Patents

Literature

33results about How to "Meet the needs of different products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

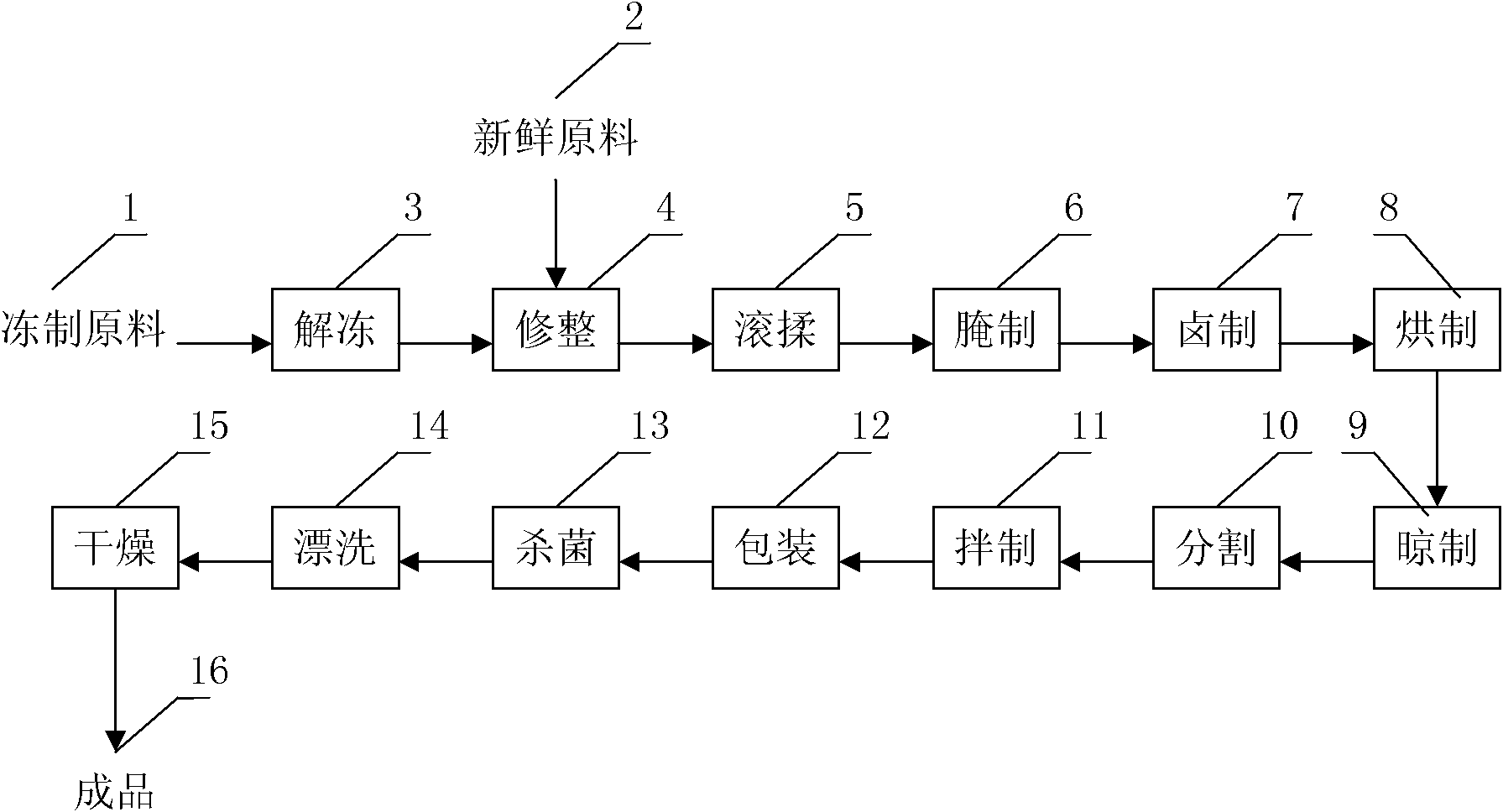

Sauced split duck leisure food and production method thereof

InactiveCN102224941AImprove bindingImprove product flexibilityFood preparationFood flavorFlavoring Agents

