Patents

Literature

250 results about "Laser crystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

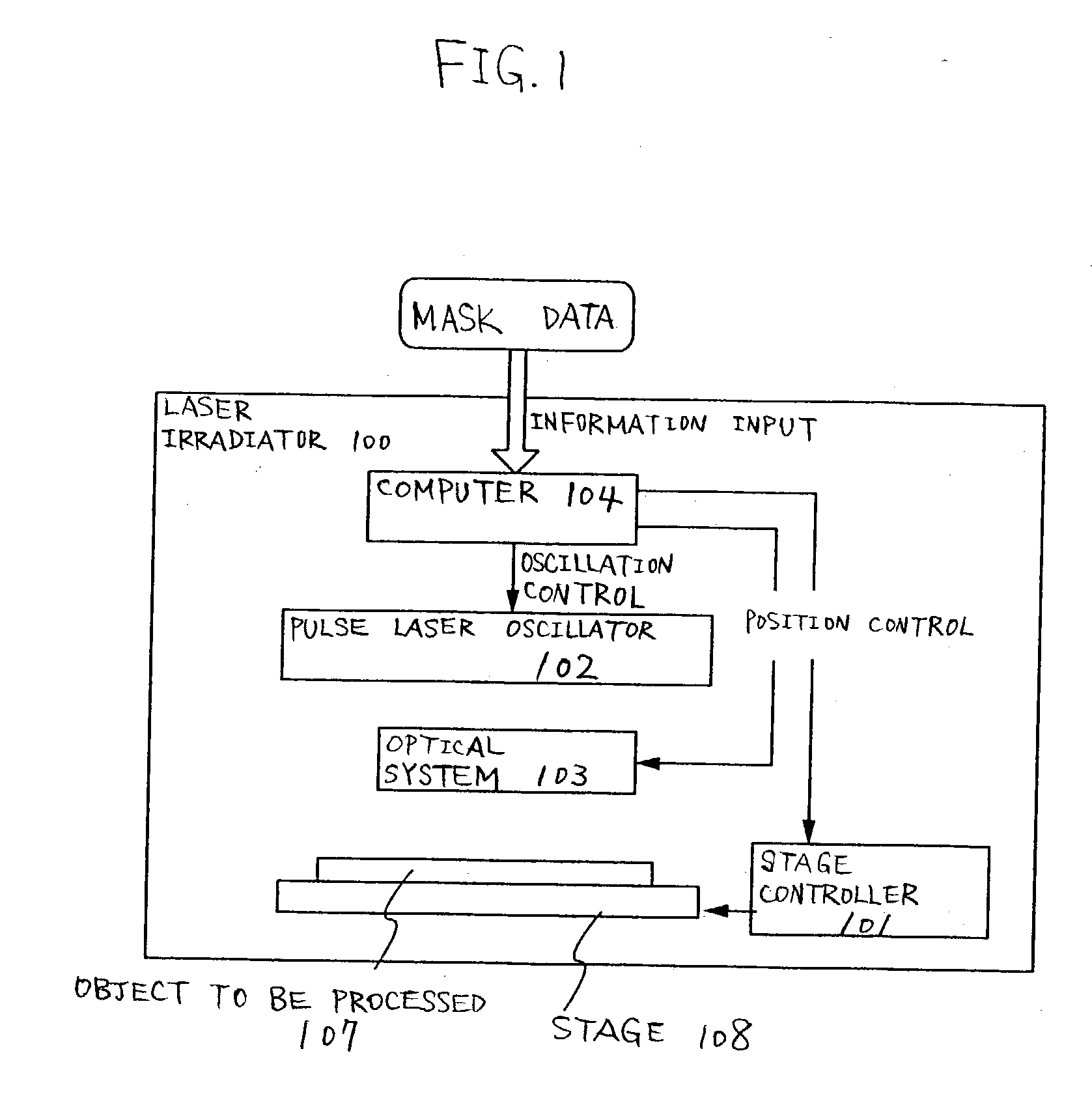

Laser irradiation method, laser irradiation apparatus, and semiconductor device

InactiveUS6535535B1Laser using scattering effectsSolid-state devicesContinuous lightLiquid-crystal display

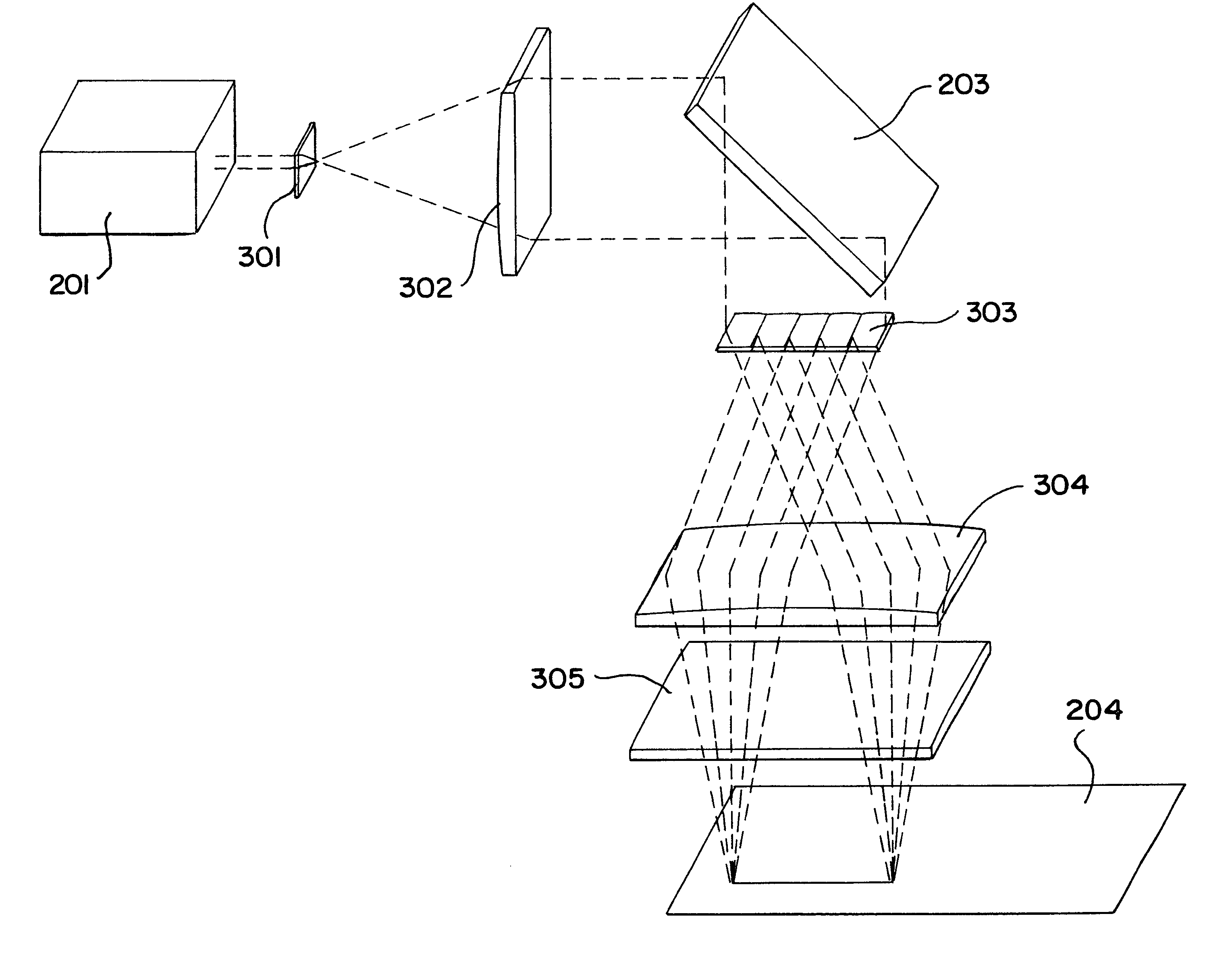

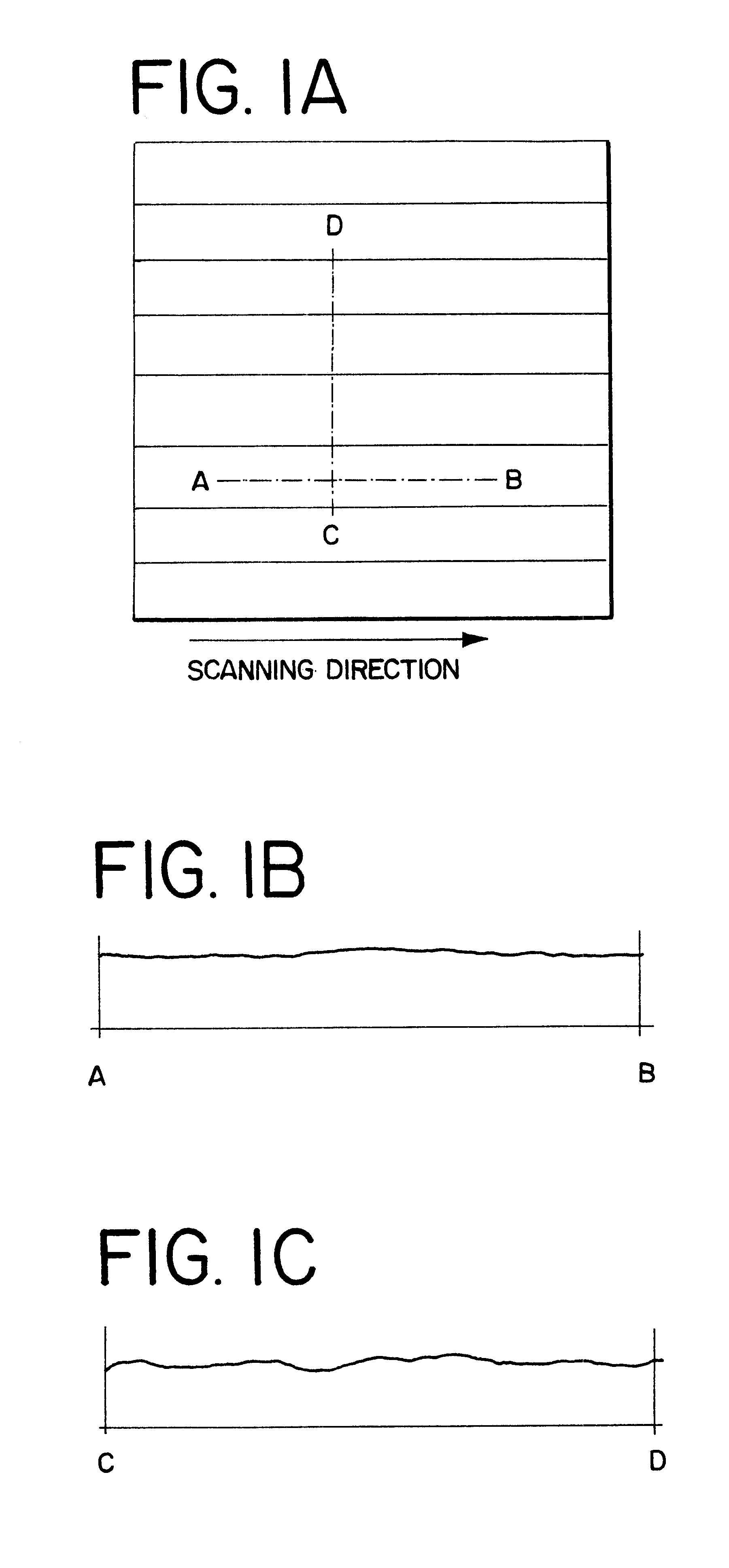

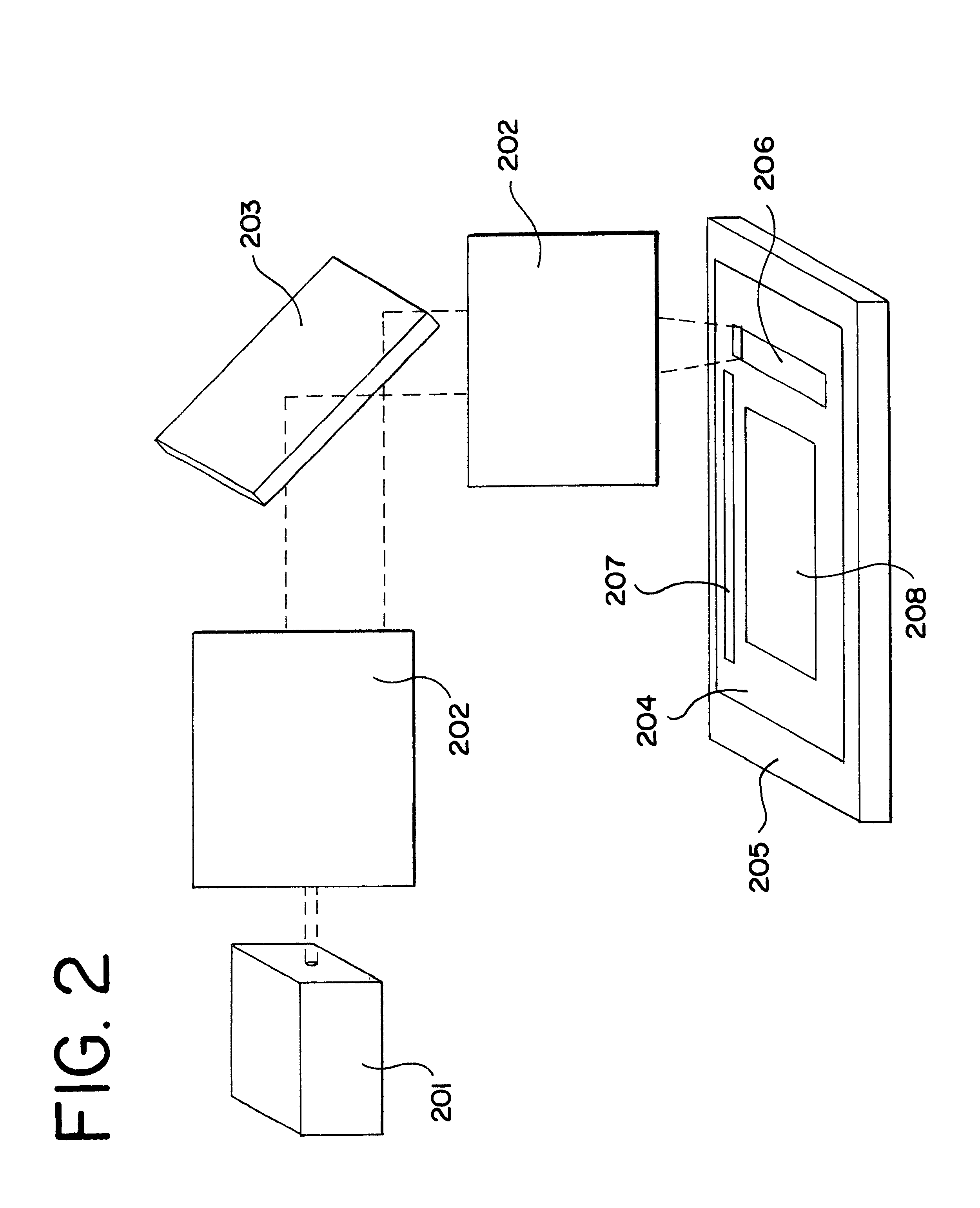

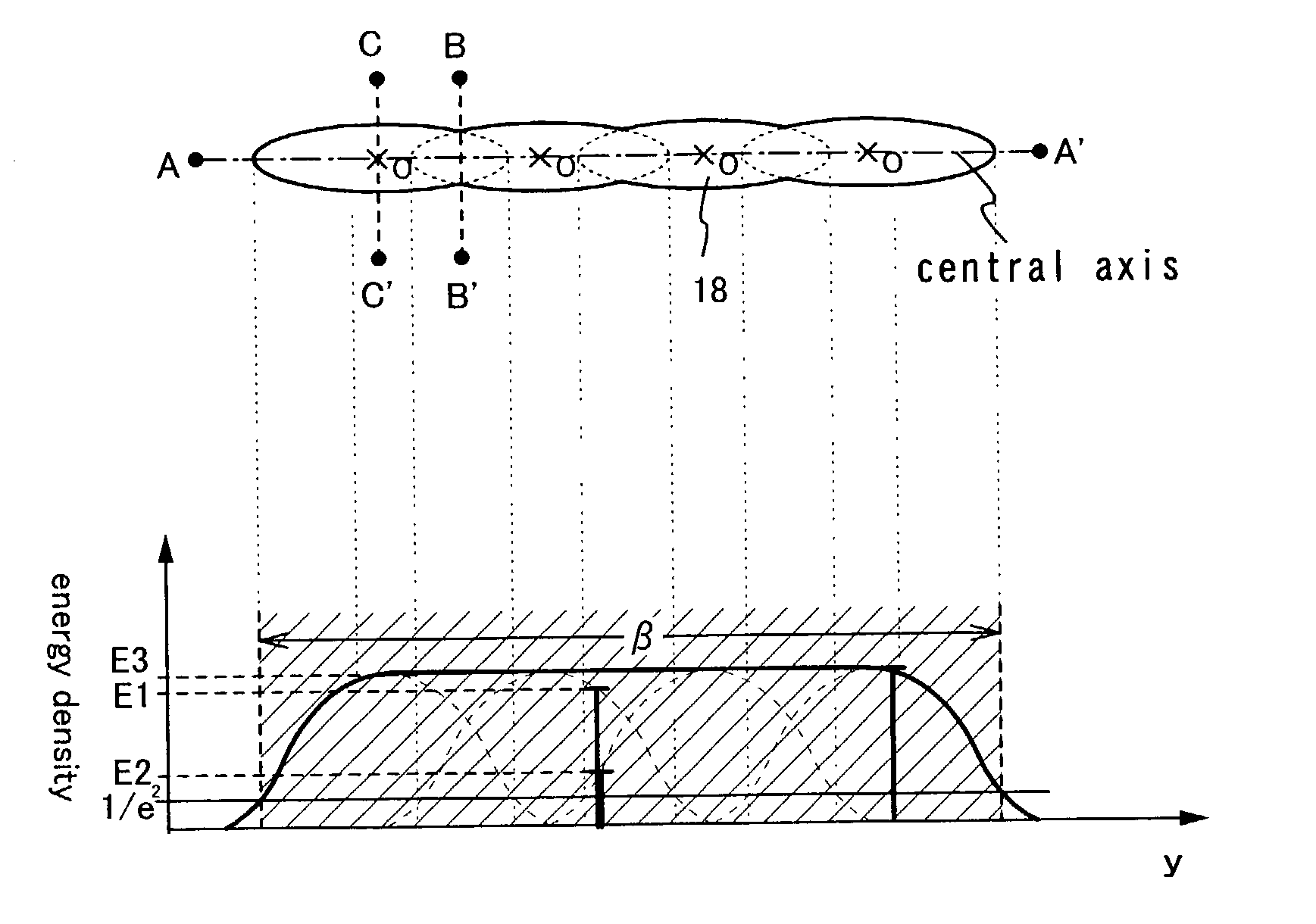

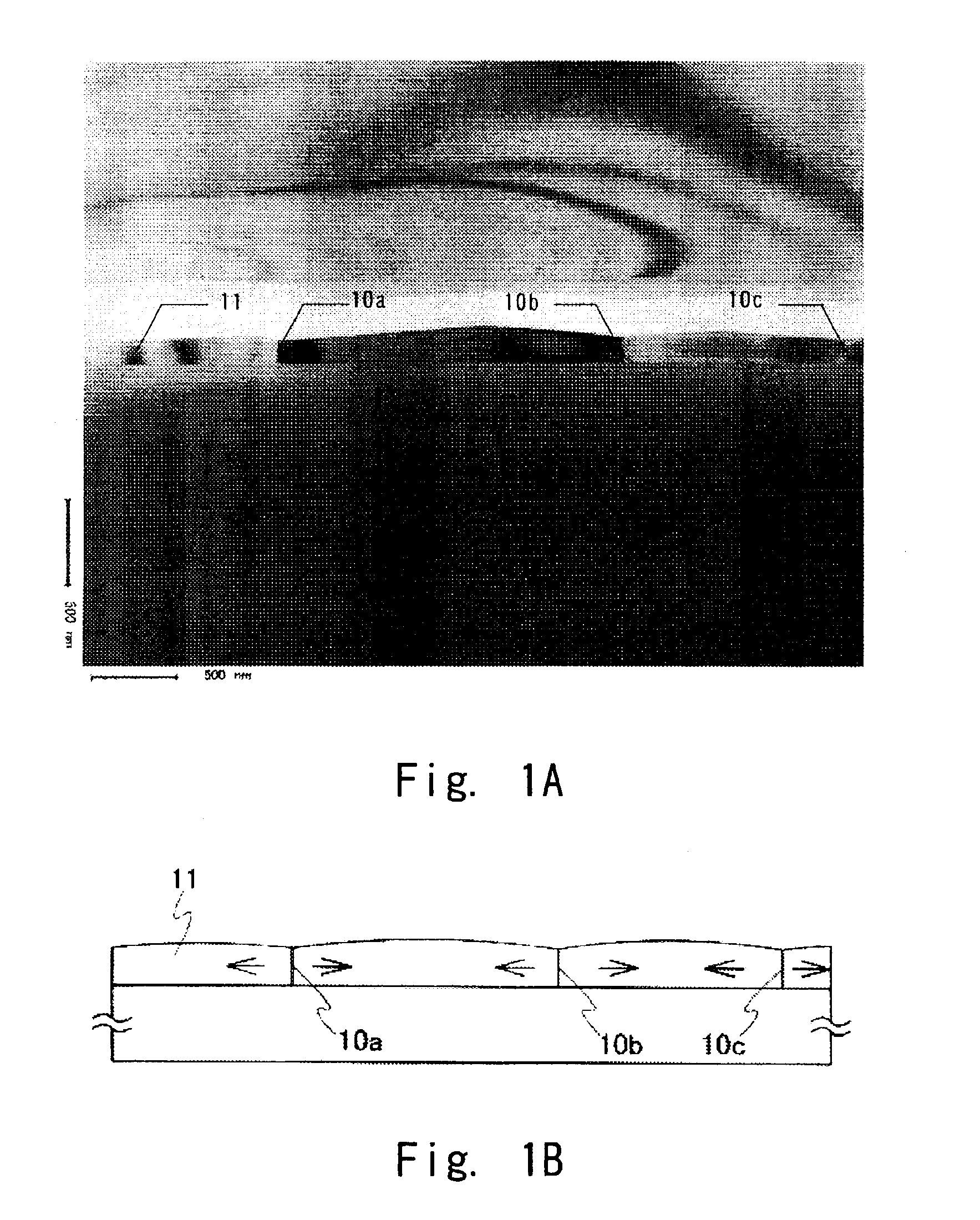

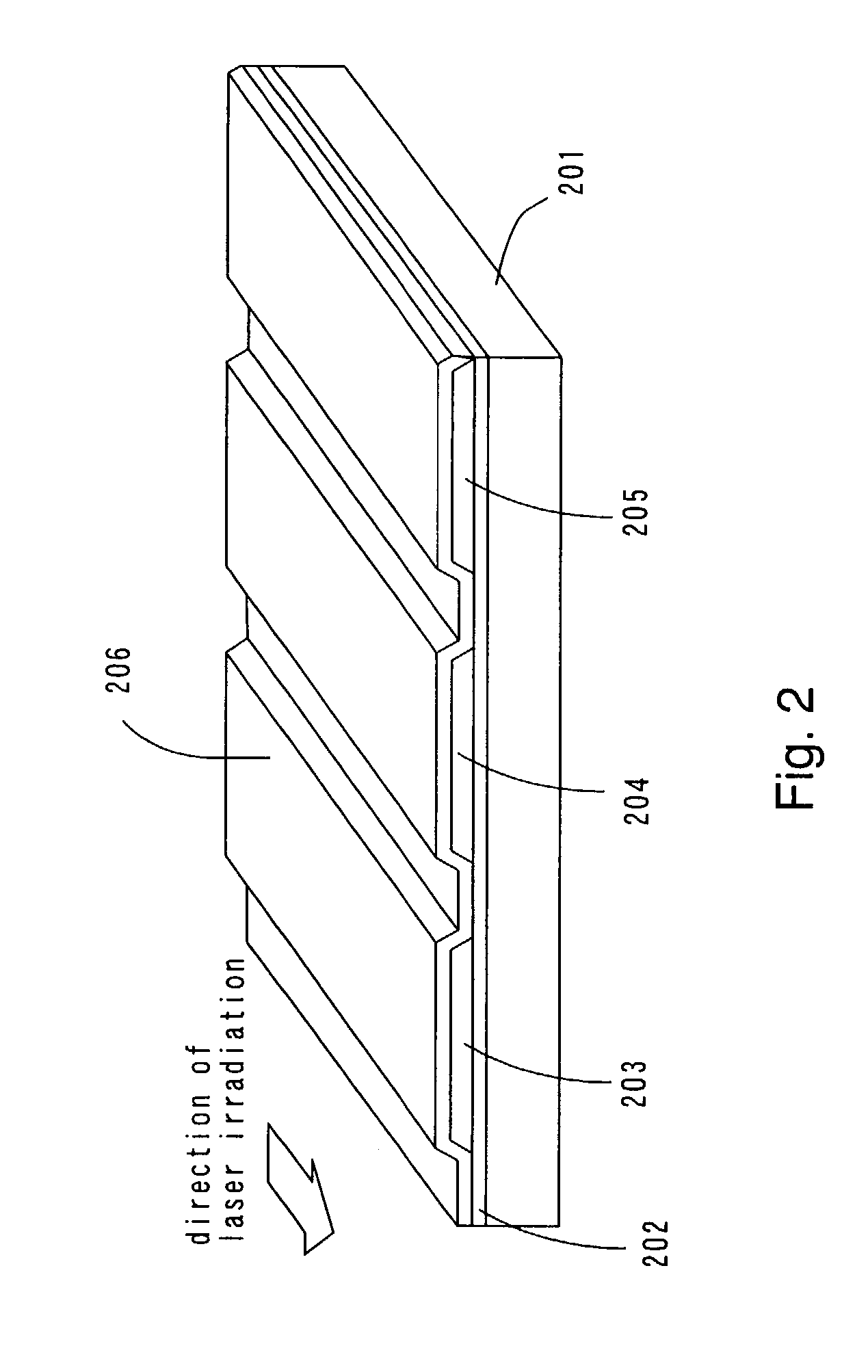

An object of the present invention is obtaining a semiconductor film with uniform characteristics by improving irradiation variations of the semiconductor film. The irradiation variations are generated due to scanning while irradiating with a linear laser beam of the pulse emission. At a laser crystallization step of irradiating a semiconductor film with a laser light, a continuous light emission excimer laser emission device is used as a laser light source. For example, in a method of fabricating an active matrix type liquid crystal display device, a continuous light emission excimer laser beam is irradiated to a semiconductor film, which is processed to be a linear shape, while scanning in a vertical direction to the linear direction. Therefore, more uniform crystallization can be performed because irradiation marks can be avoided by a conventional pulse laser.

Owner:SEMICON ENERGY LAB CO LTD

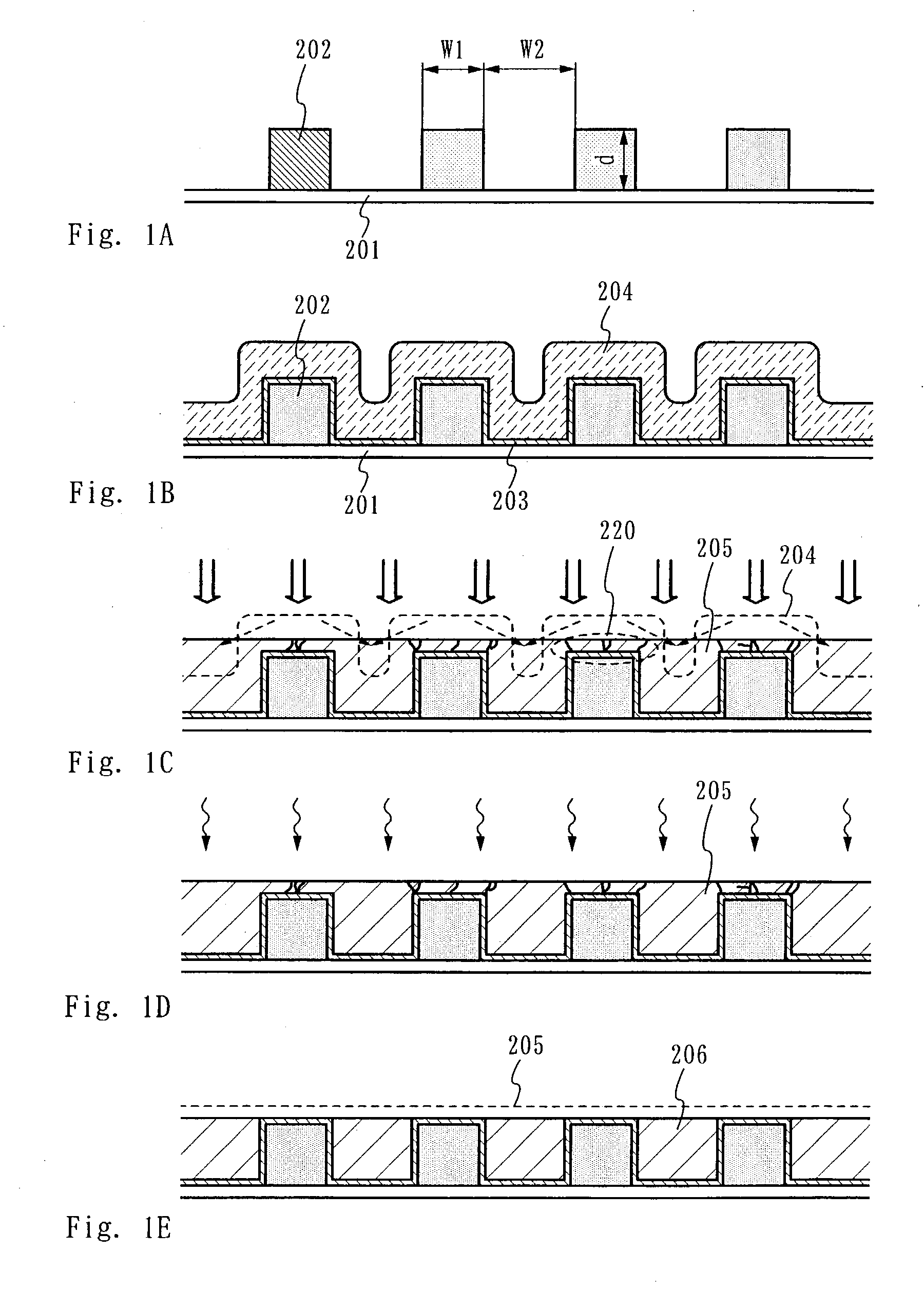

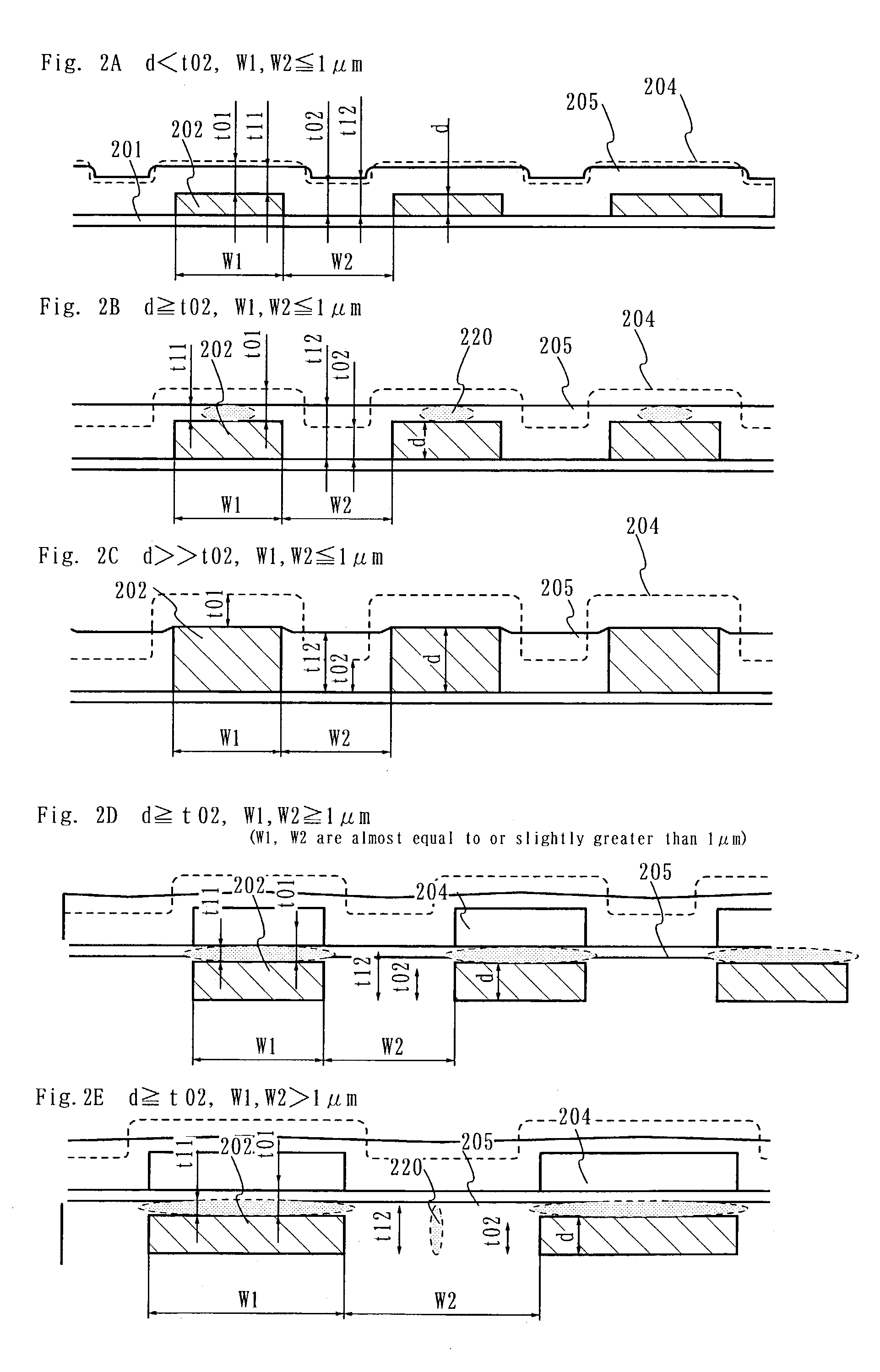

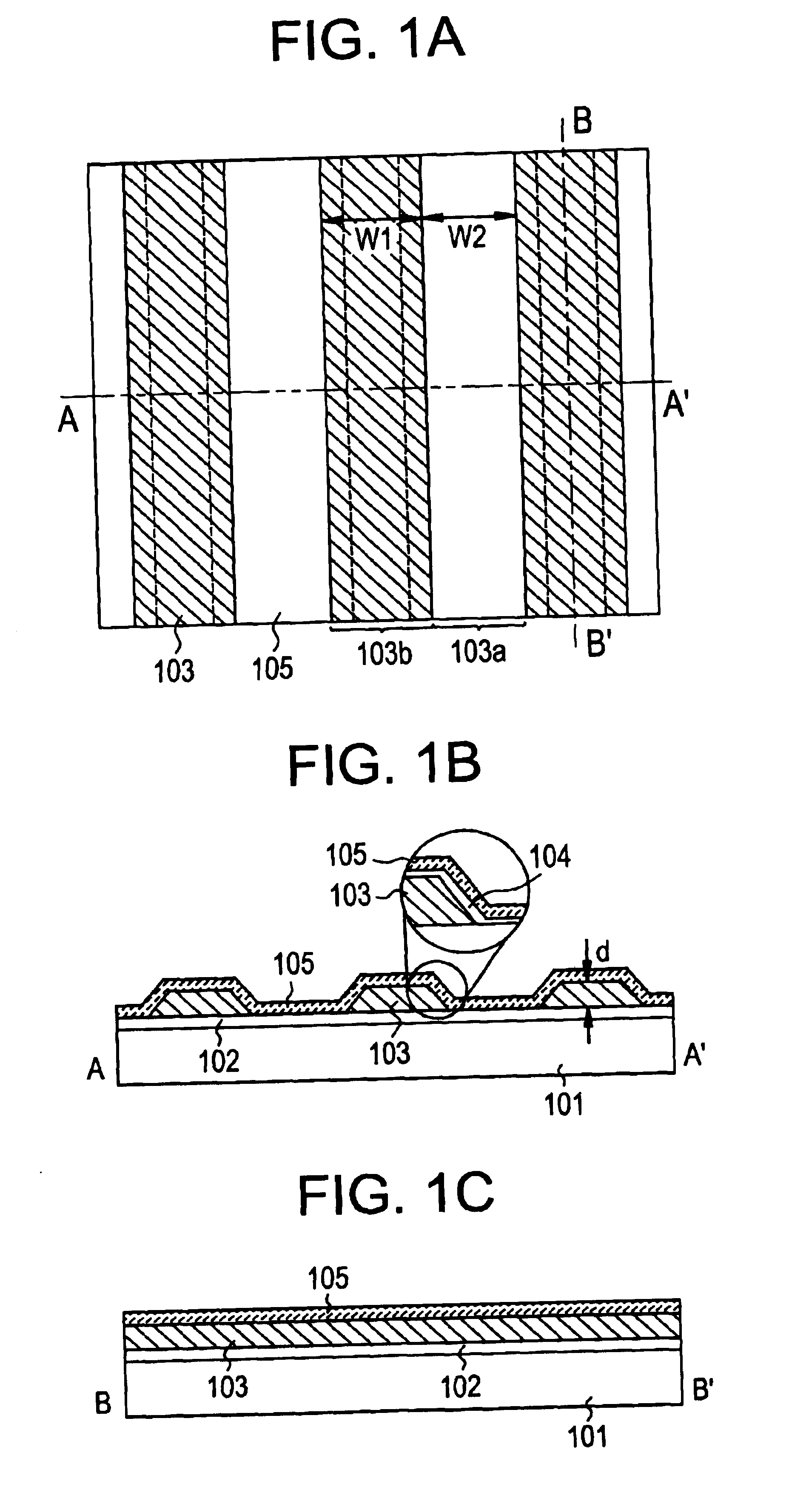

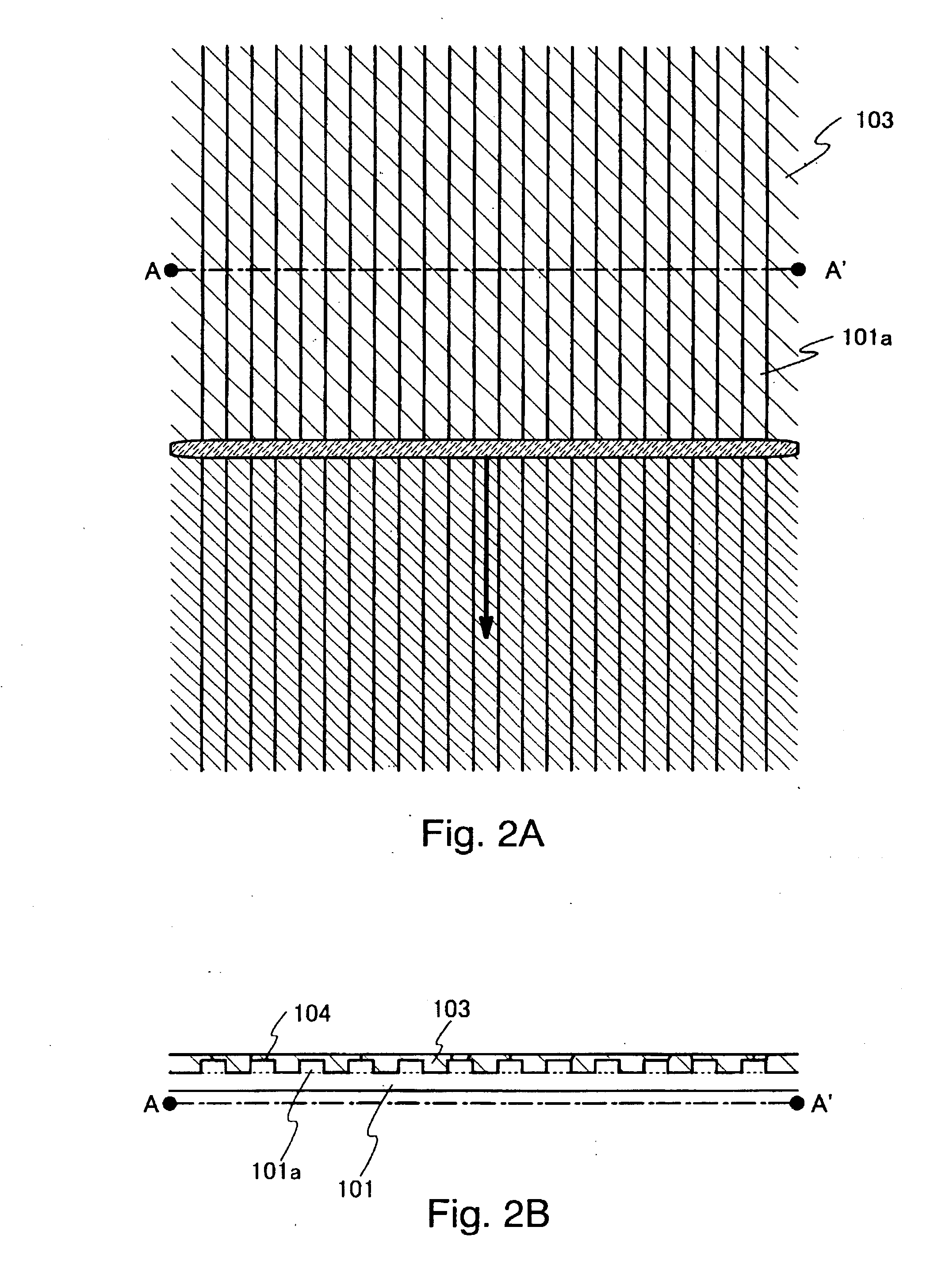

Semiconductor device and method of manufacturing the same

An objective is to provide a method of manufacturing a semiconductor device, and a semiconductor device manufactured by using the manufacturing method, in which a laser crystallization method is used that is capable of preventing the formation of grain boundaries in TFT channel formation regions, and is capable of preventing conspicuous drops in TFT mobility, reduction in the ON current, and increases in the OFF current, all due to grain boundaries. Stripe shape or rectangular shape unevenness or opening is formed. Continuous wave laser light is then irradiated to a semiconductor film formed on an insulating film. Note that although it is most preferable to use continuous wave laser light at this point, pulse wave oscillation laser light may also be used.

