Automobile sway bar ball joint lubricating grease composition and preparation method

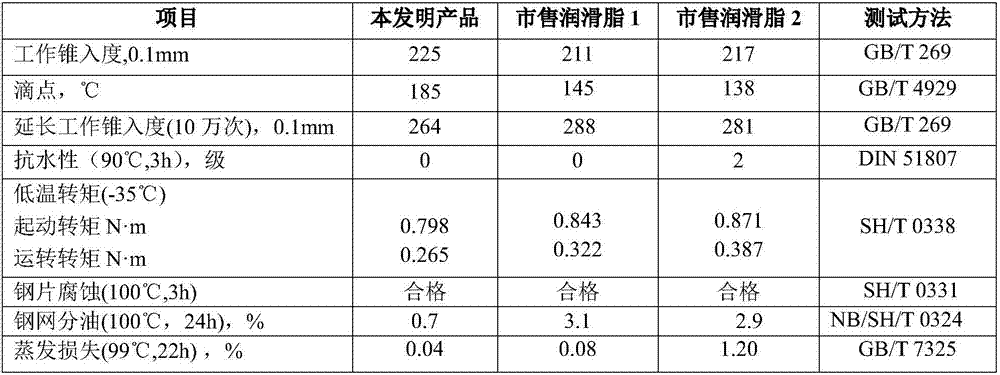

A grease composition and a technology for the composition, applied in the field of grease, can solve problems such as poor lubrication and poor performance, and achieve the effects of excellent anti-wear performance, good high and low performance, and excellent water and rust resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

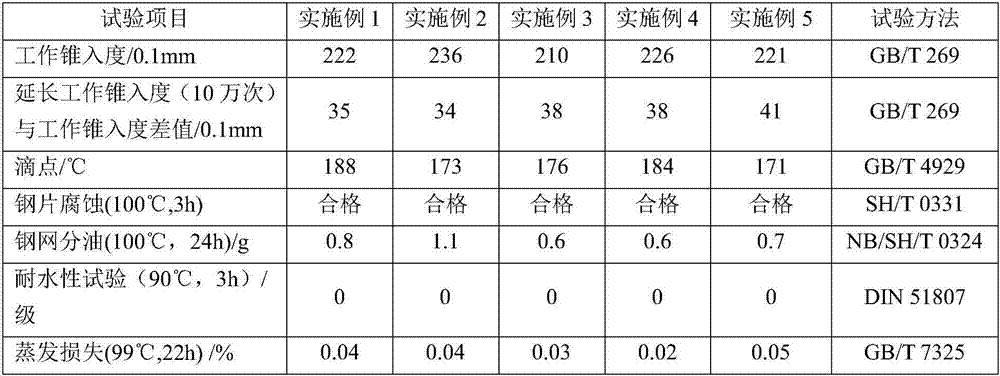

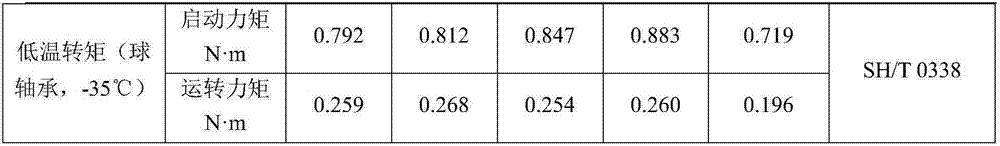

Embodiment 1

[0025] Embodiment 1: each component comprises by the total weight of composition:

[0026] (1) Thickener: 6.75%;

[0027] (2) Antioxidant: 1.0%;

[0028] (3) Rust inhibitor: 0.06%;

[0029] (4) Solid lubricant: 11.5%;

[0030] (5) Base oil: 80.69%.

[0031] 108 grams of 12-hydroxystearic acid, 27 grams of hydrogenated castor oil and 322.8 grams of polyalphaolefin base oil (the freezing point is -30 ° C, and the viscosity at 100 ° C is 101mm 2 / s) into the reaction kettle, heated to 80-85 ° C, and added 13.04 grams of lithium hydroxide monohydrate and 2.61 grams of calcium hydroxide aqueous solution configuration. Heat up to 90-105°C to start timing saponification. After saponification, heat up and add 645.5 grams of base oil to 125-145°C until the highest refining temperature is 200-220°C, then cool with 322.8 grams of base oil in the reactor After cooling, when the temperature is controlled at 160-190°C, add 32.3 grams of dimethyl glutarate and the remaining 290.5 grams ...

Embodiment 2

[0032] Embodiment 2: each component comprises by the total weight of composition:

[0033] (1) Thickener 9%;

[0034] (2) Antioxidant 1.5%;

[0035] (3) 0.08% rust inhibitor;

[0036] (4) Solid lubricant 18.0%;

[0037] (5) Base oil: 74.42%.

[0038] 144 grams of 12-hydroxystearic acid, 36 grams of hydrogenated castor oil and 297.7 grams of polyalphaolefin base oil (the freezing point is -30 ° C, the viscosity at 100 ° C is 101mm 2 / s) into the reaction kettle, heated to 80-85 ° C, and added 17.38 grams of lithium hydroxide monohydrate and 3.48 grams of calcium hydroxide aqueous solution configuration. Heat up to 90-105°C to start timing saponification. After saponification, heat up and add 595.4 grams of base oil to 125-145°C until the highest refining temperature is 200-220°C. Cool with 297.7 grams of base oil in the reactor After cooling, when the temperature is controlled at 160-190°C, add 29.8 grams of dimethyl glutarate and the remaining 267.9 grams of base oil. Whe...

Embodiment 3

[0039] Embodiment 3: each component comprises by the total weight of composition:

[0040] (1) Thickener: 4.5%;

[0041] (2) Antioxidant: 0.5%;

[0042] (3) Rust inhibitor: 0.03%;

[0043] (4) Solid lubricant: 8.0%;

[0044] (5) Base oil: 86.97%.

[0045] 72 grams of 12-hydroxystearic acid, 18 grams of hydrogenated castor oil and 348 grams of polyalphaolefin base oil (the freezing point is -30 ° C, and the viscosity at 100 ° C is 101mm 2 / s) into the reaction kettle, heated to 80-85 ° C, and added 8.69 grams of lithium hydroxide monohydrate and 1.74 grams of calcium hydroxide aqueous solution configuration. Heat up to 90-105°C to start timing saponification. After saponification, heat up and add 696 grams of base oil to 125-145°C until the highest refining temperature is 200-220°C, then cool with 348 grams of base oil in the reactor After cooling, when the temperature is controlled at 160-190°C, add 34.0 grams of dimethyl glutarate and the remaining 313 grams of base oil....

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com