Water-proof sealing cover

A waterproof sealing and sealing sleeve technology, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of poor sealing effect, tension on one side of the rubber, and reduced rubber use effect, so as to achieve good waterproof effect, good sealing effect, Good sealing and waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

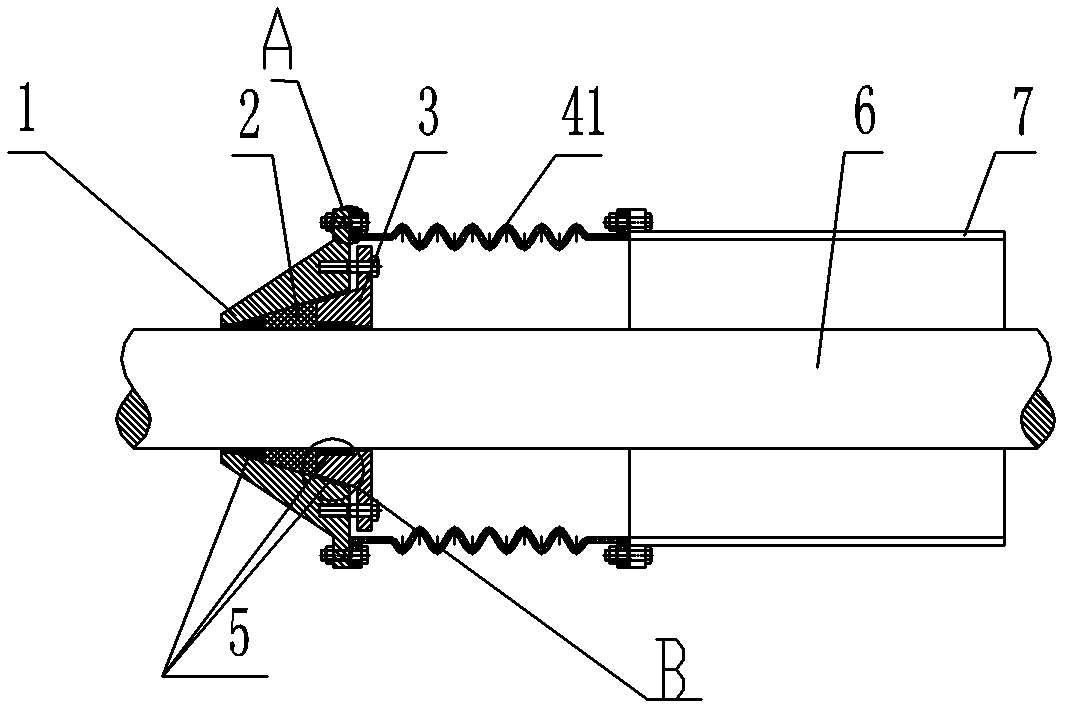

[0040] A cylindrical integral waterproof sealing cover, such as Picture 1-1 As shown, the waterproof sealing cover includes a fixed sleeve 1 of a separate structure, a sealing rubber 2, a compression ring 3 and a cylindrical integral corrugated sealing sleeve 41;

