganese oxide and barium carbonate according to the equal weight ratio. A large amount of high-silicone, low-aluminum, low-calcium and low-ignition-loss neutral coal ash is adopted as a main raw material, and the density index of the popping agent is effectively reduced; through the special processing and treating processes such as special pre-sintering on an important raw material magnesite and ultrafine grinding on batches and the composite mineralizer technology, it is effectively guaranteed that high-hardness and low-density principal crystalline phase minerals are formed in a system at high temperature, therefore, and it is guaranteed that the finished ultralow-density popping agent has high mechanical strength; the firing temperature of the popping agent is reduced, and the purposes of energy saving and consumption reduction are achieved.

Owner:洛阳赛罗帕陶瓷科技有限公司 +1

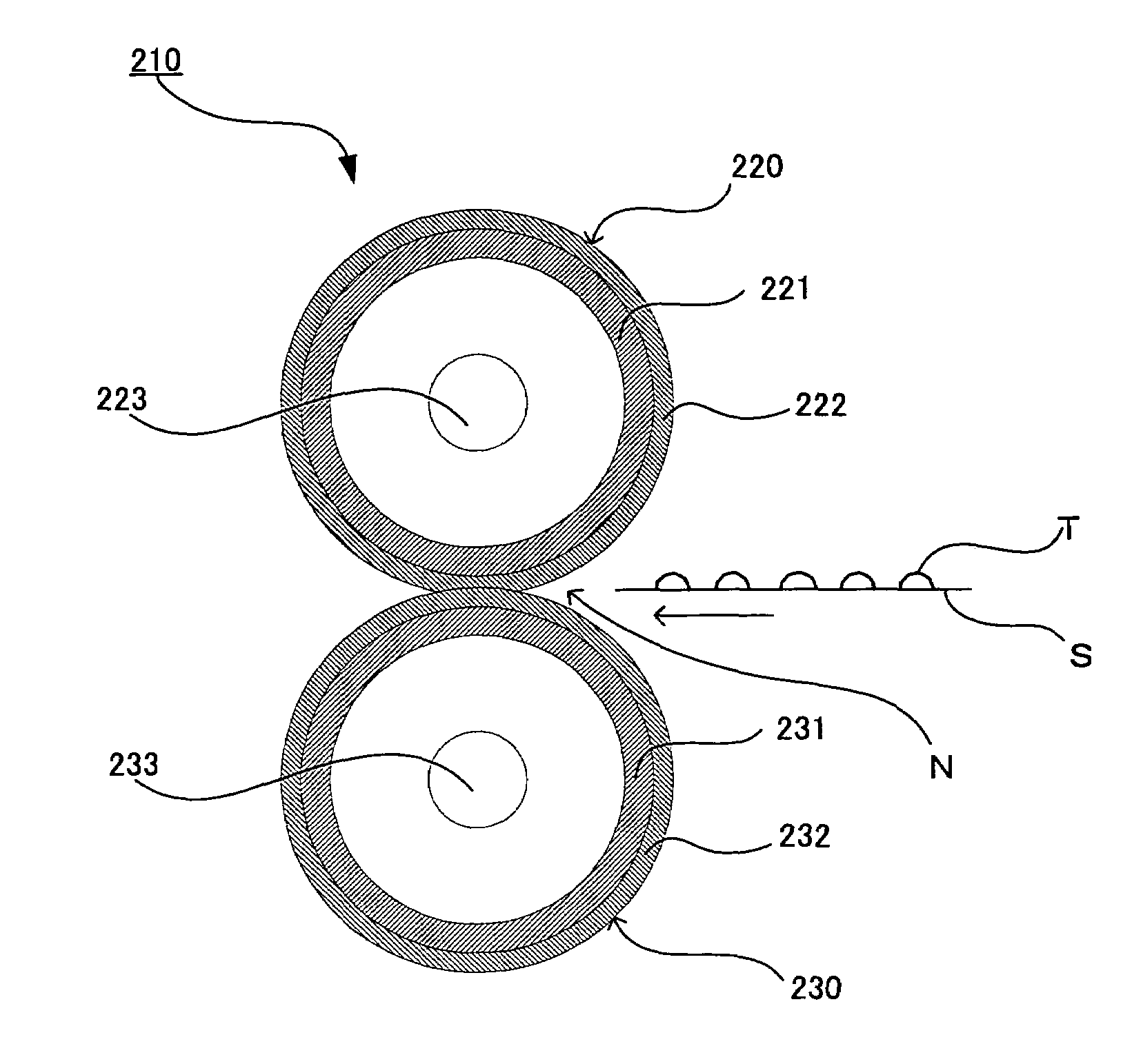

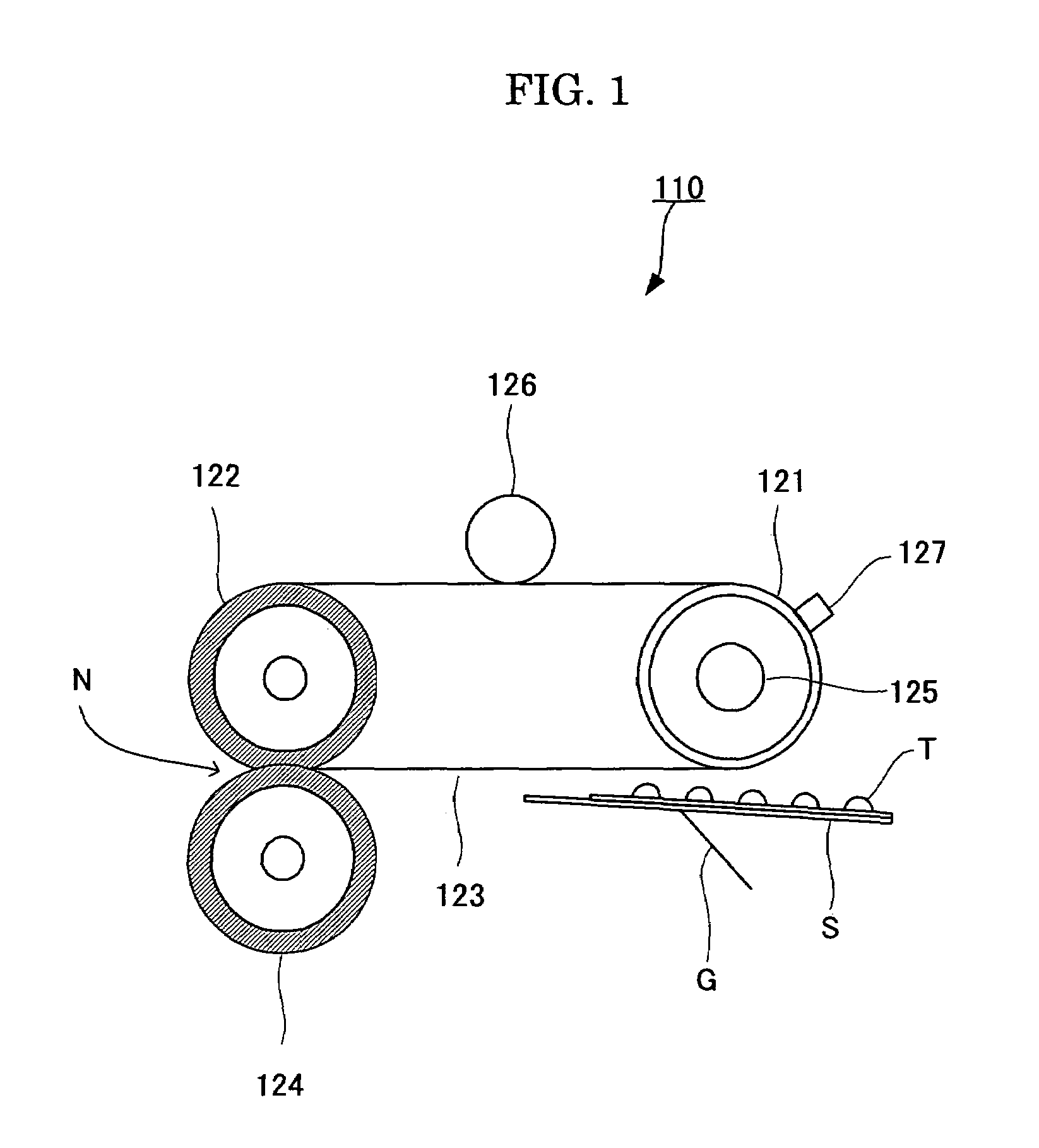

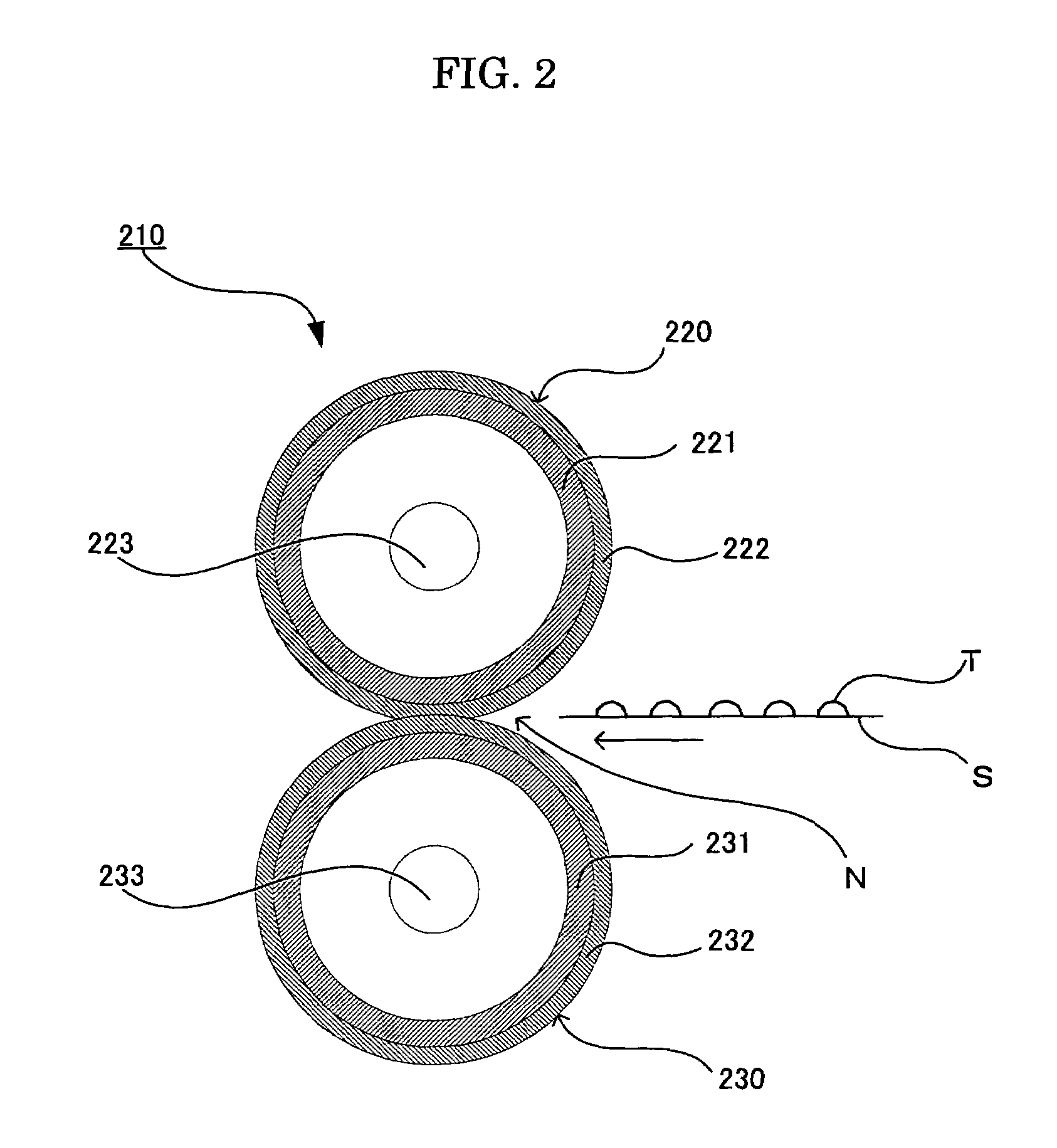

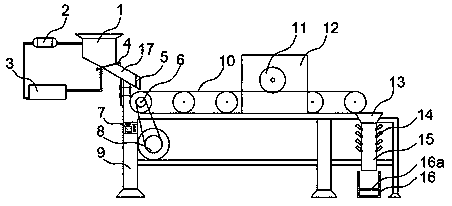

Image-fixing method and image-fixing device, and, image-forming method and image-forming apparatus

ActiveUS7560216B2Excellent glossinessReduce surface hardnessDevelopersElectrographic process apparatusWaxAliphatic hydrocarbon

An image-fixing method contains: passing a recording medium bearing an image through a nip between two or more fixing members to fix the image onto the recording medium; and ejecting the recording medium along with the fixing member contacting with a non-image-bearing surface of the recording medium, wherein the fixing member contacting with an image-bearing surface of the recording medium has a lower surface hardness than that of the fixing member contacting with the non-image-bearing surface, the image is comprised of a toner containing toner particles, each toner particle contains wax having an aliphatic hydrocarbon chain, and polyester resin having an aromatic ring, a total amount of the wax in the toner particle is 1 to 20 mass %, determined by DSC, an amount of the wax located in the specific region of the toner particle is 0.05 to 0.40 that is an intensity ratio (P2850 / P828) determined by FTIR-ATR, and the wax is partially or entirely encapsulated in the toner particle as dispersed particles.

