Lubricant composition and application thereof

A technology of lubricating oil composition and mineral oil, applied in lubricating composition, petroleum industry, etc., can solve the problems of poor economy, high dosage of lubricating oil for cold heading, etc., and achieve good anti-corrosion performance, excellent extreme pressure and anti-wear performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

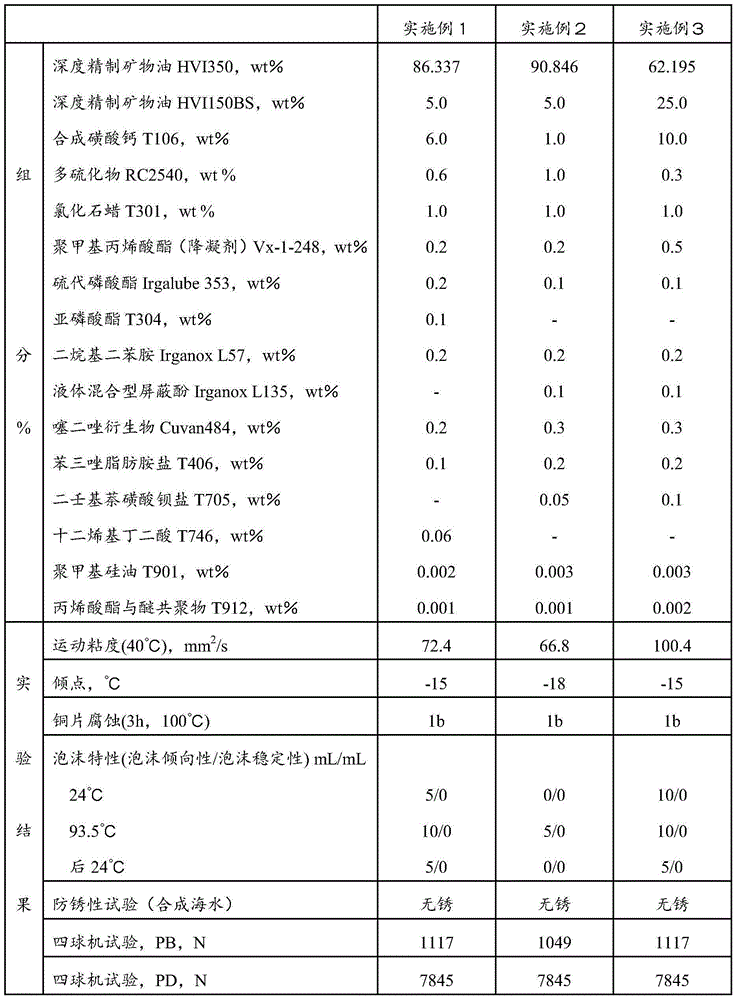

[0045] Add base oil and pour point depressant, heat up to 60°C for heating and stirring, maintain for 2 hours, then lower the temperature to 40°C; then add other ingredients, stir for 2 hours until the mixture is completely dissolved and becomes transparent, and the compound of the present invention is obtained. said composition. The specific components and product performance of the composition are shown in Table 1, wherein, Examples 1 and 2 are products of lower viscosity grades, and Example 3 is a product of higher viscosity grades.

[0046] Table 1

[0047]

[0048] As shown in the test results of the examples in the table, [Example 1-3] all performed excellent in the four-ball test, indicating that the product has excellent extreme pressure and anti-wear properties, and can fully meet the requirements of high impact and high extrusion of cold heading processing on processed parts. Condition requirements. At the same time [Example 1-3], the results of rust resistance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com