Patents

Literature

96results about How to "Adjustable dielectric constant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

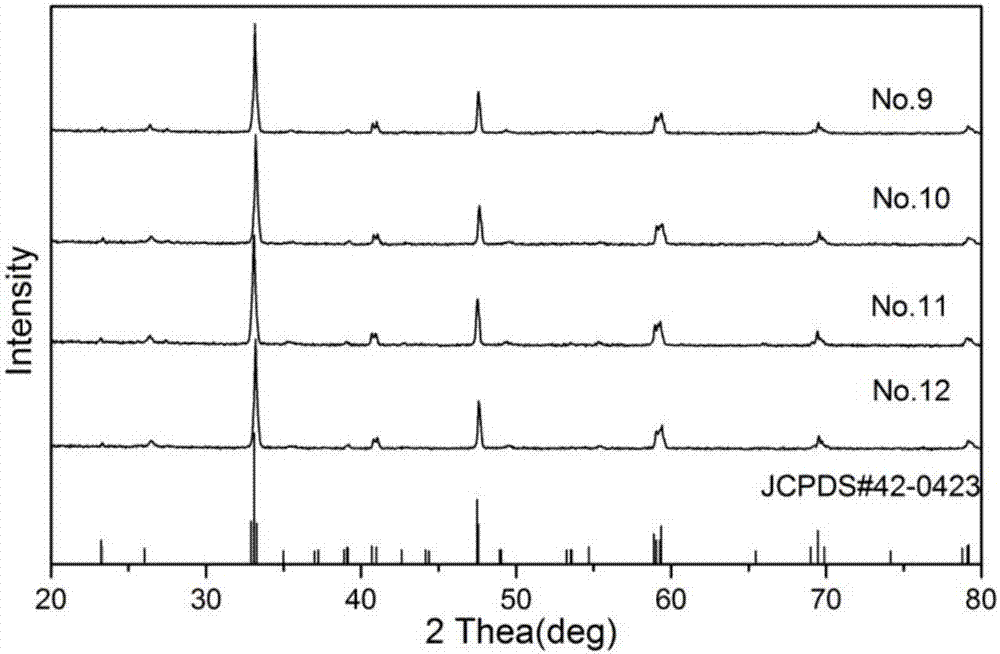

Low-loss microwave dielectric ceramic material and preparation method thereof

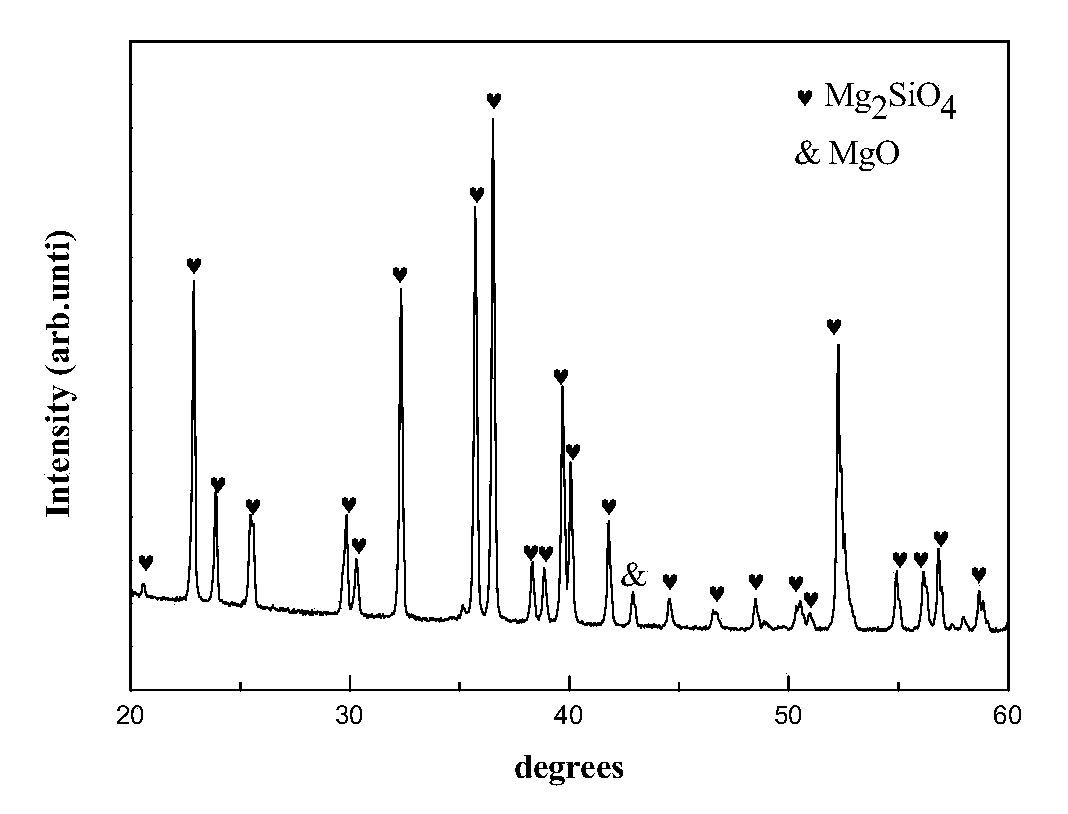

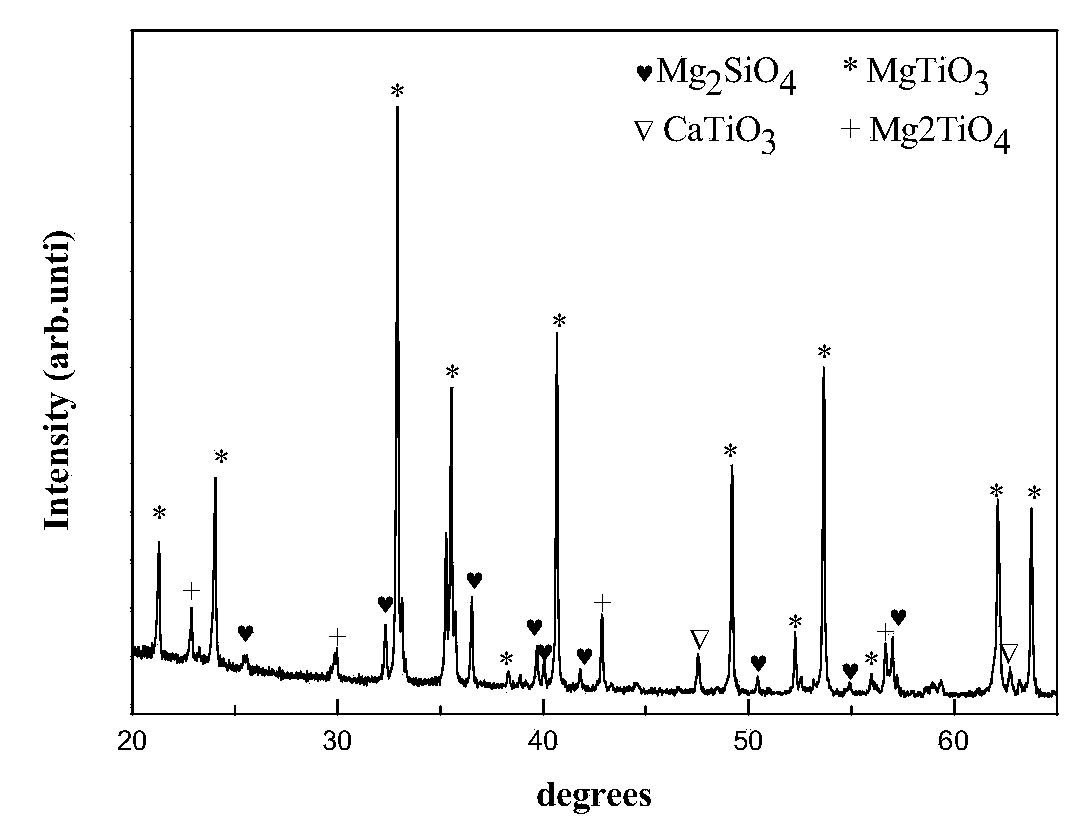

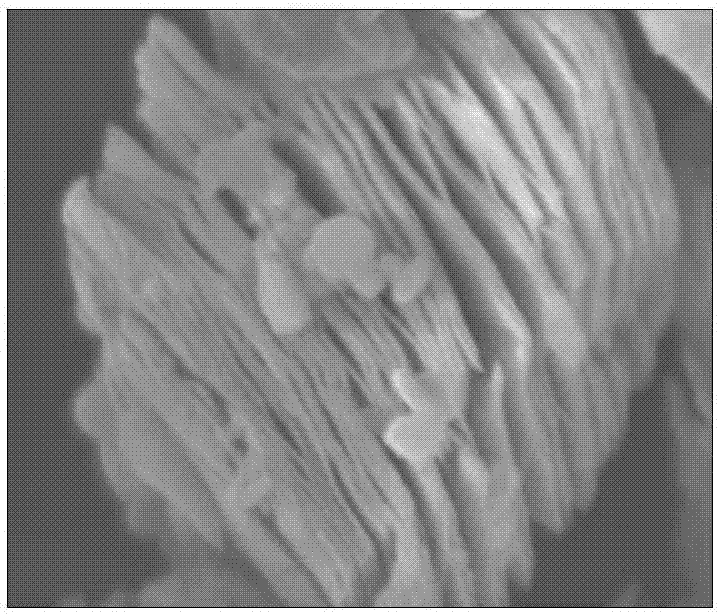

The invention relates to a low-loss microwave dielectric ceramic material and a preparation method thereof, which belongs to the technical field of an electronic information functional material and device. The low-loss microwave dielectric ceramic material comprises a main crystal phase and additives, wherein the main crystal phase comprises MgTiO3, Mg2SiO4 and CaTiO3, and the main crystal phase contains little Mg2TiO4; the additives comprise MnO2, Co2O3, CeO2 and Nb2O5; the loss of the material is detected to be low (Qxf falls in the range of 65000 to 85000GHz), the dielectric constant is adjustable (between 9 and 20), the frequency temperature coefficient is stable (within + / -10ppm / DEG C), the machinability is good, and the application requirement of a microwave communication industry can be met. The preparation method is a solid-phase sintering method and has the characteristics of simplicity, environmental friendliness and low cost, and is easy to control.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

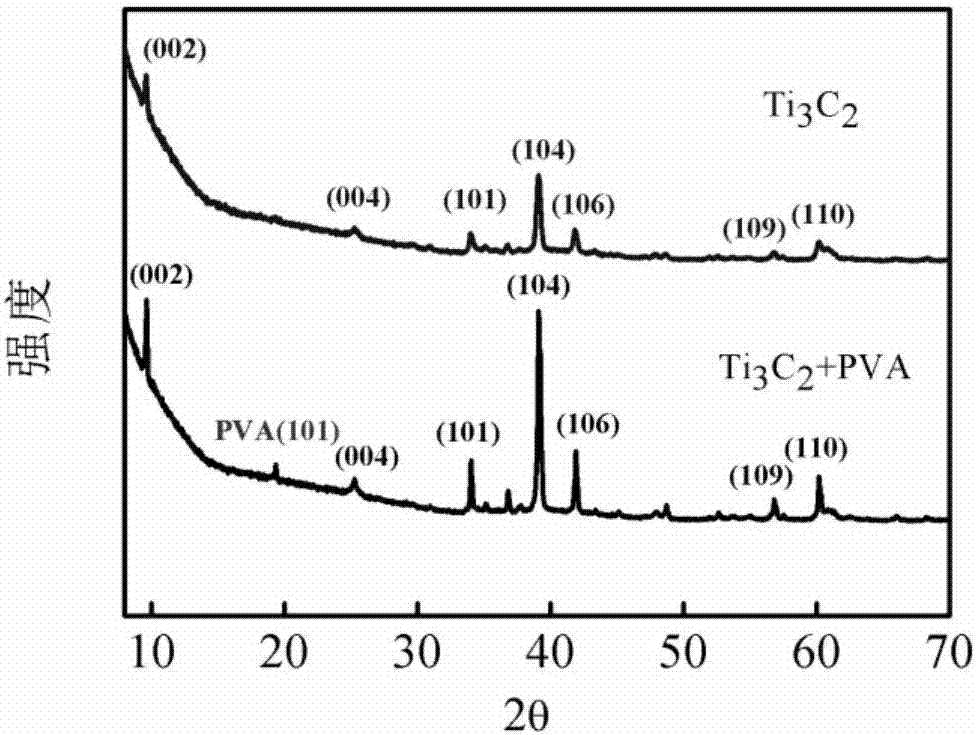

Preparation method for Ti<3>C<2>Mxene/polymer composite wave-absorbing material

InactiveCN107099054AHigh strengthQuality improvementOther chemical processesPolymer compositesLow density

The invention discloses a preparation method for a Ti<3>C<2>Mxene / polymer composite wave-absorbing material. The high-efficiency Ti<3>C<2>Mxene / polymer composite wave-absorbing material is prepared by using a solution etching method and a compounding method. The Ti<3>C<2>Mxene / polymer composite wave-absorbing material prepared in the invention has low density, high strength and an adjustable dielectric constant; and more importantly, the composite material can both absorb and reflect electromagnetic waves, so secondary pollution of electromagnetic waves to environment is reduced. The Ti<3>C<2>Mxene / polymer composite wave-absorbing material has the characteristics of light mass, thin thickness, high strength and good wave-absorbing performance and has good application prospects.

Owner:SHENZHEN UNIV

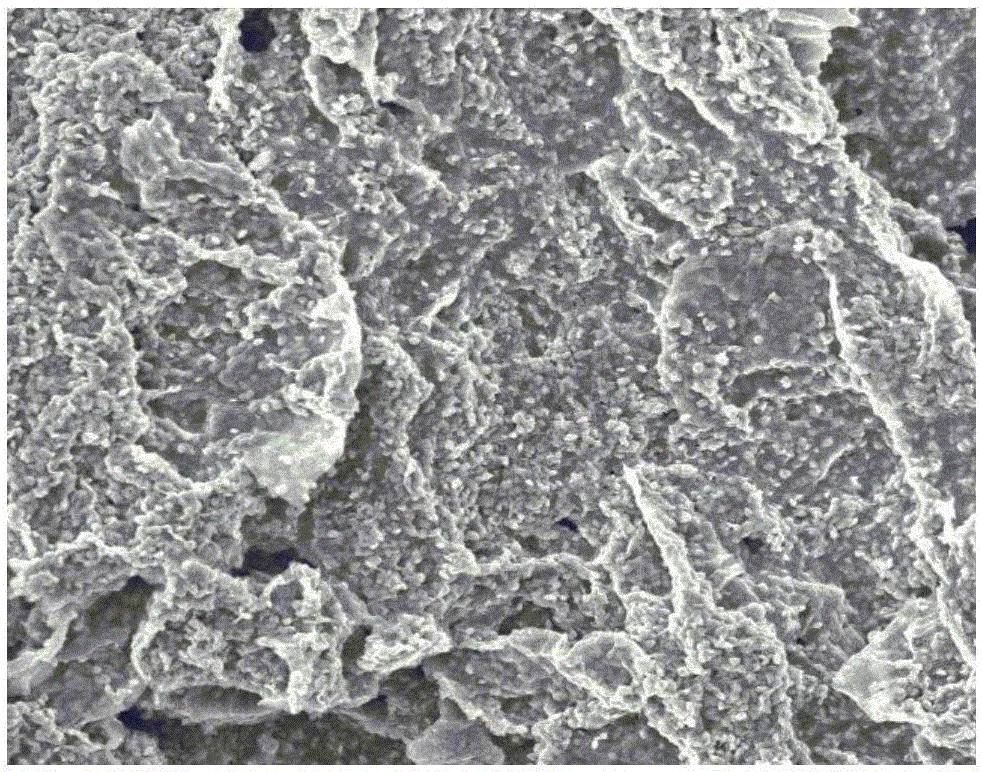

Graphene/ferroferric oxide composite wave-absorbing material and preparation method thereof

The invention is applicable to the field of wave-absorbing materials, and provides a graphene / ferroferric oxide composite wave-absorbing material and a preparation method thereof. The preparation method comprises the following steps: preparing a graphene oxide dispersion solution, a FeCl2 solution and a FeCl3 solution; mixing the three solutions, and stirring at 80-120 DEG C for 2-3 hours to obtain a graphene oxide / Fe3O4 dispersion solution; carrying out vacuum drying on the graphene oxide / Fe3O4 dispersion solution to obtain a graphene oxide / Fe3O4 aerogel; and heating the graphene oxide / Fe3O4 aerogel to obtain a graphene / Fe3O4 aerogel, and carrying out mechanical pelleting on the graphene / Fe3O4 aerogel to obtain the graphene / Fe3O4 composite material, wherein the graphene / Fe3O4 composite material is in a lamellar laminated structure. The graphene / Fe3O4 composite wave-absorbing material can absorb electromagnetic waves rather than reflect electromagnetic waves due to the electromagnetic performance matching characteristic, thereby lowering the secondary pollution of electromagnetic waves to the environment.

