Automotive iron-based powder metallurgy composite frictional material and manufacturing method thereof

An iron-based powder metallurgy and composite friction material technology, applied in the field of resin-based composite friction materials, can solve problems such as scratches on automobile brake discs or drums, friction noise, etc., and achieve good anti-wear characteristics, stable friction coefficient, and avoid scratches effect of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

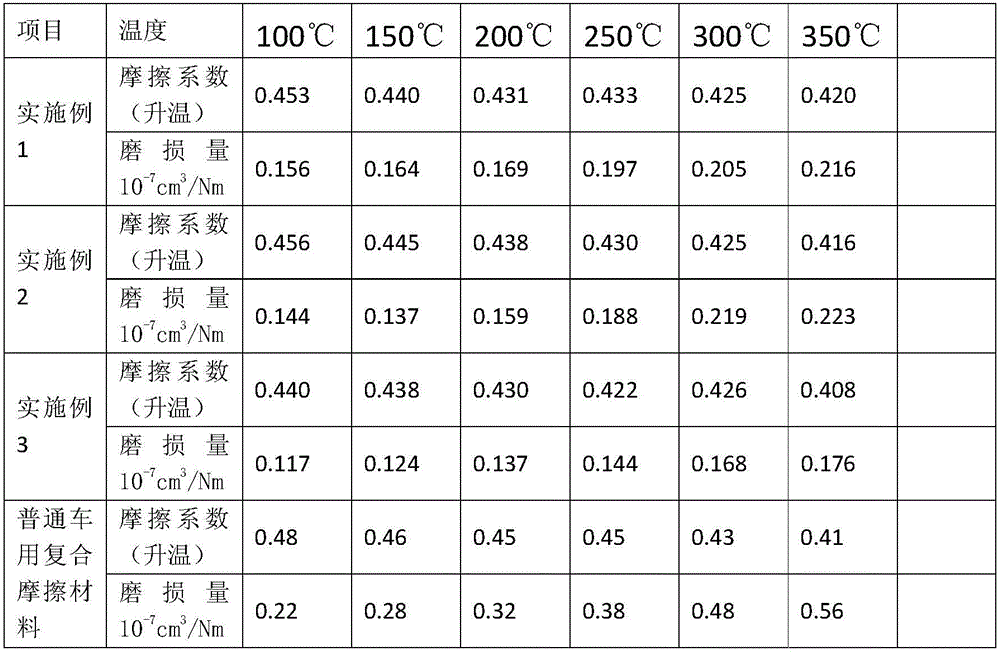

Embodiment 1

[0030] Preparation of iron-based powder metallurgy friction material: material basic raw material formula: in terms of mass percentage, the matrix material formula is 50% iron, 8% copper, 10% quartz stone powder, 5% aluminum oxide, and 1% molybdenum disulfide; Graphite powder 10%; molding agent is kerosene, based on the total weight of the mixture, the content of the molding agent is 0.2% by weight. Mix the above materials evenly, pour them into the mold with a pressure of 500MPa, and press them into a slender rod shape with a diameter of φ2mm×200mm in length, separate each slender rod-shaped green compact, and put it into a sintering furnace. Under the condition of temperature rise 1000Co, keep warm for 4h, and cool down to room temperature with the furnace.

[0031] Under dry conditions, it is placed for more than 24 hours; then it is cut, crushed, and screened with an 8-mesh sieve.

[0032] Preparation of composite friction material: basic material formula (in mass percent...

Embodiment 2

[0038] Preparation of short and fine iron-based powder metallurgy friction material: basic material formula (by mass percentage): 60% iron, 5% copper, 5% quartz powder, 10% aluminum oxide, 3% molybdenum disulfide; calcium fluoride 7%, graphite powder 10%; forming agent is kerosene, based on the total weight of the mixture, the content of the forming agent is 0.5% total weight. Mix the above materials evenly, pour them into the mold with a pressure of 400MPa, and press them into a slender rod shape with a diameter of φ2mm×200mm in length, separate each slender rod-shaped green compact, and put it into a sintering furnace. Under the conditions, the temperature rises to 900°C, keeps the temperature for 5 hours, and cools down to room temperature with the furnace.

[0039] Under dry conditions, it is placed for more than 24 hours; then it is cut, crushed, and screened with an 8-mesh sieve.

[0040] Preparation of composite friction material: material basic formula (by mass percen...

Embodiment 3

[0046] Preparation of short and fine iron-based powder metallurgy friction material: basic material formula (by mass percentage): iron 70%, copper 1%, quartz stone powder 14%, aluminum oxide 5%, graphite powder 10%;

[0047] The forming agent is kerosene, based on the total weight of the mixture, and the content of the forming agent is 0.4% by weight. Mix the above materials evenly, pour them into the mold with a pressure of 500MPa, and press them into a slender rod shape with a diameter of φ3mm×300mm in length, separate each slender rod-shaped green compact, and put it into a sintering furnace. Under the conditions, the temperature rises to 1100°C, keeps warm for 2 hours, and cools down to room temperature with the furnace.

[0048] Under dry conditions, it is placed for more than 24 hours; then it is cut, crushed, and screened with an 8-mesh sieve.

[0049] Preparation of composite friction material: basic material formula (by mass percentage): cashew nut oil modified phenoli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com