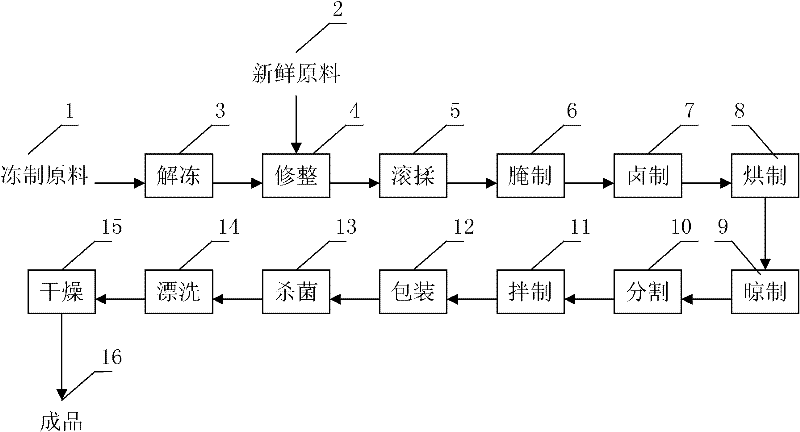

The invention discloses a production method for a sauced split duck leisure food. The method is characterized in that: the split duck and accessories thereof are adopted as raw materials; a production process of the method comprises defrosting, adjusting, rolling and kneading, sousing, bittern, baking, cutting, mixing, vacuum packaging, sterilizing, rinsing and drying. The raw materials for the sousing comprise, by weight, 100 parts of the split duck raw material, 0.80-1.20 parts of a salt substance, 0.005-0.50 parts of a flavor enhancer, 0.05-0.15 parts of a sweeting agent, 0.10-0.30 parts of a deodorization agent, 0.008-0.035 parts of a pigment, 0.005-0.06 parts of a preservative, 0.04-0.10 parts of a flavoring agent. The raw materials for the bittern comprise, by weight, 100 parts of the soused split duck, 0.20-0.40 parts of the flavor enhancer, 0.05-0.20 parts of a flavoring agent, 0.01-0.04 parts of a toner and 0.8-1.2 parts of a perfume. The products prepared by the method have delicious and rich fragrance, moderate salt taste, mellow flavor, a unique flavor of the sauced products.

Owner:CHENGDU FENGFENG FOOD CO LTD

Spicy segmented duck leisure food and production method thereof

The invention discloses a production method of spicy segmented duck leisure food which is characterized in that the production method adopts a segmented duck and its accessories as raw materials, and the production process flow comprises of: thawing, finishing, tumbling, salting, stewing, baking, segmenting, mixing, vacuum-packaging, sterilization, and drying. The salting raw materials comprise the following components: 100 parts of segmented duck raw materials, 1.20-1.60 parts of salty flavor, 1.10-1.30 parts of sweeteners, 0.30-0.50 parts of fishy-smell removing agents, 0.005-0.06 parts of pigments, 0.005-0.06 parts of preservatives, and 0.04-0.10 parts of spicy flavor; the stewing raw materials comprise the following components: 100 parts of salted segmented duck, 0.15-0.25 parts of sweeteners, 0.005-0.80 parts of seasoners, 0.04-0.25 parts of flavor enhancers, 0.005-0.02 parts of toners, and 0.8-1.2 parts of perfume. The product produced by the method has heavy fresh and fragrant smell, delicious spicy taste, pure flavor, and has unique flavor of spicy products.