Owner:贵溪穿越光电科技有限公司

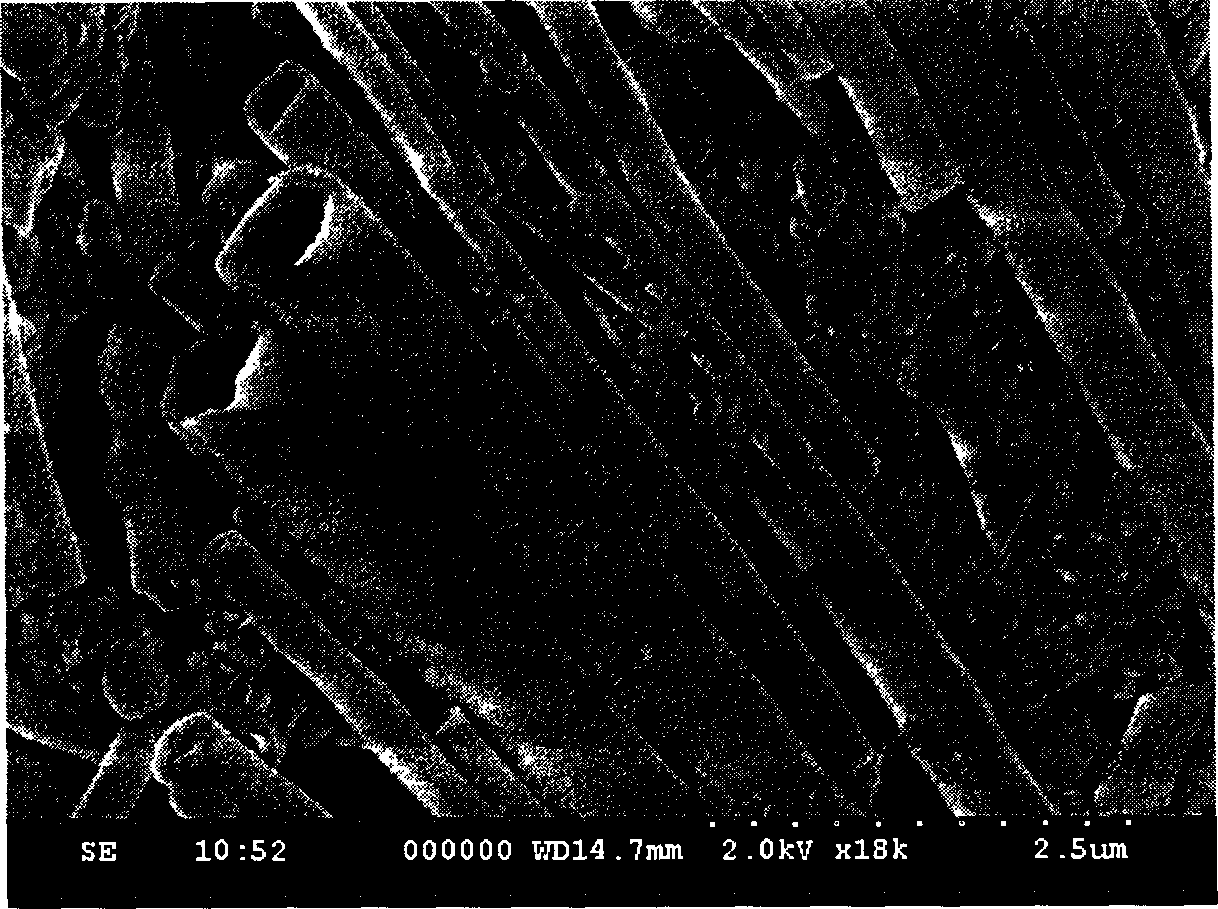

Composite wave absorbing material and preparation method thereof

ActiveCN108251054ALow densityHigh strengthOther chemical processesMagnetic/electric field screeningMXenesMaterials science

The invention relates to the field of wave absorbing materials, in particular to a composite wave absorbing material and a preparation method thereof. The composite wave absorbing material is characterized in that the surface of each of MXene layers is coated with a ferrite, and the different MXene layers and the ferrites on the surfaces of all the layers jointly form a sandwich structure. The composite wave absorbing material and the preparation method thereof provided by the invention have the benefits that MXene is prepared by adopting a chemical etching process, the ferrites prepared by adopting a hydrothermal preparation process are compounded with the MXene so as to grow in situ on the surface of MXene powder, the degree of integration between the ferrites and the MXene powder is high, and the coating is uniform and compact; the prepared MXene / ferrite composite wave absorbing material with the sandwich structure is light in density, high in strength, adjustable in dielectric constant and excellent in wave absorbing performance. In addition, the preparation method is simple, used equipment is simple, the process is stable, the production efficiency is high, the cost is reduced, the compactness and the uniformity of the material are good.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Dielectric adjustable material of ceramics burned together at low temperature, and preparation method

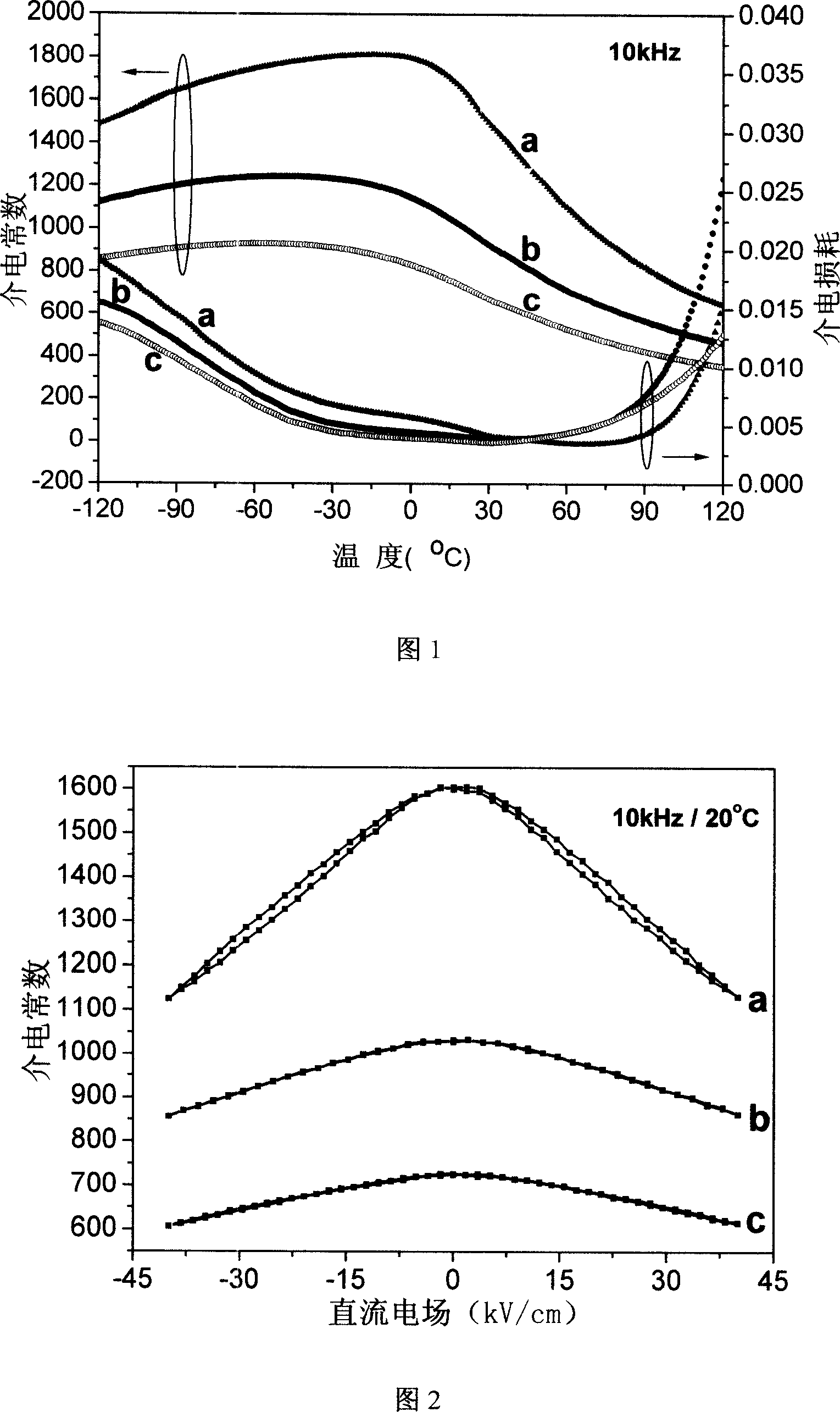

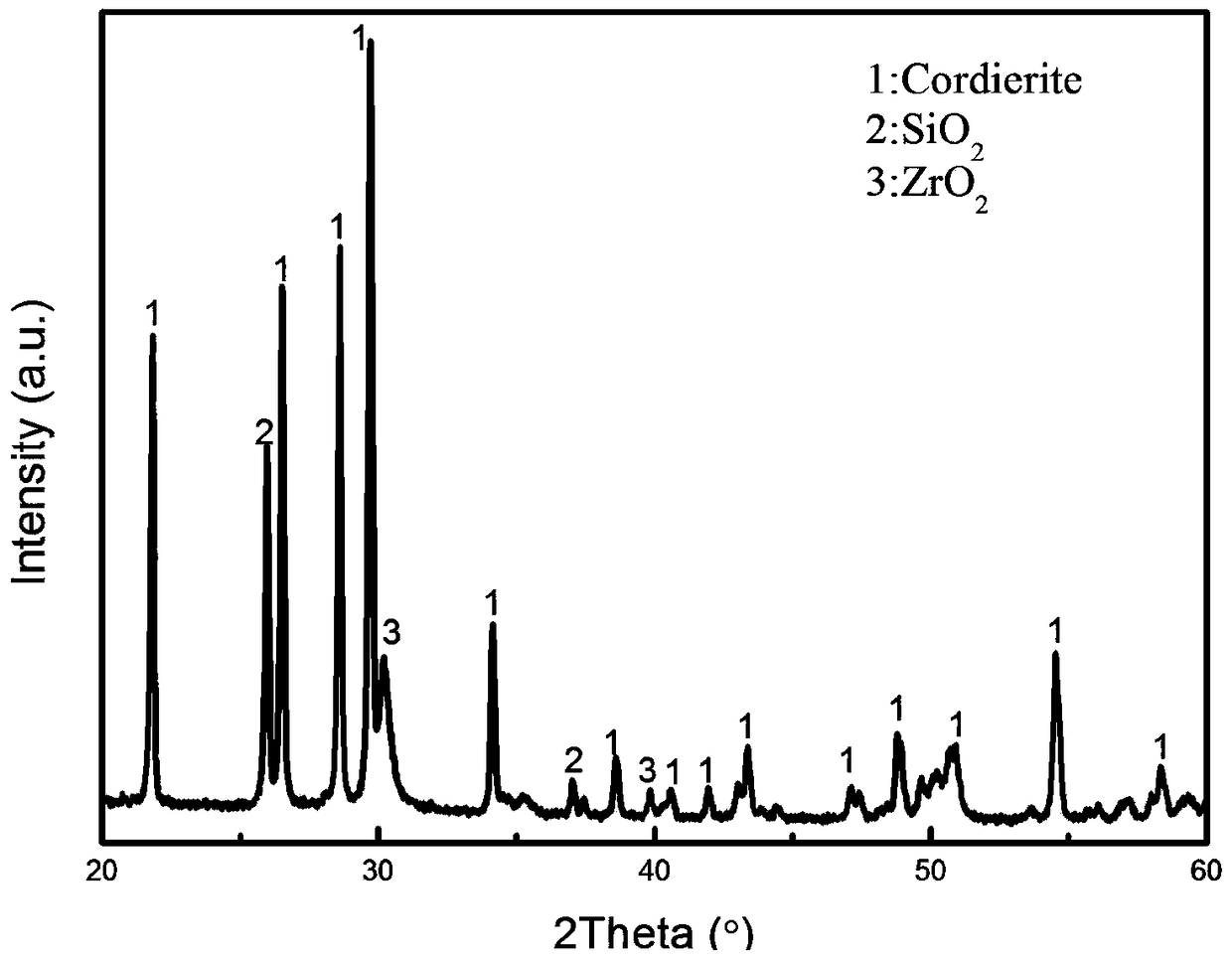

This invention relates to a method for preparing ceramic material with a sintering temperature below 950 deg.C. The ceramic material is composed of Ba1-xSrxTiO3 (x = 0.2 -0.6) 75.0-95.0 wt. %, MgO 0.15-15 wt. %, B2O3 0-1.0 wt. %, Li2CO3 3.0-10.0 wt. %. The method utilizes MgO and B2O3-Li2O sintering aid to dope and modify BST ceramic material, and the obtained ceramic material has such advantages as adjustable dielectric constant (100-2000) and low sintering temperature (850-950 deg.C). The ceramic material can be used in LTCC technique and microwave adjustable devices.

Owner:TONGJI UNIV

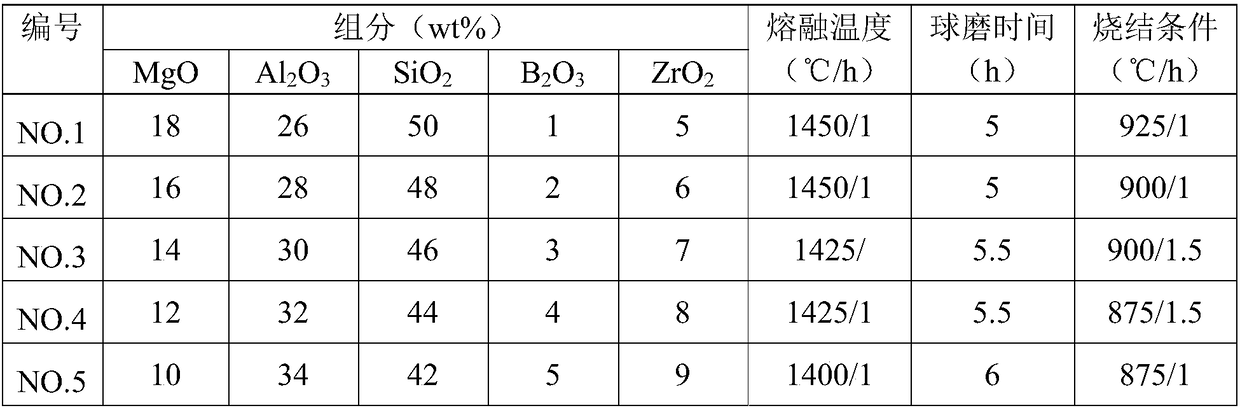

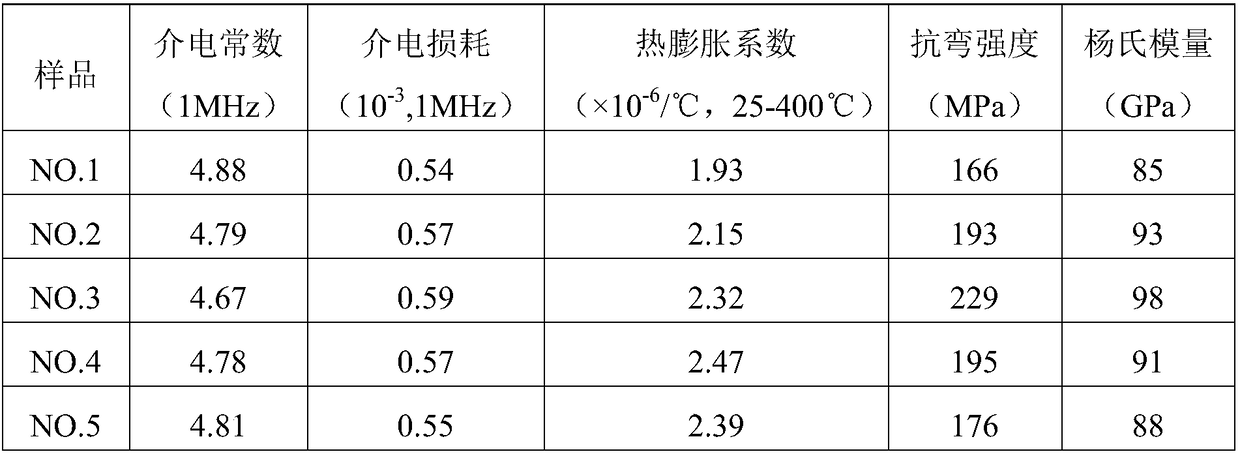

Cordierite-based microcrystalline glass material and preparation method thereof

InactiveCN108947257ARich sourcesSmall coefficient of thermal expansionFlexural strengthYoung's modulus

Belonging to the field of electronic ceramic materials, the invention provides a cordierite-based microcrystalline glass material and a preparation method thereof, and overcomes the problem of poor matching with silicon chips caused by large thermal expansion coefficient, low flexural strength, high dielectric constant, high dielectric loss and the like of existing ceramic materials. The cordierite-based microcrystalline glass material provided by the invention belongs to a magnesium-aluminum-silicon system, the principal crystalline phase is cordierite, the density is high, the flexural strength is up to 230MPa, the Young's modulus is 80-100GPa high, the thermal stability is good, the thermal expansion coefficient is 1.5-2.5*10<-6> / DEG C (20-600DEG C) low, and the cordierite-based microcrystalline glass material can form good match with silicon chips. At the same time, the dielectric constant can be adjusted to 4.5-5.0, the dielectric loss is tan Delta is less than 0.6*10<-3>, the signal transmission speed is greatly improved, and the power consumption is greatly reduced. In addition, in the preparation process, the temperature is lowered from the 1100DEG C or above in the traditional sintering process to 900DEG C or below, under the premise of improving the performance, the sintering temperature is further reduced and the production cost is saved. Moreover, the whole preparation technology has the characteristics of simple process, abundant raw material sources and energy consumption reduction, thus being of important significance for industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Preparation method of silicon carbide/carbon hollow porous microsphere wave-absorbing material

ActiveCN110819302ALow reaction temperatureLow cost of scaleOther chemical processesCarbon compositesActive agent

The invention relates to the technical field of wave-absorbing materials, in particular to a preparation method of a silicon carbide / carbon hollow porous microsphere wave-absorbing material. The invention aims to solve the technical problems of large particle size and easy agglomeration of silicon carbide particles in the silicon carbide / carbon composite material prepared by the existing method. The method includes: mixing deionized water, anhydrous ethanol and ammonia water, adding a surfactant, resorcinol, a silicon source and a formaldehyde solution, stirring the substances uniformly at room temperature, then adding melamine, performing stirring, transferring the mixture into a high-temperature and high-pressure reactor for reaction, and conducting high temperature calcination; and thenperforming mixing with magnesium powder, conducting high temperature calcination in a nitrogen atmosphere, washing off redundant magnesium powder with hydrochloric acid, and carrying out washing anddrying. The silicon carbide / carbon hollow porous microsphere obtained by the method has good chemical homogeneity and large specific surface area, and can effectively avoid agglomeration and sinteringof silicon carbide particles. The material prepared by the method provided by the invention is used for making light and efficient wave-absorbing coatings.

