Patents

Literature

183results about How to "Meet lubrication requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

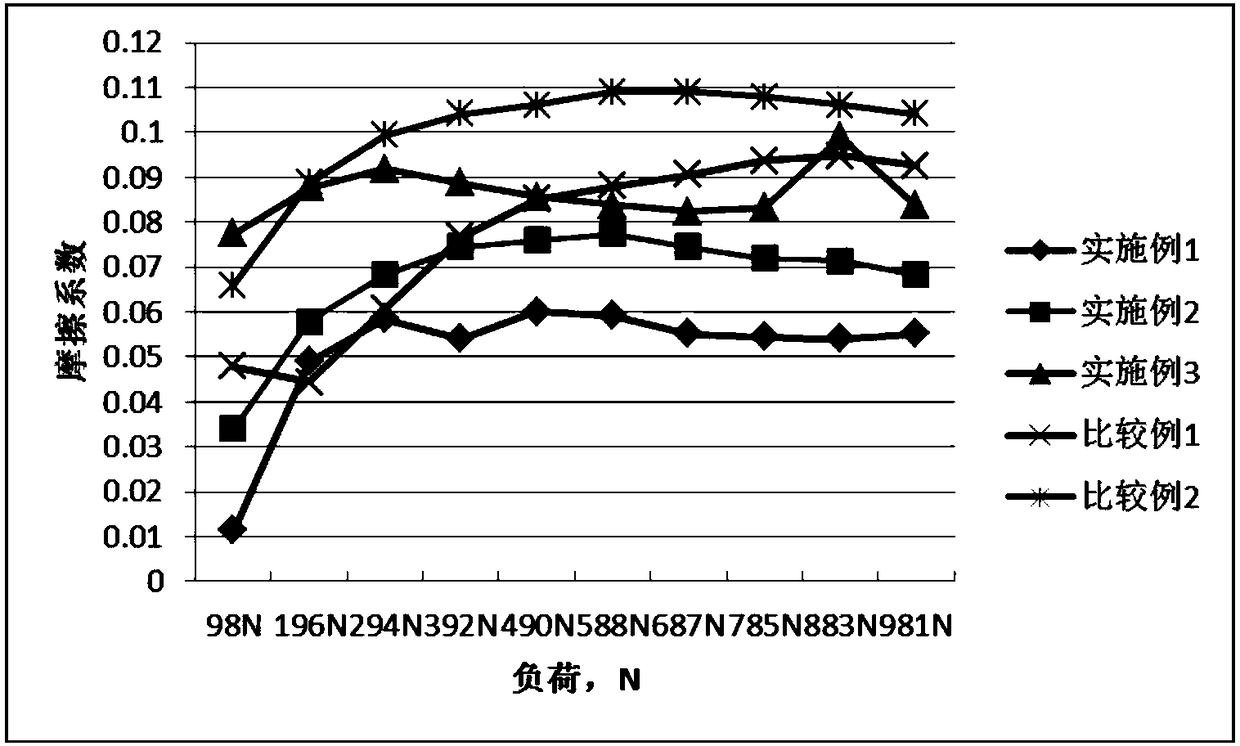

Composite lithium-base grease and method for making same

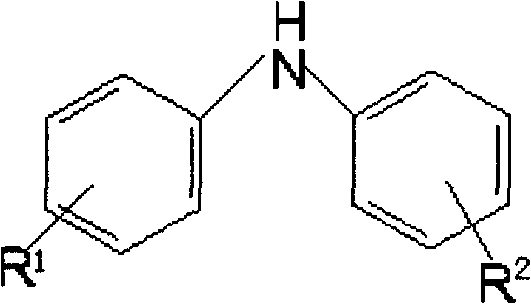

The present invention provides composite lithium-based lubricating grease and a preparation method thereof. The composite lithium-based lubricating grease consists of thickener, base oil and additive. The thickener consists of 12-hydroxy stearic acid lithium dibasic acid and / or lithium borate, and the mol ratio is 1 ®U 0.1 to 1 ®U 0.1to 1. The base oil is mineral oil or poly-alpha-olefin synthesis oil. The additive consists of organic amine compound antioxidant, benzotriazole and barium petroleum sulfonate or barium dinonylnaphthalene sulfonate anti-corrosion additive and rust protection agent, dialkyl dithiocarbamate or dibenzyl disulfide and sulfurized olefin cottonseed oil extreme pressure antiwear additive and nanometer copper powder repairing additive. The contents of the thickener and the base oil are respectively 6 percent to 18 percent and 82 percent to 94 percent according to the weight percentage. The lubricating grease has the multi-effect performances of high dripping point, good high-temperature performance and low-temperature performance, chemical invariability, colloid invariability, antiwear extreme pressure performance etc., and especially has the repairing function towards a damaged bearing.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Sedan hand gearshift case gear lubricating oil composition

ActiveCN101298578AMeet lubricationMeet lubrication requirementsAdditivesBase-materialsGear wheelBench test

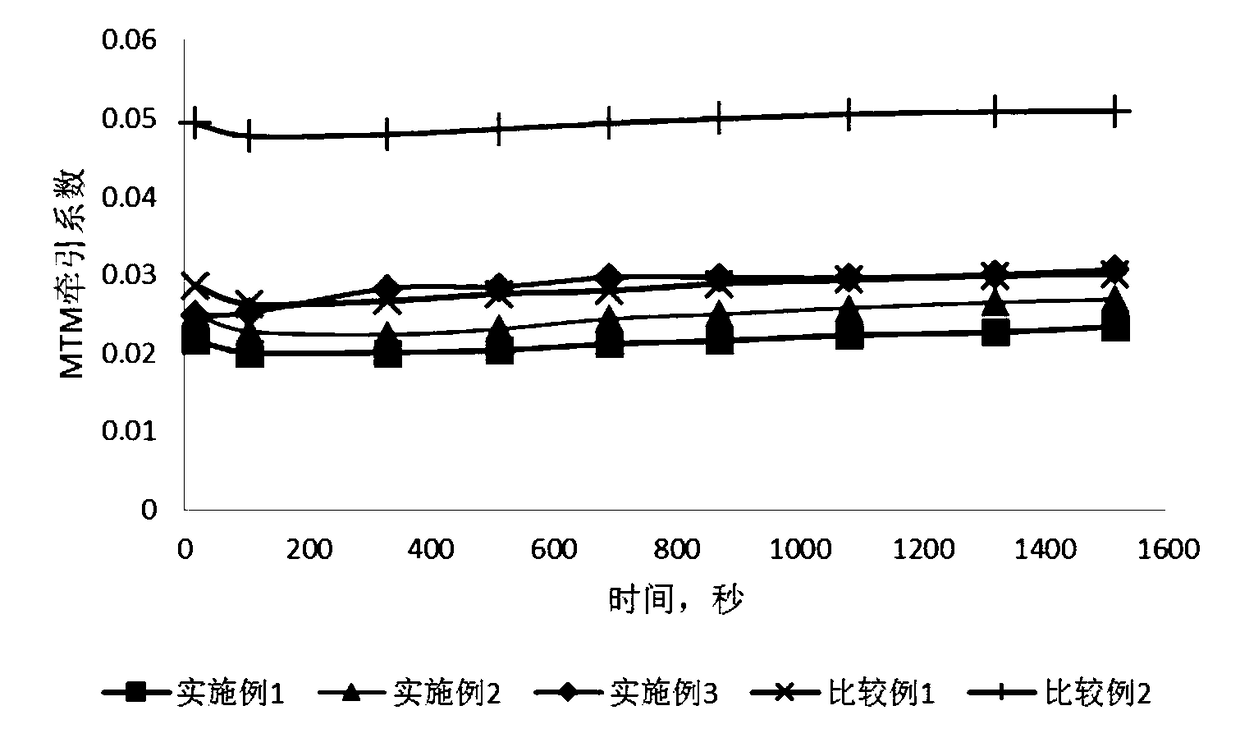

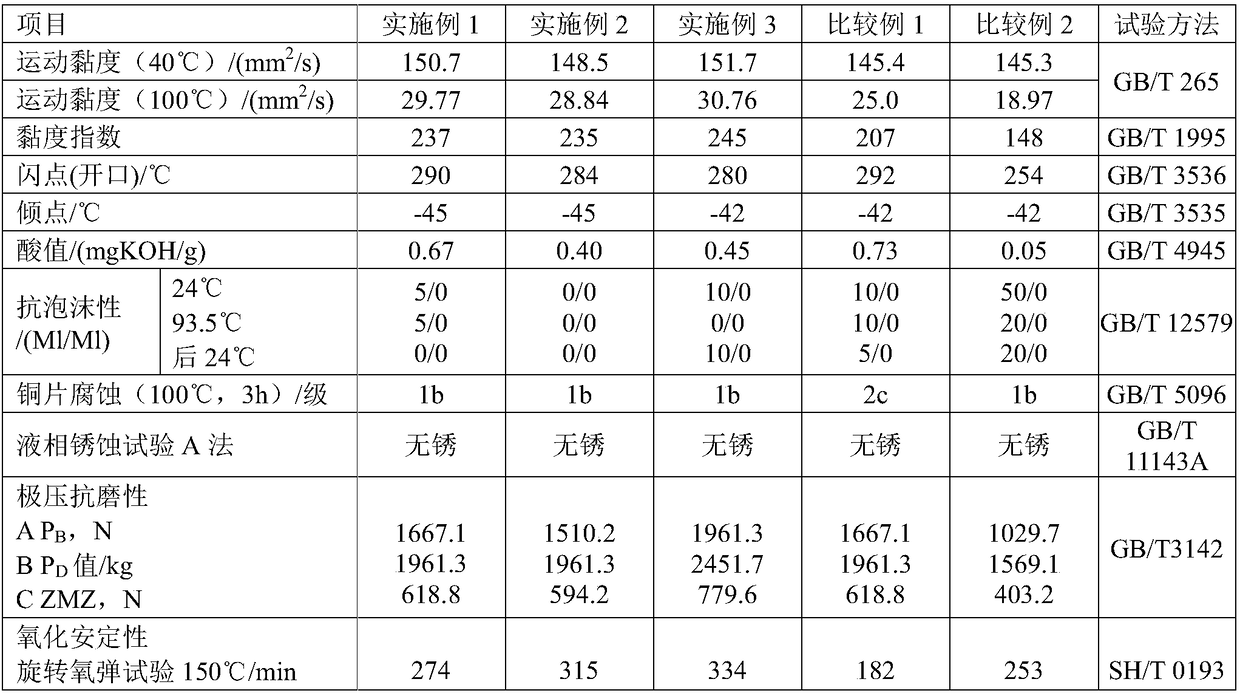

The invention provides a gear lubricant composite for manual transmissions of the light cars, comprising (A) at least one type of refining mineral oil with high viscosity index, or polyolefin synthesis oil, or ester lubricants, or a free composite of the above components, (B) at least one type of viscosity index improver, (C) at least one type of pour point depressant, (D) at least one type of extreme pressure additive with sulfurs, (E) at least one type of anti-wear additive with phosphorus, (F) at least one type of wear, oxygen, and corrosion-preventing multifunctional additive with phosphorus, (G) at least one type of anti-rusting additive, and (H) at least one type of friction modifier. The lubricant composite has excellent performance of high and low temperature, which can meet the requirements of gear oil with a viscosity grade of 75W / 90. Moreover, passing the full-size gear bench tests as CRCL-42, L-37, L-33, L-60, and L-60-1 as well as cycle bench tests for the manual transmissions of the light cars, the gear lubricant composite can meet lubrication requirements of the manual transmissions of the light top-grade cars.

Owner:PETROCHINA CO LTD

Lubricant composition for gas engine

ActiveCN102690709AImprove antioxidant capacityImprove wear resistanceAdditivesAlkaline earth metalAntioxidant