Owner:RICOH KK

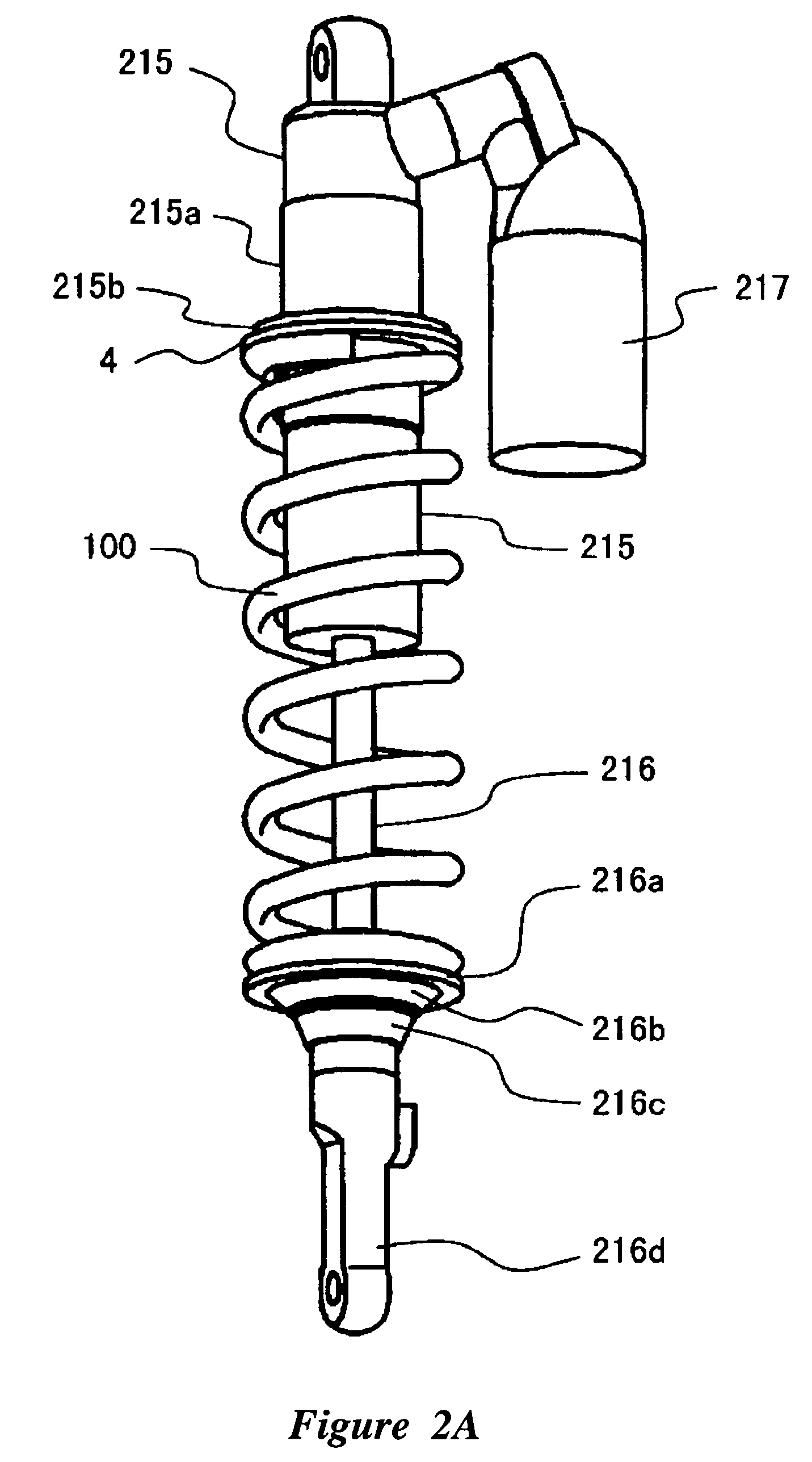

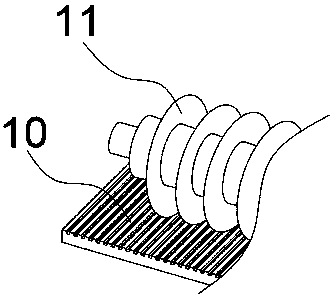

Spring spacer for a spring

A spring spacer is provided to improve the durability of a spring, which is made of Ti or the like and low in surface hardness, by preventing abrasion With the spring spacer placed between a first turn and a second turn of a Ti spring, the spring spacer prevents an end of the first turn from contacting the second turn. The spring spacer includes a contact preventive portion that is interposed between the first turn and the second turn of the Ti spring to prevent the end of the first turn from contacting with the second turn. A holding portion holds the contact preventive portion on the spring or the spring bearing surface. The spring spacer can be used in a variety of applications, including on vehicle suspension springs, engine valve spring, and similar lightweight springs.

Owner:YAMAHA MOTOR CO LTD

Steel for high-strength, high-toughness and high-wear-resistance steel ball and preparing method of steel

ActiveCN110846586AImprove hardenabilityImprove the hardness of the heartFurnace typesHeat treatment furnacesIngotSteel ball

The invention discloses steel for a high-strength, high-toughness and high-wear-resistance steel ball and a preparing method of the steel, and belongs to the technical field of steel for wear-resistant steel balls. The problems that the strength and toughness of existing steel for wear-resistant steel balls cannot meet requirements at the same time, and uniformity is poor are solved. The steel forthe wear-resistant steel ball comprises, by mass, 0.60-0.70% of C, 1.50-1.80% of Si, 0.92-1.2% of Mn, 1.30-2.00% of Cr, 0.01-0.20% of Mo, 0.25-0.60% of Ni, 0.01-0.05% of Al, 0.05-0.10% of Cu, 0.01-0.20% of V, less than or equal to 0.03% of S, 0.01-0.02% of P and the balance Fe and inevitable trace impurities, wherein the sum of Mo and V is greater than or equal to 0.08%. The preparing method includes the following steps of performing smelting to obtain molten steel, performing casting to obtain a cast ingot, forging the cast ingot to obtain a steel blank, and performing quenching and annealing treatment on the steel blank or quenching and partitioning treatment on the steel blank. The steel for the high-strength, high-toughness and high-wear-resistance steel ball is high in strength, toughness and uniformity and wide in application range.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

