Biomass fuel based on sludge, straw and raw coal, preparation method of biomass fuel and application of fuel slag

A biomass fuel and sludge technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of reducing release, reducing, and slag can not be used as resources, and achieves the effect of rich content and convenient outdoor storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

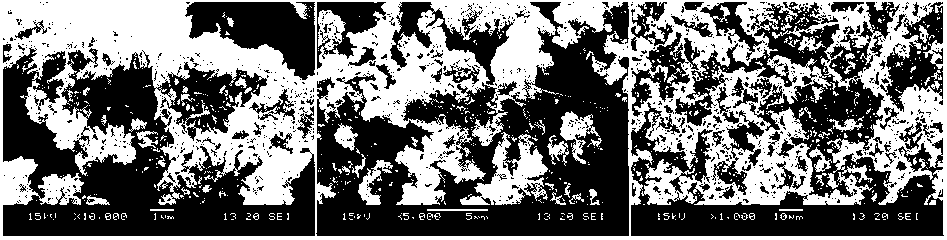

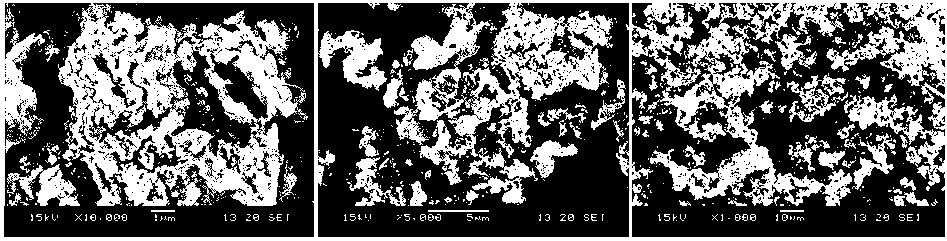

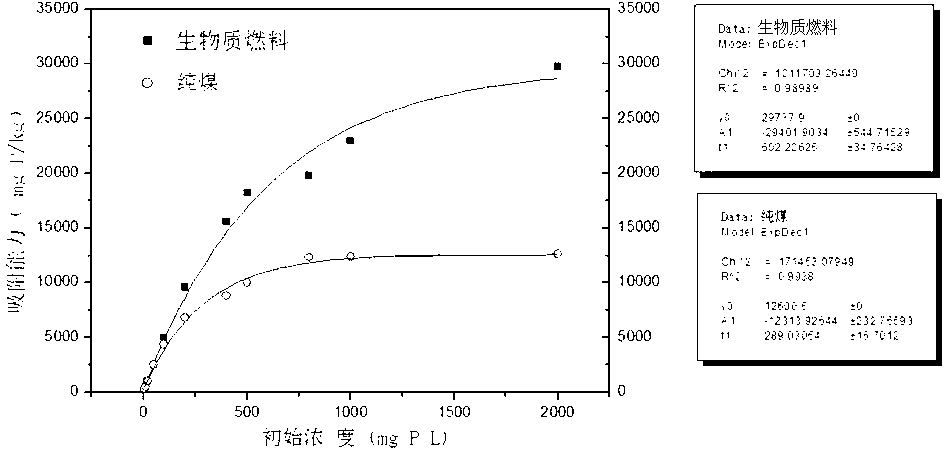

Image

Examples

Embodiment 1

[0035] (1) Raw material pretreatment: Add quicklimestone to the dewatered sludge after using aluminum salt coagulant as pretreatment. In this embodiment, the added weight of quicklimestone is 1% of the sludge weight, and the quicklimestone and The sludge is mixed evenly, and the mixing process is the pretreatment process. The aluminum oxide in the pretreated sludge is expressed as Al 2 o 3 The mass content is 7%, and the moisture content is 68%; the straw is cut and crushed into a particle size of less than 2.00cm, and the moisture content of the straw is 57% for later use. The straw in this embodiment is corn stalk, and the corn stalk material contains a certain amount of fiber Lignin and lignin, lignin is a structural monomer in the material, which can strengthen the cell wall and bind cellulose; and prepare raw coal with a calorific value of not less than 25,000 kJ / kg;

[0036] (2) Aerobic composting dehydration: According to the mass ratio of sludge, straw, and raw coal o...

Embodiment 2

[0049] (1) Raw material pretreatment: Add quicklimestone to the dewatered sludge after the application of aluminum salt coagulant as pretreatment. In this embodiment, the added weight of quicklimestone is 3% of the sludge weight, and the quicklimestone and The sludge is mixed evenly, and the oxides of aluminum in the pretreated sludge are represented by Al 2 o 3 The mass content is 6%, and the moisture content is 65%; the straw is cut and crushed into a particle size of less than 2.00cm, and the moisture content of the straw is 58% for later use. The straw in this embodiment is corn stalk, which contains certain fiber Lignin and lignin, lignin is a structural monomer in the material, which can strengthen the cell wall and bind cellulose; and prepare raw coal with a calorific value of not less than 25,000 kJ / kg;

[0050] (2) Aerobic composting dehydration: According to the mass ratio of sludge, straw, and raw coal of 1:1:3, weigh the sludge, straw, and raw coal in step (1), an...

Embodiment 3

[0064] Example 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com