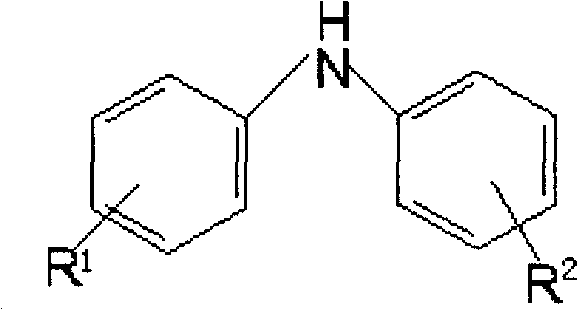

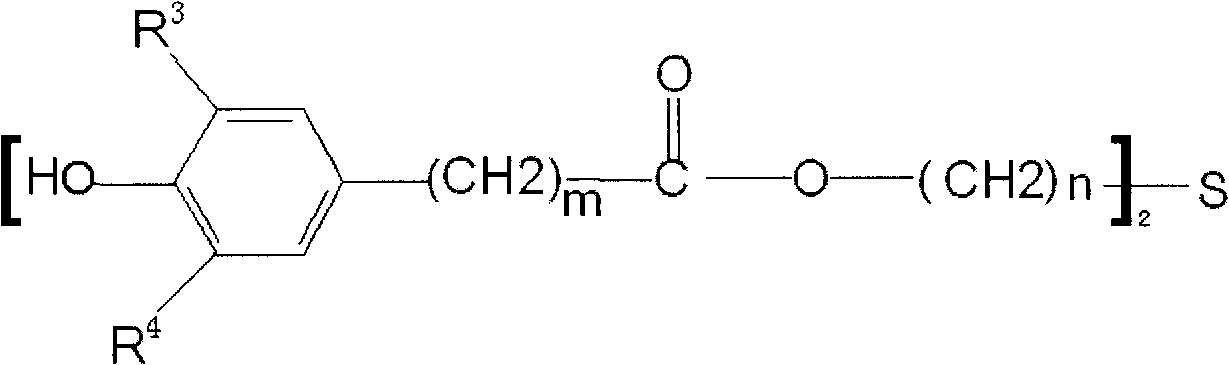

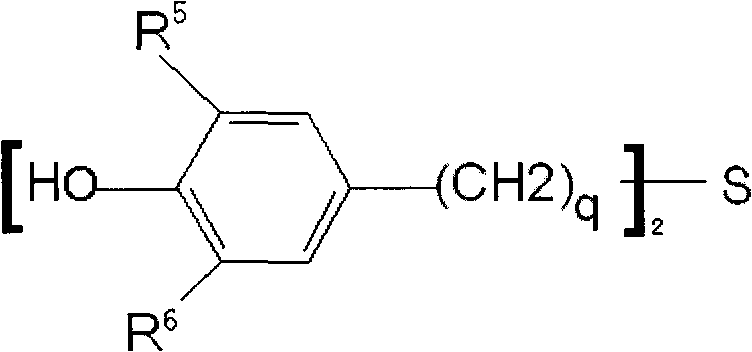

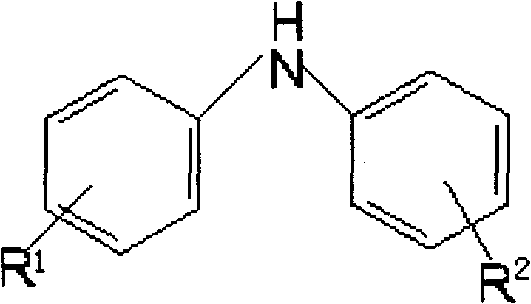

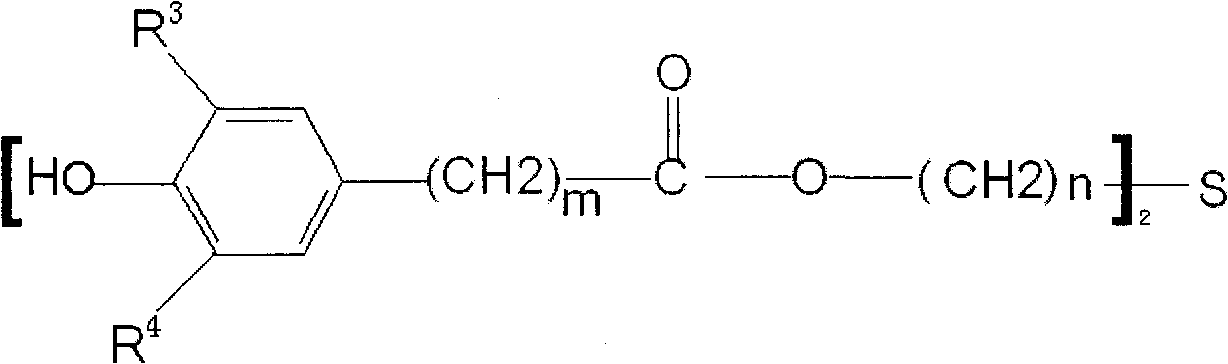

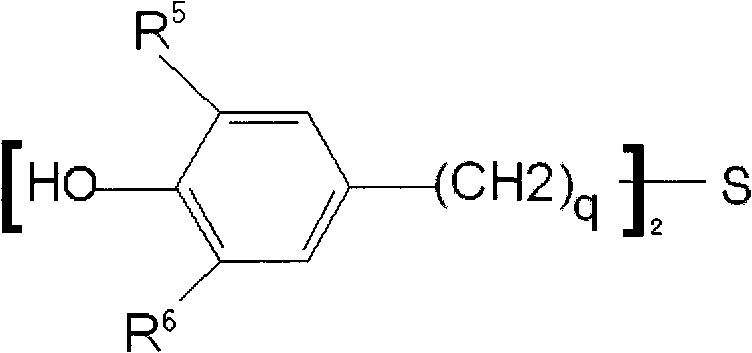

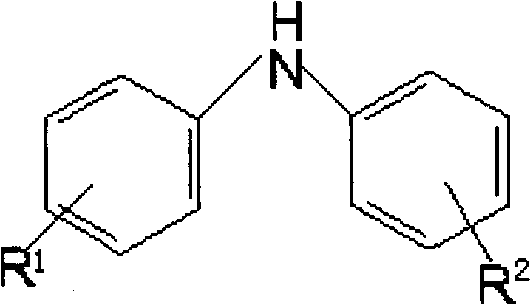

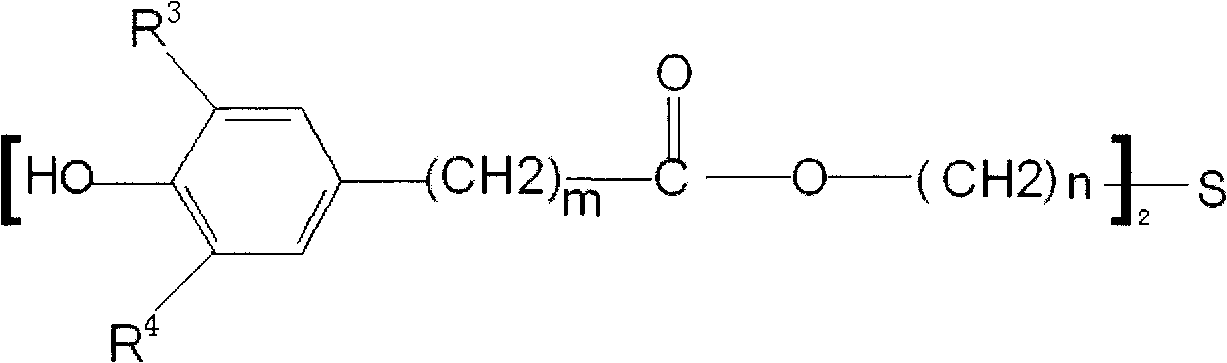

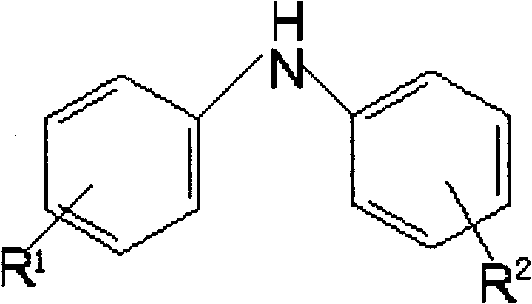

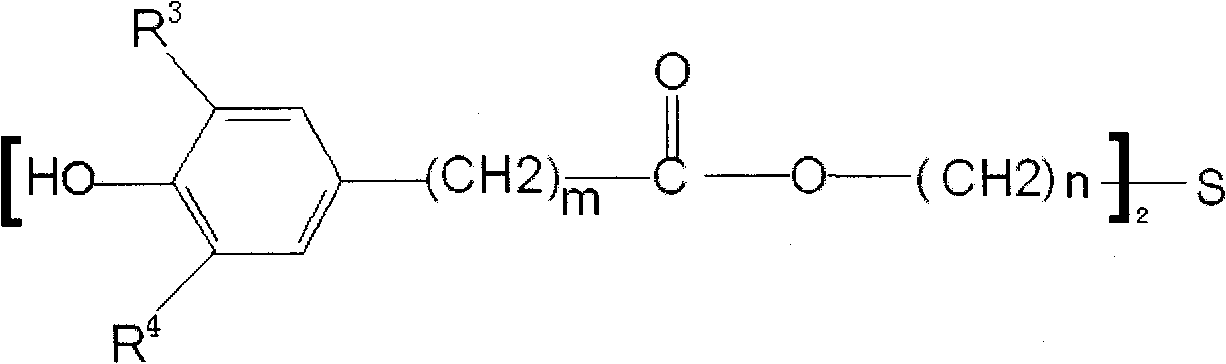

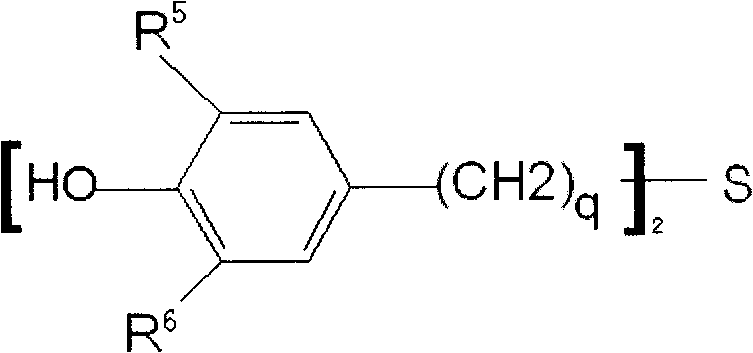

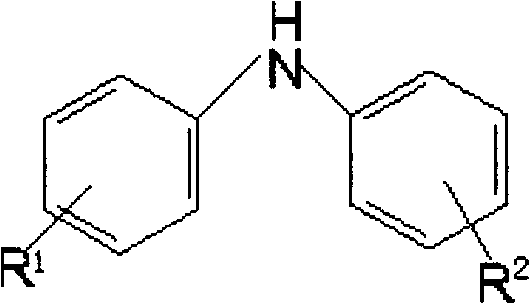

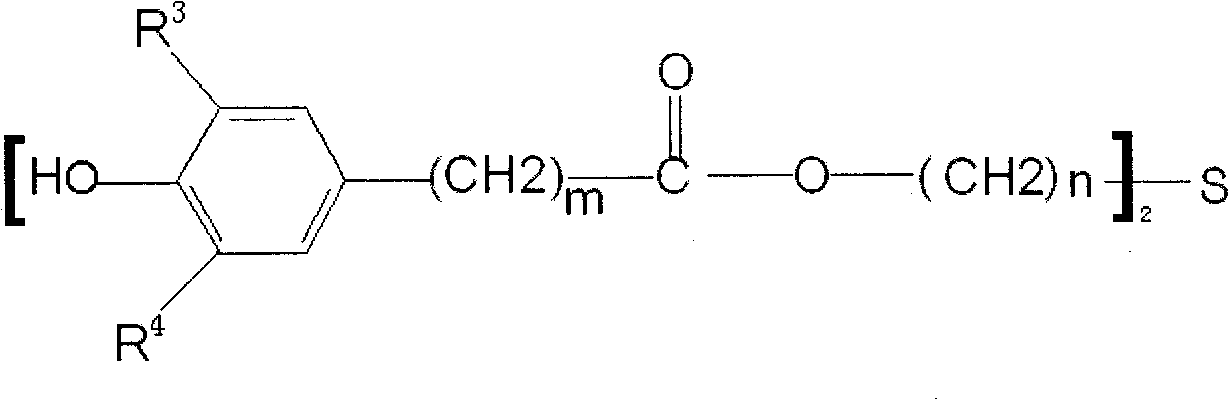

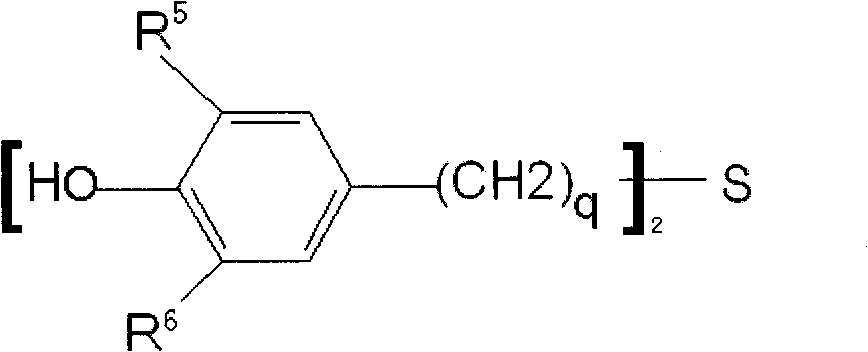

The invention relates to a lubricant composition for a gas engine. The lubricant composition contains: by mass, less than or equal to 0.08% of phosphorus and less than or equal to 0.8% of sulfate ash. The lubricant composition comprises A) a composite antioxidant comprising at least ingredients of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) a dispersant, C) one or more sulfurized alkaline earth metal alkyl phenolate cleaning agents, D) at least one zinc dialkyl dithiophosphate, E) one or more ashless friction modifiers, F) one or more metal deactivators and G) a main amount of lubricating base oil. The lubricant composition for a gas engine adopts optimized combination of the multiple ashless antioxidants, is blended with the appropriate clearing agent and the dispersant, has a synergistic effect of the additives, can satisfy high-temperature antioxidation requirements of lubricating oil for a gas engine, and has excellent piston cleanliness, high / low-temperature wear resistance and a good viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

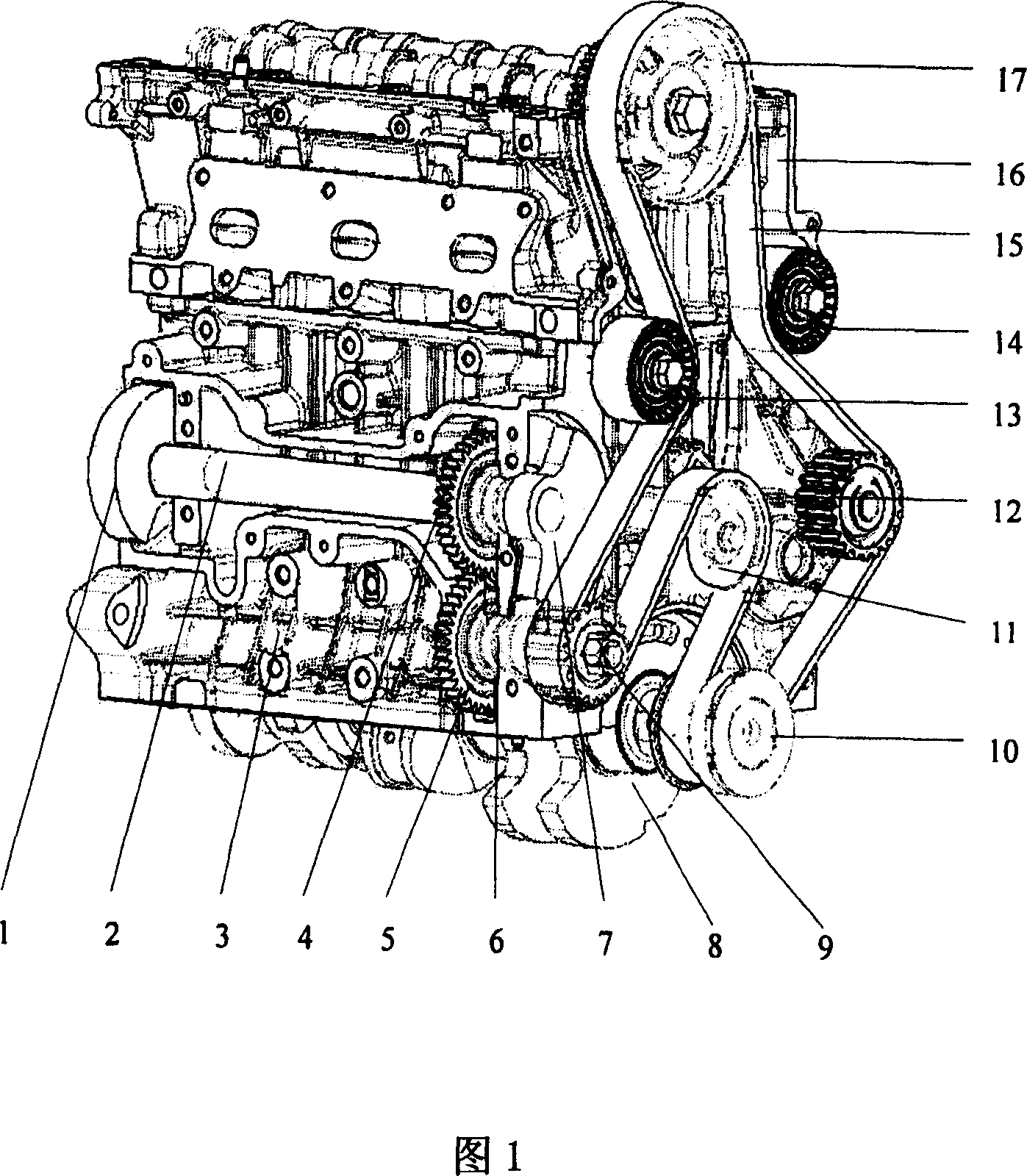

Engine crankshaft balance shaft mechanism

InactiveCN1924394ALower the altitudeCompact structureInertia force compensationGear wheelEngineering

