Patents

Literature

33results about How to "Good anti-wear properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enhanced metal ceramic abrasion-resistant composite material and preparation method thereof

The invention discloses an enhanced metal ceramic abrasion-resistant composite material and a preparation method thereof. The composite material is composed of, by mass, 25-35 parts of nano molybdenum carbide, 15-25 parts of nano ceramic powder, 10-15 parts of glass fiber, 5-10 parts of cobalt, 10-15 parts of chrome, 10-15 parts of titanium carbonitride, 1-3 parts of zirconium oxide, 3-5 parts of silicon oxide, 8-10 parts of cerium oxide, 1-3 parts of aluminium oxide, 5-10 parts of niobium carbide, 5-15 parts of silicon carbide, 1-3 parts of vanadium carbide, 4-9 parts of copper, 1-5 parts of titanium powder, 1-5 parts of coupling agents, 1-3 parts of antistatic agents and 1-3 parts of curing agents. The preparation method of the enhanced metal ceramic abrasion-resistant composite material just comprises mixing, drying, sintering and cooling. The metal ceramic composite material has good properties that the bending resistant strength is up to 2500 MPa and the Rockwell hardness is up to 93; in addition, the metal ceramic composite material also has good properties of abrasion resistance and high temperature resistance; the preparation method is simple and feasible and suitable for application and popularization on a large scale.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

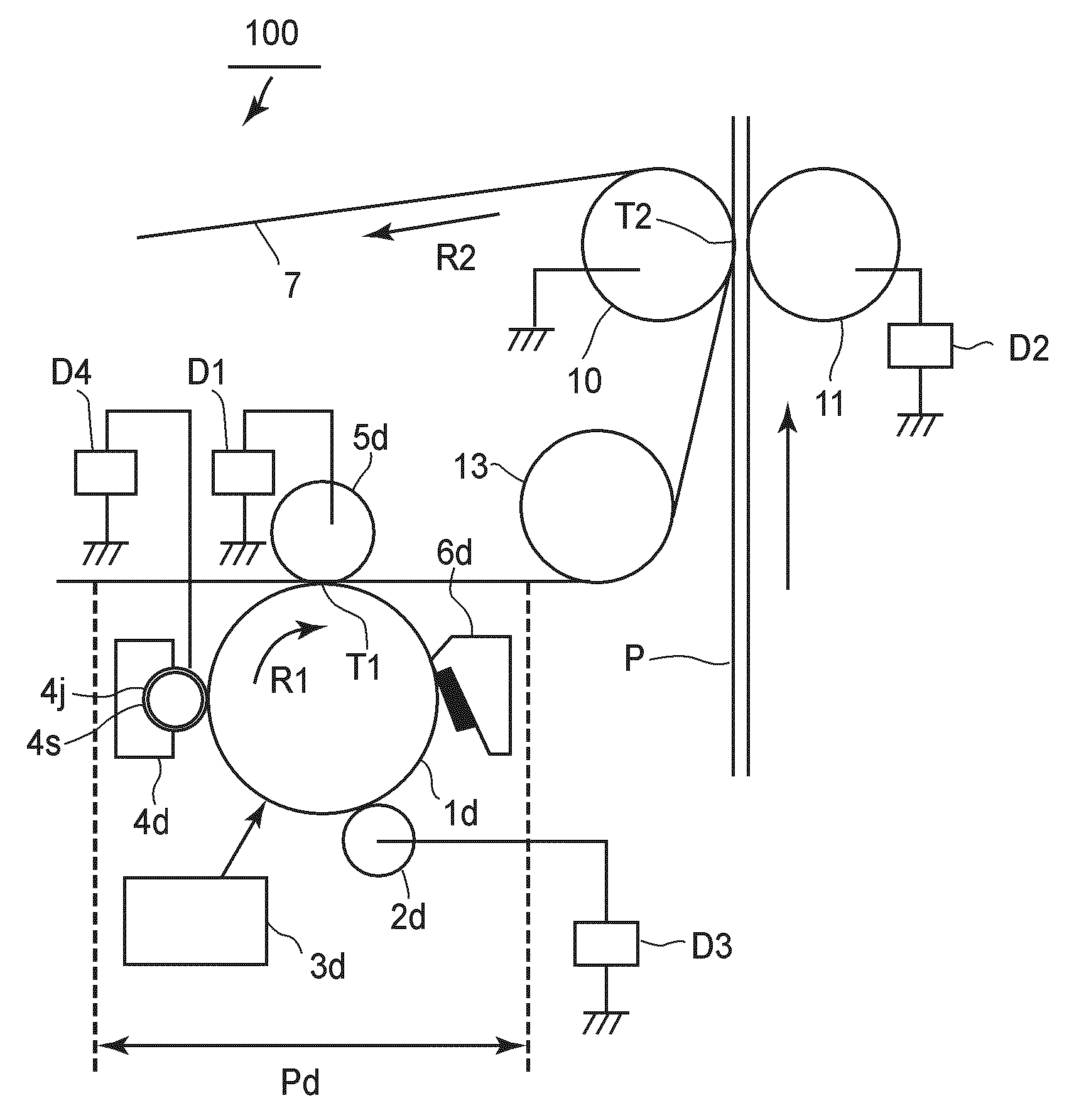

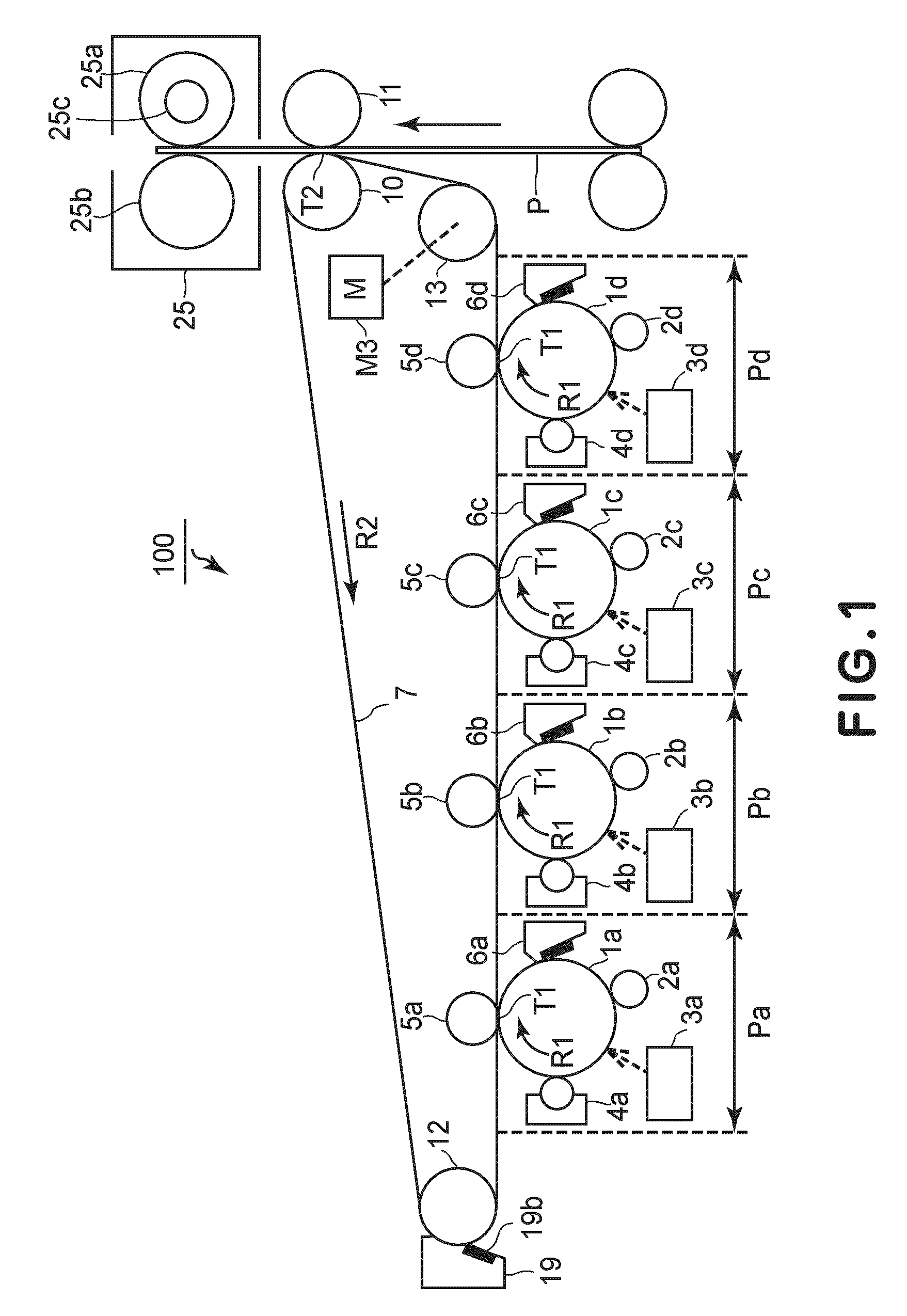

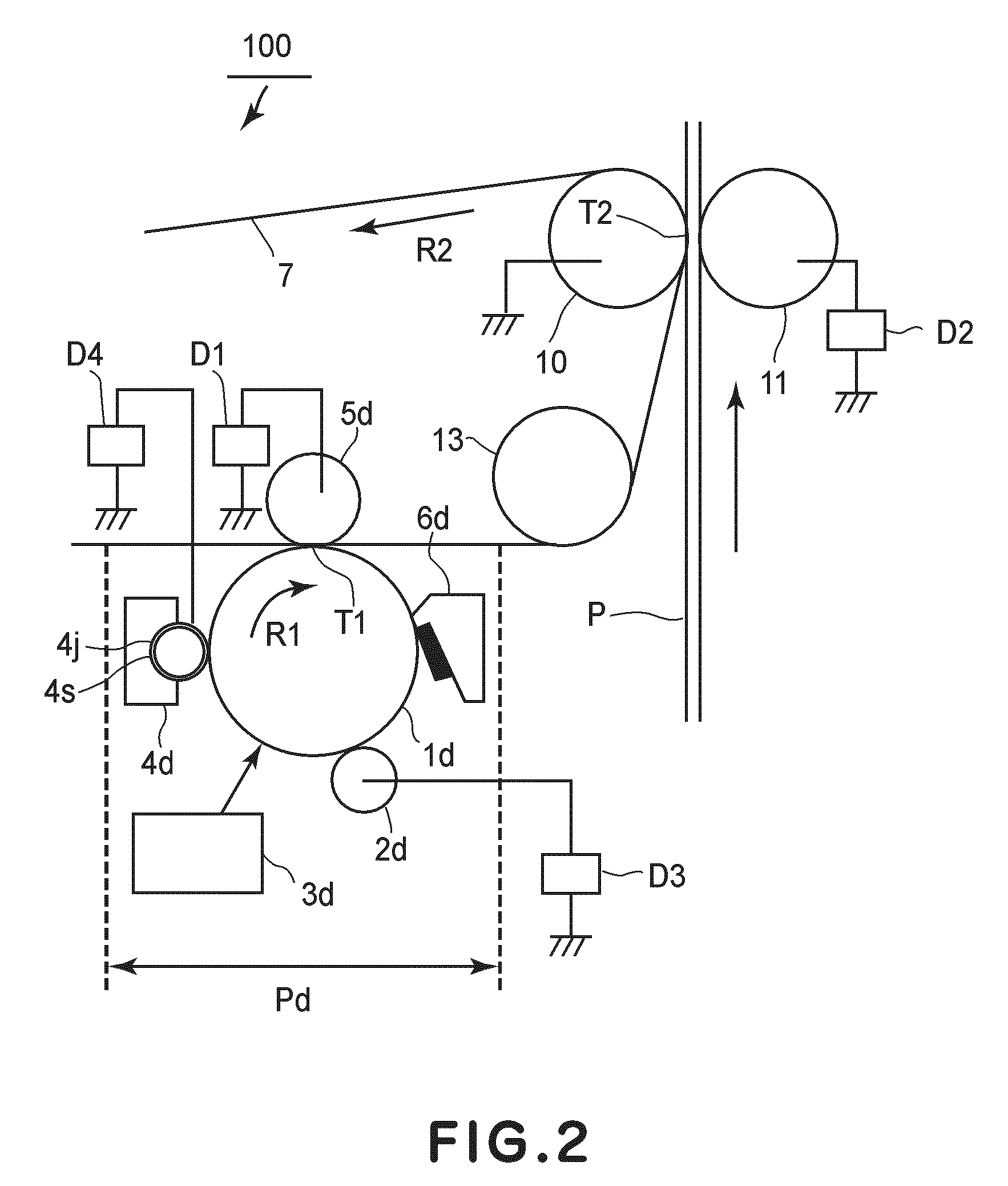

Belt member and image forming apparatus using the belt member

InactiveUS20090067895A1Excellent in anti-folding property propertyGood anti-wear propertiesElectrographic process apparatusImage formationEngineering

A belt member is rotatably extended around a plurality of rotatable members of an image forming apparatus for forming a toner image on a recording material by using a developer containing a magnetic carrier. The belt member includes a layer, formed of a crystalline resin material, having an outer peripheral surface and an inner peripheral surface. The layer has a hardness of 0.25 GPa or more and 0.40 GPa or less at the outer peripheral surface and a hardness of 0.10 GPa or more and 0.20 GPa or less at the inner peripheral surface.