Slicing device of squids

ActiveCN107836502AGuaranteed cleaning effectAvoid cloggingFish washing/descalingFish filletingIntegrated operationsSquid

The invention discloses a slicing device of squids, and belongs to the technical field of aquatic product processing devices. The slicing device of the squids comprises a bracket, a conveyor belt arranged on the bracket, and a slicing tank arranged on the conveyor belt, wherein a control panel is arranged on the bracket; a soaking tank is connected to the upper part of one end of the bracket; thelower part of the soaking tank is connected with an oblique conveying pipe; an outlet end of the conveying pipe is located above the conveyor belt; a collecting hopper is arranged at the lower part ofthe other end of the bracket; the lower part of the collecting hopper is vertically connected with a cleaner; spray nozzles are arranged on two sides of the cleaner; and a material collecting tank isarranged at the lower part of the cleaner. Through the adoption of the slicing device disclosed by the invention, the sliced pieces are uniform in thickness; slicing components are free from adhesionconditions; the automation degree is high; and integrated operations of deodorizing, slicing and washing of the squids are realized.

Owner:ZHEJIANG INT MARITIME COLLEGE

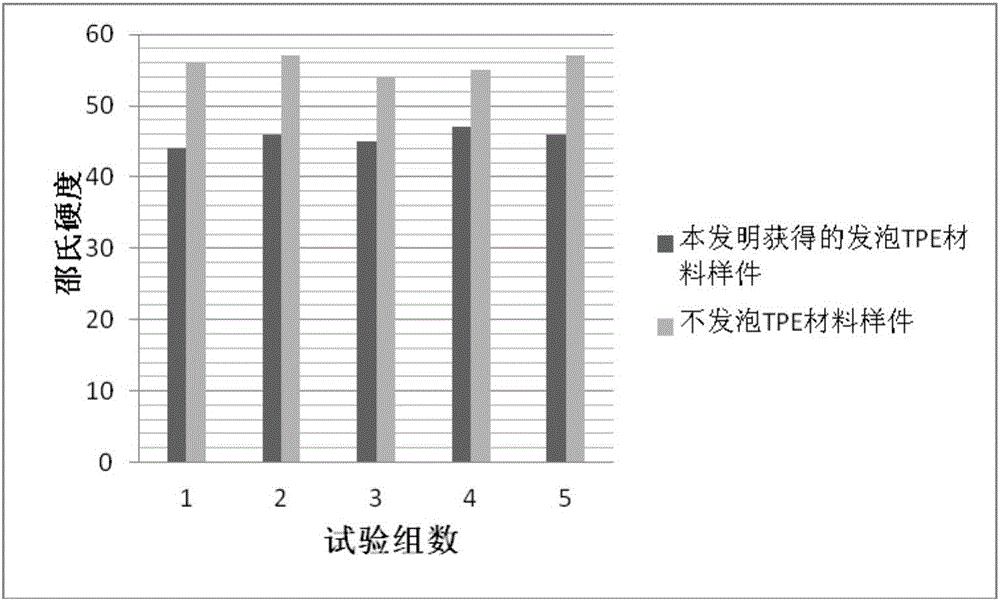

Chemically foamed thermoplastic elastomer (TPE) material and preparation method thereof

The invention relates to the technical field of high polymer materials, in particular to a chemically foamed thermoplastic elastomer (TPE) material and a preparation method thereof. The chemically foamed TPE material is characterized by being prepared from hydrogenated styrene-ethylene / butylene-styrene block copolymers (SEBS), paraffin oil, polypropylene (PP), scratch-resistant auxiliary agents, antioxidants and chemical foaming agents; and the raw materials comprise, by weight, 100 parts of hydrogenated SEBS, 120-140 parts of paraffin oil, 1-2 parts of scratch-resistant auxiliary agents, 0.4-0.6 part of antioxidants and 2-4 parts of chemical foaming agents. By adopting the chemically foamed TPE material, a shrink mark of the injection molded sample piece surface can be reduced, so that the hardness of the injection molded sample piece surface is reduced, a better sense of touch is obtained, the sense of touch is soft, and injection molding shrink is modified obviously.