Owner:CHERY AUTOMOBILE CO LTD

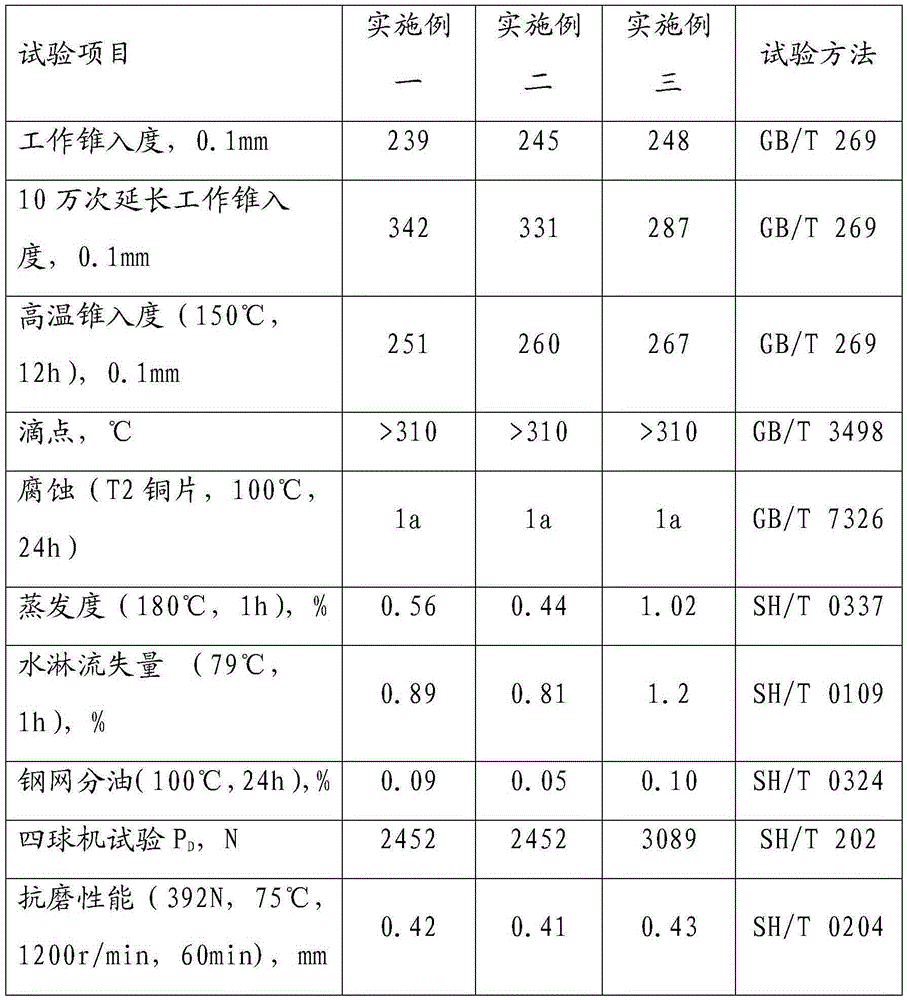

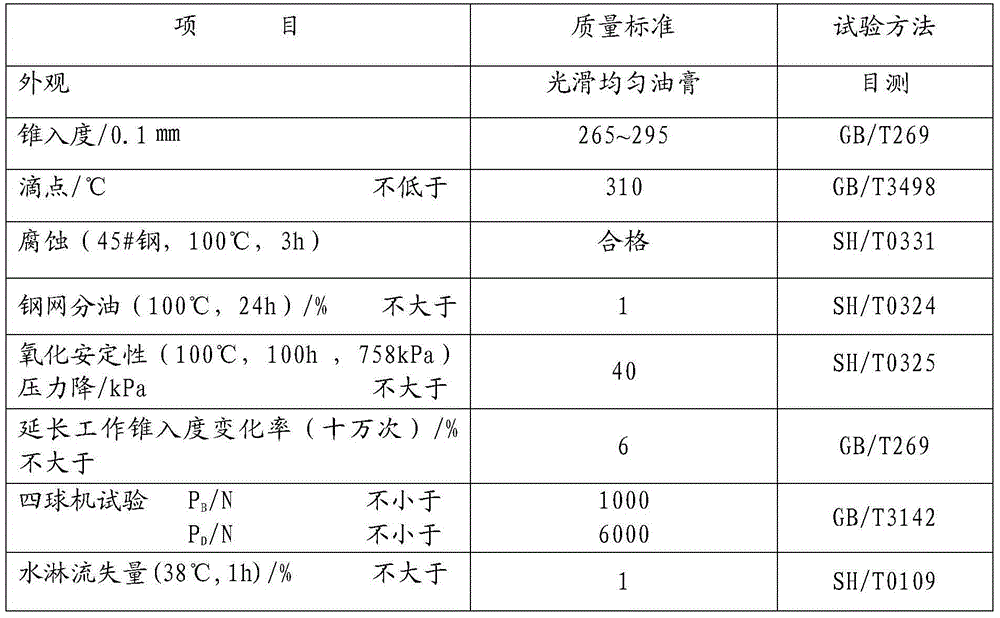

Lubricating grease composition for steering ball joint and preparation method of lubricating grease composition

InactiveCN104164286AGood high and low performanceExcellent extreme pressure and anti-wear propertiesLubricant compositionEngineeringWater resistance

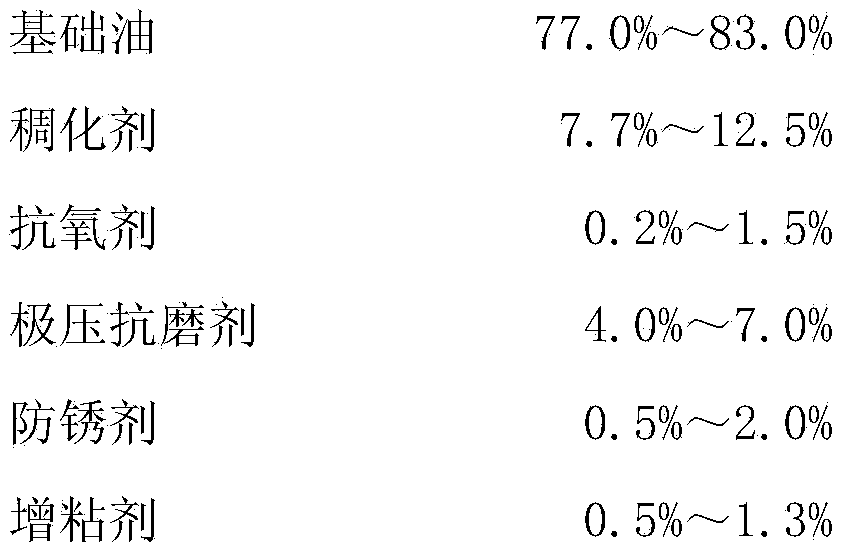

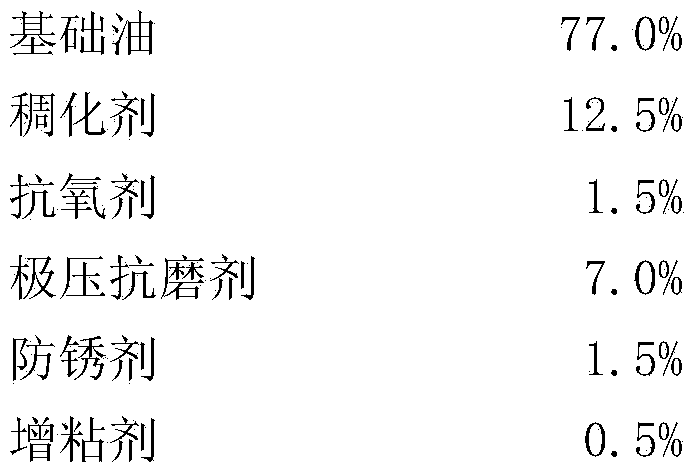

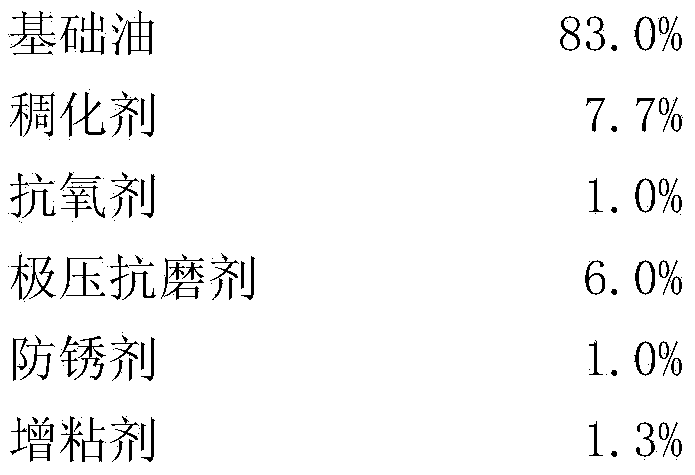

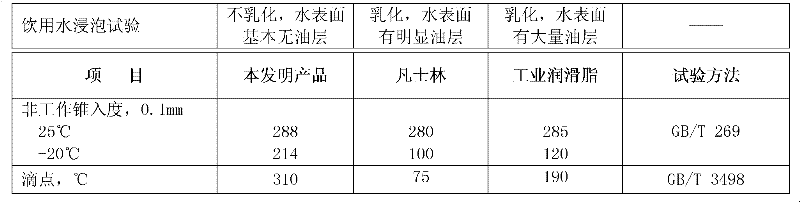

The invention discloses a lubricating grease composition for a steering ball joint and a preparation method of the lubricating grease composition. The lubricating grease composition comprises the following components in percentage by weight: 77.0%-83.0% of base oil, 7.7%-12.5% of thickening agent, 0.2%-1.5% of antioxidant, 4.0%-7.0% of extreme pressure anti-wear agent, 0.5%-2.0% of anti-rust agent and 0.5%-1.3% of tackifier. The lubricating grease composition is good in high-temperature and low-temperature performances and excellent in extreme pressure wear resistance, water resistance and rust resistance, can meet the lubricating requirements of the steering ball joint, and is especially applicable to lubricating the steel ball joints, with strict service conditions, of engineering vehicles and the like.

Owner:CHINA PETROLEUM & CHEM CORP

Food grade lubricating grease and its preparation method and application

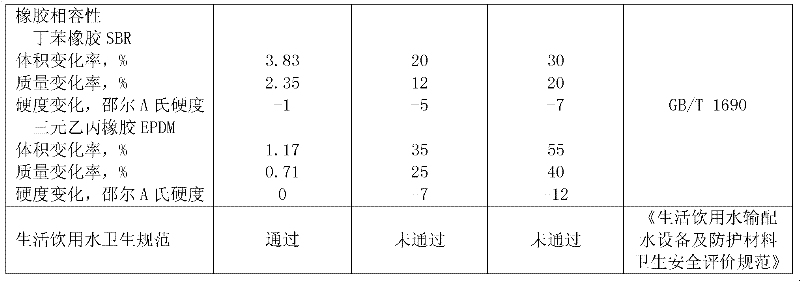

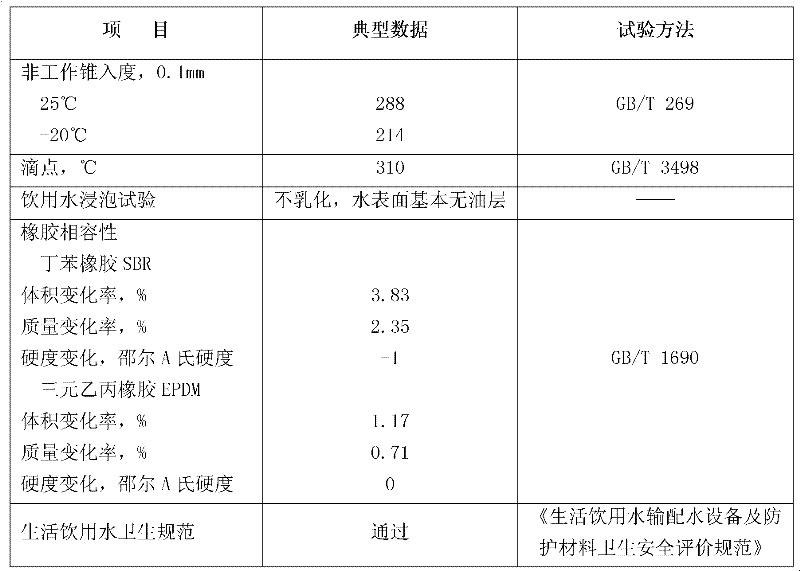

ActiveCN102268320AComply with water quality sanitation and safety requirementsSealedLubricant compositionFood gradeBase oil

The invention relates to food-grade lubricating grease as well as a preparation method and application thereof. The food-grade lubricating grease comprises the following components by weight percent: 70-80% of base oil, 6-15% of thickening agent and 10-20% of antiwear agent. The preparation method comprises the following steps: adding fatty acid, aromatic acid and organic aluminum into the base oil in a proportion, mixing and heating to 60-100 DEG C, and carrying out a recombination reaction for 1-2 hours; further heating the combined material to 100-140 DEG C, adding tap water with a certain proportion and then maintaining the constant temperature for 1-2 hours, wherein water equivalent is 1-3 times that of organic aluminum; further heating the combined material to 150-180 DEG C and the nmaintaining the constant temperature for 0.5-1 hour; then adding quenching oil and evenly mixing, wherein the amount of quenching oil is about 30%-40% of that of base oil; and further cooling the material to the temperature below 140 DGE C, and adding the antiwear agent and then evenly mixing, so as to obtain the required product. In the invention, a one-step method is adopted for direct recombination reaction, thus process is simple, energy consumption is reduced, production cost is reduced, and the quality of the product produced by the process is relatively stable.