Owner:CANON KK

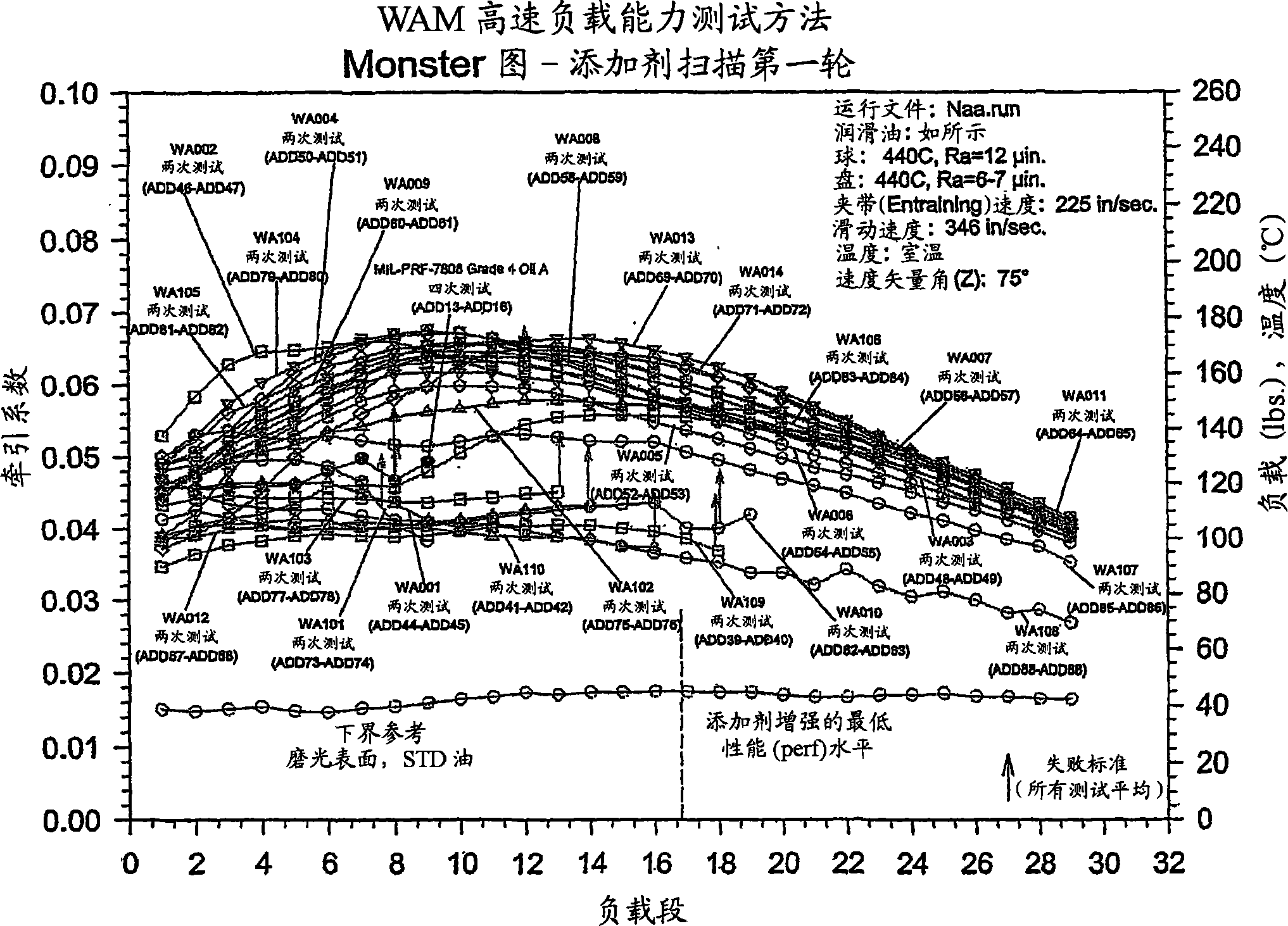

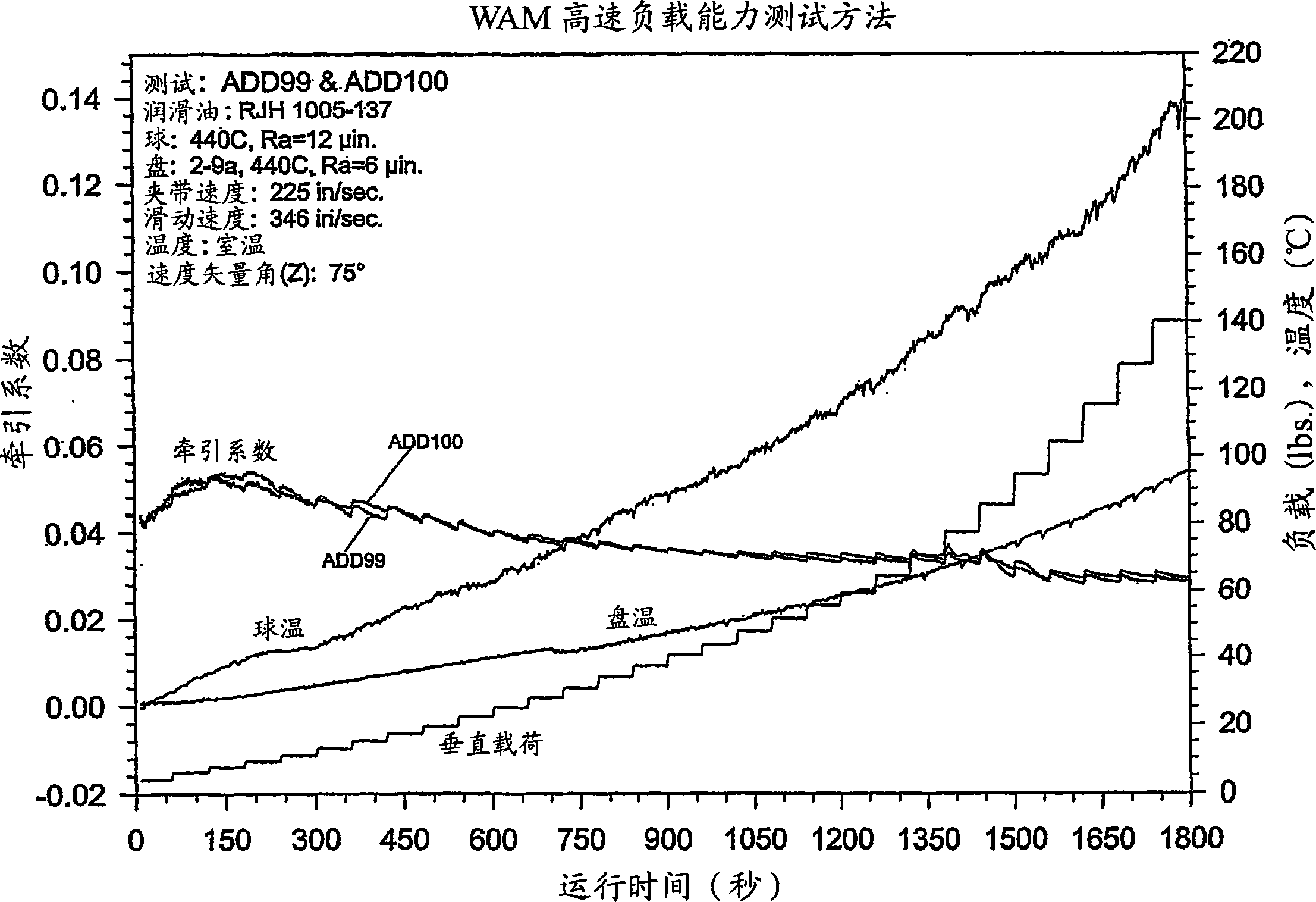

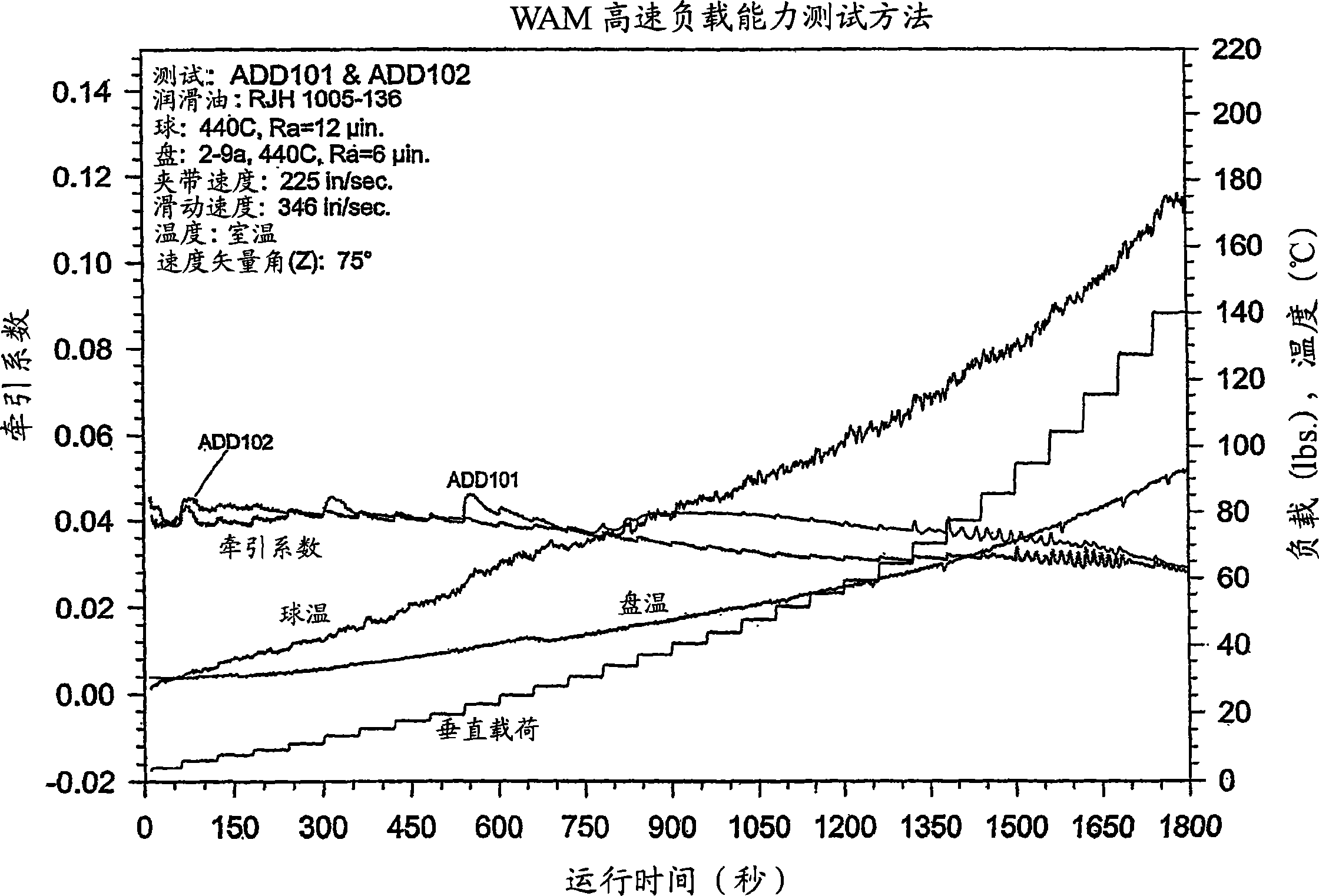

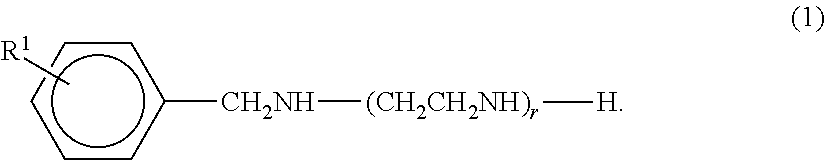

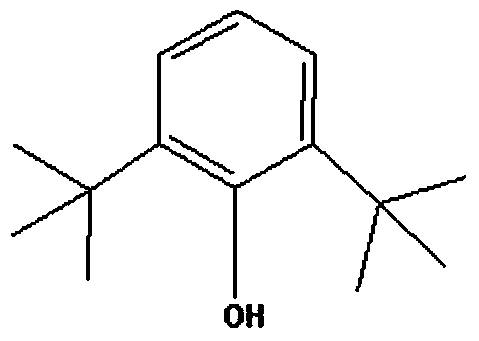

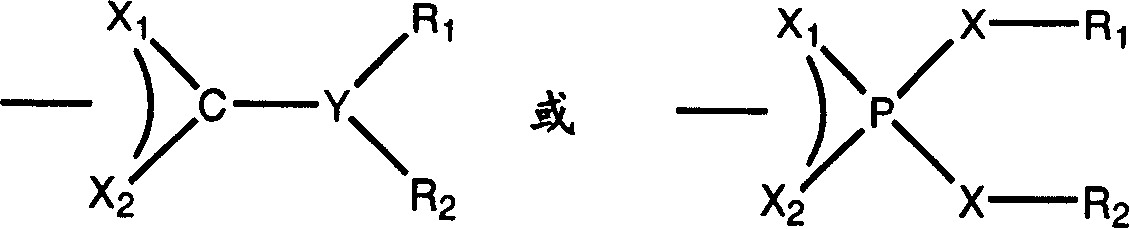

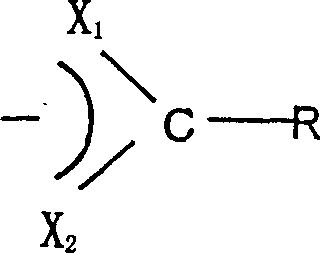

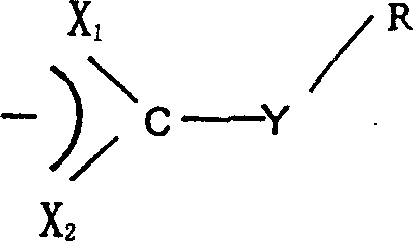

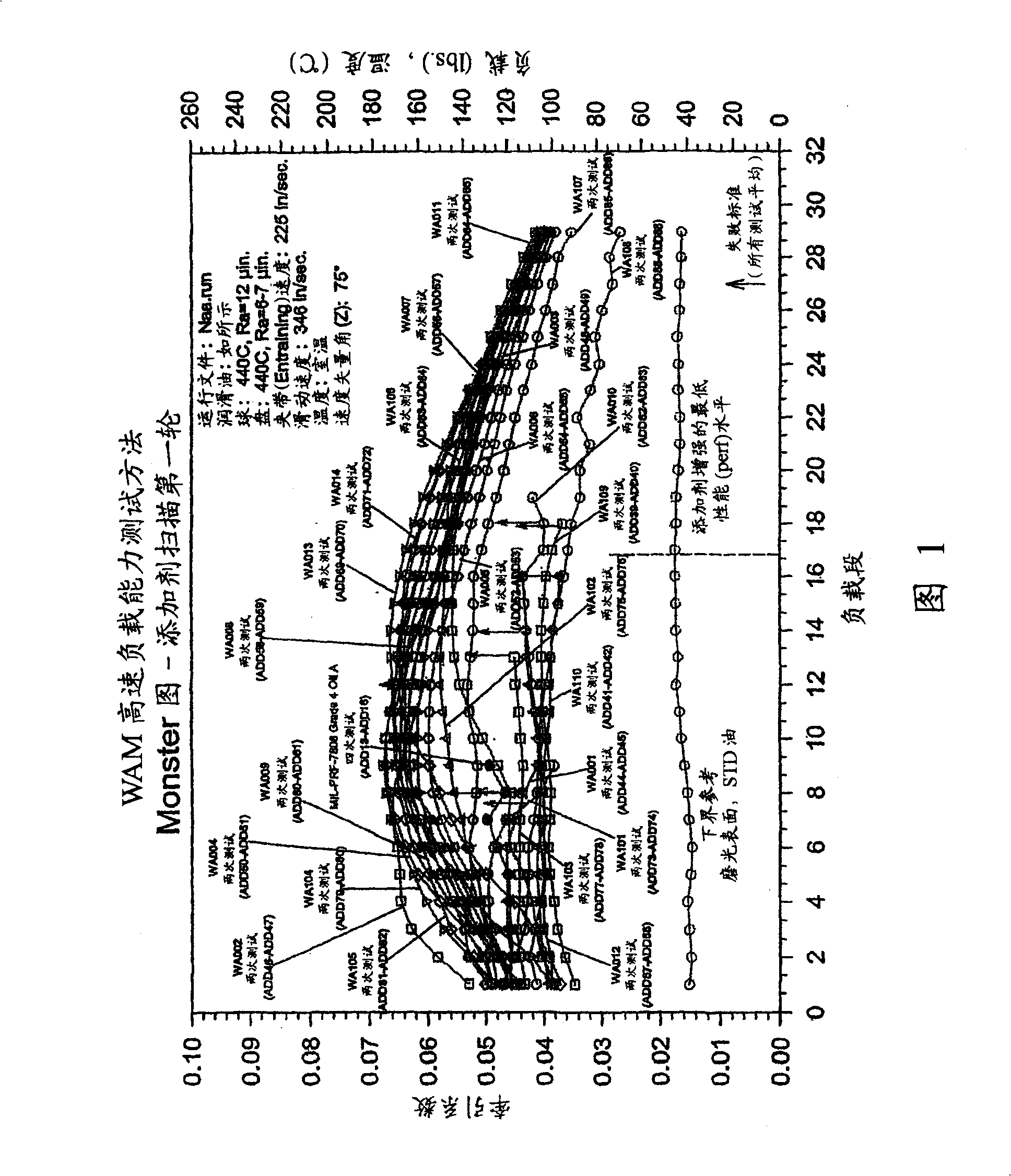

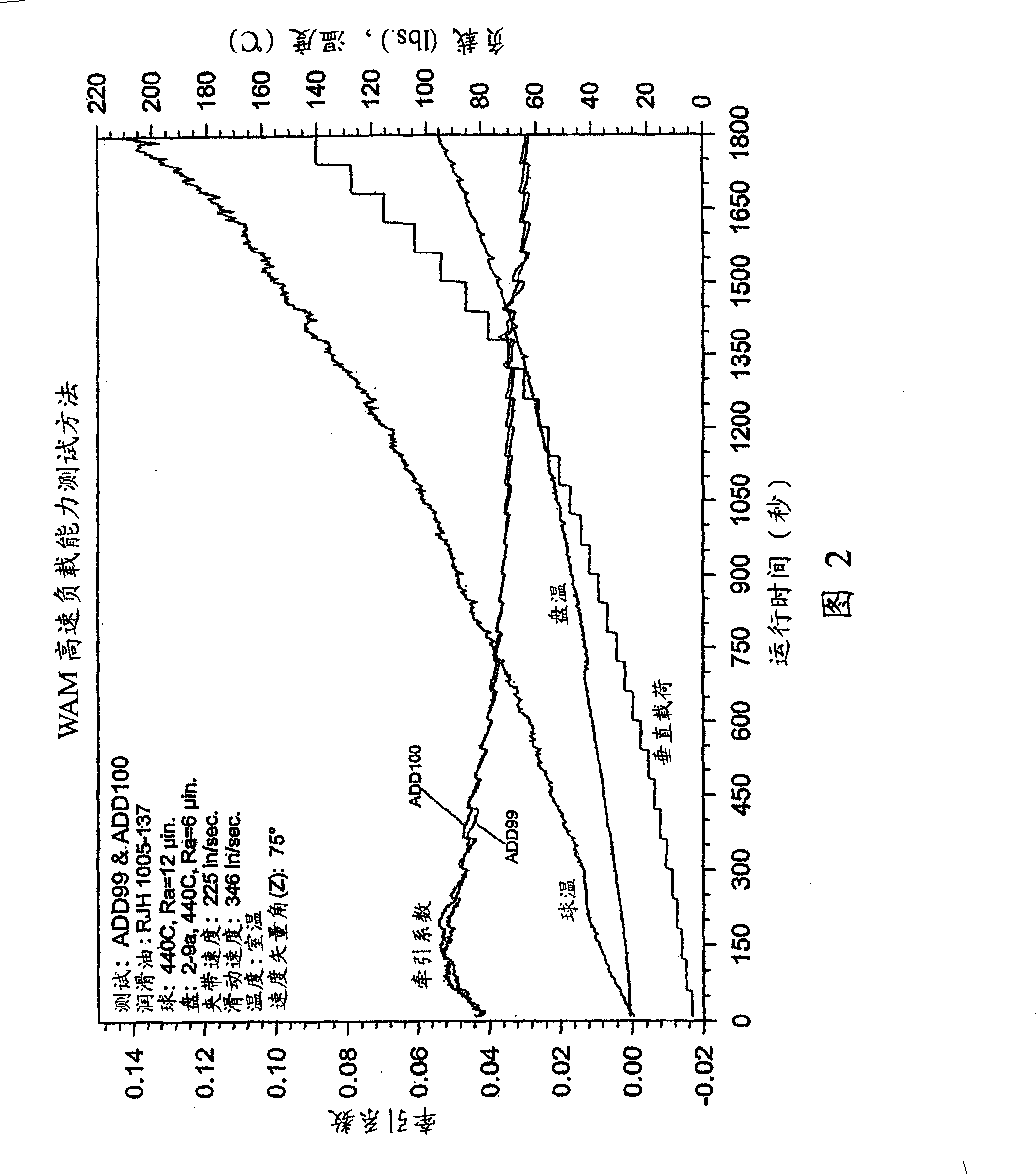

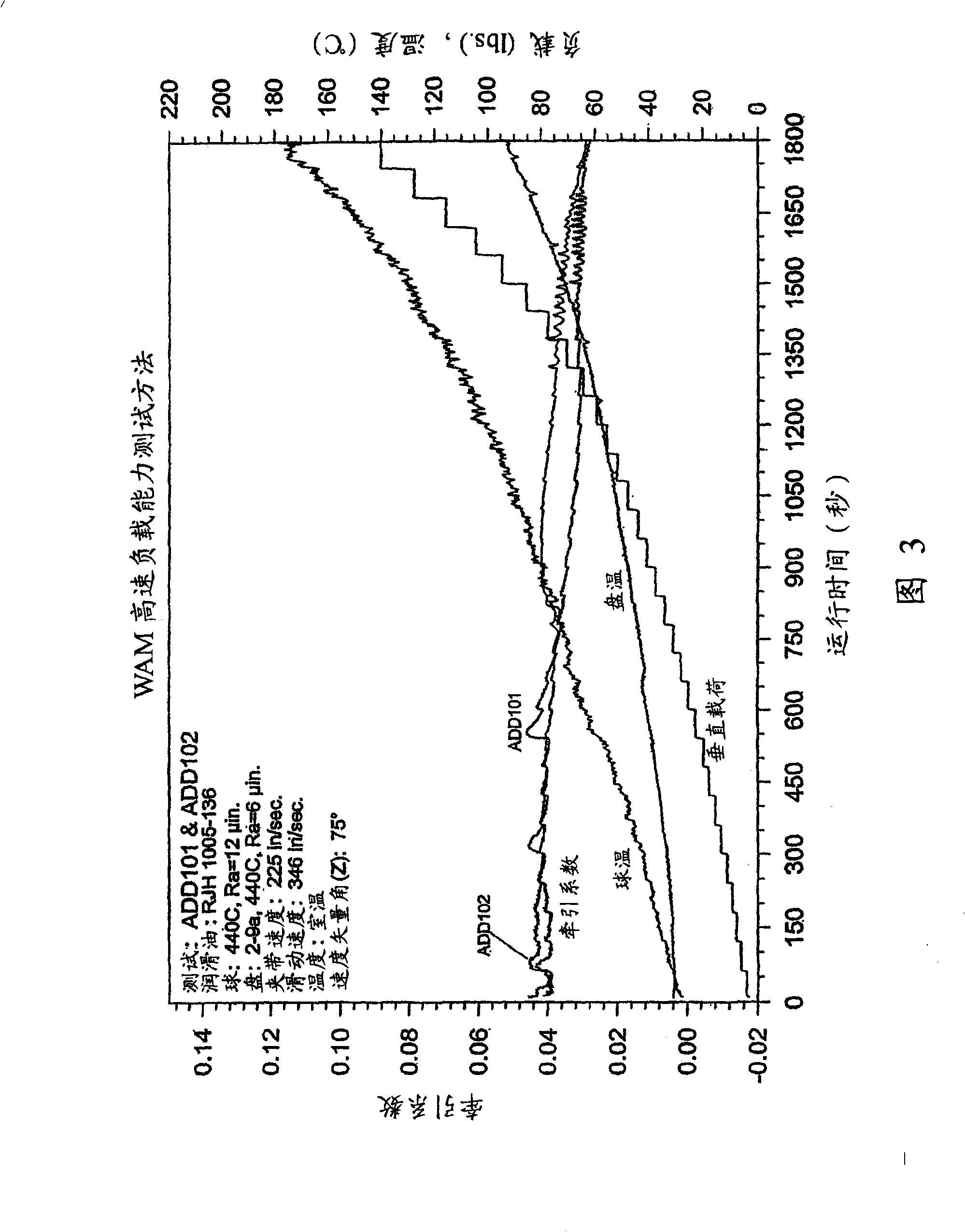

Lubricating compositions containing synthetic ester base oil, molybdenum compounds and thiadiazole-based compounds

ActiveCN1867656AThe result is obviousExcellent traction coefficientAdditivesCompound aMolybdenum compounds

A lubricating composition providing excellent anti-wear protection for corrosion-resistant materials which comprises a major amount of a synthetic ester base oil, and a minor amount of a molybdenum compound and an anti-wear additive selected from the group consisting of 1,3,4-thiadiazole derivatives as an anti-wear additive, the reaction products of 2,5-dimercapto-1,3,4-thiadiazole dimers and poly(ether)glycols, and 2,5-dimercapto-1,3,4-thiadiazole monomer and mixtures thereof. Also described is a method for imparting anti-wear properties to a corrosion resistant material, comprising using the lubricating composition of the invention.