Owner:SEMICON ENERGY LAB CO LTD

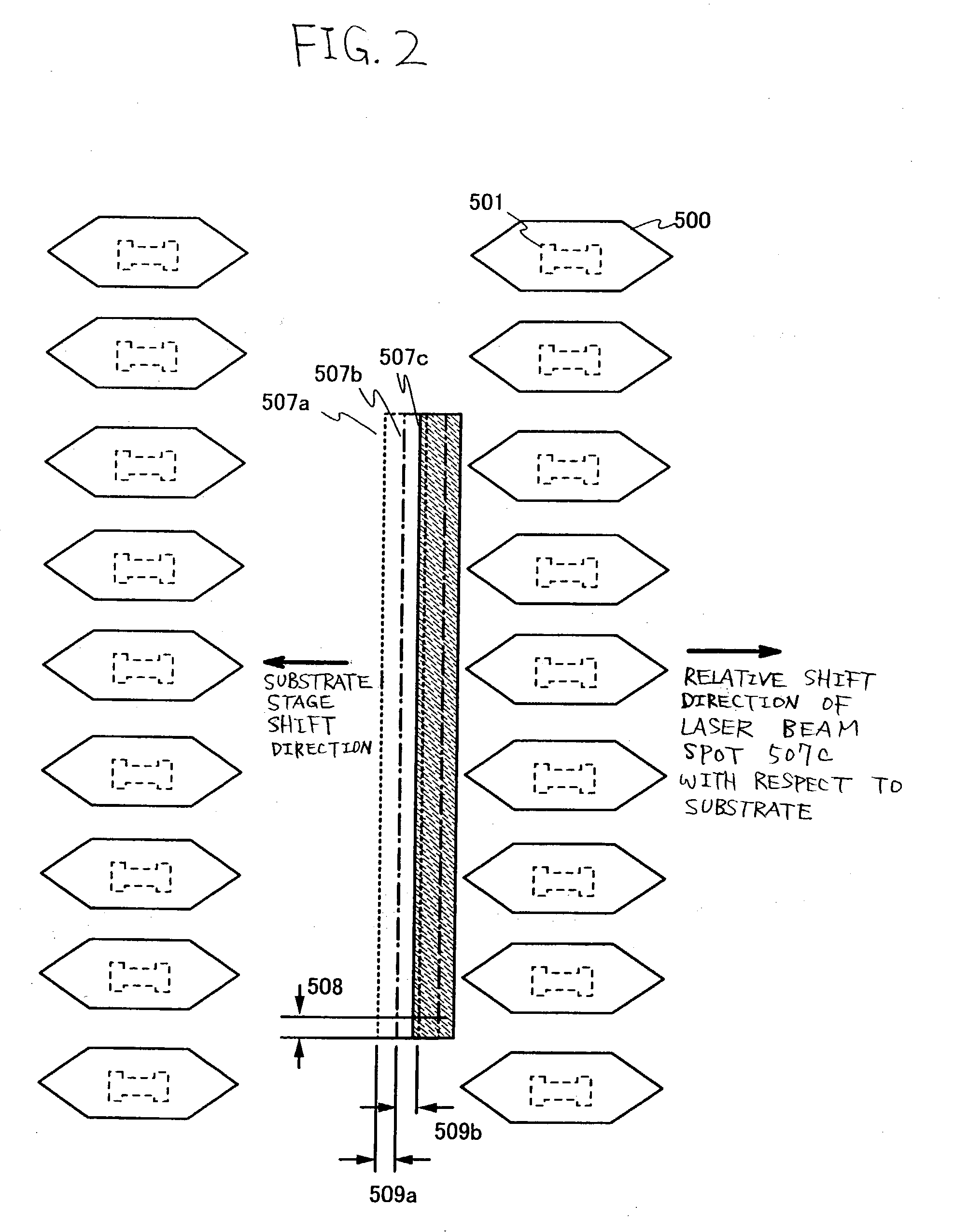

Process and system for laser crystallization processing of film regions on a substrate to minimize edge areas, and a structure of such film regions

InactiveUS20060030164A1Increase speedSmall sizeTransistorLaser detailsLaser crystallizationCrystallization

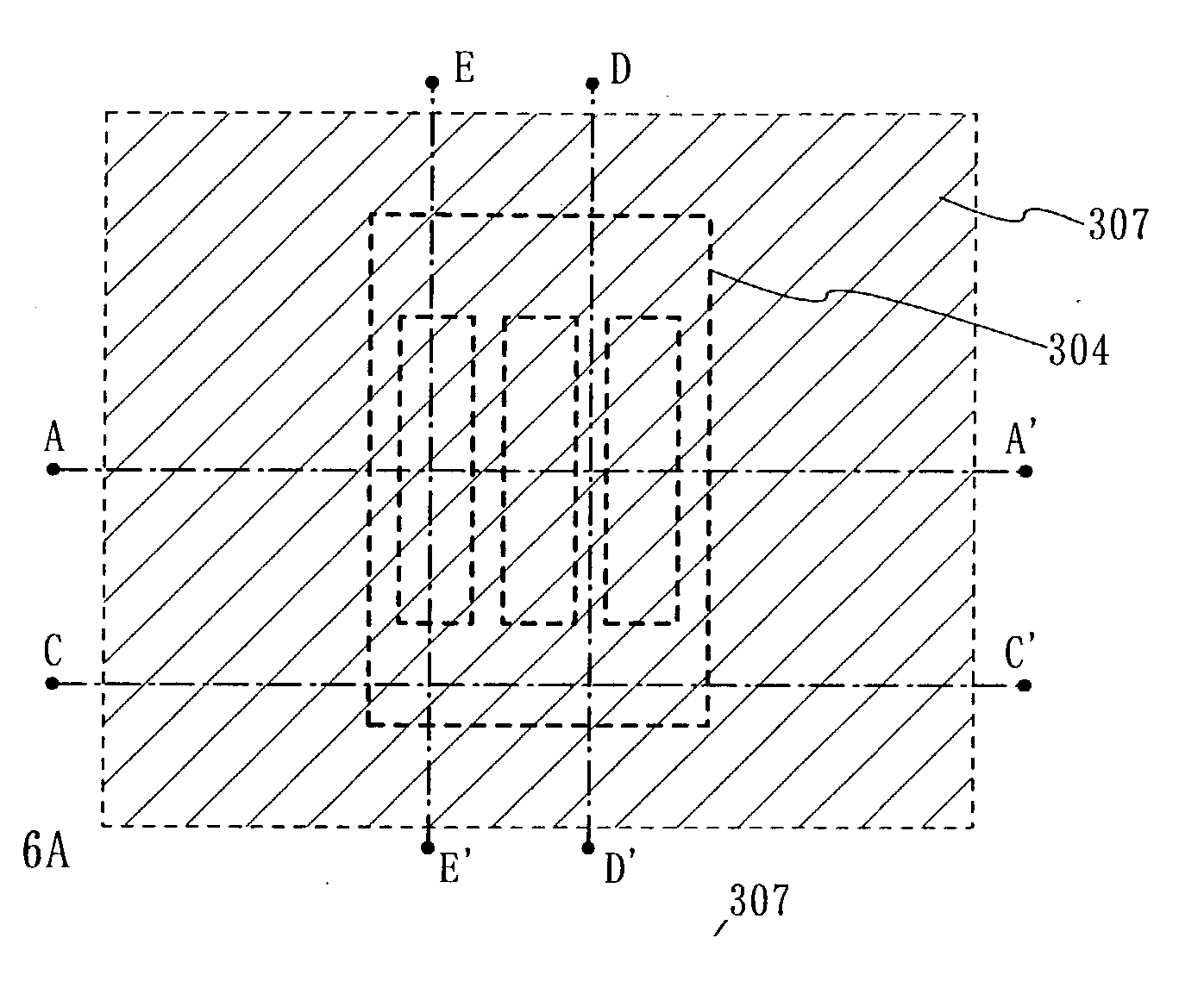

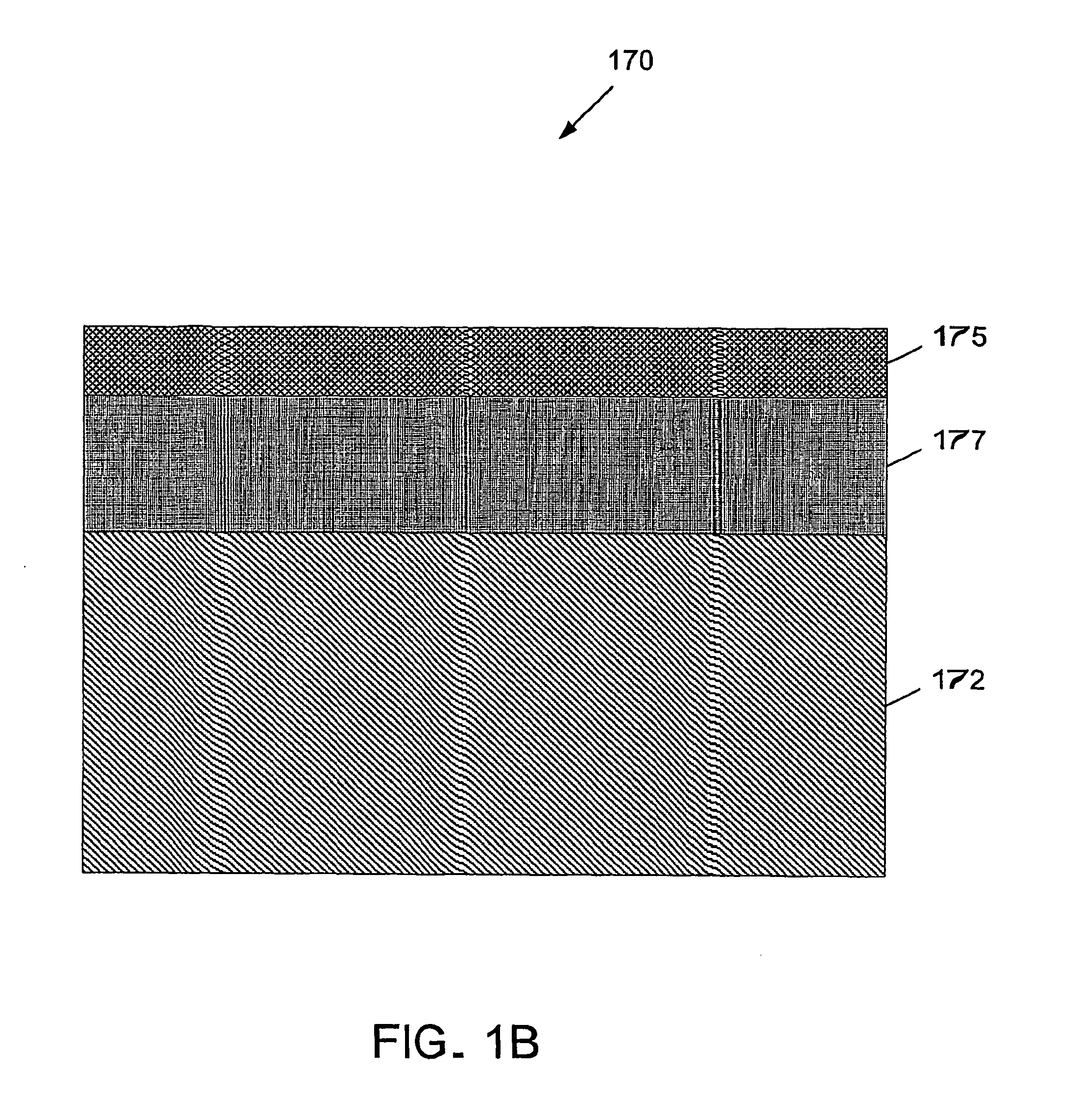

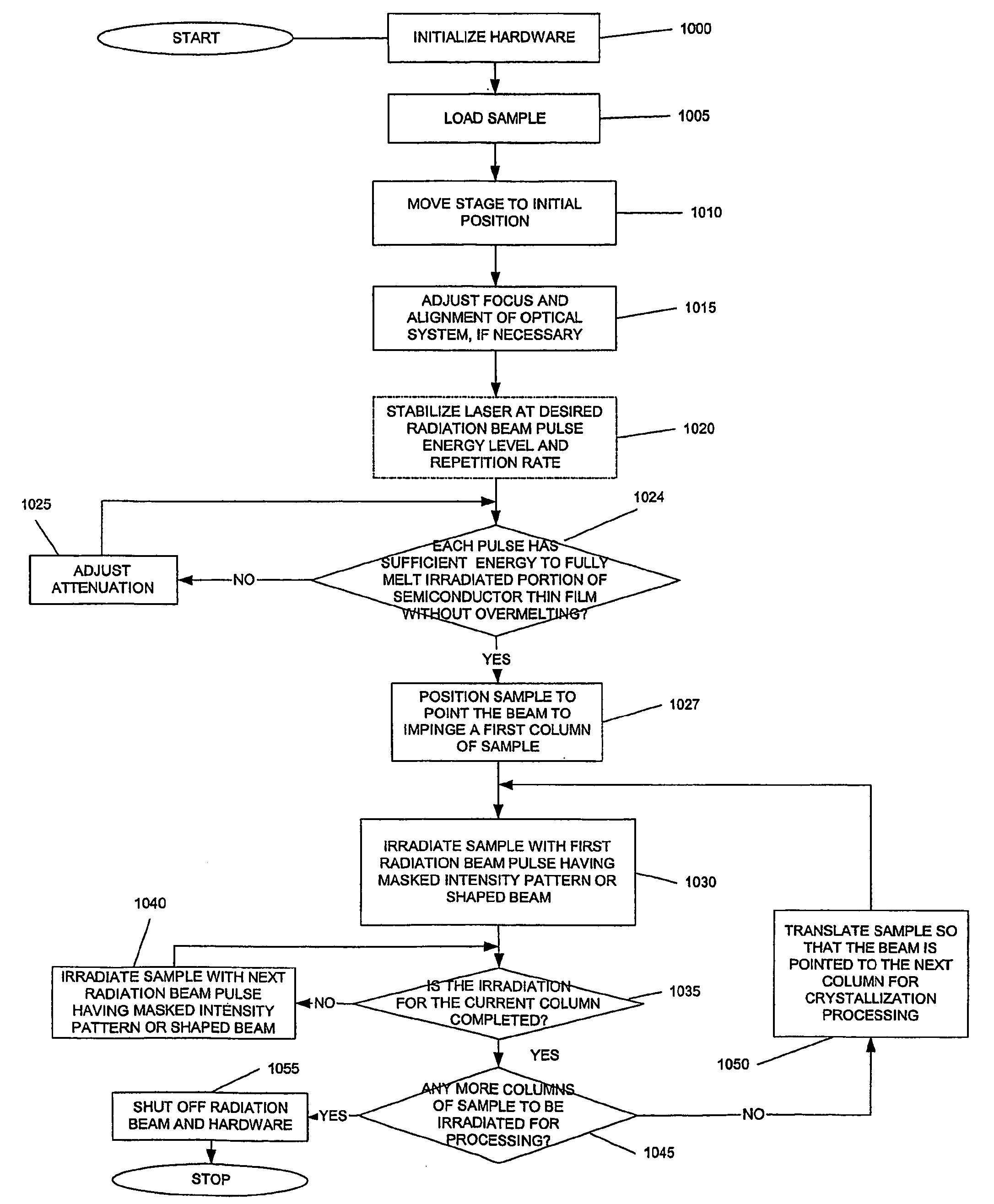

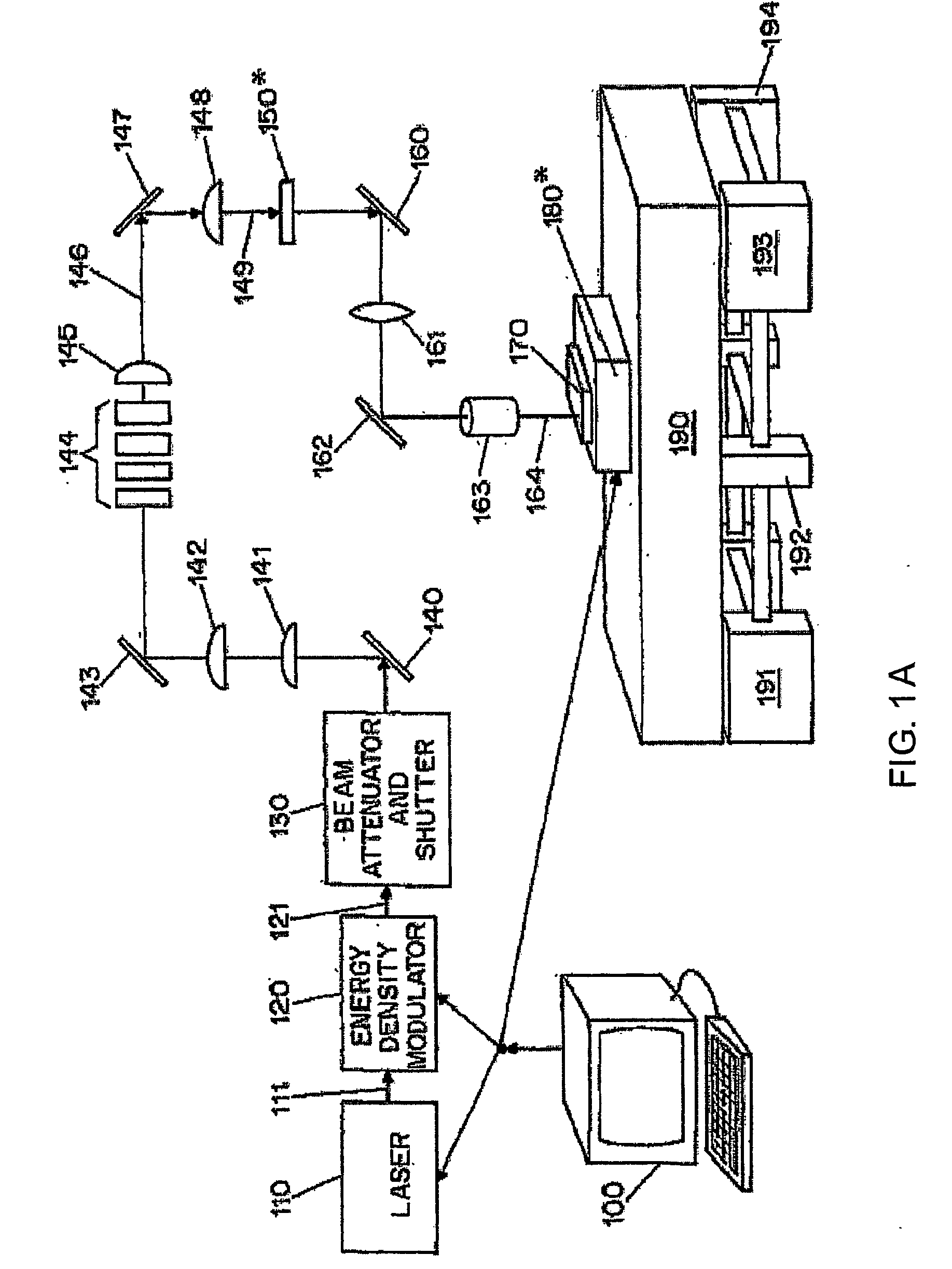

A process and system for processing a thin film sample are provided. In particular, a beam generator can be controlled to emit at least one beam pulse. The beam pulse is then masked to produce at least one masked beam pulse, which is used to irradiate at least one portion of the thin film sample. With the at least one masked beam pulse, the portion of the film sample is irradiated with sufficient intensity for such portion to later crystallize. This portion of the film sample is allowed to crystallize so as to be composed of a first area and a second area. Upon the crystallization thereof, the first area includes a first set of grains, and the second area includes a second set of grains whose at least one characteristic is different from at least one characteristic of the second set of grains. The first area surrounds the second area, and is configured to allow an active region of a thin-film transistor (“TFT”) to be provided at a distance therefrom.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