Owner:WUHAN UNIV OF TECH

Resin based powder metallurgy composite friction material for vehicles and preparation method thereof

InactiveCN105838023AIncreased frictional surface roughnessIncrease porosity coefficientFriction liningResin-Based CompositeMachining

The invention discloses a preparation method of a resin based powder metallurgy composite friction material for vehicles, wherein the preparation method comprises the following steps: 1) preparing a powder metallurgy friction material: mixing evenly a base material and a forming agent, pouring the mixture into a mold, pressing to slender rods, separating the slender rod-shaped pressed blanks, and sintering, to obtain a powder metallurgy friction material; 2) shearing, crushing and screening; 3) mixing: according to the mass percentage, evenly co-mixing 10-20% of high-temperature-resistant modified resin, 40-60% of the powder metallurgy friction material, 10-20% of a reinforcing fiber, 5-15% of an abrasive, 10-20% of a lubricating material and 5-20% of a filler; 4) producing and preparing a resin based composite friction material; 5) post-treating; and 6) carrying out mechanical processing. The resin based powder metallurgy composite friction material retains the stable friction coefficient and good anti-abrasion properties of the powder metallurgy friction material. The service life and the high-temperature stability of the friction material are improved.

Owner:SOUTH CHINA UNIV OF TECH

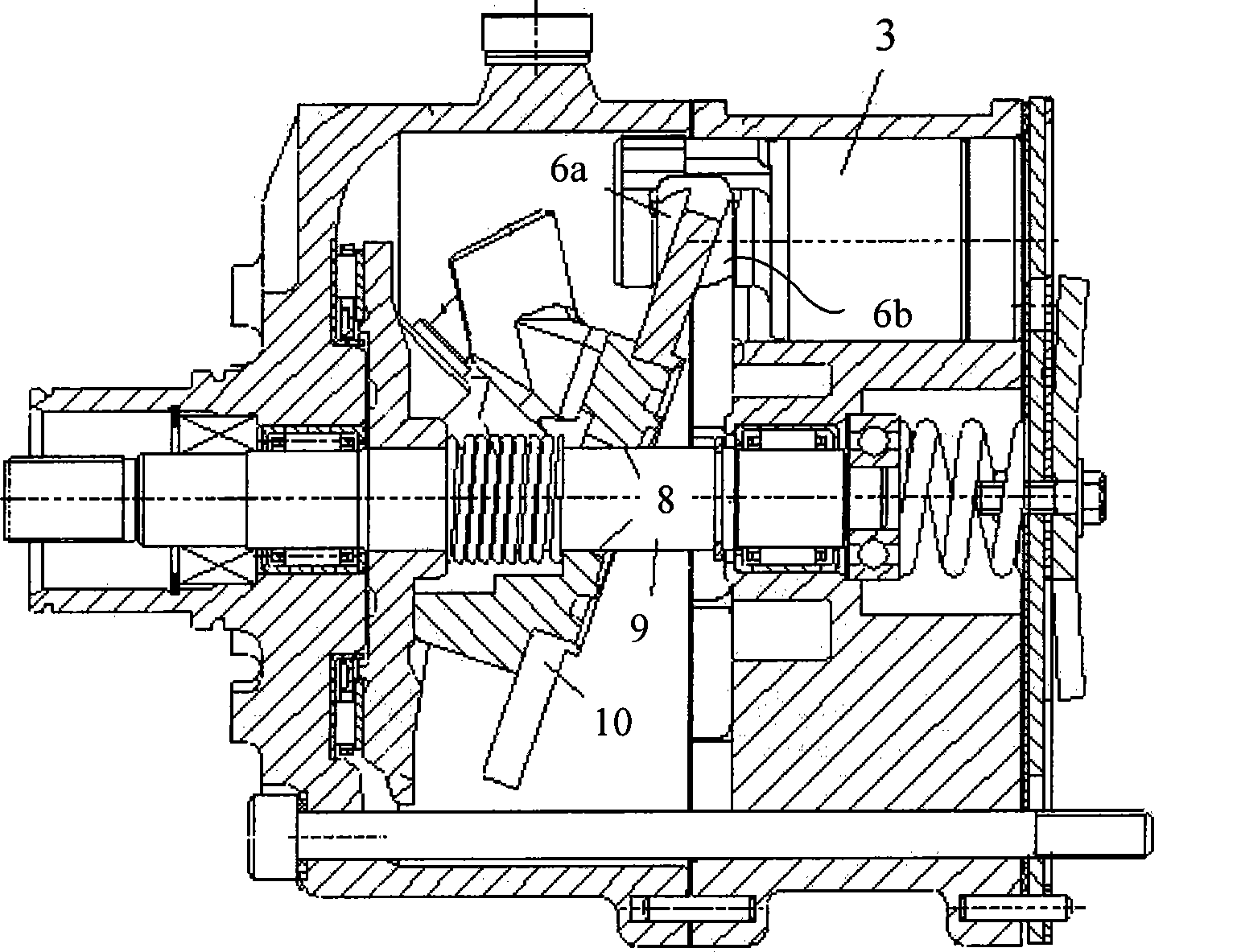

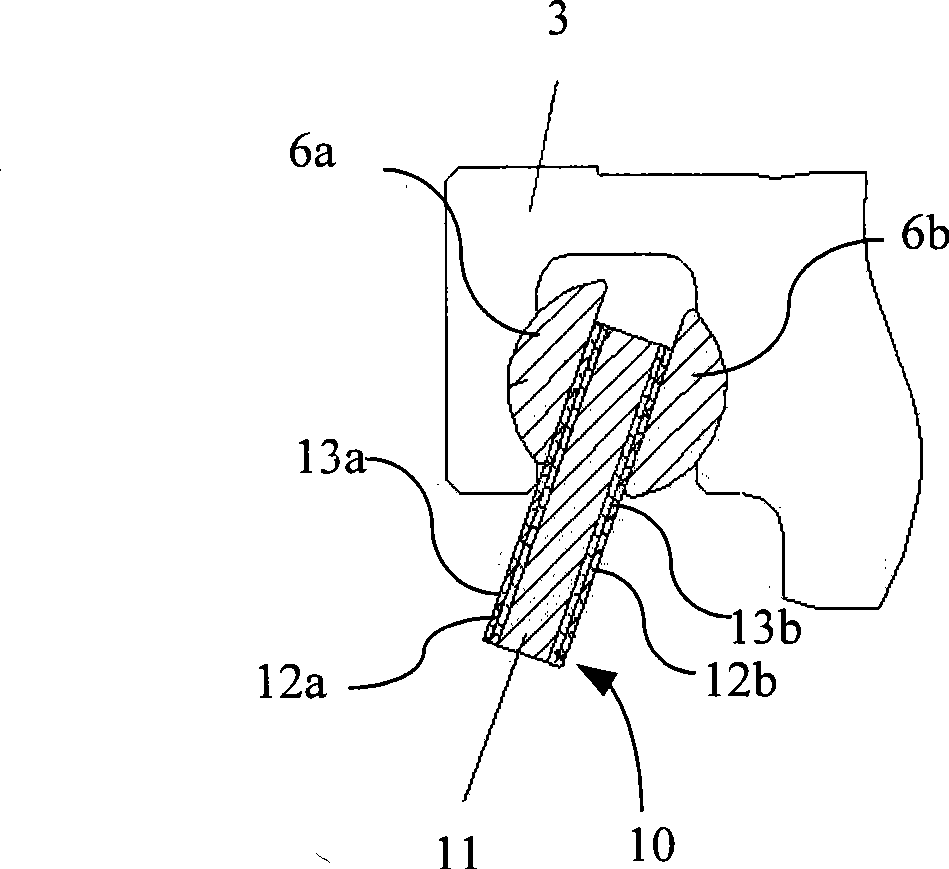

Swash plate of swash plate compressor

InactiveCN101469687AReduce surface hardnessImprove the lubrication effectPositive displacement pump componentsMulti-stage pumpsState of artCompound structure

The present invention relates to a swash plate in swash plate compressor, which includes a basal body with two sides of the basal body provides with a superficial layer, wherein material of each superficial layer is copper alloy, and weight percentage is as following: copper 78-82%, lead 9-11% and tin 9-11%. The superficial hardness of the compound structure swash plate is lower than that of hard anodic oxidation aluminum alloy surface in prior art, better lubricating property, and more suitable to assort with steel quantity to form sliding friction pairs.

