Locomotive rim solid lubricant and preparation method thereof

A solid lubricant, locomotive technology, applied in lubricating compositions, additives, petroleum industry, etc., can solve the problems of wear, high cost, large consumption, etc., and achieve the effects of good lubrication effect, simple structure, and convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

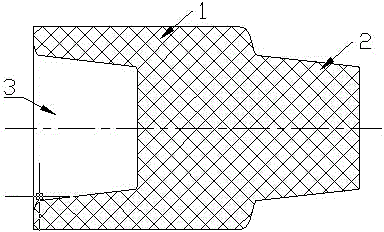

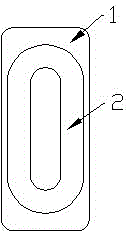

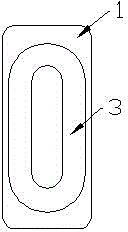

Image

Examples

Embodiment 1

[0055] A locomotive rim solid lubricant, the raw material formula in parts by weight is as follows: 60 parts of molding resin, 24 parts of molybdenum disulfide, 1 part of halogen-free flame retardant, 7 parts of graphite, and 8 parts of aluminum oxide. According to the above formula, the raw materials are mixed into a mass by internal mixer, the mass is weighed and preformed, and the one-time filler is added to the mold to ensure that the cavity of the mold is filled, and then molded. Molding temperature: 160~180°C, pressure : 4~10MPa, time: 10~20min.

Embodiment 2

[0057] A locomotive rim solid lubricant, the raw material formula in parts by weight is as follows: 29 parts of molding resin, 41 parts of molybdenum disulfide, 5 parts of halogen-free flame retardant, 12 parts of graphite, and 13 parts of aluminum oxide. According to the above formula, the raw materials are mixed into a mass by internal mixer, the mass is weighed and preformed, and the one-time filler is added to the mold to ensure that the cavity of the mold is filled, and then molded. Molding temperature: 160~180°C, pressure : 4~10MPa, time: 10~20min.

[0058] Optionally, the molding resin is specifically at least one of epoxy resin, phenolic resin, polytetrafluoroethylene resin and unsaturated resin, and the effect is better when unsaturated polyester resin is selected.

[0059] As an optional mode, the particle size of the molybdenum disulfide is 2000 mesh (the smaller the particle size, the better), and the purity is above 95%. Molybdenum disulfide in the obtained mater...

Embodiment 3

[0064] A locomotive rim solid lubricant has the following raw material formula in parts by weight: 47 parts of molding resin, 30 parts of molybdenum disulfide, 3 parts of halogen-free flame retardant, 10 parts of graphite, and 10 parts of aluminum oxide. According to the above formula, the raw materials are mixed into a mass by internal mixer, the mass is weighed and preformed, and the one-time filler is added to the mold to ensure that the cavity of the mold is filled, and then molded. Molding temperature: 160~180°C, pressure : 4~10MPa, time: 10~20min. Exhaust air 2-3 times during molding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com