Lubrication apparatus, lubrication method and rolling oil for metal plate strip cold rolling

A technology for metal strips and lubricating equipment, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve problems such as low recovery rate and energy consumption, achieve simple adjustment methods, reduce rolling oil consumption, and improve surface quality. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

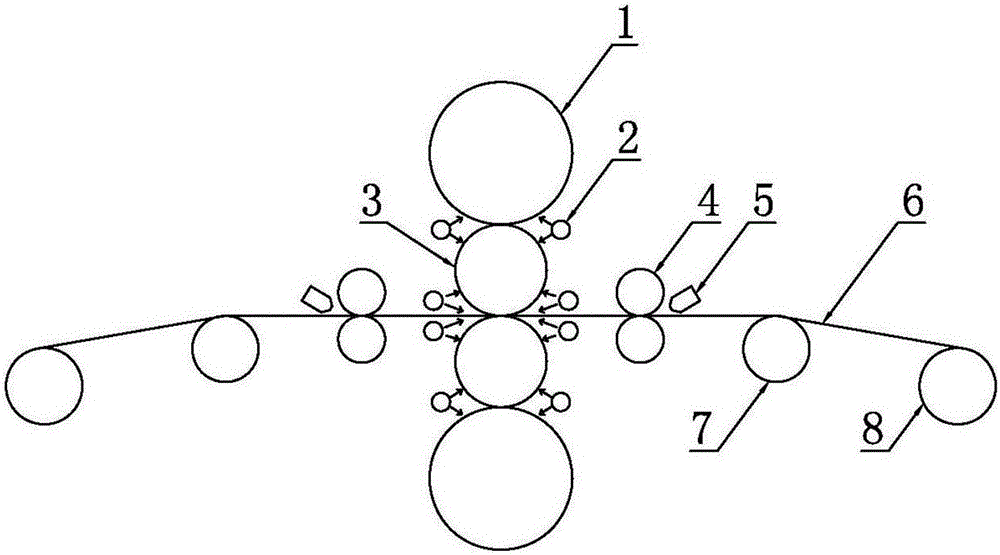

[0035] Such as figure 1 As shown, a lubricating equipment for cold rolling of metal strips includes a backup roll 1, a work roll 3 and an auxiliary roll 4, the backup roll 1 and the work roll 3 are interlocked and connected, and the metal strip 6 passes through the two auxiliary rolls 4 in sequence The gap between the two work rolls 3, because the metal strip 6 passes through the work roll 3 under high temperature and high pressure, therefore, beside the gap between the back-up roll 1 and the work roll 3, the two An emulsion nozzle 2 is installed beside the gap between the work rolls 3; in order to provide lubrication, a rolling oil atomizing injection device 5 is installed next to the gap between the two auxiliary rolls 4 of the present invention, and the rolling oil atomizing injection device 5 Spray atomized rolling oil between the gaps of the auxiliary rolls 4 or on the metal strip 6 to achieve lubrication.

[0036] Such as figure 1 In the reversible rolling mill shown, ...