Owner:HARBIN INST OF TECH

Hybrid film of polyimide modified by silicon dioxide tube, and preparation method

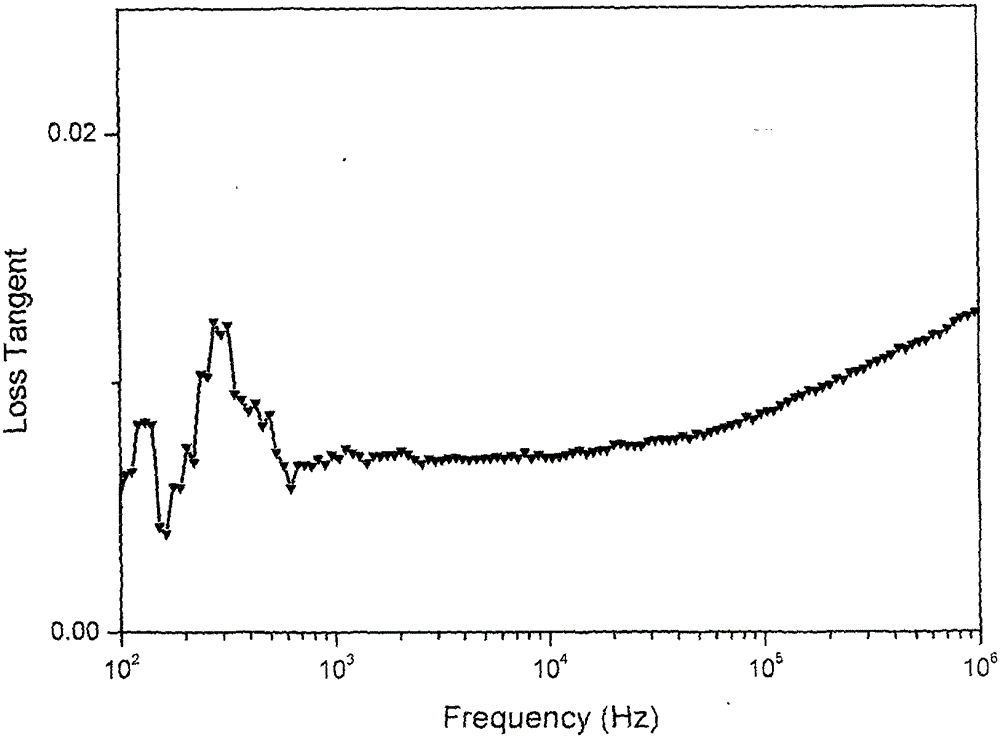

A SiO2 nanotube modified polyimide hybridized film with adjustable dielectric constant is prepared through proportionally adding SiO2 nanotubes to the solution of coupling agent, stirring while reaction, adding ODA monomer, ultrasonic dispersing, stirring while adding PMDA monomer, in-situ polymerizing reaction, coating it on glass plate, drying in the air, putting it in oven, and thermal iminating.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Low-temperature co-fired ceramic dielectric material and preparation method thereof

The invention relates to a low-temperature co-fired ceramic dielectric material and a preparation method thereof. The LTCC dielectric material comprises an oxide dielectric material having a high sintering temperature and an oxide activator, and the LTCC dielectric material concretely comprises 1-20 wt% of the oxide activator, and the balance of the oxide dielectric material having the high sintering temperature; the oxide dielectric material with the high sintering temperature is an oxide of M, wherein M is at least one of Mg, Al, Ti, Ca, Zr, Nd, MgTi, MgAl, CaTi and NdAl; and the oxide activator comprises an oxide of A and an oxide of B, A is at least one of Zn, Cu, Mn, Sn, Fe, Co and Ni, B is at least one of V, Nb, Ta, Ti and Si, and the mass of the oxide of A is 10-100% of the total mass of the oxide activator.

Owner:ZHEJIANG SIRAMIC TECH CO LTD

Low-temperature co-fired ceramic material emitting white light and preparation method thereof

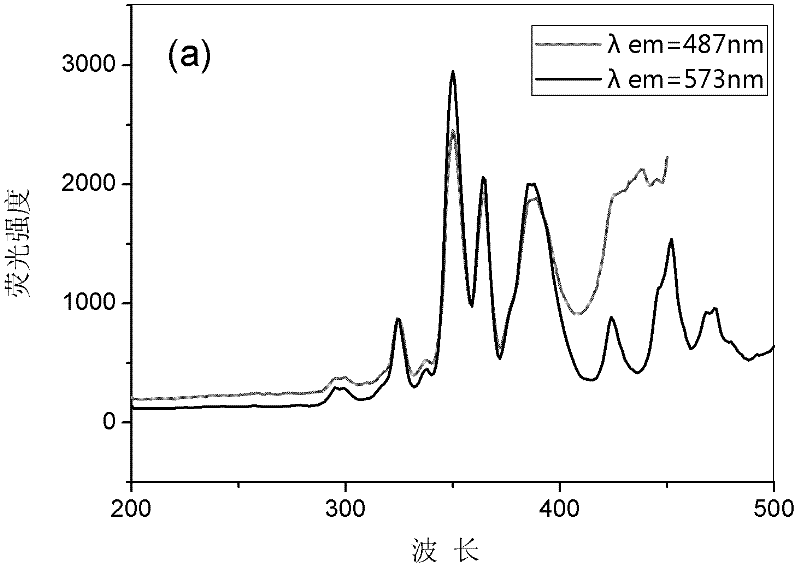

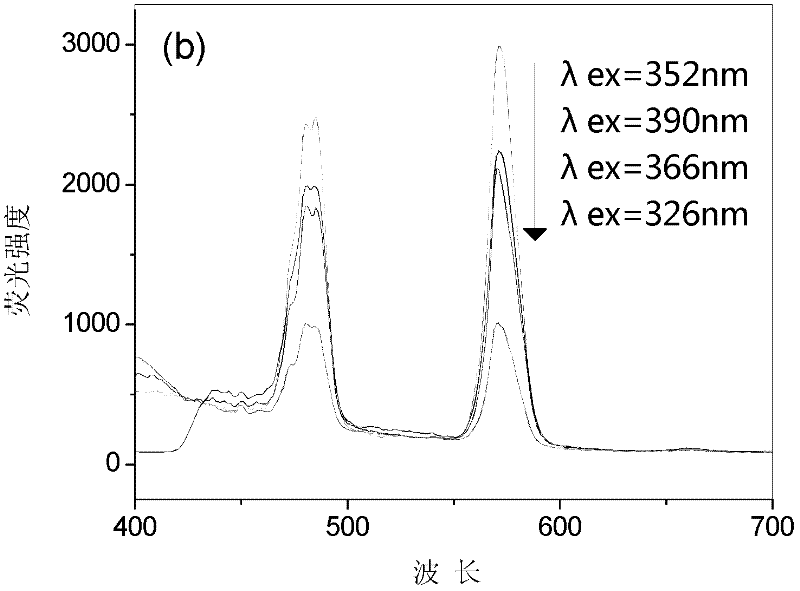

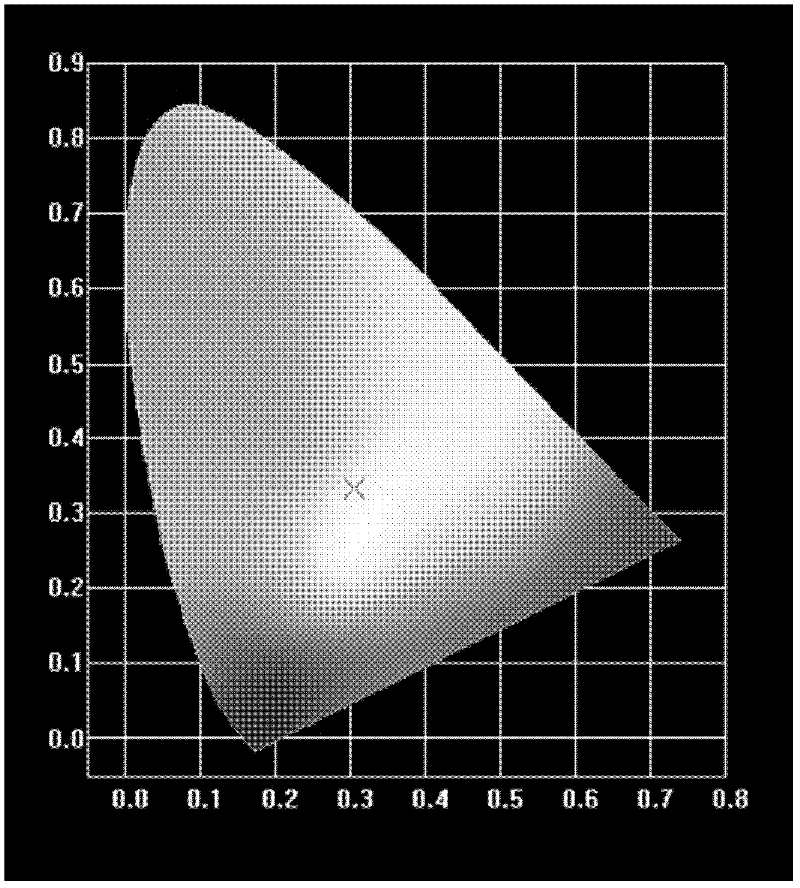

The invention provides a low-temperature co-fired ceramic material emitting white light and a preparation method thereof. The ceramic material comprises the following components in percentage by mol: 10 to 20 percent of CaO, 20 to 30 percent of B2O3, 50 to 60 percent of SiO2, and 1 to 9 percent of optical activating agent ions. The invention also relates to the preparation method of the material, namely, a sol-gel method for preparing the low-temperature co-fired ceramic material emitting white light. The invention has the advantages that: 1, the preparation process is simple and advanced, the sintering temperature is low by adopting the Sol-gel method and is between 800 DEG C and 900 DEG C, the sintering shrink rate at the temperature is controllable between 13 percent and 17 percent, and a glass ceramic material has a flat and smooth surface, as well as higher strength; 2, the dielectric constant is adjustable between 4(1MHz) and 6 (1MHz), and the coefficient of dielectric loss is lower than 0.002; 3, the light emission intensity is high, the material can emit yellow and blue light under activation of ultraviolet light with the wavelength of between 320nm and 410nm, the white light obtained by mixing the blue light and the yellow light can be used for illuminating and displaying; and 4, based on the advantages, the low-temperature co-fired ceramic material can be applied to the fields of white light LED (Light Emitting Diode) lamps, integrated ceramic substrates and other electronic devices and semiconductors, as well as microelectronic packaging materials.

Owner:UNIV OF SCI & TECH BEIJING

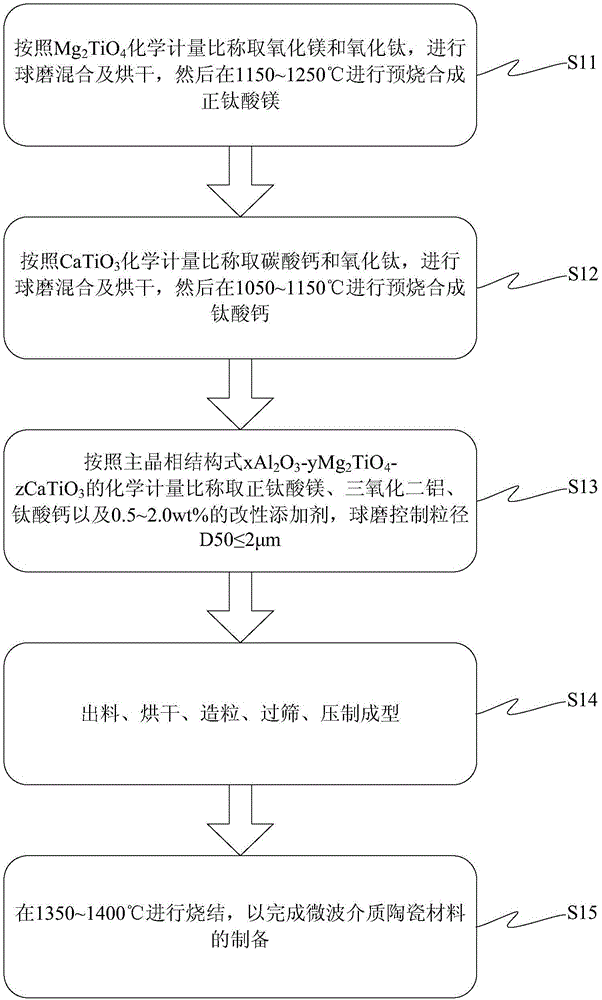

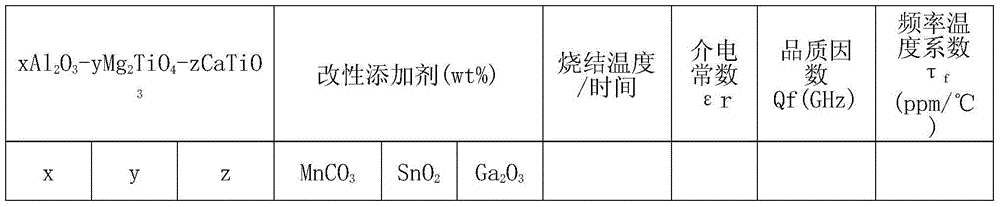

Microwave dielectric ceramic material and preparation method thereof

ActiveCN105985102ARaw materials are cheap and easy to getSimple preparation processElectricityDielectric

The invention provides a microwave dielectric ceramic material with an adjustable dielectric constant and a near-zero frequency temperature coefficient and a preparation method thereof. The microwave dielectric ceramic material includes a main crystal phase and a modification additive, and the structural formula of the main crystal phase is xAl 2 o 3 -yMg 2 TiO 4 ‑zCaTiO 3 , wherein: x+y+z=1.0, 0.2≤x≤0.6, 0.3≤y≤0.75, 0.05≤z≤0.10; the modified additive is MnCO 3 , SnO 2 , Ga 2 o 3 Any one or a mixture of two or more of them. The microwave dielectric ceramic material of the present invention has the following advantages: 1) The dielectric constant is adjustable in a wide range, and εr is adjustable from 12 to 17; 2) It has low loss: Q*f≥60000GHz; 3) Near zero frequency The temperature coefficient τf is 0±5ppm / ℃; 4) The raw materials are cheap and easy to obtain, non-toxic and environmentally friendly; 5) The preparation process is simple, no special equipment and harsh process conditions are required, it is suitable for industrial production, and can be widely used in various fields of microwave communication.