Owner:CHINA PETROLEUM & CHEM CORP

Lubricant composition for intermediate-speed trunk piston-type engine of ship

ActiveCN102690710AGood antioxidant propertiesGood high temperature cleanAdditivesOxidation resistantAntioxidant

The invention relates to a lubricant composition for an intermediate-speed trunk piston-type engine of a ship. The lubricant composition comprises A) a composite antioxidant composing at least components of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) a polyisobutylene succinimide ashless dispersant, C) a mixture of magnesium sulfate and sulfurized calcium alkyl phenate, D) at least one zinc dialkyldithiophosphate, E) dialkyldithiocarbamate, F) one or more metal deactivators, G) one or more ashless friction modifiers, and H) a main amount of lubricating base oil. The lubricant composition utilizes optimized combination of the multiple ashless antioxidants, is compounded with the appropriate clearing agent and the dispersant, has a synergistic effect of the additives, can satisfy high-temperature antioxidation requirements of lubricating oil for an intermediate-speed trunk piston-type engine of a ship, and has excellent piston cleanliness, high / low-temperature wear resistance and a good viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

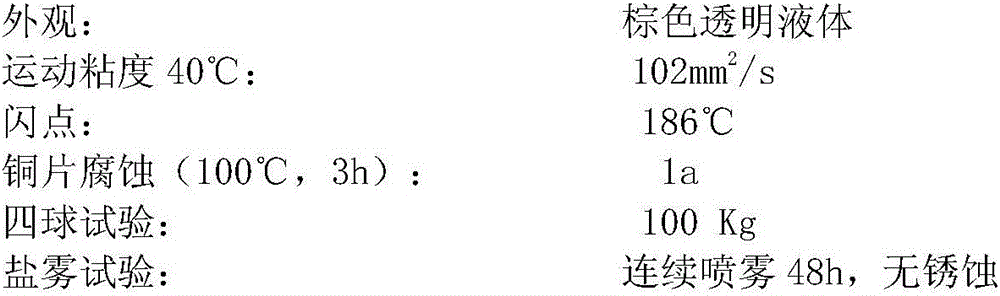

Compsn. of rust inhibiting lubricant special for chain

InactiveCN1415713AGood rust resistanceExcellent extreme pressure and wear resistanceAdditivesEnvironmental chemistryP-Cresol

A composite antirust hebricant for chain contains sulfonate as antirust agent, olefine butanedioic acid type antirust agent, dialkyldithiophosphate-formaldehyde-lipoamin condensate, plant oil, phenyltriazole lipoamine salt, polyisobutylene, vaseline, 2,6-ditert-butyl p-cresol, and basic oil. Its advantages are excellent resistance to rust, salt fog and abrasion, high adhesive, and good water displacing nature.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lubricant composition for methanol engine

ActiveCN102690706AImprove antioxidant capacityImprove wear resistanceAdditivesAntioxidantPolyisobutylene succinimide

The invention relates to a lubricant composition for a methanol engine. The lubricant composition comprises A) a composite antioxidant comprising at least ingredients of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) a polyisobutylene succinimide ashless dispersant and / or a polyisobutylene succinate dispersant, C) a mixture of magnesium sulfonate and sodium sulfonate, D) at least one zinc dialkyl dithiophosphate, E) one or more oil-soluble organic molybdenum friction modifiers, and F) a main amount of lubricating base oil. The lubricant composition for a methanol engine utilizes optimized combination of the multiple ashless antioxidants, is compounded with the appropriate clearing agent and the dispersant, has a synergistic effect of the additives, can satisfy high-temperature antioxidation requirements of lubricating oil for a methanol engine, and has excellent piston cleanliness, high / low-temperature wear resistance and a good viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ashless antiwear oil film bearing lubricant composition

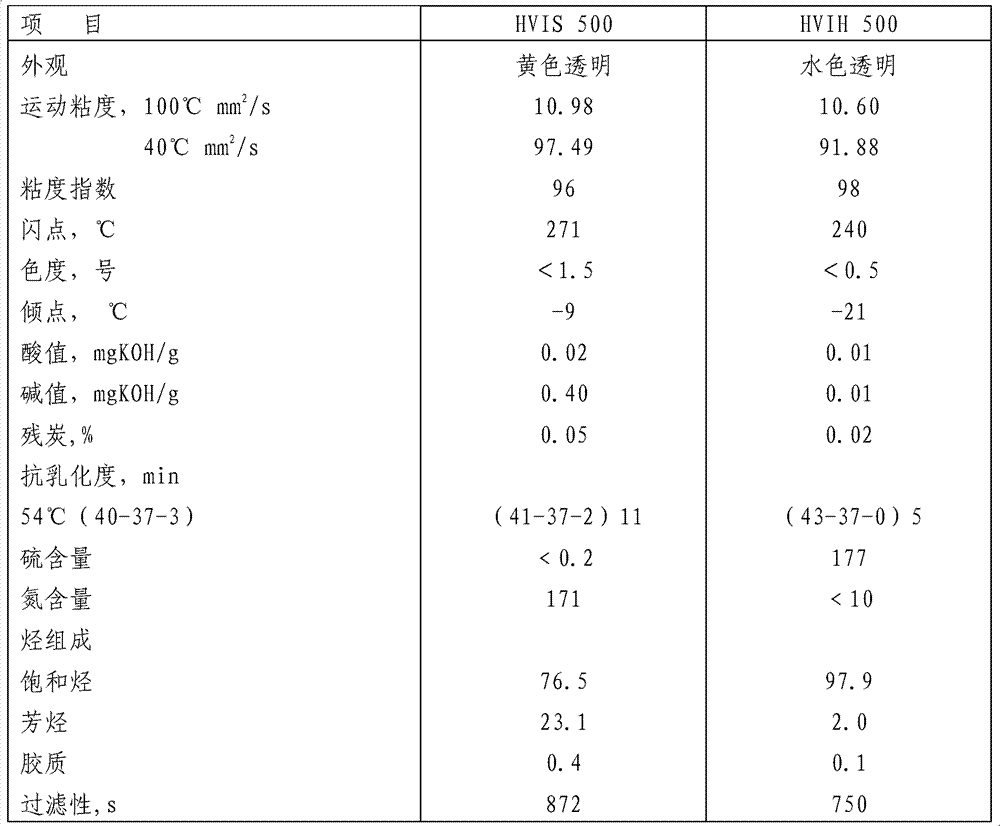

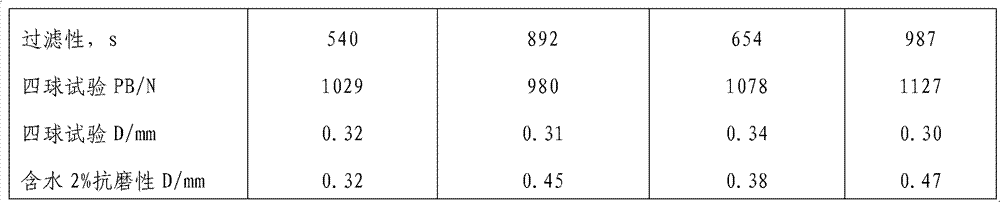

ActiveCN102766505AImprove filtering effectGood demulsibilityLubricant compositionWire rodFoaming agent

The invention provides an ashless antiwear oil film bearing lubricant composition, which comprises: (A) at least a highly refined mineral oil with high viscosity index; (B) at least an emulsifier; (C) at least an anti-foaming agent; (D) at least an ashless phosphorus-containing antiwear additive; (E) at least an anti-oxidant; and (F) at least a metal passivator. The above lubricant component has excellent demulsibility, filterability, anti-foaming property, air release property, abrasion resistance and oxidation resistance, passes through FAG FE-8 bearing wear experiments, SKFEMCOR bearing corrosion experiments and FLENDER anti-foaming experiments, and is suitable for lubricating various bearings and industrial gears, especially lubricating highspeed wire rod oil film bearings.

Owner:PETROCHINA CO LTD

High-temperature lubricating grease for food processing and preparation method thereof

The invention relates to lubricating grease and a preparation method thereof, in particular to high-temperature lubricating grease for food processing and a preparation method thereof, and belongs to the technical field of chemistry. The high-temperature lubricating grease is prepared from base oil accounting for 70%-92% of the total weight of the lubricating grease, an inorganic thickening agent accounting for 3%-20% of the total weight of the lubricating grease, a tackifier accounting for 2%-6% of the total weight of the lubricating grease, an auxiliary dispersant accounting for 0.1%-1.5% of the total weight of the lubricating grease, an antioxidant accounting for 0.3%-1.0% of the total weight of the lubricating grease, a corrosion inhibitor accounting for 0.05%-1% of the total weight of the lubricating grease, a friction modifier accounting for 0.1%-0.5% of the total weight of the lubricating grease and a solid additive accounting for 2%-10% of the total weight of the lubricating grease. The high-temperature lubricating grease has the advantages of being capable of not being fused at high temperature, high in dropping point, few in high-temperature consistence change, good in colloid stability and the like and especially suitable for lubricating and sealing high-temperature food processing equipment.

Owner:JIANGSU LOPALTECH

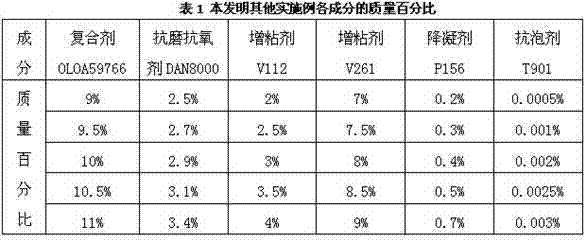

Formula and production process of engine oil

ActiveCN102391905AGood high and low temperature performanceHigh viscosity indexLubricant compositionFoaming agentBase oil

The invention relates to a formula and a production process of engine oil. The engine oil comprises base oil and additives, wherein the base oil comprises mineral base oil and synthetic base oil; the additives comprise complexing agent OLOA59766, anti-wear and anti-oxidation agent DAN8000, viscosity increaser V112, viscosity increaser V261, pour point reducer P156 and anti-foaming agent T901; and the base oil and the additives are mixed in a certain ratio. The engine oil is a product with ultra-long oil change period and low oil consumption, has good abrasion performance and high bearing capacity, has repair function on the abraded surface, has no pollution to the environment, improves energy conservation and prolongs the service life.

Owner:浙江丹弗中绿科技股份有限公司

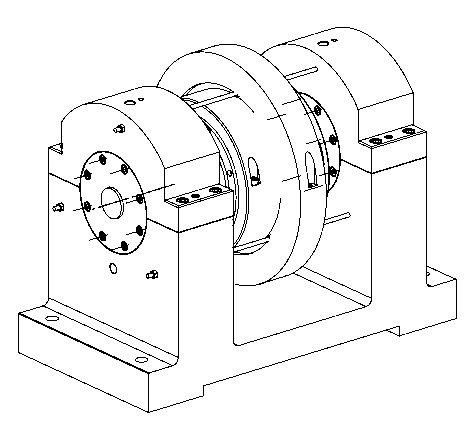

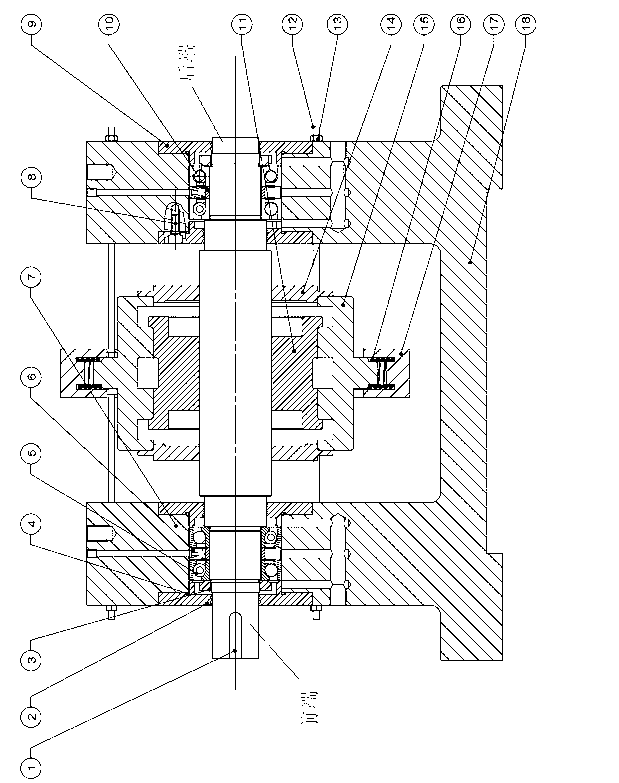

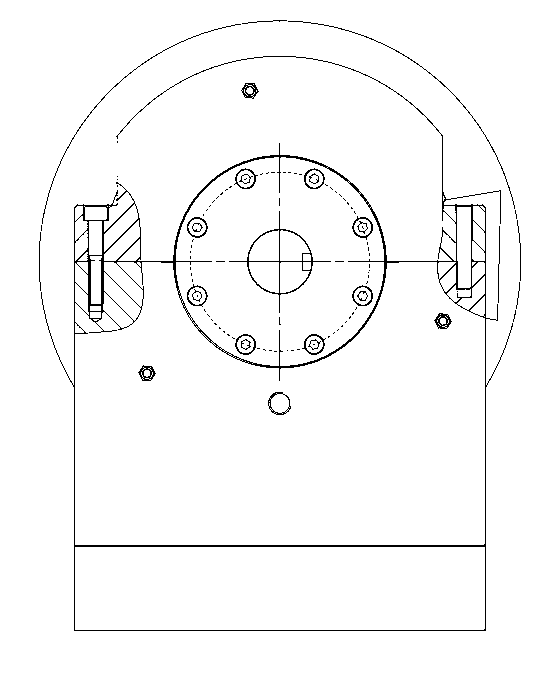

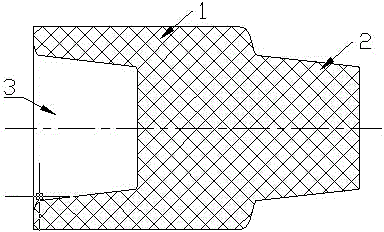

Radial sliding bearing test bed with elastic support

InactiveCN103323243AReduce the impactAvoid influenceMachine bearings testingRadial planeRolling-element bearing

The invention relates to a radial sliding bearing test bed with an elastic support. The radial sliding bearing test bed with the elastic support is assembled by a test bed base, back-up bearings, a main shaft, a testing bearing, a jet device and a main shaft locating device. The test bed base is used for carrying out location on the back-up bearings and providing lubricating oil channels, the two ends of the main shaft are supported by the back-up bearings, the back-up bearings are angular contact bearings mounted in pairs in a back to back mode, the inner ring and the outer ring of the back-up bearing at the front end of the main shaft are both axially fixed, the inner ring of the back-up bearing at the rear end of the main shaft is axially fixed, and certain axial movement is allowed on the outer ring of the back-up bearing at the rear end of the main shaft. The testing bearing is suspended in the middle of the main shaft and capable of floating up and down, guiding devices are mounted at the two ends of the testing bearing to prevent the testing bearing from deflection without limiting the movement of the testing bearing in the radial plane, an elastic element is mounted outside the testing bearing, and the support stiffness of the testing bearing can be adjusted by changing the stiffness of a spring. Bolt mounting holes are formed in the test bed base, and the test bed can be mounted on a suitable T-shaped groove platform.

