Graphene lubricating oil additive and preparation method thereof

A lubricating oil additive, graphene technology, applied in the direction of additives, petroleum industry, lubricating composition, etc., can solve the problems of high pollutants, emissions, environmental pollution, etc., achieve good high-temperature lubricity, simplify the production process, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

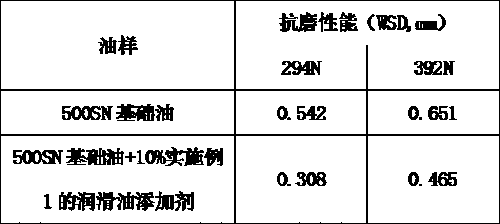

Embodiment 1

[0013] Graphene lubricating oil additive, gets raw material and comprises by weight percentage:

[0014] Graphene 0.1%, hydrogenated styrene-diene copolymer 1%, oleic acid 1.5%, borate 15%, oily solvent 82.4%;

[0015] Among them: the diameter of graphene is 1um-5um, the thickness is 1nm-10nm, and the specific surface area is 500-1000㎡ / g; the borate ester component is 2-(4-dodecylphenoxy) hydroxyl Ethylaminodiethoxy borate 40%, 2-(4-dodecylphenoxy)heptadecylaminodiethoxyborate 20%, and 2-(4-deca Dialkylphenoxy) oleate hydroxyethylaminodiethoxy borate 40%; oily solvent is 500SN base oil.

[0016] The preparation method of graphene lubricating oil additive comprises the steps:

[0017] Add the boric acid ester to the oily solvent and stir thoroughly at 50-60°C for 30 minutes, then add the hydrogenated styrene-diene copolymer for electromagnetic stirring for 30 minutes, then add graphene for electromagnetic stirring for 30 minutes, and finally use 300W, 20-40Hz under the condit...

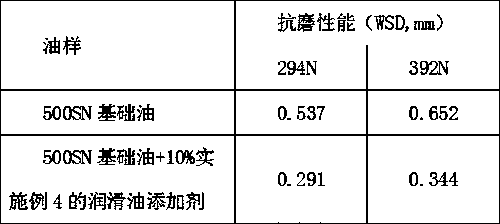

Embodiment 2

[0021] Graphene lubricating oil additive, gets raw material and comprises by weight percentage:

[0022] 0.1% graphene, 1% hydrogenated styrene-diene copolymer, 2% oleic acid, 15% borate, 81.9% oily solvent;

[0023] Among them: the diameter of graphene is 1um-5um, the thickness is 1nm-10nm, and the specific surface area is 500-1000㎡ / g; the borate ester component is 2-(4-dodecylphenoxy) hydroxyl Ethylaminodiethoxy borate 40%, 2-(4-dodecylphenoxy)heptadecylaminodiethoxyborate 20%, and 2-(4-deca Dialkylphenoxy) oleate hydroxyethylaminodiethoxy borate 40%; oily solvent is 500SN base oil.

[0024] The preparation method of graphene lubricating oil additive comprises the steps:

[0025] Add the boric acid ester to the oily solvent and stir thoroughly at 50-60°C for 30 minutes, then add the hydrogenated styrene-diene copolymer for electromagnetic stirring for 30 minutes, then add graphene for electromagnetic stirring for 30 minutes, and finally use 300W, 20-40Hz under the conditio...

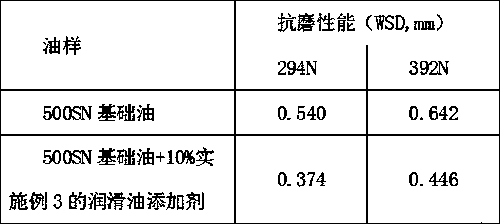

Embodiment 3

[0029] Graphene lubricating oil additive, gets raw material and comprises by weight percentage:

[0030] 0.5% graphene, 1% hydrogenated styrene-diene copolymer, 6% oleic acid, 20% borate, 72.5% oily solvent;

[0031] Among them: the diameter of graphene is 1um-5um, the thickness is 1nm-10nm, and the specific surface area is 500-1000㎡ / g; the borate ester component is 2-(4-dodecylphenoxy) hydroxyl Ethylaminodiethoxy borate 40%, 2-(4-dodecylphenoxy)heptadecylaminodiethoxyborate 20%, and 2-(4-deca Dialkylphenoxy) oleate hydroxyethylaminodiethoxy borate 40%; oily solvent is 500SN base oil.

[0032] The preparation method of graphene lubricating oil additive comprises the steps:

[0033] Add the boric acid ester to the oily solvent and stir thoroughly at 50-60°C for 30 minutes, then add the hydrogenated styrene-diene copolymer for electromagnetic stirring for 30 minutes, then add graphene for electromagnetic stirring for 30 minutes, and finally use 300W, 20-40Hz under the conditio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com