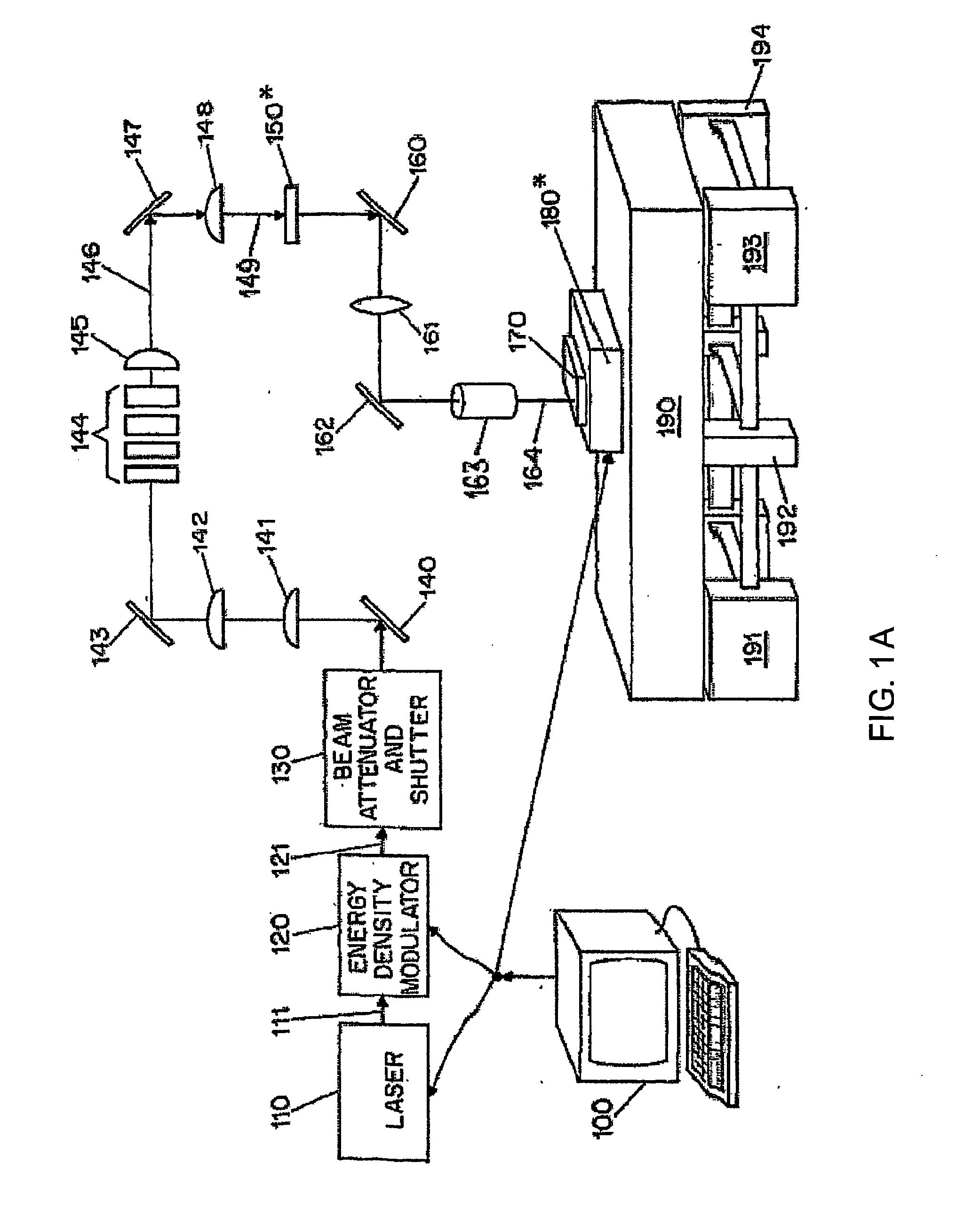

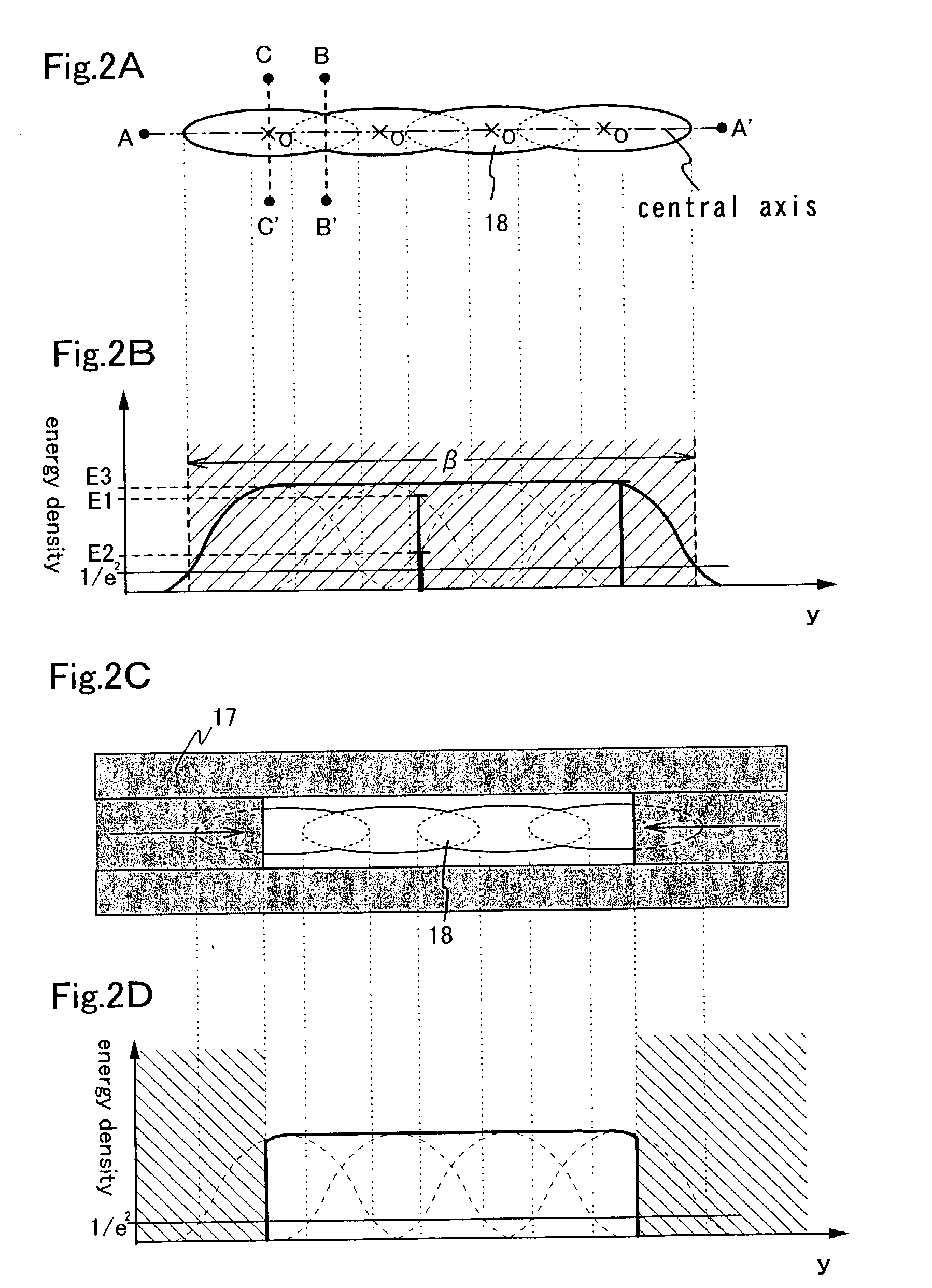

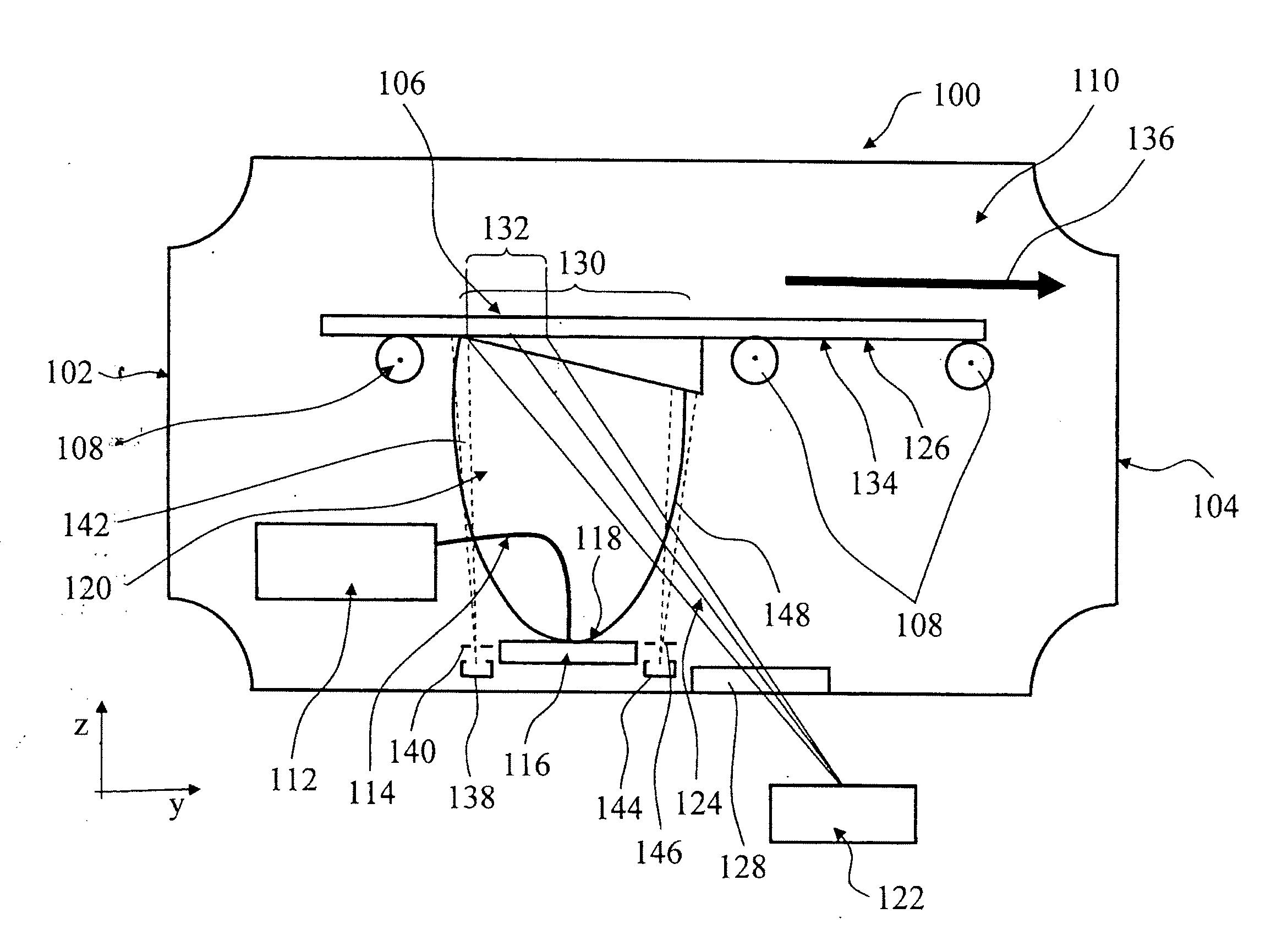

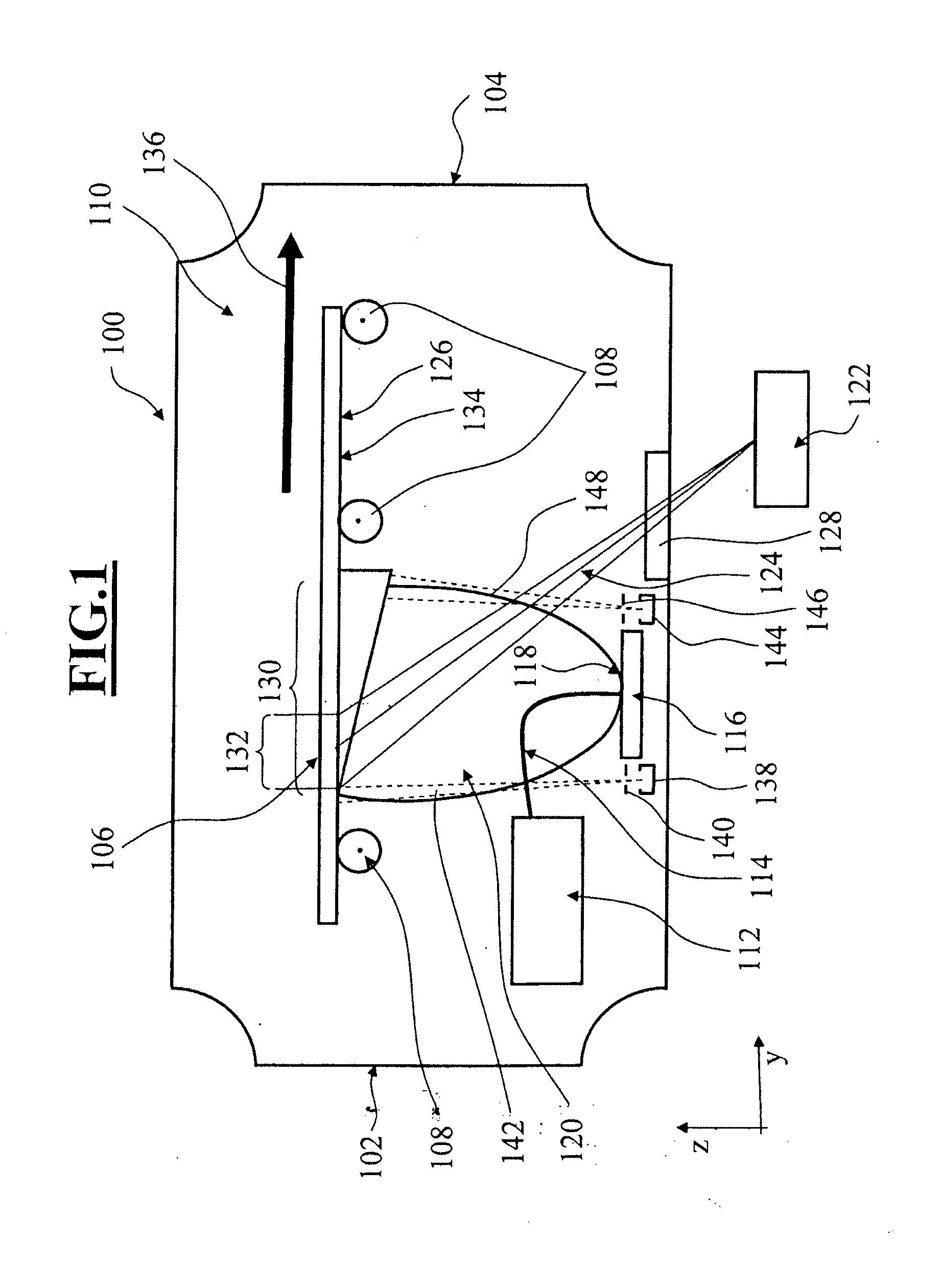

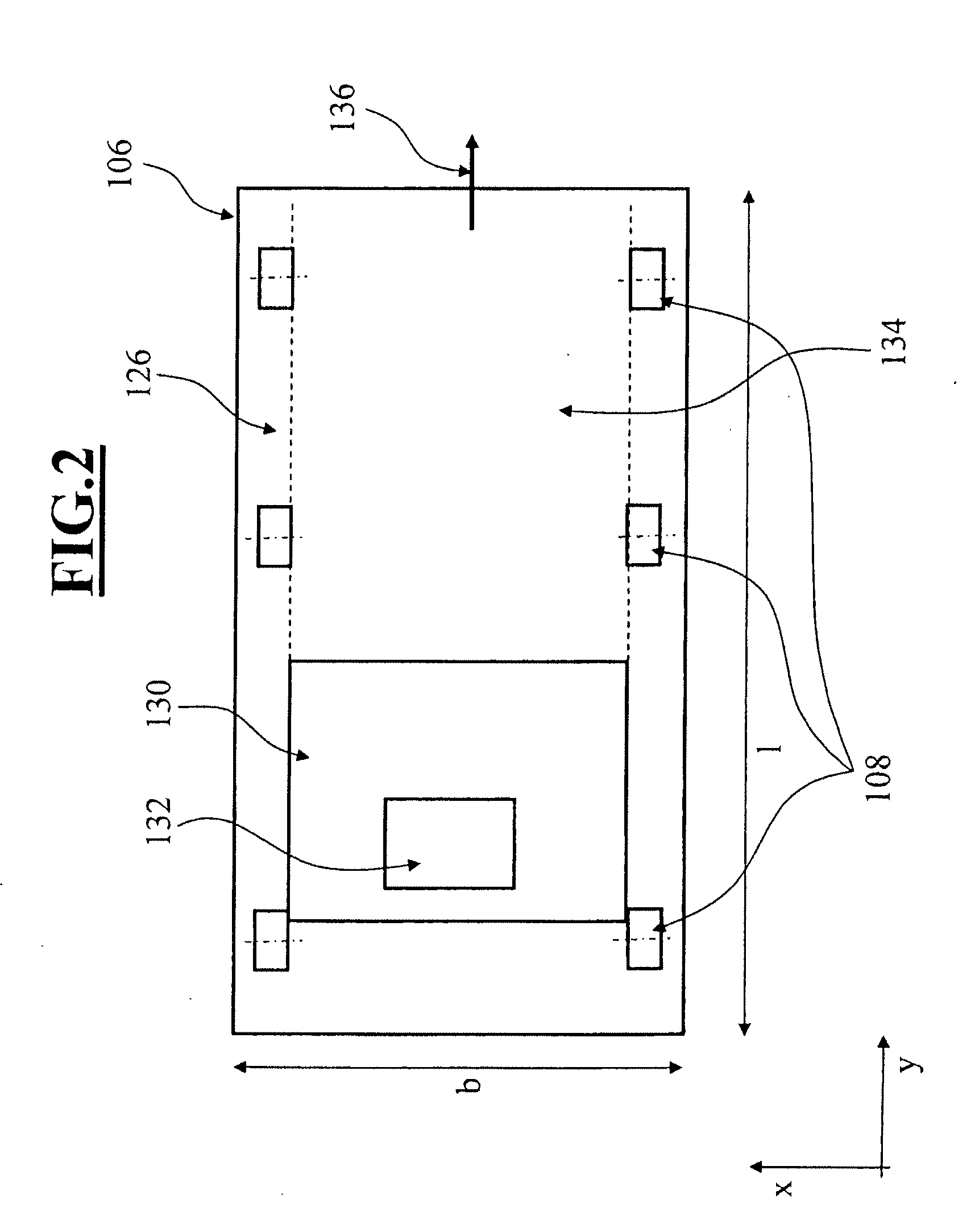

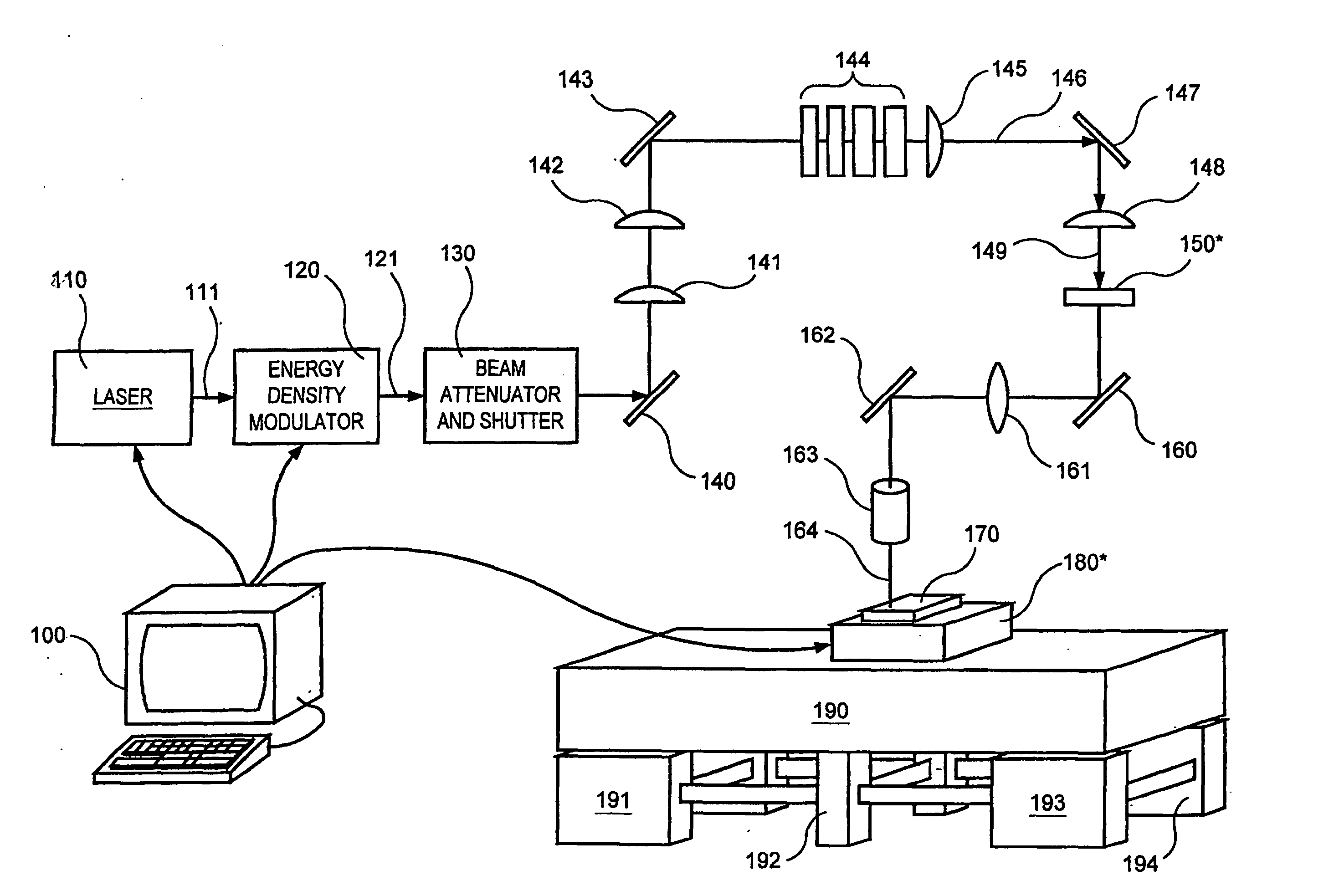

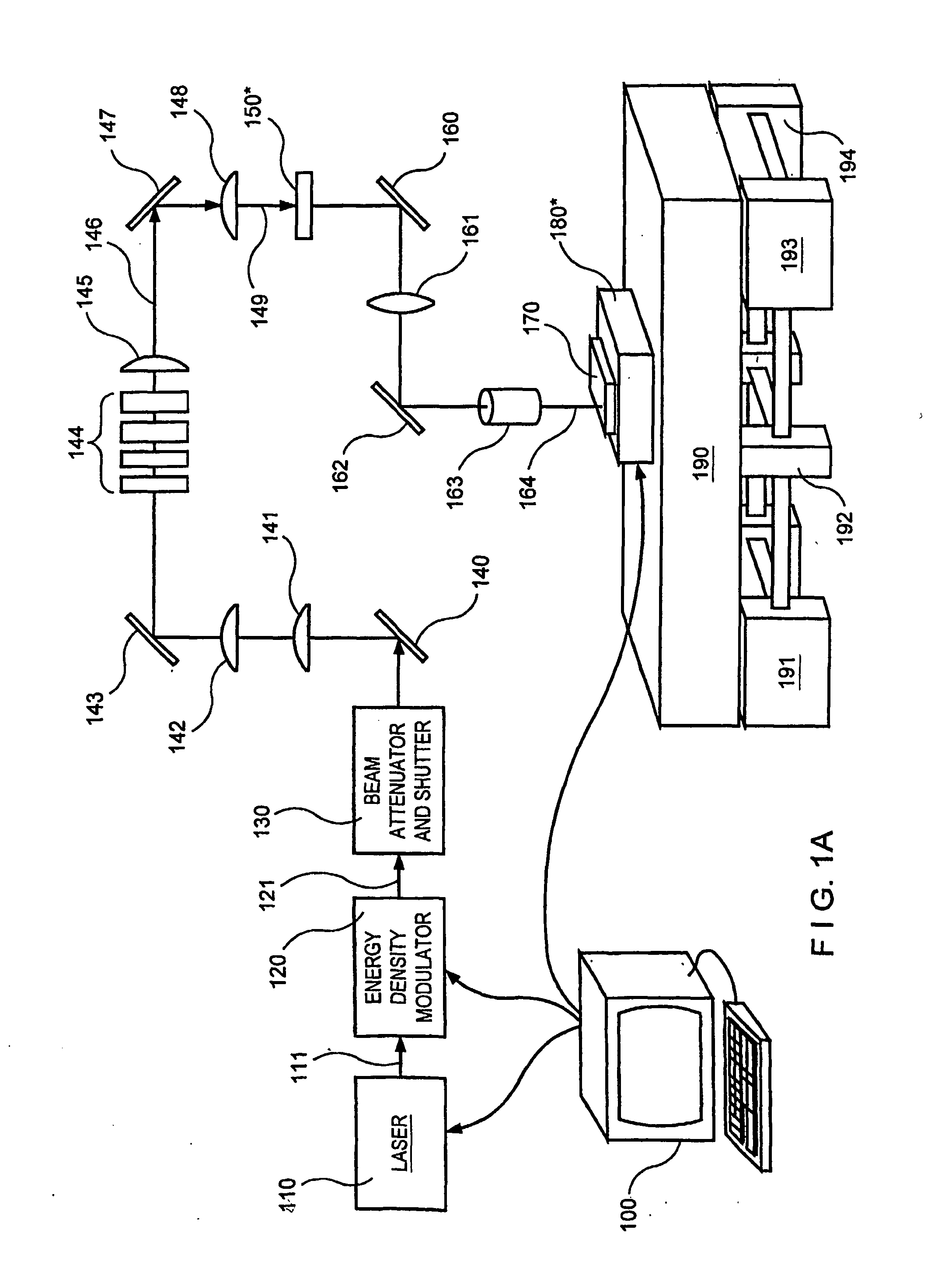

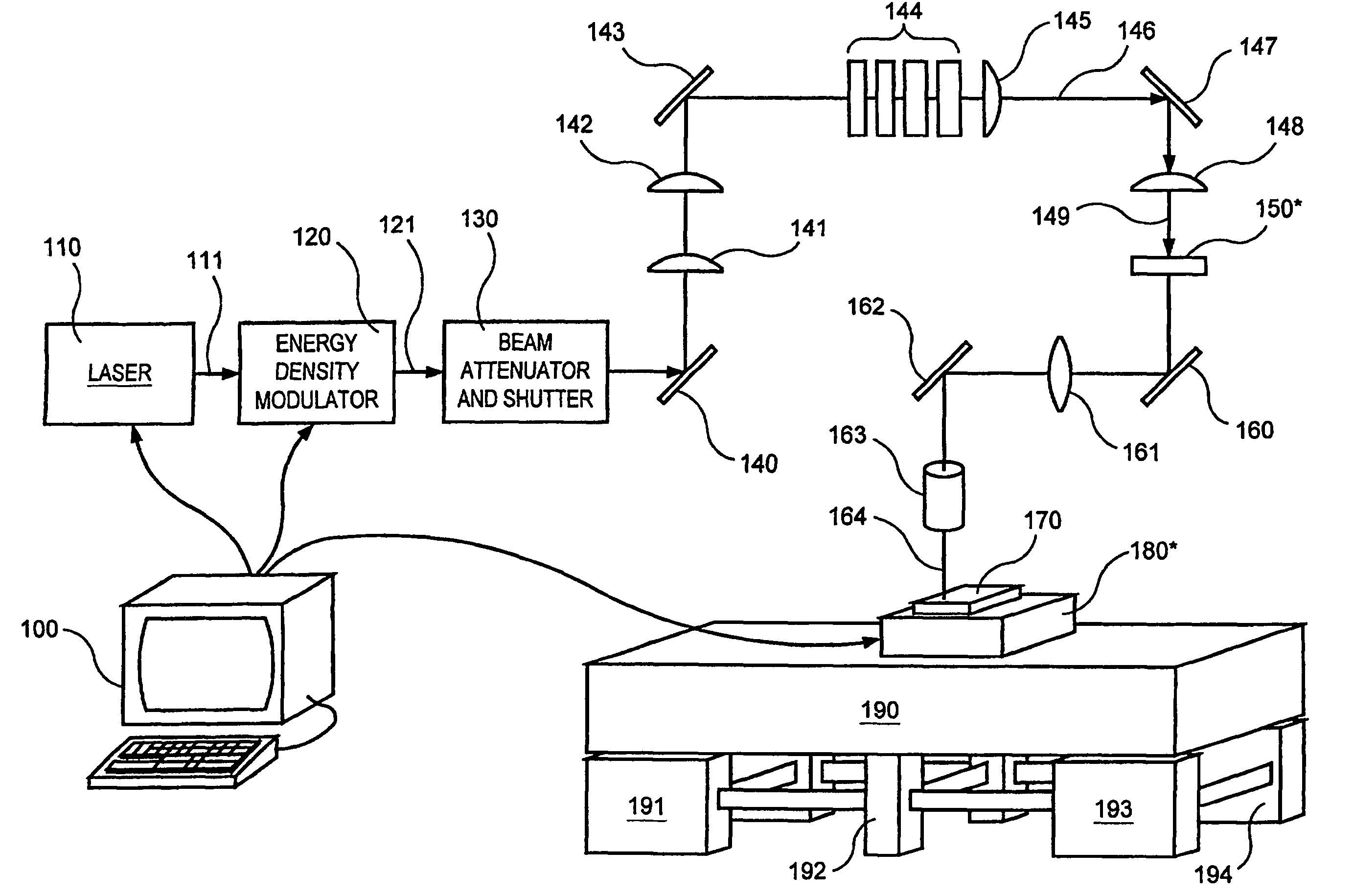

Systems and methods for implementing an interaction between a laser shaped as a line beam and a film deposited on a substrate

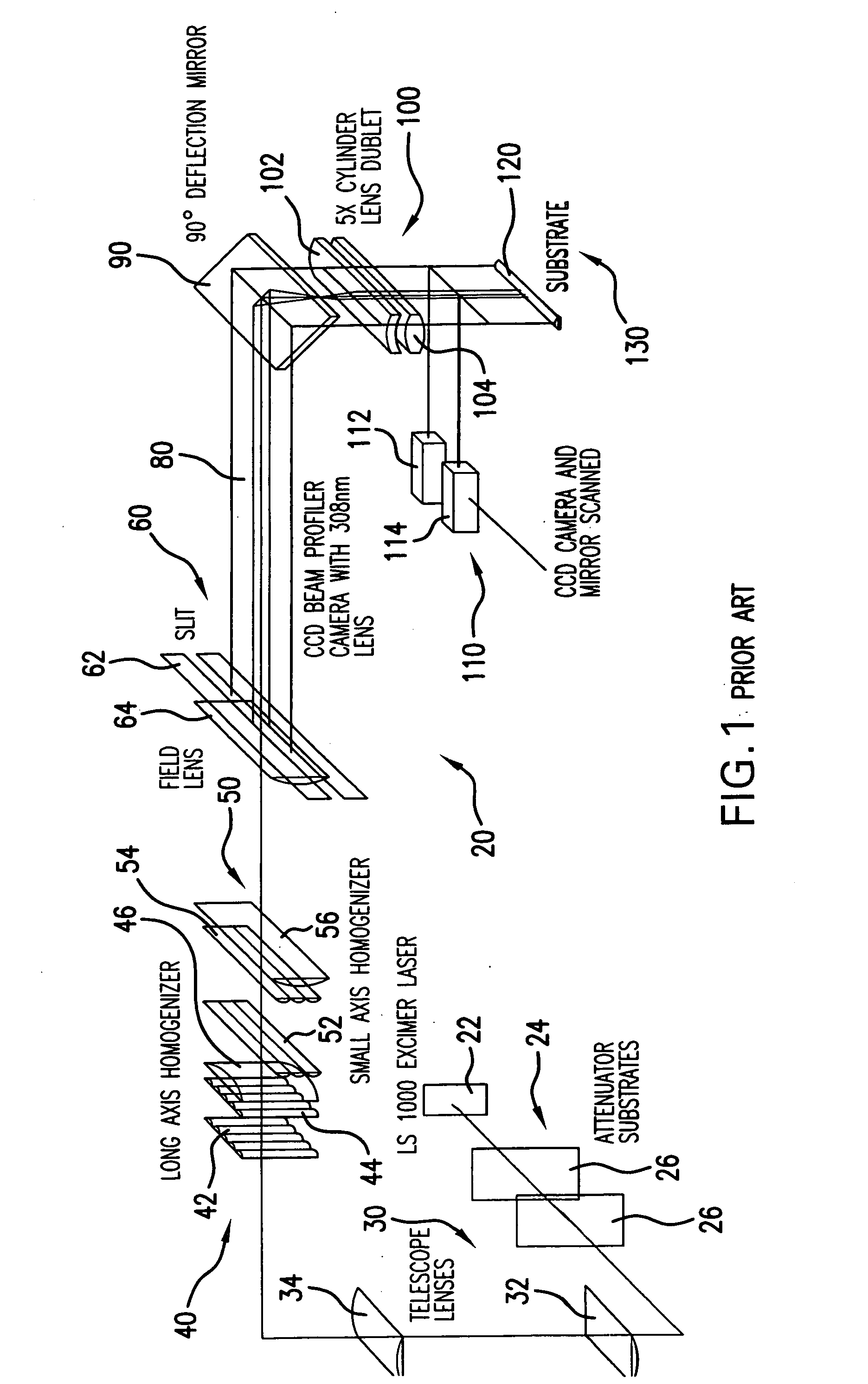

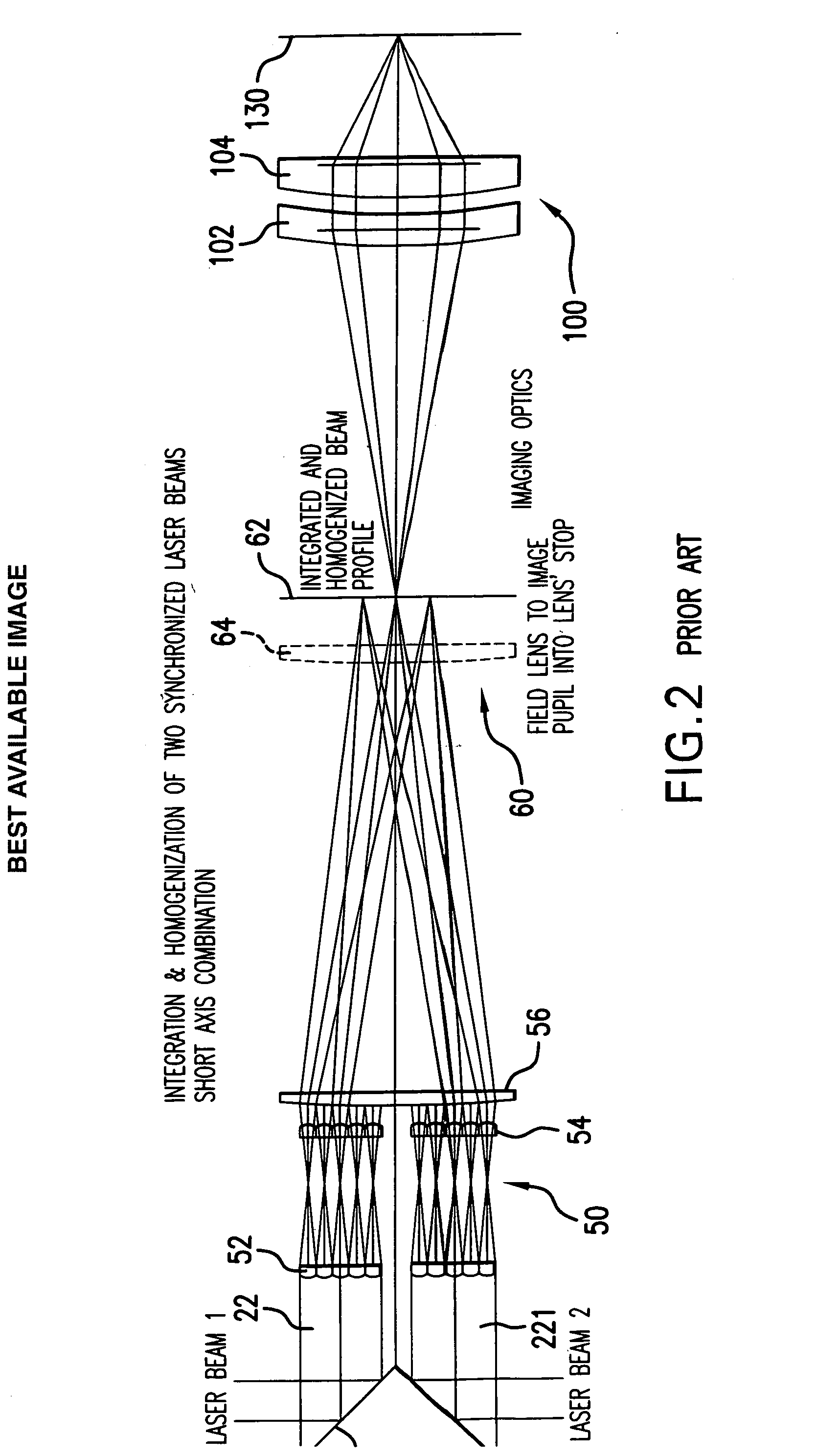

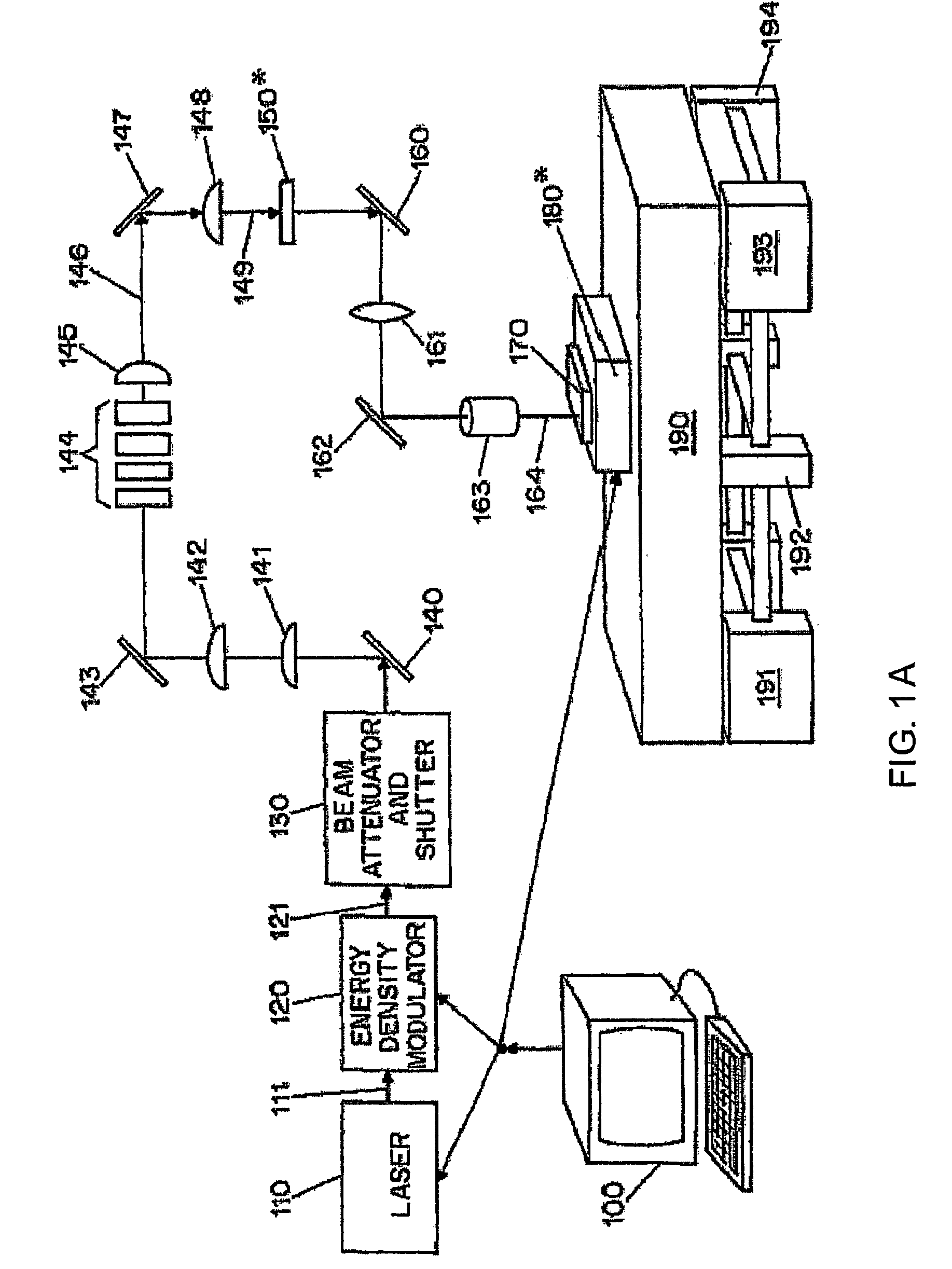

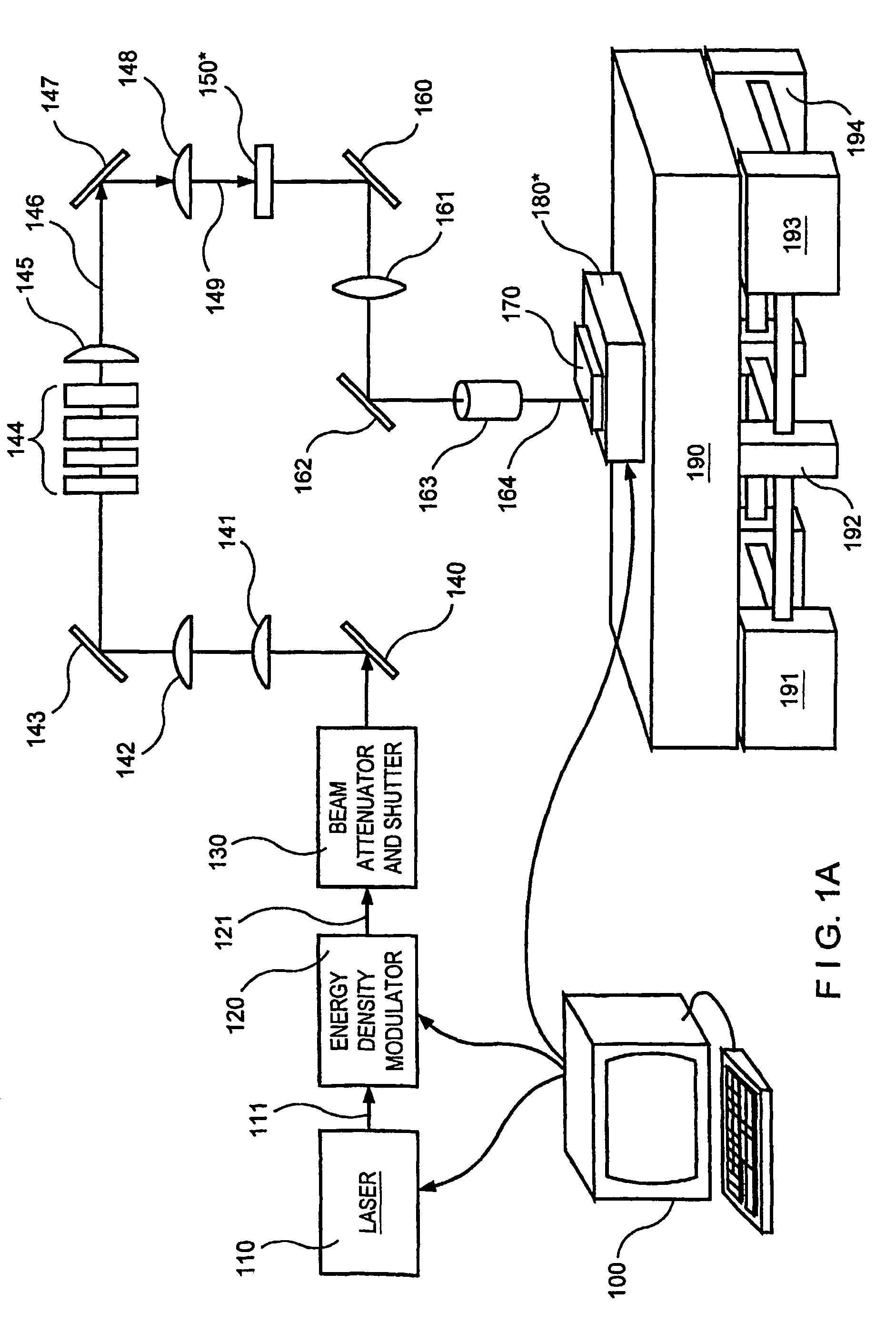

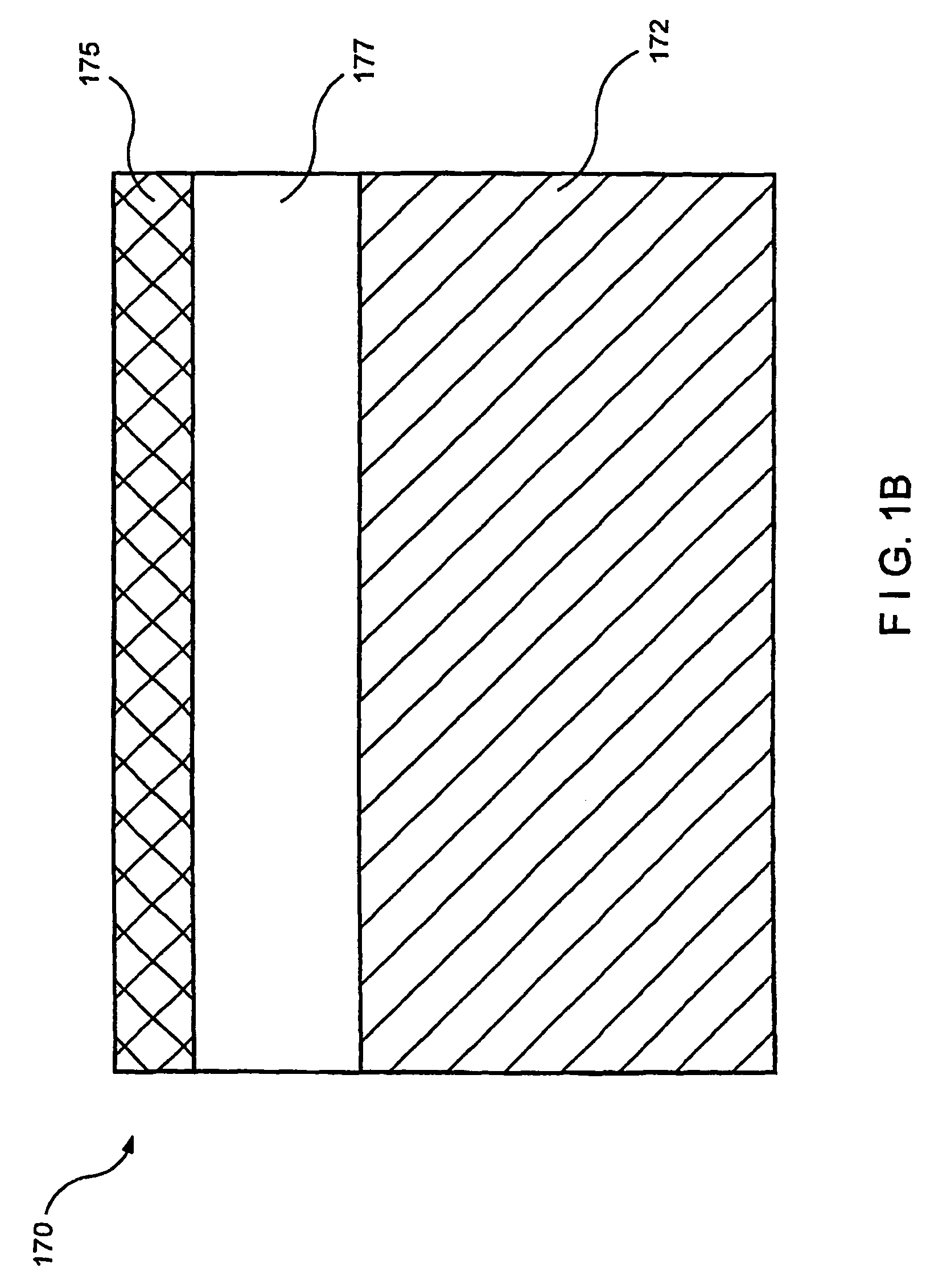

InactiveUS20050259709A1Maintain energy densityFrom solid stateBy zone-melting liquidsLaser crystallizationLight beam

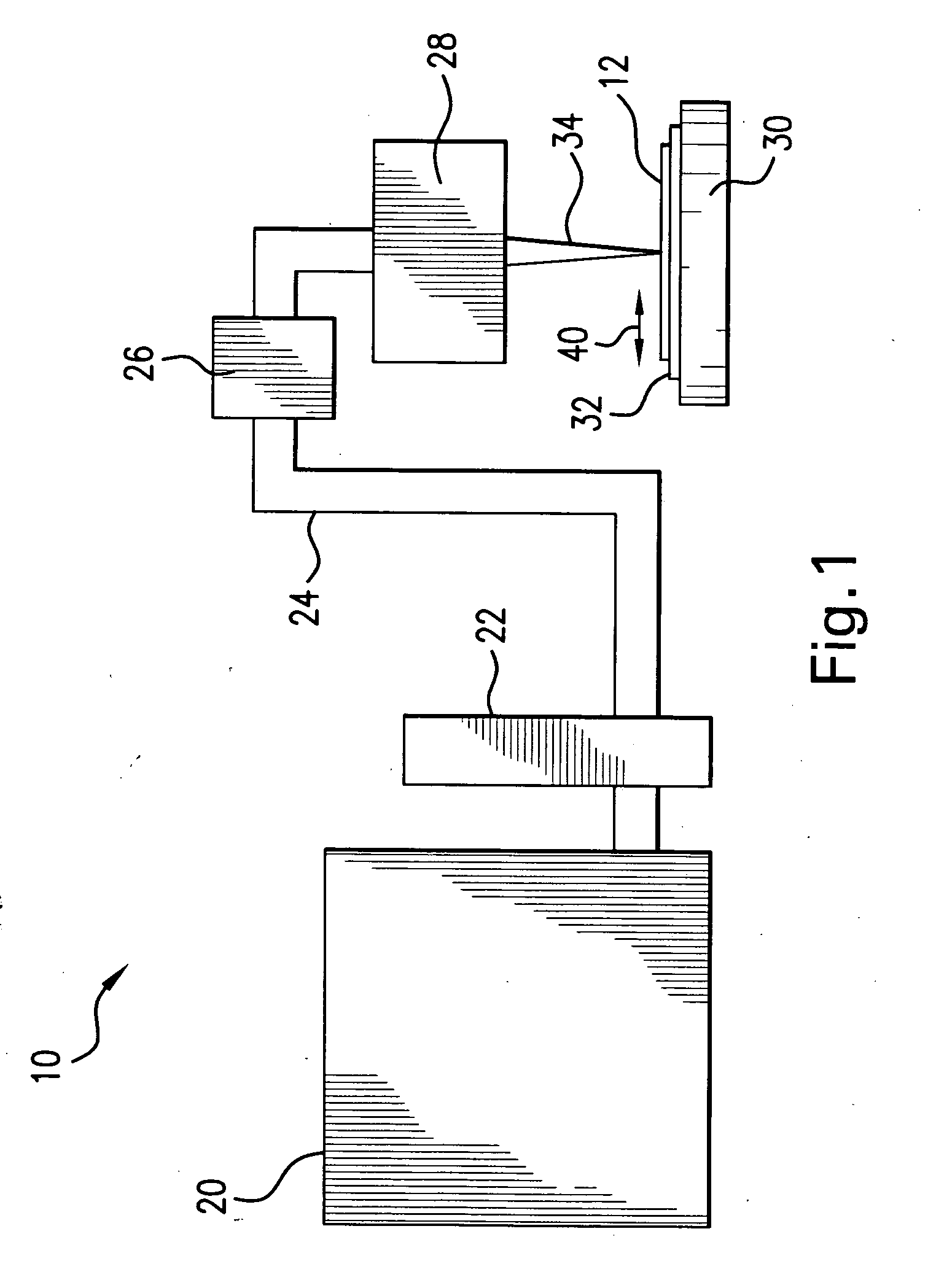

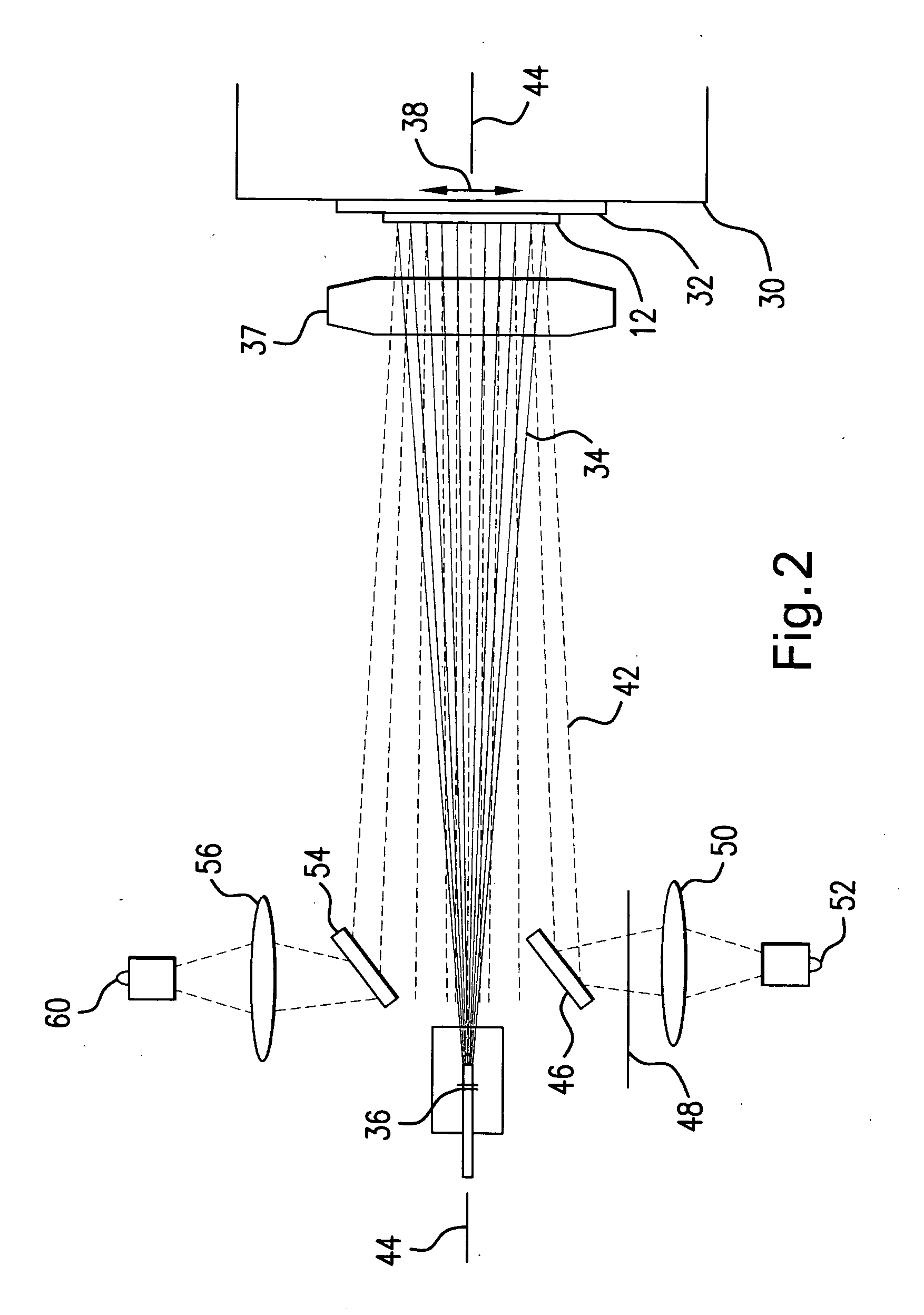

A laser crystallization apparatus and method are disclosed for selectively melting a film such as amorphous silicon that is deposited on a substrate. The apparatus may comprise an optical system for producing stretched laser pulses for use in melting the film. In still another aspect of an embodiment of the present invention, a system and method are provided for stretching a laser pulse. In another aspect, a system is provided for maintaining a divergence of a pulsed laser beam (stretched or non-stretched) at a location along a beam path within a predetermined range. In another aspect, a system may be provided for maintaining the energy density at a film within a predetermined range during an interaction of the film with a shaped line beam.

Owner:CYMER INC

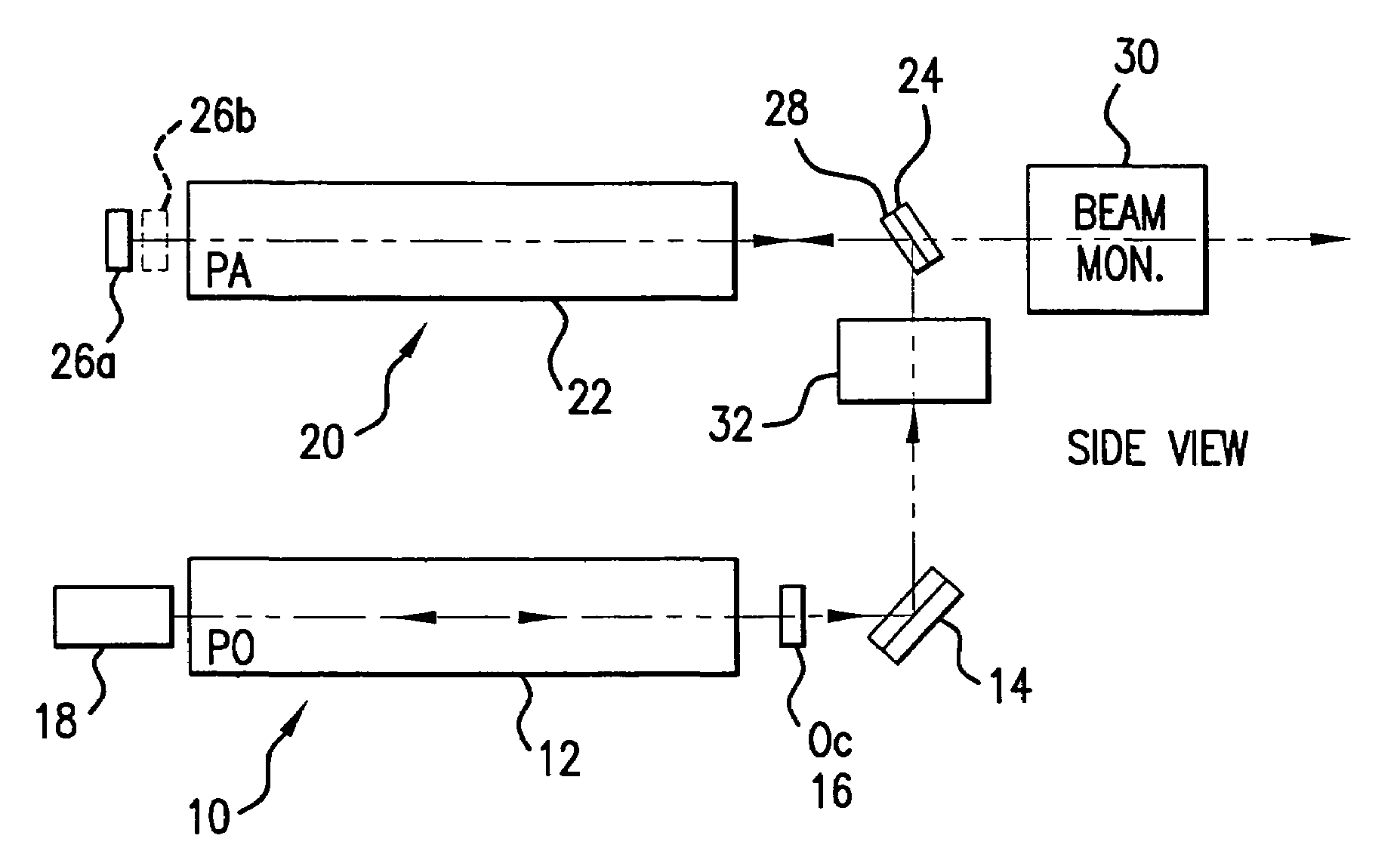

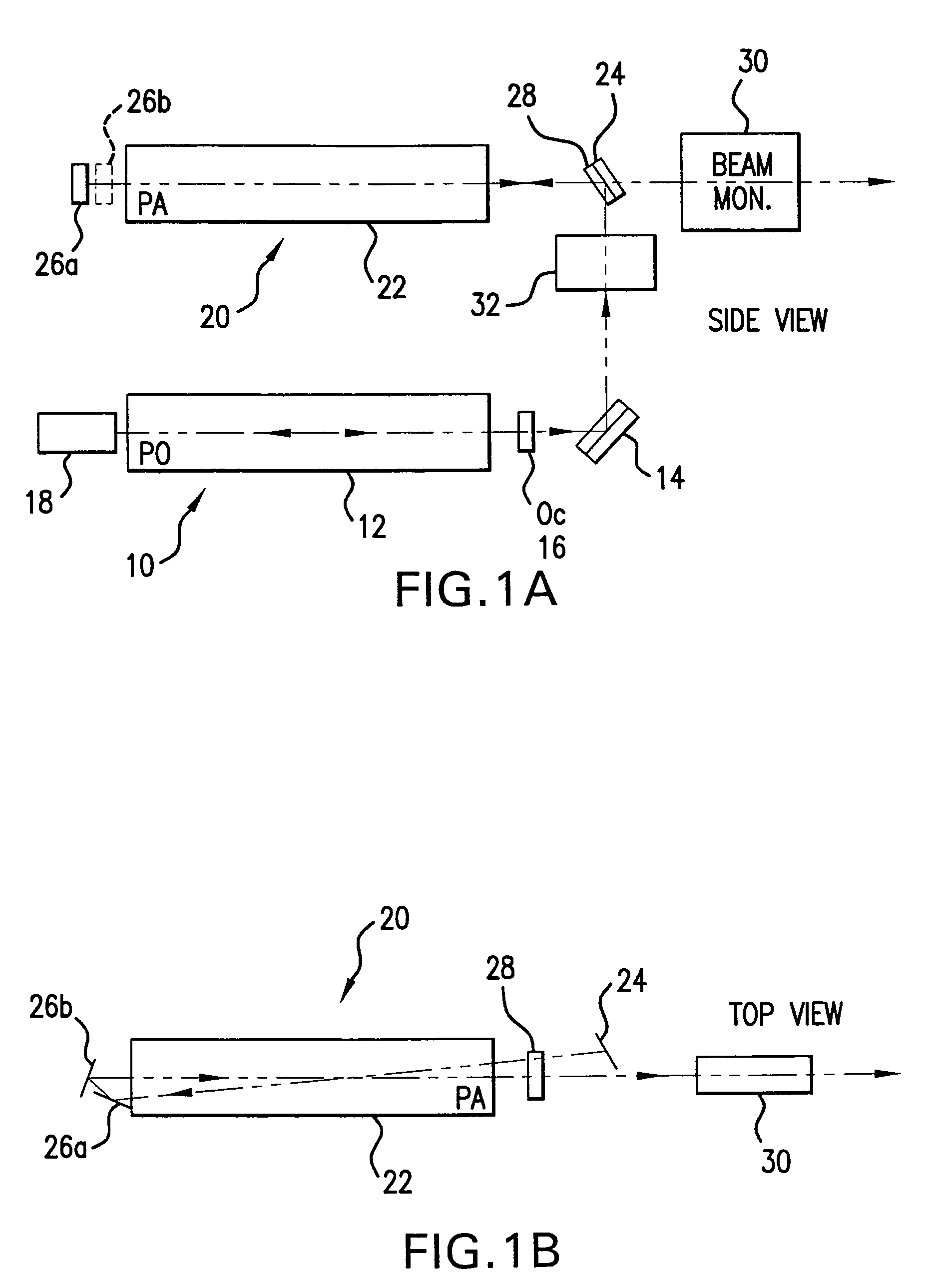

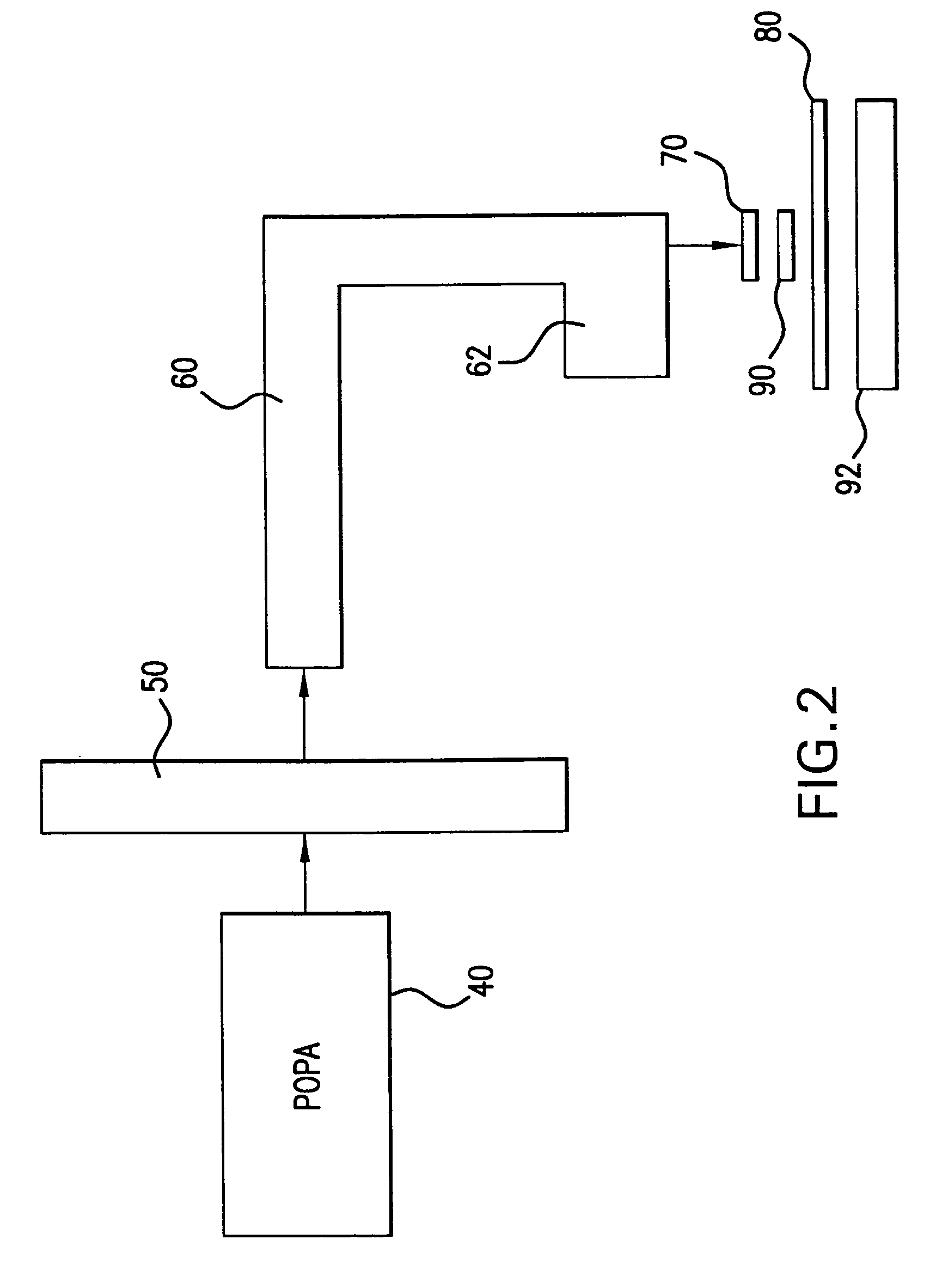

Laser thin film poly-silicon annealing system

InactiveUS20050141580A1High repetition rateIncrease powerSemiconductor/solid-state device manufacturingLaser arrangementsPulse beamMetrology