Owner:SHANGHAI UNIV

Lubricant composition for four-stroke motorcycle engine

ActiveCN102690715AImprove cleanlinessMeet lubrication requirementsAdditivesAntioxidantPolyisobutylene succinimide

The invention relates to a lubricant composition for a four-stroke motorcycle engine. The lubricant composition comprises A) a composite antioxidant comprising at least components of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) a polyisobutylene succinimide dispersant and / or a polyisobutylene succinate dispersant, C) a mixture of calcium sulfonate and sulfurized calcium alkyl phenate, D) at least one zinc dialkyl dithiophosphate, E) one or more ashless friction modifiers, and F) a main amount of lubricating base oil. The lubricant composition adopts optimized combination of the multiple ashless antioxidants, is blended with the appropriate clearing agent and the dispersant, has a synergistic effect of the additives, can satisfy high-temperature antioxidation requirements of lubricating oil for a four-stroke motorcycle engine, and has excellent piston cleanliness, high / low-temperature wear resistance and a good viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gasholder sealing oil composition with high corrosion resistance and oxidation resistance

ActiveCN102337174AImprove corrosion resistanceImprove antioxidant capacityAdditivesDemulsifierChemical composition

The invention provides a gasholder sealing oil composition with high corrosion resistance and oxidation resistance. The gasholder sealing oil composition comprises the following components in percentage by weight: 0.1 to 1.2 percent of antioxidant, 0.01 to 0.8 percent of dispersant, 0.05 to 1.0 percent of antioxidant and anti-corrosion agent, 0.01 to 1.0 percent of cleaning agent, 0.01 to 0.2 percent of demulsifier, 1 to 11 percent of viscosity index improver, 0.1 to 2 percent of pour point depressant and the balance of base oil. The gasholder sealing oil composition has excellent antioxidation stability, is suitable for various working conditions and has long service life; raw materials are reasonably mixed; and the preparation method has the advantages of simplicity, wide application range and readily available raw materials.

Owner:CHINA PETROLEUM & CHEM CORP

Lubricating oil composition for industrial robot speed reducer

InactiveCN109401820AImprove performanceTechnically difficultLubricant compositionLinear polymerDefoaming Agents

The invention discloses a lubricating oil composition for an industrial robot speed reducer. The lubricating oil composition comprises 84.0-95.91wt% of polyalkylene glycol, 3-10wt% of a sealing applicability improver, 0.1-2.0wt% of an extreme pressure anti-wearing additive, 0.01-1.0wt% of a metallic deactivator, 0.05-1.0wt% of an anti-rusting corrosion inhibitor, 0.5-3.0wt% of an anti-oxidation additive and 10-20mu g / g of a defoaming agent, wherein the polyalkylene glycol is a linear polymer taking ethylene oxide and propylene oxide as main raw materials; the polymer comprises 50-70% of an EO(Ethylene Oxide) unit and 30-50% of a PO (Propylene Oxide) unit; the sealing applicability improver is a saturated polyol ester or diester. The lubricating oil composition has excellent viscosity-temperature performance and low-temperature performance, excellent oxidation stability and good extreme pressure wearing resistance, anti-rusting corrosion resistance and foam resistance, an oil film canbe rapidly formed, operation temperatures can be reduced, energy consumption can be reduced, the transmission efficiency of a speed reducer is degraded, the wearing of tooth surfaces can be reduced, and lubricating requirements of multi-stage speed reducers of multi-axis industrial robots can be met.

Owner:PETROCHINA CO LTD

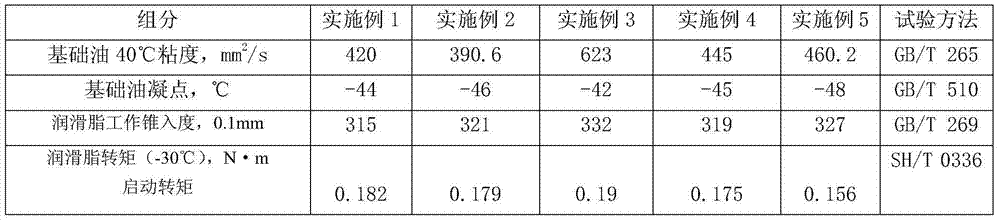

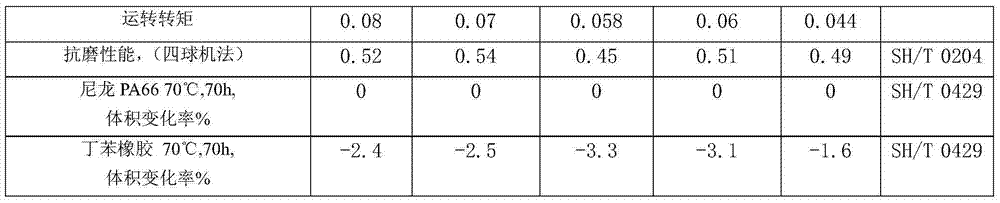

Lubricating grease composition for automobile door opening stoppers and preparation method thereof

InactiveCN104327926AGood low temperatureGood compatibilityLubricant compositionPhenolic antioxidantBoron nitride

The invention relates to a lubricating grease composition for automobile door opening stoppers, which comprises the following components in percentage by weight: 3-10% of thickener, 84-95% of base oil and 2-10% of additives. The 40 DEG C kinematic viscosity of the base oil is 100-670 mm<2> / s, and the condensation point is not higher than -42 DEG C. The additives comprise 0.2-8% of polytetrafluoroethylene, 0-1% of amine antioxidant, 0-1% of phenolic antioxidant, 0-1% of rust inhibitor, 0.2-5% of boron nitride, 0.2-5% of melamine cyanurate and 0.2-5% of nano calcium carbonate. The lubricating grease has the advantages of favorable low-temperature fluidity and favorable lubricating property. When the SH / T 0336 standard method is used for preparing the -30 DEG C torque, the pull-in torque value is less than 0.2 N.m, the operation torque is less than 0.06 N.m, and the compatibility volume change rate for nylon materials is zero. Thus, the lubricating grease has certain advantages when being used in automobile accessories and especially door stoppers.

Owner:CHINA PETROLEUM & CHEM CORP

Acid-and-alkali-corrosion-resistant environment-friendly lubricating grease composition and preparation method

ActiveCN105255553AGood acid and alkali resistanceReduce the content of heavy metal ionsAdditivesPhosphoric acidIon exchange

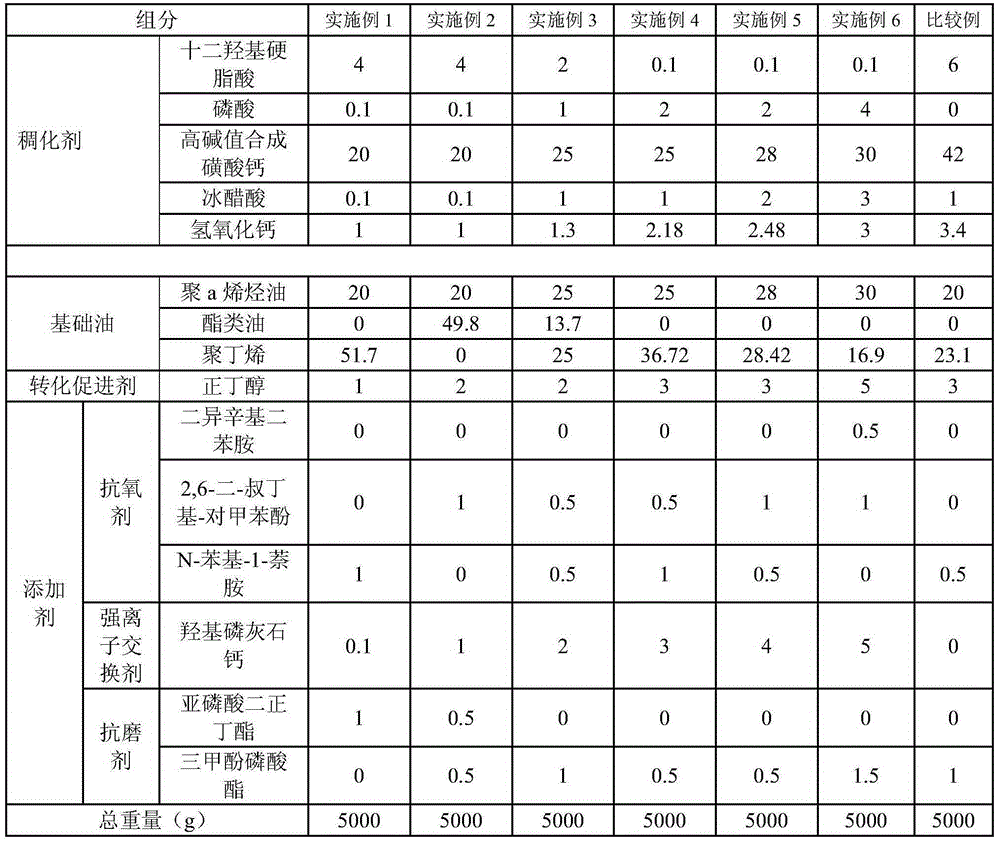

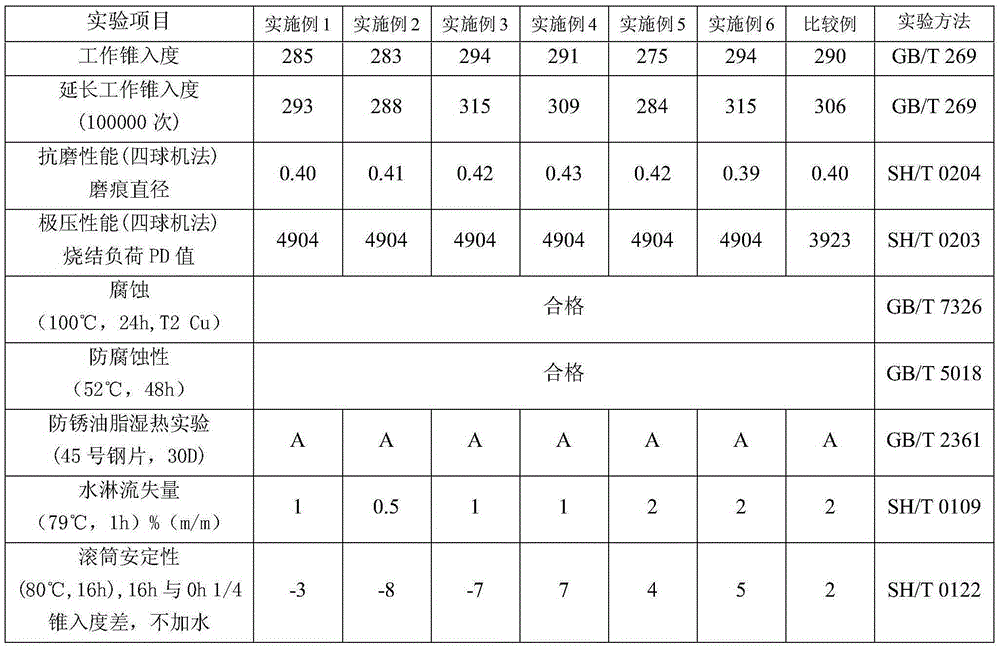

The invention relates to an acid-and-alkali-corrosion-resistant environment-friendly lubricating grease composition and a preparation method. The acid-and-alkali-corrosion-resistant environment-friendly lubricating grease composition is prepared from 20%-30% of high alkali synthesis calcium sulfonate, 0.1%-2% of conversion accelerant, 0.1%-3% of glacial acetic acid, 1%-4% of fatty acid, 0.1%-4% of phosphoric acid, 1%-3% of calcium hydroxide, 1.5%-7.5% of additives and high-viscosity synthetic base oil. An acid solution or an alkaline solution with the mass fraction of 10% is added to lubricating grease for conducting performance testing again, and the lubricating grease prepared from high alkali synthesis calcium sulfonate has the better water resistance, corrosion resistance, shearing resistance and extreme pressure antiwear property. Due to the characteristics of the high-viscosity synthetic base oil and a calcium sulfonate thickening agent, no emulsification or thinning phenomenon occurs to the lubricating grease when the lubricating grease is immersed in the acid solution or the alkaline solution, and the good adhesion property is achieved. Due to the fact that a strong ion exchanger, namely, calcium hydroxylapatite is added, calcium ions in molecules can replace heavy metal ions and the like in a water solution, and the good environment-friendly effect is shown.

