Method for preparing soluble dietary fibers of bean dregs

A dietary fiber and soluble technology, which is applied in the field of food processing, can solve the problems of low yield and high cost of soluble dietary fiber, and achieve the effect of improving sensory quality, low strength, and increasing yield

Active Publication Date: 2013-04-03

迟玉杰

View PDF7 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The technical problem solved by the present invention: solves the problem of comprehensive utilization of bean dregs, a by-product of soybean processing, and also solves the problem of low yield and high cost of soluble dietary fiber from bean dregs prepared by the prior art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a method for preparing soluble dietary fibers of bean dregs, which solves the problems of low yield and high cost of the soluble dietary fibers of the bean dregs in the prior art. According to the method, mechanical, chemical and enzyme methods are creatively combined, so compared with the conventional single or two-method combined preparation method, the method has the advantages of high product yield, high quality and low cost; the sequence is a continuous operating process, and the three kinds of treatment is sequential and synergetic; and the method has the greatest significance that the yield and the quality of the soluble dietary fibers in the bean dregs are improved, and the yield is improved by 42 to 43.8 percent. The method is simple, easy to operate and short in period, and does not require complex equipment. In the double-screw extrusion process, the conventional thought of high-temperature extrusion is broken, and an extrusion mode of low temperature and high shear is utilized; and cellulose, xylanase and pectinase are creatively combined and used in a specific ratio and used for preparing the soluble dietary fibers of the bean dregs together to achieve a good effect.

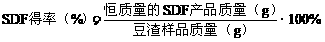

Description

technical field [0001] The invention provides a method for preparing soybean dregs soluble dietary fiber, relates to a soybean dietary fiber processing technology, and belongs to the technical field of food processing. Background technique [0002] As a functional food base material, dietary fiber is widely used in the food industry and has become the seventh largest nutrient after sugar, protein, fat, water, minerals and vitamins. According to the different solubility of dietary fiber, it can be divided into soluble dietary fiber (soluble dietary fiber, SDF) and insoluble dietary fiber (insoluble dietary fiber, IDF). Cellulose, lignin. Many studies have shown that SDF has stronger physiological functions than IDF in many aspects, and its application range is wider than IDF. However, most of the dietary fiber from natural sources is IDF, and the content of SDF is relatively low. Therefore, it is particularly important to increase the content of SDF in natural dietary fiber...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A23L1/308

Inventor 迟玉杰迟媛胥伟景言

Owner 迟玉杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com