Owner:VANDERBILT CHEM LLC

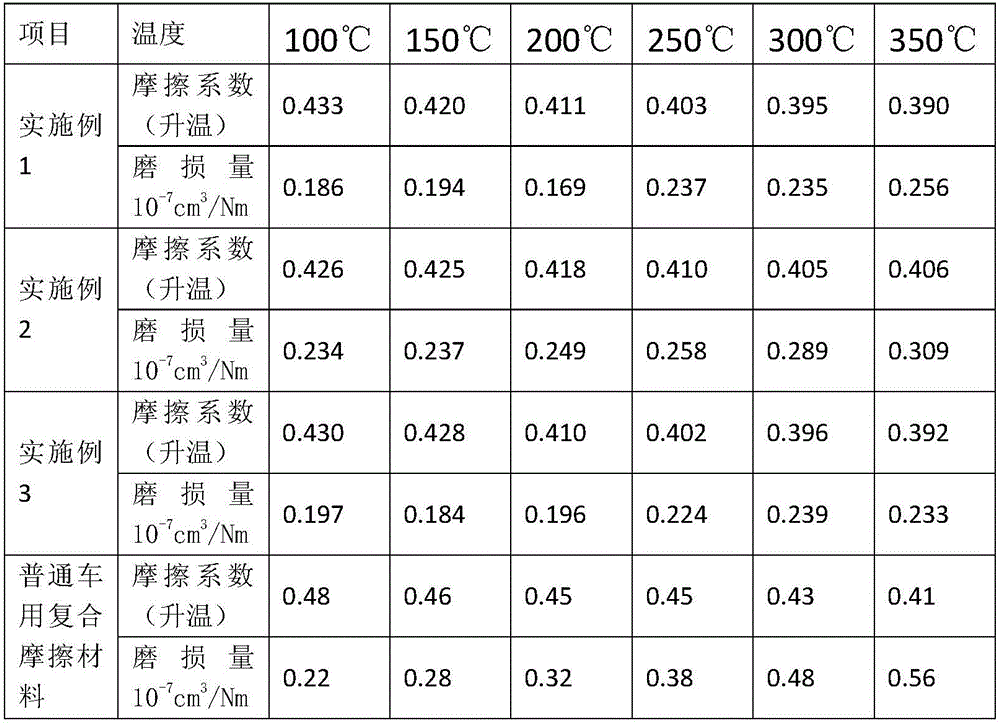

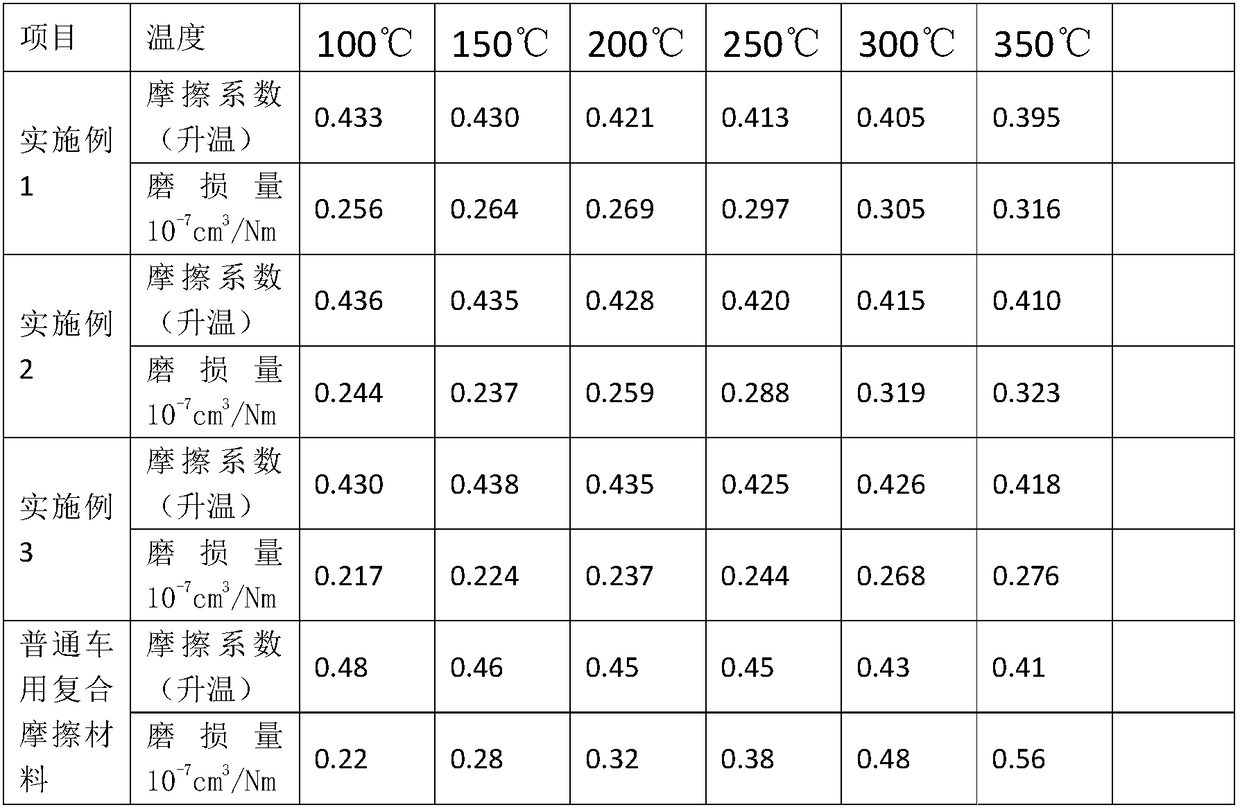

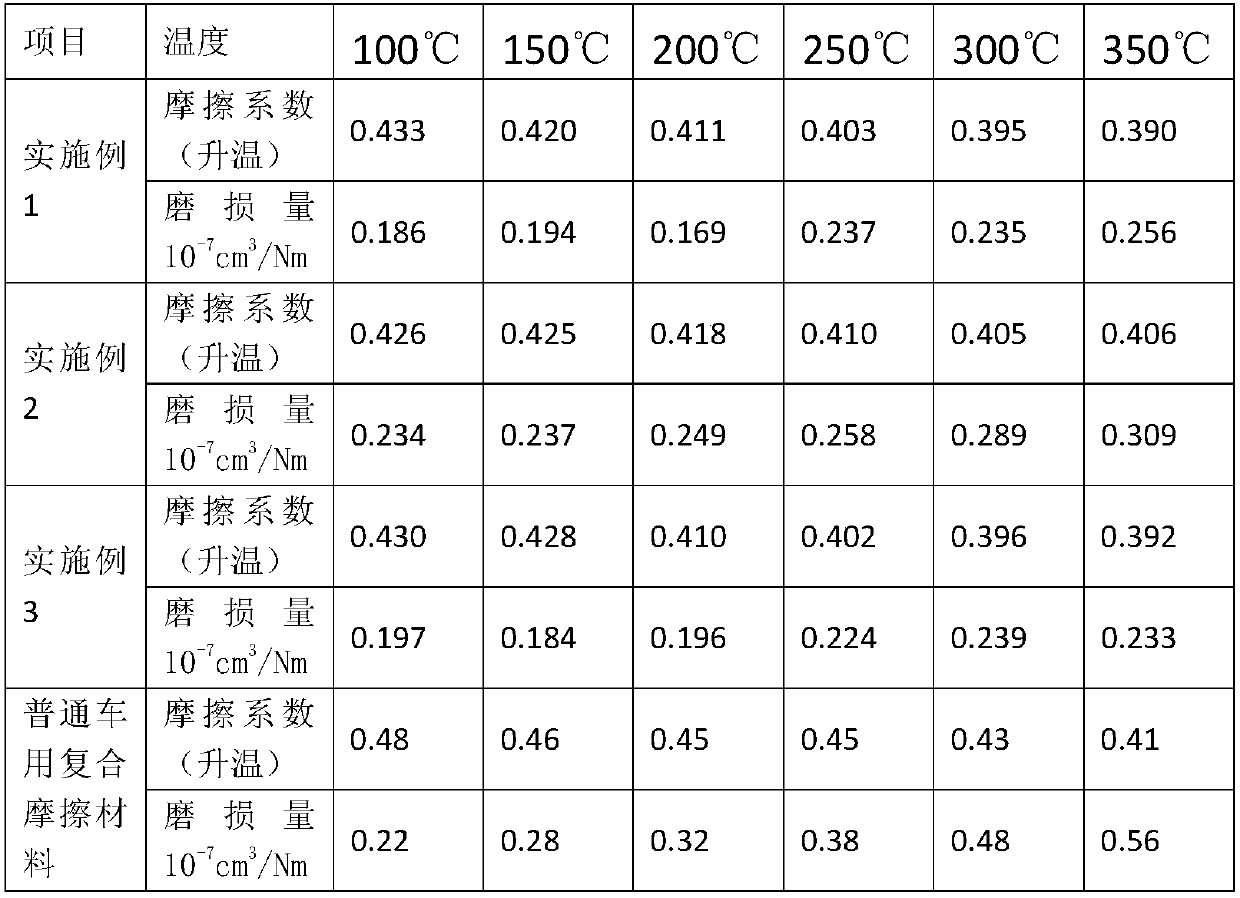

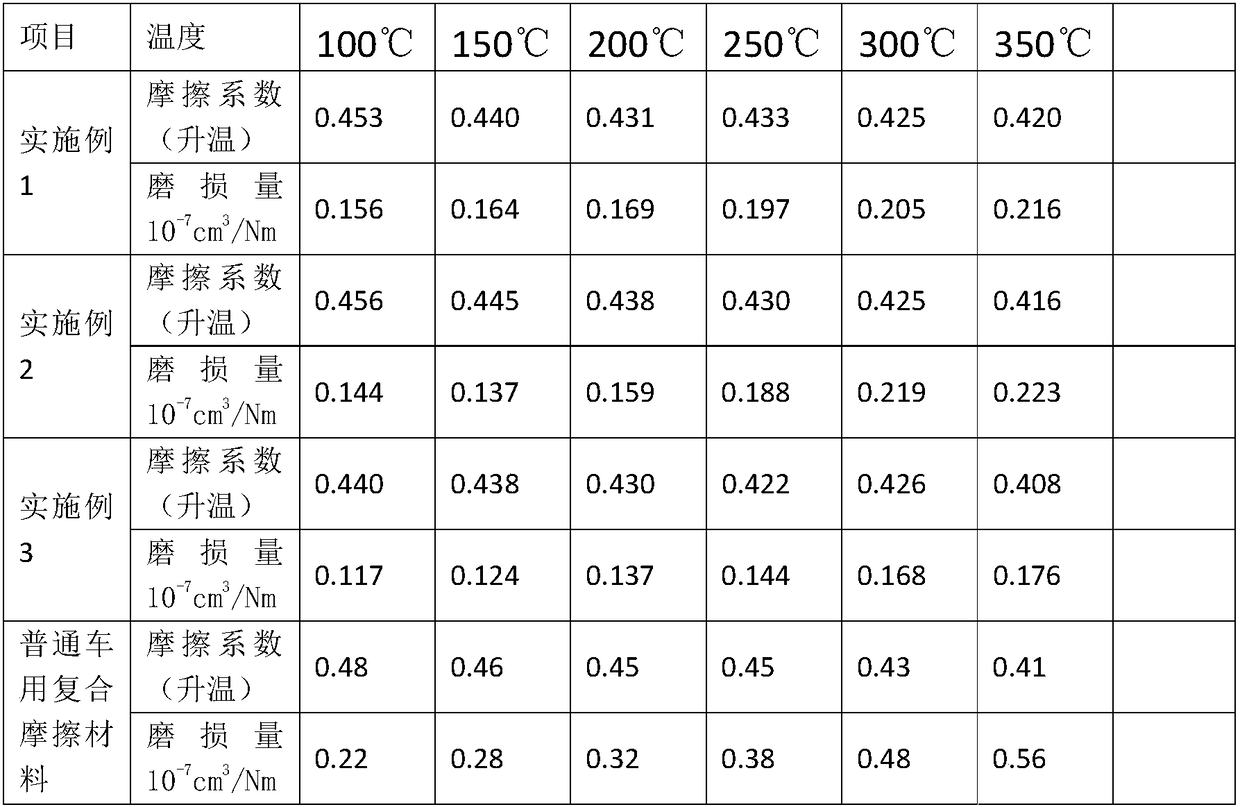

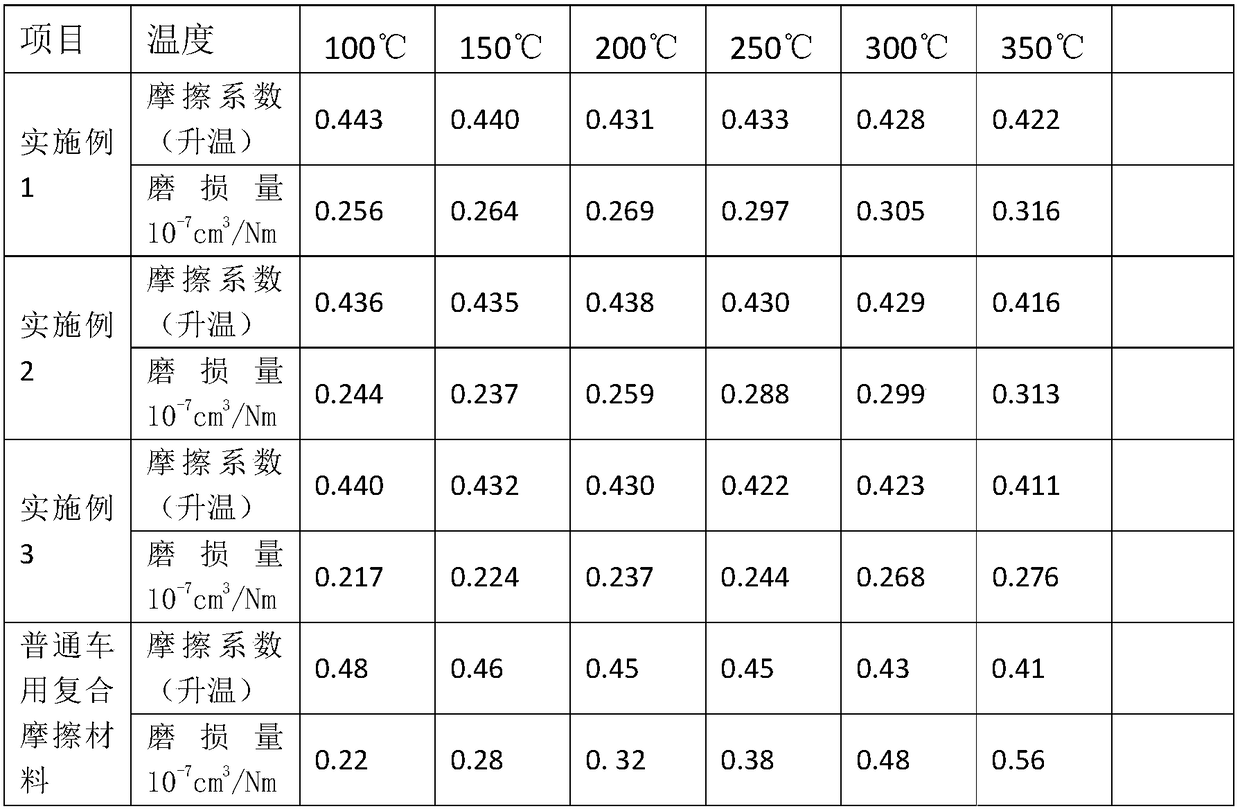

Composite frictional material and preparation method thereof

The invention provides a preparation method of a composite frictional material. The preparation method comprises the following steps that 1, a ferrous-based powder metallurgical frictional material is prepared; 2, shearing, smashing and screening are performed; 3, material mixing is performed; 4, the composite frictional material is prepared; 5 posttreatment is performed; 6, the composite frictional material is machined. Compared with the prior art, the composite frictional material integrates the characteristics of high temperature resistance and low abrasion resistance of the ferrous-based powder metallurgical frictional material and the characteristics of good toughness and low hardness of a resin-based composite material and has the advantages of high temperature resistance, low abrasion resistance, good toughness and low hardness. The ferrous-based powder metallurgical frictional material is used for preparing an automobile braking accessory, scratching of an automobile brake disc or drum is effectively avoided based on good braking performance, and frictional noise is small.

Owner:CHONGQING AOSHUNTE MACHINERY MFG

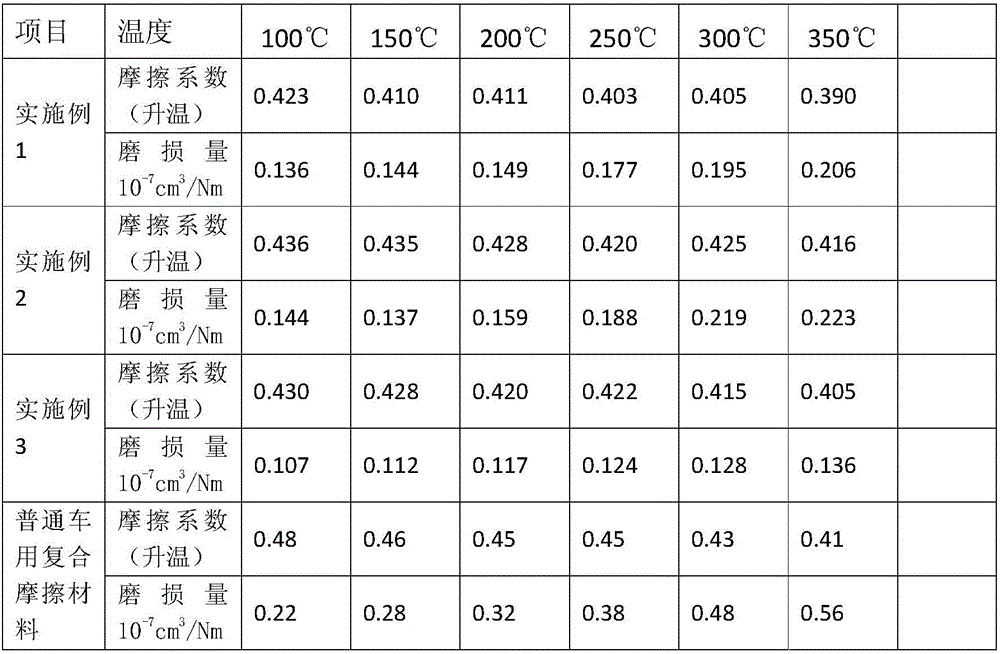

Resin based powder metallurgy composite friction material for vehicles and preparation method thereof

InactiveCN105838023AIncreased frictional surface roughnessIncrease porosity coefficientFriction liningResin-Based CompositeMachining

The invention discloses a preparation method of a resin based powder metallurgy composite friction material for vehicles, wherein the preparation method comprises the following steps: 1) preparing a powder metallurgy friction material: mixing evenly a base material and a forming agent, pouring the mixture into a mold, pressing to slender rods, separating the slender rod-shaped pressed blanks, and sintering, to obtain a powder metallurgy friction material; 2) shearing, crushing and screening; 3) mixing: according to the mass percentage, evenly co-mixing 10-20% of high-temperature-resistant modified resin, 40-60% of the powder metallurgy friction material, 10-20% of a reinforcing fiber, 5-15% of an abrasive, 10-20% of a lubricating material and 5-20% of a filler; 4) producing and preparing a resin based composite friction material; 5) post-treating; and 6) carrying out mechanical processing. The resin based powder metallurgy composite friction material retains the stable friction coefficient and good anti-abrasion properties of the powder metallurgy friction material. The service life and the high-temperature stability of the friction material are improved.

Owner:SOUTH CHINA UNIV OF TECH

Polymer-ceramic composite material

The invention discloses a polymer composite material for manufacturing a roller, which is prepared from the following materials in percentage by weight: 35-45% of nylon 6 (PA6), 20-35% of ceramic powder, 15-25% of glass fiber and 3-8% of composite solid lubricant, wherein the composite solid lubricant is prepared by mixing supramoly, graphite and other solid lubricant according to a weight ratio of 1:1-2. After being mixed according to the ratio, all the materials are mixed and extruded by a screw extruder, are subject to water-cooling pelleting, and are processed by an injection molding machine to be molded into a belt roller. The belt conveyor roller made of the composite material combines performance characteristics of polymer materials and ceramic materials, has the advantages of high strength, abrasion resistance, antistatic performance, flame retardance, corrosion prevention, light weight, low noise for high-speed operation, long service life, low price and the like, and can be widely used in industries or fields of smelting, mining, thermal power generation and the like.