Owner:SHANGHAI LINEPRINTING MATERIALS CO LTD +1

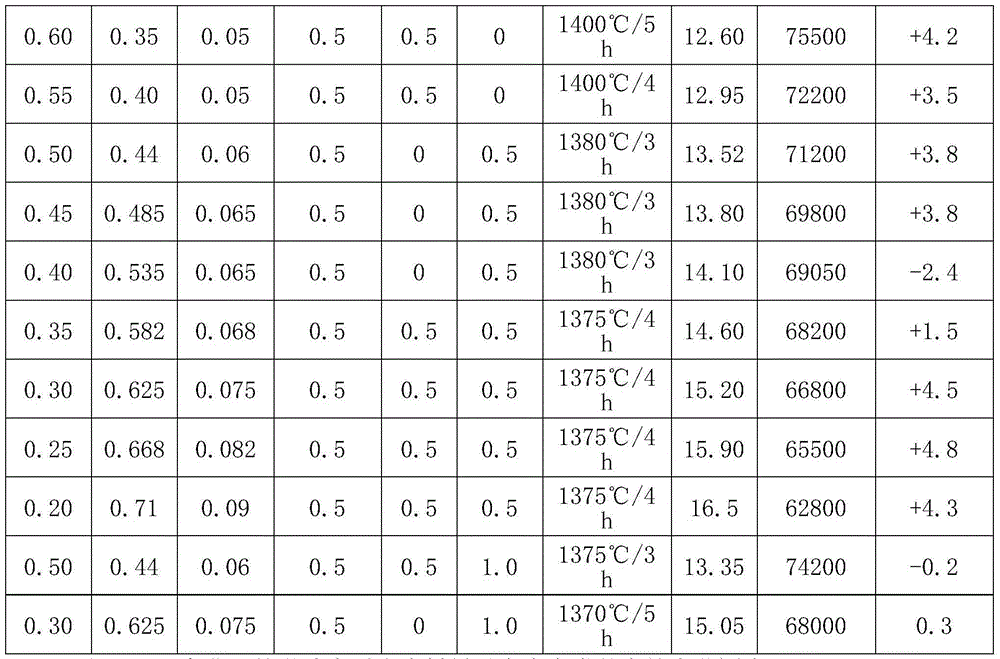

Microwave dielectric ceramics and polytetrafluoroethylene-ceramic composite substrate, and preparation methods thereof

The invention discloses microwave dielectric ceramics and a polytetrafluoroethylene-ceramic composite substrate, and preparation methods thereof, and belongs to the field of organic / inorganic composite materials. A microwave dielectric ceramic material is represented by the general formula: Na[0.5-x-y]Li[x]K[y]Sm[0.5-m-n]Nd[m]Bi[n]TiO[3], wherein 0.3<=x<=0.5, 0<=y<=0.05, 0.3<=m<=0.5, and 0<=n<=0.05. The microwave dielectric ceramics have the advantages of high dielectric constant, low dielectric loss, adjustable dielectric constant and temperature coefficient and the like.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA +1

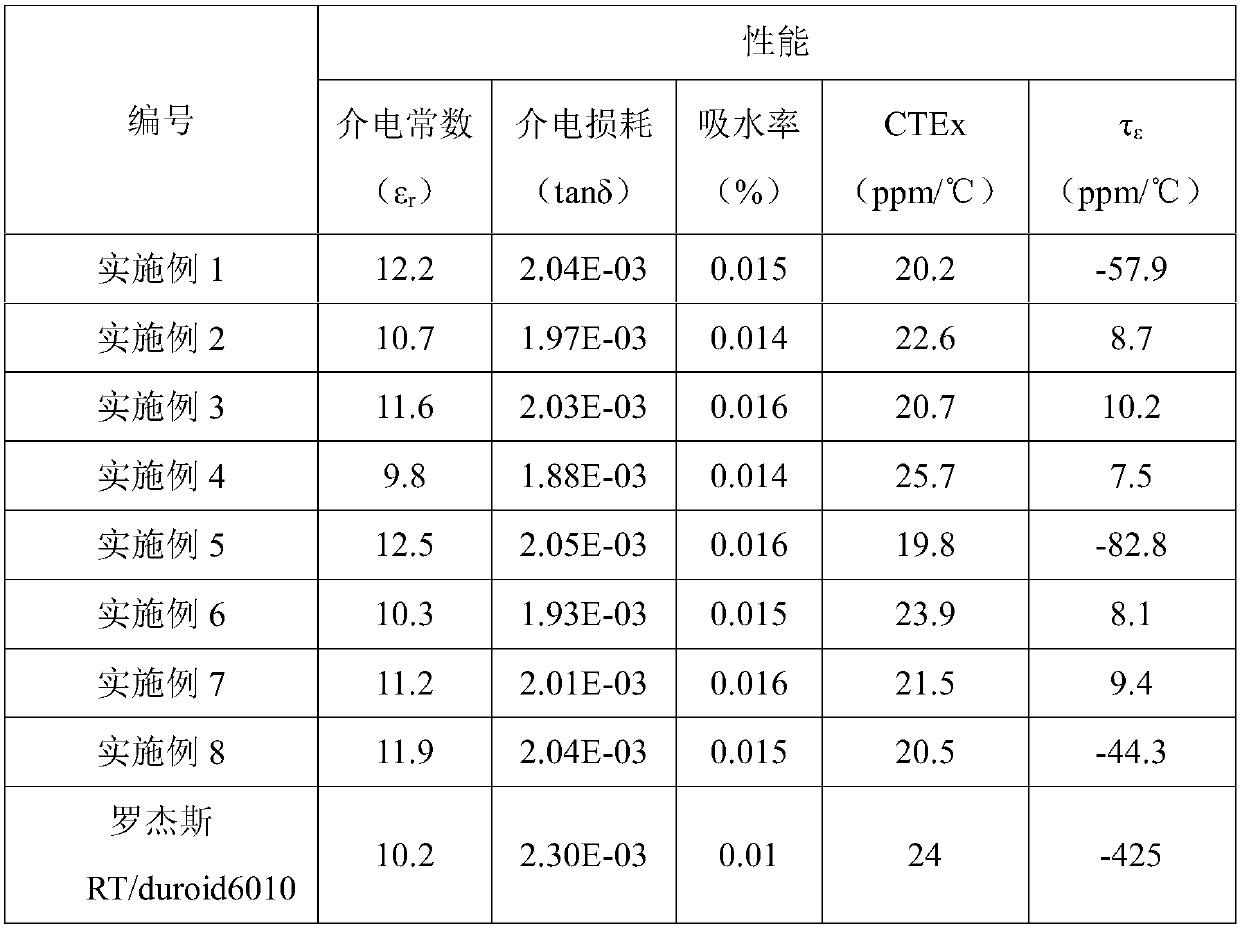

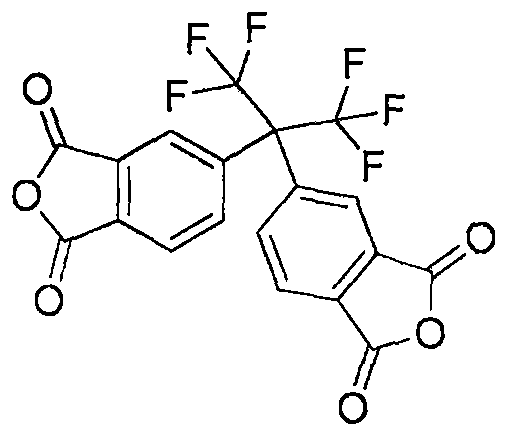

Low dielectric polyimide fiber and preparation method thereof

InactiveCN105019047AThe synthesis method is simpleExtensive sources of raw materialsMonocomponent synthetic polymer artificial filamentDiaminePolyamide

The present invention discloses a low dielectric polyimide fiber and a preparation method thereof, and belongs to the field of functional organic fibers. The fiber is prepared as follows: a copolymer polyamide acid spinning solution is prepared by condensation polymerization of hexafluorodianhydride (6FDA) and other dianhydride diamine; wet or dry-wet spinning process is used for spinning, poly amidoacid as-spun fiber is obtained by solidification and water washing; and the low dielectric polyimide fiber is prepared by thermal imidization and drawing processing of the fiber by gradient temperature, the tensile strength is up to 2.46GPa, initial modulus reaches 82.5GPa, and dielectric constant is as low as 2.55. The present invention provides a preparation method of the low dielectric polyimide fiber, has the characteristics of simple preparation method, low equipment requirements, extensive sources of raw materials, and continuous spinning production, and is suitable for industrial promotion.

Owner:JIANGSU XIANNUO NEW MATERIAL TECH

Preparation method for high-dielectric high temperature-resistant microwave dielectric composite material

InactiveCN104817290AAvoid the problem of too low viscosityAchieve preparationCompression moldingManufacturing technology

The invention relates to a microwave dielectric material and provides a preparation method for a high-dielectric high temperature-resistant microwave dielectric composite material, which belongs to the field of manufacturing technology for composite materials. The objective of the invention is to overcome the technical problem of low ceramic solid phase content in traditional preparation methods. The preparation method comprises the following steps: 1, surface modification of a ceramic filling material in virtue of a silane coupling agent; 2, mixing of ceramic powder with resin powder; and 3, compression molding. The composite material prepared in the invention has the characteristics of a high dielectric constant, low loss, high temperature resistance, high thermal conductivity, a small thermal expansion coefficient, simplicity and environmental protection. The preparation method provided by the invention is used for preparation of the high-dielectric high temperature-resistant microwave dielectric composite material.

Owner:HARBIN INST OF TECH

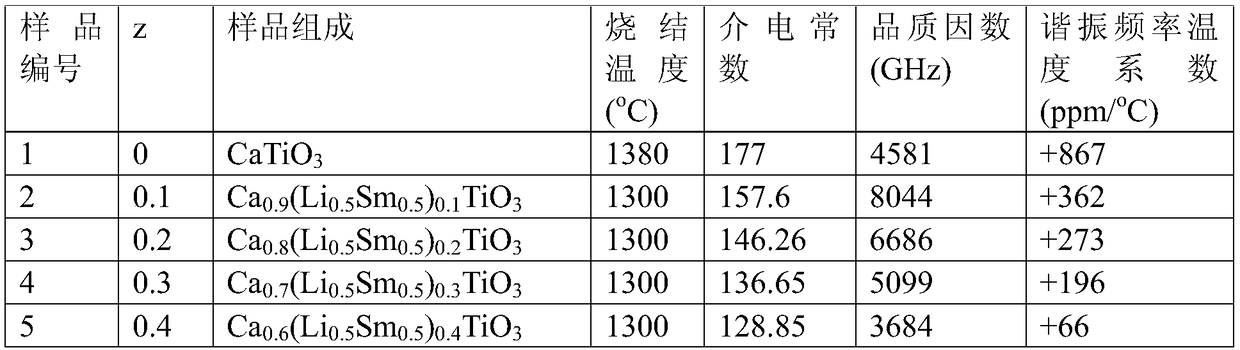

Microwave medium ceramic material and preparation method thereof

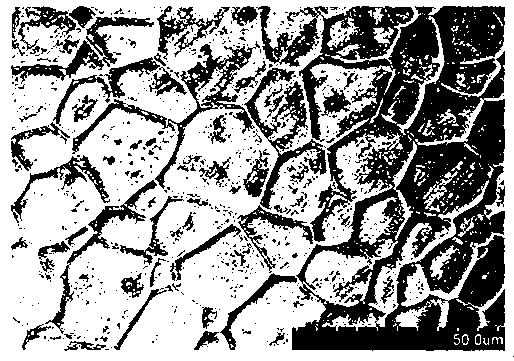

ActiveCN107188557AInhibit volatilizationAlleviate abnormal grain growthTemperature coefficientMicrowave

The invention discloses a microwave medium ceramic material and a preparation method thereof, and belongs to the field of electronic ceramics and manufacturing of the electronic ceramics. The preparation method of the ceramic material provided by the invention comprises the following steps of performing ball milling mixing, granulation, shaping, rubber discharging and sintering on 96.4 to 97.6 mass percent of (CaLiSm)TiO3 system ceramics and 2.4 to 3.6 mass percent of doping agents to prepare the microwave medium ceramic material using CaTiO3 as a main crystal phase. A quality factor is not obviously reduced; meanwhile, regulating a frequency temperature coefficient to a value near zero is realized; a dielectric constant is adjustable; the lithium volatilization in the ceramic material is inhibited; the crystal particle abnormal increase phenomenon is relieved; the structure compactness of the ceramic material is improved. Meanwhile, the ceramic material provided by the invention has the advantages that the process is simple; the sintering temperature range is wide; good process adaptability is realized; the industrial production is easy; the requirements in microwave communication industry can be favorably met.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Modified PZT piezoelectric ceramics with Nano powder being added to preburning material, and preparation method

ActiveCN1958510AExcellent dielectric propertiesAdjustable dielectric constantPiezoelectric/electrostrictive/magnetostrictive devicesCeramicNanometre

This invention relates to a method for preparing nanopowder-modified lead zirconate titanate piezoelectric ceramic. The method pre-sinters the raw materials without nanopowder, and then adds TiO2 and / or ZrO2 nanopowder as a substitute for micropowder into the pre-sintered raw materials, which can reduce pre-sintering temperature by 100-300 deg.C and final-sintering temperature by 50-100 deg.C, and can adjust the crystalline and properties of pre-sintered sample as well as the electrical properties of the sintered piezoelectric ceramic. Nanopowder-modified piezoelectric ceramic sintered at 1150 deg.C has a Curie point increased by 50-100 deg.C. Besides, the piezoelectric ceramic has excellent impact stability (TC = 350-400 deg.C; epsiv = 350-900; KP = 0.42-0.65), stable process and good repeatability. The piezoelectric ceramic can be used to produce ceramic frequency discriminator and ceramic filter.

Owner:ZHEJIANG JIAKANG ELECTRONICS CO LTD +1

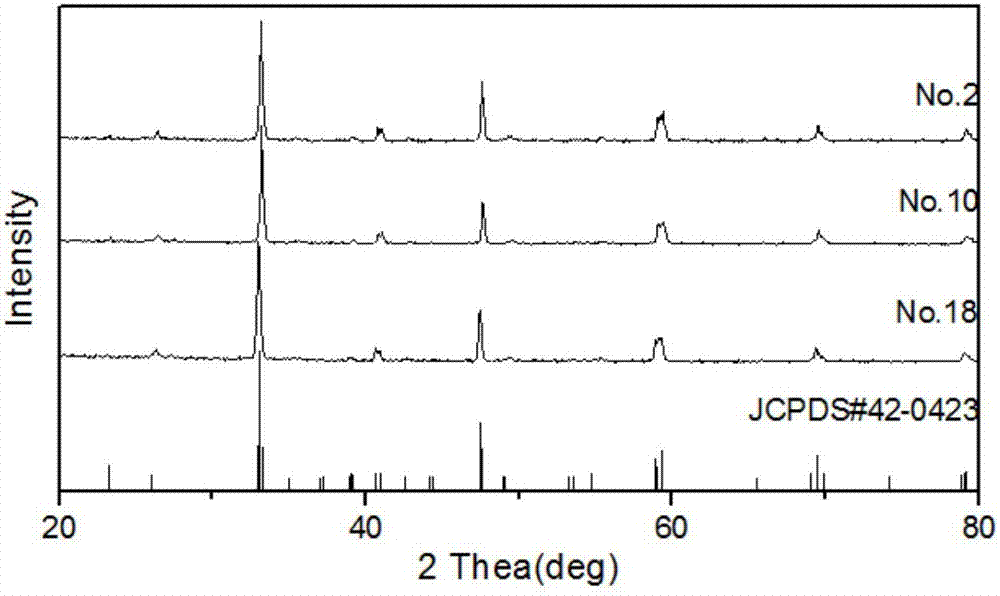

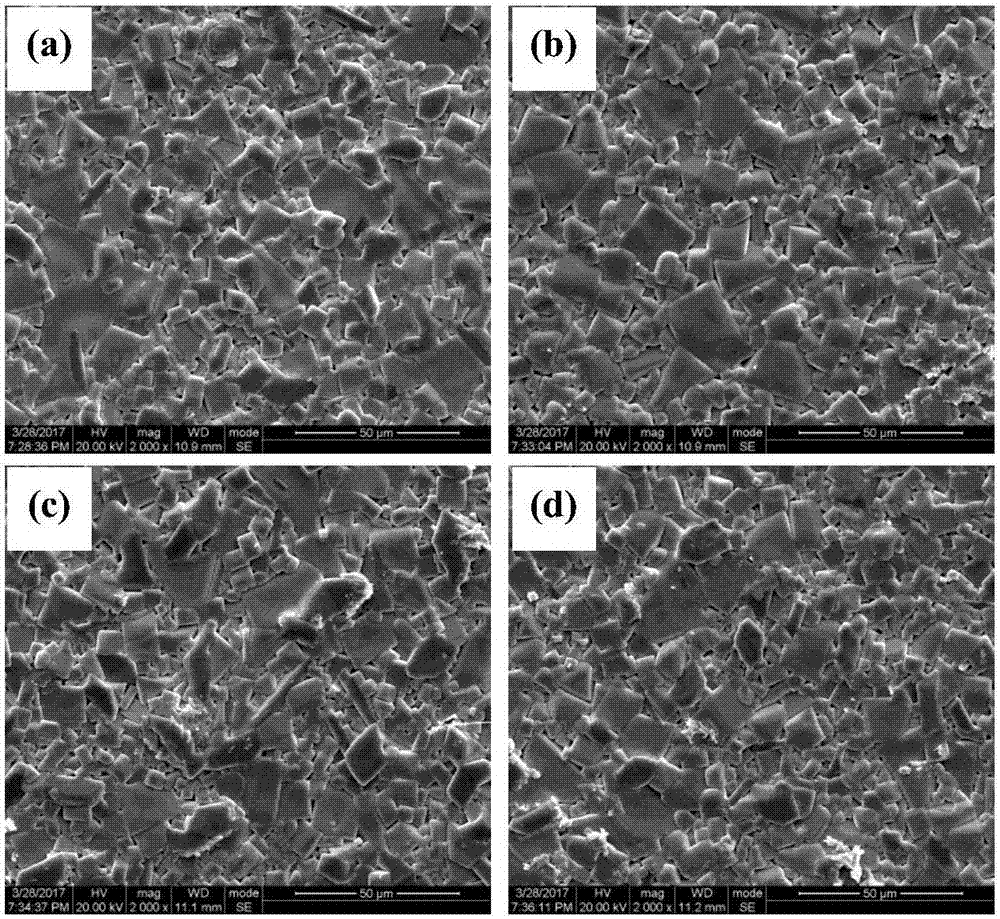

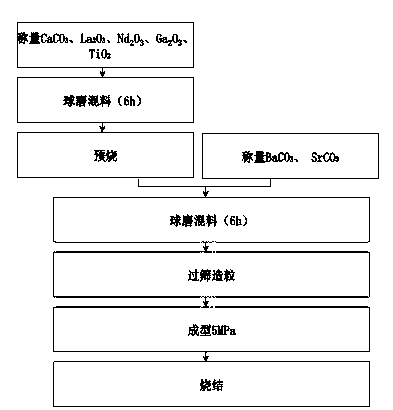

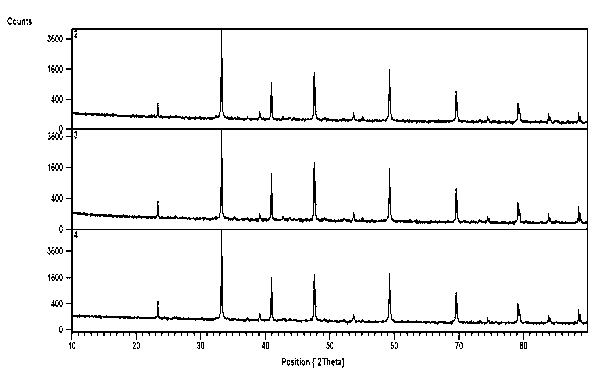

Microwave dielectric ceramics and preparation method thereof

The invention discloses a high-performance microwave dielectric ceramics and a preparation method thereof. The principal crystalline phase is (1-x)CaTiO3-x(LayNd(1-y))GaO3, CaCO3, TiO2, La2O3, Ga2O3 and Nd2O3 are taken as raw materials, and the modified doping agent comprises BaCO3 and SrCO3. The (1-x)CaTiO3-x(LayNd(1-y))GaO3 microwave dielectric ceramics is prepared according to the traditional solid-phase reaction method. The provided microwave dielectric ceramic material has excellent microwave dielectric performance, the relative dielectric constant epsilon r is adjustable between 40 and 45, Q*f is 40000-45000GHz, the resonant frequency temperature coefficient can be continuously adjusted, and the microwave dielectric ceramics can be widely applied to preparing dielectric resonators, filters, duplexers and other microwave devices in the modern communication base station.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

