Acid-and-alkali-corrosion-resistant environment-friendly lubricating grease composition and preparation method

A lubricating grease composition and technology of the composition, applied in the field of lubricating grease, can solve the problems of unscaled production and high price of fluorine grease, achieve good acid and alkali resistance, reduce the content of harmful metal ions and heavy metal ions, and resist water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

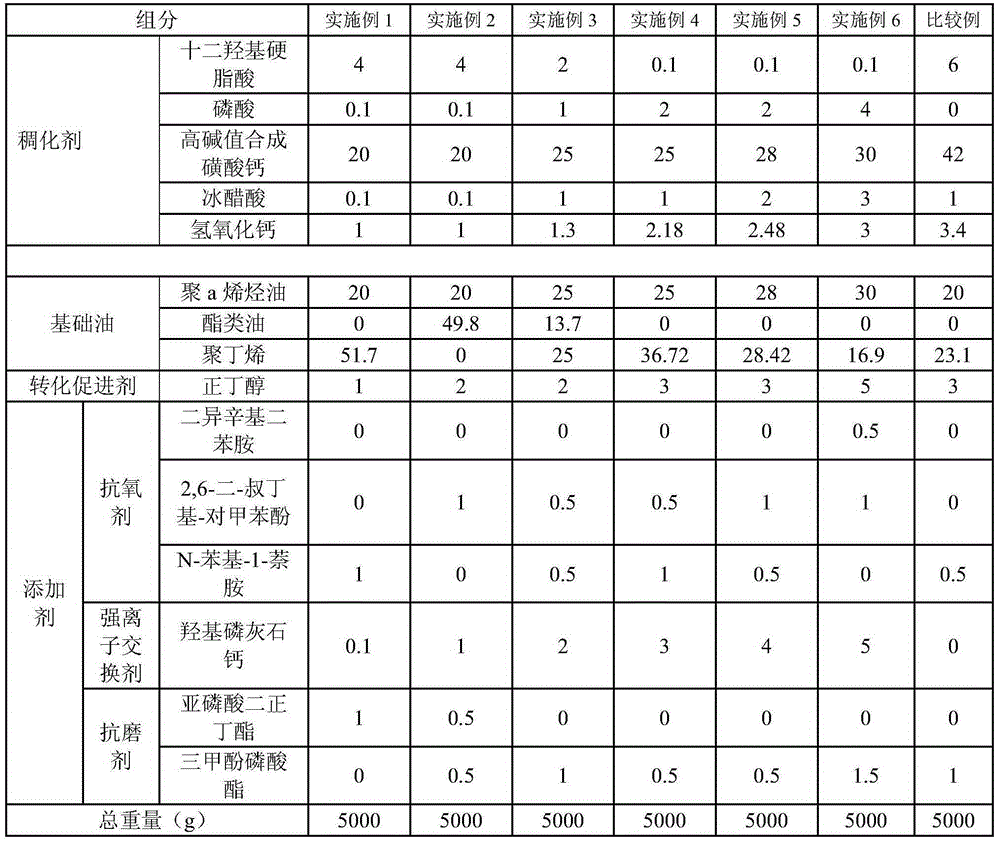

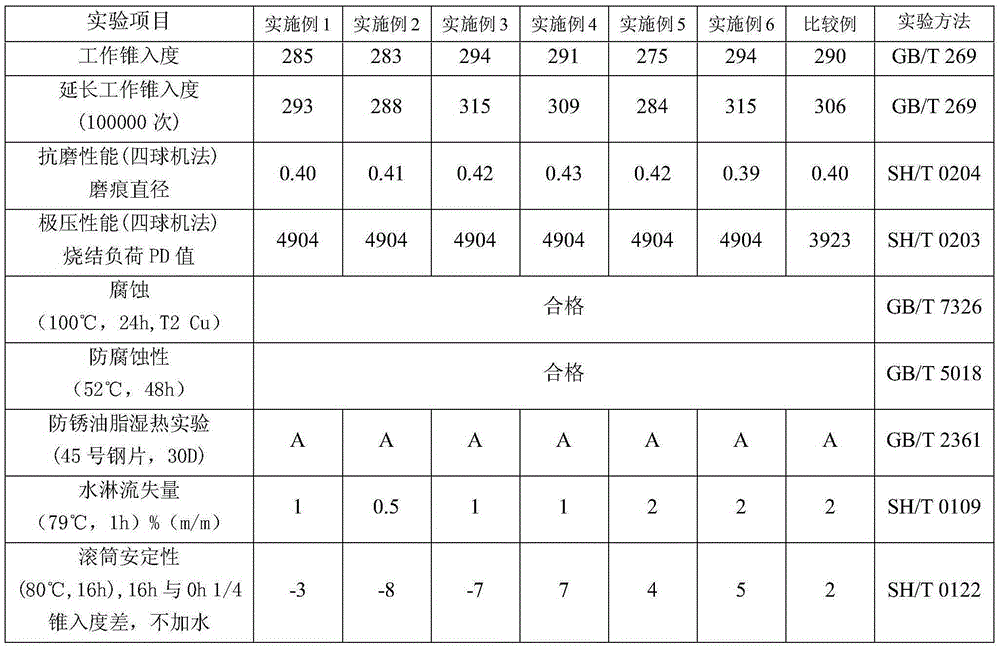

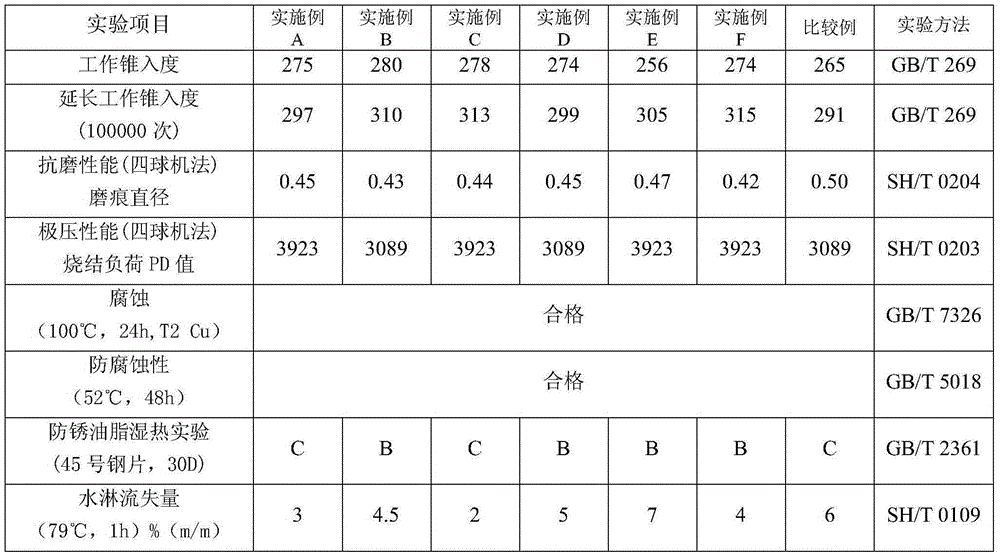

Examples

Embodiment 1

[0036] Embodiment 1 preparation method is as follows:

[0037] Add the total base number 360-425mgKOH / g high base number synthetic calcium sulfonate and the high viscosity polyalpha olefin oil of the same weight and account for the grease gross weight 10% in the saponification kettle of the laboratory small test. Mix -20% water, stir evenly, heat up to 75-95°C, add 0.1% glacial acetic acid to the total weight of grease, glacial acetic acid needs to be diluted with 2-3 times water in advance, the weight of water is not included in the total weight, stir After three to ten minutes, add 1% n-butanol by the total weight of the grease, stir, and keep the temperature at 75-95°C for 1-2 hours. After the constant temperature is over, take 1-2g samples for Fourier transform infrared spectrometer testing. When the infrared spectrogram shows that the characteristic absorption peak of amorphous calcium carbonate in the raw material 862-865cm-1 peak position disappears, and a strong sharp ...

Embodiment 2

[0038] Embodiment 2 preparation method is as follows:

[0039] Add the total base number 360-425mgKOH / g high base number synthetic calcium sulfonate and the high viscosity polyalpha olefin oil of the same weight and account for the grease gross weight 10% in the saponification kettle of the laboratory small test. Mix -20% water, stir evenly, heat up to 75-95°C, add 0.1% glacial acetic acid to the total weight of grease, glacial acetic acid needs to be diluted with 2-3 times water in advance, the weight of water is not included in the total weight, stir After three to ten minutes, add 2% n-butanol by the total weight of the grease, stir, and keep the temperature at 75-95°C for 1-2 hours. After the constant temperature is over, take 1-2g sample for Fourier transform infrared spectrometer test. When the infrared spectrogram shows that the characteristic absorption peak of amorphous calcium carbonate in the raw material 862-865cm-1 peak position disappears, and a strong sharp abso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com