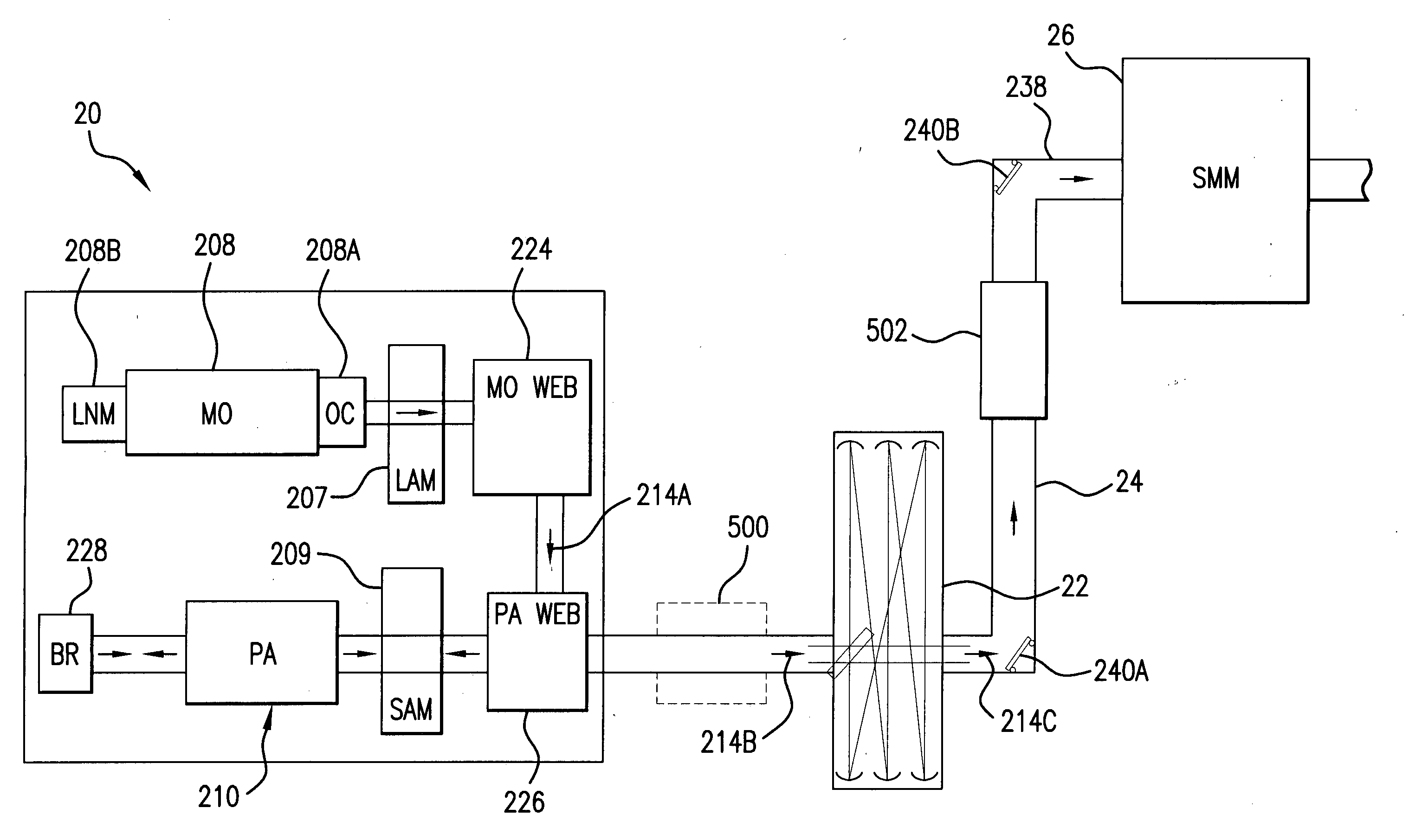

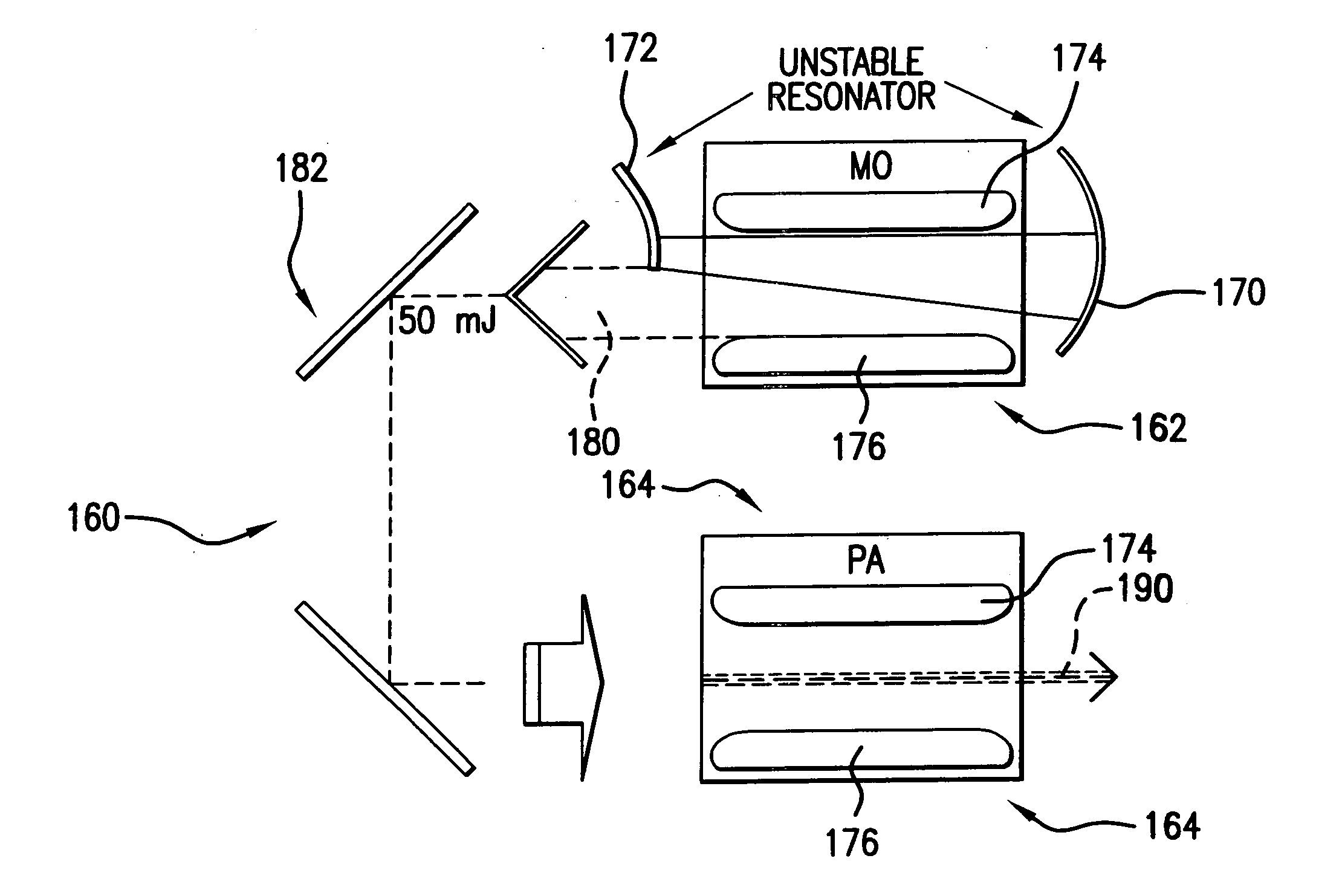

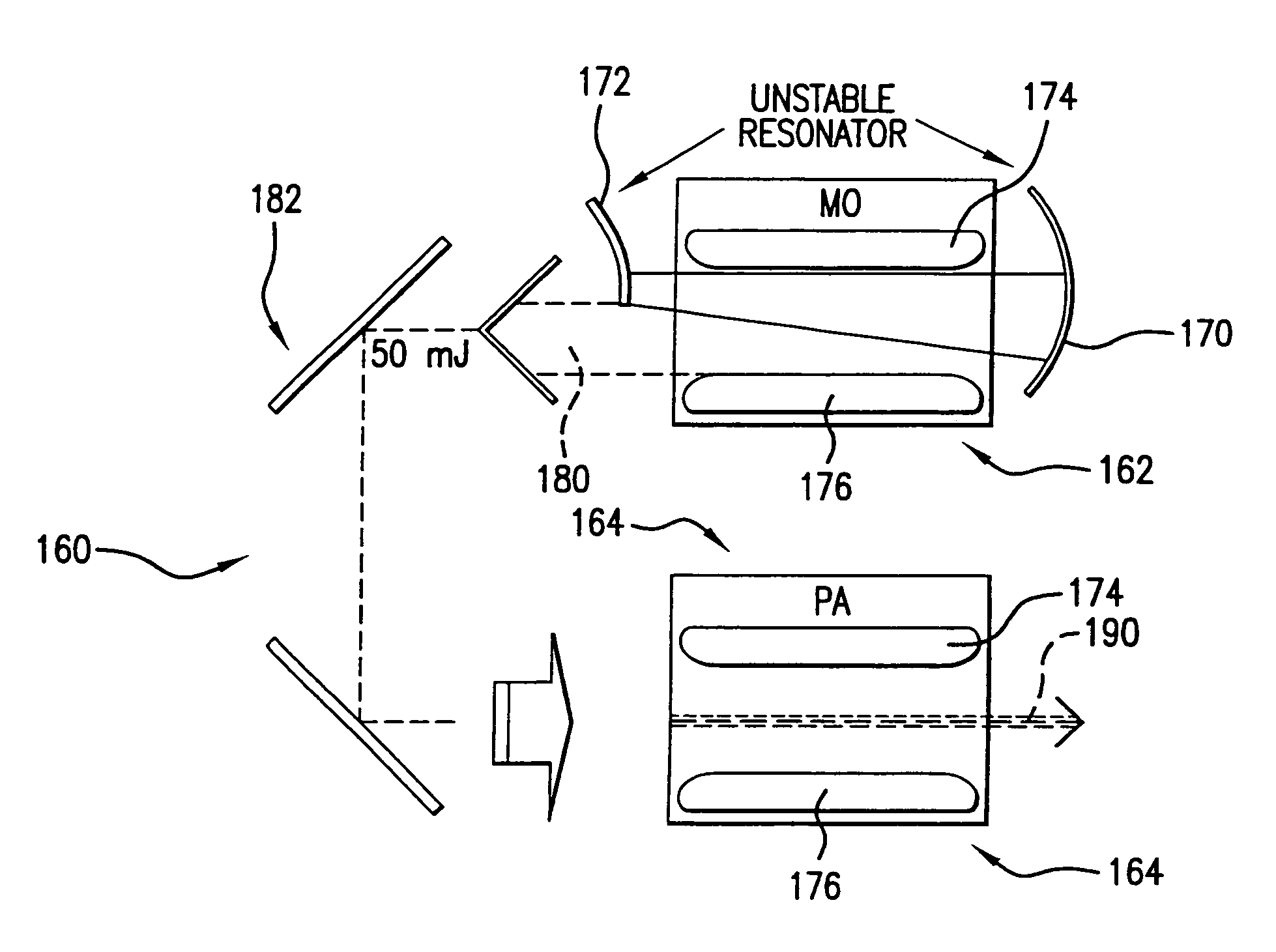

A gas discharge laser crystallization apparatus and method for performing a transformation of a crystal makeup or orientation in a film on a workpiece is disclosed, which may comprise a master oscillator power amplifier MOPA or power oscillator power amplifier configured XeF laser system producing a laser output light pulse beam at a high repetition rate and high power with a pulse to pulse dose control; an optical system producing an elongated thin pulsed working beam from the laser output light pulse beam. The apparatus may further comprise the laser system is configured as a POPA laser system and further comprising: relay optics operative to direct a first output laser light pulse beam from a first laser PO unit into a second laser PA unit; and, a timing and control module timing the creation of a gas discharge in the first and second laser units within plus or minus 3 ns, to produce the a second laser output light pulse beam as an amplification of the first laser output light pulse beam. The system may comprise divergence control in the oscillator laser unit. Divergence control may comprise an unstable resonator arrangement. The system may further comprise a beam pointing control mechanism intermediate the laser and the workpiece and a beam position control mechanism intermediate the laser and the workpiece. Beam parameter metrology may provide active feedback control to the beam pointing mechanism and active feedback control to the beam position control mechanism.

Owner:CYMER INC

Laser thin film poly-silicon annealing system

InactiveUS7061959B2Semiconductor/solid-state device manufacturingLaser arrangementsPulse beamMetrology

A gas discharge laser crystallization apparatus and method for performing a transformation of a crystal makeup or orientation in a film on a workpiece is disclosed, which may comprise a master oscillator power amplifier MOPA or power oscillator power amplifier configured XeF laser system producing a laser output light pulse beam at a high repetition rate and high power with a pulse to pulse dose control; an optical system producing an elongated thin pulsed working beam from the laser output light pulse beam. The apparatus may further comprise the laser system is configured as a POPA laser system and further comprising: relay optics operative to direct a first output laser light pulse beam from a first laser PO unit into a second laser PA unit; and, a timing and control module timing the creation of a gas discharge in the first and second laser units within plus or minus 3 ns, to produce the a second laser output light pulse beam as an amplification of the first laser output light pulse beam. The system may comprise divergence control in the oscillator laser unit. Divergence control may comprise an unstable resonator arrangement. The system may further comprise a beam pointing control mechanism intermediate the laser and the workpiece and a beam position control mechanism intermediate the laser and the workpiece. Beam parameter metrology may provide active feedback control to the beam pointing mechanism and active feedback control to the beam position control mechanism.

Owner:CYMER INC

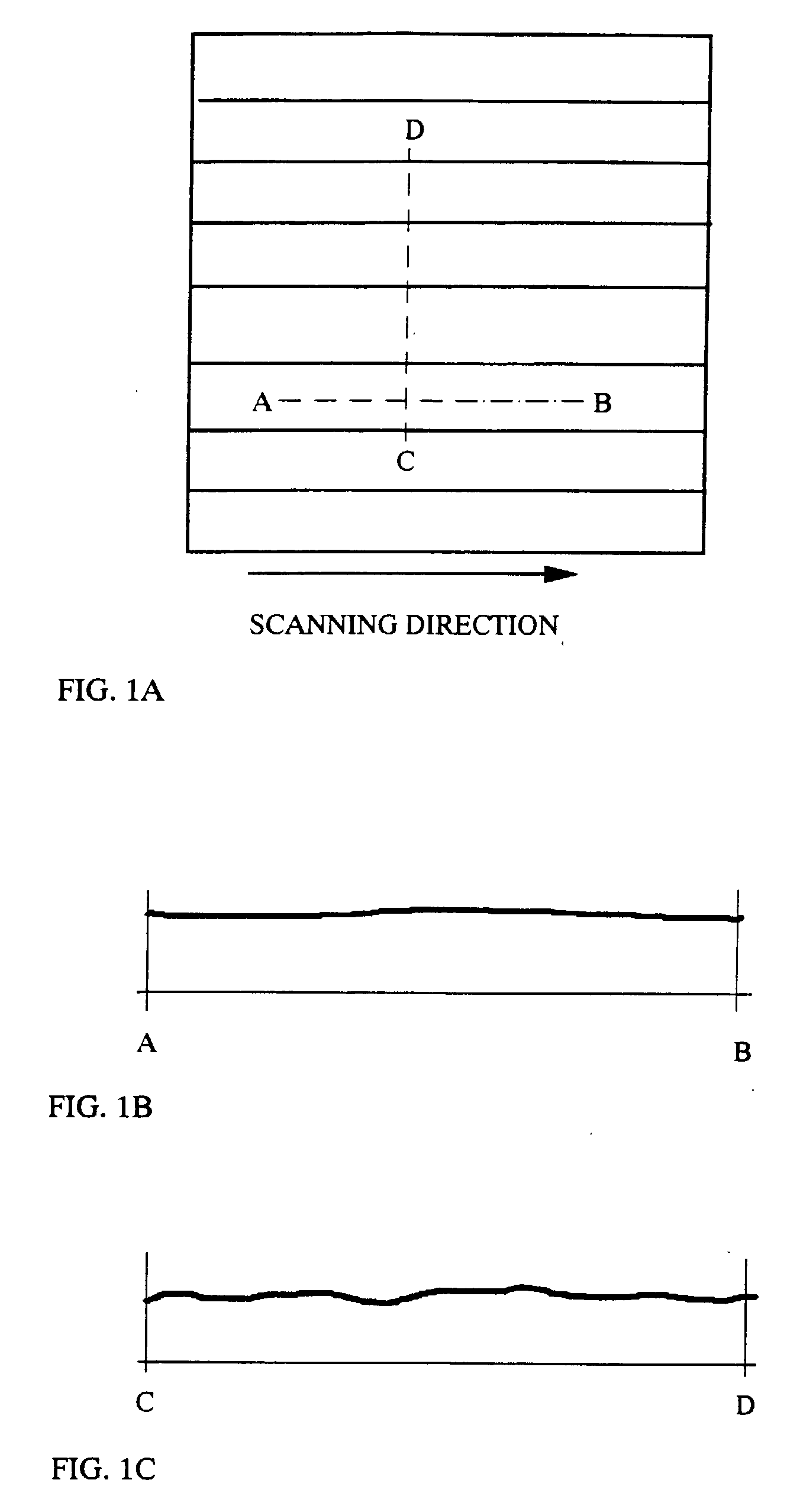

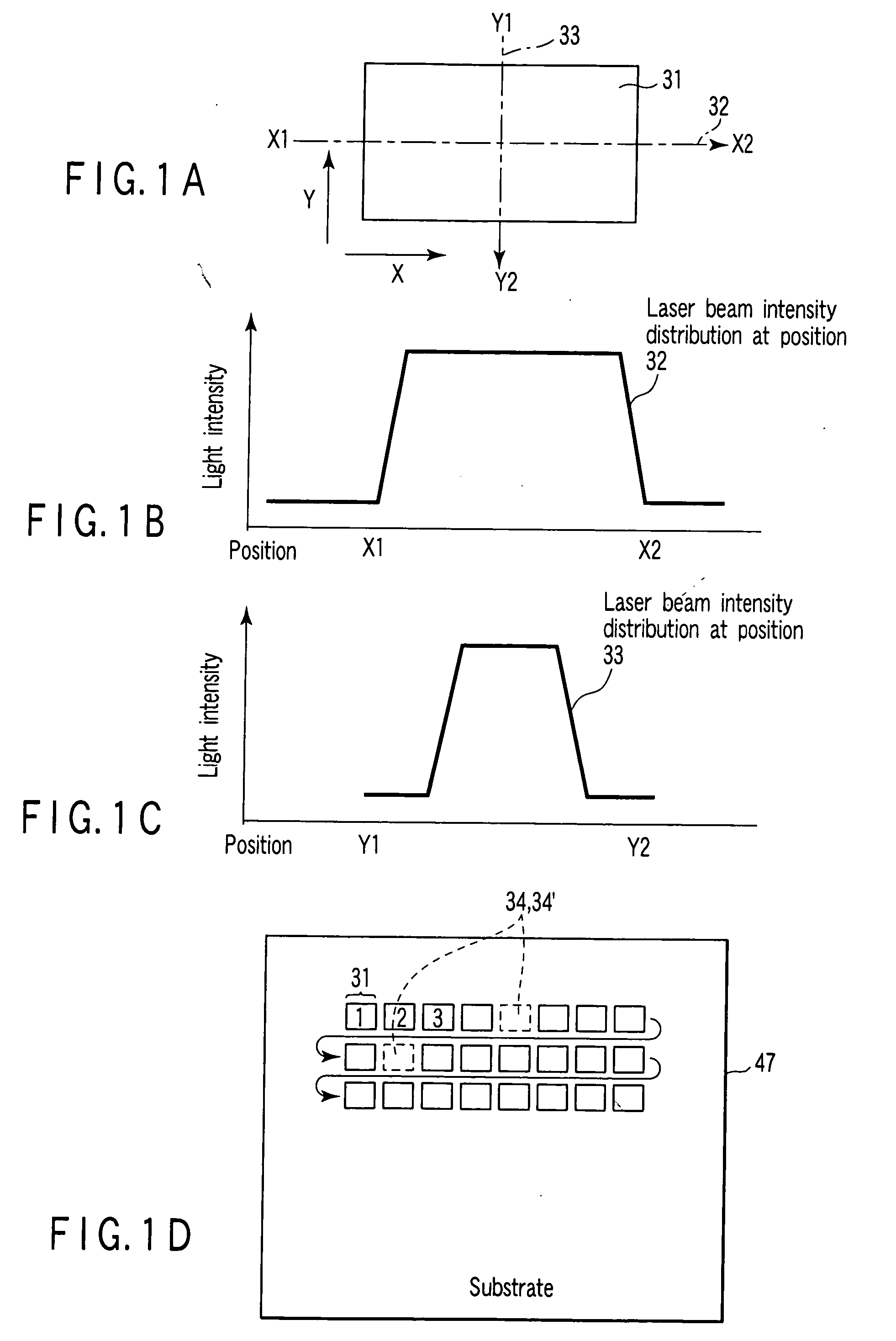

Processes and systems for laser crystallization processing of film regions on a substrate utilizing a line-type beam, and structures of such film regions

ActiveUS20070010104A1Similar performanceAvoid radiationAfter-treatment apparatusFrom solid stateLaser crystallizationIrradiation

Process and system for processing a thin film sample, as well as at least one portion of the thin film structure are provided. Irradiation beam pulses can be shaped to define at least one line-type beam pulse, which includes a leading portion, a top portion and a trailing portion, in which at least one part has an intensity sufficient to at least partially melt a film sample. Irradiating a first portion of the film sample to at least partially melt the first portion, and allowing the first portion to resolidify and crystallize to form an approximately uniform area therein. After the irradiation of the first portion of the film sample, irradiating a second portion using a second one of the line-type beam pulses to at least partially melt the second portion, and allowing the second portion to resolidify and crystallize to form an approximately uniform area therein. A section of the first portion impacted by the top portion of the first one of the line-type beam pulses is prevented from being irradiated by trailing portion of the second one of the line-type beam pulses.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

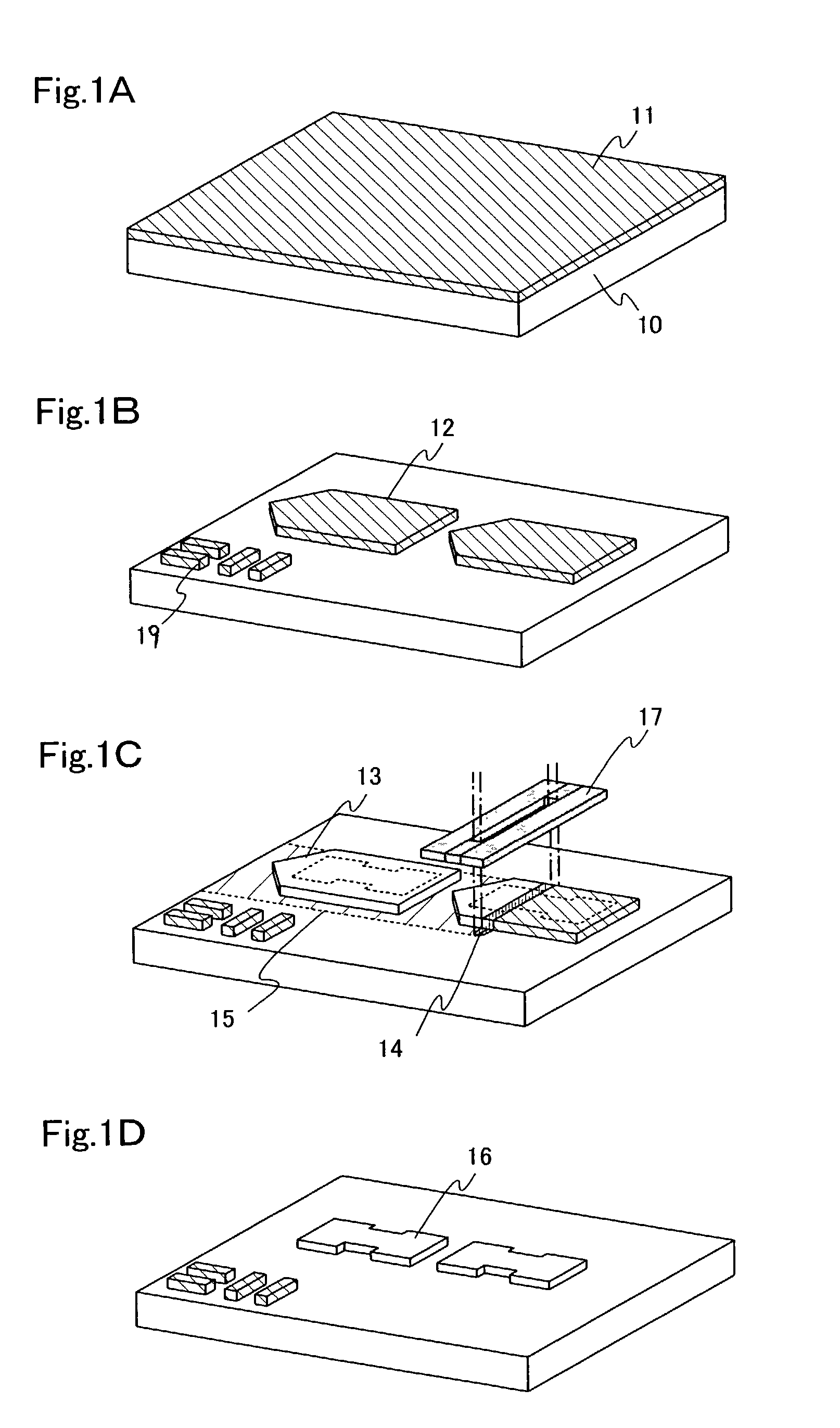

Laser irradiation method and method of manufacturing a semiconductor device

InactiveUS20030228723A1TransistorSemiconductor/solid-state device testing/measurementLaser scanningLaser crystallization

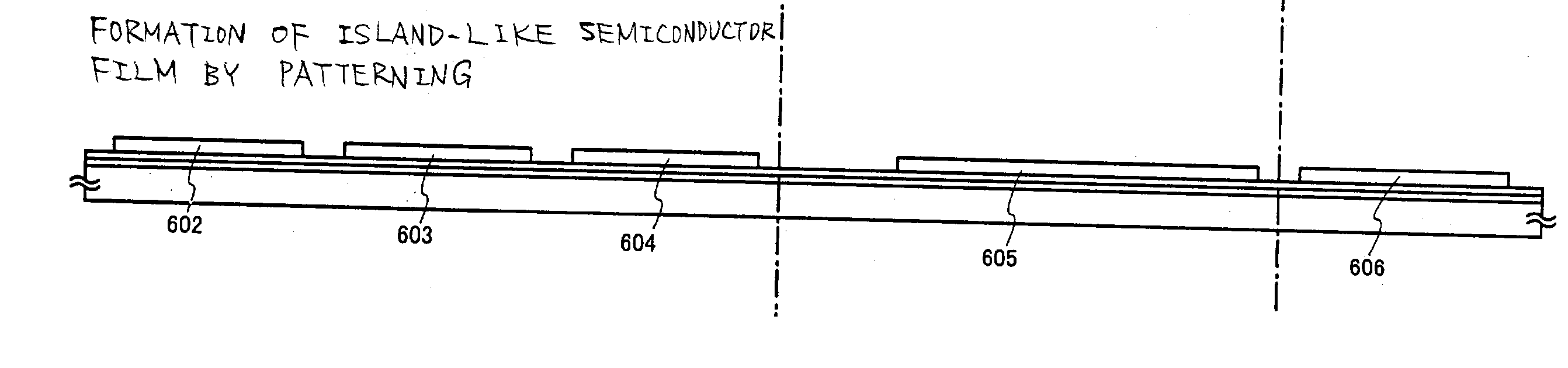

A method of manufacturing a semiconductor device is provided which uses a laser crystallization method capable of increasing substrate processing efficiency. An island-like semiconductor film including one or more islands is formed by patterning (sub-island). The sub-island is then irradiated with laser light to improve its crystallinity, and thereafter patterned to form an island. From pattern information of a sub-island, a laser light scanning path on a substrate is determined such that at least the sub-island is irradiated with laser light. In other words, the present invention runs laser light so as to obtain at least the minimum degree of crystallization of a portion that has to be crystallized, instead of irradiating the entire substrate with laser light.

Owner:SEMICON ENERGY LAB CO LTD

Continuous coating installation, methods for producing crystalline solar cells, and solar cell

InactiveUS20100024865A1Improve throughputIncrease powerCellsFinal product manufactureElectrical batteryLaser crystallization

A continuous coating installation is disclosed. The installation includes a vacuum chamber having a supply opening for supplying a substrate to be coated and a discharge opening for discharging the coated substrate. The installation also includes a physical vapour deposition device for coating a surface of the substrate, and a laser crystallization system for simultaneously illuminating at least one sub-partial area of a currently coated partial area of the surface of the substrate with at least one laser beam. The installation further includes a transport device for transporting the substrate in a feedthrough direction from the supply opening to the discharge opening and for continuously or discontinuously moving the substrate during the coating thereof in the feedthrough direction.