Owner:CHINA PETROLEUM & CHEM CORP

Lubricant composition for crosshead ship engine crankcase system

ActiveCN102690712AImprove cleanlinessMeet lubrication requirementsAdditivesAntioxidantOxidation resistant

The invention relates to a lubricant composition for a crosshead ship engine crankcase system. The lubricant composition comprises A) a composite antioxidant comprising at least components of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) polyisobutylene succinimide, C) a mixture of magnesium sulfonate and calcium sulfonate, D) at least one zinc dialkyl dithiophosphate, E) one or more dialkyl dithiocarbamates, F) one or more metal deactivators, and G) a main amount of lubricating base oil. The lubricant composition adopts optimized combination of the multiple ashless antioxidants, is blended with the appropriate clearing agent and the dispersant, has a synergistic effect of the additives, can satisfy high-temperature antioxidation requirements of lubricating oil for a crosshead ship engine crankcase system, and has excellent piston cleanliness, high / low-temperature wear resistance and a good viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

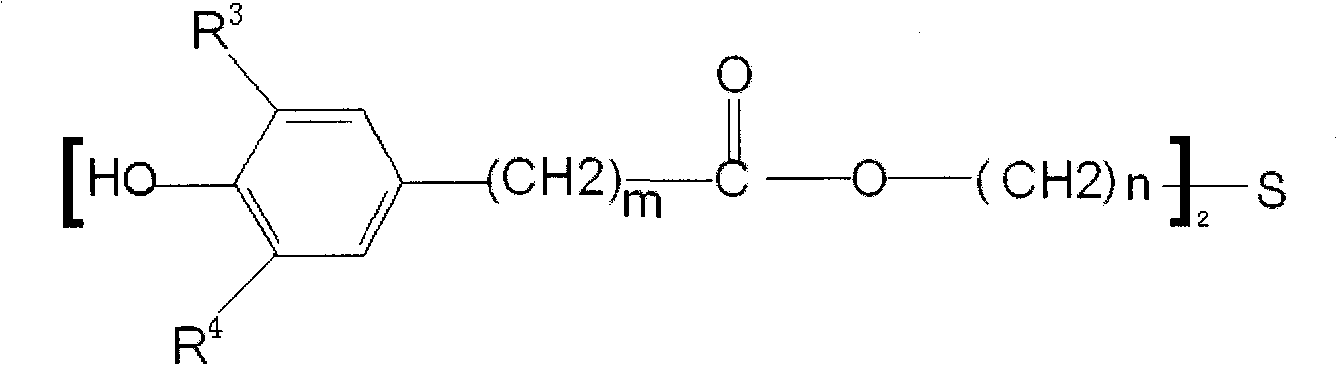

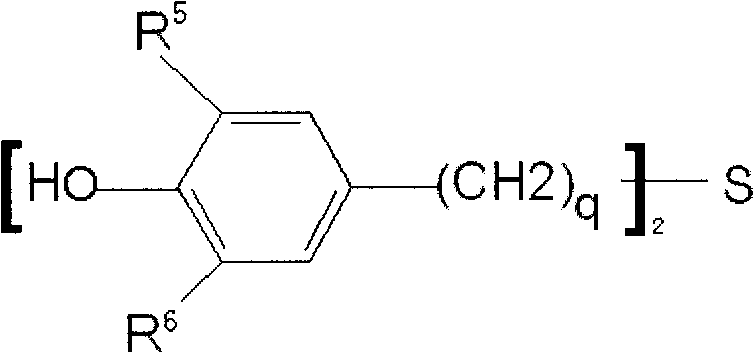

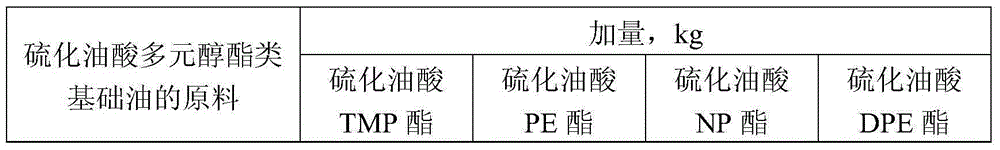

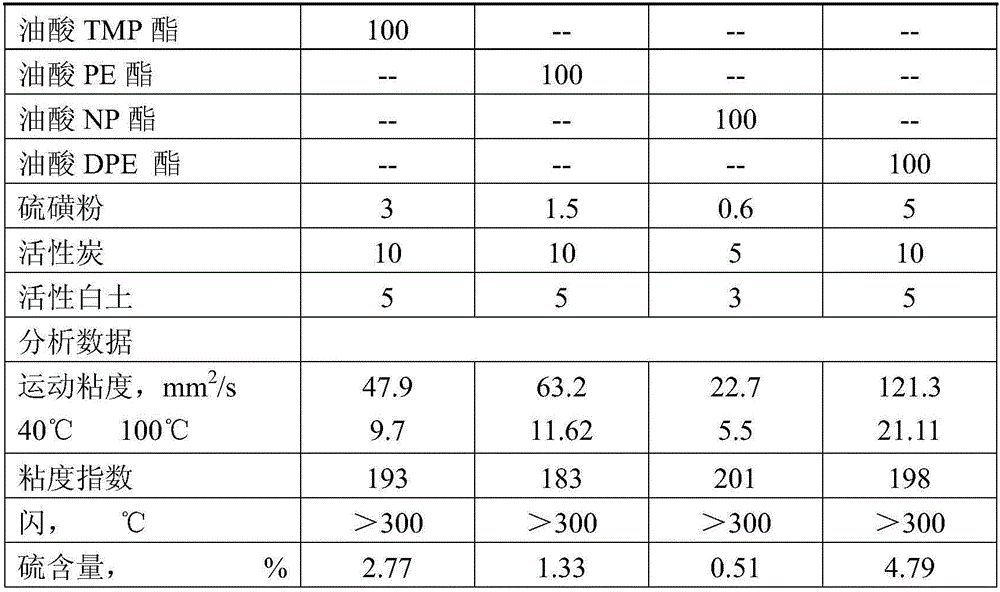

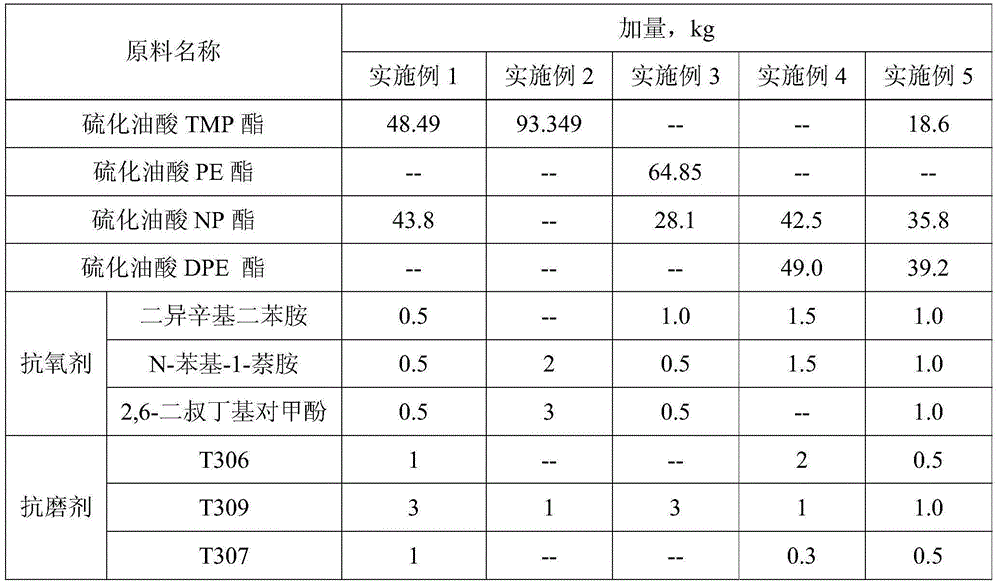

Ester-type fire resistant hydraulic oil and production method thereof

ActiveCN105001946AEasy to oxidizeImprove antioxidant capacityLubricant compositionAntioxidantSulfide

The invention relates to ester-type fire resistant hydraulic oil and a production method thereof. The ester-type fire resistant hydraulic oil comprises, by weight, the following raw materials of 90-95% of sulfide oleic acid polyol ester base oil, 0.1-5.0% of antioxidants, 1-5.0% of antiwear agents, 0.1-1.0% of clearing agents, 0.01-1.0% of demulsifier, 0.001-0.1% of anti-foaming agents and 0.05-0.5% of metal deactivator. According to the ester-type fire resistant hydraulic oil and the production method thereof, the novel sulfide oleic acid polyol ester base oil is adopted, unsaturated bonds in oleic acid polyol esters are partially or fully saturated, the problem that the unsaturated bonds are extremely prone to being oxidized is solved, and therefore the oxidation resistance of the ester-type fire resistant hydraulic oil is significantly improved; the oil change period is significantly prolonged, and the use cost of the oil is low; the extreme pressure property is improved, the bearing capacity of the oil is significantly improved, and the lubrication requirements of a high-speed heavy-load gear oil pump are met.

Owner:SHANDONG NORTH ZITE SPECIAL OIL

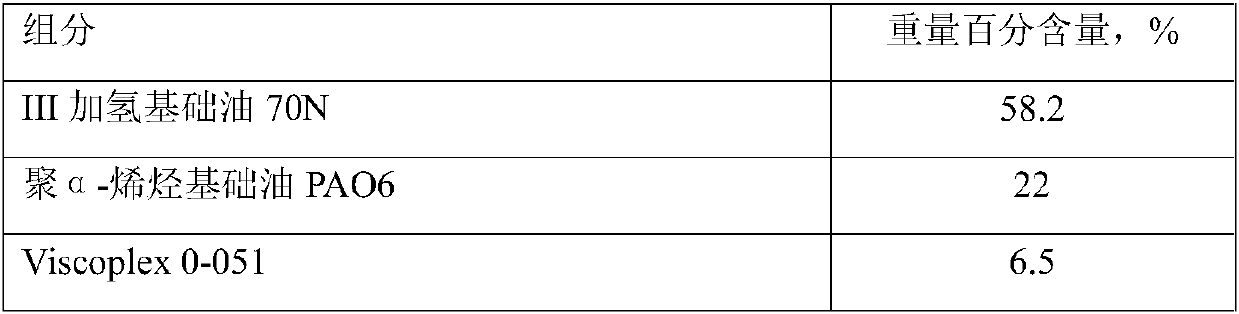

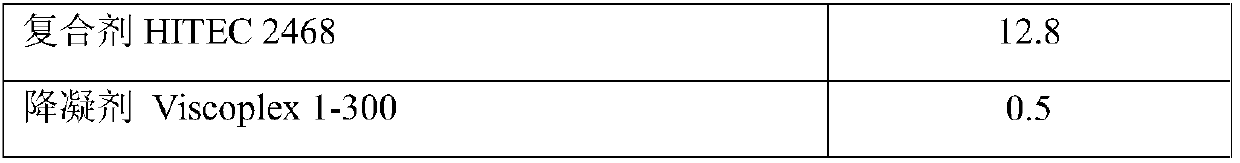

Lubricating oil composition for electric vehicle gearbox and preparation method of lubricating oil composition

ActiveCN107828481AGood shear stabilityViscosity unchangedLubricant compositionStability indexElectric vehicle

The invention discloses a lubricating oil composition for an electric vehicle gearbox and a preparation method of the lubricating oil composition. The composition is prepared from the following components in percentages by weight: 79.8 to 84.5% of base oil, 4 to 7% of polymethacrylate viscosity index improver, 10 to 13% of special complexing agent for transmission oil and 0.3 to 0.5% of pour pointdepressant, wherein the polymethacrylate viscosity index improver is a comb-shaped polymer, and a shear stability index of the polymethacrylate viscosity index improver KRL 20h is not greater than 28. The lubricating oil composition for the electric vehicle gearbox and the preparation method have the advantages that prepared oil maintains viscosity unchanged under long-term high-speed shearing force, provides reliable protection for the electric vehicle gearbox, has excellent shear stability, outstanding low-temperature rheological property, and capability of greatly increasing high-temperature thickening ability of the oil with low dosage, has good dispersibility, can reduce deposition of oil oxides, and can be used together with a special complexing agent for gearbox to improve cleaningand dispersion performance of the oil.

Owner:JIANGSU LOPALTECH

Flame-retardant lubricating grease composition and preparation method thereof

InactiveCN104357197AImprove flame retardant performanceImprove stabilityLubricant compositionImidazolidineToluene diisocyanate

The invention discloses flame-retardant lubricating grease composition and a preparation method thereof. The flame-retardant lubricating grease composition is prepared from components in parts by weight as follows: 70-85 parts of base oil, 10-14 parts of dialkenyl succinimide, 3.2-7.6 parts of 4,4-dimethyl imidazolidine, 3-5 parts of zinc borate, 2-4 parts of a flame retardant, 2-3 parts of toluene diisocynate, 0.5-3 parts of sodium dodecyl sulfate, 1.8-2 parts of graphite and 0.5-1 part of an antioxidant. The preparation method of the flame-retardant lubricating grease composition comprises steps as follows: (1) weighing 70-85 parts of the base oil, 10-14 parts of the dialkenyl succinimide, 3.2-7.6 parts of the 4,4-dimethyl imidazolidine and 0.5-3 parts of the sodium dodecyl sulfate, and evenly stirring the components at the temperature of 80 DEG C; (2) adding 3-5 parts of the zinc borate, 2-3 parts of the toluene diisocynate, 1.8-2 parts of the graphite, 2-4 parts of the flame retardant and 0.5-1 part of the antioxidant to a product of the Step (1), placing the mixture into a reaction kettle, heating the mixture to the temperature of 56-66 DEG C under the pressure of 0.5-1.2 MPa for reaction for 0.5-1 hour, and performing homogenization and degassing to obtain the flame-retardant lubricating grease composition.

Owner:WUXI FEITIAN GREASE

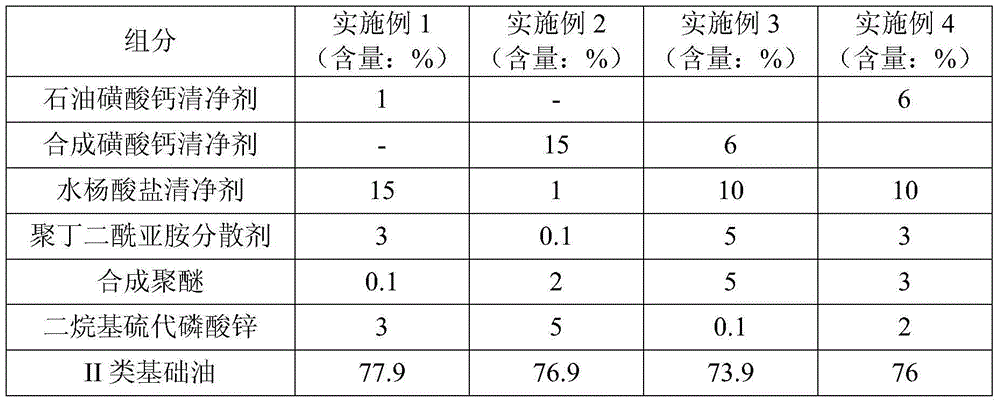

Boat plunger-type engine lubricating oil composition

ActiveCN104531269AImprove rust resistanceImprove antioxidant capacityAdditivesChemical compositionSludge

The invention provides a boat plunger-type engine lubricating oil composition. The boat plunger-type engine lubricating oil composition comprises, by mass, 1-15% of an alkyl sulfonate clearing agent, 1-15% of an alkyl salicylate clearing agent, 0.1-5% of synthetic polyether, 0.1-5% of a dispersant, 0.1-5% of an antiwear agent and the balance II-type base oil. The boat plunger-type engine lubricating oil composition has good antirust and antioxidation performances, utilizes alkyl salicylate structure particularity, can well be dissolved in an underburned part of heavy fuel and can effectively inhibit black oily sludge produced from the underburned part of the heavy fuel. Through use of the synthetic polyether, the boat plunger-type engine lubricating oil composition can be used in the II-type base oil so that good lubrication performances are obtained and boat plunger-type engine lubricating requirements are satisfied.

