Pocket type dust removal device

A bag-type dust removal and lifting device technology, which is used in transportation and packaging, dispersed particle filtration, membrane filters, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

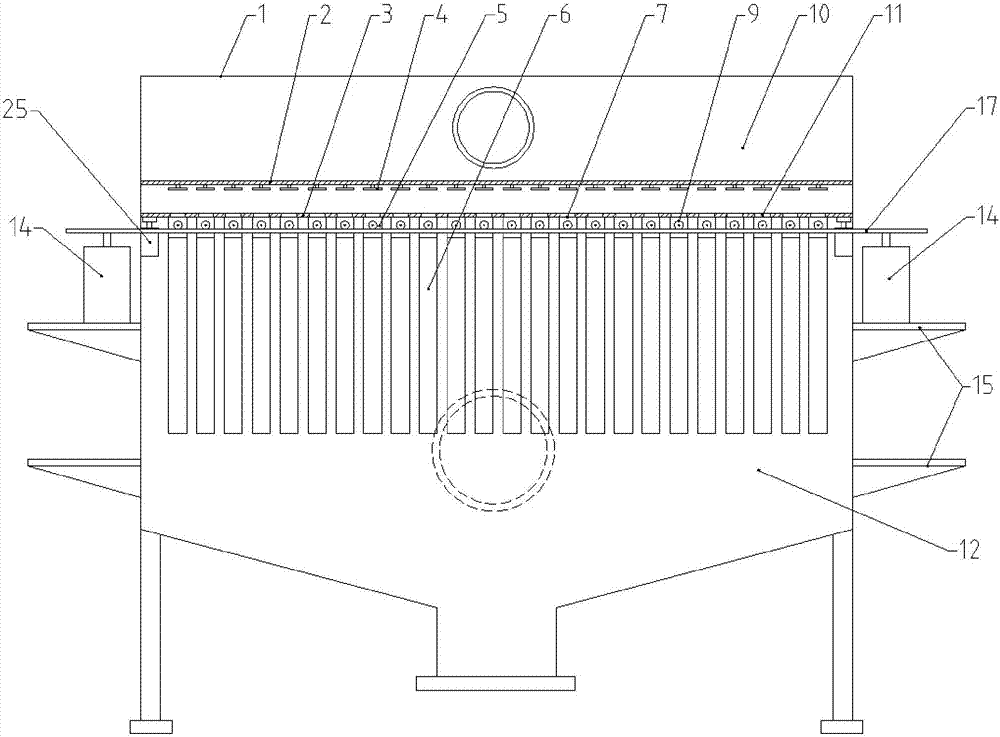

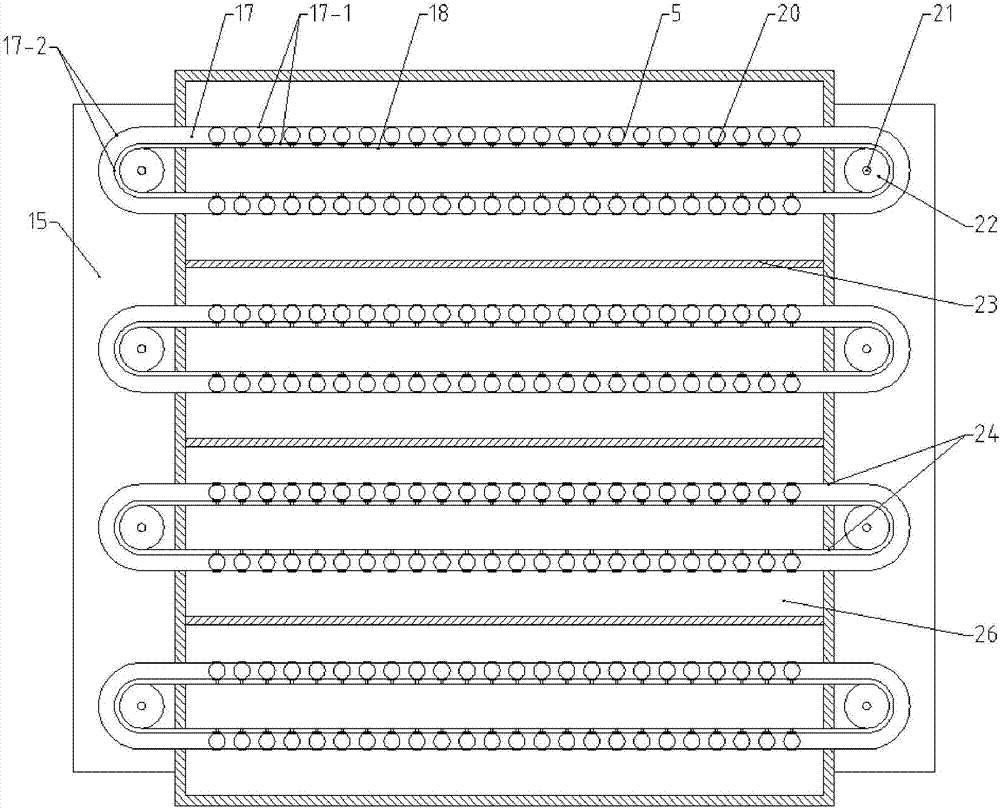

[0029] A bag-type dedusting device, comprising a housing 1, a flower plate 3 arranged inside the housing 1, and a plurality of bag cages 5 with filter bags 6 set therein, an air outlet 7 is opened at the upper end of the bag cage 5, and the flower plate 3 will The interior of the shell is divided into an upper clean air chamber 11 and a lower filter chamber 12. It is characterized in that: in the shell 1, a plurality of elliptical circular guide rails 17 are horizontally arranged below the flower plate 3, and the two ends of the long axis of the circular guide rails 17 are respectively Stretch out housing 1, be provided with the bag cage outlet 24 that is provided with for bag cage 5 on the casing 1, ring-shaped driving chain 18 is arranged on the inner side of ring guide rail 17, and the inner and outer sides of bag cage 5 top are respectively provided with ring guide rail 17 cooperation. The inner side of the bag cage 5 is provided with a connecting piece 20 connecting the dr...

Embodiment 2

[0033] This embodiment is improved on the basis of Embodiment 1:

[0034] The circular guide rail 17 includes a linear guide rail 17-1 and an arc guide rail 17-2 at both ends of the linear guide rail 17-1. The linear guide rail 17-1 is installed horizontally inside the housing 1, and the two ends of the linear guide rail 17-1 protrude from the housing 1. The arc-shaped guide rail 17-2 is arranged outside the housing 1, and the motor 14 is arranged at the arc-shaped guide rail 17-2.

[0035] The advantages of the above improvements are: the circular guide rail is composed of a linear guide rail and an arc guide rail. Compared with the oval guide rail, it occupies a smaller area, and the bag cage is more stable when moving on the guide rail. The motor is arranged outside the shell. In order to prevent the dust inside the dust removal device from affecting the normal operation of the motor.

Embodiment 3

[0037] This embodiment is improved on the basis of the above embodiments:

[0038] A baffle frame 2 fixed on the inner wall of the housing 1 is arranged horizontally above the flower plate 3, and a plurality of circular baffle plates 4 are arranged on the lower surface of the baffle frame 2, and the baffle plates 4 are directly opposite to the air holes 11 below. Rubber sealing rings are provided on the upper and lower surfaces of the plate 3 at the air hole 11 .

[0039] The advantages of the above improvements are: a baffle frame with a baffle is set above the flower plate. When the flower plate rises, the baffle on the baffle frame just covers the vent hole on the flower plate, so as to prevent the dust-containing gas in the filter chamber from entering. In the clean air chamber, the rubber sealing ring can be squeezed and deformed when the flower plate is in contact with the bag cage and baffle, thereby sealing the contact surface and preventing the dust-laden gas from esc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com