Owner:HUNAN YINGHONG SCI & TECH

High-polymer ceramic composite material

The invention provides a high-polymer ceramic composite material which is prepared from the following raw materials in parts by weight: 20-40 parts of polyethylene, 10-15 parts of nylon, 30-50 parts of nano ceramic powder, 10-15 parts of glass fiber, 1-5 parts of graphite, 1-5 parts of coupling agent, 1-3 parts of antistatic agent and 1-3 parts of curing agent. The ceramic composite material provided by the invention has the advantages of favorable mechanical strength, favorable toughness, favorable wear resistance, light weight, long service life and low cost, and also has favorable properties in the aspects of flame retardancy, static resistance and the like by utilizing the high hardness and wear resistance of the ceramic and the corrosion resistance and impact resistance of the plastic.

Owner:昆山艾士比高分子科技有限公司

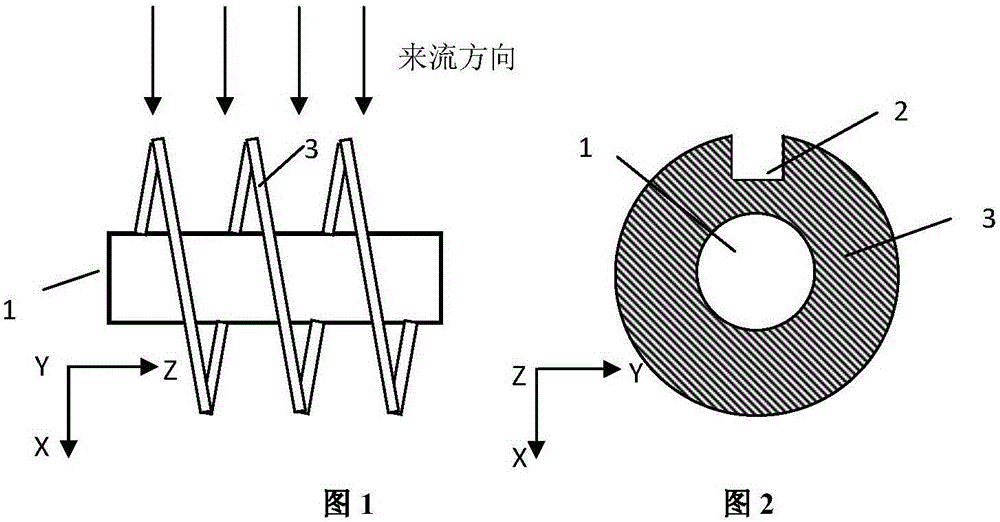

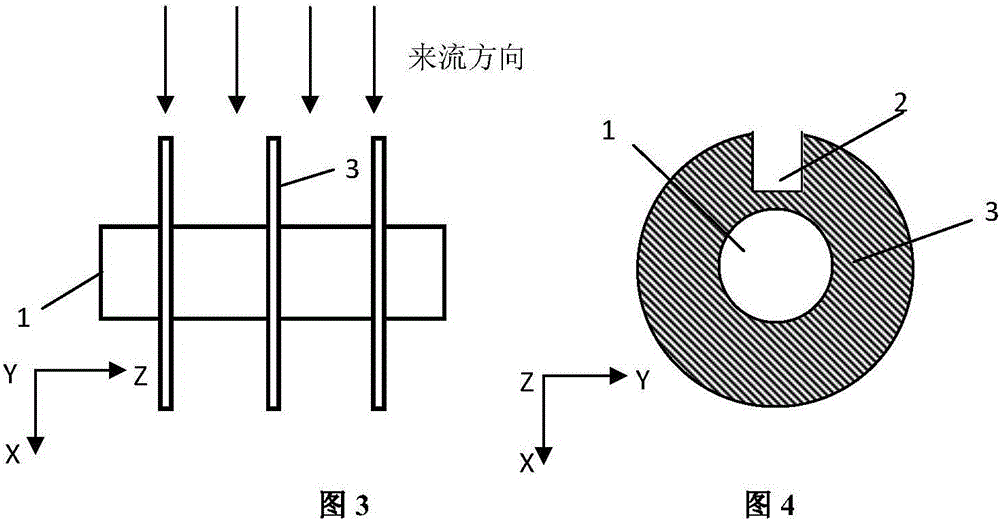

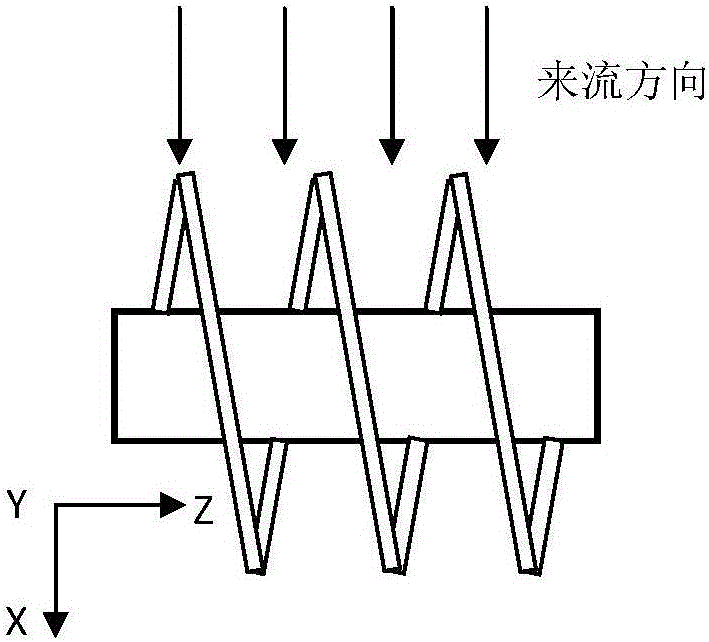

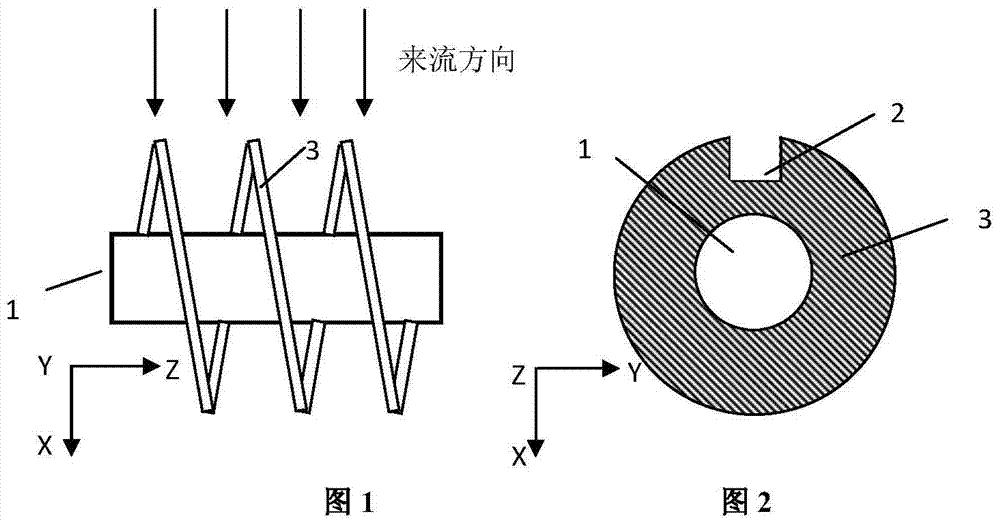

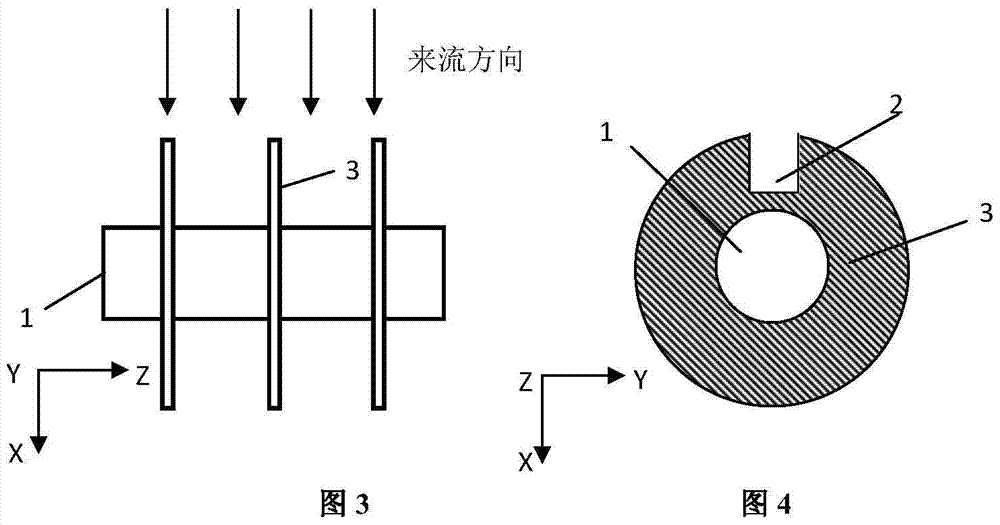

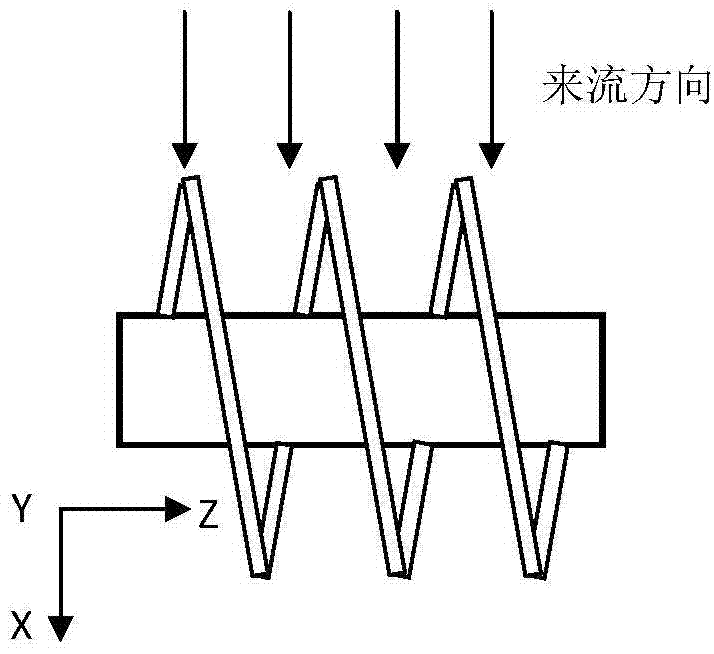

Abrasion resistance finned tube and heat exchanger

InactiveCN105021080AGuaranteed heat transfer efficiencyImprove the flow fieldTubular elementsThermodynamicsEngineering

The invention discloses an abrasion resistance finned tube and a heat exchanger. The abrasion resistance finned tube comprises a base tube and fins arranged on the outer surface of the base tube. The abrasion resistance finned tube is characterized in that a drainage groove with an opening at the upper end is formed in the incident flow surfaces of the fins, and the height of the drainage groove is 1 / 2 to 4 / 5 of the height of the fins; and the width of the drainage groove is 1 / 6-1 / 4 of the diameter of the base tube; and the fins are parallel fins or spiral fins arranged at internals. Compared with the prior art, according to the abrasion resistance finned tube, the groove is formed in the incident flow surfaces of the fins on spiral or circular finned tubes, the influence on the extension surface area of the finned tubes is not large, and the advantage of large heat exchange areas of the finned tubes is retained. Through the adjustment of the height and the width of the drainage groove, the abrasion condition of traditional spiral finned tubes or circular finned tubes is effectively improved, and the abrasion resistance property is superior to that of H type finned tubes. Meanwhile, since the fins of the abrasion resistance finned tube are in a circular arc shape, the advantage of the abrasion resistance property of the fins is more obvious than the advantage of the H type finned tubes

Owner:SOUTHEAST UNIV +1

Resin-based powder metallurgy steel fiber friction material used for vehicle and production method thereof

InactiveCN106084645AReduce surface hardnessModerate modulus of elasticityTransportation and packagingMetal-working apparatusNitrile rubberHydrogen

The invention discloses a method for producing a resin-based powder metallurgy steel fiber friction material used for vehicle. The method comprises the following steps: uniformly mixing a matrix powder material and a forming agent, dumping a mixture in a die for compacting the mixture to obtain several elongated rods, compacting the elongated rods, separating the rods, putting the rods in a sintering furnace, heating the material under condition of introduction of nitrogen or hydrogen to obtain a copper-based powder metallurgy friction material; shearing the material, crushing the material, and sieving the material; uniformly mixing 10-20% of nitrile rubber-modified phenolic resin, 20-40% of the copper-based powder metallurgy friction material, 15-30% of steel fiber, 5-15% of an abrasive, 10-20% of a lubrication material, and 5-20% of a filling material; performing hot press molding, cooling the material, and discharging. According to the enhancement effect of the steel fiber, by combining the characteristics of high temperature resistance, low abrasion of the copper-based powder metallurgy friction material as well as good toughness and low hardness of the resin-based composite friction material, the obtained material has the characteristics of high temperature resistance, low abrasion, good flexible performance and low hardness.

Owner:SOUTH CHINA UNIV OF TECH

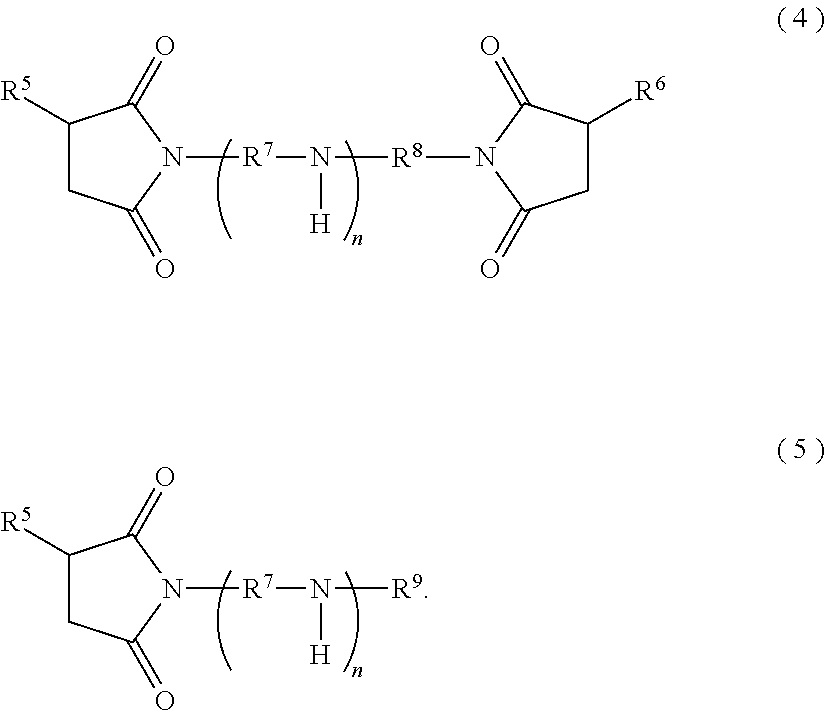

Lubricating oil composition

A lubricating oil composition containing a lubricating base oil and on the basis of the total mass of the composition, (A) a boron-containing ashless dispersant in an amount of 100 to 500 ppm by mass as boron, (B) a phosphorous additive in an amount of 300 to 800 ppm by mass as phosphorus, (C) an amide- and / or imide-based friction modifier in an amount of 1 to 4 percent by mass, and (D) an alkali metal- and / or alkaline earth metal-based detergent in an amount of 100 to 300 ppm by mass as metal, and having a 40° C. kinematic viscosity of 30 mm2 / s or lower is provided. The lubricating oil composition, which has a low viscosity to improve fuel efficiency, also has superior anti-wear, anti-seizure, and anti-shattering properties, even when the composition is degraded by oxidation or by the elution of compounds from sealing materials after long term use.

