Chain cleaning composition and preparation method thereof

A technology of composition and cleaning agent, which is applied in the field of lubricating grease, can solve problems such as chain corrosion and environmental pollution, and achieve the effects of preventing rust damage, excellent lubricating performance, and excellent anti-oxidation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

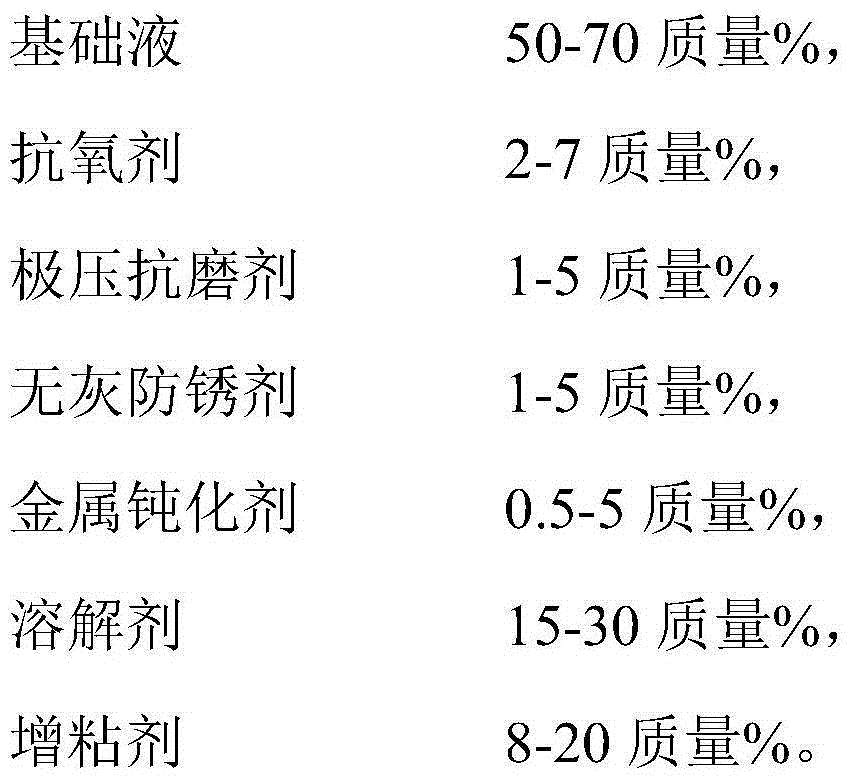

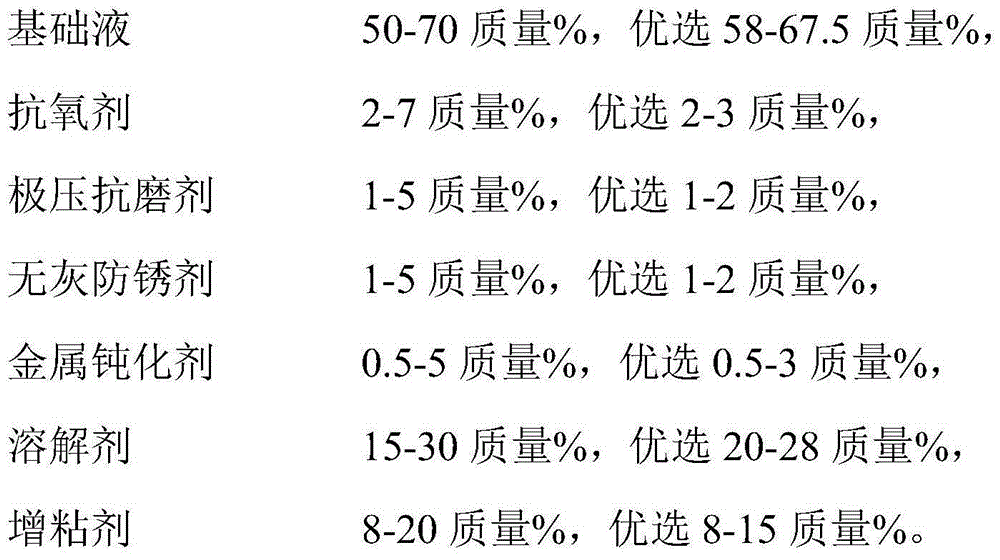

Method used

Image

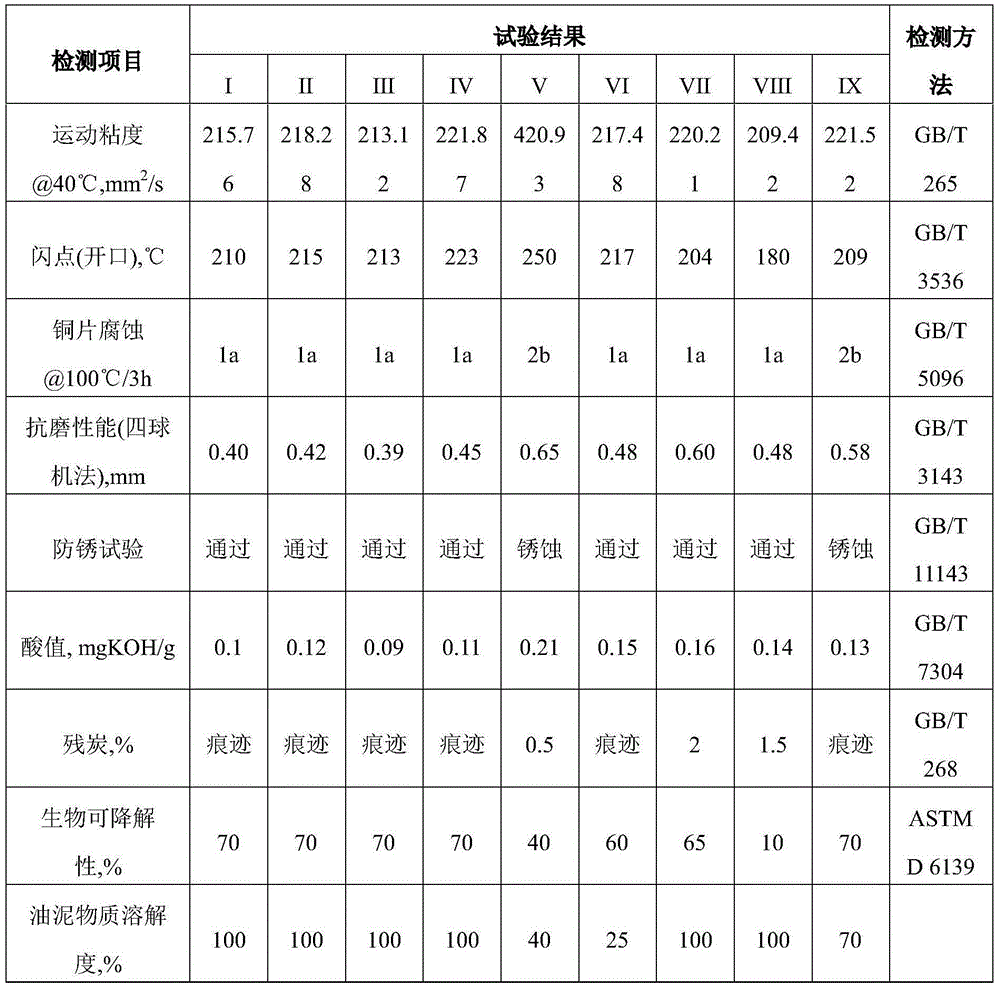

Examples

preparation example Construction

[0039] The present invention also provides a preparation method of the chain cleaning agent composition, including the step of mixing the components of the composition.

[0040] Preferably, the method comprises the steps of:

[0041] (1) Pour the base liquid into a clean stainless steel blending kettle, heat to 85°C-95°C, and stir evenly for 20-40 minutes;

[0042] (2) Keep the temperature at 85-95°C, add antioxidant, and stir evenly for 20-40 minutes;

[0043] (3) Cool down to 50-60°C, add extreme pressure anti-wear agent, ashless rust inhibitor, metal passivator, tackifier, and stir evenly for 20-40 minutes;

[0044] (4) Cool down to 35-40°C, add a dissolving agent, stir evenly for 20-40 minutes, and filter to obtain the finished composition.

Embodiment 1

[0047] Pour 58 parts of the base liquid pentaerythritol ester (British Croda Company, brand Priolube 3987, the same below) into a clean stainless steel blending kettle, heat to 90°C, and stir evenly for 20 minutes; add antioxidant p-, p-octyl di 3 parts of aniline (Germany BASF company, brand Irganox L01, the same below) were kept