Corn ear fast air drying machine and method

A corn ear and air dryer technology, which is applied in dryers, local stirring dryers, and static material dryers, etc., can solve the problems of unsustainable breeding and scientific research work, drying of unfertile seeds, and inability to mix different seeds. To achieve the effect of easy adjustment and control, good seed activity and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

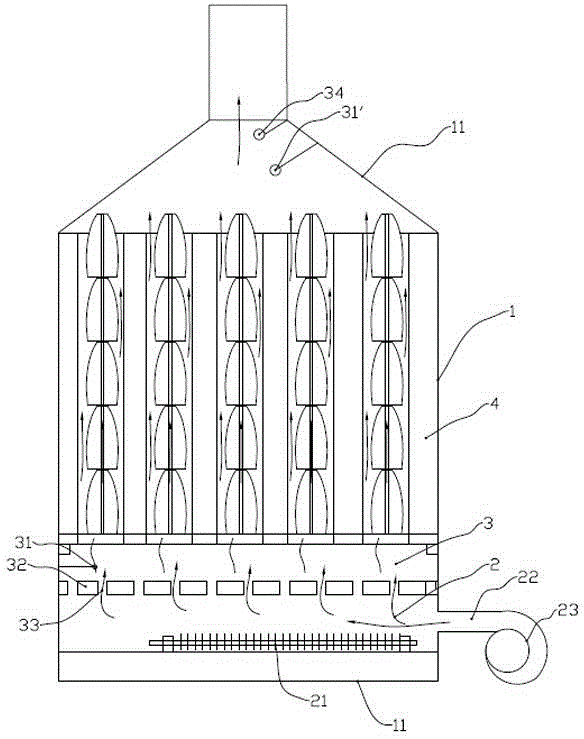

[0042] For corn breeding needs, enterprises above the medium breeding scale generally have about 20,000 breeding combinations in a single season, and will produce 24,000 new seeds, with about 3-5 ears per seed. The number is quite large.

[0043] In order to speed up the pace of maize breeding, Hainan is used for supplementary breeding in areas north of Guangxi in my country. Due to the climate characteristics of Hainan, it is generally advisable to sow around the end of September, and late sowing will cause a decrease in seed setting rate due to high temperatures in the later period. Therefore, after harvesting corn in the northern region, it should be dried as soon as possible and then tested for planting, so that it can be added to Hainan. Corn in the north (especially in the Huanghuaihai region) has a high moisture content (about 30-35%) when harvested, and the weather is not easy to dry and mildew is prone to occur, which will cause the seeds to lose their vitality. If i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com