Owner:CARL ZEISS SMT GMBH +1

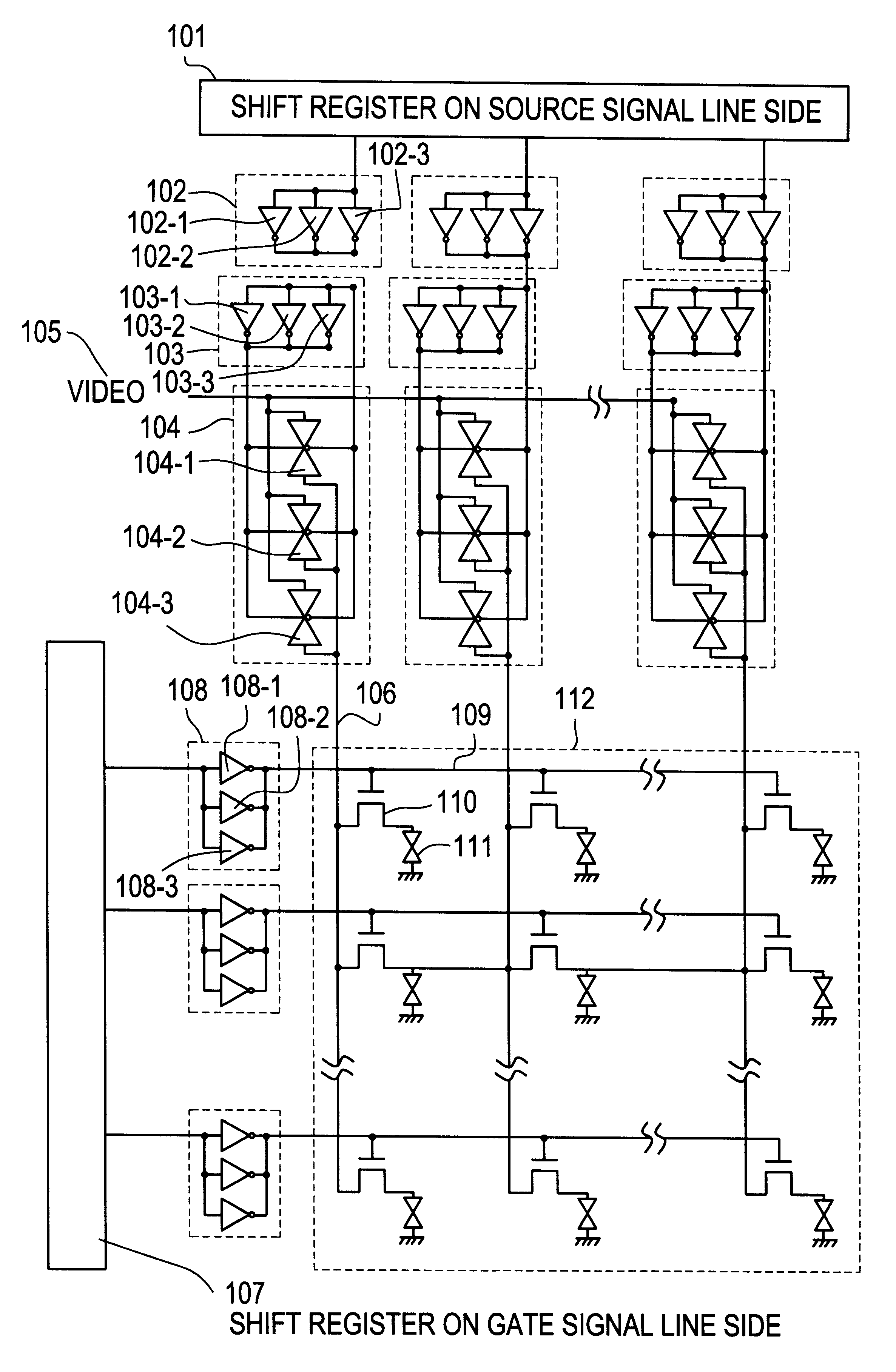

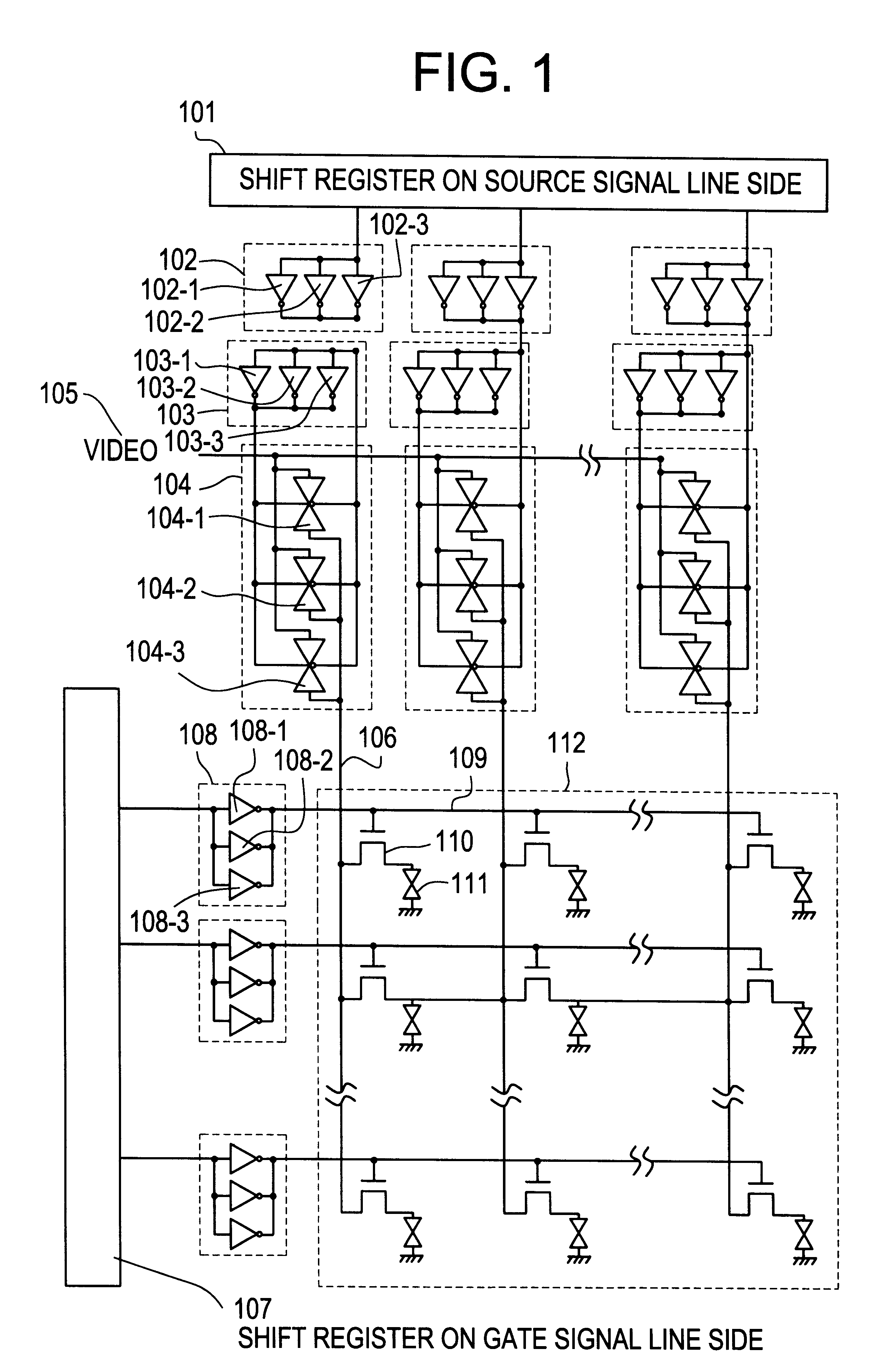

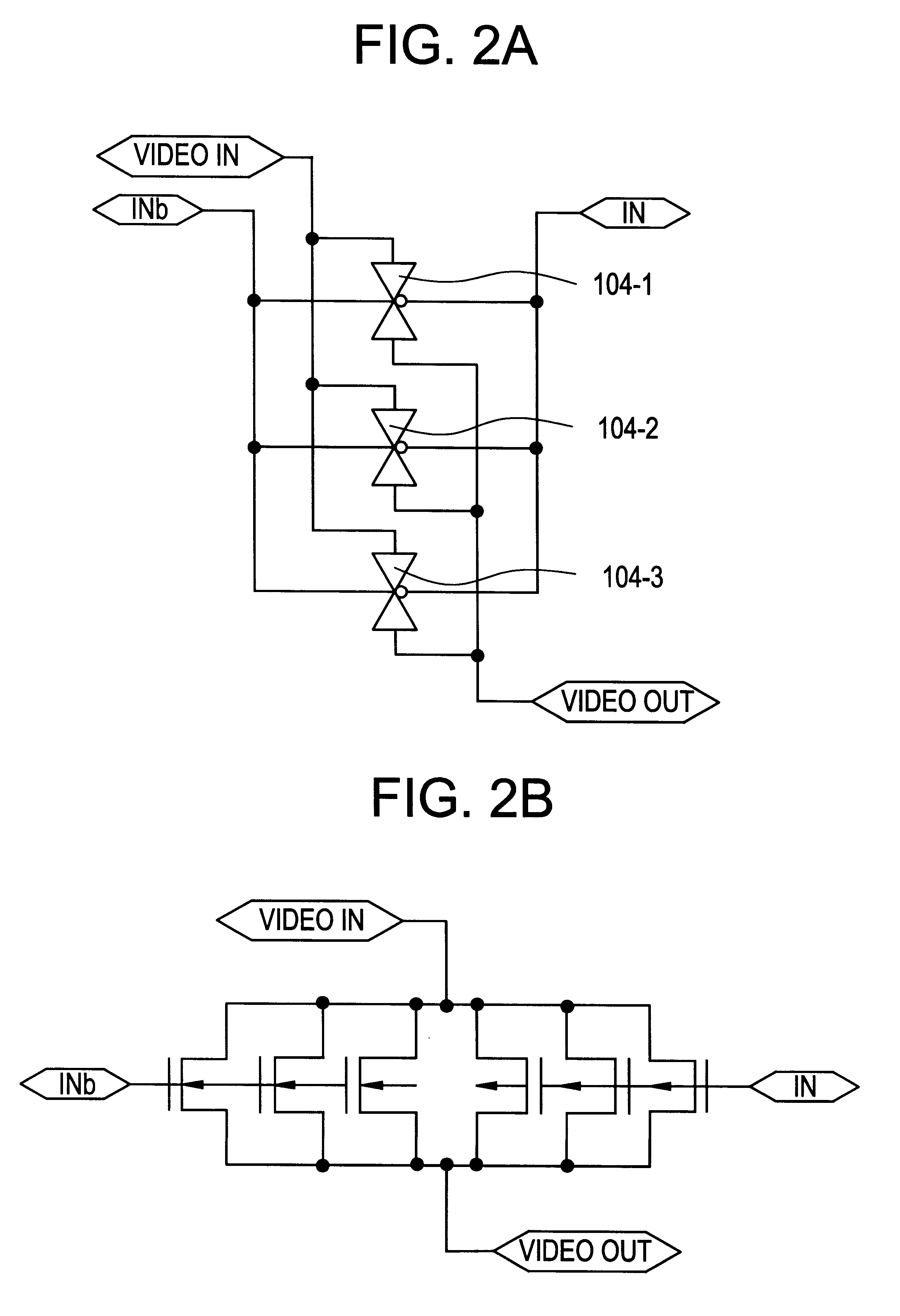

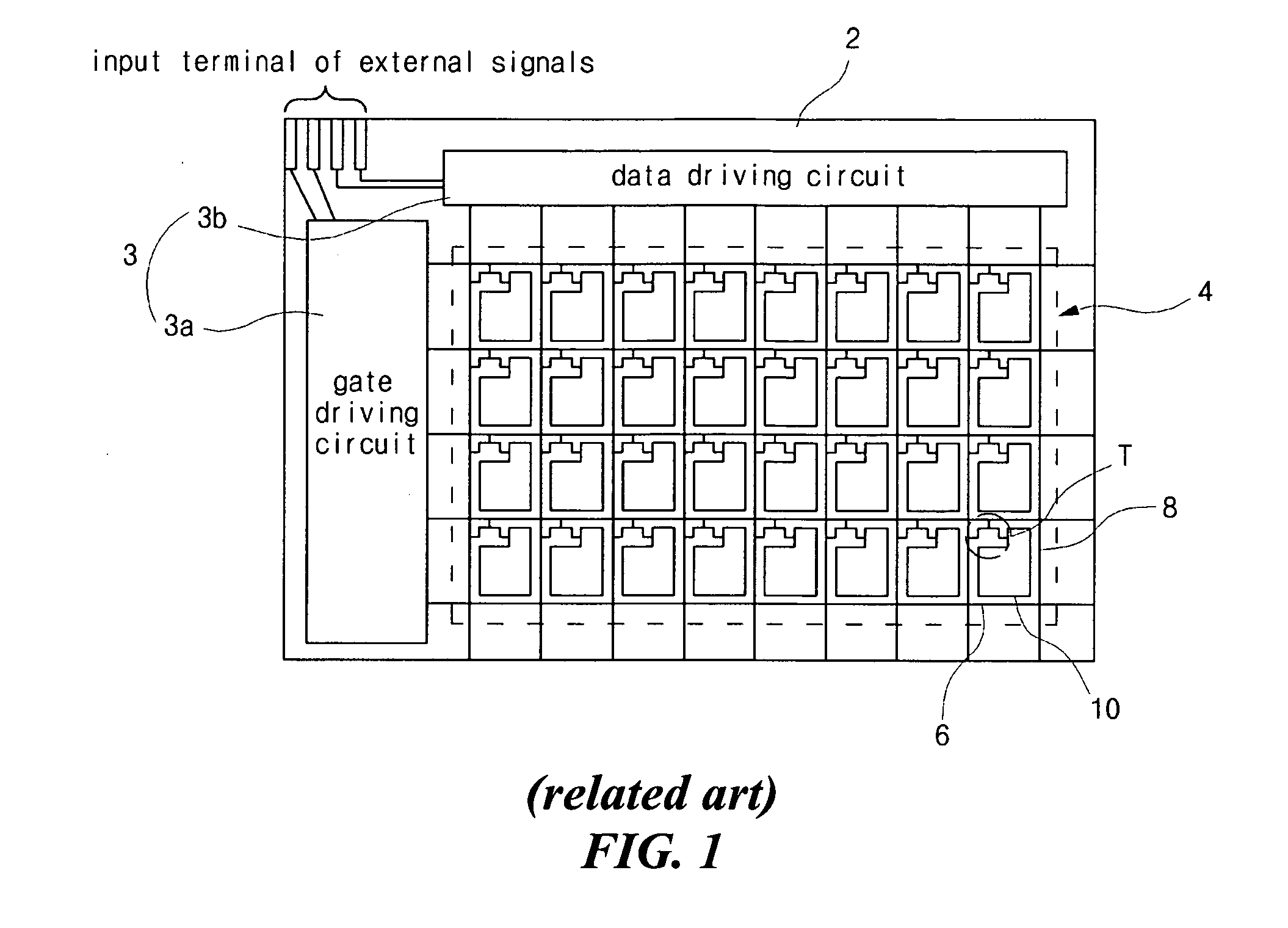

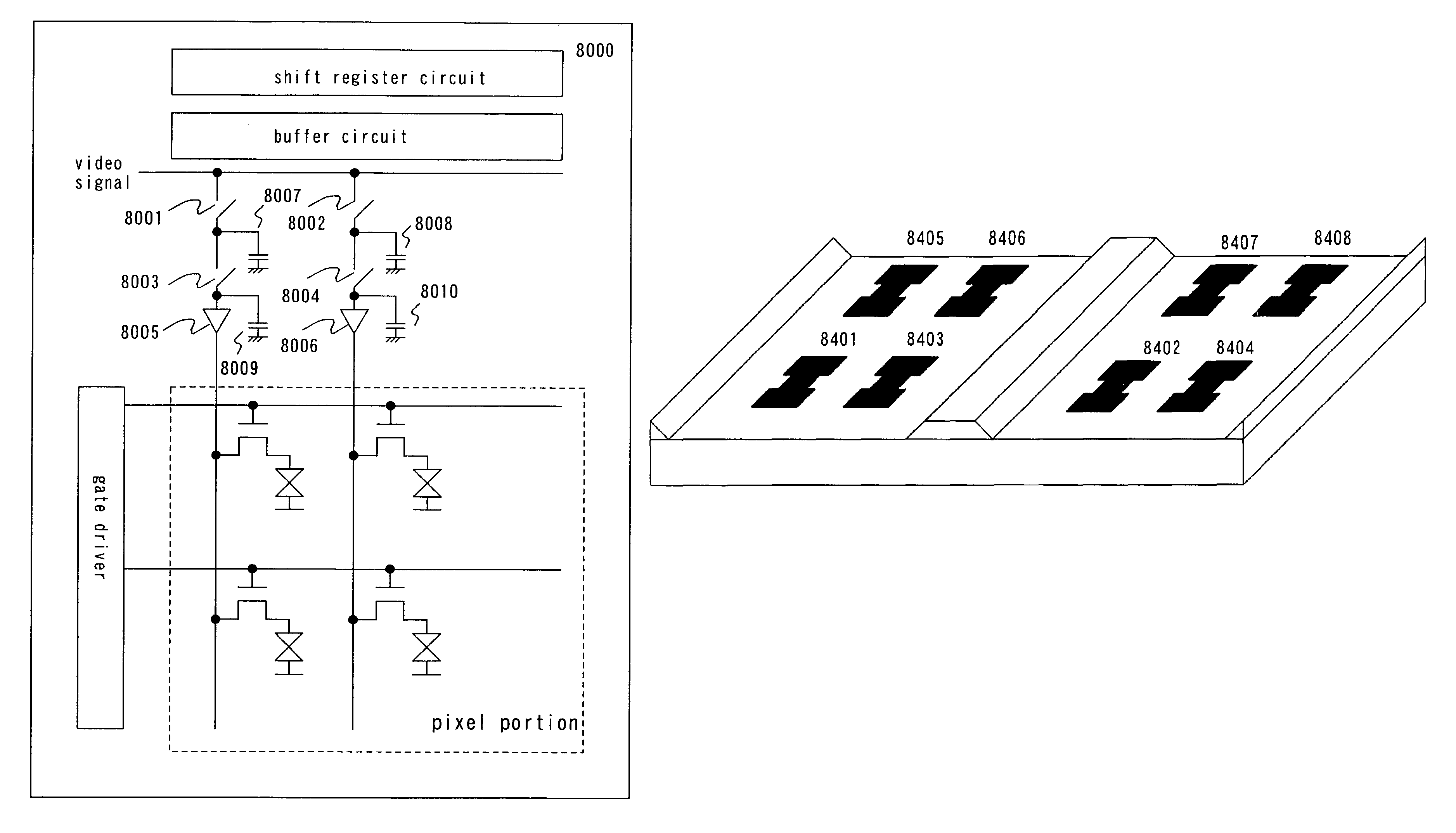

Semiconductor display device

An active matrix semiconductor device is provided which is free of unevenness in image. The analog switch and buffer in a drive circuit are structured by a plurality of parallel-connected analog switches and buffers each formed by a TFT with a small channel width. The carrier moving direction of these TFTs are oblique relative to a scanning direction of a linear laser used for laser crystallization. By doing so, the analog switch and the buffer are decreased in characteristic variation with deterioration suppressed. Thus an active matrix semiconductor device is realized which is free of unevenness in image.

Owner:SEMICON ENERGY LAB CO LTD

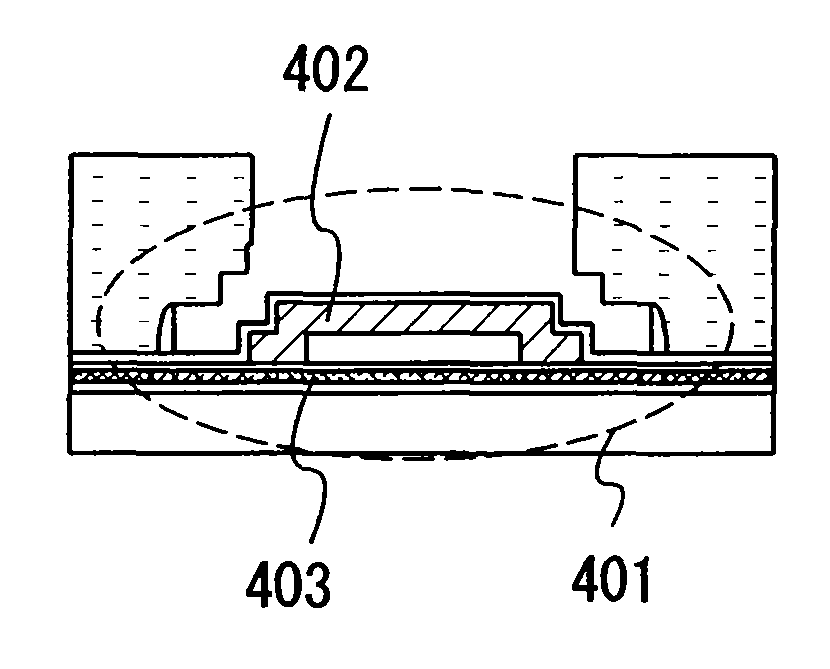

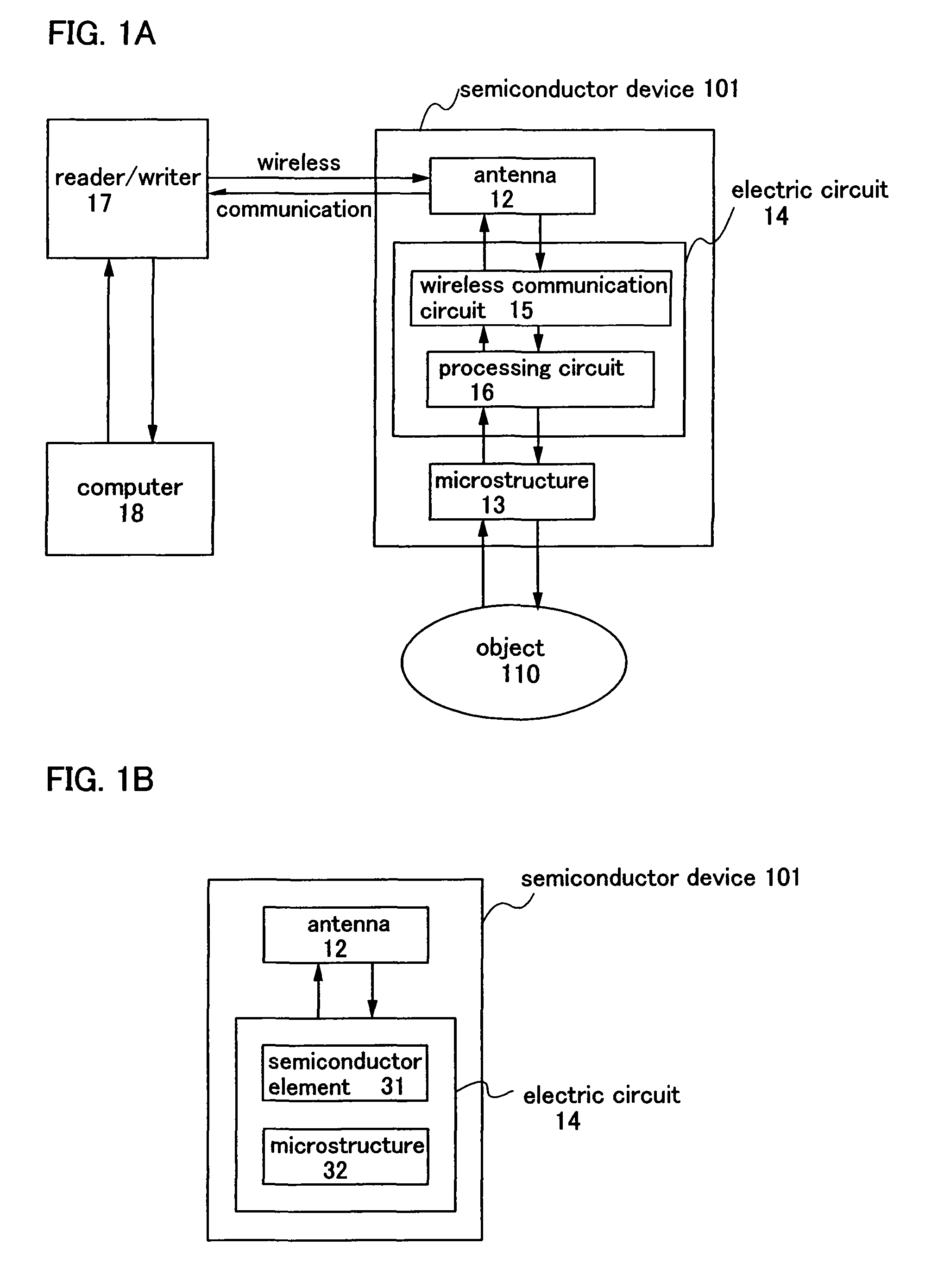

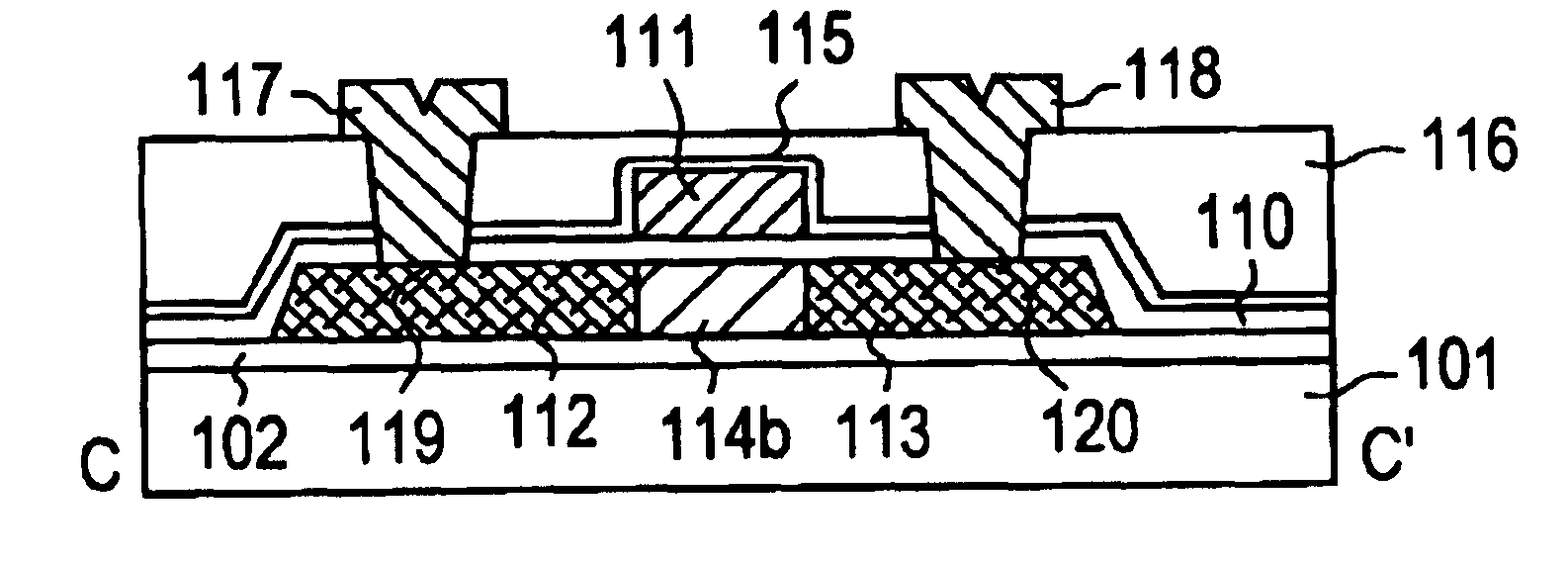

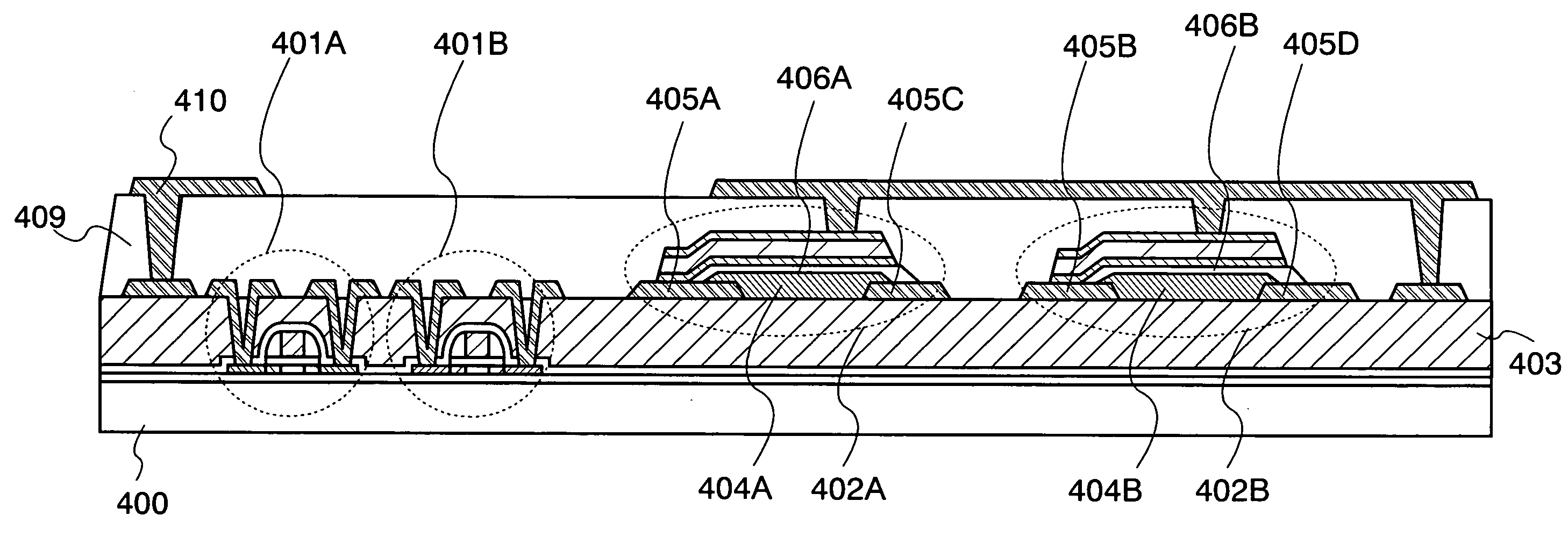

Semiconductor device and manufacturing method thereof

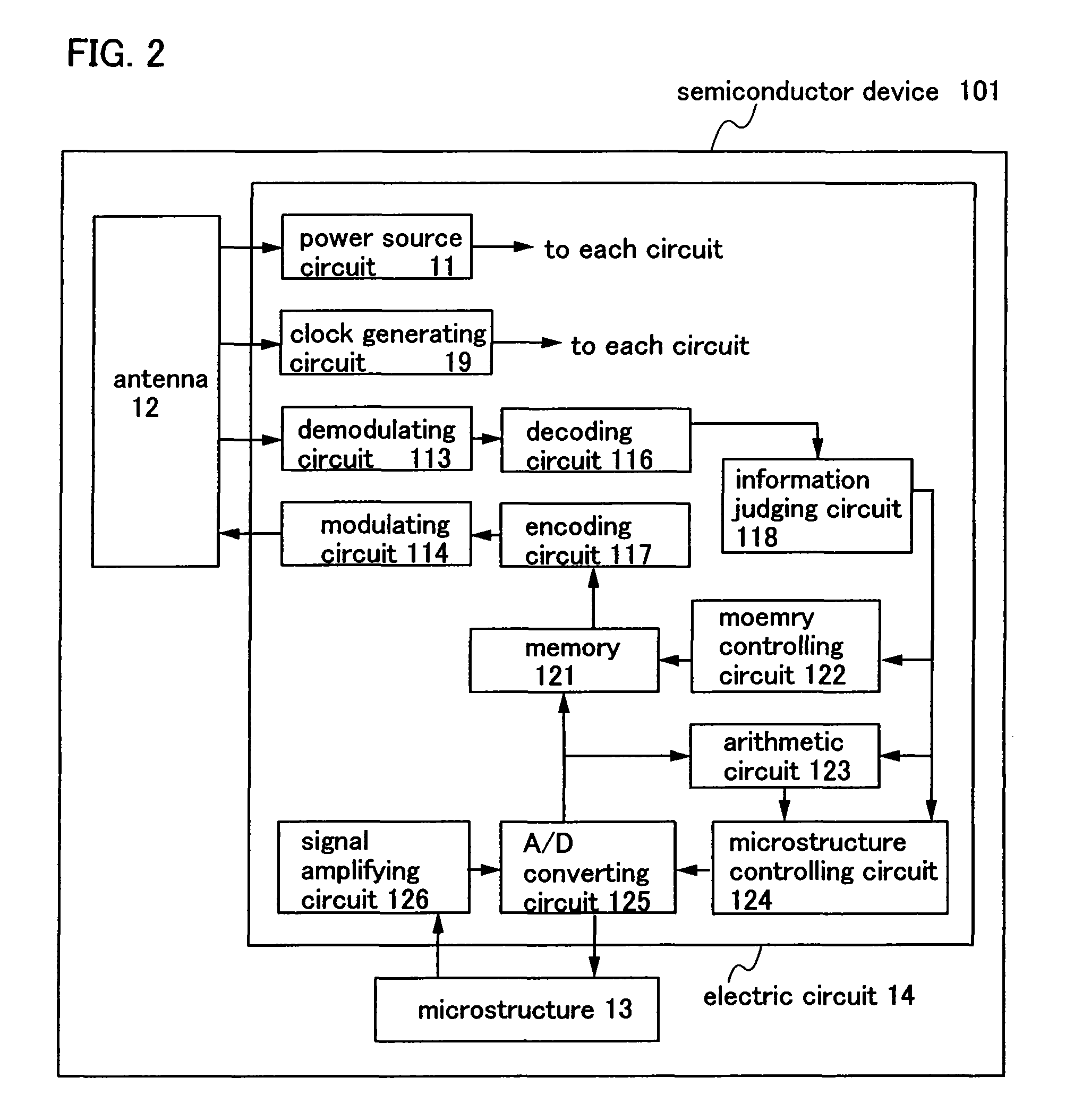

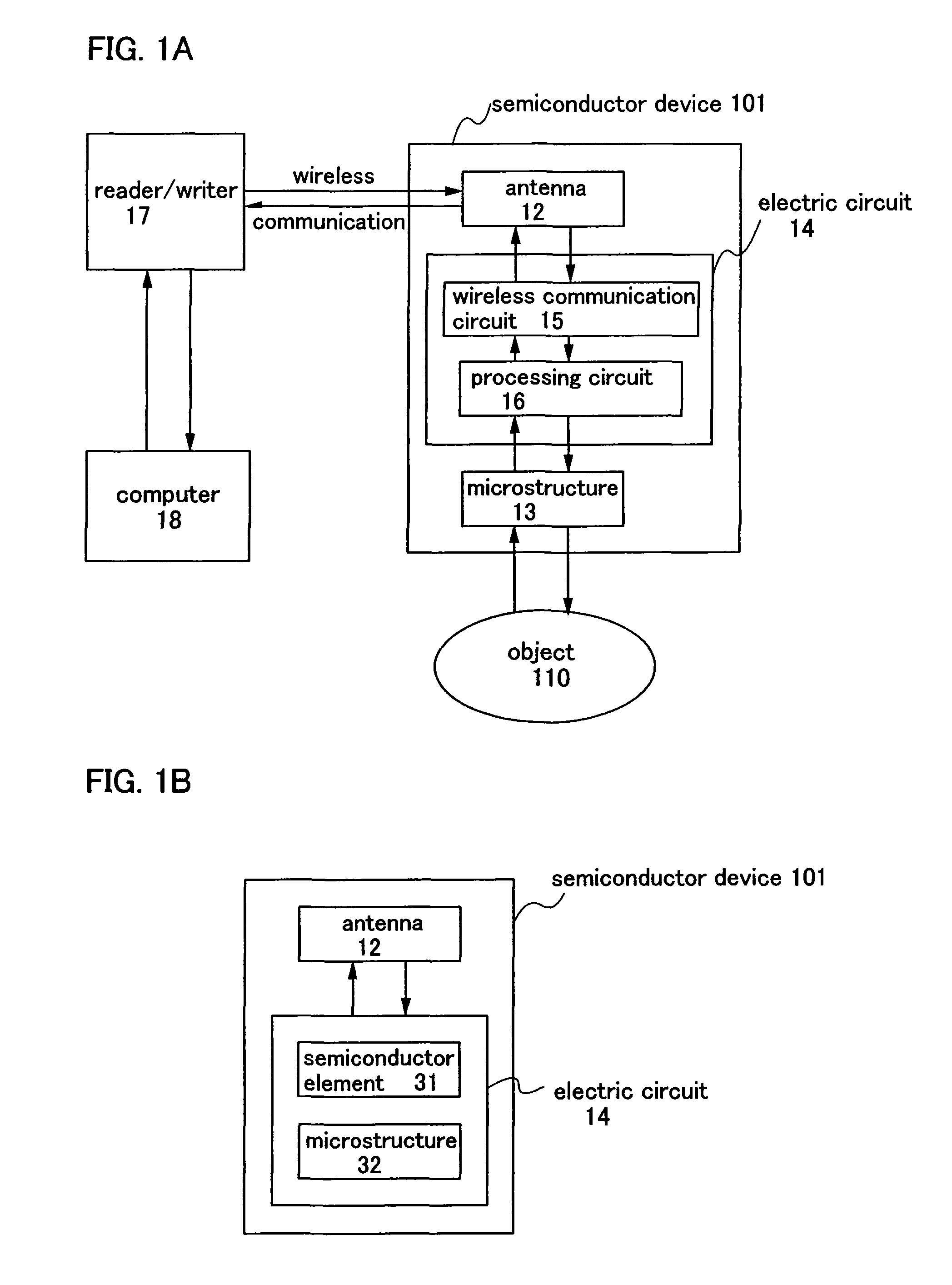

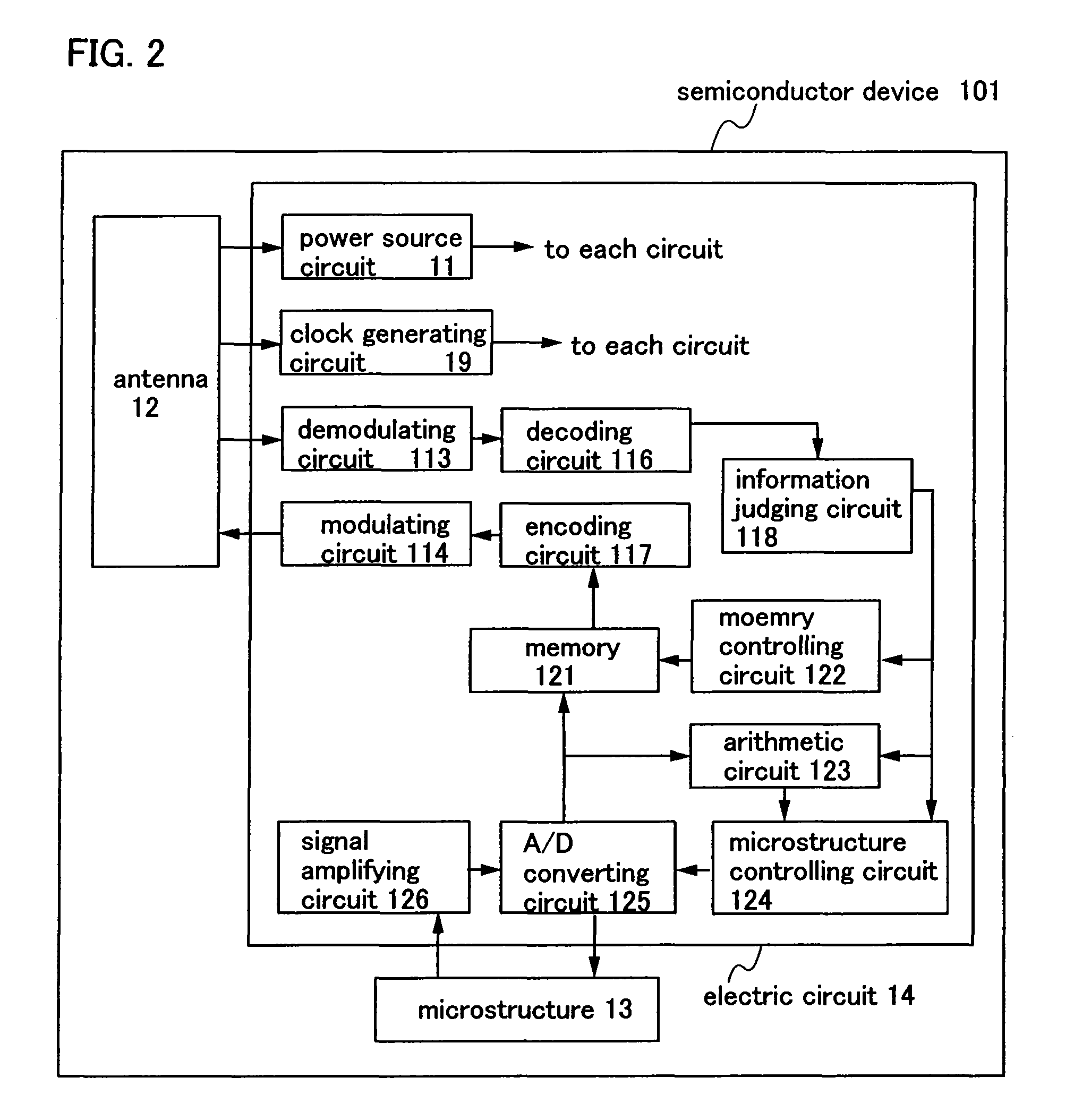

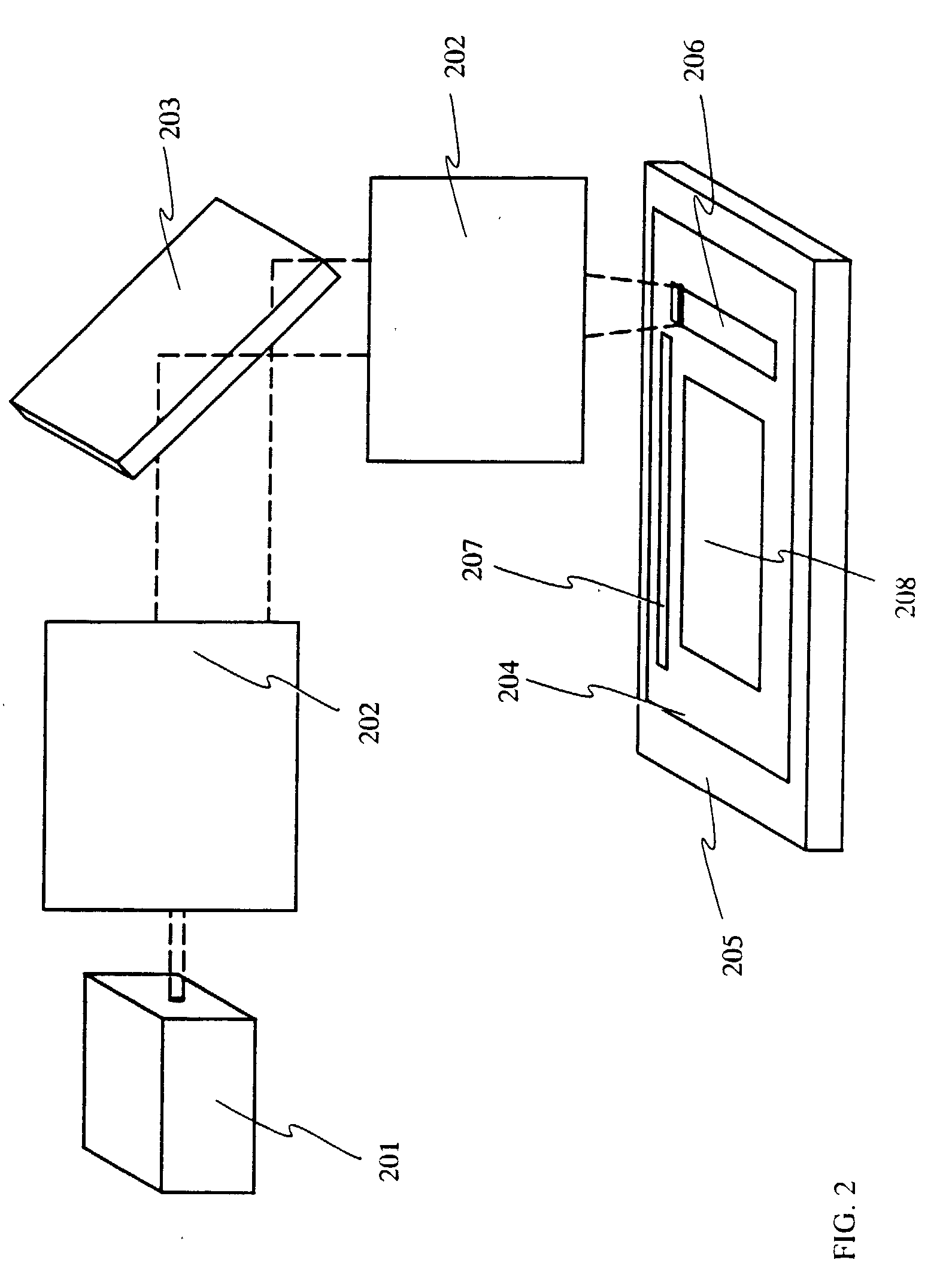

InactiveUS7642612B2Reduce stepsLow pour pointSemiconductor/solid-state device detailsSolid-state devicesLaser crystallizationCommunication circuits

It has been difficult to manufacture a semiconductor device equipped with a microstructure having a space, an electric circuit for controlling the microstructure, and the like over one substrate.In a semiconductor device, a microstructure and an electric circuit for controlling the microstructure can be provided over one substrate by manufacturing the microstructure in such a way that a structural layer having polycrystalline silicon obtained by laser crystallization or thermal crystallization using a metal element is formed and processed at low temperature. As the electric circuit, a wireless communication circuit for carrying out wireless communication with an antenna is given.

Owner:SEMICON ENERGY LAB CO LTD

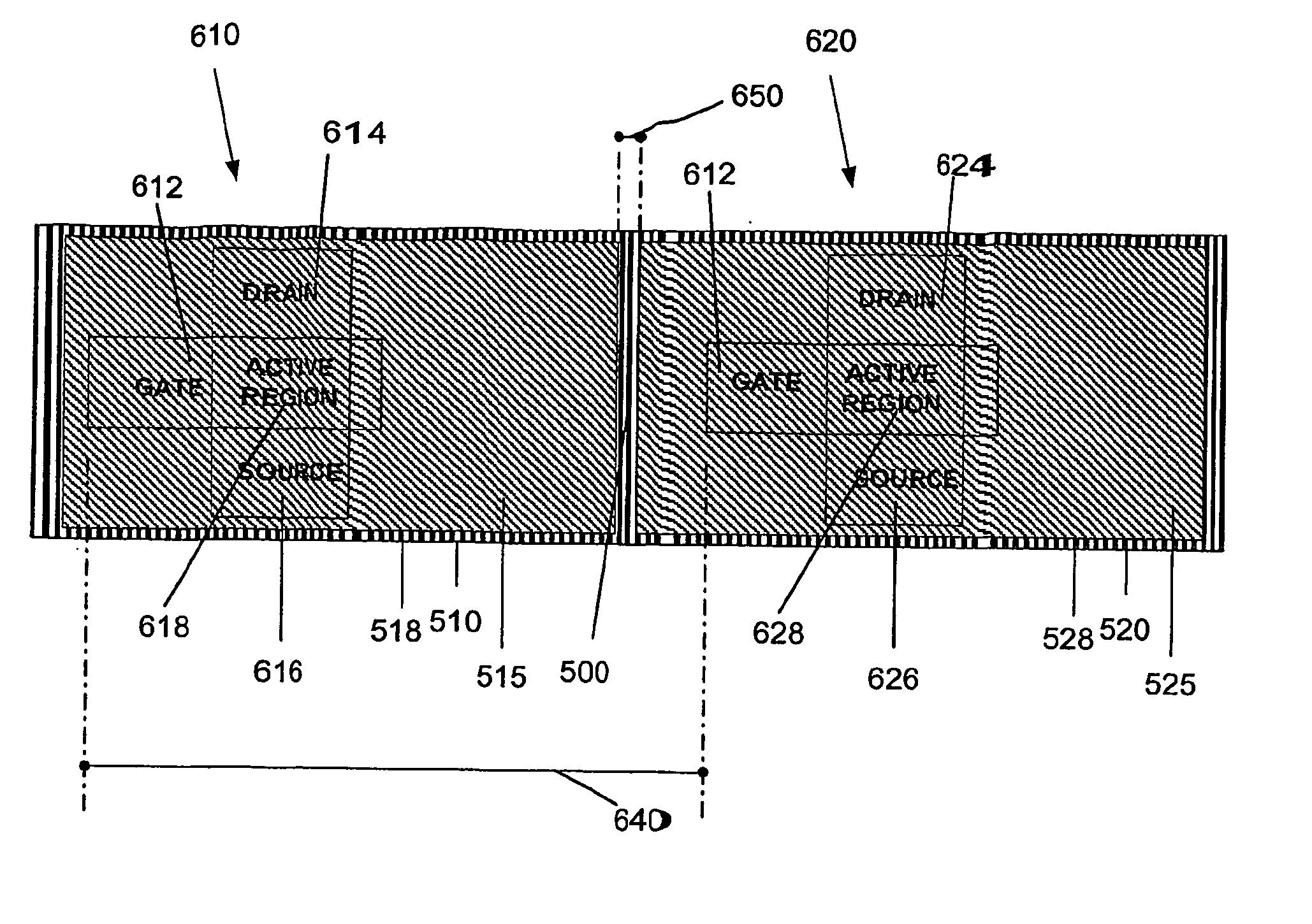

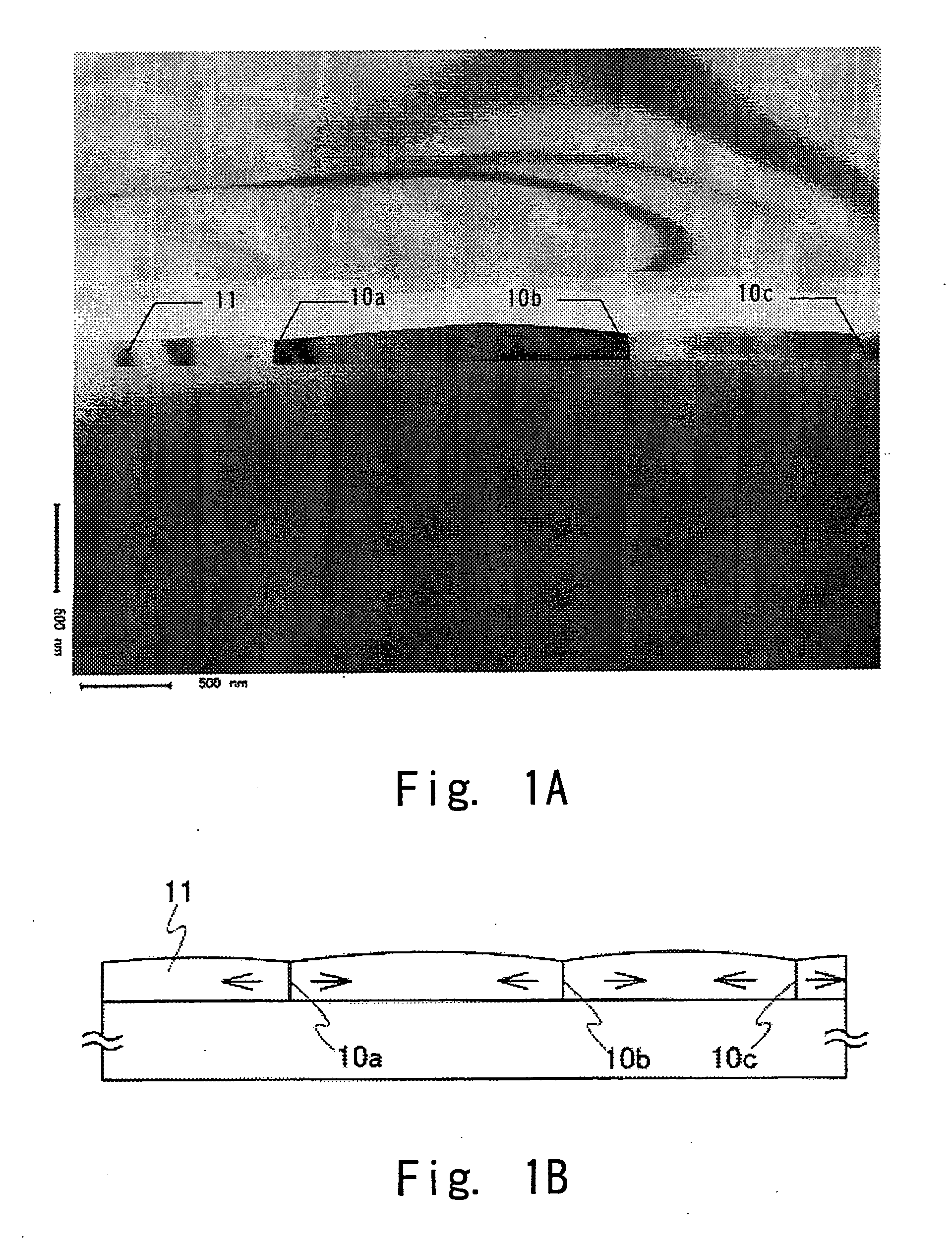

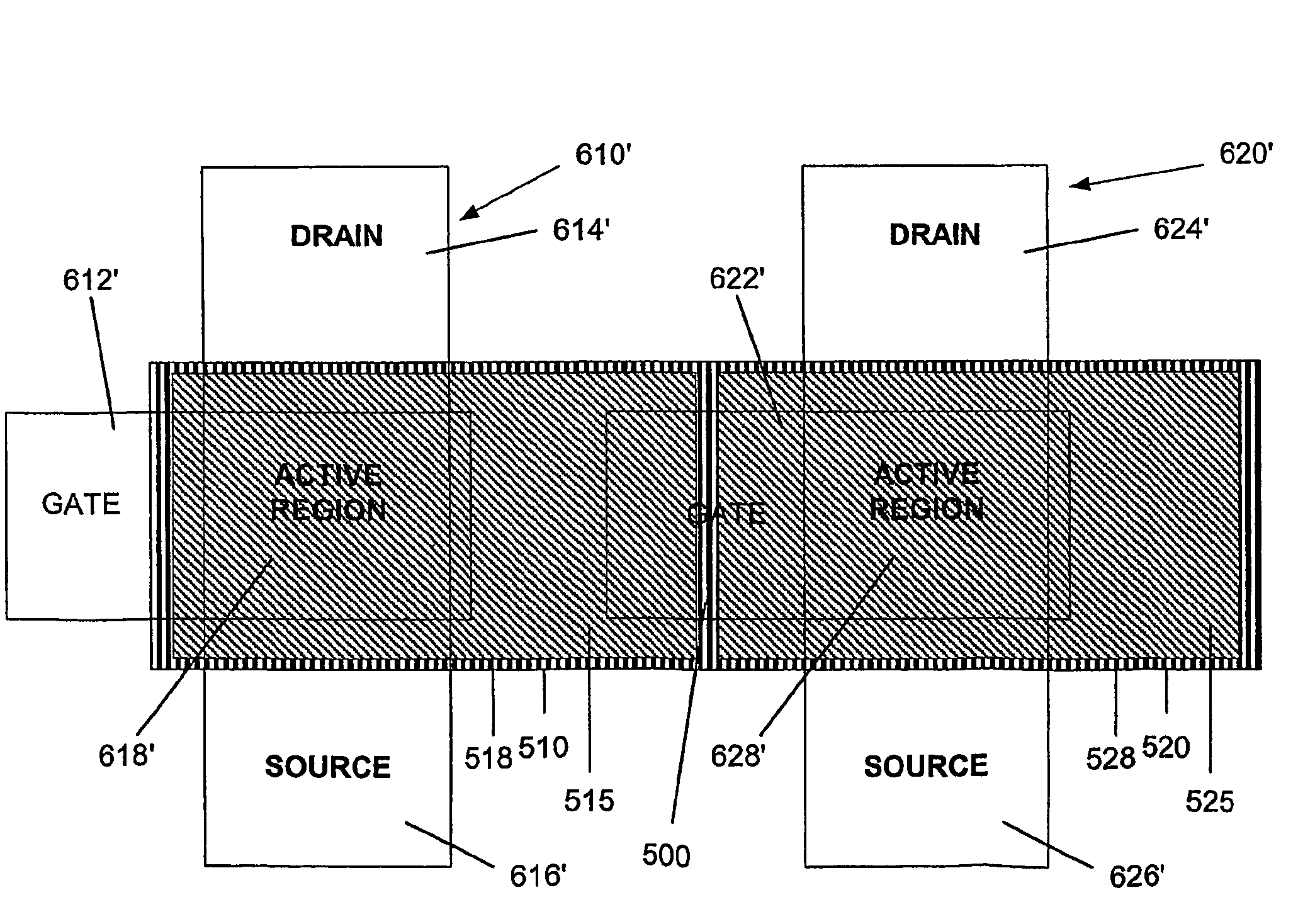

Process and system for laser crystallization processing of film regions on a substrate to provide substantial uniformity, and a structure of such film regions