at a constant temperature of 90°C and stirred evenly for 30 minutes; the temperature was lowered to 55°C, and the extreme pressure and antiwear agent antimony dialkyldithiocarbamate (Vanderbilt, USA) was added. Special company, brand Vanlube 73, the same below) 2 parts, ashless rust inhibitor amine phosphate mixture (Germany BASF company, brand IRGALUBE 349, the same below) 1 part, metal deactivator benzotriazole derivatives (Germany BASF company, Brand: IRGAMET 39, the same below) 1 part, thickener complex ester Priolube 3986 (British Croda Company, brand Priolube 3986, the same below) 15 parts, stir evenly for 30 minutes; cool down to 40 ° C, add so...

Embodiment 2

[0049] Pour 58 parts of the base liquid pentaerythritol ester into a clean stainless steel mixing kettle, heat to 90°C, and stir evenly for 20 minutes; add the antioxidant high molecular weight phenol containing thioether group (Germany BASF company, brand Irganox L115, the same below) 3 2 parts, keep the temperature at 90°C, stir evenly for 30 minutes; cool down to 55°C, add 2 parts of extreme pressure anti-wear agent amine phosphate compound (Vanderbilt Company of the United States, brand: Vanlube 692, the same below) 2 parts, ashless rust inhibitor 1 part of zinc naphthenate (Xinji Luhua Petrochemical Co., Ltd., brand: T704, the same below), 1 part of metal deactivator benzotriazole derivative, 398615 parts of thickening agent complex ester Priolube, stir evenly for 30 minutes; cool down To 40°C, add 20 parts of isoparaffin solvent ISOPAR M as a dissolving agent, stir evenly for 30 minutes, and filter to obtain the finished composition II.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com