Food grade lubricating grease and its preparation method and application

A food-grade grease technology, applied in the field of food-grade grease, can solve the problem of food-grade grease literature and patent reports that cannot meet the hygienic water quality standards, backward lubrication and sealing, and have not found drinking water pipelines and valve lubrication and sealing and other problems, to achieve superior high and low temperature performance, reduce maintenance costs, and not easy to deteriorate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

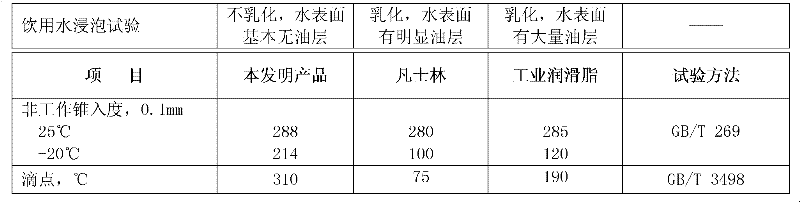

[0027] Add 110 grams of stearic acid and 61 grams of benzoic acid to 1560 grams and the viscosity is 100mm 2 / s food-grade mineral oil, heat to 60°C, add 86 grams of aluminum isopropoxide, rise to 80°C, react for 1 hour, continue to heat to 100°C, add 12.5 grams of tap water, keep the temperature for 1 hour, and continue to heat up the material To 150 DEG C, keep the temperature for 30 minutes, add 700 grams of food-grade mineral oil for rapid cooling, when the temperature drops below 100 DEG C, add 400 grams of polytetrafluoroethylene micropowder, and carry out post-processing after stirring to obtain the finished product fat. The lubricating grease performance that process formula of the present invention makes is listed in the following table:

[0028]

[0029] It can be seen from the above table that the rubber compatibility, high and low temperature performance and water resistance performance of the lubricating grease of the present invention are all very good.

[00...

example 2

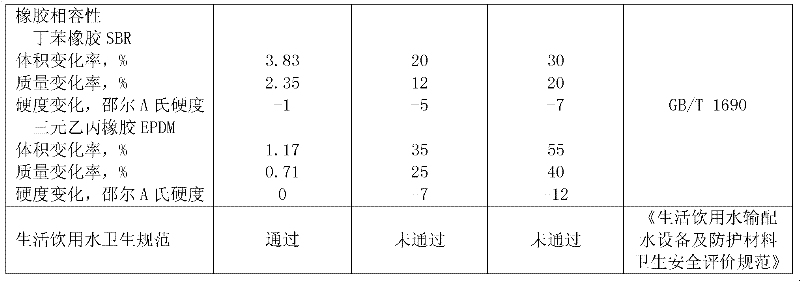

[0039] Add 104 grams of stearic acid and 76 grams of benzoic acid to 580 grams of viscosity to be 1000mm 2 / s food-grade synthetic oil, heat to 80°C, add 74.6 grams of aluminum isopropoxide, rise to 90°C, react for 2 hours, continue to heat to 110°C, add 5.7 grams of tap water, keep the temperature for 1 hour, and continue to heat up the material To 180 DEG C, keep the temperature for 40 minutes, add 320 grams of food-grade synthetic oil for rapid cooling, when the temperature drops below 130 DEG C, add 120 grams of polytetrafluoroethylene micropowder, and carry out aftertreatment after stirring to obtain the finished product fat. The lubricating grease performance that process formula of the present invention makes is listed in the following table:

[0040]

[0041] It can be seen from the above table that the rubber compatibility, high and low temperature performance and water resistance performance of the lubricating grease of the present invention are all very good.

...

example 3

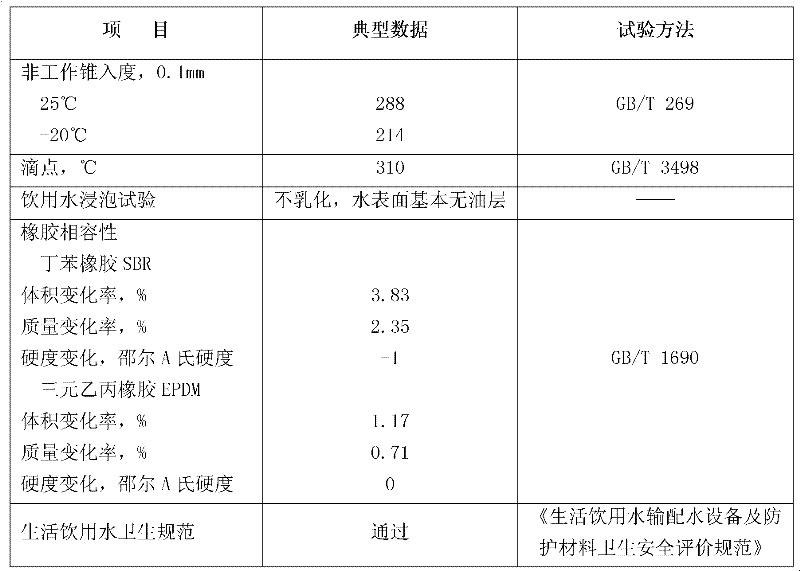

[0051] Add 284 grams of stearic acid and 122 grams of benzoic acid to 1710 grams and the viscosity is 10mm 2 / s food-grade mineral oil, heat to 100°C, add 245 grams of aluminum isopropoxide, rise to 100°C, react for 1 hour, continue heating to 140°C, add 65 grams of tap water, keep the temperature for 2 hours, and continue to heat up the material To 170 DEG C, keep the temperature for 60 minutes, add 1130 grams of food-grade mineral oil for rapid cooling, when the temperature drops below 140 DEG C, add 812 grams of polytetrafluoroethylene micropowder, carry out aftertreatment after stirring to obtain the finished product fat. The lubricating grease performance that process formula of the present invention makes is listed in the following table:

[0052]

[0053] It can be seen from the above table that the rubber compatibility, high and low temperature performance and water resistance performance of the lubricating grease of the present invention are all very good.

[0054] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com