Totally-synthesized over-load antiwear extreme-pressure industrial gear oil and preparation method thereof

An industrial gear oil and overload technology, applied in the field of lubricating oil, can solve the problems of surface tension drop, extreme pressure, insufficient anti-wear performance, insufficient thermal stability, etc., to achieve the ability to improve extreme pressure and overload, excellent extreme Compression and anti-wear properties, obvious anti-wear and anti-friction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0029] A preparation method of fully synthetic super-load anti-wear extreme pressure industrial gear oil, comprising the steps of:

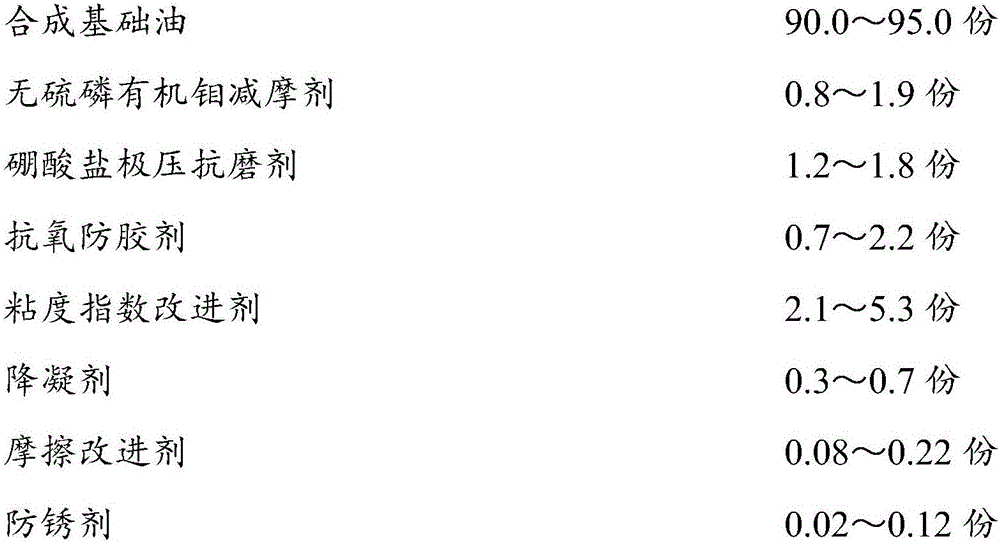

[0030] Step 1: Weigh each component by the following parts by weight:

[0031]

[0032]

[0033] Step 2: Add synthetic base oil into the reaction kettle, stir and heat to 65°C;

[0034] Step 3: Add pour point depressant and viscosity index improver to the reactor in turn, and stir for 30 minutes at a speed of 500r / min;

[0035] Step 4: Continue to add sulfur-free phosphorus organic molybdenum friction reducer and borate extreme pressure antiwear agent to the reaction kettle in sequence, and stir for 70 minutes at a speed of 350r / min;

[0036] Step 5: Finally, add anti-oxidation and anti-adhesive agent, friction modifier, and anti-rust agent to the reaction kettle in sequence, and stir for 80 minutes at a speed of 150r / min;

[0037] Step 6: Transfer the materials in the reaction kettle to the storage tank and let it stand for 60 minutes to...

no. 2 Embodiment

[0040] A preparation method of fully synthetic super-load anti-wear extreme pressure industrial gear oil, comprising the steps of:

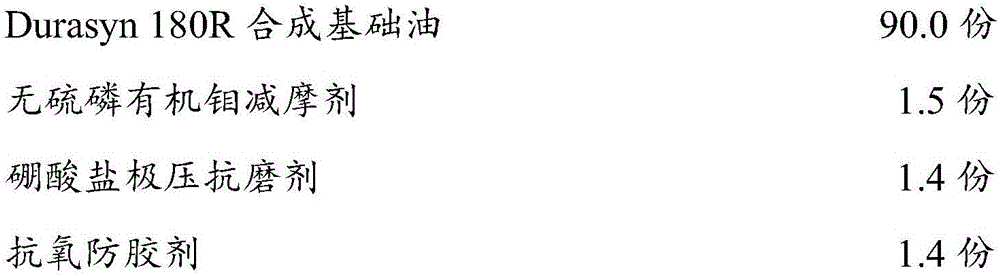

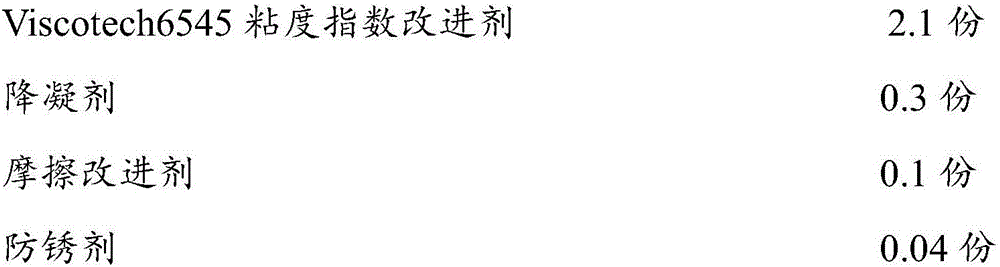

[0041] Step 1: Weigh each component by the following parts by weight:

[0042]

[0043]

[0044] Step 2: Add Durasyn 180R synthetic base oil into the reactor, stir and heat to 65°C;

[0045] Step 3: Add pour point depressant and viscosity index improver to the reactor in turn, and stir for 30 minutes at a speed of 500r / min;

[0046] Step 4: Continue to add sulfur-free phosphorus organic molybdenum friction reducer and borate extreme pressure antiwear agent to the reaction kettle in sequence, and stir for 60 minutes at a speed of 400r / min;

[0047] Step 5: Finally, add anti-oxidation and anti-adhesive agent, friction modifier, and anti-rust agent to the reaction kettle in sequence, and stir for 90 minutes at a speed of 100r / min;

[0048] Step 6: Transfer the materials in the reaction kettle to the storage tank and let it stand for 65 minut...

no. 3 Embodiment

[0051] A kind of preparation method of fully synthetic overload anti-wear extreme pressure industrial gear oil comprises the following steps:

[0052]

[0053]Step 2: Add Durasyn 180R synthetic base oil into the reactor, stir and heat to 65°C;

[0054] Step 3: Add pour point depressant and viscosity index improver to the reactor in turn, and stir for 30 minutes at a speed of 500r / min;

[0055] Step 4: Continue to add sulfur-free phosphorus organic molybdenum friction reducer and borate extreme pressure antiwear agent to the reaction kettle in sequence, and stir for 90 minutes at a speed of 300r / min;

[0056] Step 5: Finally, add anti-oxidation and anti-adhesive agent, friction modifier, and anti-rust agent to the reaction kettle in sequence, and stir for 75 minutes at a speed of 200r / min;

[0057] Step 6: Transfer the materials in the reaction kettle to the storage tank and let it stand for 70 minutes to obtain a fully synthetic super-load anti-wear extreme pressure indust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com