Owner:PETROCHINA CO LTD

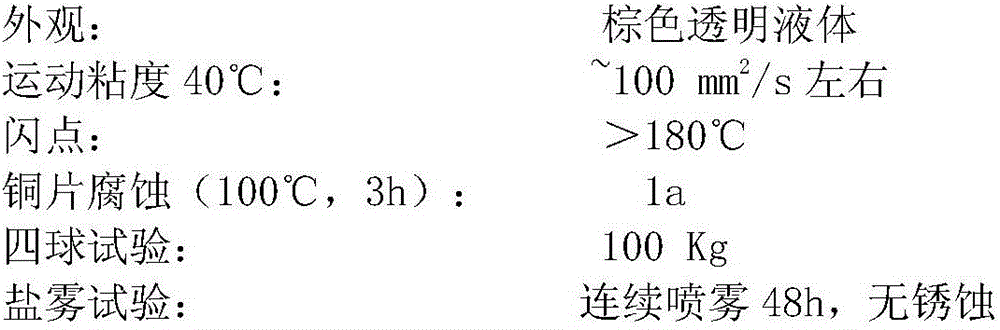

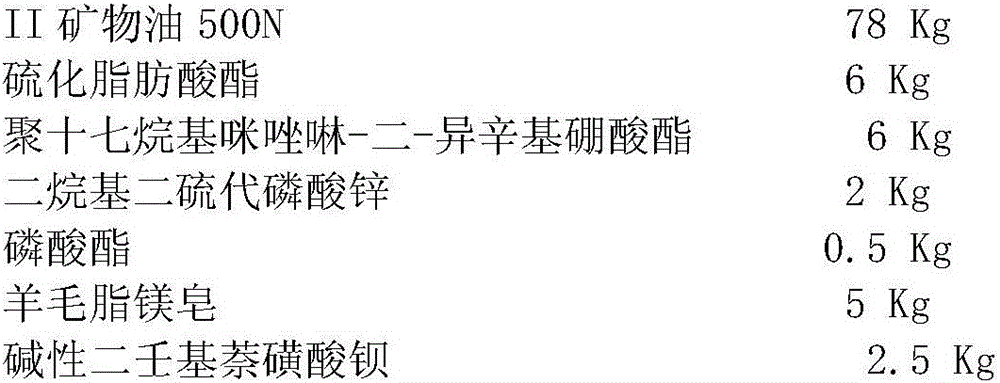

High-performance punching oil used for thick plate

The invention discloses high-performance punching oil used for a thick plate, belongs to the field of metal processing operating fluid, and particularly relates to operating fluid for metal stamping processing. The high-performance punching oil comprises, by mass, 60%-80% of refined mineral oil, 5%-10% of a sulfur-containing extreme pressure agent, 5%-15% of a macromolecule polymerization ester extreme pressure agent, 0.5%-5% of an antiwear agent and 5%-10% of an antirust agent. One of sulfide aliphatic acid ester and over-based sulfosalt or a mixture of the sulfide aliphatic acid ester and the over-based sulfosalt is selected as the sulfur-containing extreme pressure agent. Polyheptadecylimidazoline-di-isooctyl borate is selected as the macromolecule polymerization ester extreme pressure agent. According to the high-performance punching oil, under the synergistic effect of the macromolecule polymerization ester extreme pressure agent and the sulfur-containing extreme pressure agent, excellent lubricating performance and anti-corrosion performance can be given to the punching oil, and the high-performance punching requirements for the thick plate are met. Moreover, the rusting problem of punched products and the ecological environment problem are solved without chlorinated paraffin.

Owner:BOER TECH WUHAN

Grease for calender and preparation method thereof

ActiveCN104152218ARaise the refining temperatureDrop point highThickenersLithium hydroxideOxidation stability

The invention relates to a grease for a calender and a preparation method, the grease comprises the following raw materials by weight: 6-10 parts of high-molecular aliphatic acid, 3-5 parts of low molecular acid, 4-6 parts of lithium hydroxide, 20-30 parts of water, 60-80 parts of base oil A, 20-40 parts of base oil B, 0.2-0.5 parts of anti-oxidant A, 1.0-2.0 parts of anti-oxidant B, 0.5-1.0 parts of antirust agent, 0.5-1 part of anti-wear reagent at extreme pressure A, 1-3 parts of anti-wear reagent at extreme pressure B and 5-15 parts of an adhesion agent. While preparing, raw materials are stirred and mixed according to different temperature and certain sequence, and then processed according to the relative technology requirement. The grease has high dropping point, excellent oxidation stability, water-resistance, colloid stability and machinery stability, and has excellent extreme pressure and anti-wear property as well as long usage life.

Owner:安徽中天石化股份有限公司

Locomotive rim solid lubricant and preparation method thereof

The invention discloses a locomotive rim solid lubricant and a preparation method thereof. The locomotive rim solid lubricant includes molded resin, molybdenum disulfide, halogen-free flame retardant, graphite and alumina. The lubricant is blocky, and can be directly attached to the rim of the locomotive when in use, and is convenient to use, reliable in performance, capable of fully lubricating the rime of the locomotive and durable; and dust generated by friction is environment-friendly and pollution-free.

Owner:CHENGDU SEEFAR RUBBER PLASTICS

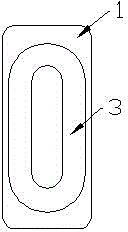

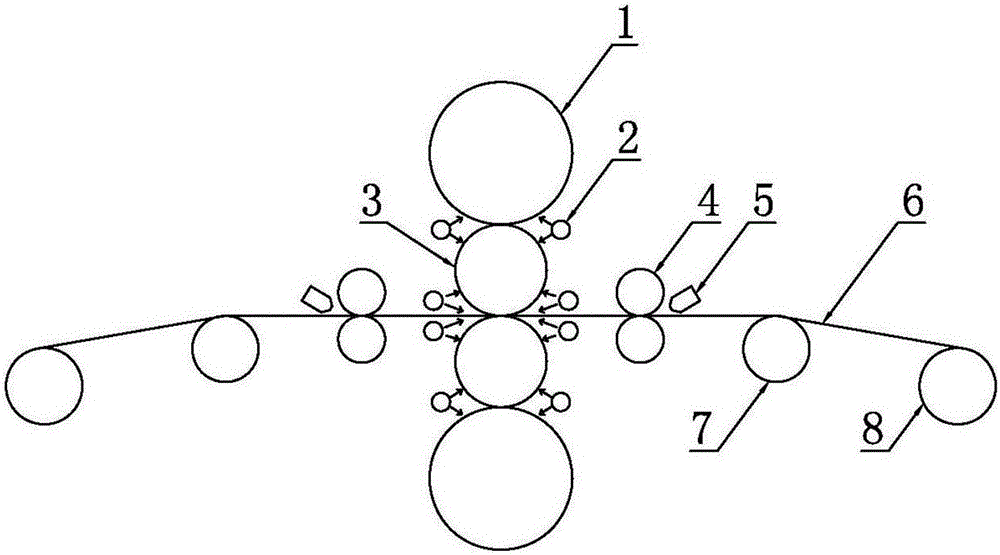

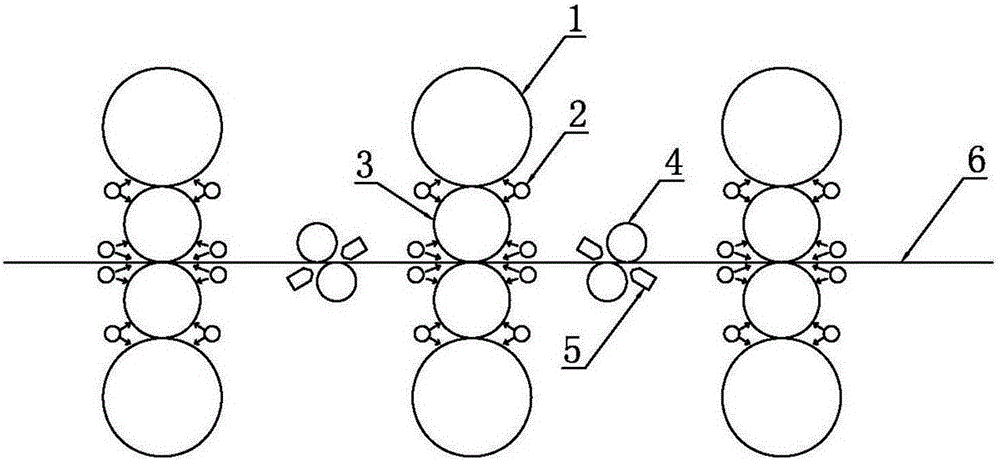

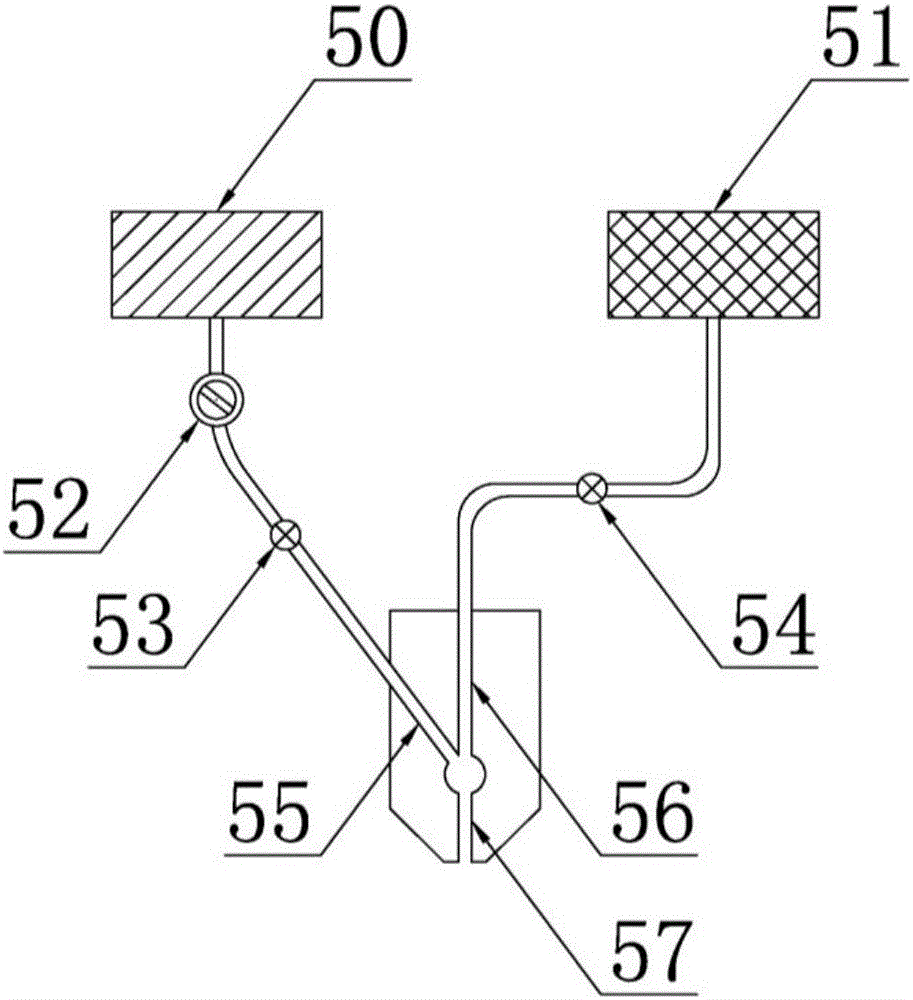

Lubrication apparatus, lubrication method and rolling oil for metal plate strip cold rolling

ActiveCN104985009AGood film-forming propertiesImprove wettabilityWork treatment devicesMetal rolling arrangementsSludgeMetal powder

The invention discloses a lubrication apparatus for metal plate strip cold rolling. The lubrication apparatus includes a rolling oil atomization and spray device which is arranged beside a gap between auxiliary rollers; an oil-way passage, a gas-way passage and a fog-way passage are formed in the rolling oil atomization and spray device; after being communicated with each other, the oil-way passage and the gas-way passage are connected with the fog-way passage; and the outlet end of the fog-way passage is provided with an atomization nozzle. The invention also discloses a method for lubrication by using the above lubrication apparatus and rolling oil used in the method. With the spay mode in the invention adopted, the consumption of the rolling oil is 50% to 80% of that of an existing spay mode, and little metal powder and waste oil sludge are generated in a rolling process, and energy consumption for recovery processing can be decreased, and environmental protection can be benefitted; and the oil flow adjustment method of the rolling oil is simple and convenient.

