Lubricating grease composition for steering ball joint and preparation method of lubricating grease composition

A lubricating grease composition and composition technology, applied in the field of lubricating grease, can solve problems such as abnormally worn metal, unsmooth steering operation, and endangering the safety of automobile driving, and achieve good high and low performance, excellent extreme pressure and anti-wear performance, and excellent anti-friction The effect of water rust resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

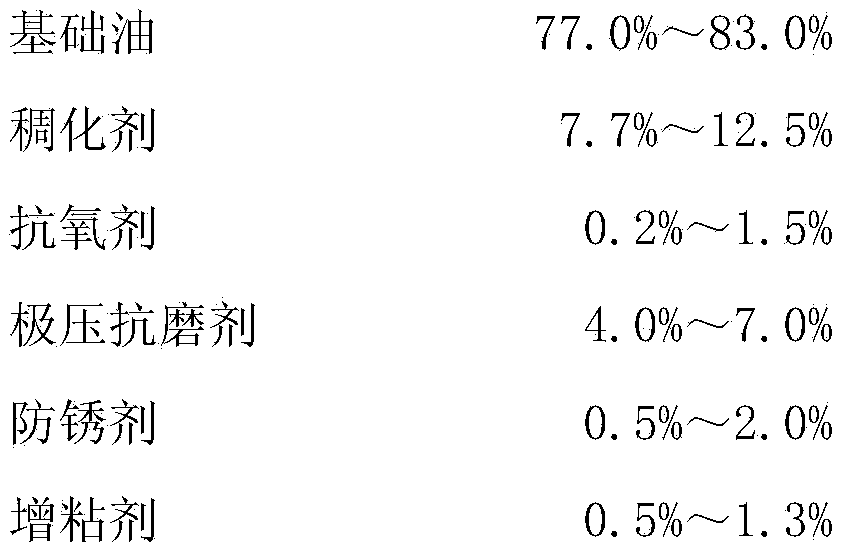

Method used

Image

Examples

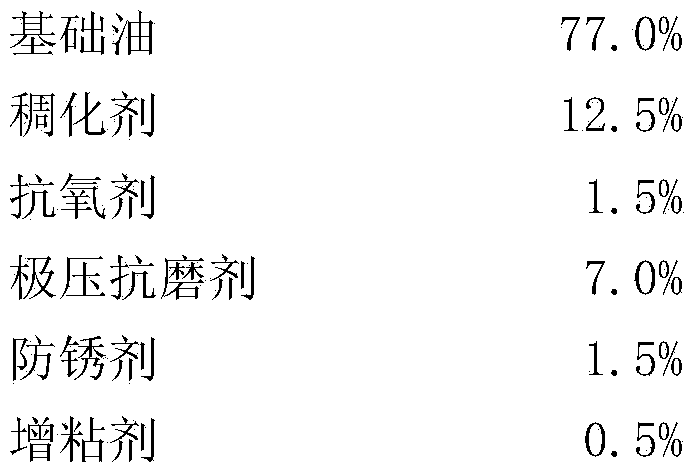

Embodiment 1

[0025]

[0026] (1) Mix 375g of 12-hydroxystearic acid and 1510g of polyalphaolefin synthetic oil (the kinematic viscosity at 40°C is 130mm 2 / s) into the reactor to heat up; (2) when the reactor was heated to 90°C, the aqueous solution of 41g of lithium hydroxide monohydrate and 25g of calcium hydroxide was added to the reactor for saponification reaction; (3) saponification After the end, continue to heat up, and when the temperature rises to 170°C, add 45g of diphenylamine; (4) continue to heat up, after the temperature rises to 210°C, keep the temperature constant for 10 minutes, and then add 400g of poly-α-olefin synthetic oil into the reaction kettle for cooling and cooling , then cool down naturally, and when the temperature drops below 100°C, adjust the consistency of the grease with 400g of poly-α-olefin synthetic oil; (5) After the product has a suitable consistency, add 3g of benzotriazole, dinonylnaphthalenesulfonic acid Barium 42g, sulfurized isobutylene 60g, t...

Embodiment 2

[0028]

[0029] (1) 1490g of base oil mixture prepared with 231g of 12-hydroxystearic acid, poly-α-olefin synthetic oil and refined mineral oil (40°C kinematic viscosity is 150mm 2 / s) into the reactor to heat up; (2) when the reactor was heated to 85°C, the aqueous solution of lithium hydroxide monohydrate 25g and calcium hydroxide 7.5g was added to the reactor to carry out saponification reaction; (3) Continue to heat up after saponification, when the temperature rises to 150°C, add 30g of diisooctyl diphenylamine; (4) continue to heat up, after the temperature rises to 205°C, keep the temperature constant for 10 minutes, add 500g of base oil mixture to the reaction kettle Cool down, and then cool down naturally. When the temperature drops below 100°C, adjust the grease consistency with 500g of base oil mixture; (5) After the product has a suitable consistency, add 1.5g of benzotriazole, dinonylnaphthalenesulfonic acid 28.5g of barium, 60g of sulfurized isobutylene, 30g o...

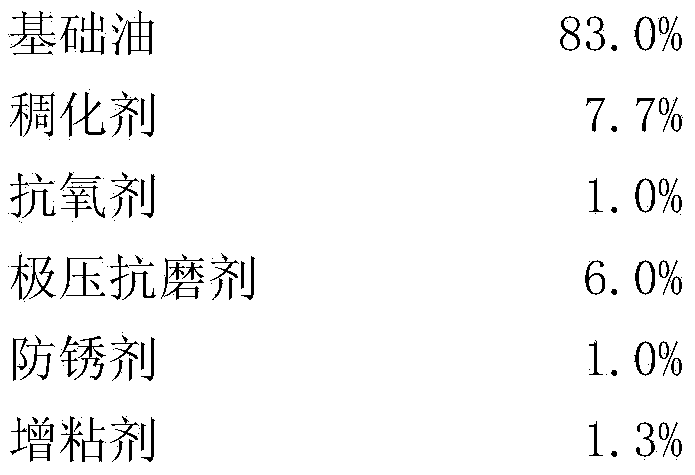

Embodiment 3

[0031]

[0032] (1) 1530g of base oil mixture prepared with 276g of 12-hydroxystearic acid, poly-α-olefin synthetic oil and refined mineral oil (the kinematic viscosity at 40°C is 170mm 2 / s) into the reactor to heat up; (2) when the reactor was heated to 80°C, the aqueous solution of 30g of lithium hydroxide monohydrate and 9g of calcium hydroxide was added to the reactor for saponification reaction; (3) saponification Continue to heat up after the end, when the temperature rises to 160°C, add 39g of diisooctyl diphenylamine; (4) continue to heat up, after the temperature rises to 200°C, keep the temperature constant for 10 minutes, add 500g of base oil mixture into the reaction kettle to process the material Cool, then cool down naturally. When the temperature drops below 100°C, adjust the grease consistency with 400g of base oil mixture; (5) After the product has a suitable consistency, add 1.5g of benzotriazole and 58.5g of barium petroleum sulfonate in sequence, Sulfur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com