InactiveUS20050202654A1Increase speedUniform materialAfter-treatment apparatusTransistorLaser crystallizationGrain structure

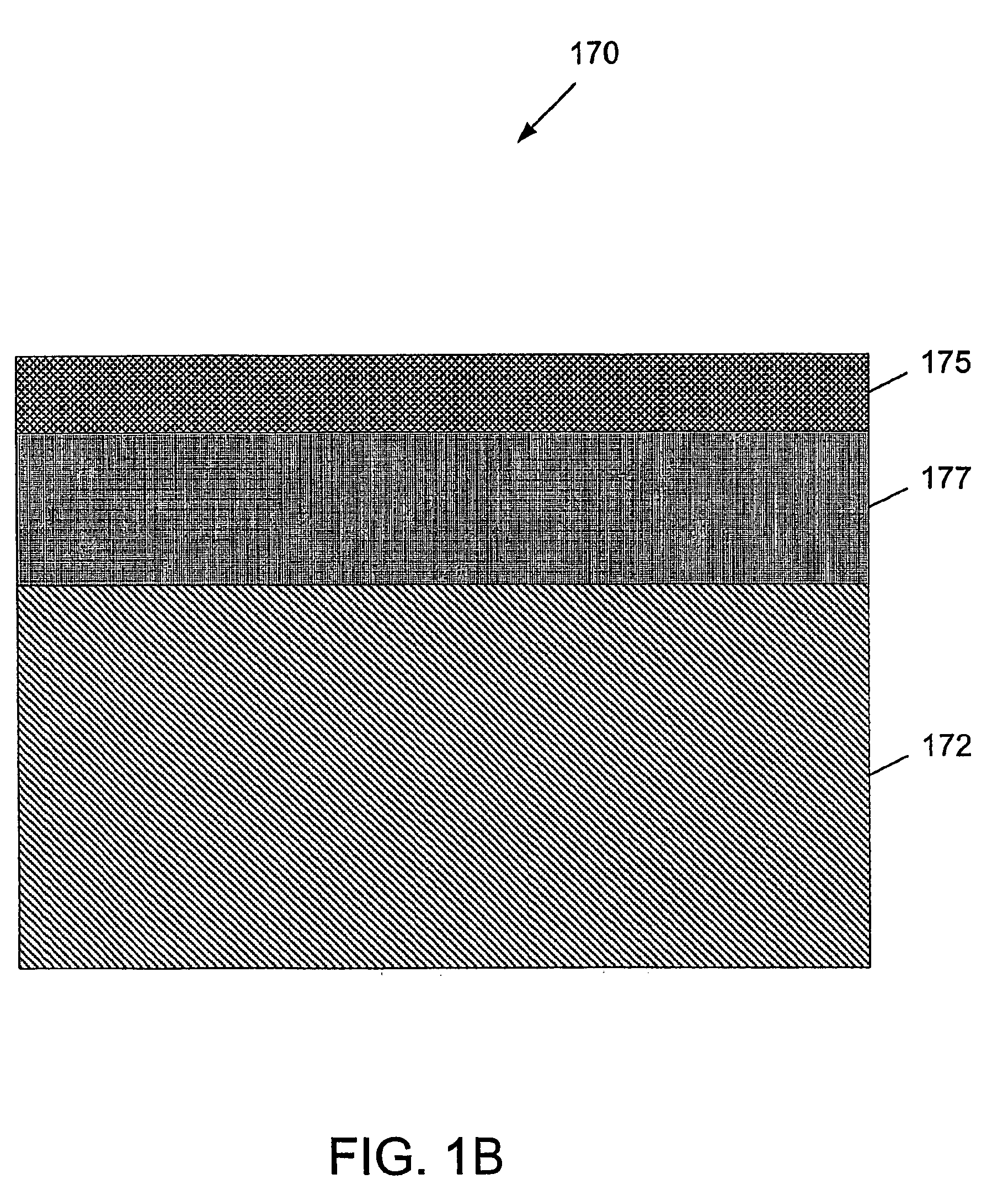

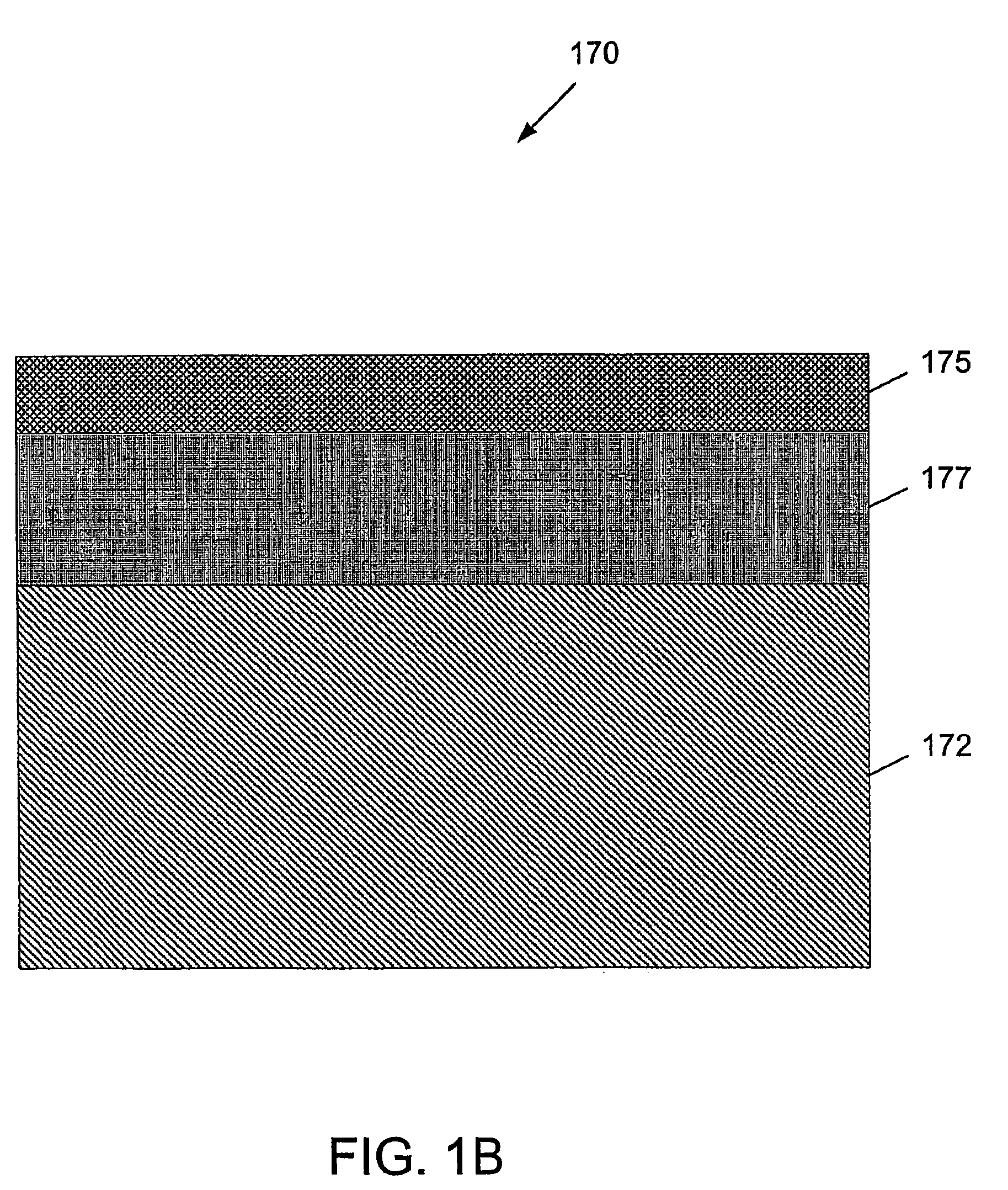

A process and system for processing a thin film sample (e.g., a semiconductor thin film), as well as the thin film structure are provided. In particular, a beam generator can be controlled to emit at least one beam pulse. With this beam pulse, at least one portion of the film sample is irradiated with sufficient intensity to fully melt such section of the sample throughout its thickness, and the beam pulse having a predetermined shape. This portion of the film sample is allowed to resolidify, and the re-solidified at least one portion is composed of a first area and a second area. Upon the re-solidification thereof, the first area includes large grains, and the second area has a region formed through nucleation. The first area surrounds the second area and has a grain structure which is different from a grain structure of the second area. The second area is configured to facilitate thereon an active region of an electronic device.

Owner:IM JAMES S

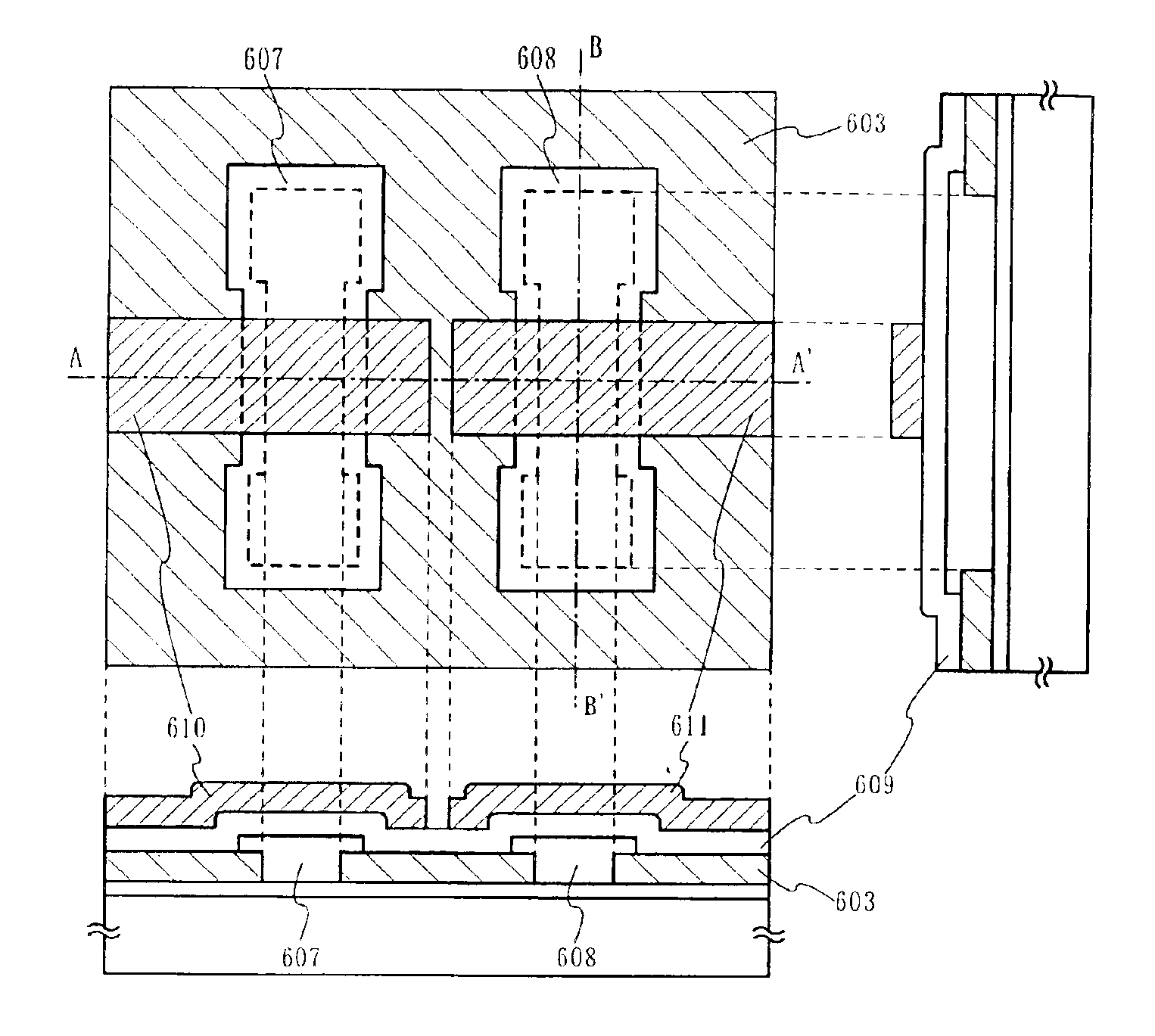

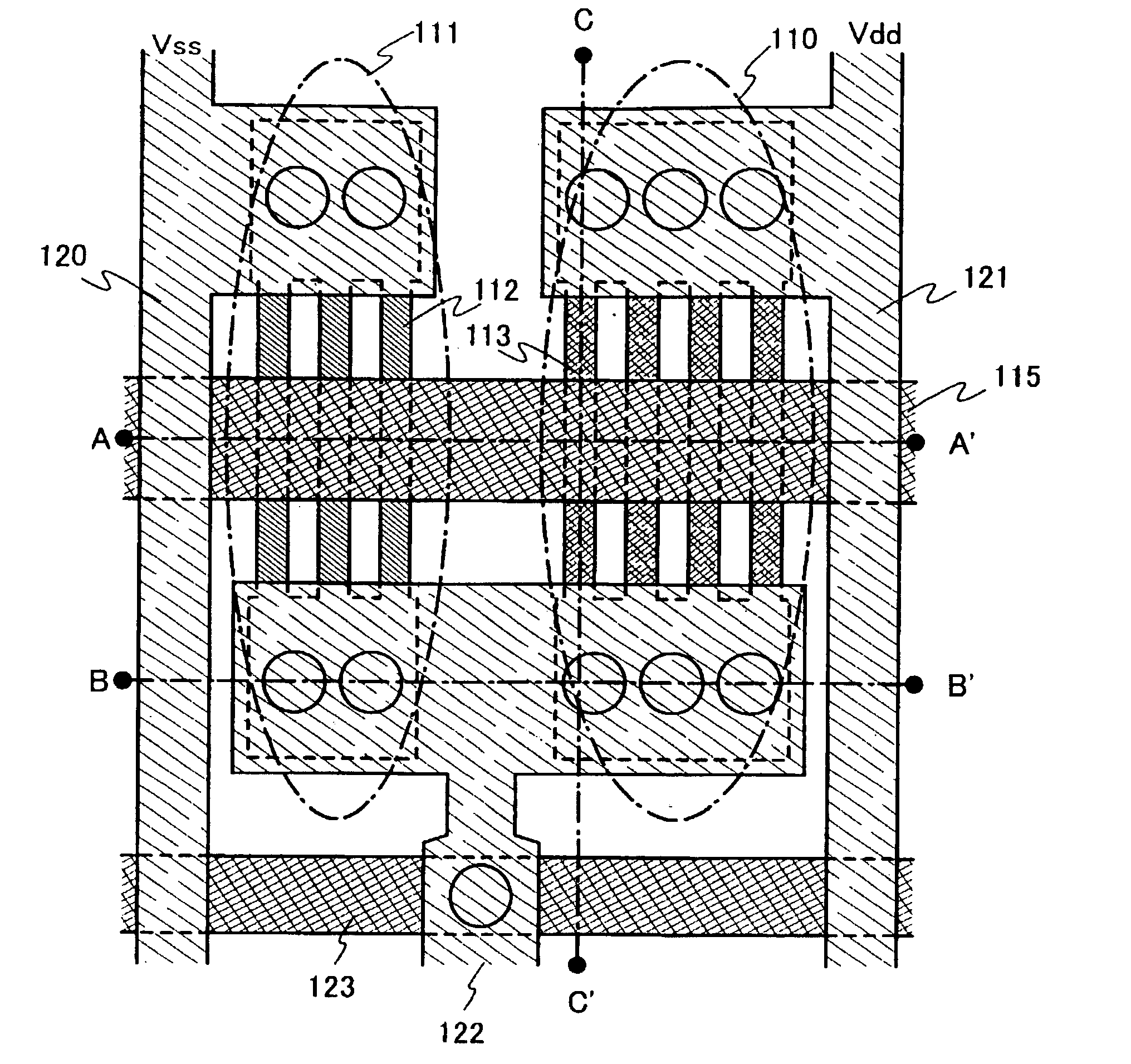

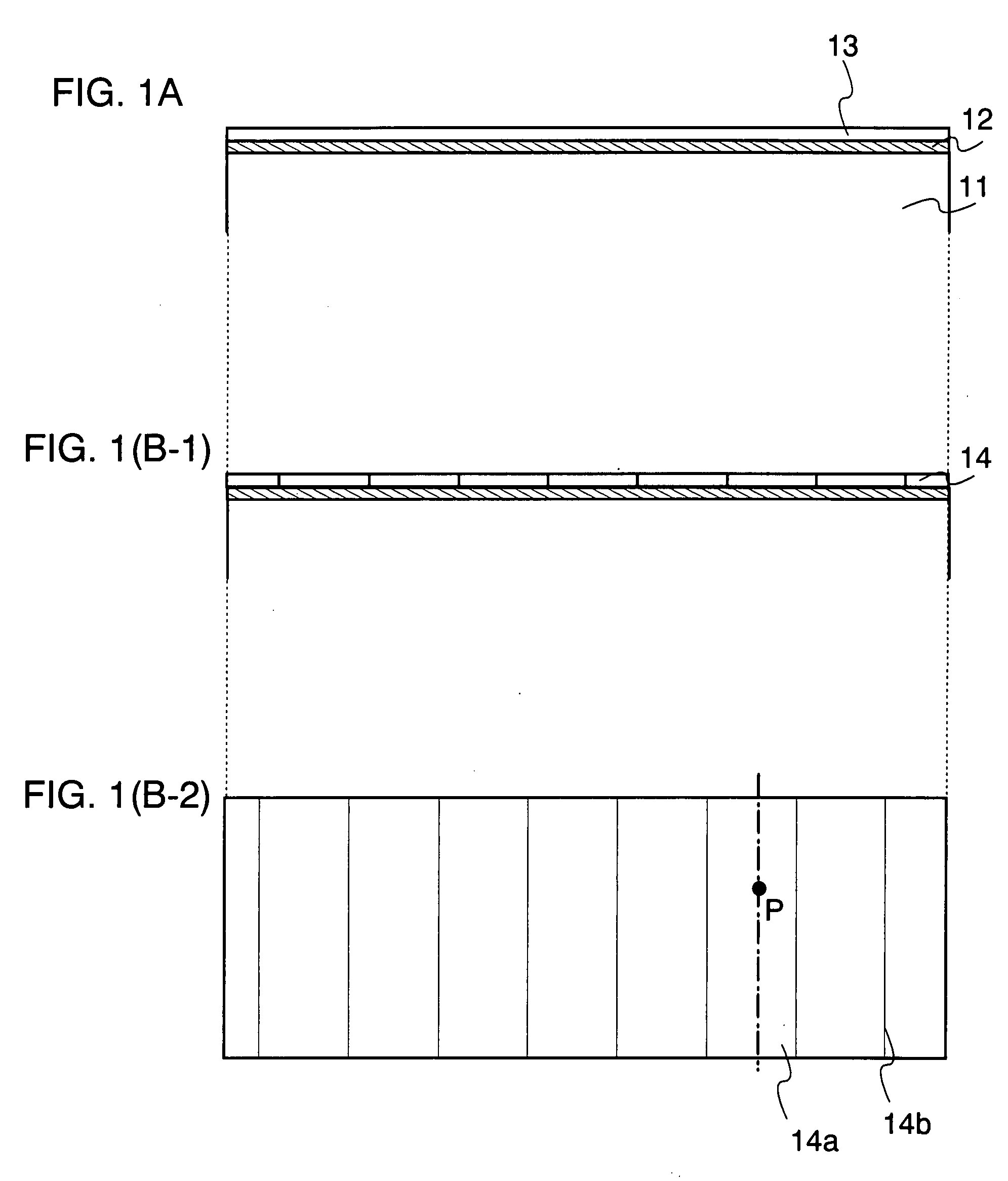

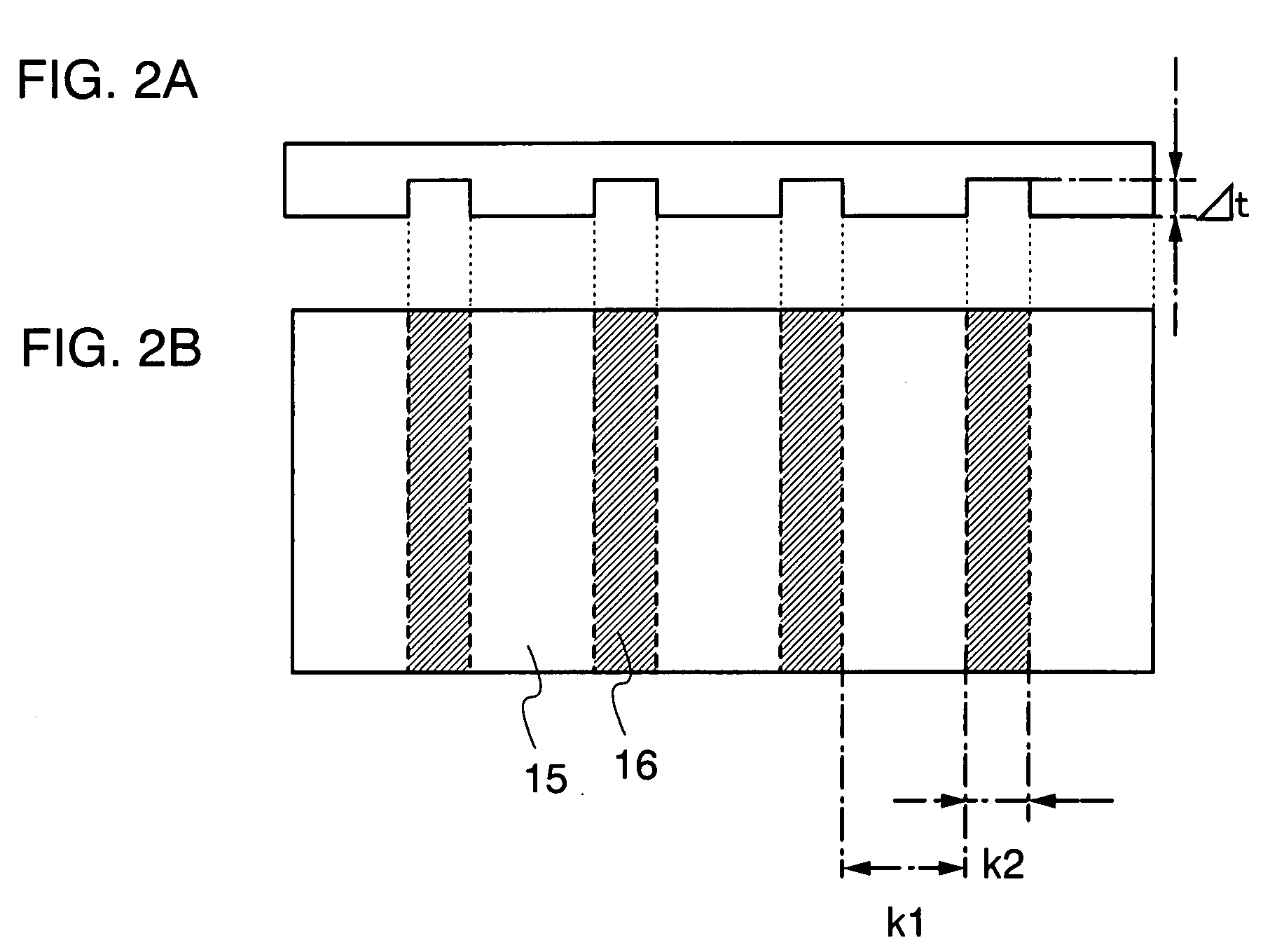

Semiconductor device and semiconductor device production system

InactiveUS6933527B2Improve barrier propertiesImprove stressTransistorSolid-state devicesStress concentrationLaser crystallization