Owner:ENEOS CORP

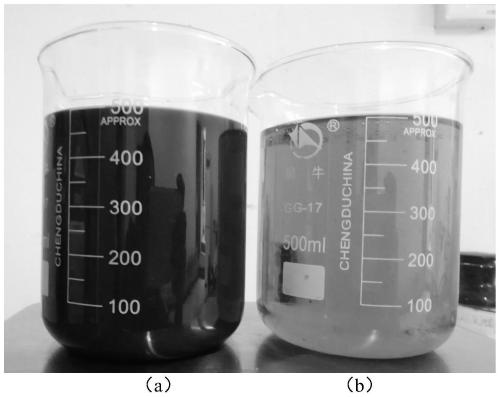

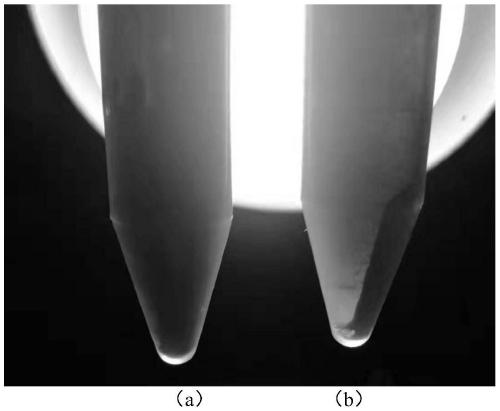

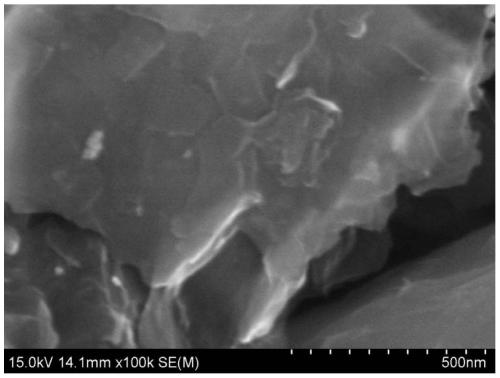

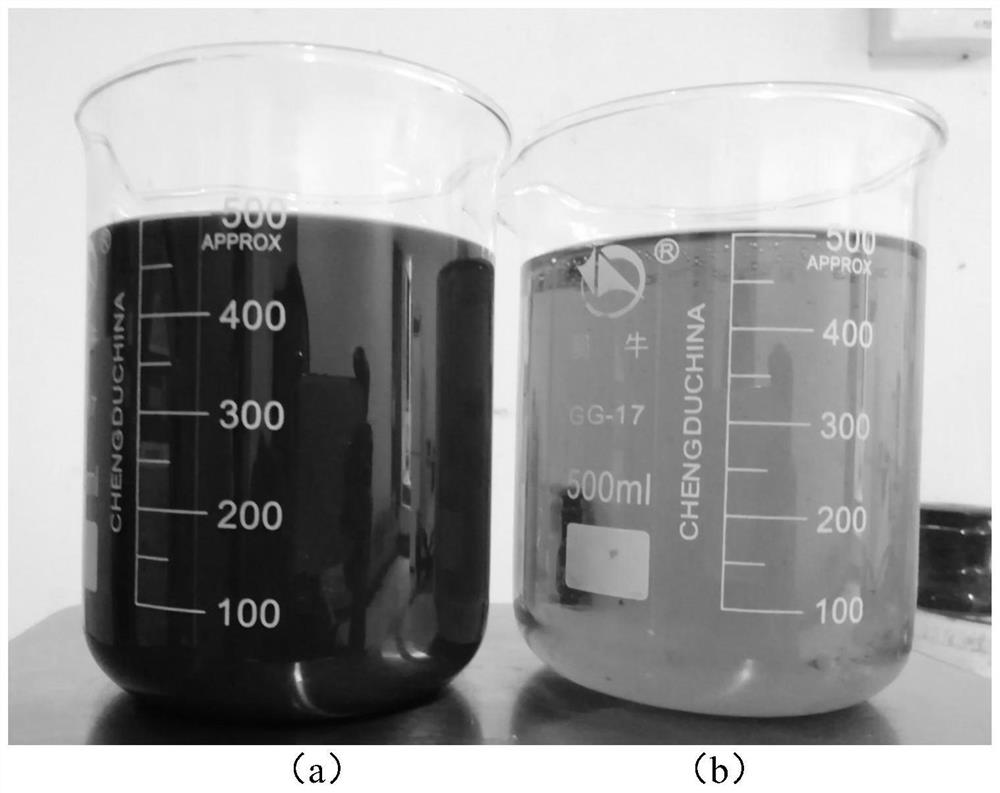

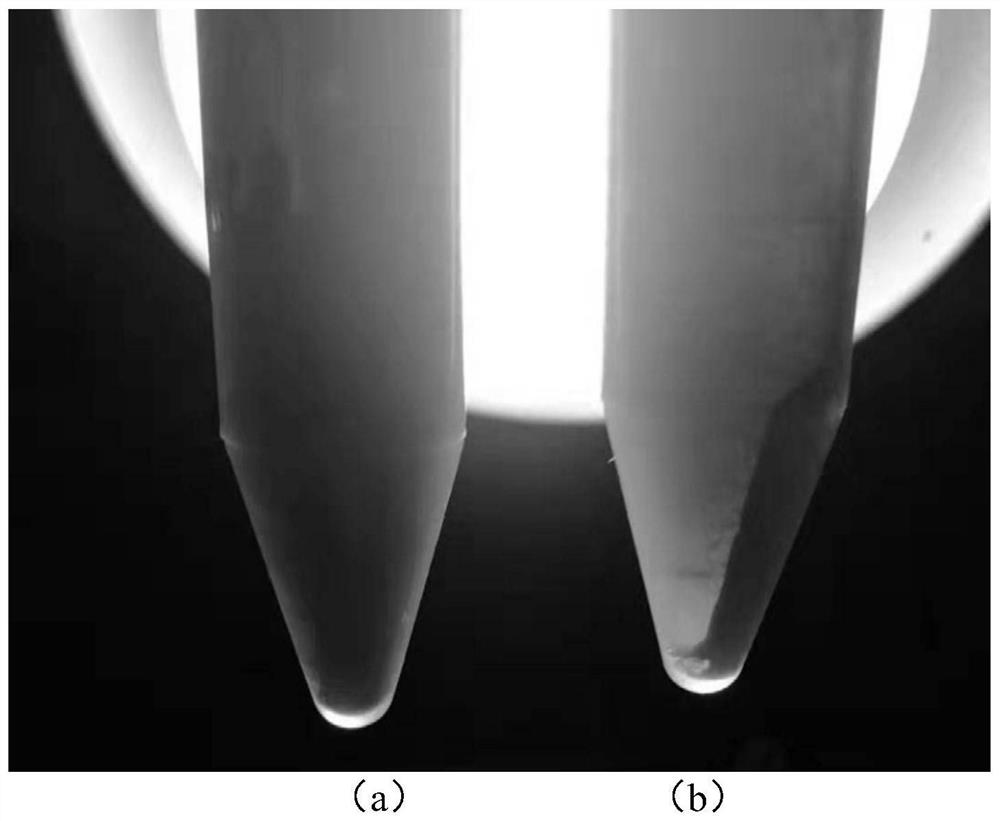

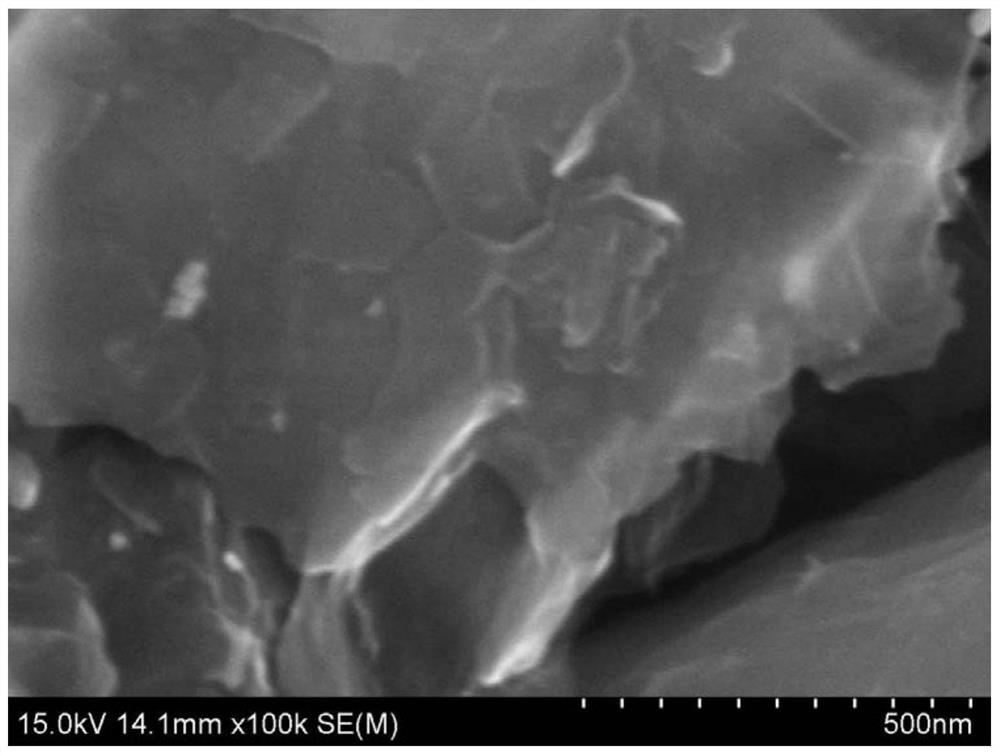

Preparation method of graphene lubricating oil, graphene lubricating oil and application

The invention provides a preparation method of graphene lubricating oil, the graphene lubricating oil and an application thereof, and relates to the technical field of lubricating oil. According to the preparation method of the graphene lubricating oil, a dispersion liquid formed from graphite and lubricating base oil is treated under the treatment pressure of 180-380 MPa by adopting an ultrahigh-pressure microjet method, so that the graphene lubricating oil is obtained. According to the preparation method, the graphite in the dispersion liquid does not need to be subjected to chemical modification treatment and the graphite is treated directly under specific pressure so that the graphite is converted into graphene and the stable graphene lubricating oil is obtained. The preparation methodhas the advantages of simple process, convenient operation, low energy consumption, no pollution to the environment, safety, environmental protection, low production cost, suitableness for industrialproduction, and nearly zero discharge of waste water and waste gas. The invention further provides the graphene lubricating oil which is prepared by adopting the preparation method.

Owner:贵州瑞诚新材料技术有限公司

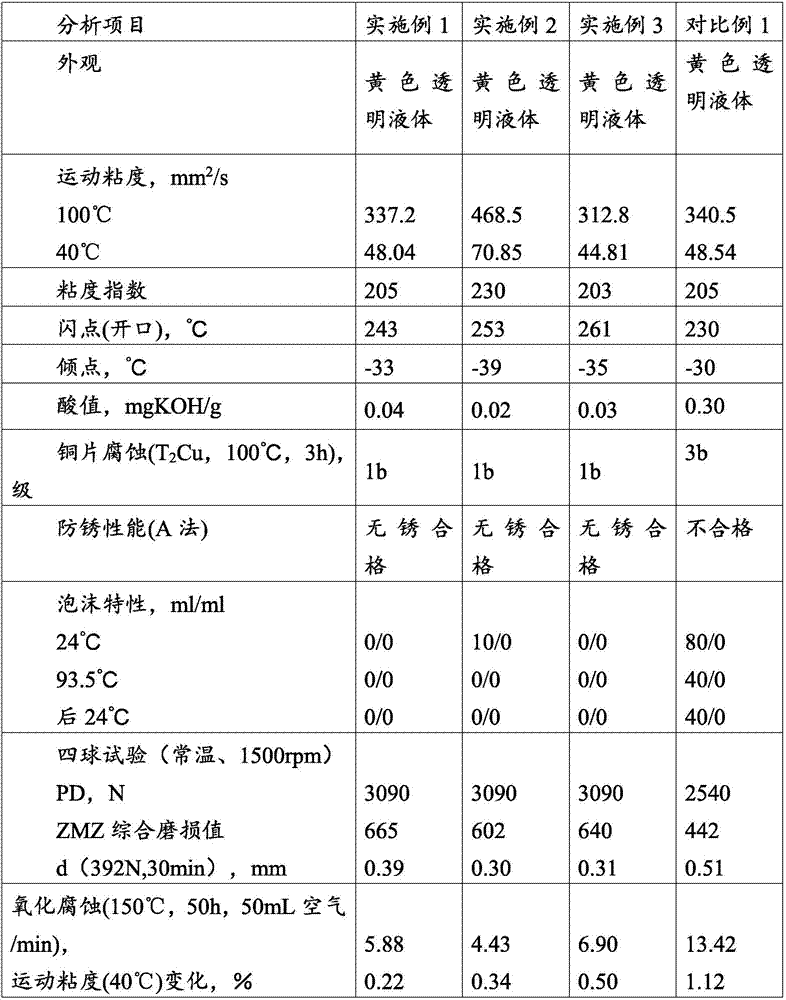

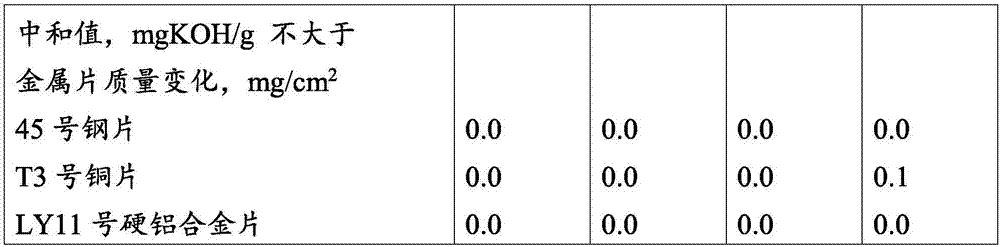

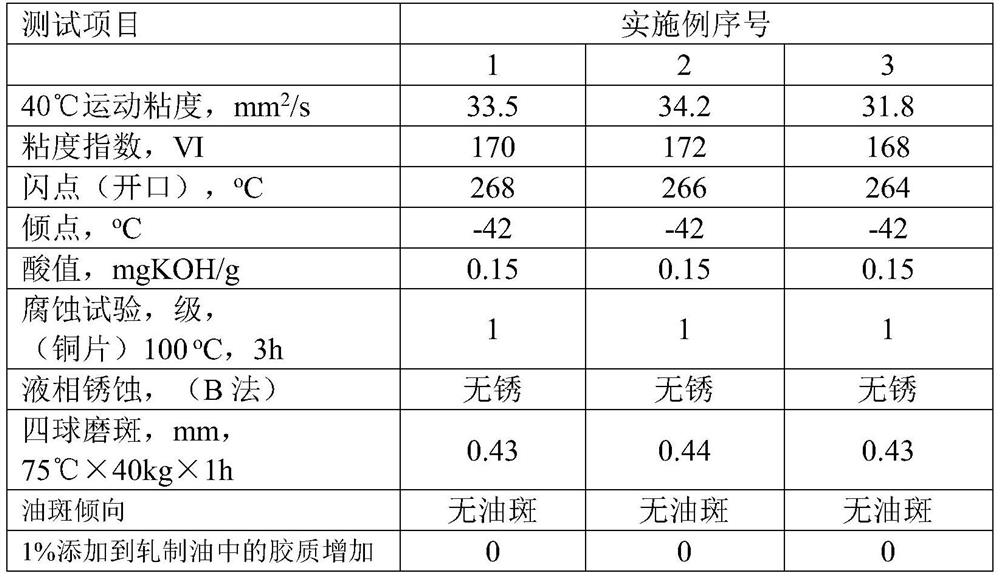

Lubricating oil for elevator traction machines and preparation method of lubricating oil