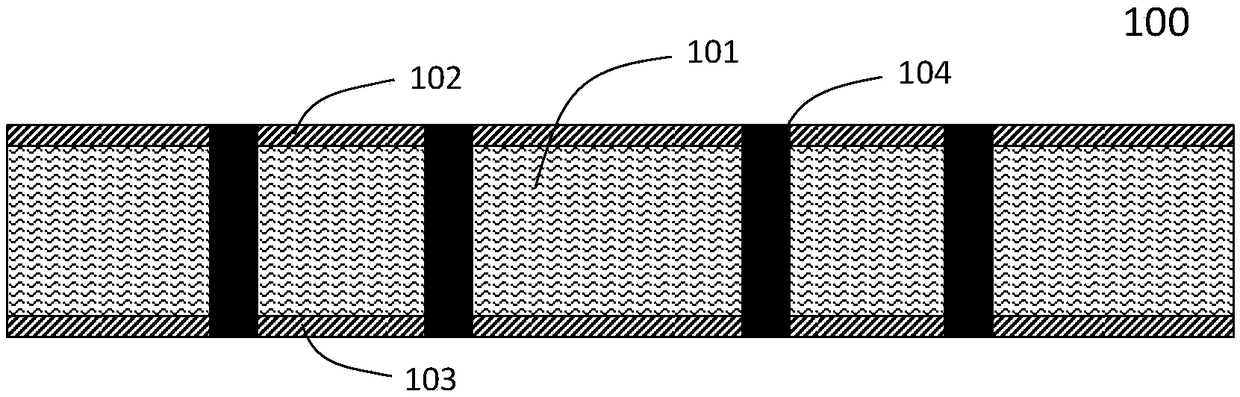

Ceramic adapter plate structure and manufacturing method thereof

ActiveCN108598061AHigh thermal conductivityHigh temperature resistantSemiconductor/solid-state device detailsSolid-state devicesMetallurgyCeramic substrate

The invention discloses a ceramic adapter plate structure, which comprises a ceramic substrate, a first surface insulating layer, a second surface insulating layer and a conductive through hole, wherein the first surface insulating layer is arranged at the first side of the ceramic substrate; the second surface insulating layer is arranged at the second side, opposite to the first side, of the ceramic substrate; and the conductive through hole is arranged in the ceramic substrate and penetrates through the ceramic substrate.

Owner:SHANGHAI JIAO TONG UNIV

Low-temperature-sintered temperature-stable composite microwave dielectric ceramic and preparation method thereof

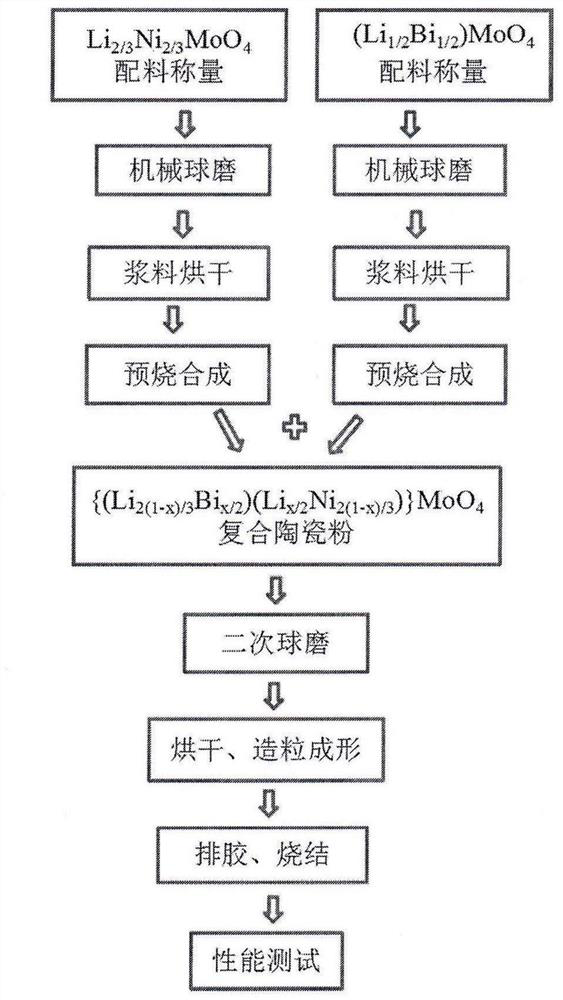

ActiveCN113149645ALower sintering temperatureImprove temperature stabilityChemical industryCeramic sinteringDielectric

The invention relates to a low-temperature-sintered temperature-stable composite microwave dielectric ceramic and a preparation method thereof. The composite microwave dielectric ceramic comprises the following components: a low-temperature-sintered microwave dielectric ceramic material with a negative resonant frequency temperature coefficient and a low-temperature-sintered microwave dielectric ceramic material with a positive resonant frequency temperature coefficient. According to the invention, the low-temperature-sintered microwave dielectric ceramic material with a negative resonant frequency temperature coefficient or the low-temperature-sintered microwave dielectric ceramic material with the positive resonant frequency temperature coefficient is used as a main material, a low-temperature-sintered microwave dielectric ceramic material with the same structure and an opposite resonant frequency temperature coefficient is added as an adjusting material through a two-phase compounding method, and compounding is conducted to form a multiphase ceramic material or a solid solution so as to obtain a low-temperature-sintered microwave dielectric ceramic material having a nearly-zero resonance frequency temperature coefficient. The problems that existing microwave dielectric ceramic is high in sintering temperature, and the temperature coefficient of resonance frequency changes greatly along with temperature are solved. The microwave dielectric ceramic material has a wide application scope in the LTCC low-temperature-sintered microwave dielectric ceramic materials.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

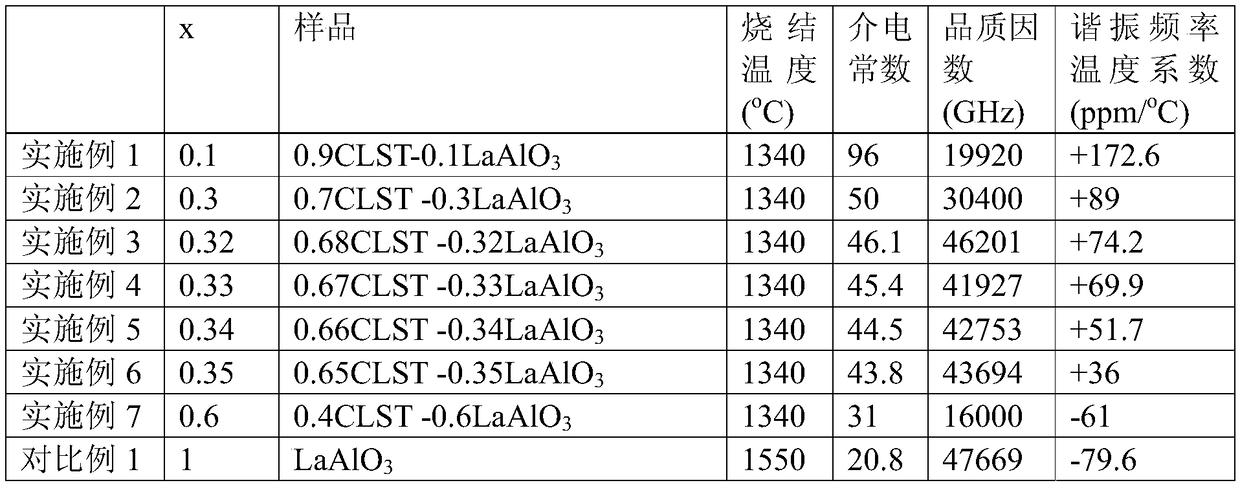

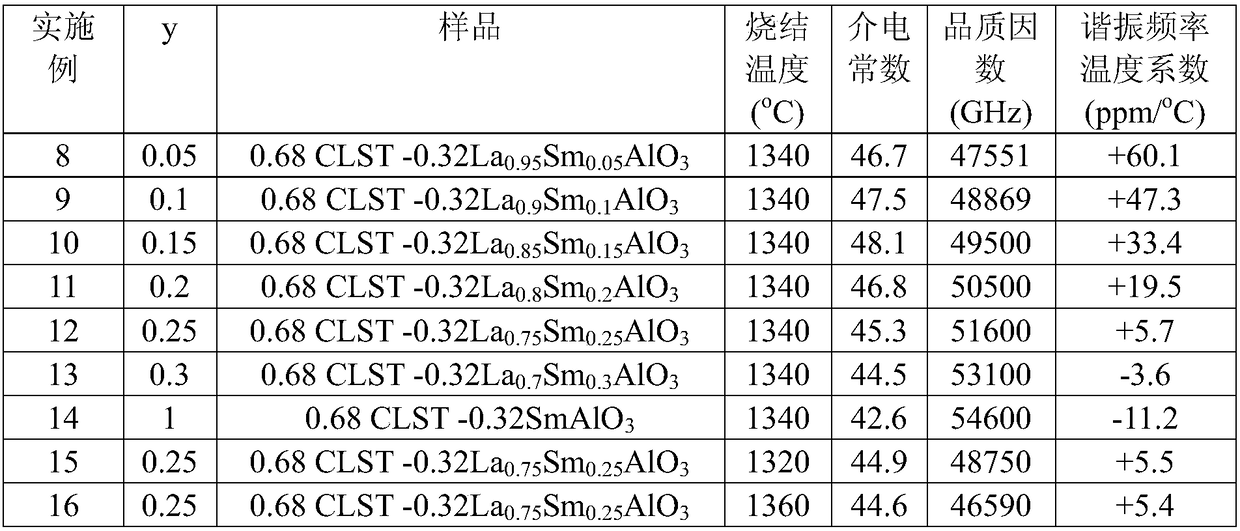

Microwave dielectric ceramics of perovskite structure and preparation method thereof

ActiveCN109437901AExcellent microwave dielectric propertiesLower sintering temperatureLithiumChemical composition

The invention provides microwave dielectric ceramics of a perovskite structure and a preparation method thereof. The chemical composition of the ceramics is (1-x)Ca1-z(Li0.5Sm0.5)zTiO3-xLa1-ySmyAlO3,wherein x is greater than or equal to 0.1 and less than or equal to 0.6, y is greater than or equal to 0 and less than or equal to 1, and z is greater than or equal to 0 and less than or equal to 0.4.The preparation method comprises the following steps that 1) a calcium source, a lithium source, a samarium source and a titanium source are mixed and are subjected to primary crushing, and roastingis carried out so as to obtain Ca1-z(Li0.5Sm0.5)zTiO3; and 2) the Ca1-z(Li0.5Sm0.5)zTiO3, an aluminum source and a rare-earth metal source are mixed and then are subjected to primary crushing, roasting is carried out, secondary crushing and pressing are carried out, and sintering is carried out to form the ceramics so as to obtain the ceramics. According to the ceramics, the relative dielectric constant is adjustable, the loss is low, and the temperature coefficient of resonant frequency is adjustable.

Owner:无锡鑫圣慧龙纳米陶瓷技术有限公司

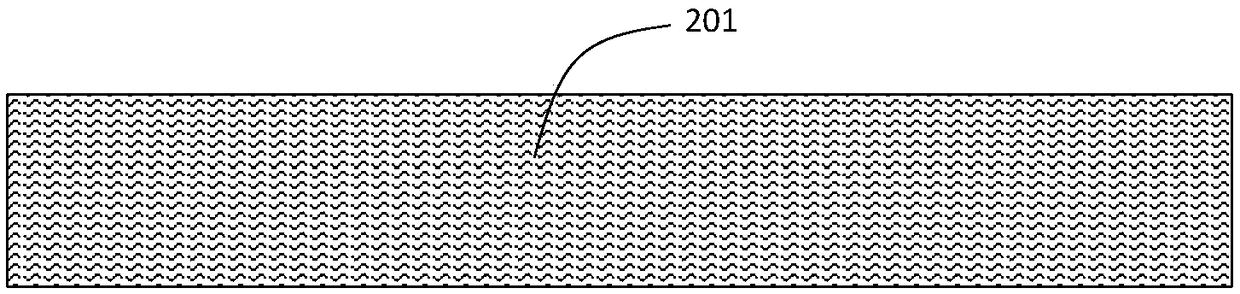

High-performance polytetrafluoroethylene film, and manufacturing method of microwave substrate thereof

ActiveCN110746725ALow water absorptionOvercoming the problem of poor adhesionSynthetic resin layered productsElectrical equipmentGlass fiberPolymer science

The invention belongs to the field of communication, and particularly relates to a high-performance polytetrafluoroethylene (PTFE) film, and a manufacturing method of a microwave substrate thereof. The high-performance PTFE film comprises 10-70 parts of a filler and 30-90 parts of polytetrafluoroethylene resin, and the filler comprises nanometer silicon nitride, a glass fiber and a cationic polyurethane, and a mass ratio of the glass fiber to the cationic polyurethane to the nanometer silicon nitride is (3-7):(2-6):(1-4). An ultrathin high-performance PTFE film is prepared by a self-made ultrathin PTFE film device, and is used for preparing the microwave substrate. The obtained PTFE film has a low water absorption rate and a good bonding performance, and the microwave substrate has excellent thermodynamic and electrical properties.

Owner:珠海国能新材料股份有限公司

Li-Nb-Ti-based microwave dielectric ceramic material

The present invention discloses a low-temperature sintering moderate permittivity Li-Nb-Ti-based microwave dielectric ceramic material and a preparation method thereof. The material is prepared from a lithium niobium titanium-based material and a glass burning reducing agent accounting for 0.5 to 6.0 wt% of a principal crystalline phase by solid-phase reaction, the lithium niobium titanium based material composition is LiaNbbTicO3, wherein a is greater than 1.2 and less than 1.4, b is greater than 0.3 and less than 0.4, and c is greater than0.5 and less than 0.7. The glass burning reducing agent is prepared from the raw materials comprising lithium carbonate (Li2CO3), zinc oxide (ZnO), aluminum oxide (Al2O3), silicon dioxide (SiO2), diboron trioxide (B2O3) and a trace additive component. The low-temperature sintering LTCC (low temperature co-fired ceramic) microwave dielectric ceramic prepared by the method is good in sintering at 850-900 DEG C, high in moderate dielectric constant (epsilon r of 45 to 50) and quality factor Q * f (greater than or equal to 8000GHz), can be used in manufacturing of low-temperature co-fired ceramic systems (LTCC), multilayer dielectric resonators, microwave antennas, filters and other microwave devices, and has a great use value in the industry.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