Owner:张正秀

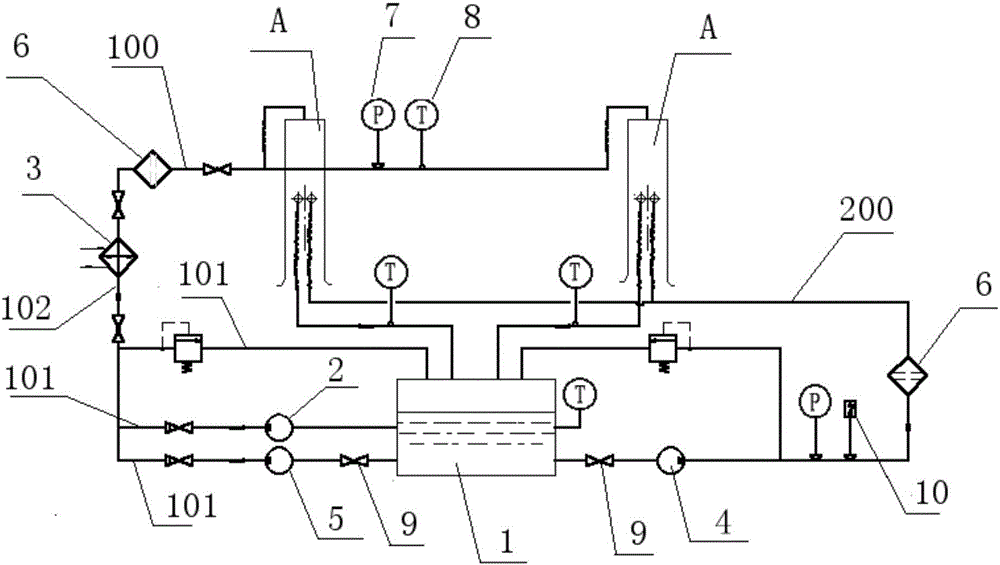

Lubricating oil system of power generator

InactiveCN106439463AMeet lubrication requirementsPrevent wear startBearing coolingEngine lubricationEngineeringChiller

The invention discloses a lubricating oil system of a power generator. The lubricating oil system comprises two circulating pipelines, namely a first circulating pipeline and a second circulating pipeline as well as a lubricating oil tank, a main oil pump, an oil cooler, a jacking oil pump, an emergency oil pump, a filter, a pressure meter, a thermometer and valves, wherein the first circulating pipeline comprises a plurality of branch pipelines and a primary pipeline; the main oil pump and the oil cooler sequentially communicate with one branch pipeline; the emergency oil pump and the oil cooler separately communicate with the other branch pipeline; the filter, the pressure meter, the thermometer and the plurality of valves are arranged on the primary pipeline; and the jacking oil pump, the filter, the pressure meter, the thermometer and the plurality of valves are arranged on the second circulating pipeline in a communication mode. The lubricating oil system of the power generator provided by the invention can effectively implement lubricating protection on a bearing of the power generator, is more remarkable in lubricating effect, and is higher in reliability and safety.

Owner:SUZHOU DISEN BIOLOGICAL ENERGY +1

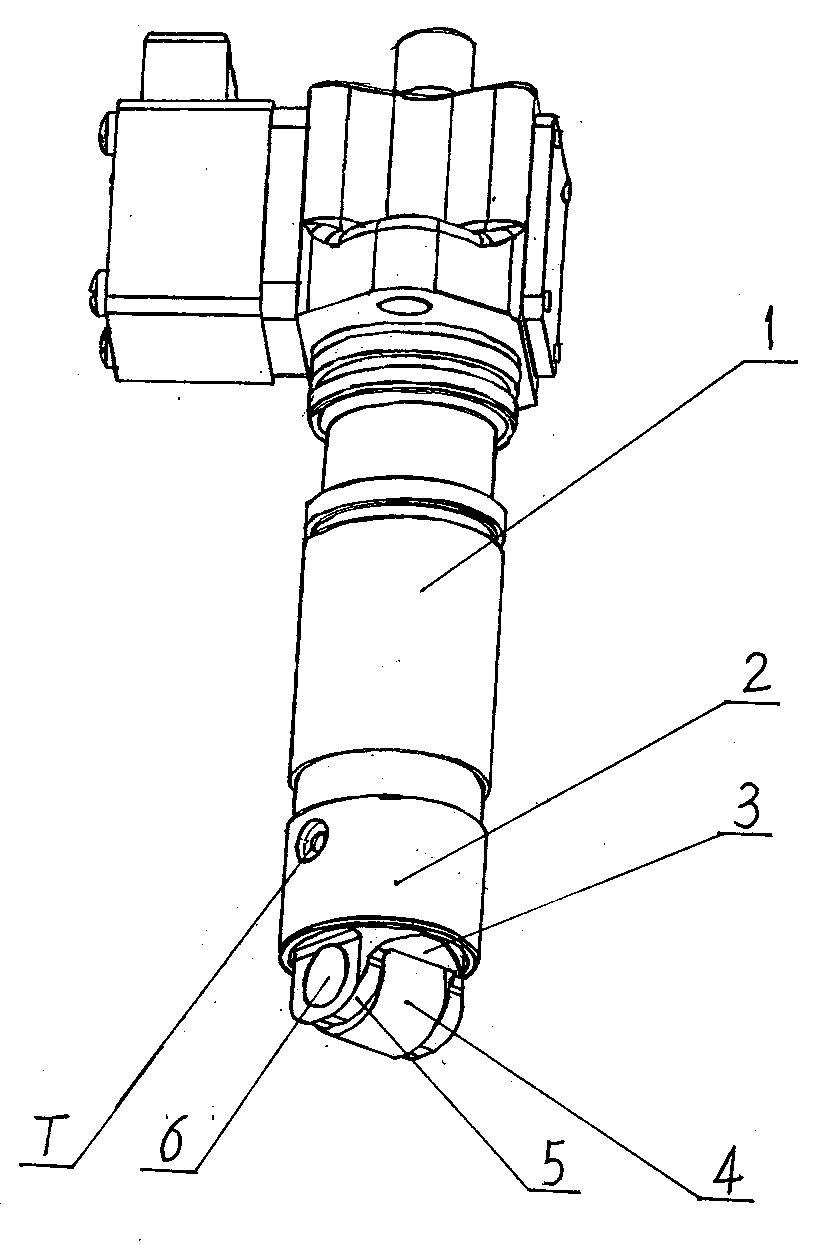

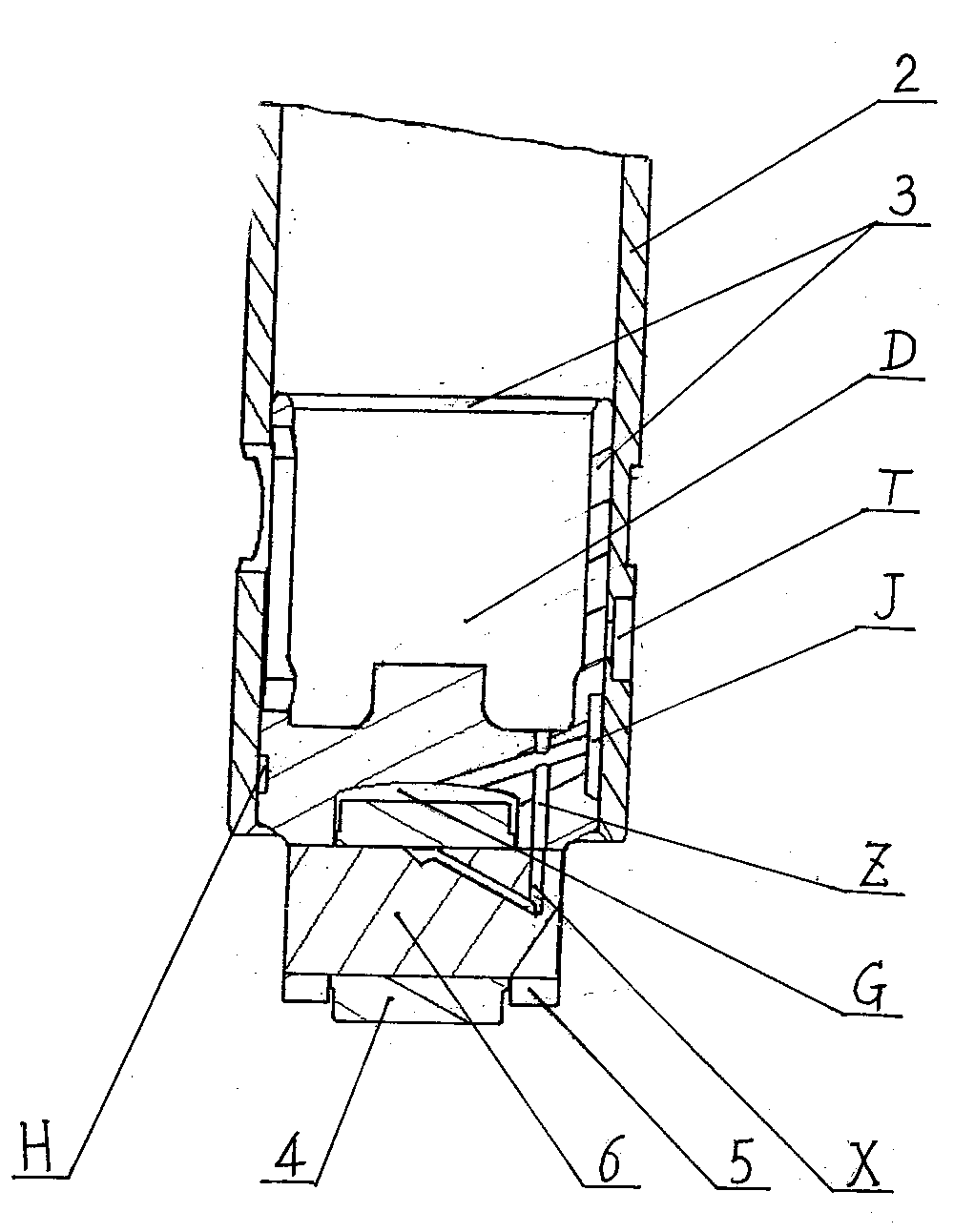

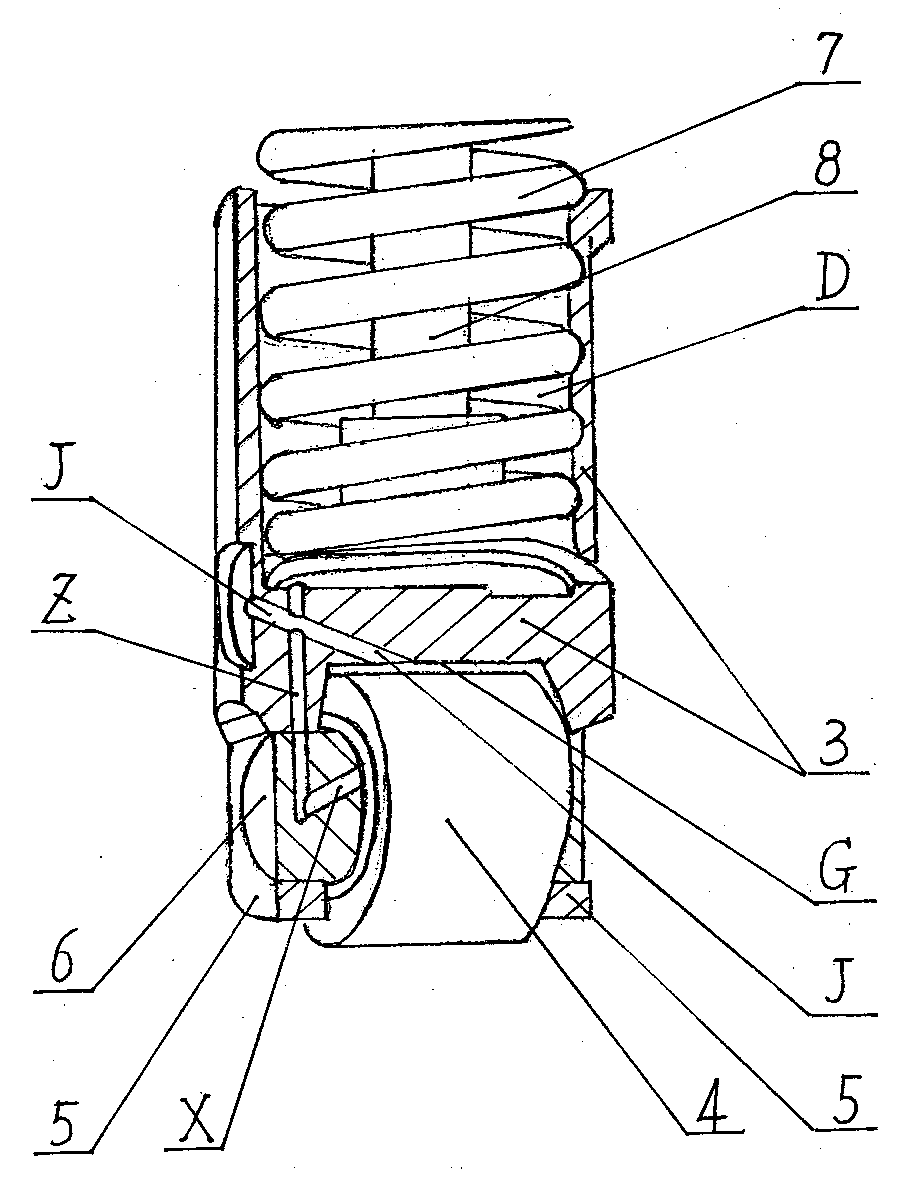

Single body fuel injection pump self-lubricating tappet body roller

InactiveCN103343723AMeet lubrication requirementsImprove performancePositive displacement pump componentsFuel injecting pumpsTappetFuel injection

The invention discloses a single body fuel injection pump self-lubricating tappet body roller. A roller pin fuel channel (X) is formed on a roller pin (6); an axial lubricating fuel channel (Z) is formed on the end part of a tappet body (3), and is communicated with a tappet cavity (D) and the roller pin fuel channel (X); an annular fuel groove (H) connected with a tappet body fuel inlet (J) is formed on the cylindrical surface of the tappet body (3); a straight hole of the roller pin fuel channel (X) is communicated with the axial lubricating fuel channel (Z), and an oblique hole of the roller pin fuel channel (X) is communicated with a conical oil groove (V) on the top surface of the roller pin (6); the axial lubricating fuel channel (Z) and the tappet body fuel inlet (J) are crossed and communicated; the tappet body fuel inlet (J) is communicated with a roller chamber (G); partial lubricating oil entering the tappet cavity (D) through the axial lubricating fuel channel (Z), partial lubricating oil entering the roller pin fuel channel (X), and partial lubricating oil entering the roller chamber (G) respectively lubricate the roller (4), the roller pin (6), and a spring (7) and a plunger (8) in the tappet cavity (D) in a forced mode automatically; the frictional wear of moving elements is relieved; the service life is prolonged.

Owner:SHANDONG XINYA IND +1

Lubricant composition for railway high-speed diesel engine

ActiveCN102690714AImprove antioxidant capacityGood high temperature cleanAdditivesAntioxidantOxidation resistant

The invention relates to a lubricant composition for a railway high-speed diesel engine. The lubricant composition comprises A) a composite antioxidant comprising at least components of 1, an alkylated diphenylamine antioxidant, 2, a thiophenolic ester antioxidant and 3, an unessential phenolic thioether antioxidant, B) a polyisobutylene succinimide ashless dispersant and / or a polyisobutylene succinate dispersant, C) a mixture of calcium sulfonate and calcium naphthenate, D) at least one extreme pressure anti-wear agent, E) one or more ashless friction modifiers, and F) a main amount of lubricating base oil. The lubricant composition has a synergistic effect of the additives, can satisfy high-temperature antioxidation requirements of lubricating oil for a railway high-speed diesel engine, and has excellent piston cleanliness, high / low-temperature wear resistance and a good viscosity increasing control capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com