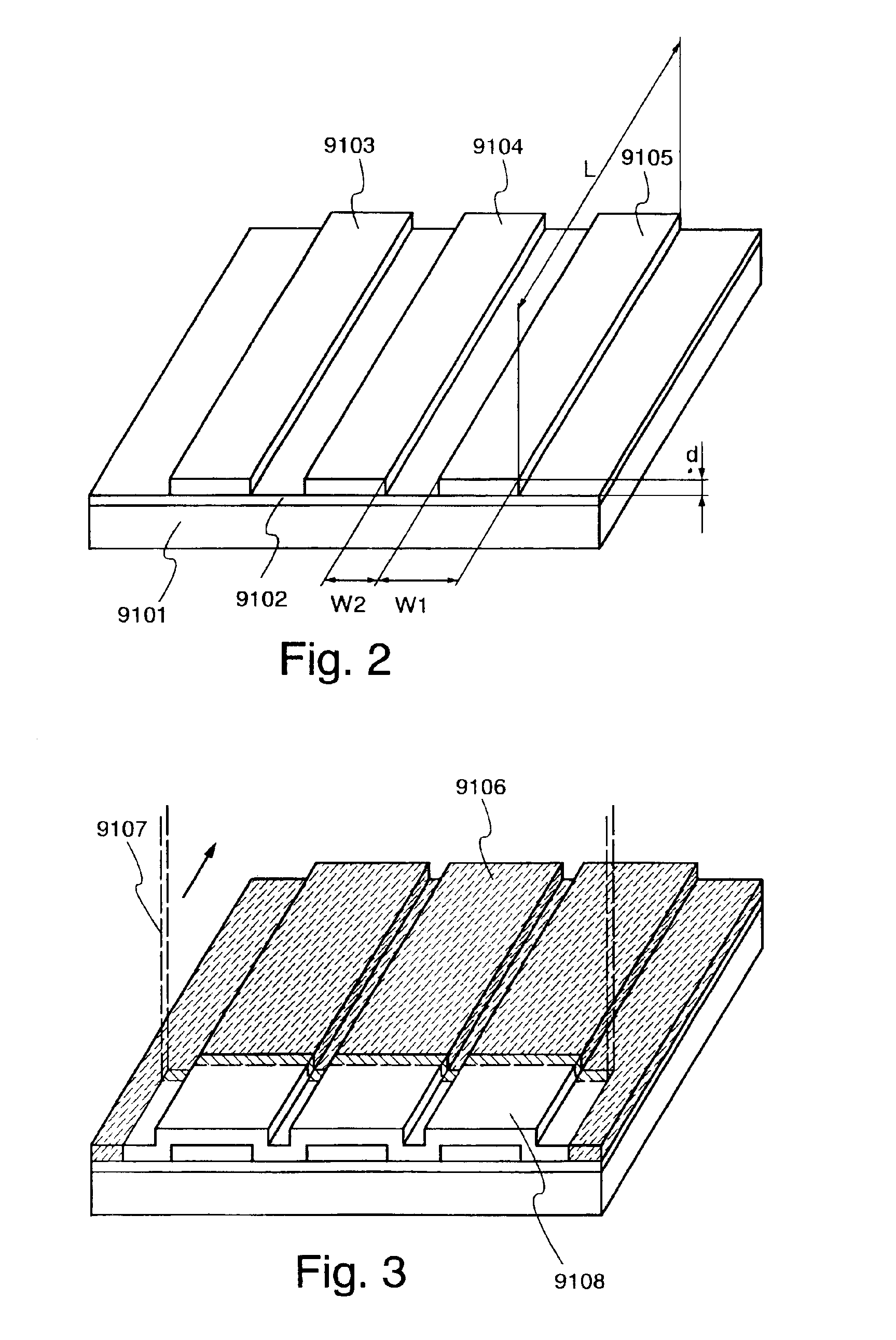

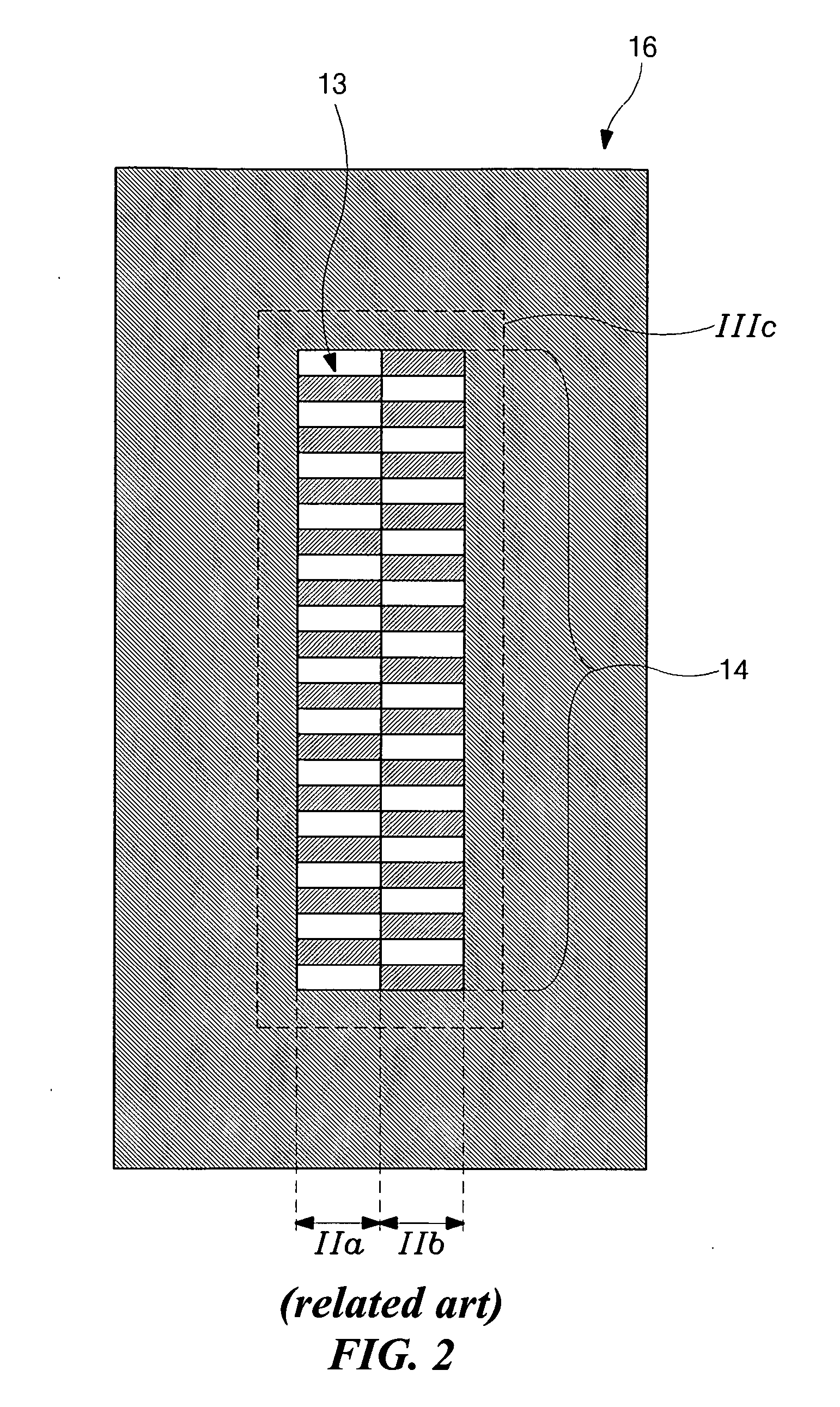

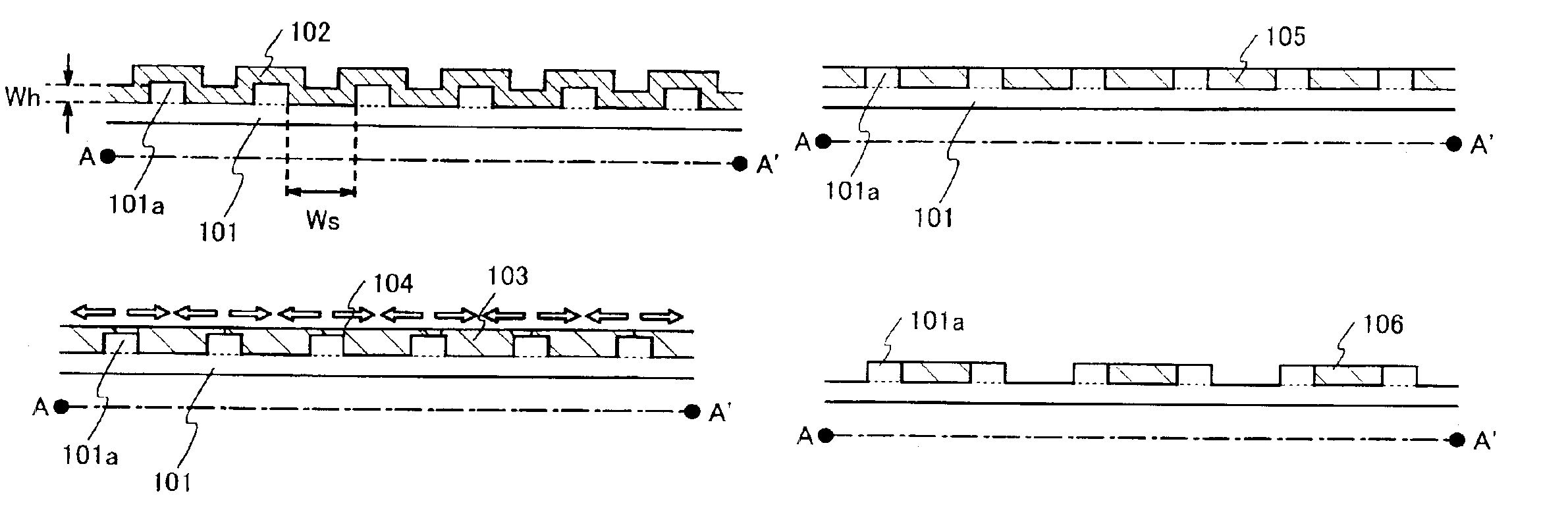

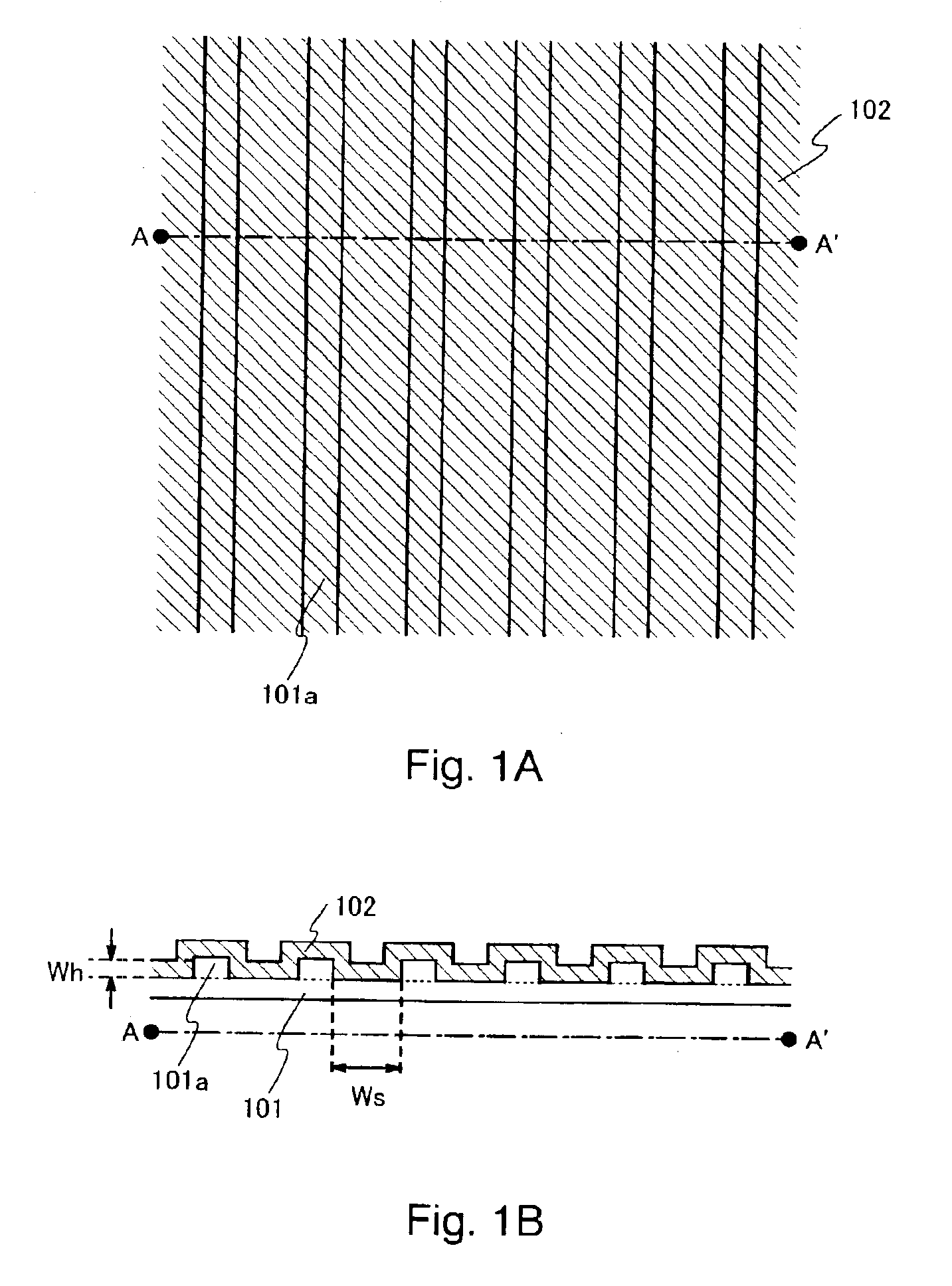

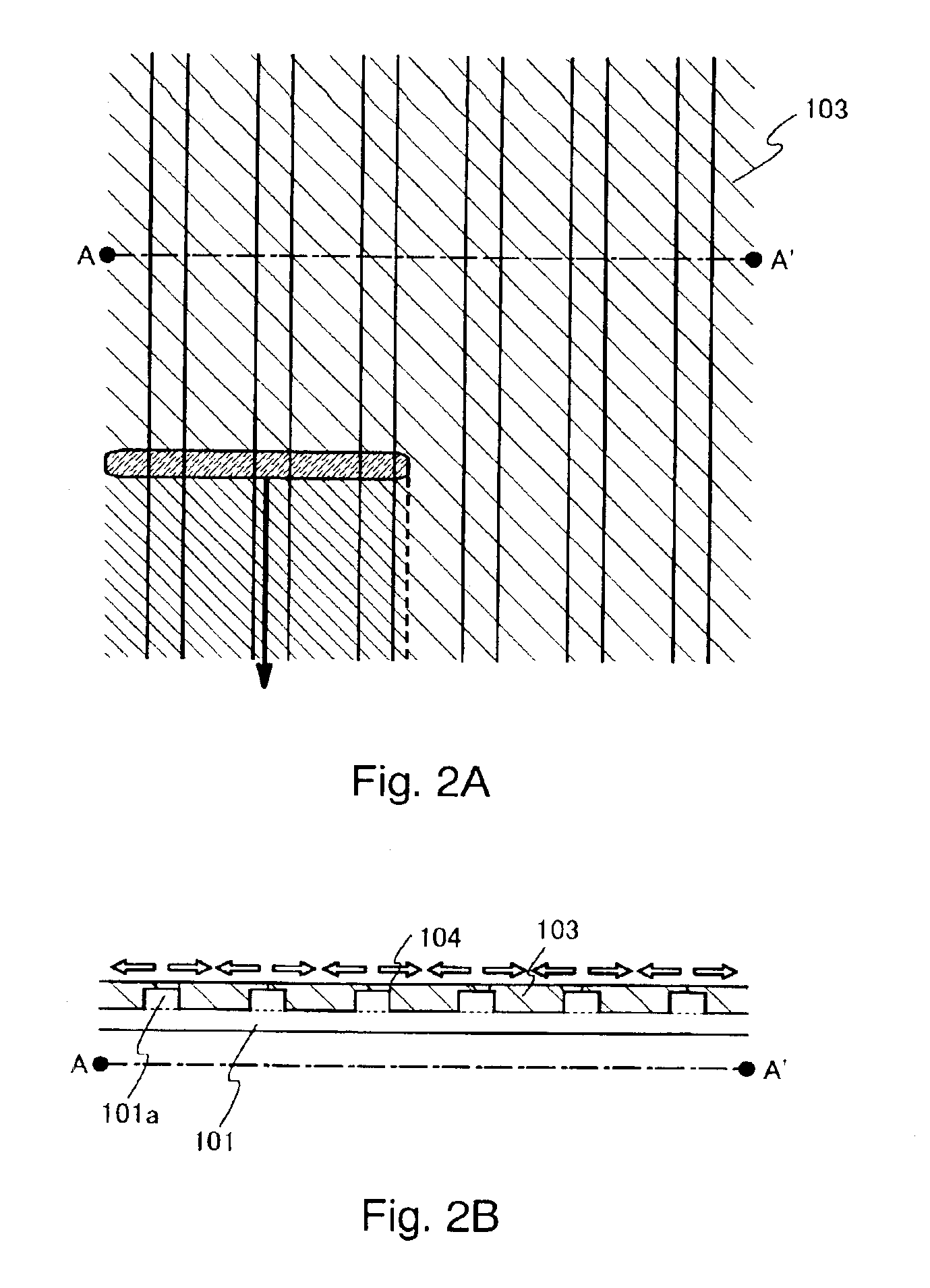

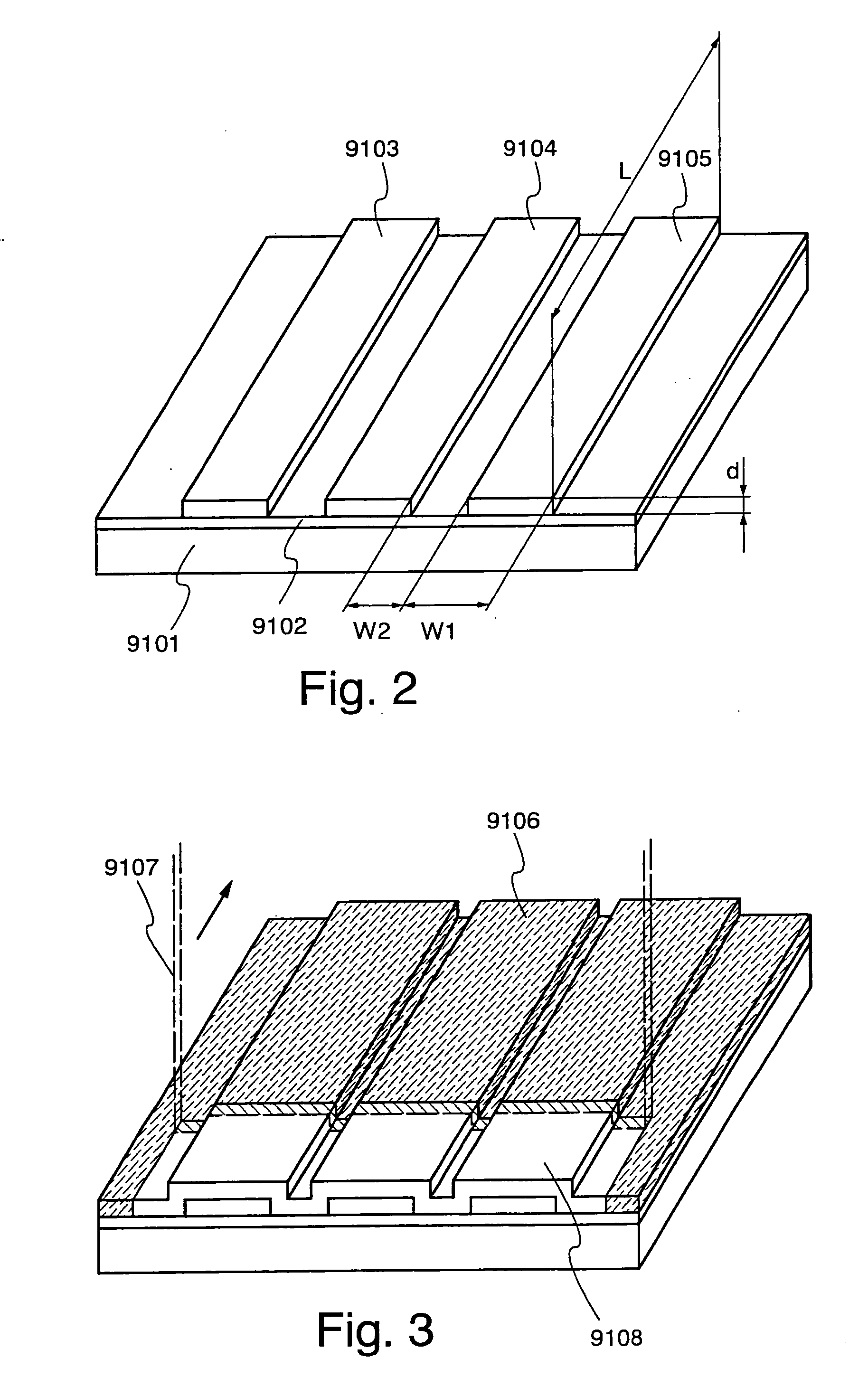

It is a problem to provide a semiconductor device production system using a laser crystallization method capable of preventing grain boundaries from forming in a TFT channel region and further preventing conspicuous lowering in TFT mobility due to grain boundaries, on-current decrease or off-current increase. An insulation film is formed on a substrate, and a semiconductor film is formed on the insulation film. Due to this, preferentially formed is a region in the semiconductor film to be concentratedly applied by stress during crystallization with laser light. Specifically, a stripe-formed or rectangular concavo-convex is formed on the semiconductor film. Continuous-oscillation laser light is irradiated along the striped concavo-convex or along a direction of a longer or shorter axis of rectangle.

Owner:SEMICON ENERGY LAB CO LTD

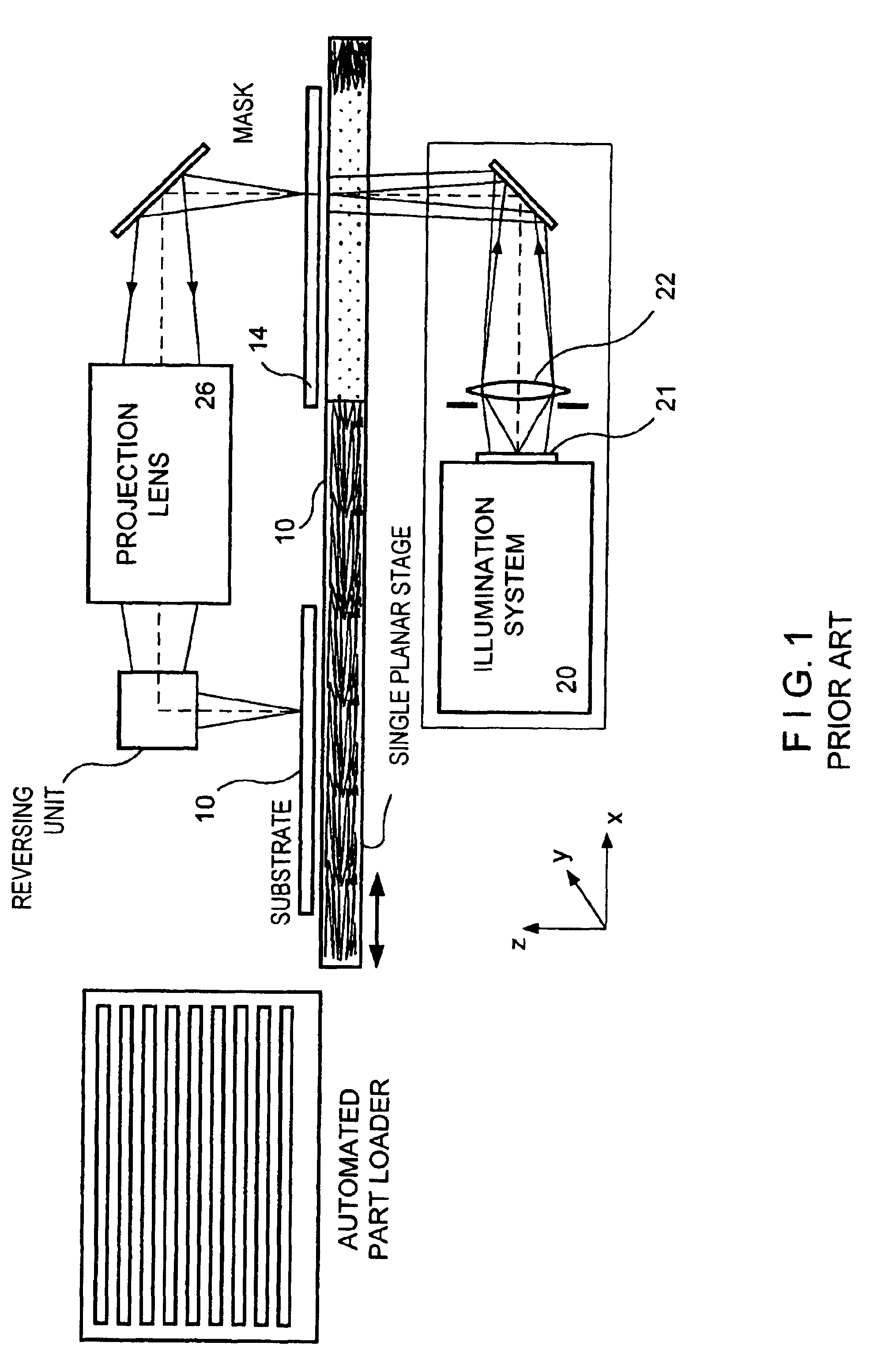

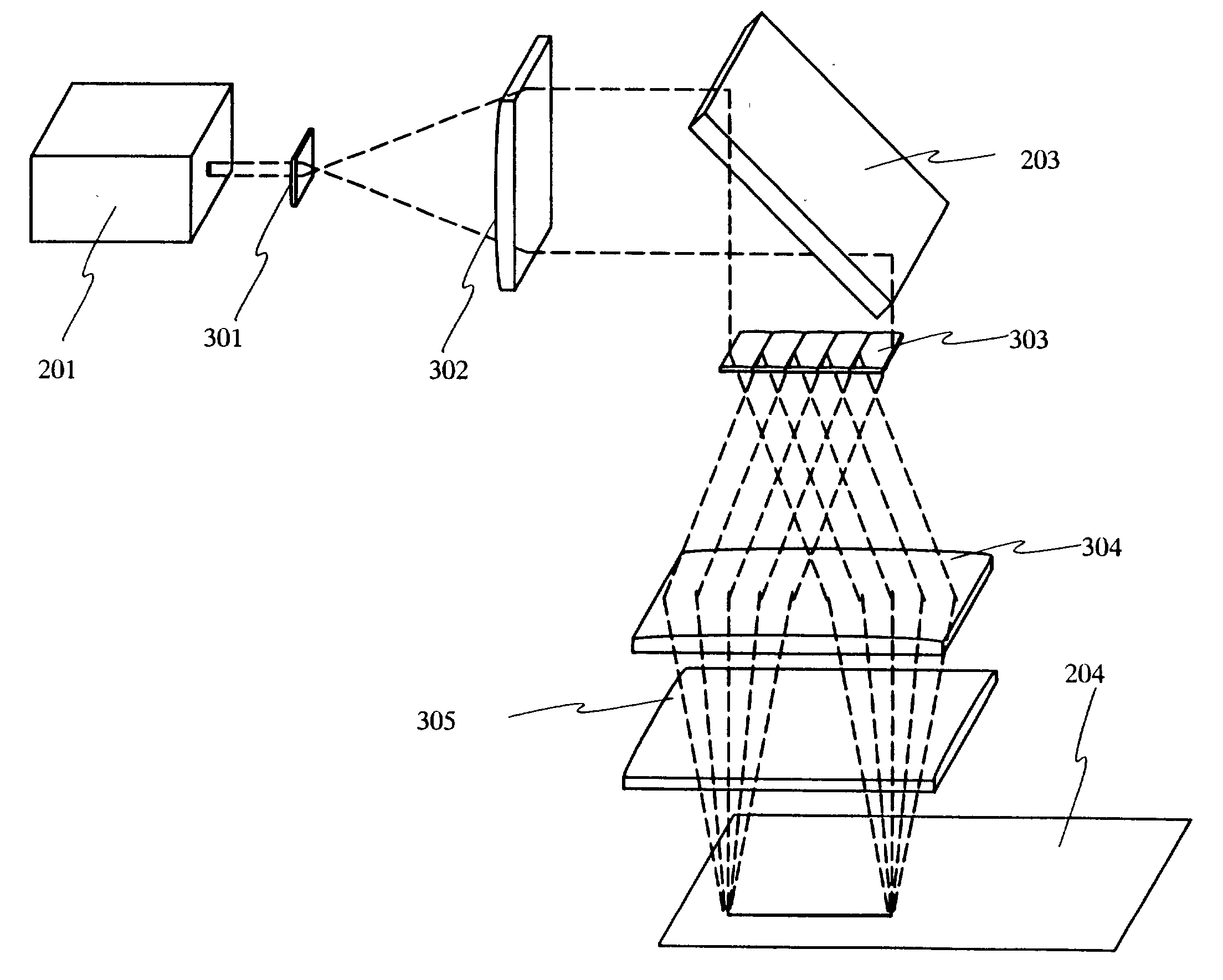

Process and mask projection system for laser crystallization processing of semiconductor film regions on a substrate

InactiveUS6961117B2Extended service lifeEmission reductionLaser detailsSemiconductor/solid-state device manufacturingLight beamLaser crystallization

A process and system for processing a silicon thin film on a sample are provided. In particular, an irradiation beam generator is controlled to emit irradiation beam pulses at a predetermined repetition rate. These irradiation beam pulses are then separated into a first set of beam pulses and a second set of beam pulses. The first set of beam pulses are caused to irradiate through a mask to produce a plurality of beamlets. The second set of beam pulses and the beamlets are caused to impinge and irradiate at least one section of the silicon thin film. When the second set of beam pulses and the beamlets simultaneously irradiate the section of the silicon thin film, this combination of the beamlets and second set of beam pulses provides a combined intensity which is sufficient to melt the section of the silicon thin film throughout an entire thickness of the section.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Process and system for laser crystallization processing of film regions on a substrate to provide substantial uniformity within arears in such regions and edge areas thereof, and a structure of film regions

ActiveUS20060060130A1Reduce perceptionKeep the same performanceTransistorPolycrystalline material growthLaser crystallizationThin membrane

A process and system for processing a thin film sample, as well as the thin film structure are provided. In particular, a beam generator can be controlled to emit successive irradiation beam pulses at a predetermined repetition rate. Each irradiation beam pulse may be masked to define a first plurality of beamlets and a second plurality of beamlets. The first and second plurality of beamlets of each of the irradiation pulses being provided for impinging the film sample and having an intensity which is sufficient to at least partially melt irradiated portions of the section of the film sample. A particular portion of the section of the film sample is irradiated with the first beamlets of a first pulse of the irradiated beam pulses to melt first areas of the particular portion, the first areas being at least partially melted, leaving first unirradiated regions between respective adjacent ones of the first areas, and being allowed to resolidify and crystallize. After the irradiation of the particular portion with the first beamlets, the particular portion is again irradiated with the second beamlets of a second pulse of the irradiated beam pulses to melt second areas of the particular portion, the second areas being at least partially melted, leaving second unirradiated regions between respective adjacent ones of the second areas, and being allowed to resolidify and crystallize. The first irradiated and re-solidified areas and the second irradiated and re-solidified areas are intermingled with one another within the section of the film sample. In addition, the first areas correspond to first pixels, and the second areas correspond to second pixels.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Mask for laser crystallization and crystallization method using the same

ActiveUS20050142451A1Liquid surface applicatorsCrystallization separationLaser crystallizationCrystallization

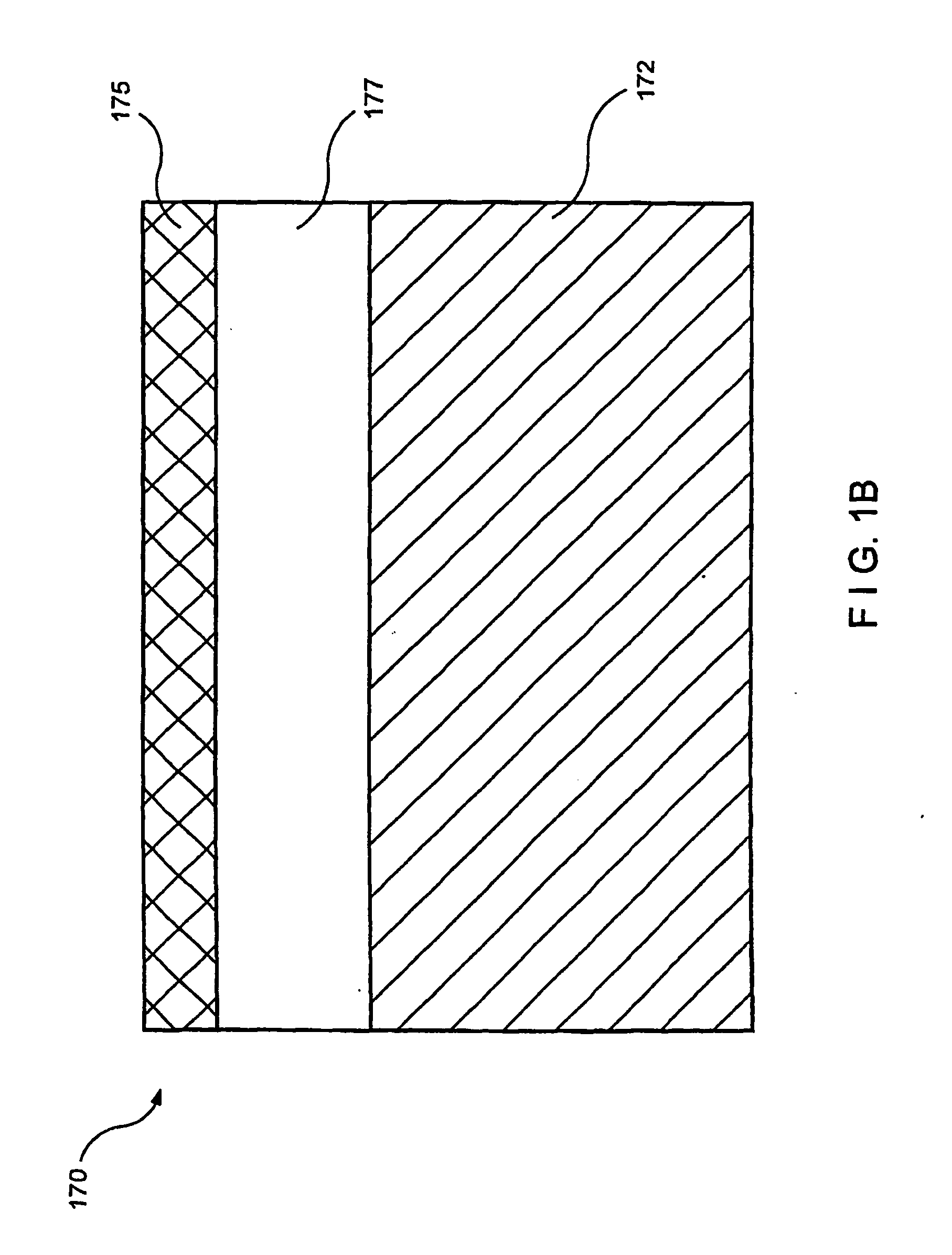

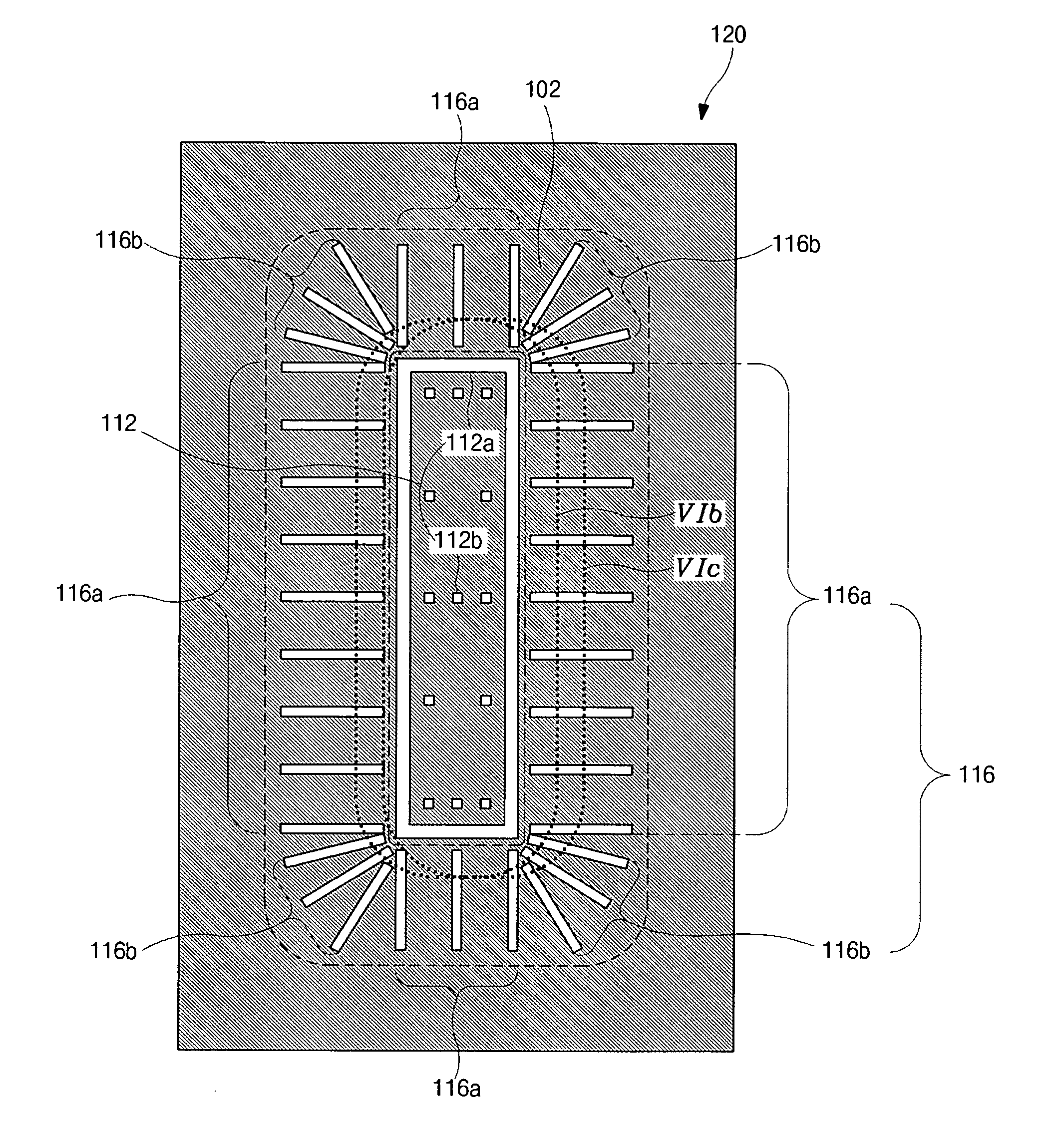

A mask for laser crystallization includes a transmissive portion defining a crystallization pattern and an alignment pattern. The alignment pattern includes a first pattern group having a size corresponding to the crystallization pattern and a second pattern group having a plurality of radial bars surrounding the first pattern group. A shielding portion surrounds the transmissive portion.

Owner:LG DISPLAY CO LTD

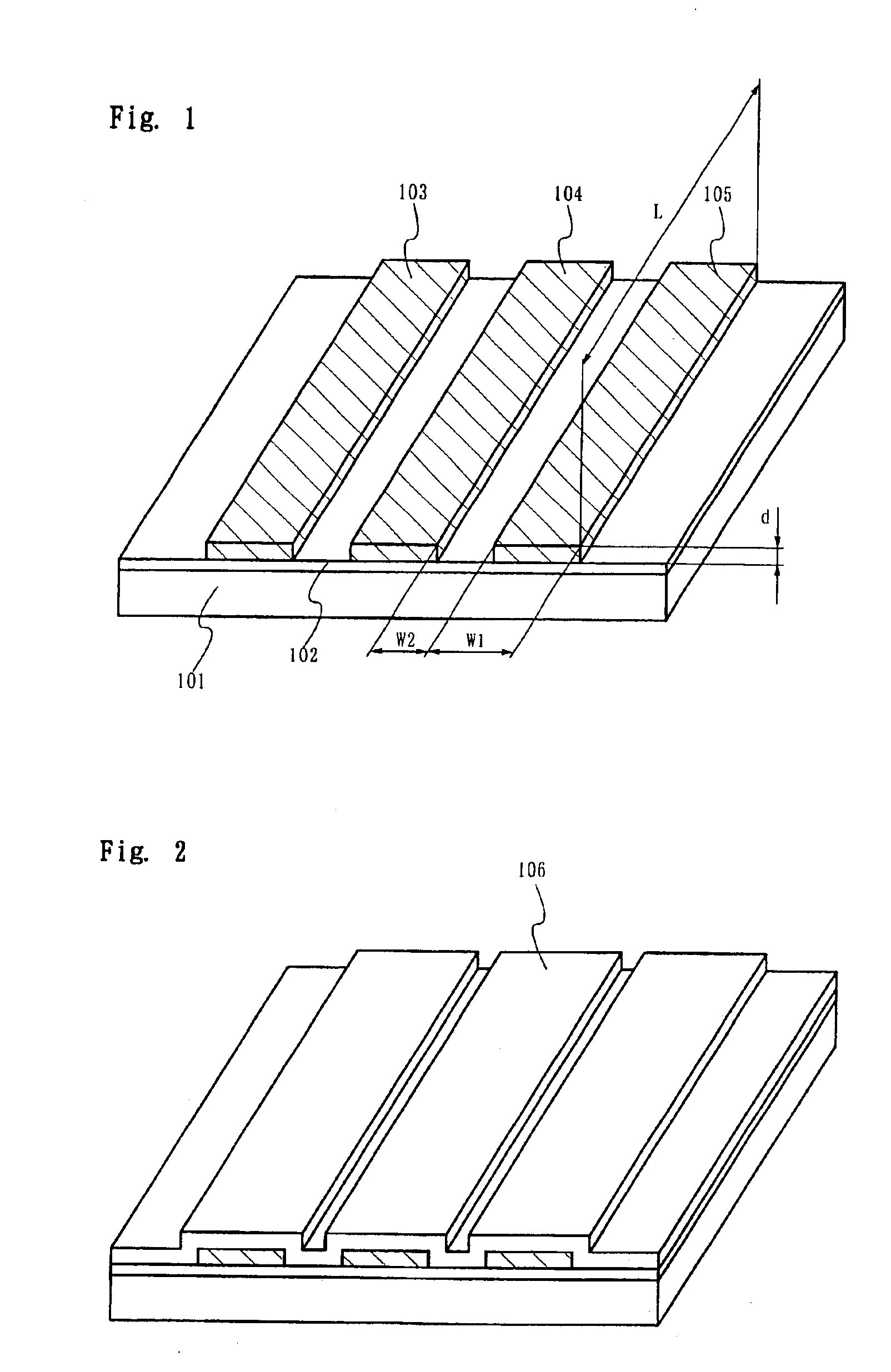

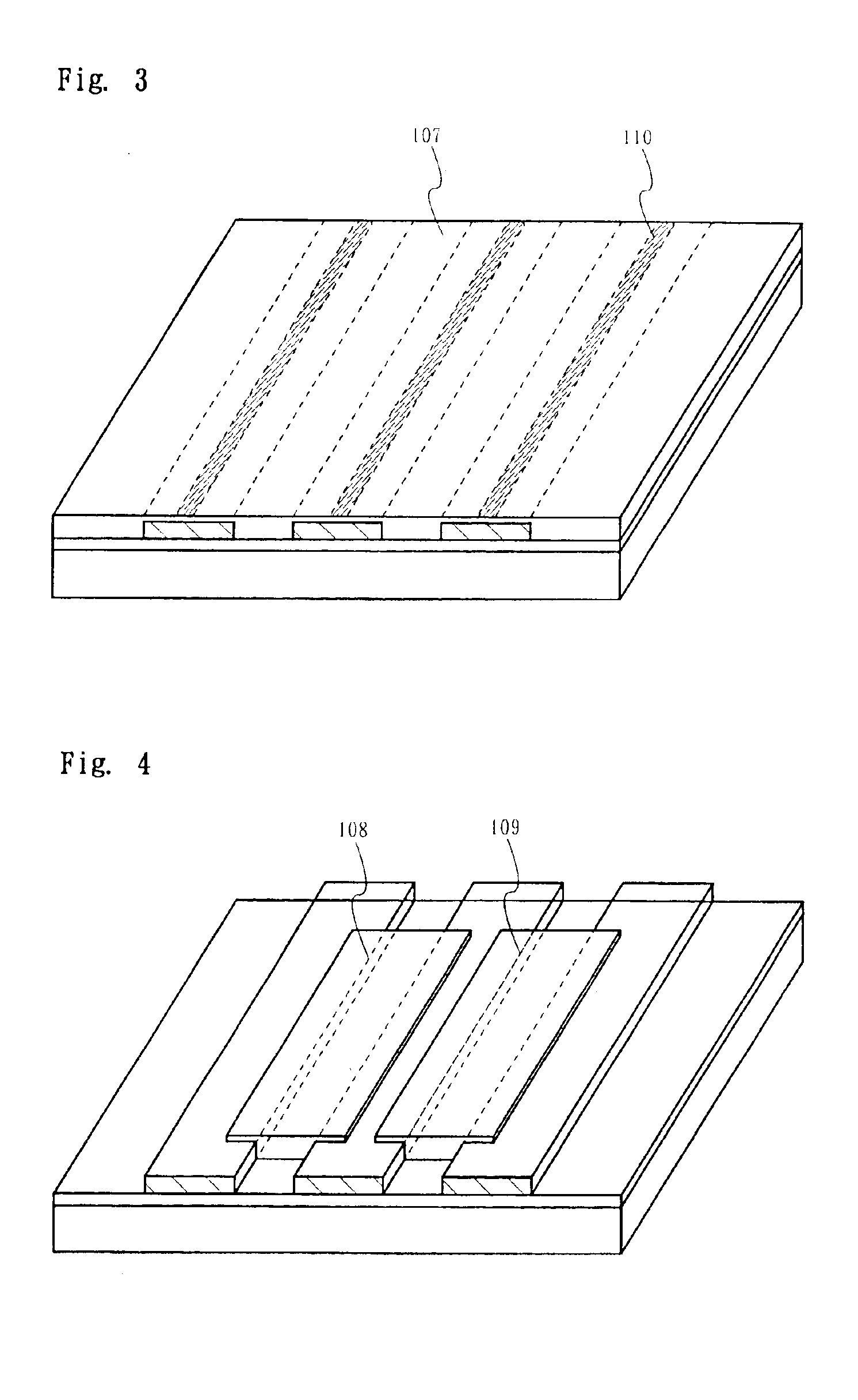

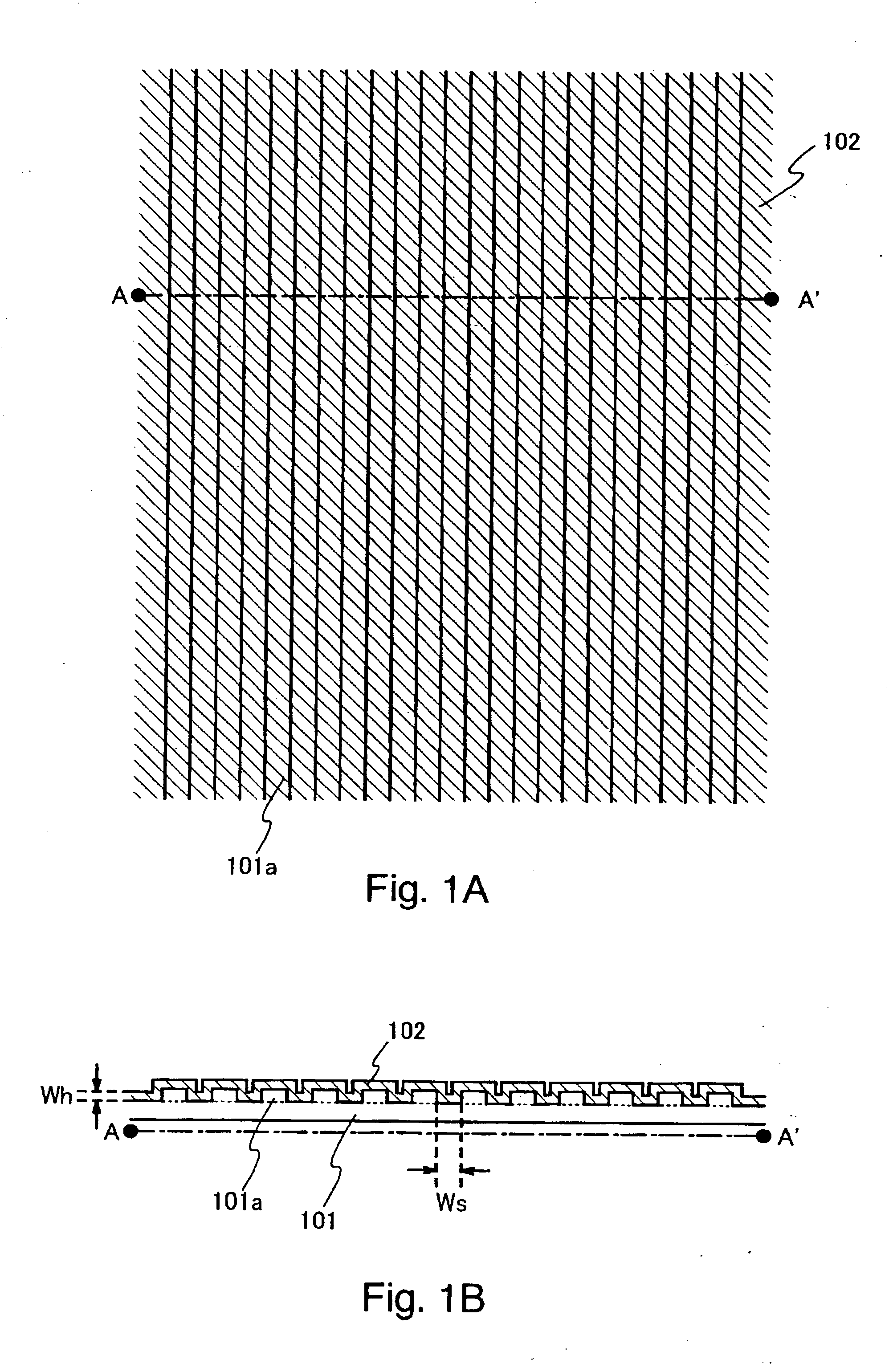

Semiconductor device and method of manufacturing the same

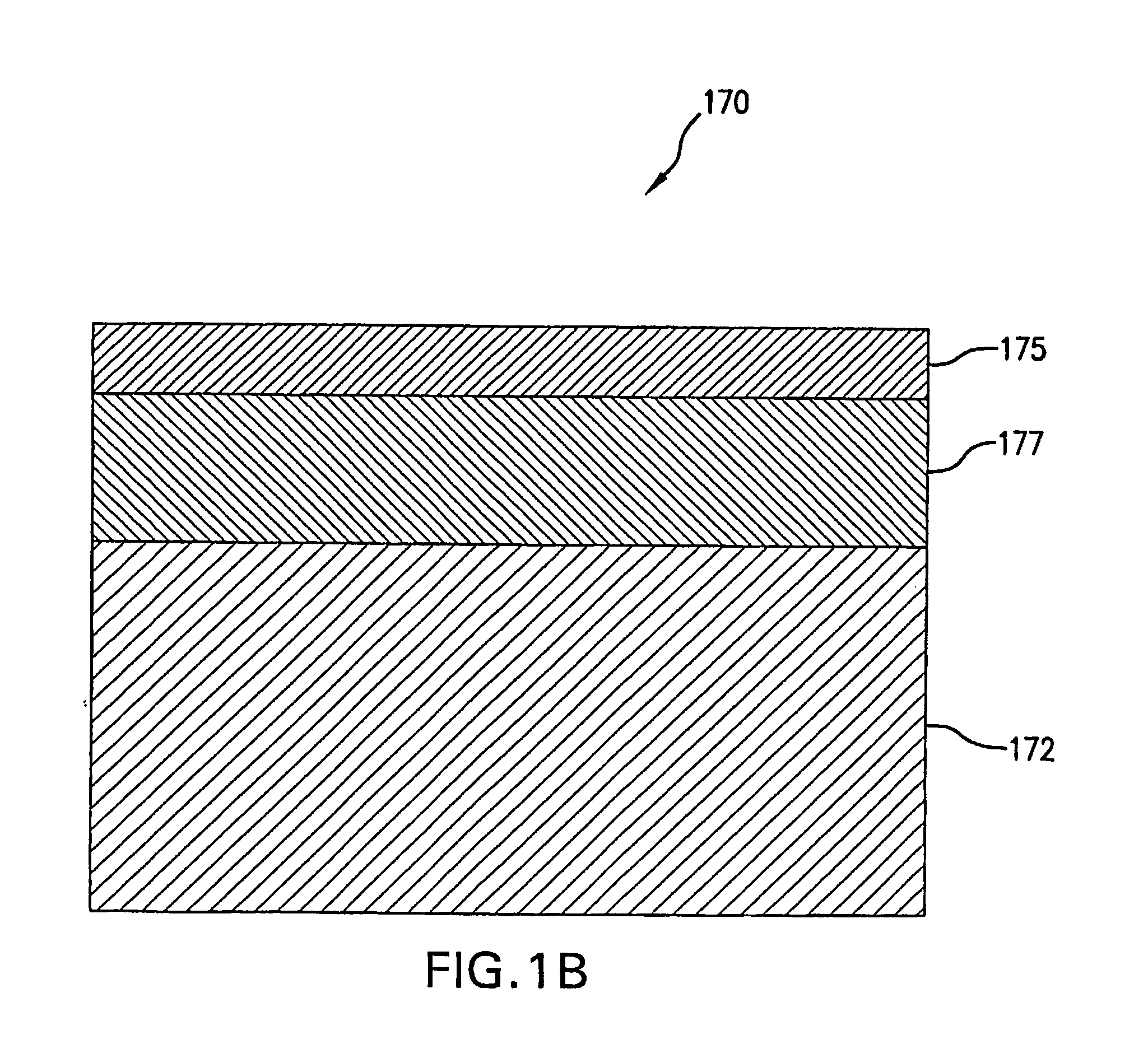

InactiveUS7105392B2Improve performancePrevent fallingTransistorSolid-state devicesTransverse axisDevice material

An objective is to provide a method of manufacturing a semiconductor device, and a semiconductor device manufactured by using the manufacturing method, in which a laser crystallization method is used that is capable of preventing the formation of grain boundaries in TFT channel formation regions, and is capable of preventing conspicuous drops in TFT mobility, reduction in the ON current, and increases in the OFF current, all due to grain boundaries. Depressions and projections with stripe shape or rectangular shape are formed. Continuous wave laser light is then irradiated to a semiconductor film formed on an insulating film along the depressions and projections with stripe shape of the insulating film, or along a longitudinal axis direction or a transverse axis direction of the rectangular shape. Note that although it is most preferable to use continuous wave laser light at this point, pulse wave laser light may also be used.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device and manufacturing method thereof

InactiveUS20060284183A1Reduce manufacturing costIncrease freedomSemiconductor/solid-state device detailsSolid-state devicesDevice materialLaser crystallization

It has been difficult to manufacture a semiconductor device equipped with a microstructure having a space, an electric circuit for controlling the microstructure, and the like over one substrate. In a semiconductor device, a microstructure and an electric circuit for controlling the microstructure can be provided over one substrate by manufacturing the microstructure in such a way that a structural layer having polycrystalline silicon obtained by laser crystallization or thermal crystallization using a metal element is formed and processed at low temperature. As the electric circuit, a wireless communication circuit for carrying out wireless communication with an antenna is given.

Owner:SEMICON ENERGY LAB CO LTD

Manufacturing method of semiconductor device

InactiveUS20030215973A1Increasing substrate processing efficiencyShorten the timeSemiconductor/solid-state device detailsSolid-state devicesLaser crystallizationIrradiation

Island-like semiconductor films and markers are formed prior to laser irradiation. Markers are used as positional references so as not to perform laser irradiation all over the semiconductor within a substrate surface, but to perform a minimum crystallization on at least indispensable portion. Since the time required for laser crystallization can be reduced, it is possible to increase the substrate processing speed. By applying the above-described constitution to a conventional SLS method, a means for solving such problem in the conventional SLS method that the substrate processing efficiency is insufficient, is provided.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device and manufacturing method therefor

InactiveUS6884668B2Low costPoor heat resistanceSolid-state devicesSemiconductor/solid-state device manufacturingLaser crystallizationLaser light

To provide devices relating to a manufacturing method for a semiconductor device using a laser crystallization method, which is capable of reducing a cost involved in a design change, preventing a grain boundary from developing in a channel formation region of a TFT, and preventing a remarkable reduction in mobility of the TFT, a decrease in an ON current, and an increase in an OFF current due to the grain boundary and to a semiconductor device formed by using the manufacturing method. In a semiconductor device according to the present invention, among a plurality of TFTs formed on a base film, some TFTs are electrically connected to form logic elements. The plurality of logic elements are used to form a circuit. The base film has a plurality of projective portions having a rectangular or stripe shape. Island-like semiconductor films included in each of the plurality of TFTs are formed between the plurality of projective portions and also, are crystallized by a laser light scanned in a longitudinal direction of the projective portions.