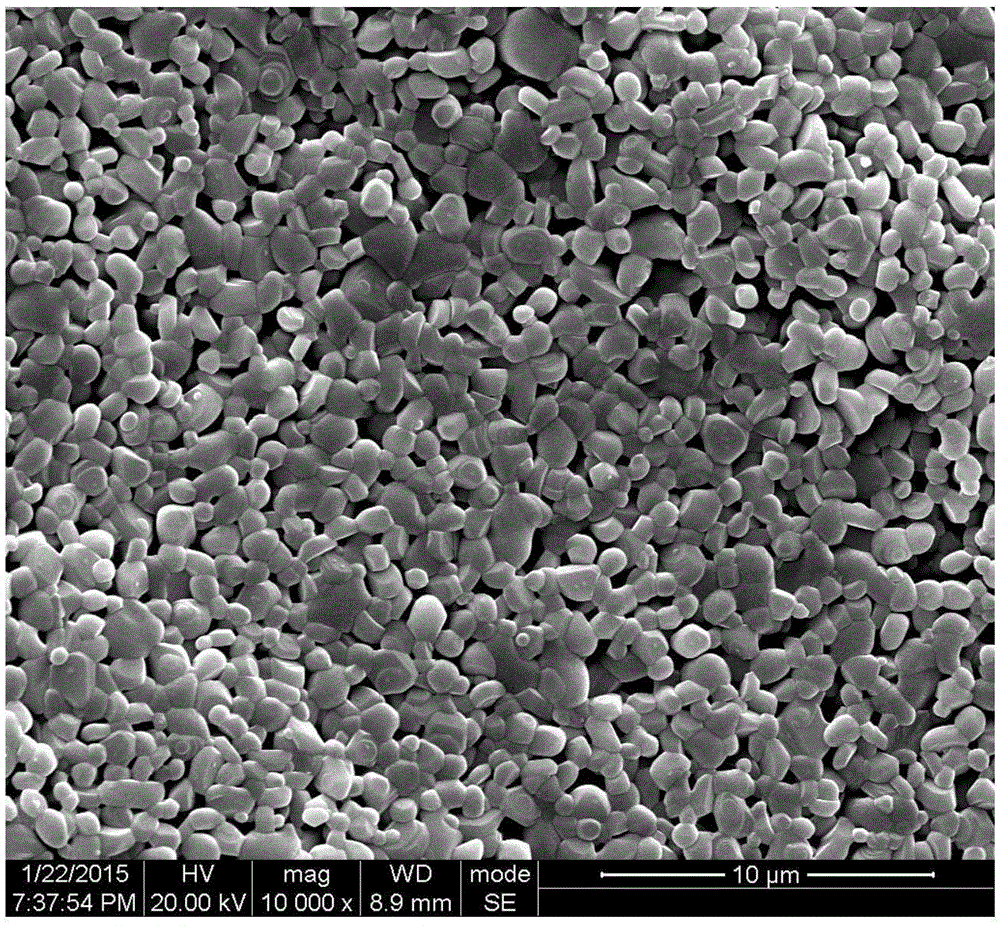

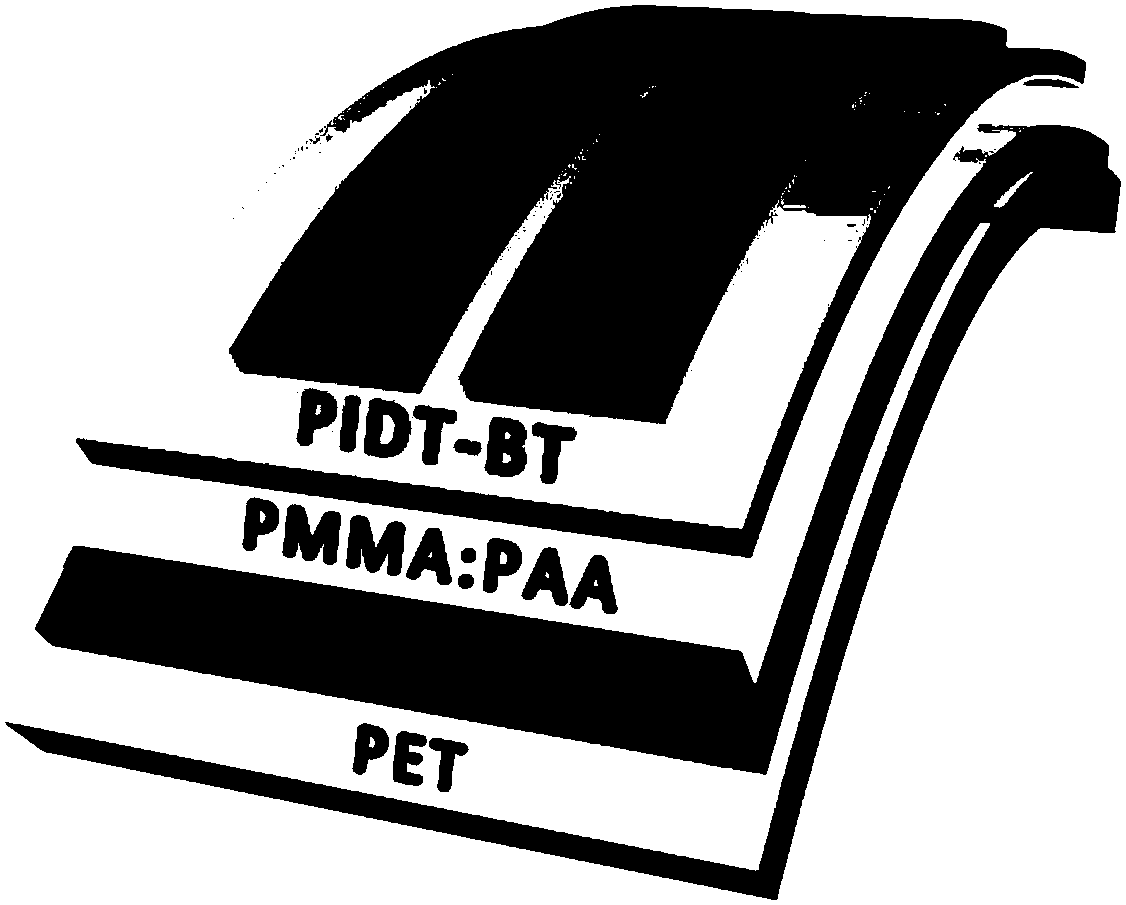

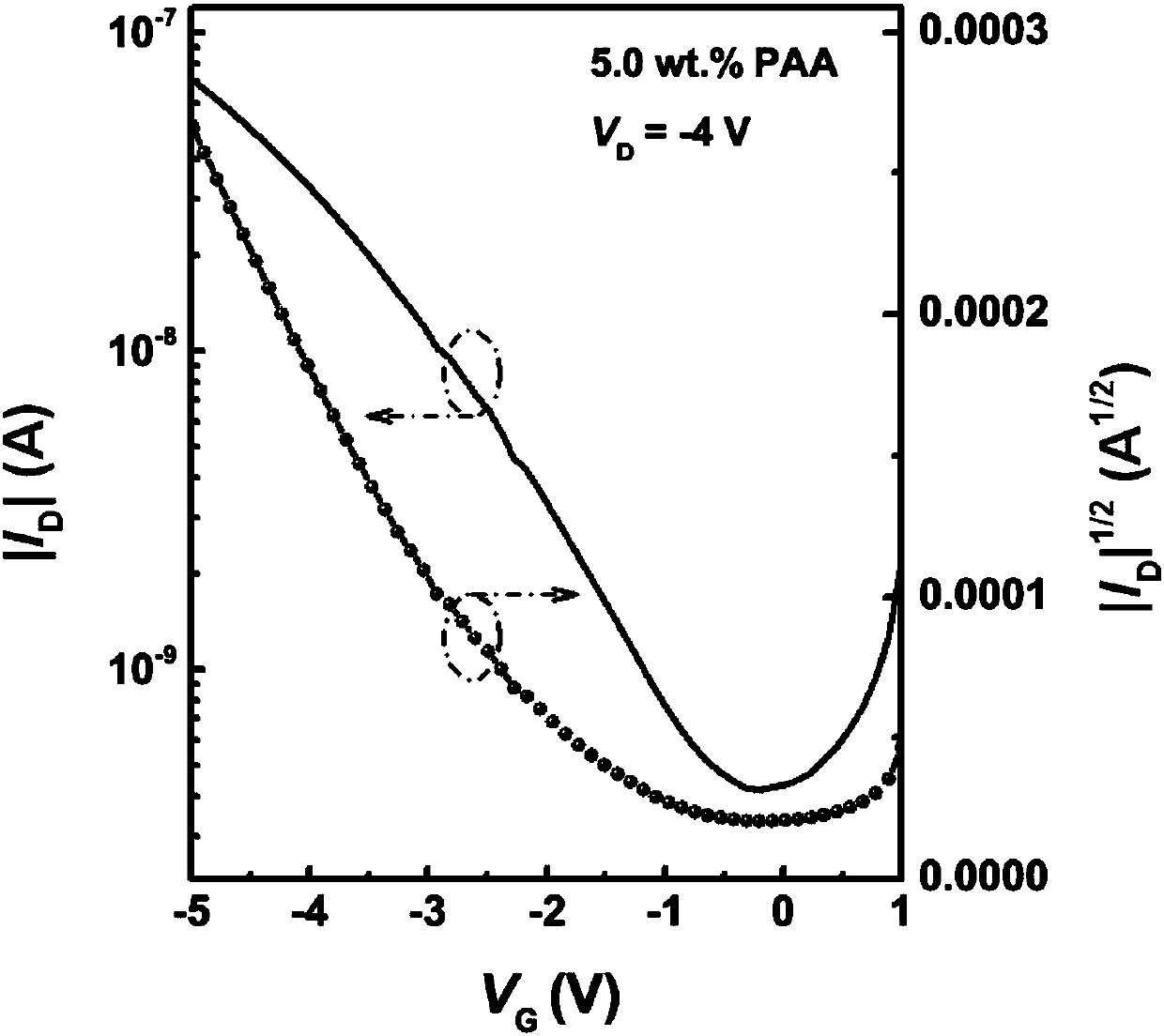

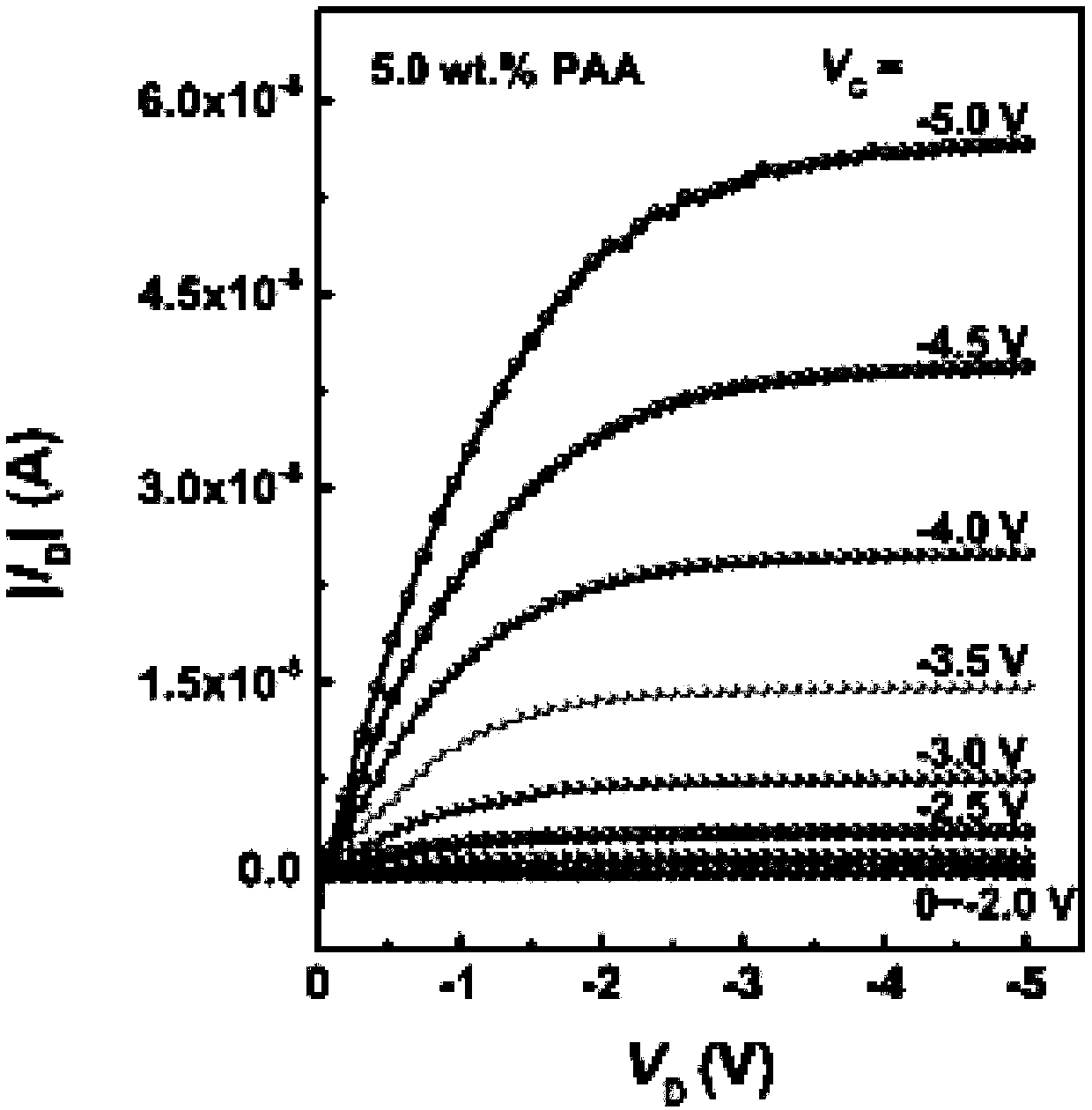

Flexible dielectric film and organic field effect transistor prepared thereby

ActiveCN107611262AReduce leakageAdjustable dielectric constantSolid-state devicesSemiconductor/solid-state device manufacturingOrganic field-effect transistorElectrical performance

The invention provides a dielectric material, a dielectric film, a flexible organic field effect transistor (OFET) prepared by the dielectric film, a preparation method of the flexible organic field effect transistor (OFET), and the application thereof in the field of electronic equipment. The dielectric material and the dielectric film contain polymethyl methacrylate and polyacrylic acid. The thickness of the dielectric film is 1-2 microns. According to the preparation method of the flexible OFET, the dielectric film is processed on a substrate covered with a grid electrode. After that, the spin-coated treatment of an organic semiconductor layer is conducted with a solution. Finally, a source electrode and a drain electrode are evaporated. The dielectric film disclosed by the invention issmall in electricity leakage, adjustable in dielectric constant, controllable in thickness, and high in strength / flexibility. The dielectric film and the flexible OFET are good in electrical performance, and excellent in application prospect in the aspect of low-energy-consumption flexible electronic equipment. The preparation method of the dielectric film and the flexible OFET is low in cost andsimple and convenient in process.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

