Preparation method for Ti<3>C<2>Mxene/polymer composite wave-absorbing material

A composite wave absorbing material and polymer technology, applied in the field of chemical materials, can solve the problems of poor mechanical properties, high density and difficult adhesion of MXene, and achieve the effects of adjustable dielectric constant, thin thickness and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] This embodiment provides a Ti 3 C 2 The preparation method of MXene / polymer composite wave-absorbing material comprises the steps:

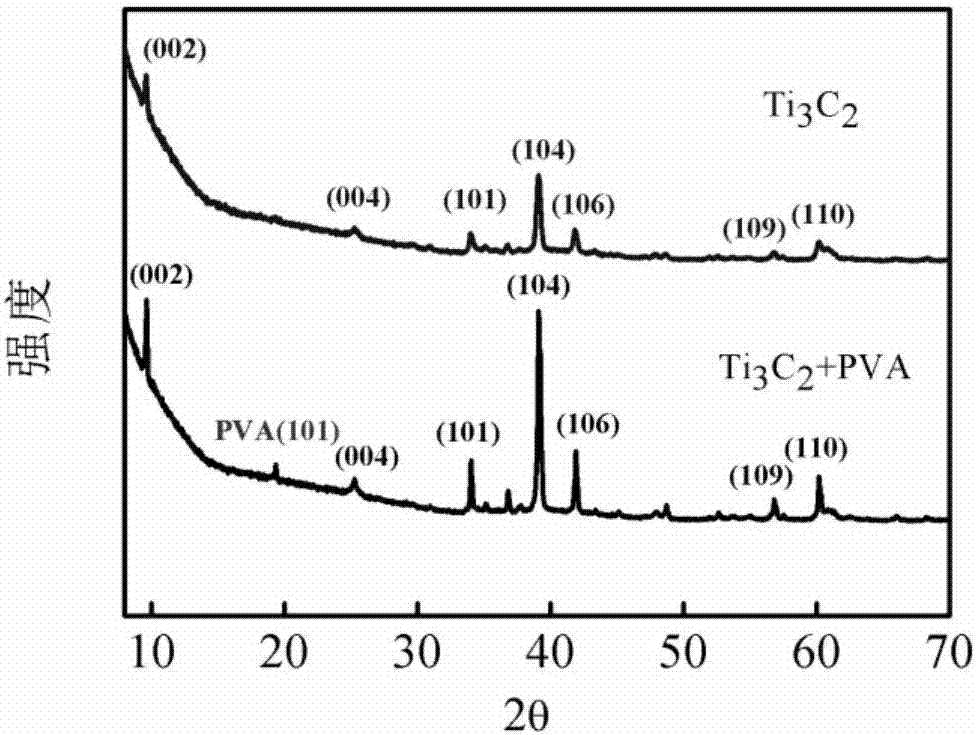

[0022] First: Ti 3 C 2 Preparation of MXenes

[0023] 1) Weigh 1g Ti of MAX phase 3 AlC 2 , and dissolve it in HF with a concentration of 50%, and react for 18-24h under stirring;

[0024] 2) Filter the reaction solution of the above step 1), wash the solid with a large amount of water, and then dry it at 40-60 degrees to obtain Ti 3 C 2 MXene powder.

[0025] Then: Ti 3 C 2 Preparation of MXene / polymer films

[0026] 1) Weigh 1g Ti 3 C 2 MXene powder is dissolved in dimethyl sulfoxide solution, ultrasonicated at 100w-300w for 15-30min;

[0027] 2) the Ti in the above step 1) 3 C 2 The MXene solution is mixed with the polymer and stirred for 1-2h; wherein, the polymer includes PVA, PMMA, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com