Owner:SANDEN HUAYU AUTOMOTIVE AIR CONDITIONING CO LTD

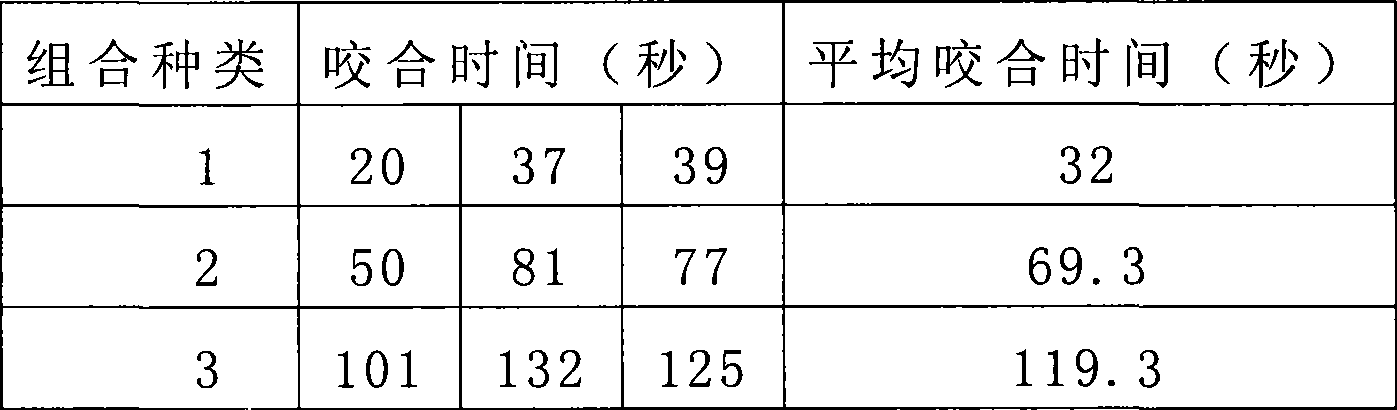

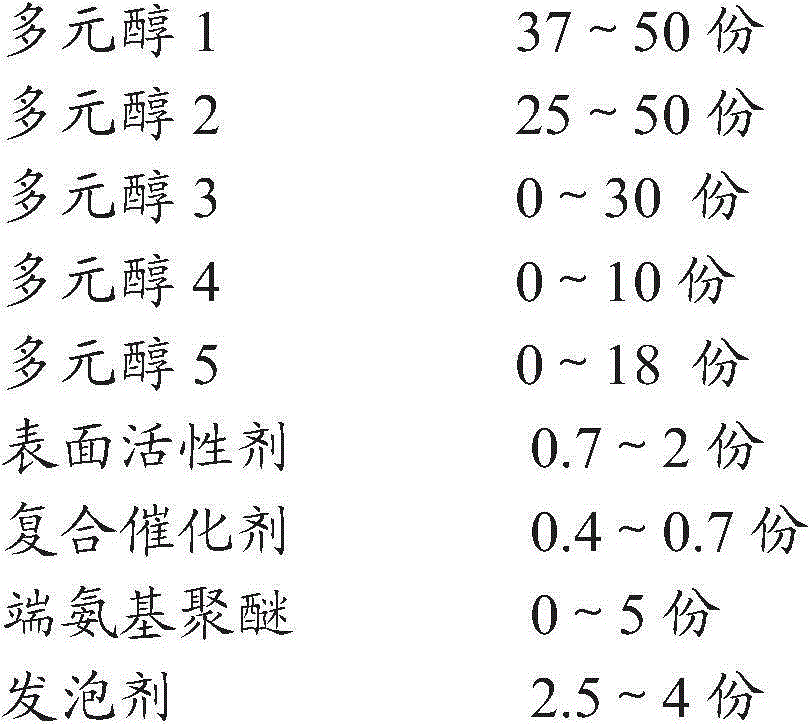

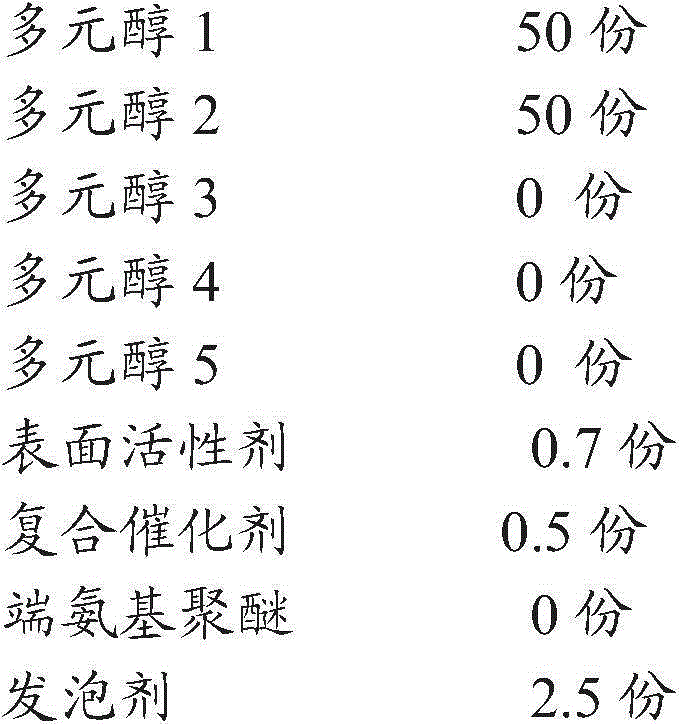

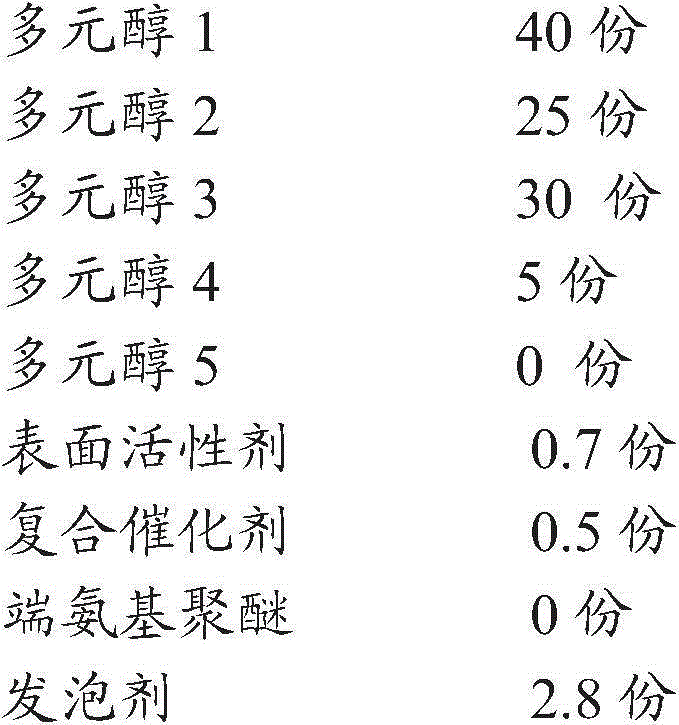

Polyurethane foam with ultralow surface hardness and high press-to-sink ratio and preparation method thereof

The invention discloses polyurethane foam with ultralow surface hardness and a high press-to-sink ratio. The foam is prepared from a component A and a component B. The component A is prepared from 37-50 parts of polyhydric alcohol 1, 25-50 parts of polyhydric alcohol 2, 0-30 parts of polyhydric alcohol 3, 0-10 parts of polyhydric alcohol 4, 0-18 parts of polyhydric alcohol 5, 0.7-2 parts of surface active agent, 0.4-0.7 part of composite catalyst, 0-5 parts of amine-terminated polyether and 2.5-4 parts of foaming agent. The component B is prepared from 26-42 parts of isocyanate. Polyhydric alcohol 1 is oxirane and epoxypropane copolymerized polyhydric alcohol, polyhydric alcohol 2 is epoxypropane polyether polyol, polyhydric alcohol 3 is allyl alcohol polyether polyol, polyhydric alcohol 4 is vegetable oil polyether polyol, polyhydric alcohol 5 is oxirane end capped epoxypropane polyether polyol, and isocyanate is diphenylmethane diisocyanate. The polyurethane foam has ultralow surface hardness, extremely good supporting performance, the high press-to-sink ratio, and hydrophilia insensitive to temperature changes.