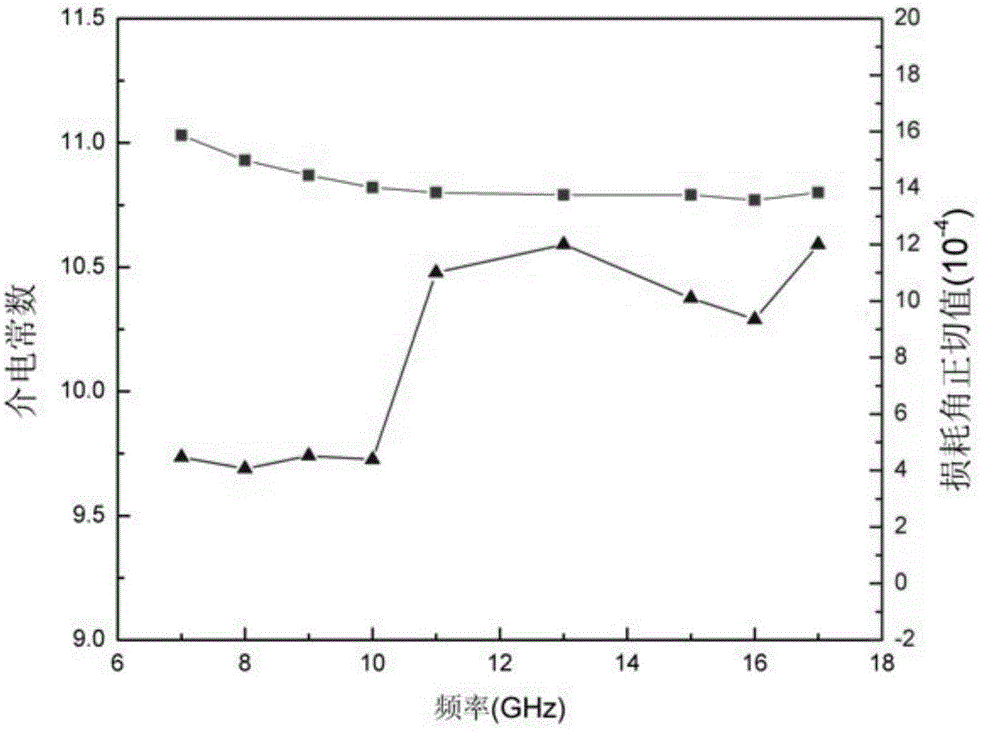

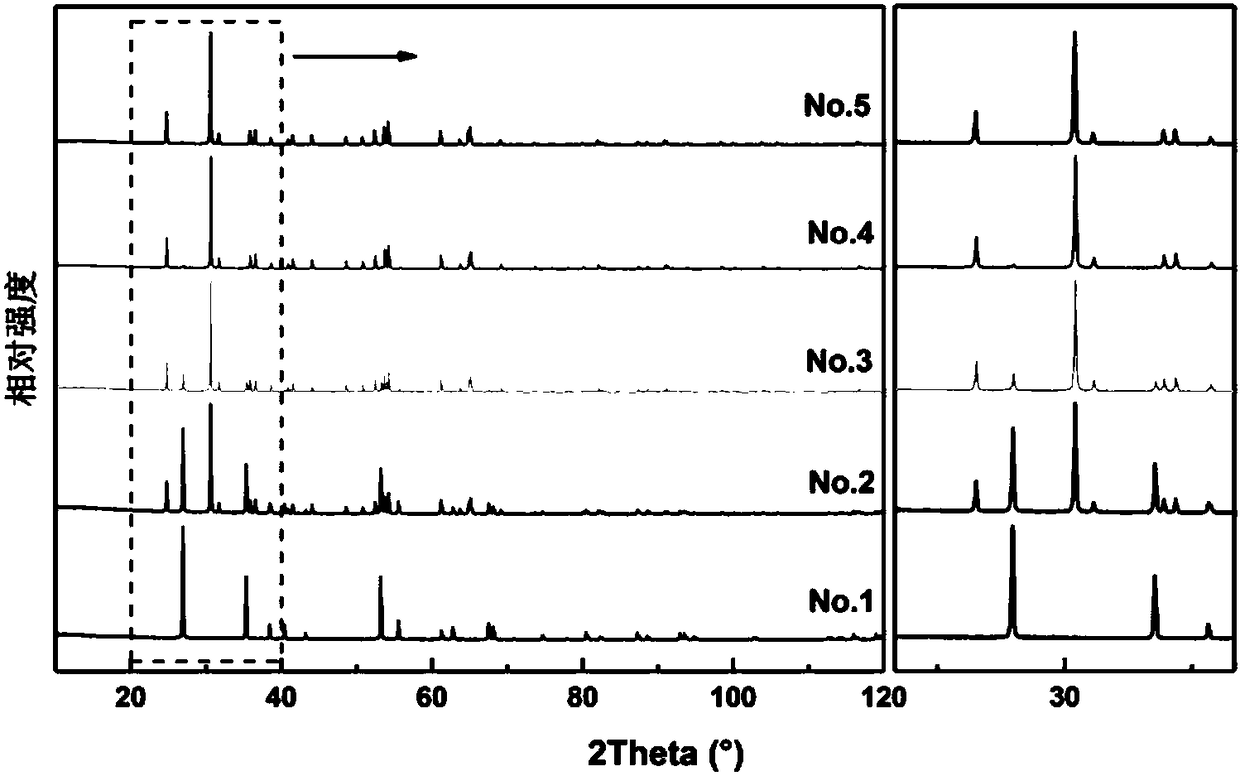

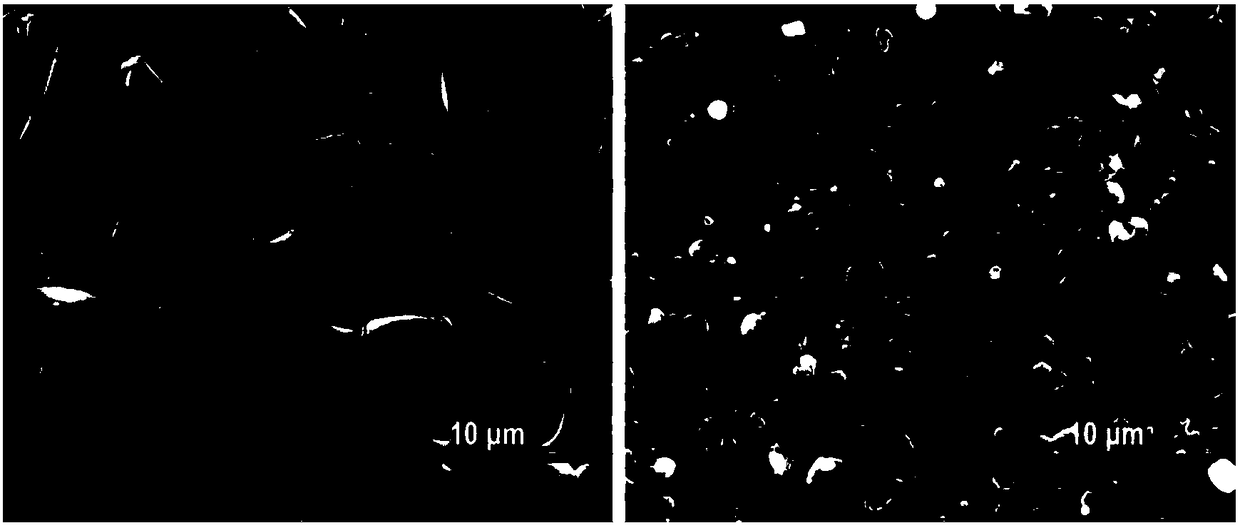

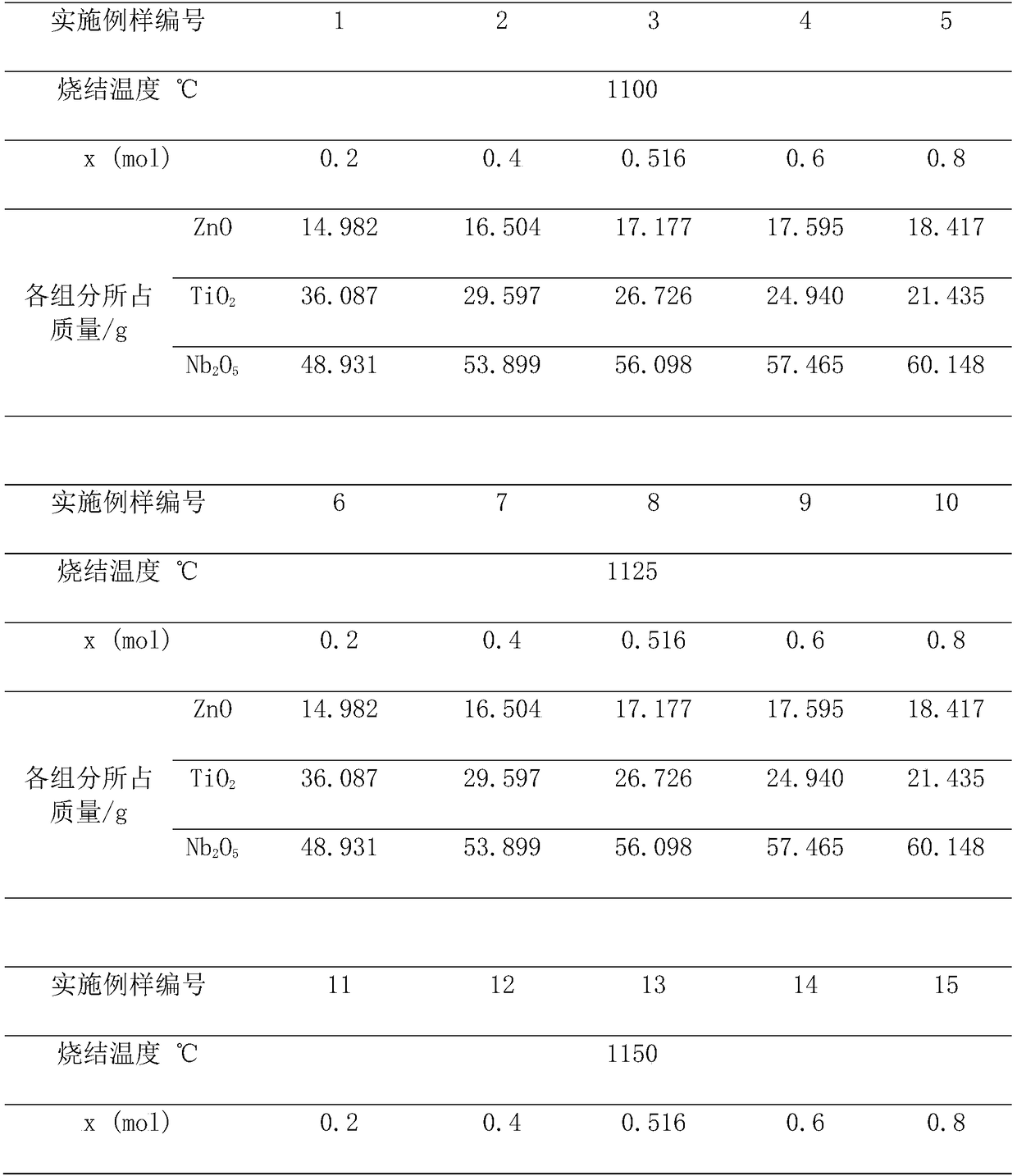

Compound microwave dielectric ceramic material and preparation method thereof

ActiveCN108455986AExcellent dielectric propertiesLower sintering temperatureElectricityDielectric resonator

The invention belongs to field of electronic ceramic and manufacturing thereof and in particular relates to a compound microwave dielectric ceramic material and a preparation method thereof. A chemical formula of the material is Zn0.15+0.35xTi0.55-0.05xNb0.3+0.7xO2+2x (x is equal to 0.2 to 0.8mol); the material is prepared from raw materials including ZnO, TiO2 and Nb2O5 and is prepared through asolid-phase method; the material has a medium dielectric constant (40 to 84) and low loss (1.10*10<-4> to 3.02*10<-4>), and the frequency-temperature coefficient is nearly zero. The content of two phases is adjusted through adjusting an x numerical value, low sintering temperature is ensured and the effect of improving the microwave dielectric performance is realized. The compound microwave dielectric ceramic material is applicable to manufacturing of multilayered dielectric resonators, microwave antennas, microwave capacitors, filters and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

High dielectric constant microwave dielectric ceramic with adjustable dielectric constant and preparation method thereof

The invention relates to high dielectric constant microwave dielectric ceramic with an adjustable dielectric constant and a preparation method thereof. The ceramic comprises: xCaTiO3.y(Li0.5Sm0.5)TiO3+awt%CeO, wherein 0.3< / =x< / =0.5, 0.5<=y<=0.7, and 0.1< / =a< / =0.5, wherein x and y are added as molar ratios and a is added as mass percent. The invention provides a microwave dielectric ceramic formulation having a dielectric constant 112.5 that is adjustable in a certain range (Er: 90-ER: 130) and a preparation method thereof, CaTiO3-(Li0.5Sm0.5)TiO3 system is used as an object of study, CeO is used as an adjusting microwave dielectric ceramic temperature coefficient to comprehensively adjust microwave dielectric performance of material.

Owner:JIANGSU JIANGJIA ELECTRONICS +1

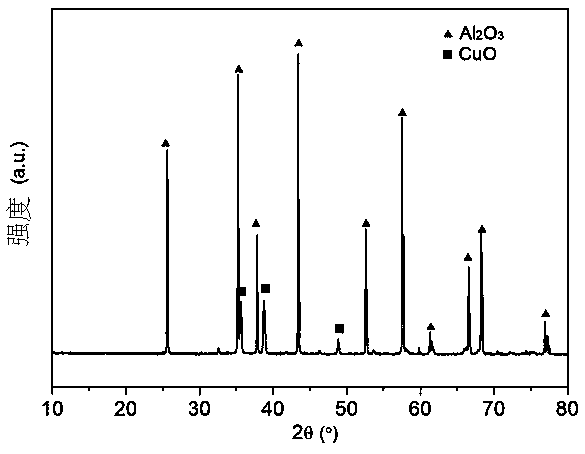

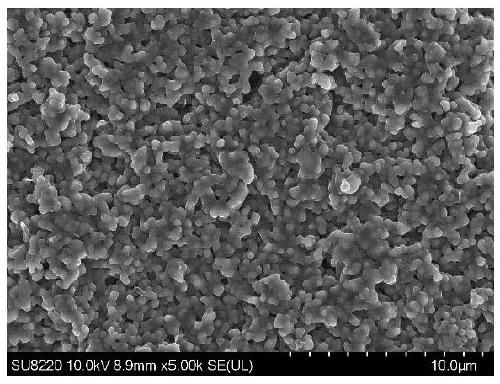

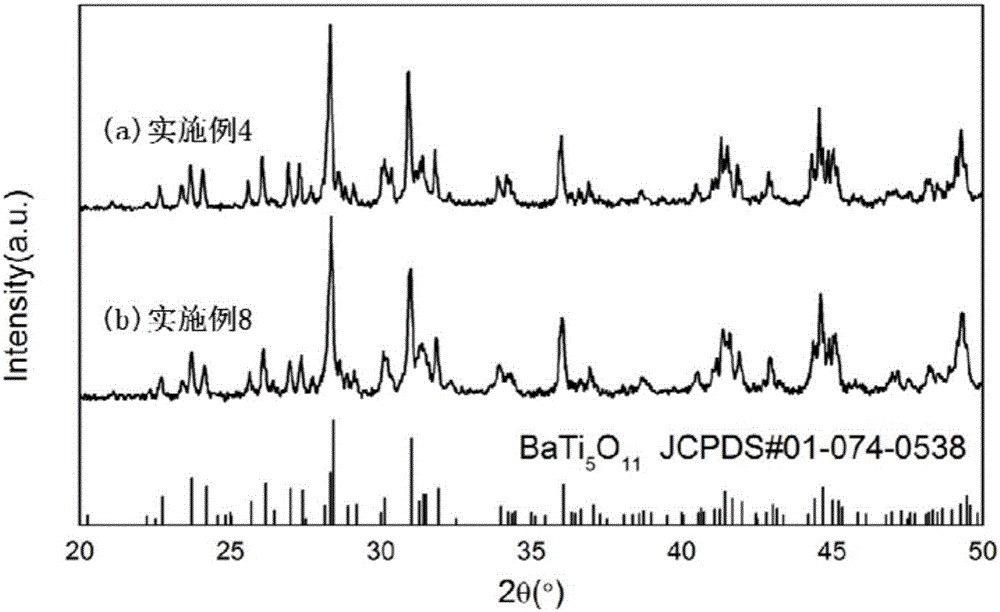

Low-temperature-sintered composite microwave dielectric ceramic material and preparation method thereof

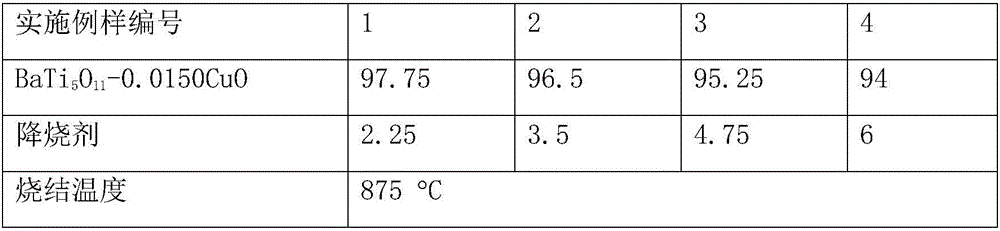

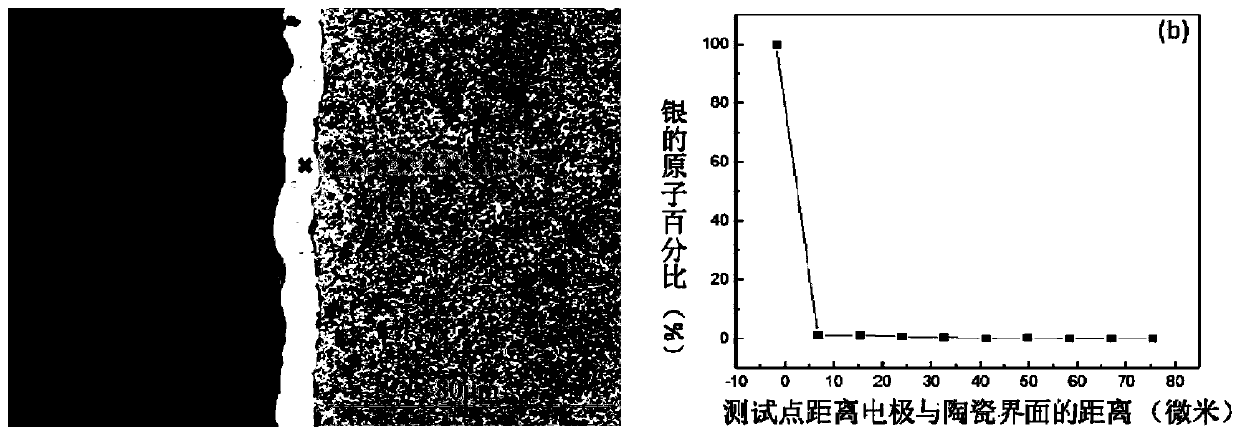

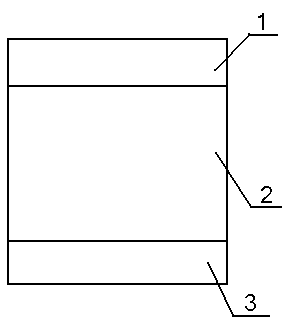

The invention belongs to the field of electronic ceramics and manufacturing thereof, and particularly relates to a low-temperature-sintered composite microwave dielectric ceramic material and a preparation method thereof. The low-temperature-sintered composite microwave dielectric ceramic material uses BaTi5O11-nCuO-xM as a base material, wherein according to a weight ratio, n is greater than or equal to 0.005 and is smaller than or equal to 0.020, M is a sintering improver, and x is greater than or equal to 0.010 and is smaller than or equal to 0.075; M specifically comprises the following components in percent by weight: greater than or equal to 27.25% and smaller than or equal to 46.74% of Ba2CO3, greater than or equal to 4.25% and smaller than or equal to 7.47% of Li2CO3, greater than or equal to 8.65% and smaller than or equal to 9.19% of SiO2, greater than or equal to 25.59% and smaller than or equal to 38.29% of B2O3, greater than or equal to 20.88% and smaller than or equal to 32.95% of ZnO, greater than or equal to 1.58% and smaller than or equal to 9.83% of Al2O3, and greater than or equal to 0.29% and smaller than or equal to 0.95% of MnCO3. The low-temperature-sintered composite microwave dielectric ceramic material provided by the invention has the sintering temperature of 875-920 DEG C, has a dense system, has the dielectric constant of 30-40, the loss greater than or equal to 10-4 and the Qxf (GHz) of 20000-30000, can be co-fired with silver well in an LTCC (low temperature co-fired ceramics) process, and can be easily produced industrially; the low-temperature-sintered composite microwave dielectric ceramic material can be widely applied to low-temperature high-dielectric constant microwave dielectric core materials in dielectric resonators, filters, oscillators and other microwave devices in satellite communication, and has an important industrial application value.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Dielectric powder for 5G filter and preparation method of dielectric powder