Owner:SEMICON ENERGY LAB CO LTD

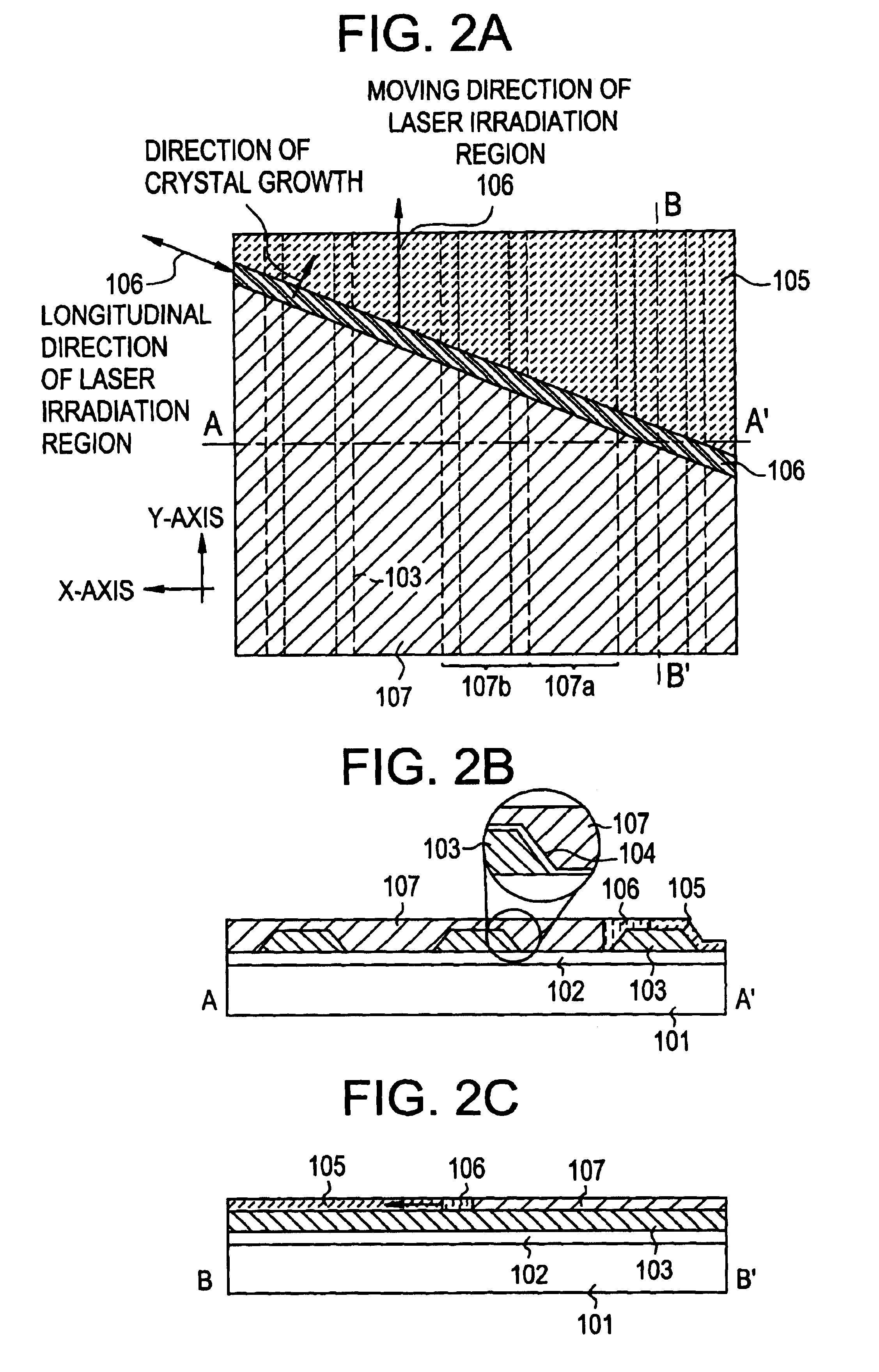

Method of fabricating semiconductor device

InactiveUS6841434B2Improve cleanlinessAvoid pollutionTransistorPolycrystalline material growthBand shapeLaser crystallization

The objective of the invention is to provide a method of fabricating semiconductor device using a laser crystallization method capable of preventing a grain boundary from being formed on the channel-forming region of a TFT and preventing the mobility of the TFT from extremely deteriorating, on-current from decreasing, or off-current from increasing due to a grain boundary and a semiconductor device fabricated by the fabrication method. Striped (banded) or rectangular concave and convex portions are formed. Then, a semiconductor film formed on an insulating film is irradiated with a laser beam diagonally to the longitudinal direction of concave and convex portions on the insulating film.

Owner:SEMICON ENERGY LAB CO LTD

Very high energy, high stability gas discharge laser surface treatment system

InactiveUS7167499B2Semiconductor/solid-state device manufacturingLaser arrangementsPulse beamNoble gas

A gas discharge laser crystallization apparatus and method for performing a transformation of a crystal makeup or orientation in the substrate of a workpiece is disclosed which may comprise, a multichamber laser system comprising, a first laser unit comprising, a first and second gas discharge chamber; each with a pair of elongated spaced apart opposing electrodes contained within the chamber, forming an elongated gas discharge region; a laser gas contained within the chamber comprising a halogen and a noble gas selected to produce laser light at a center wavelength optimized to the crystallization process to be earned out on the workpiece; a power supply module comprising, a DC power source; a first and a second pulse compression and voltage step up circuit connected to the DC power source and connected to the respective electrodes, comprising a multistage fractional step up transformer having a plurality of primary windings connected in series and a single secondary winding passing through each of the plurality of primary windings, and a solid state trigger switch; and a laser timing and control module operative to time the closing of the respective solid state switch based upon operating parameters of the respective first and second pulse compression and voltage step up circuit to effect operation of the first and second laser units as either a POPA configured laser system or a POPO configured laser system to produce a single output laser light pulse beam. As a POPA laser system relay optics may be operative to direct a first output laser light pulse beam from the first laser unit into the second gas discharge chamber; and, the timing and control module operates to create a gas discharge between the second pair of electrodes while the first output laser light pulse beam is transiting the second discharge region, within plus or minus 3 ns and as a POPO, combining optics combine the output beams, and timing creates pulse separation in the combined output a preselected time plus or minus 3 ns.

Owner:CYMER INC

Semiconductor device and semiconductor device production system

InactiveUS20050161742A1Improve barrier propertiesImprove stressTransistorSolid-state devicesStress concentrationDevice material

It is a problem to provide a semiconductor device production system using a laser crystallization method capable of preventing grain boundaries from forming in a TFT channel region and further preventing conspicuous lowering in TFT mobility due to grain boundaries, on-current decrease or off-current increase. An insulation film is formed on a substrate, and a semiconductor film is formed on the insulation film. Due to this, preferentially formed is a region in the semiconductor film to be concentratedly applied by stress during crystallization with laser light. Specifically, a stripe-formed or rectangular concavo-convex is formed on the semiconductor film. Continuous-oscillation laser light is irradiated along the striped concavo-convex or along a direction of a longer or shorter axis of rectangle.

Owner:SEMICON ENERGY LAB CO LTD

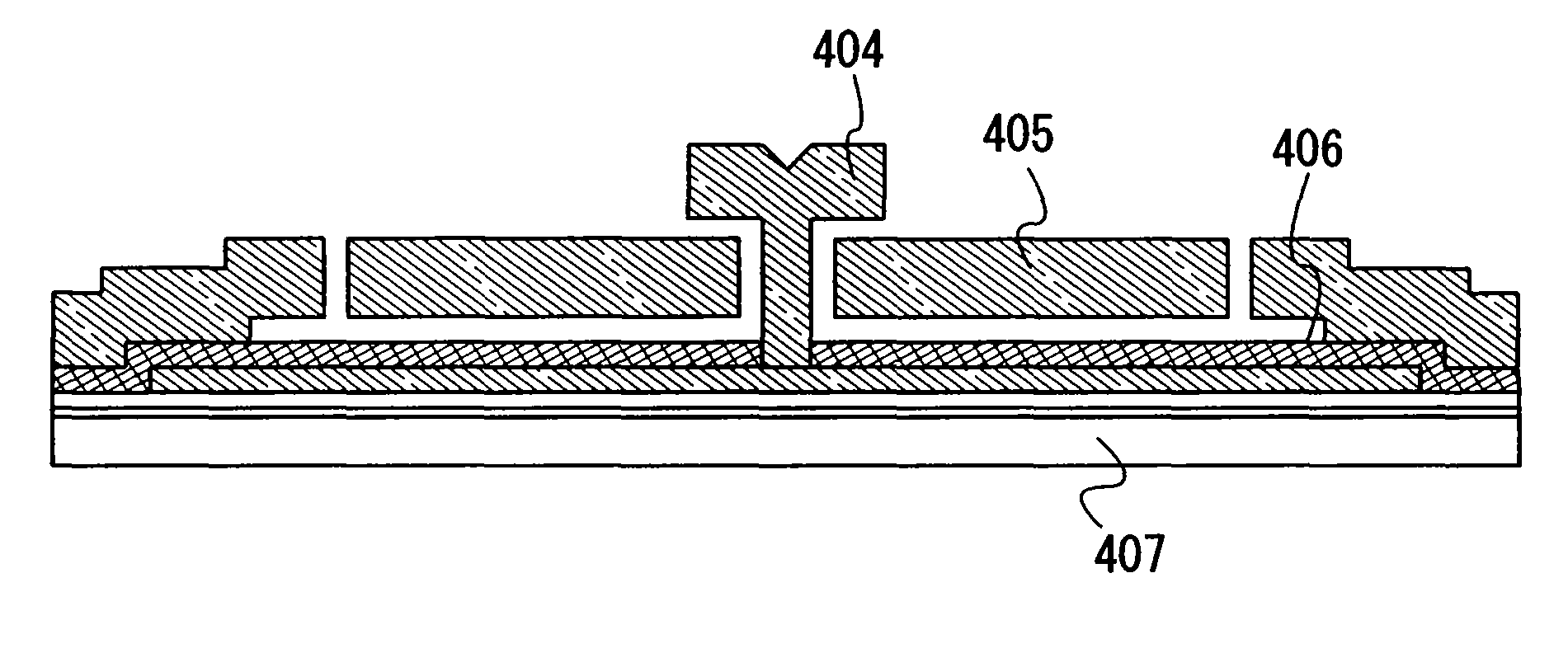

Display device and electronic device using the same

InactiveUS7312473B2Reduce variationLow mobilityTransistorStatic indicating devicesDisplay deviceLaser crystallization

In display devices using thin film transistors, a graphoepitaxy is used for a semiconductor layer crystallizing process. Thus, a display device in which crystallinity is improved, a variation in characteristics of thin film transistors is reduced, display nonuniformity is less, and a display quality is superior is provided. Steps are formed on a substrate in advance and an amorphous silicon film is formed thereon, and then laser crystallization is conducted in a direction perpendicular to the steps.

Owner:SEMICON ENERGY LAB CO LTD

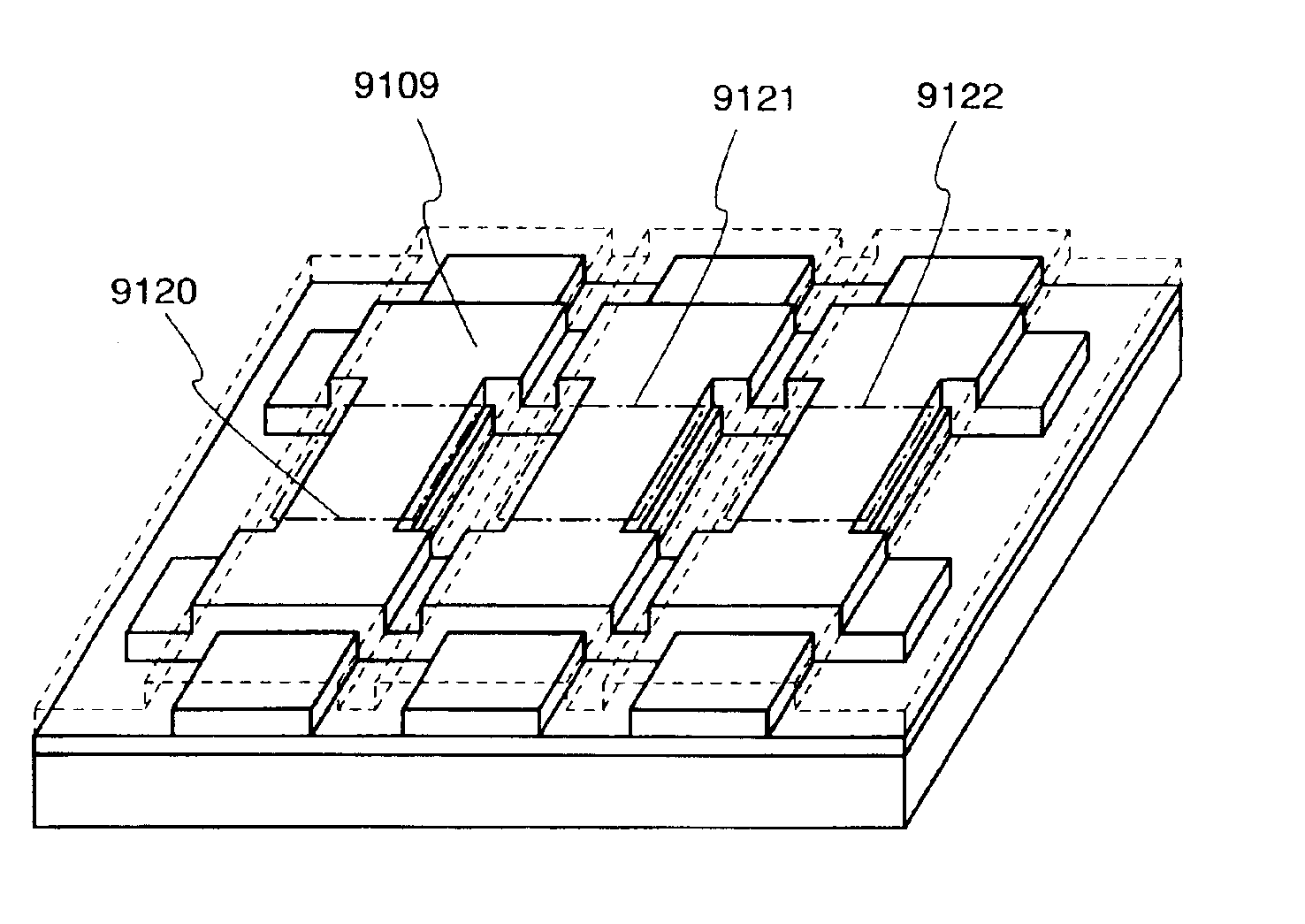

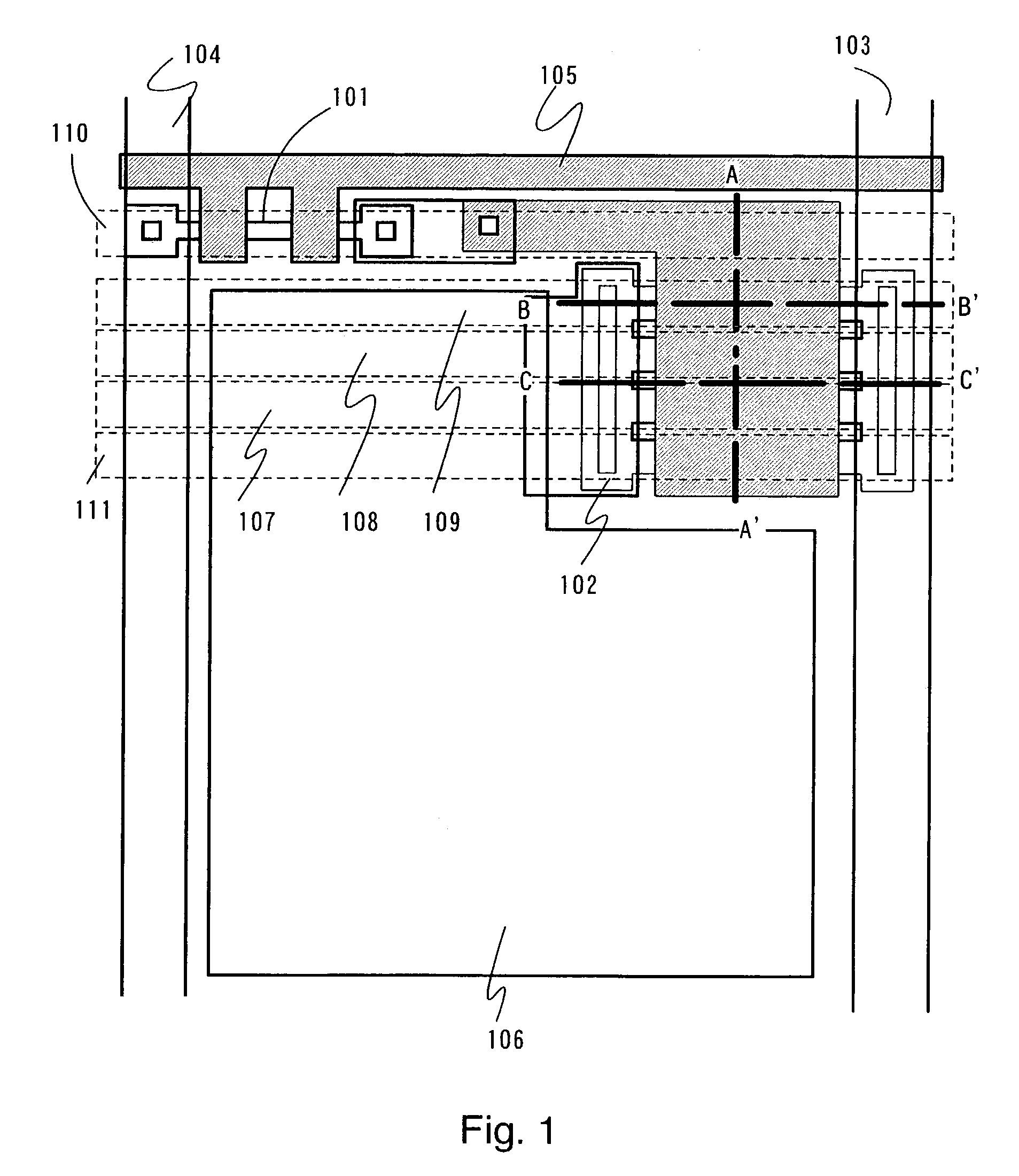

Semiconductor device, method of manufacturing the same, and method of designing the same

An object of the present invention is to provide a semiconductor device formed by laser crystallization by which formation of grain boundaries in the TFT channel formation region can be avoided, and a method of manufacturing the same. Still another object of the present invention is to provide a method of designating the semiconductor device. The present invention relates to a semiconductor device with a plurality of cells each having a plurality of TFTs that have the same channel length direction, in which the plural cells form a plurality of columns along the channel length direction, in which an island-like semiconductor film of each of the plural TFTs is crystallized by laser light running in the channel length direction, in which a channel formation region of the island-like semiconductor film is placed on a depressive portion of a base film that has a rectangular or stripe pattern concave and convex with the channel length direction matching the longitudinal direction of the depressive portion, and in which a plurality of wires for electrically connecting the plural cells with one another are formed between the plural columns.

Owner:SEMICON ENERGY LAB CO LTD

Process and system for laser crystallization processing of film regions on a substrate to provide substantial uniformity, and a structure of such film regions

InactiveUS7259081B2Increase speedUniform materialTransistorAfter-treatment apparatusLaser crystallizationGrain structure

A process and system for processing a thin film sample (e.g., a semiconductor thin film), as well as the thin film structure are provided. In particular, a beam generator can be controlled to emit at least one beam pulse. With this beam pulse, at least one portion of the film sample is irradiated with sufficient intensity to fully melt such section of the sample throughout its thickness, and the beam pulse having a predetermined shape. This portion of the film sample is allowed to resolidify, and the re-solidified at least one portion is composed of a first area and a second area. Upon the re-solidification thereof, the first area includes large grains, and the second area has a region formed through nucleation. The first area surrounds the second area and has a grain structure which is different from a grain structure of the second area. The second area is configured to facilitate thereon an active region of an electronic device.

Owner:IM JAMES S

Laser irradiation method, laser irradiation apparatus, and semiconductor device

InactiveUS20030224587A1Laser using scattering effectsSolid-state devicesContinuous lightActive matrix

An object of the present invention is obtaining a semiconductor film with uniform characteristics by improving irradiation variations of the semiconductor film. The irradiation variations are generated due to scanning while irradiating with a linear laser beam of the pulse emission. At a laser crystallization step of irradiating a semiconductor film with a laser light, a continuous light emission excimer laser emission device is used as a laser light source. For example, in a method of fabricating an active matrix type liquid crystal display device, a continuous light emission excimer laser beam is irradiated to a semiconductor film, which is processed to be a linear shape, while scanning in a vertical direction to the linear direction. Therefore, more uniform crystallization can be performed because irradiation marks can be avoided by a conventional pulse laser.

Owner:SEMICON ENERGY LAB CO LTD

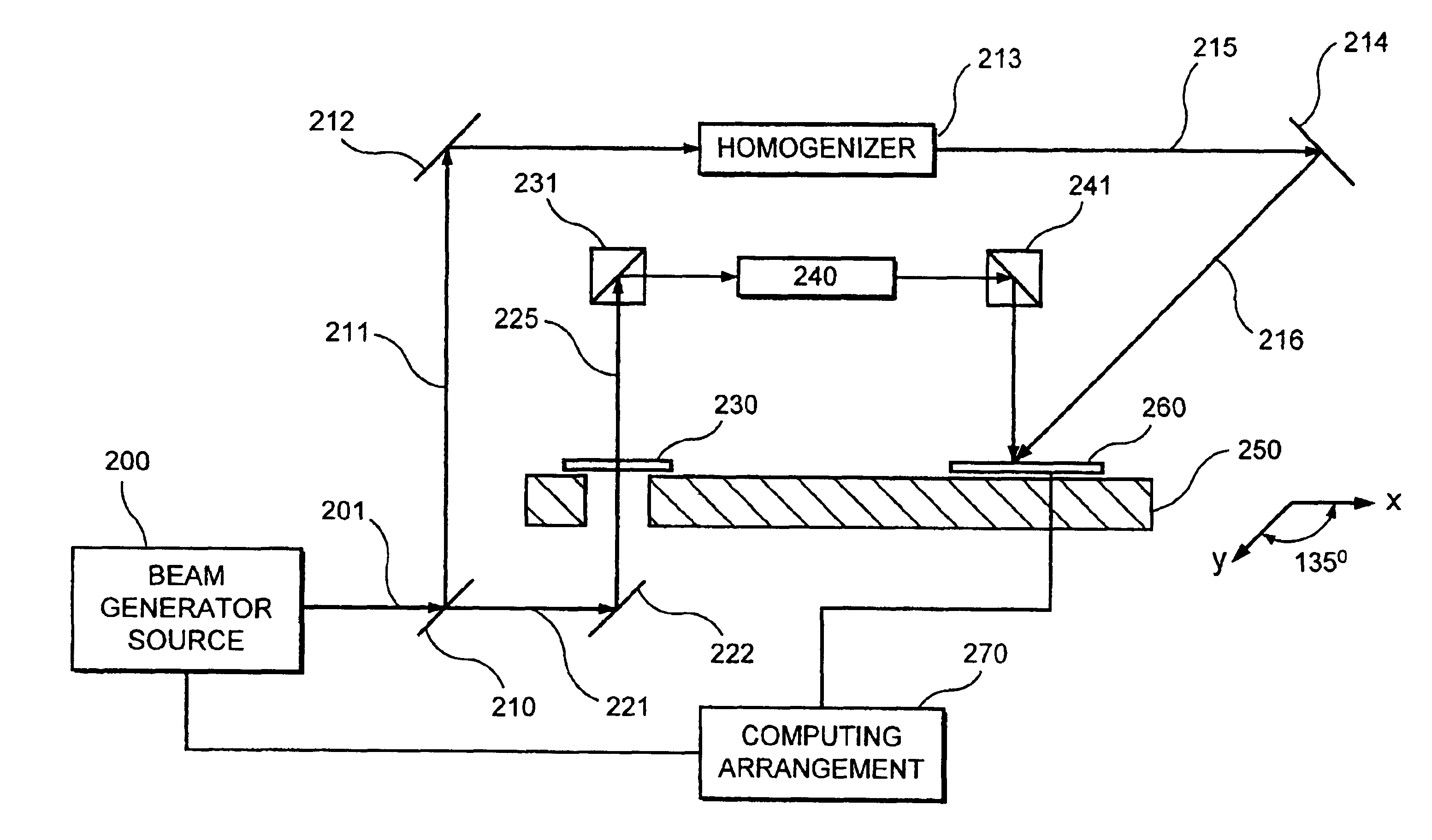

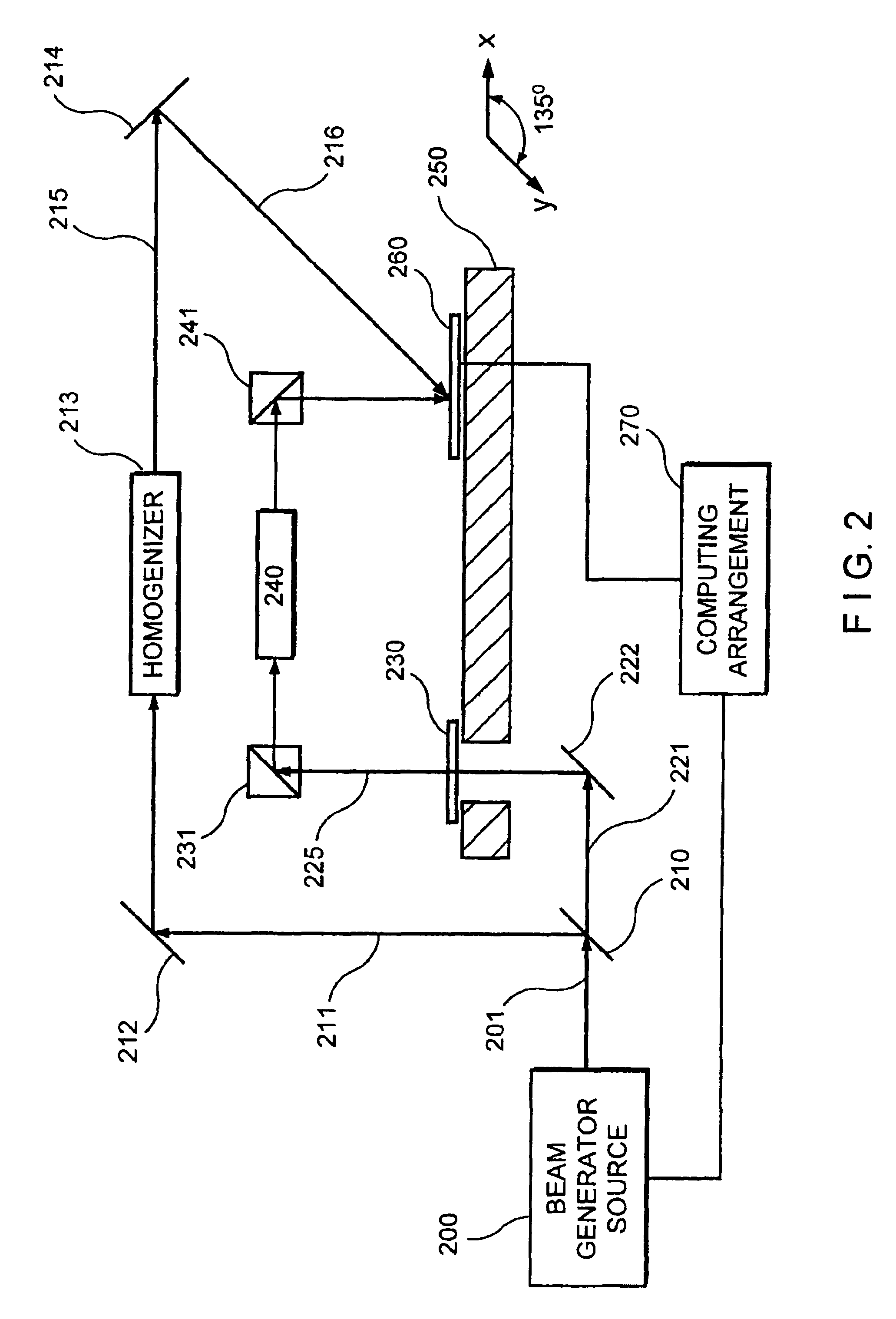

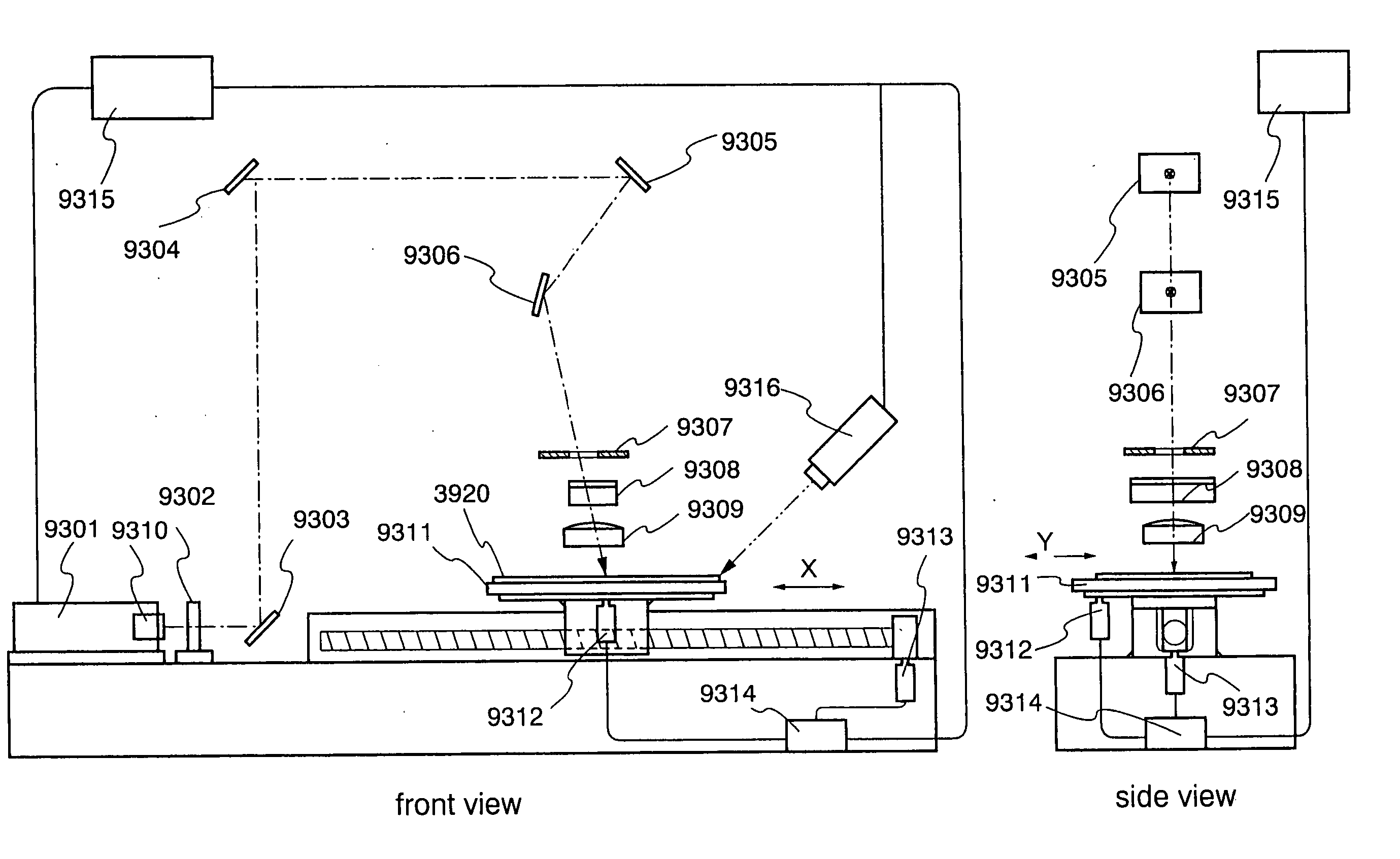

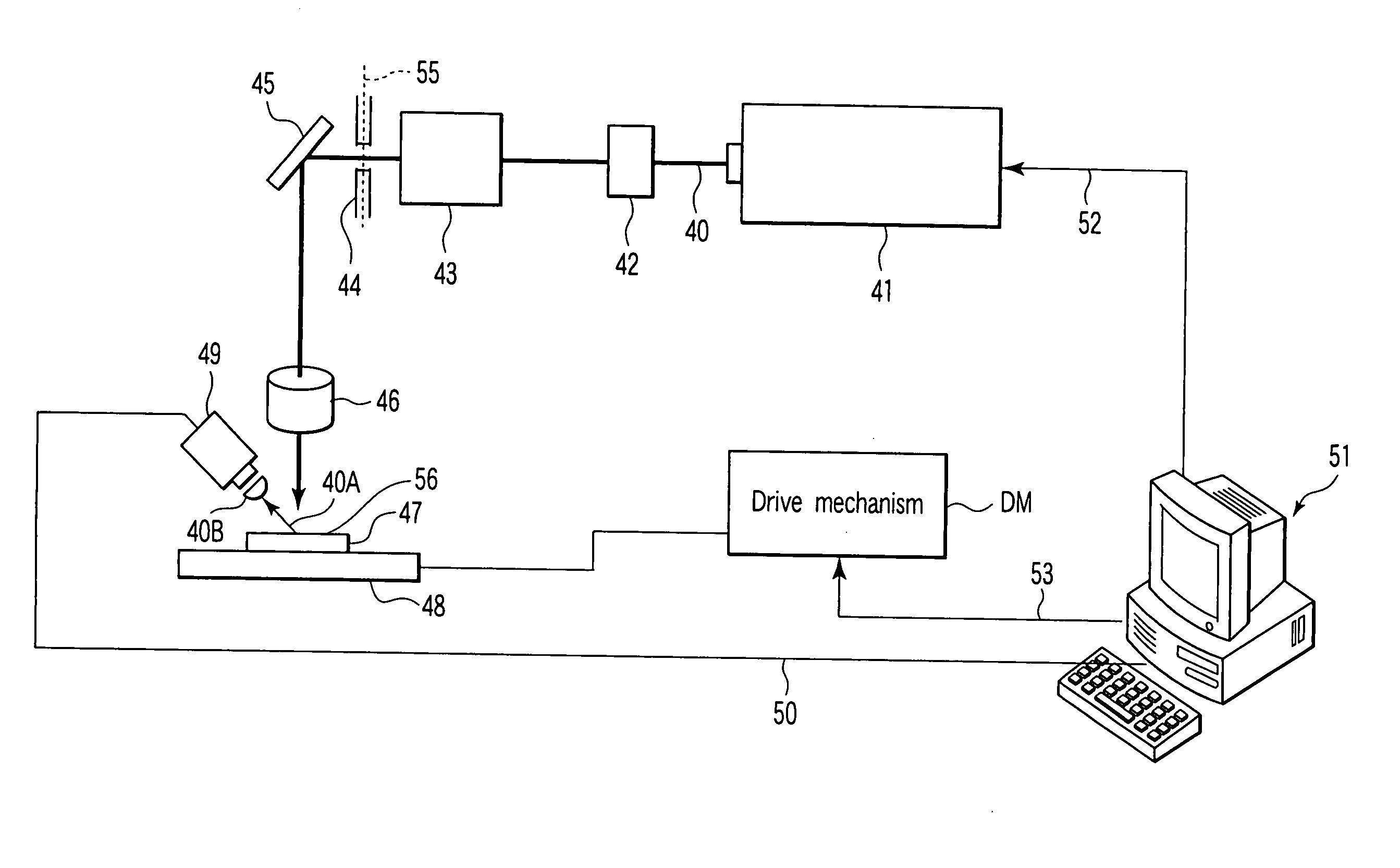

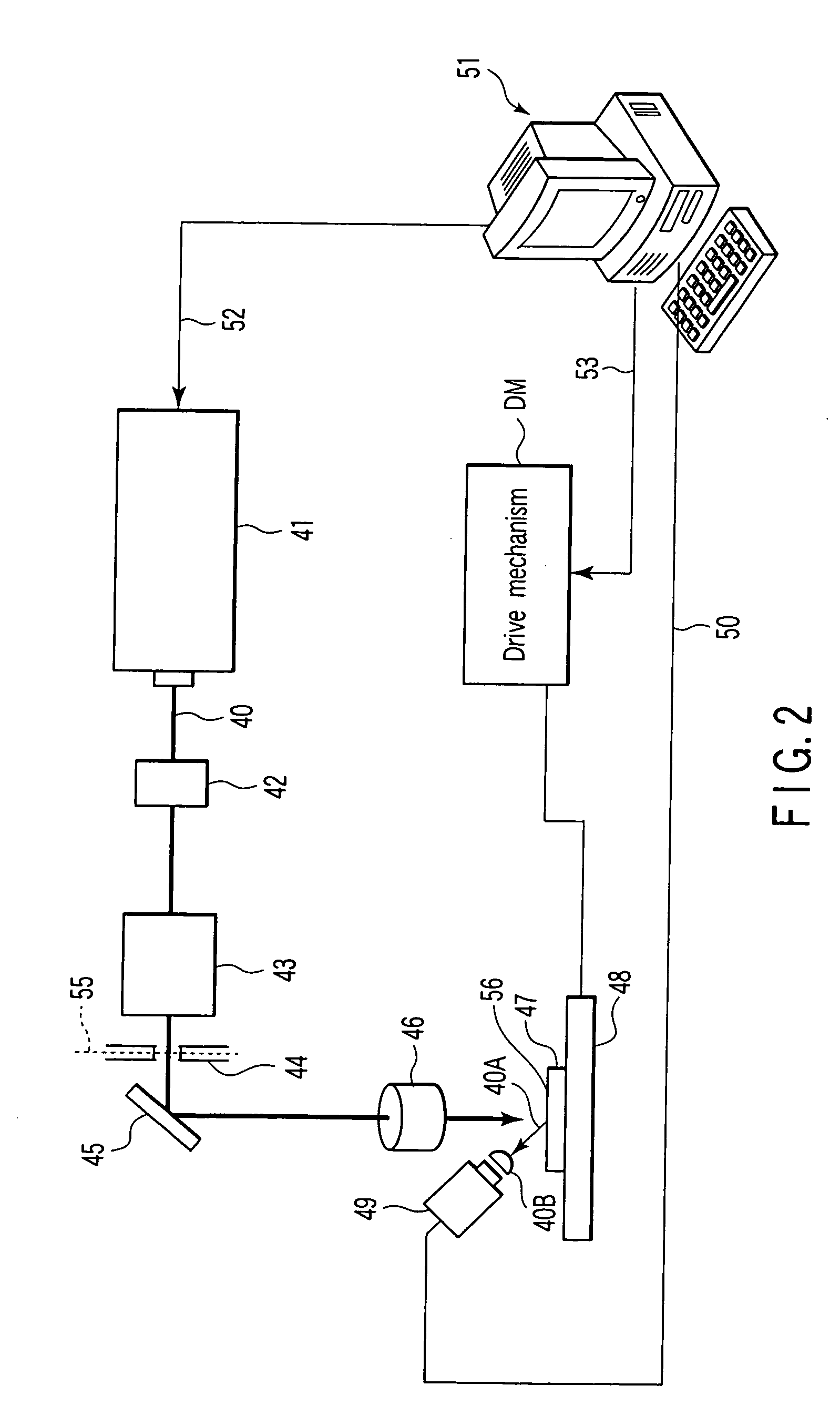

Processing method, processing apparatus, crystallization method and crystallization apparatus using pulsed laser beam

InactiveUS20060131289A1Excellently perform laser crystallizationYield ratio decreaseMetal working apparatusSpecial data processing applicationsLaser processingPhotovoltaic detectors

In a laser processing method and a laser processing apparatus which irradiate a processing target body with a laser beam pulse-oscillated from a laser beam source, a processing state is monitored by a photodetector, and the laser beam source is again subjected to oscillation control on the moment when erroneous laser irradiation is detected, thereby performing laser processing. Further, in a laser crystallization method and a laser crystallization apparatus using a pulse-oscillated excimer laser, a homogenizing optical system, an optical element and a half mirror are arranged in an optical path, light from the half mirror is detected by a photodetector, and a light intensity insufficient irradiation position is again irradiated with a laser beam to perform crystallization when the detection value does not fall within a range of a predetermined specified value.

Owner:ADVANCED LCD TECH DEVMENT CENT

Thin film transistor, manufacturing method thereof, and semiconductor device

ActiveUS20080210945A1Improve mobilityDirection is limitedTransistorPolycrystalline material growthLaser crystallizationLaser light

By a laser crystallization method, a crystalline semiconductor film in which grain boundaries are all in one direction is provided as well as a manufacturing method thereof. In crystallizing a semiconductor film formed over a substrate with linear laser light, a phase-shift mask in which trenches are formed in a stripe form is used. The stripe-form trenches formed in the phase-shift mask are formed so as to make a nearly perpendicular angle with a major axis direction of the linear laser light. CW laser light is used as the laser light, and a scanning direction of the laser light is nearly parallel to a direction of the stripe-form trenches (grooves). By changing luminance of the laser light periodically in the major axis direction, a crystal nucleation position in a semiconductor that is completely melted can be controlled.

Owner:SEMICON ENERGY LAB CO LTD

Laser crystallization and selective patterning using multiple beamlets

ActiveUS7300858B2Reduce perceptionKeep the same performanceTransistorPolycrystalline material growthLaser crystallizationLight beam

A process and system for processing a thin film sample, as well as the thin film structure are provided. In particular, a beam generator can be controlled to emit successive irradiation beam pulses at a predetermined repetition rate. Each irradiation beam pulse may be masked to define a first plurality of beamlets and a second plurality of beamlets. The first and second plurality of beamlets of each of the irradiation pulses being provided for impinging the film sample and having an intensity which is sufficient to at least partially melt irradiated portions of the section of the film sample. A particular portion of the section of the film sample is irradiated with the first beamlets of a first pulse of the irradiated beam pulses to melt first areas of the particular portion, the first areas being at least partially melted, leaving first unirradiated regions between respective adjacent ones of the first areas, and being allowed to resolidify and crystallize. After the irradiation of the particular portion with the first beamlets, the particular portion is again irradiated with the second beamlets of a second pulse of the irradiated beam pulses to melt second areas of the particular portion, the second areas being at least partially melted, leaving second unirradiated regions between respective adjacent ones of the second areas, and being allowed to resolidify and crystallize. The first irradiated and re-solidified areas and the second irradiated and re-solidified areas are intermingled with one another within the section of the film sample. In addition, the first areas correspond to first pixels, and the second areas correspond to second pixels.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com