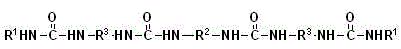

Polytetraurea lubricant grease

A technology of polytetraurea lubricating grease and lubricating grease, which is applied in lubricating compositions and the petroleum industry, etc., can solve the problems of polytetraurea’s poor oiling ability to low-viscosity bases, and achieve excellent anti-wear extreme pressure performance, volatile The effect of low resistance and excellent low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Mix polyalphaolefin PAO4 and diisooctyl sebacate uniformly at a mass ratio of 1:1 to obtain base oil.

[0024] Add 1400g of base oil and 308g of TDI (2,4-toluene diisocyanate) into the reactor, heat to 75°C, after dissolving, add 2500g of base oil, 48.2g of ethylenediamine, 220g of octadecylamine and 80g of cyclohexanol under stirring. Hexylamine, continue to stir at 75°C for half an hour, then heat up to 140°C, keep warm for 1 hour, cool to 95°C, add 140g tricresyl phosphate (TCP) and 130g 2,6-di-tert-butyl-4-methylphenol (BHT ), stirred evenly, cooled to room temperature, and ground into fat.

Embodiment 2

[0026] The base oil is obtained by uniformly mixing pentaerythritol tetraisooctanoate and polyalphaolefin PAO4 at a mass ratio of 1:2.

[0027] Add 1200g base oil and 308g TDI (2,4-toluene diisocyanate) into the reaction kettle, heat to 70°C, after dissolving, add 2600g base oil, 48.2g ethylenediamine, 220g octadecylamine and 80g cyclic Hexylamine, continue to stir at 70°C for half an hour, then heat up to 170°C, keep warm for 30 minutes, cool to 110°C, add 140g tricresyl phosphate (TCP) and 120g N-phenyl α-naphthylamine, stir well, cool to room temperature, grind into fat.

Embodiment 3

[0029] Diisooctyl sebacate and polyalphaolefin PAO8 are uniformly mixed at a mass ratio of 1:1 to obtain a base oil.

[0030] Add 1000g base oil and 308g TDI (2,4-toluene diisocyanate) into the reaction kettle, heat to 75°C, after dissolving, add 3000g base oil, 86.8g o-phenylenediamine, 220g octadecylamine and 80g Cyclohexylamine, continue to stir at 75°C for half an hour, then heat up to 150°C, keep warm for 40 minutes, cool to 110°C, add 130g tricresyl phosphate (TCP) and 110g diisooctyl diphenylamine, stir well, cool to room temperature, Grind into fat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com