Synthetic waterless hydraulic lubricant

A lubricant and synthetic technology, applied in lubricating compositions, petroleum industry, etc., can solve problems such as the increase of colloid in rolling oil, and achieve the effects of high viscosity index, excellent anti-wear characteristics, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a method for preparing the above-mentioned synthetic non-staining hydraulic lubricant, which includes the following steps: adding component B into a mixing tank with a stirrer and heating to 60-70°C; then adding an antioxidant, sulfur-containing or Phosphorus extreme pressure anti-wear agent, antirust agent and metal passivator, blend at 80-90°C for 2-4 hours until the mixture is uniform and transparent, finally add component A, blend for 0.5-1 hour until uniform.

[0033] The technical scheme of concrete implementation of the present invention comprises:

Embodiment 1

[0035] A synthetic non-staining hydraulic lubricant comprising the following components in parts by weight:

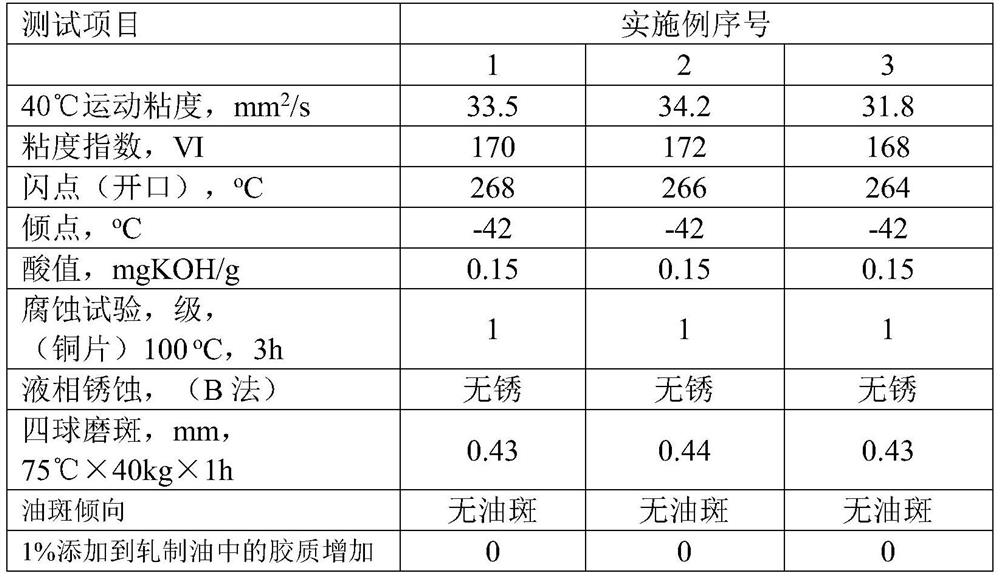

[0036] Component A: 60 parts by weight, Component B: 5 parts by weight, antioxidant: 0.5 parts by weight, extreme pressure antiwear agent containing sulfur or phosphorus: 0.01 parts by weight, rust inhibitor: 0.01 parts by weight, metal passivation Agent: 0.001 parts by weight; the main component of component A is polyalkylene glycol, wherein the proportion of ethylene oxide is 50% or 40%; component B is diester, pentaerythritol ester, trimethylol acrylate, One or more of trimellitate. The main test properties of the synthetic non-staining hydraulic lubricant obtained in Example 1 are shown in Table 1.

Embodiment 2

[0038] A synthetic non-staining hydraulic lubricant comprising the following components in parts by weight:

[0039] Component A: 80 parts by weight, Component B: 20 parts by weight, antioxidant: 3 parts by weight, extreme pressure antiwear agent containing sulfur or phosphorus: 0.5 parts by weight, rust inhibitor: 0.5 parts by weight, metal passivation Agent: 0.25 parts by weight; the main component of component A is polyalkylene glycol, wherein the proportion of ethylene oxide is 50% or 40%; component B is diester, pentaerythritol ester, trimethylol acrylate, One or more of trimellitate. The main test properties of the synthetic non-staining hydraulic lubricant obtained in Example 2 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com