Metal interconnection layer with adjustable dielectric constants and manufacture method of metal interconnection layer

A technology of metal interconnection layer and dielectric constant, applied in the direction of circuits, electrical components, electric solid devices, etc., can solve the problems of dielectric constant of dielectric layer, reduce adjustment, etc., achieve low cost, increase device speed, and simple method easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be explained in detail below in conjunction with the accompanying drawings.

[0034] The metal interconnection layer of the embodiment of the present invention and its fabrication method include:

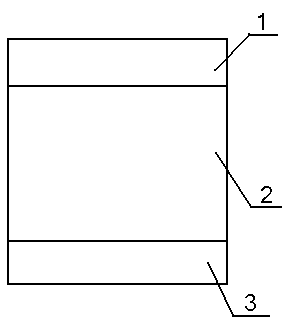

[0035] Such as figure 1 As shown in , step 1 includes sequentially depositing a barrier layer 3, a dielectric layer 2, and a cover layer 1; the barrier layer 3 is preferably a SiCN layer; the dielectric layer 2 is preferably selected from orthoethyl silicate (TEOS) film, fluorosilicate glass (FSG ) film, SiCOH or low dielectric constant film; Covering layer 1 is preferably silicon dioxide layer, silicon oxynitride layer;

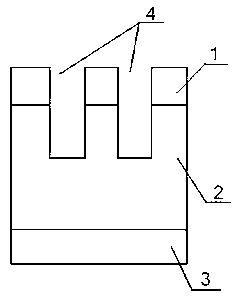

[0036] Such as figure 2 As shown in , the groove 4 is formed by photolithography and etching;

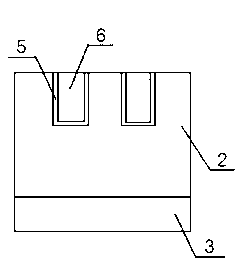

[0037] Such as image 3 As shown in , the metal wire layer 6 is formed by electroplating and grinding, preferably a copper wire layer, and preferably a metal diffusion barrier layer 5 is also provided on the periphery of the metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com