Embodiment 2

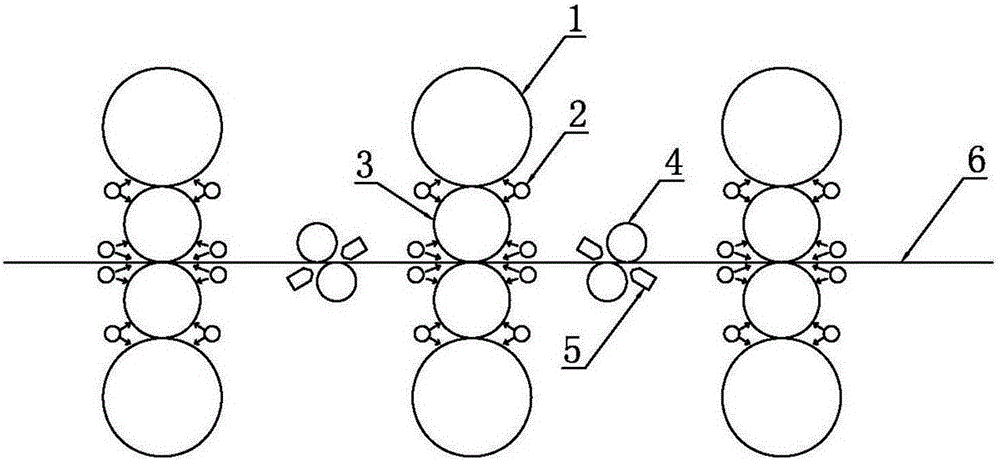

[0039] The application principle of embodiment two is basically the same as that of embodiment one, the difference is that embodiment two is a continuous rolling mill, and the two auxiliary rolls 4 are respectively a dam roll and a tension roll. The rolls are staggered. The rolling oil atomization injection device 5 sprays the gap between the dam roll and the metal strip 6, the gap between the tension roll and the metal strip 6, and the surface of the metal strip 6, so as to realize the cleaning of the metal strip during the rolling process. 6. Lubrication.

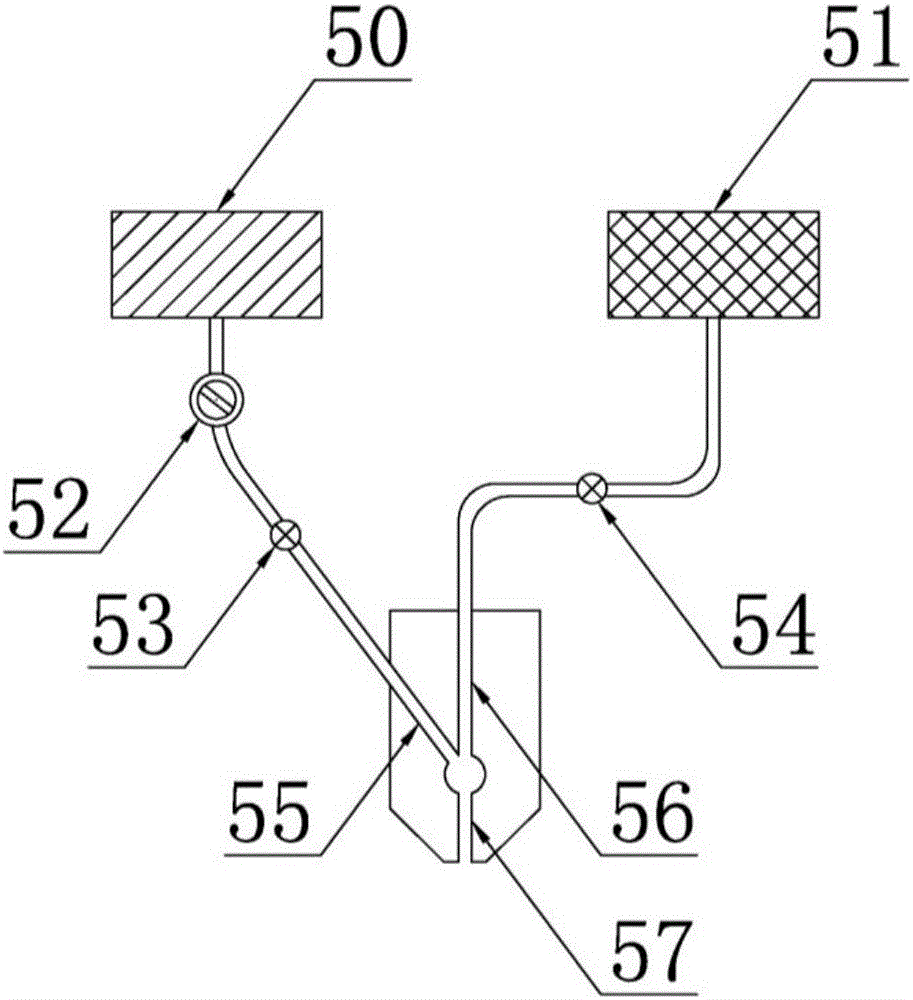

[0040] The invention also discloses a lubricating method for cold rolling of metal strips. The rolling oil is atomized by an air compressor 51 and a rolling oil atomizing spray device 5, and the atomized rolling oil is atomized by the rolling oil The injection device 5 sprays on the auxiliary roll 4 or the surface of the steel strip to lubricate the metal strip 6 before cold rolling. After the metal strip 6 with rolling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com