ActiveCN106978243AMeet lubrication requirementsGood anti-wear propertiesLubricant compositionPhenolic antioxidantBase oil

The invention provides lubricating oil for elevator traction machines. The lubricating oil comprises, by weight, 100 parts of PAG base oil, 1-2 parts of antioxidant, 2.0-4.0 parts of anti-wear reagent at extreme pressure, 1.0-2.0 parts of anticorrosive agent and 0.005-0.10 part of antifoaming agent, wherein the antioxidant is compounded by a phenolic antioxidant and an amine antioxidant. The lubricating oil has the advantages that the PAG base oil, the anti-wear reagent at extreme pressure, the anticorrosive agent and the antifoaming agent are combined to prepare the lubricating oil, the obtained lubricating oil can form an extremely strong oil film on the surface of metal when the lubricating oil is used in a toothed elevator traction gearbox, a good anti-wear feature is achieved, the lubricating requirements of the worm gear and worm gearbox of the steel-copper friction pairs of an elevator traction machine can be satisfied by adding the specific antioxidant composition, and the lubricating oil is good in lubricating performance, low-temperature flowability and thermal oxidation stability and applicable to the lubricating of escalator chains.

Owner:CHINA PETROLEUM & CHEM CORP

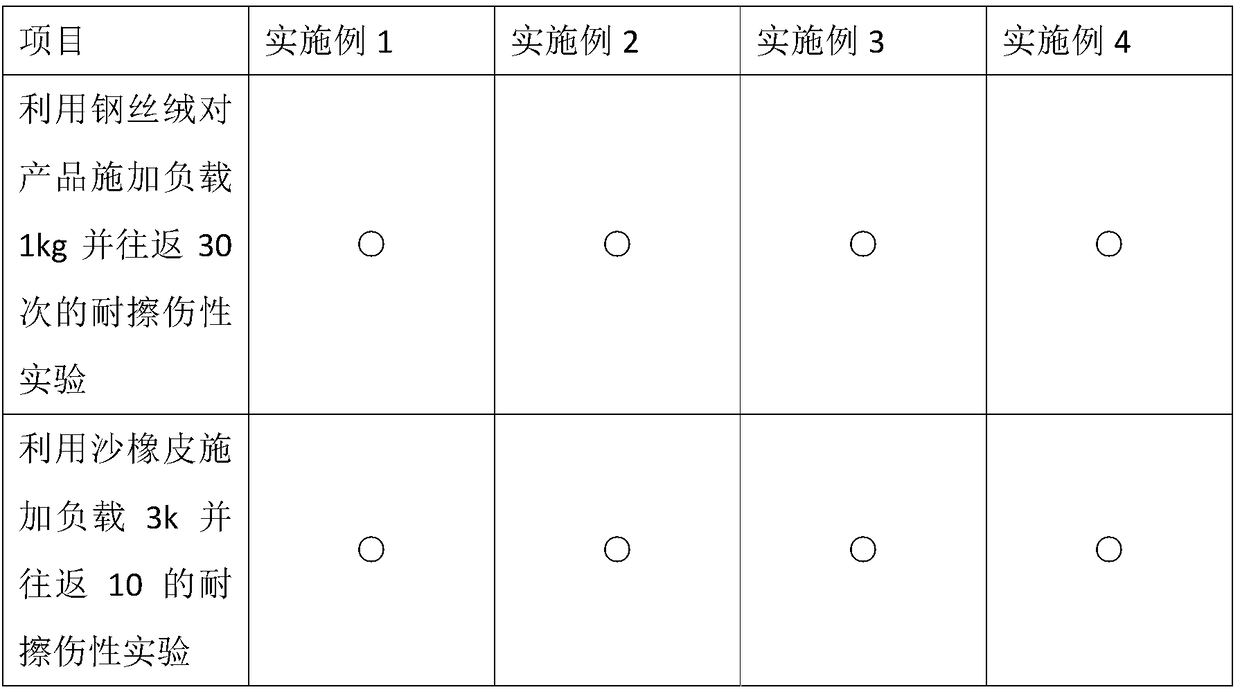

Wear-resistant resin lens and preparation method thereof

InactiveCN109369947AImprove wear resistanceExtended service lifeCoatingsOptical partsWear resistantPolystyrene

The invention discloses a wear-resistant resin lens and a preparation method thereof. The lens comprises a PMMA chip and wear-resistant layers adhered to two surfaces of the PMMA chip directly or indirectly, wherein the PMMA chip comprises the following raw materials in parts by weight: 100 parts of PMMA resin, 10-20 parts of polycarbonate, 10-15 parts of polystyrene resin, 3-8 parts of polypropylene glycol, 0.5-5 parts of initiator, 0.5-1.5 parts of sodium cocoly lactate and 1-3 parts of ultraviolet light absorber. The preparation method comprises the following steps: (1) weighing raw materials for preparing the PMMA chip in parts by weight, adding into a mixing kettle, thermally stirring for 30-40 minutes, cooling to room temperature, extruding the chip in a twin-screw extruder; and (2)putting the PMMA chip into a vacuum evaporator, and vacuumizing; uniformly bombarding a nano-material by utilizing an electronic gun when the vacuum degree is reached until the material is evaporatedat the melting point, and coating to form a nano-film; and evaporating again to complete two sides of evaporation. According to the wear-resistant resin lens, the lens chip surface is coated, the wearresistance of glasses can be improved, and the service life of the glasses can be prolonged.

Owner:苏新智能标签(江苏)有限公司

Iron-base molybdenum disulfide composite plating liquid for tank plating and producing process thereof

The present invention relates to iron base composite MoS2 plating solution for bath plating and its preparation process. The composite plating solution consists of FeCl2 360-440 g / L, MoS2 9-11 g / L, OP emulsifier 0.9-1.1 g / L and polyglycol 1.35-1.65 g / L, and has pH value of 1.0-2.0. The preparation process includes the technological steps of: dissolving MoS2 grain in absolute ethanol, adding polyoxyethylene alkylphenol ether as non-ionic surfactant and polyglycol while intense stirring, setting the compounded solution inside non-woven fabric bag and setting the bag inside FeCl2 solution. After the plating solution is used for some period, the bag is eliminated for mixing MoS2 grain solution and FeCl2 solution completely. The present invention has stable iron solution and homogeneously dispersed MoS2, and the plating solution may be used in forming excellent coating.

