Efficient mounting method for waterproof plate coating-free sealant

An installation method and sealant technology, which are used in material gluing, engine sealing, protection devices, etc., can solve the problems of cumbersome operation, heavy workload, low installation efficiency, etc., to improve installation efficiency, ease obstacles, and speed up air convection. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

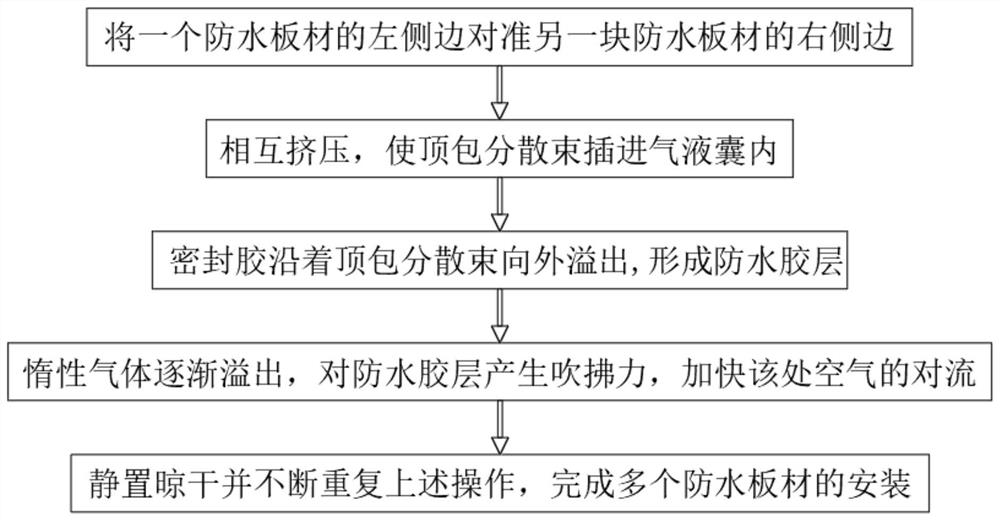

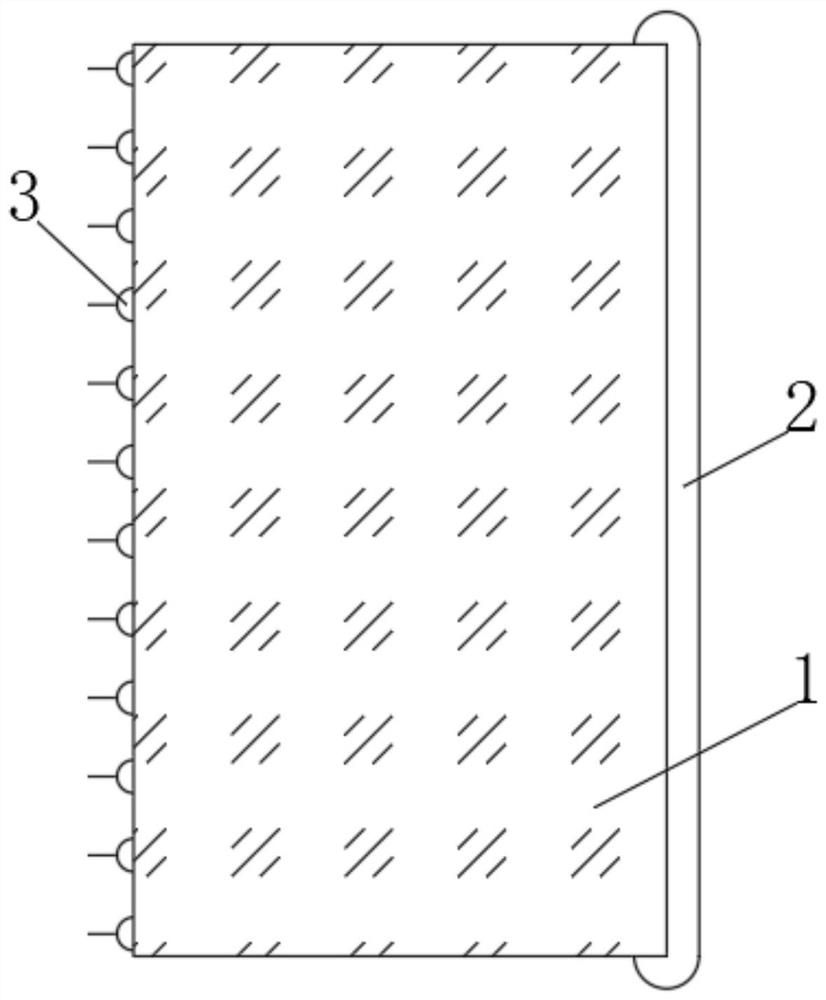

[0043]Seefigure 1 , An efficient installation method for waterproof board without applying sealant, including the following steps:

[0044]S1. First align two waterproof boards 1 side by side, and then align the left side of one waterproof board 1 with the right side of the other waterproof board 1;

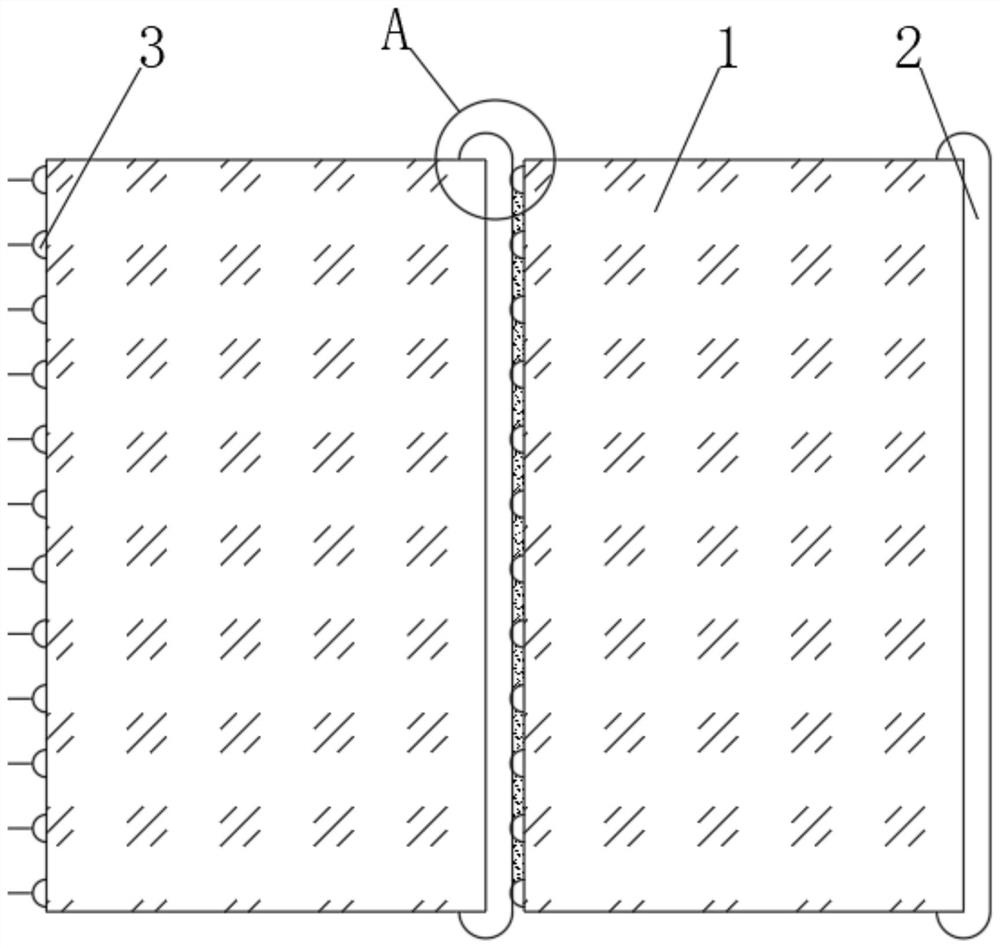

[0045]S2, squeeze the two to the middle, so that the top bag dispersion bundle 3 at the contact point of the two waterproof plates 1 is inserted into the air inlet liquid bag 2;

[0046]S31, seeimage 3 , The sealant in the gas-liquid sac 2 overflows along the top bag dispersion bundles, thereby filling and filling the gap between two adjacent top bag dispersion bundles 3, forming a waterproof glue layer;

[0047]S32. Along the top bag dispersion beam, the inert gas in the gas-liquid bag 2 gradually overflows, generating blowing force on the waterproof glue layer between the two top bag dispersion beams 3, and accelerating the convection of air there;

[0048]S4. After standing for a period of time, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com