Owner:林凯旋

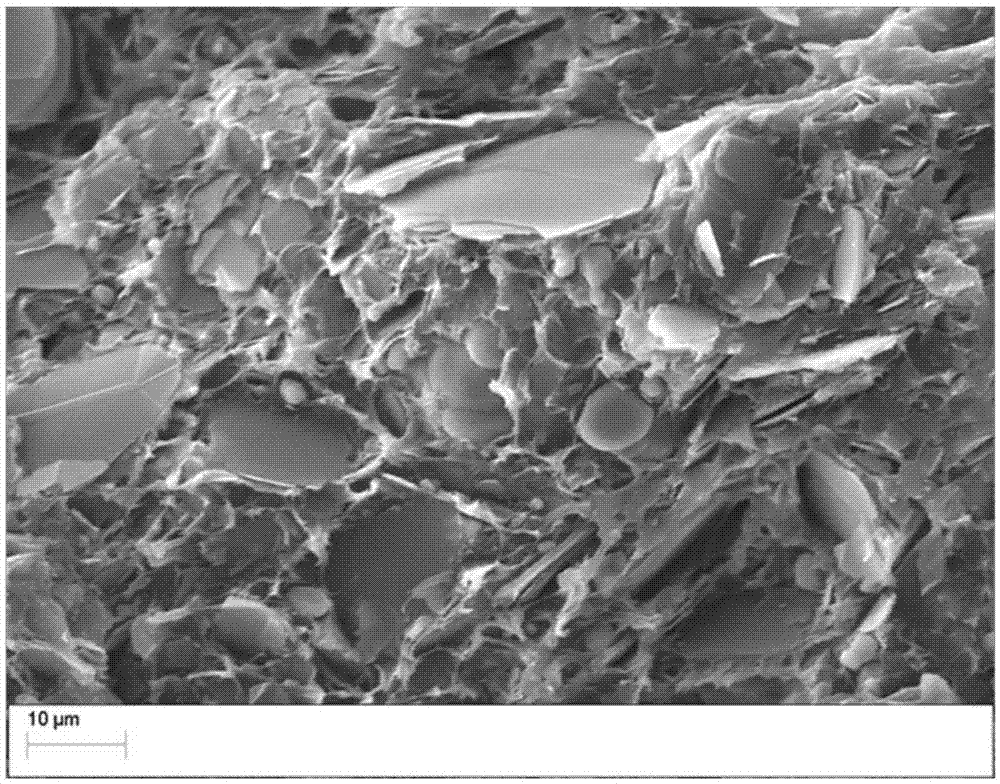

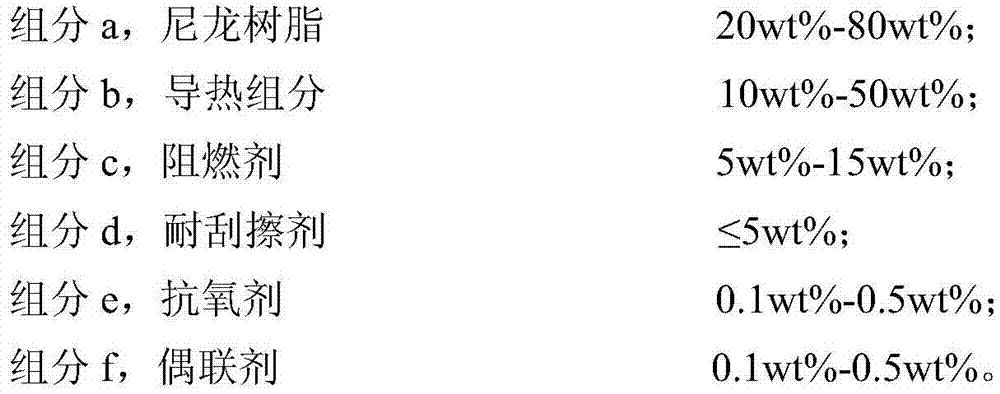

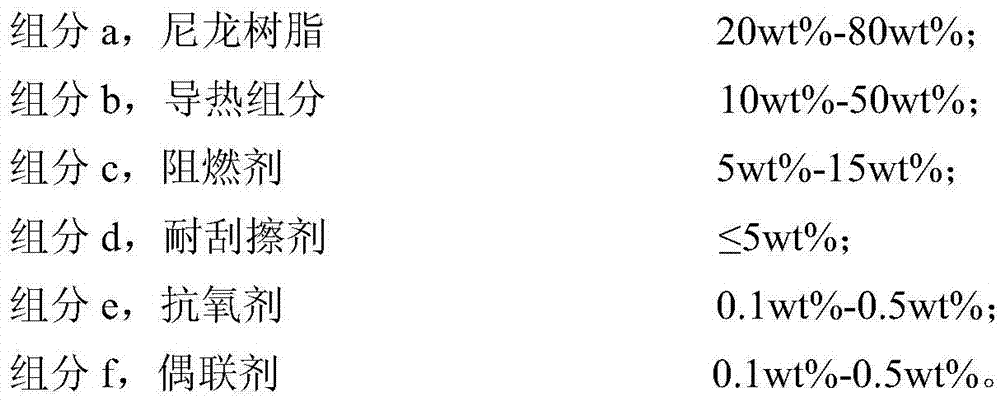

Impact-resistant scratch-resistant thermal-conduction nylon composite material and preparation method thereof

The present invention relates to an impact-resistant scratch-resistant thermal-conduction nylon composite material and a preparation method thereof, wherein a nylon composition containing copolymerized nylon is adopted as a resin matrix, and the impact-resistant scratch-resistant thermal-conduction nylon composite material is prepared from the nylon composition, a thermal conduction component, a flame retardant agent, an antioxidant, a coupling agent and an optional scratch-resistant agent through a two-step melt blending method. According to the present invention, the impact-resistant scratch-resistant thermal-conduction nylon composite material has advantages of good toughness, good low temperature impact resistance, low surface hardness, excellent scratch resistance, good thermal conduction performance, good mechanical property and good flame-retardant property, and can be widely used in electric tool shells, battery pack shells, LED heat dissipators, vehicle LED brackets, and other plastic part fields having high heat dissipating requirements.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com