Owner:HOHAI UNIV

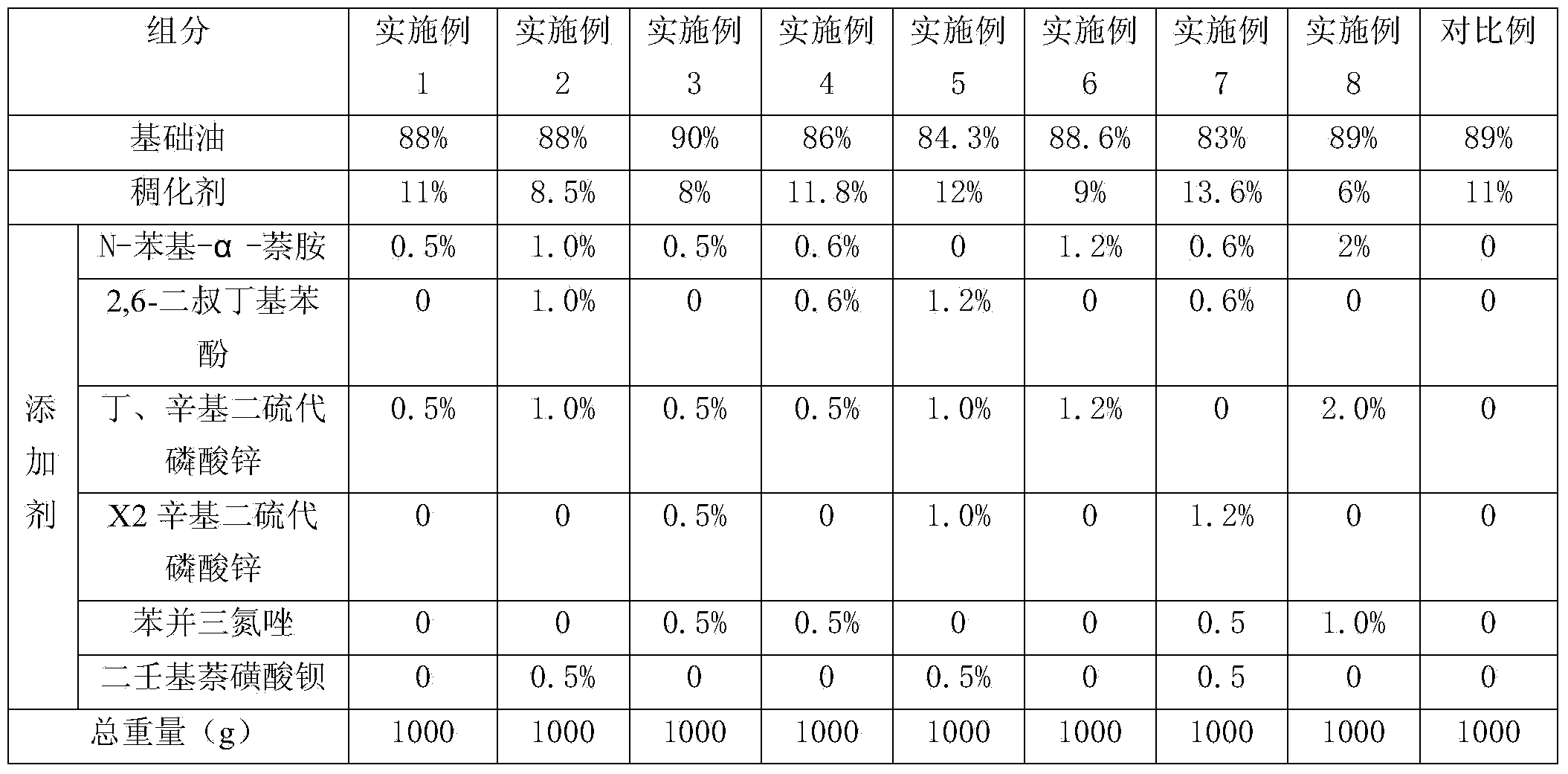

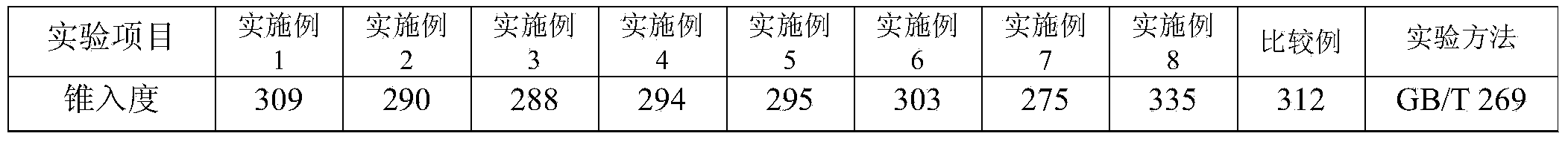

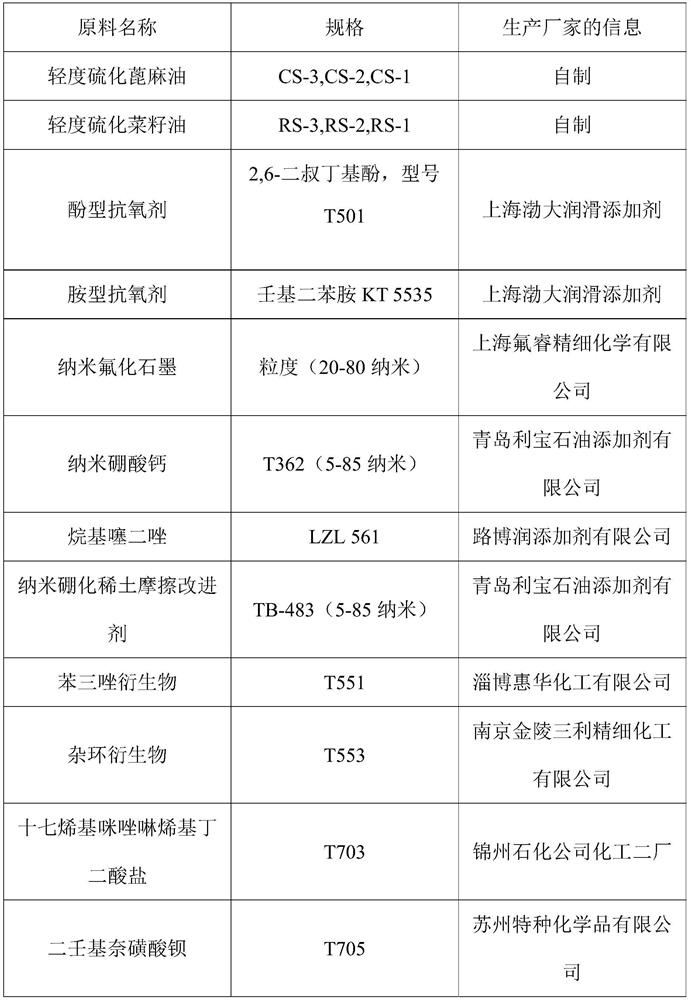

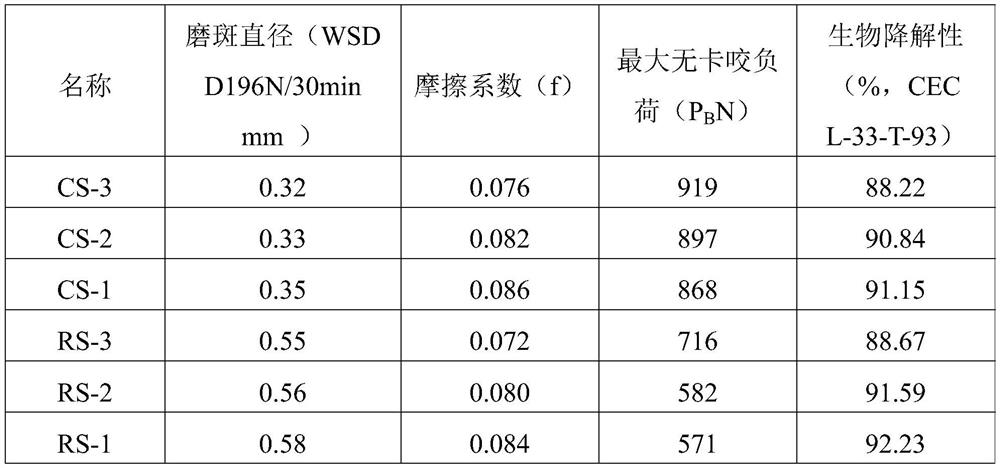

Lubricating grease for blast-furnace gun and preparation method thereof

The invention relates to lubricating grease for a blast-furnace gun and a preparation method thereof. The lubricating grease is prepared from the following components in percentage by weight: 6-13.6% of densifier, 83-90% of base oil and 1-5% of additives, wherein the kinematic viscosity of the base oil at 40 DEG C is 120-200mm<2> / s, and the viscosity index of the base oil is not less than 92 and the condensation point of the base oil is not higher than minus 10 DEG C; the additives comprise (a) 0.5-2% of antioxidant, (b) 0.5-2% of antiwear agent and (c) 0-1% of antirust agent. The lubricating grease produced by the method has a good high-temperature dropping point, long oxidation induction time, low long wear value under a certain load and good anti-corrosion performance in the presence of moisture. The wear scar diameter of the lubricating grease verified by an SH / T0204 method is not greater than 0.5mm. The oxidation induction time of the lubricating grease tested by SH / T0790 is greater than 13 minutes at 210 DEG C. The comprehensive problems that the lubricating grease simultaneously satisfies high temperature resistance, long service life, wear resistance, rust prevention, centralized pumping and the like are solved.

Owner:CHINA PETROLEUM & CHEM CORP

Environment-friendly lubricating oil and preparation method thereof

PendingCN112500909AImprove stabilityImprove Oxidation StabilityLubricant compositionVulcanizationVegetable oil

The invention relates to environment-friendly lubricating oil and a preparation method thereof. The environment-friendly lubricating oil is prepared from the following components in parts by weight: 74.2 to 90.2 parts of slightly vulcanized vegetable oil, 1.3 to 5.6 parts of an antioxidant, 0.5 to 2.8 parts of a friction improver, 2.1 to 4.3 parts of an antioxidant preservative, 2.4 to 5.3 parts of an extreme-pressure anti-wear agent, 0.3 to 1.8 parts of a defoaming agent, 2.0 to 3.8 parts of a metal deactivator and 1.2 to 2.2 parts of an antirust agent. Compared with the prior art, the lubricating oil has the advantages of excellent thermal stability and oxidation stability, good wear resistance, obvious antifriction performance, passivation resistance, good rust resistance, corrosion resistance, environmental friendliness and easiness in biodegradation.

Owner:SHANGHAI INST OF TECH

Iron-base molybdenum disulfide composite plating liquid for brush plating and producing process thereof

InactiveCN1673420ASolve instabilityExcellent anti-wear propertiesElectrolytic coatingsChemistryWoven fabric

The present invention relates to iron base composite MoS2 plating solution for brush plating and its preparation process. The composite plating solution consists of FeSO4 270-330 g / L, MoS2 36-44 g / L, polyoxyethylene alkylphenol ether 1.5-2 g / L and polyglycol 1.5-2 g / L, and has pH value of 1.5-2.0. The preparation process includes the technological steps of: dissolving MoS2 grain in absolute ethanol, adding polyoxyethylene alkylphenol ether as non-ionic surfactant while intense stirring, adding proper main salt and polyglycol while stirring, and setting non-woven fabric bag holding iron powder in 1 g / L inside the plating solution. The present invention has stable iron solution and homogeneously dispersed MoS2, and the plating solution may be used in forming excellent coating.

Owner:HOHAI UNIV

Ceramic composite material

The invention relates to the technical field of ceramic composite materials, in particular to a ceramic composite material. The ceramic composite material comprises the following components in parts by mass: 23-32 parts of boron fiber, 45-60 parts of ceramic particle, 15-25 parts of nano kaolin, 5-12 parts of aluminum oxide, 13-18 parts of nano silicon carbide, 22-28 parts of methyl methacrylate, 5-9 parts of nanosilicon dioxide, 12-16 parts of nano ceramic powder, 6-10 parts of diatomite and 5-10 parts of an antistatic agent. After adoption of the formula, the ceramic composite material has good mechanical strength, toughness, and wear resistance; the ceramic composite material takes advantage of high hardness and wear resistance of ceramic and corrosion prevention and impact resistance of plastic, has flame-retardant and anti-static properties and the like, and is light in weight, long in service life and low in cost.

Owner:汤彬

Lubricant composition

InactiveCN1236030CImprove wear resistanceAntioxidant is goodAdditivesGroup 6/16 organic compounds without C-metal linkagesChemical compositionViscosity

A lubricating oil composition is provided comprising a major amount of an oil of lubricating viscosity and a minor amount of, as an additive, at least one compound comprising a polynuclear molybdenum core and bonded thereto one or more anionic ligands capable of rendering the compound oil-soluble or oil-dispersible, wherein the ratio of the number of molybdenum atoms in the core to the number of said ligands is 1:1, such as 3:2 or greater.

Owner:INFINEUM INT LTD

Iron-base molybdenum disulfide composite plating liquid for brush plating and producing process thereof

InactiveCN100346002CNot easily oxidizedSolve the lack of instabilityElectrolytic coatingsIron powderPolyethylene glycol

Owner:HOHAI UNIV

Copper-based powder metallurgy composite friction material for vehicle and preparation method thereof

InactiveCN105778406BReduce surface hardnessModerate modulus of elasticityPowder mixtureResin-Based Composite

The invention discloses an automotive copper-based powder metallurgy composite friction material and a manufacturing method thereof. The manufacturing method includes that firstly, a basis powder material is mixed with a molding agent uniformly to obtain a mixture, the mixture is poured into a mold and is shaped into slender rods by pressing, the slender rods are compacted and separated and then charged into a sintering furnace, and the sintering furnace is heated up under protection of nitrogen gas or hydrogen gas so that a copper-based powder metallurgy friction material is obtained; secondly, the copper-based powder metallurgy friction material is subjected to processes of shearing, grinding and screening; thirdly, by mass percent, 10-20% of cashew nut oil modified phenolic resin, 30-60% of the copper-based powder metallurgy friction material, 10-20% of reinforced fibers, 5-15% of abrasives, 10-20% of lubricants and 5-20% of fillers are mixed uniformly to obtain a powder mixture, and the powder mixture is then subjected to hot press molding, is cooled to the room temperature and then is discharged from the furnace. The automotive copper-based powder metallurgy composite frictional material has both advantages of high temperature resistance and low abrasion as the copper-based powder metallurgy friction material and high ductility and low hardness as the resin-based composite friction material.

Owner:SOUTH CHINA UNIV OF TECH

Resin-based powder metallurgy composite friction material for vehicle and preparation method thereof

InactiveCN105838023BIncreased frictional surface roughnessIncrease porosity coefficientFriction liningResin-Based CompositeMachining

Owner:SOUTH CHINA UNIV OF TECH

Polymer-ceramic composite material

ActiveCN101875777BHigh mechanical strengthImprove toughnessCeramic compositeInjection molding machine

The invention discloses a polymer composite material for manufacturing a roller, which is prepared from the following materials in percentage by weight: 35-45% of nylon 6 (PA6), 20-35% of ceramic powder, 15-25% of glass fiber and 3-8% of composite solid lubricant, wherein the composite solid lubricant is prepared by mixing supramoly, graphite and other solid lubricant according to a weight ratio of 1:1-2. After being mixed according to the ratio, all the materials are mixed and extruded by a screw extruder, are subject to water-cooling pelleting, and are processed by an injection molding machine to be molded into a belt roller. The belt conveyor roller made of the composite material combines performance characteristics of polymer materials and ceramic materials, has the advantages of high strength, abrasion resistance, antistatic performance, flame retardance, corrosion prevention, light weight, low noise for high-speed operation, long service life, low price and the like, and can be widely used in industries or fields of smelting, mining, thermal power generation and the like.

Owner:HUNAN YINGHONG SCI & TECH

Iron-based powder metallurgy composite friction material for vehicle and preparation method thereof

Owner:SOUTH CHINA UNIV OF TECH

Synthetic waterless hydraulic lubricant

PendingCN114196464AGood thermo-oxidative stabilityGood anti-wear propertiesLubricant compositionMethacrylateLubrication

The invention discloses a synthetic waterless hydraulic lubricant which comprises the following components in parts by weight: 5-30 parts of a component A, 0.5-8 parts of an antioxidant, 0.01-1 part of a sulfur-containing or phosphorus-containing anti-wear reagent at extreme pressure, 0.01-1 part of an anti-rust agent and 0.01-1 part of a metal deactivator, and the balance of a component B, a component B, an antioxidant, a sulfur-containing or phosphorus-containing anti-wear reagent at extreme pressure, an anti-rust agent and a metal deactivator, 0.001 to 0.5 part by weight of a metal deactivator; the main component of the component A is polyalkyl glycol, and the proportion of ethylene oxide is 50% or 40%; and the component B is one or more of diester, pentaerythritol ester, trihydroxymethyl acrylate and trimellitate. The synthetic waterless hydraulic lubricant disclosed by the invention has excellent thermal oxidation stability, excellent wear resistance and very high viscosity index, is particularly suitable for lubrication of a hydraulic system of an aluminum plate strip foil rolling mill, and does not cause increase of rolling oil colloid even if leakage occurs; in addition, the synthetic waterless hydraulic lubricant has the advantage of long service life.

Owner:上海森帝润滑技术有限公司

Preparation method of graphene lubricating oil, graphene lubricating oil and application

The invention provides a preparation method of graphene lubricating oil, graphene lubricating oil and application thereof, and relates to the technical field of lubricating oil. The preparation method of the graphene lubricating oil is to obtain the graphene lubricating oil by adopting an ultra-high pressure micro-jet method to treat the dispersion liquid formed by graphite and lubricating base oil at a processing pressure of 180-380MPa; wherein, the preparation method does not need to The graphite in the dispersion is chemically modified, and the graphite is directly processed under a specific pressure to realize the transformation from graphite to graphene and obtain a stable graphene lubricating oil. The preparation method is simple, easy to operate, and low in energy consumption. , the discharge of waste water and waste gas approaches zero, will not pollute the environment, is safe and environmentally friendly, has low production costs, and is suitable for industrial production. The present invention also provides a graphene lubricating oil, which is prepared by the above preparation method.

Owner:贵州瑞诚新材料技术有限公司

Lubricating compositions containing synthetic ester base oil, molybdenum compounds and thiadiazole-based compounds

ActiveCN100412178CThe result is obviousExcellent traction coefficientAdditivesCompound aMolybdenum compounds

A lubricating composition providing excellent anti-wear protection for corrosion-resistant materials which comprises a major amount of a synthetic ester base oil, and a minor amount of a molybdenum compound and an anti-wear additive selected from the group consisting of 1,3,4-thiadiazole derivatives as an anti-wear additive, the reaction products of 2,5-dimercapto-1,3,4-thiadiazole dimers and poly(ether)glycols, and 2,5-dimercapto-1,3,4-thiadiazole monomer and mixtures thereof. Also described is a method for imparting anti-wear properties to a corrosion resistant material, comprising using the lubricating composition of the invention.

Owner:VANDERBILT CHEM LLC

Automotive resin-based powder metallurgy potassium titanate fiber friction material and preparation method thereof

The invention discloses a method for producing a resin-based powder metallurgy potassium titanate fiber friction material used for vehicle. The method comprises the following steps: uniformly mixing a matrix powder material and a forming agent, dumping a mixture into a die, compacting the mixture to several elongated rods, compacting the elongated rods, separating the elongated rods, putting the elongated rods in a sintering furnace, under condition of introducing nitrogen or hydrogen, heating the materials to obtain a Fe-based powder metallurgy friction material; shearing the Fe-based powder metallurgy friction material, crushing the Fe-based powder metallurgy friction material, and sieving; by metering with mass percentage, uniformly mixing 10-20% of cashew oil-modified phenolic resin, 30-50% of the Fe-based powder metallurgy friction material, 10-30% of potassium titanate fiber, 5-15% of an abrasive, 10-20% of a lubrication material, and 5-20% of a filling material; performing hot press molding on the materials, cooling the materials, and discharging. The friction material combines the characteristics of high temperature resistance and low abrasion of the Fe-based powder metallurgy friction material as well as good toughness and low hardness of the potassium titanate resin-based composite friction material, and the obtained material has the characteristics of high temperature resistance, low abrasion, good toughness, and low hardness.

Owner:SOUTH CHINA UNIV OF TECH

Wear-resistant finned tubes and heat exchangers

InactiveCN105021080BExtended surface area has little effectImprove heat transfer efficiencyTubular elementsPlate heat exchangerWear resistant

Owner:SOUTHEAST UNIV +1

Iron-base molybdenum disulfide composite plating liquid for tank plating and producing process thereof

InactiveCN100383293CEasy to storeEvenly dispersedElectrolytic coatingsActive agentPolyethylene glycol

The present invention relates to iron base composite MoS2 plating solution for bath plating and its preparation process. The composite plating solution consists of FeCl2 360-440 g / L, MoS2 9-11 g / L, OP emulsifier 0.9-1.1 g / L and polyglycol 1.35-1.65 g / L, and has pH value of 1.0-2.0. The preparation process includes the technological steps of: dissolving MoS2 grain in absolute ethanol, adding polyoxyethylene alkylphenol ether as non-ionic surfactant and polyglycol while intense stirring, setting the compounded solution inside non-woven fabric bag and setting the bag inside FeCl2 solution. After the plating solution is used for some period, the bag is eliminated for mixing MoS2 grain solution and FeCl2 solution completely. The present invention has stable iron solution and homogeneously dispersed MoS2, and the plating solution may be used in forming excellent coating.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com