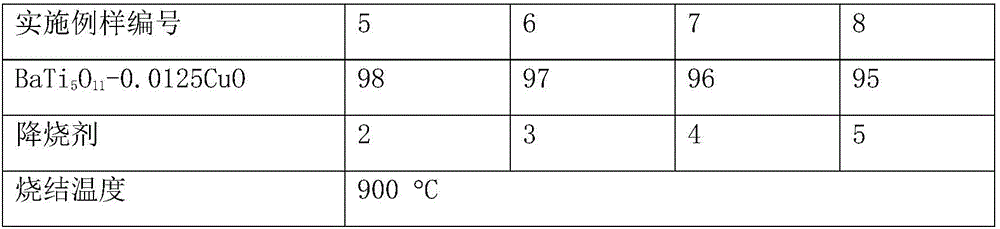

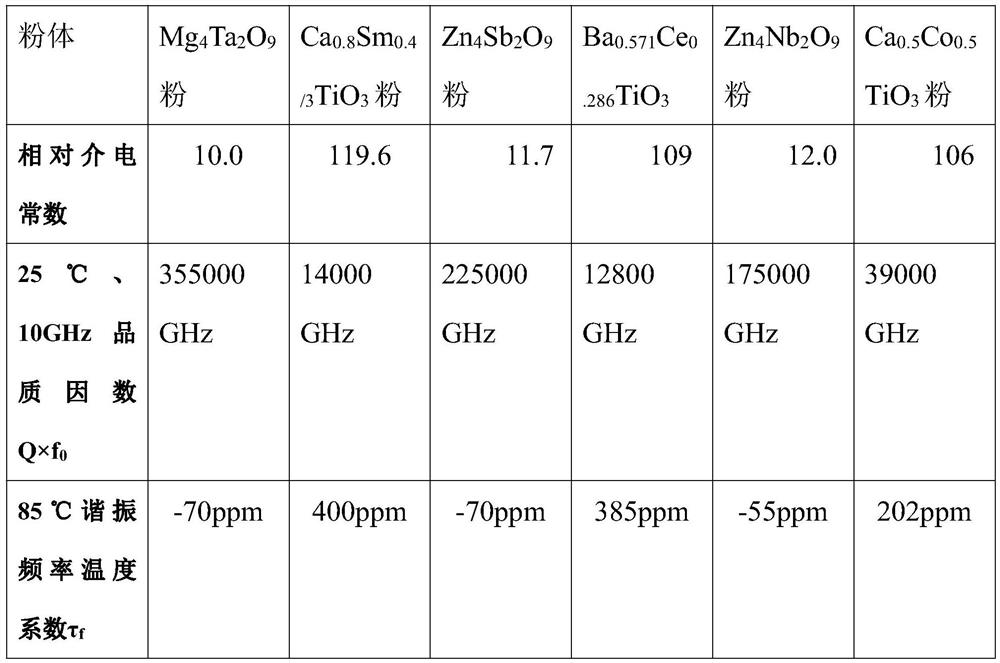

The invention discloses dielectric powder for a 5G filter and a preparation method of the dielectric powder. The chemical structural formula of the dielectric powder for the 5G filter is (1-z)A4M2O9-zBxDyTiO3, wherein the phase A is composed of two crystal phases of A4M2O9 and BxDyTiO3, z is the molar fraction of the BxDyTiO3 phase, A is one of Mg and Zn, M is one of Sb, Ta, Nb and V, z is largerthan 0.1 and smaller than 0.48, and x is larger than 0 and smaller than 0.48; B is one of Ca, Sr and Ba, D is at least one of Sr, Sm, La, Ce, Nd, Sn and Co, and the total valence algebraic sum of BxDyTiO3 is zero due to the valence combination of the x, y and B and D elements, wherein 0.5 < x < 0.9, y < 1. The invention discloses dielectric powder for a 5G filter and a preparation method of the dielectric powder, belongs to the technical field of preparation of dielectric ceramic raw materials, and proves that the dielectric ceramic powder has the characteristics of adjustable dielectric constant, high quality factor and near-zero temperature drift, and is stable in performance, wide in application prospect and relatively large in popularization potential when being applied to a 5G communication filter.

Owner:四会市康荣新材料有限公司

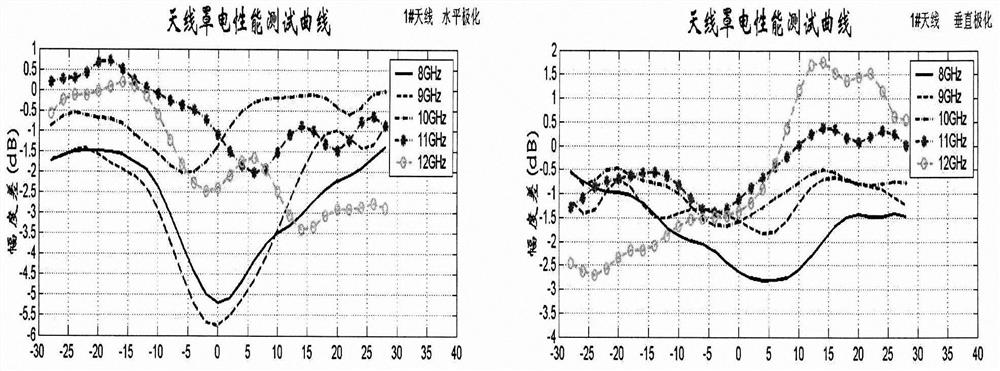

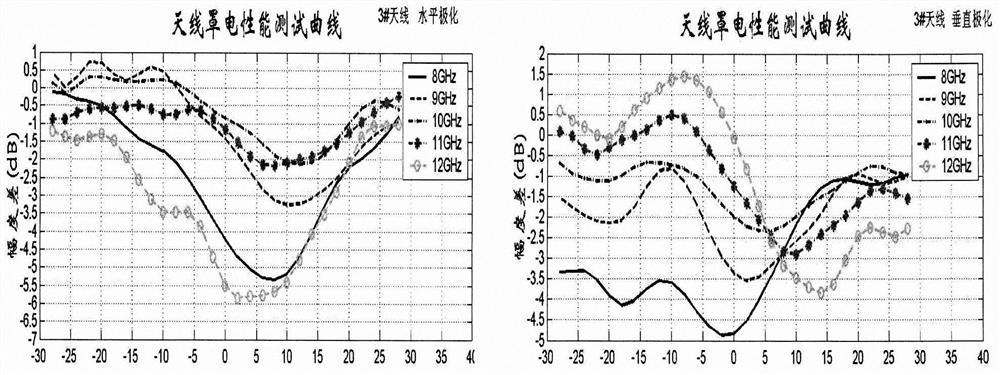

Ceramic-based double-layer structure radome and its preparation method

ActiveCN113348773BHigh temperature resistantImprove mechanical propertiesRadiating element housingsCeramic layered productsSurface layerTemperature resistance

The invention belongs to the technical field of aerospace and air vehicles, and in particular relates to a high-temperature-resistant, wide-band double-layer structure radome and a preparation method thereof. The radome body is a double-layer structure composed of a core layer and a surface layer, the core layer is made of quartz fiber reinforced quartz composite material, and the surface layer is made of quartz fiber reinforced nitride-phosphate composite material; the core layer material The dielectric constant is 2.0-3.1, and the dielectric constant of the surface layer material is 4.0-6.0; the core layer and the surface layer are packaged together after impregnation and firing, and processed into a radome. The radome has the characteristics of high temperature resistance, good mechanical properties and resistance to catastrophic damage, and has good wave transmittance in the range of centimeter waves and millimeter waves.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

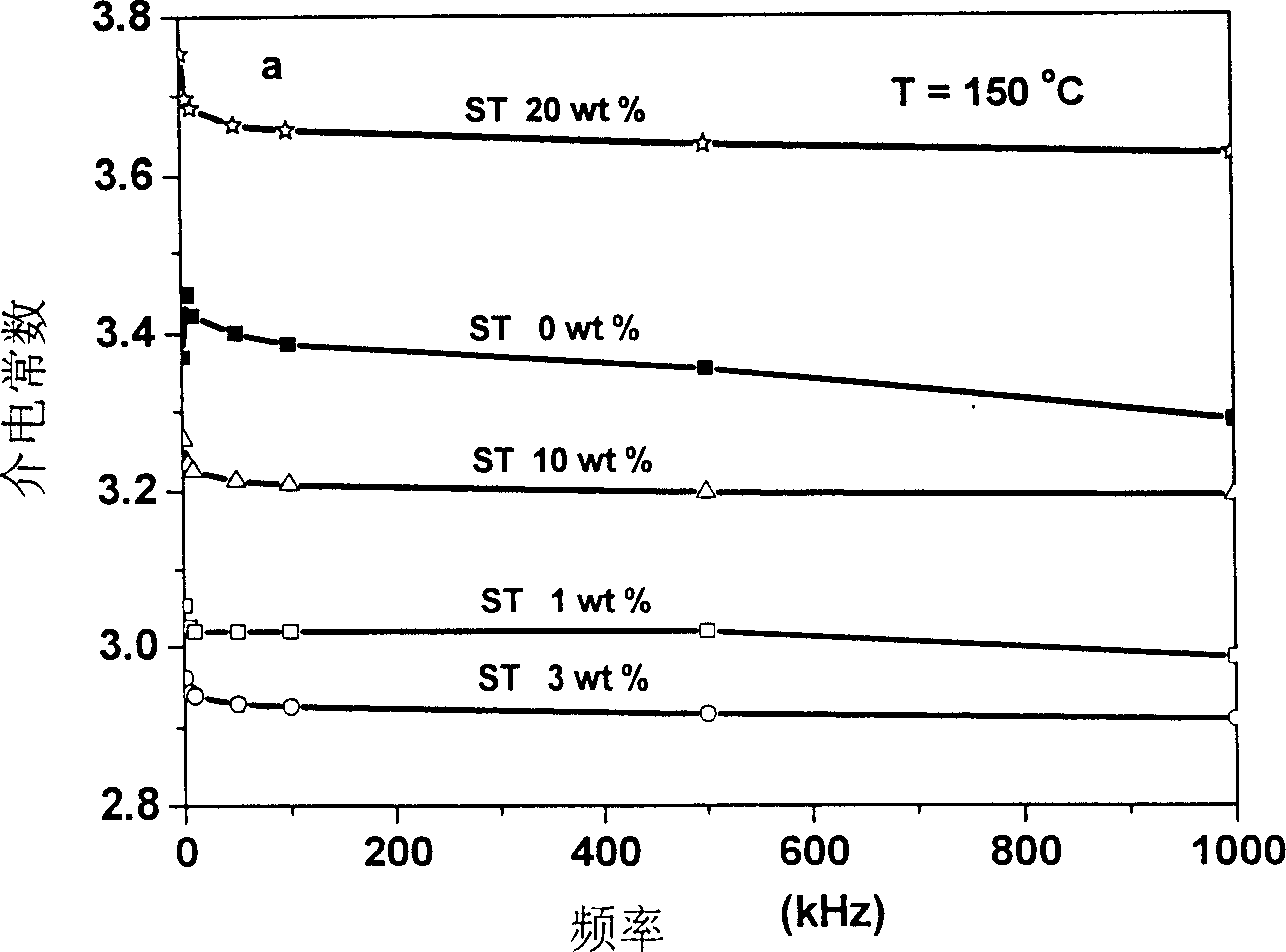

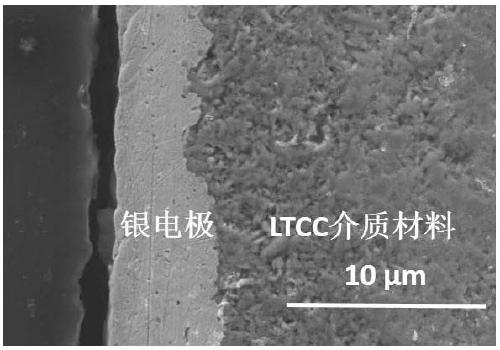

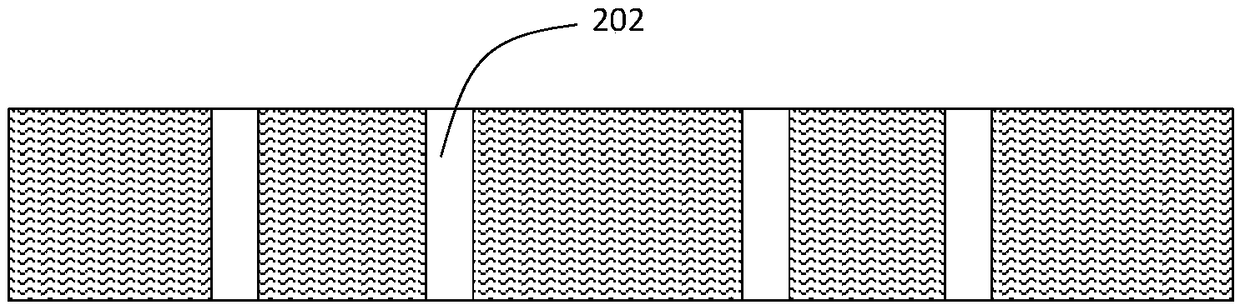

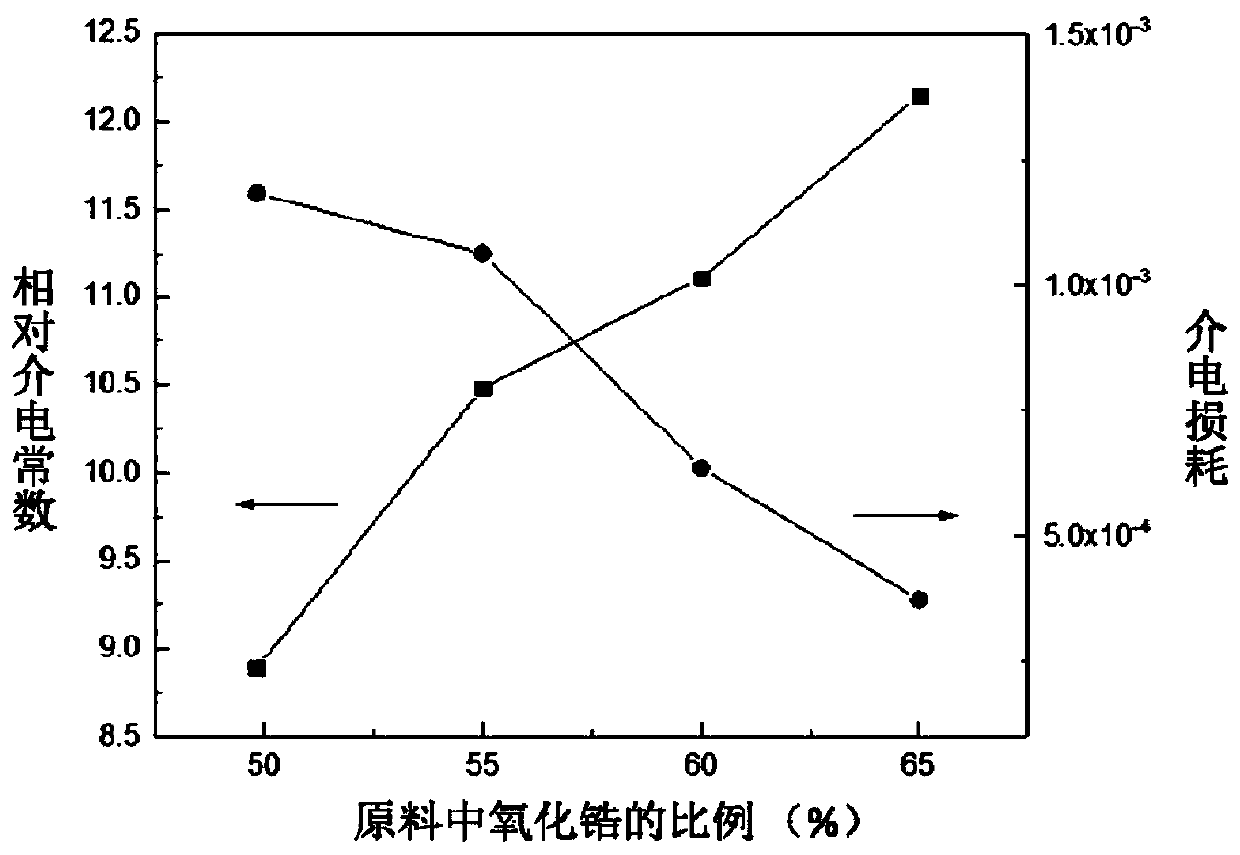

Dielectric constant series adjustable low-temperature co-fired dielectric material and preparation method thereof

ActiveCN111302792ADielectric constant series adjustableAdjustable dielectric constantCeramicsSilver electrodeDielectric loss

The invention discloses a dielectric constant series adjustable low-temperature co-fired dielectric material. The low-temperature co-fired dielectric material comprises a zirconia main phase and a silicon-based amorphous phase filler, wherein a weight ratio of the zirconia main phase to the silicon-based amorphous phase filler is (40-65): (35-60), and the weight percentage of SiO2 in the silicon-based amorphous phase filler is greater than or equal to 50%. By controlling the ratio of the zirconium oxide main phase to the silicon-based amorphous phase filler, the dielectric constant of the obtained material is continuously adjustable within a relatively wide range of 7-12, and dielectric loss can be as low as 0.1%@1 MHz. A material system obtained in the invention can be sintered at 800-900DEG C, can be compatibly co-sintered with a silver electrode, and can be used as a low-temperature co-sintered dielectric material. The invention also discloses a preparation method of the dielectricconstant series adjustable low-temperature co-fired dielectric material.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Metal interconnection layer with adjustable dielectric constants and manufacture method of metal interconnection layer

ActiveCN102938399AAdjustable dielectric constantHigh speedSemiconductor/solid-state device detailsSolid-state devicesInterconnectionDiffusion barrier

The invention provides a metal interconnection layer with adjustable dielectric constants. The metal interconnection layer comprises a barrier layer, a dielectric layer, metal wire layers and a metal diffusion barrier layer which are sequentially deposited, the metal wire layers are arranged in the dielectric layer, a closed gap is arranged at the position in the dielectric layer, and the position in the dielectric layer is located between the metal wire layers. The metal interconnection layer is simple in structure and low in cost, and a method is simple and convenient to implement; and by means of the metal interconnection layer, metal interlayer dielectric layer thin films with the low and adjustable dielectric constants can be obtained on the condition that dielectric layer thin films are fixed, device speeds are improved, and requirements of different products are met.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com