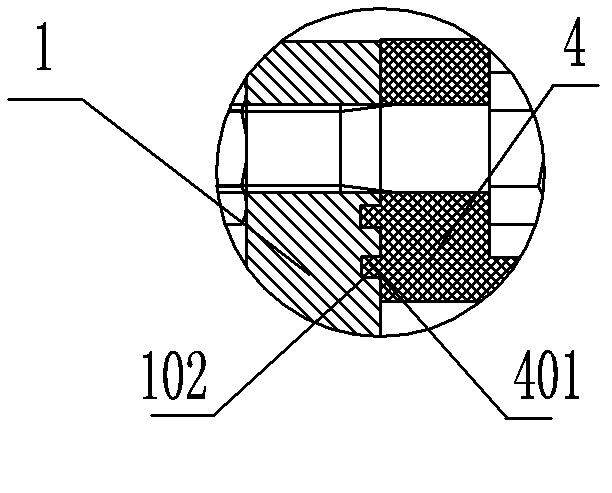

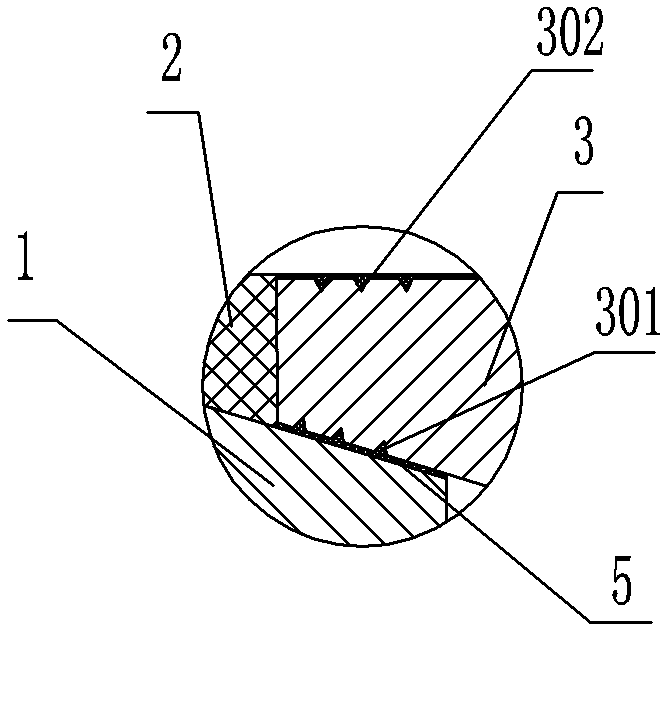

[0041] The fixed sleeve 1 is a truncated cone with an inner tapered hole (see Figure 2-1 to Figure 2-3 ), the sealing rubber 2 is a truncated cone with an inner hole (see Figure 3-1~Figure 3-2 , the taper of the inner tapered hole of the fixed sleeve 1 cooperates with the outer tapered surface of the frustum-shaped sealing rubber 2;

[0042] The compression ring 3 is composed of a cone and a flange as a whole (see Figure 4-1~Figure 4-2 ), there are 1 to 5 sealing grooves 301, 302 ( Figure 1-3 There are 3 sealing grooves respectively), the outer tapered surface of the cone is matched with the inner tapered surface of the fixed sleeve; bolt holes 303 are evenly distributed on the flange for the connection of th...

Embodiment 2

[0049] A cylindrical split type waterproof sealing cover, such as Figure 6 As shown, the basic structure of the waterproof sealing cover is the same as the first embodiment, the difference is that: the fixed sleeve 1, the sealing rubber 2, the compression ring 3, and the corrugated sealing sleeve are all two-half structures, and the corrugated sealing The sleeve 42 is a cylindrical bellows with a two-half structure, and side wings 402 are provided on both sides of each half of the corrugated sealing sleeve 42 body, and screw holes 403 for connecting the two halves of the body are provided on the side wings; Stainless steel plates 8 are provided on both sides and end faces of the body of the half corrugated sealing sleeve 42, and the two cylindrical split type corrugated sealing sleeves 42 are either straight or concave-convex at the two halves of the butt joint (see Figure 5-1~Figure 5-2 , Figure 6 ), Figure 5-1~Figure 5-2 Only planar butt joints are drawn in .

[0050]...

Embodiment 3

[0052] A kind of cone integral waterproof sealing cover, such as Figure 7 As shown, the basic structure of the waterproof sealing cover is the same as that of the first embodiment, the difference is that the corrugated sealing cover of the waterproof sealing cover is a cone-shaped integral structure, and the cone tube is pre-installed according to the size of the anchor head during construction. The integral corrugated sealing sleeve 43 is set on the cable body and fixed at the position to be installed; after the tensioning of the cable is completed, the position to be installed is determined, and the fixing sleeve 1 is installed first, then the sealing rubber is installed, and the sealing medium is filled, and then Install the compression ring so that the fixed sleeve is completely fixed on the cable body, clean up the excess sealing medium that is squeezed out, fill the gaps that still exist with sealing medium, and finally install the corrugated sealing sleeve 43 (see Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com