Owner:CHENGDU FENGFENG FOOD CO LTD

Manufacturing method of imitated cow top layer leather oily leather

ActiveCN104532474AIncrease brightnessDelicate patternFabric breaking/softeningPattern makingPolymer sciencePolyether polyurethane

The invention relates to a manufacturing method of imitated cow top layer leather oily leather. The method includes the process steps: (1) manufacturing a non-woven fabric with the density of 0.25-0.27g / m<2>; (2) impregnating the non-woven fabric in mixed impregnation solution of polyether polyurethane and polymeric carbon polyurethane; (3) reducing methylbenzene; (4) arranging a substrate; (5) performing dry process overlaying; (6) overlaying a release paper coating film obtained in the fifth step and an imitated cow top layer leather superfine fiber polyurethane synthetic leather substrate obtained in the fourth step in an aligned manner to obtain imitated cow top layer leather; (7) performing embossing and third-edition machine treatment for the made imitated cow top layer leather to obtain the imitated cow top layer leather oily leather. The manufacturing method is simple, the made imitated cow top layer leather oily leather is high in brightness, fine and smooth in stripe and strong in oil wax feeling and suspension feeling, and the requirements of different products can be met.

Owner:WUXI DOUBLE ELEPHANT MICRO FIBER MATERIAL

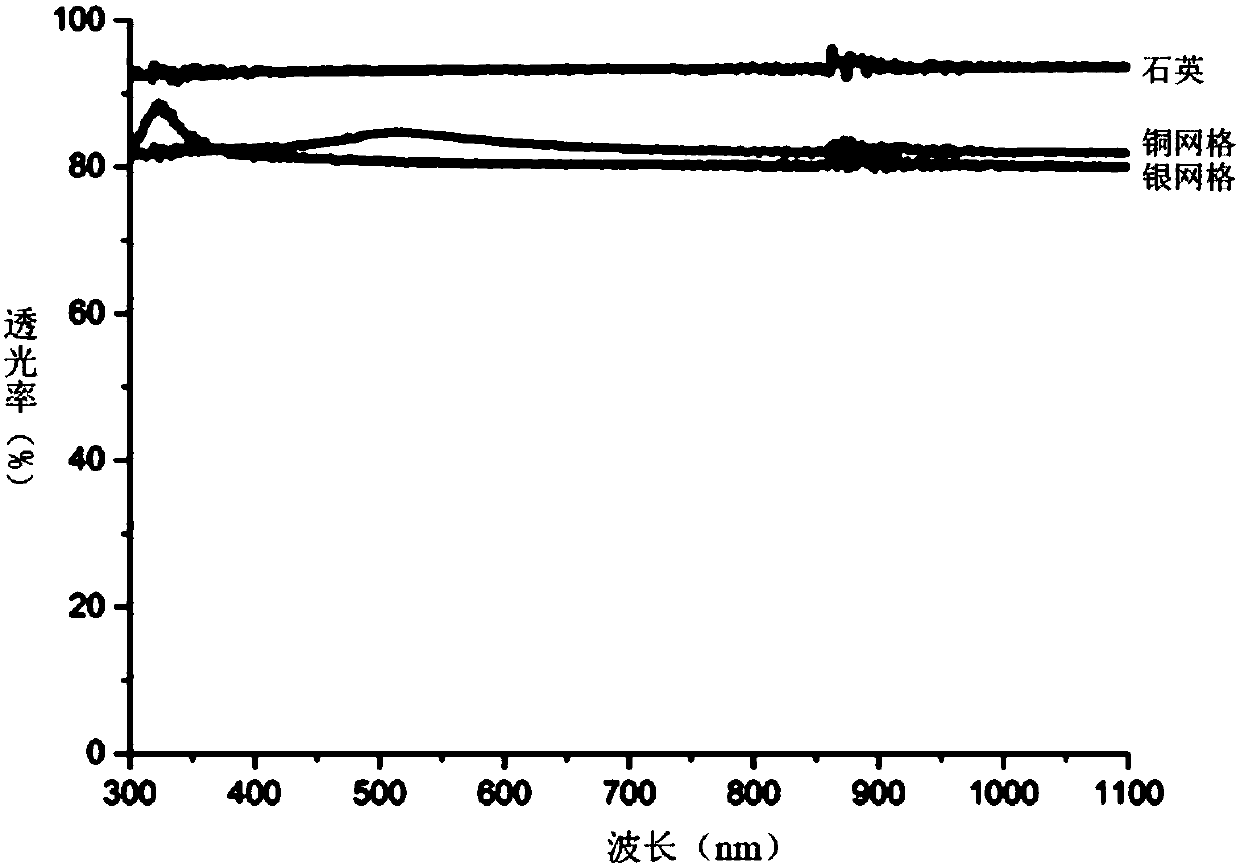

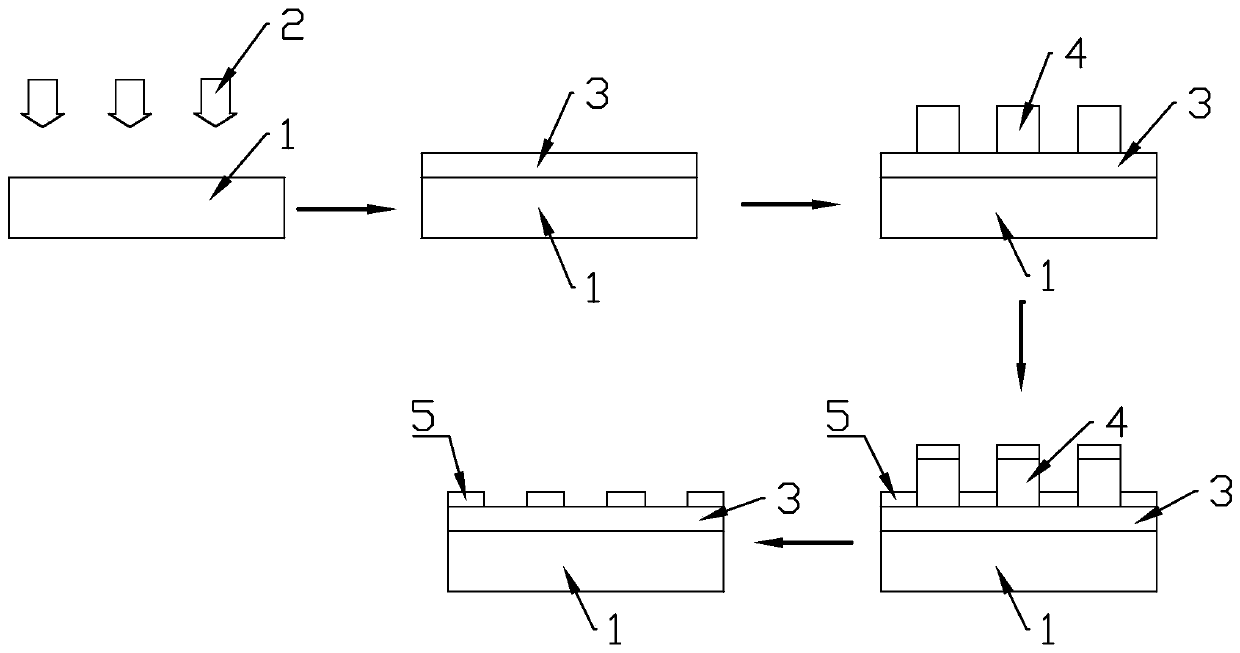

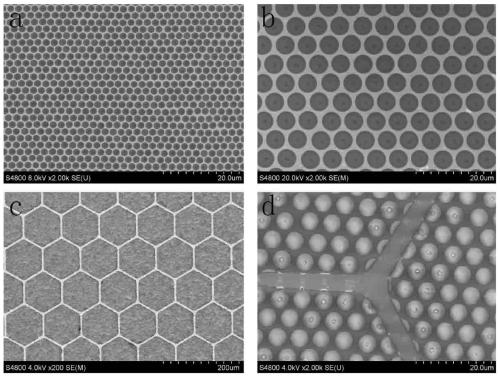

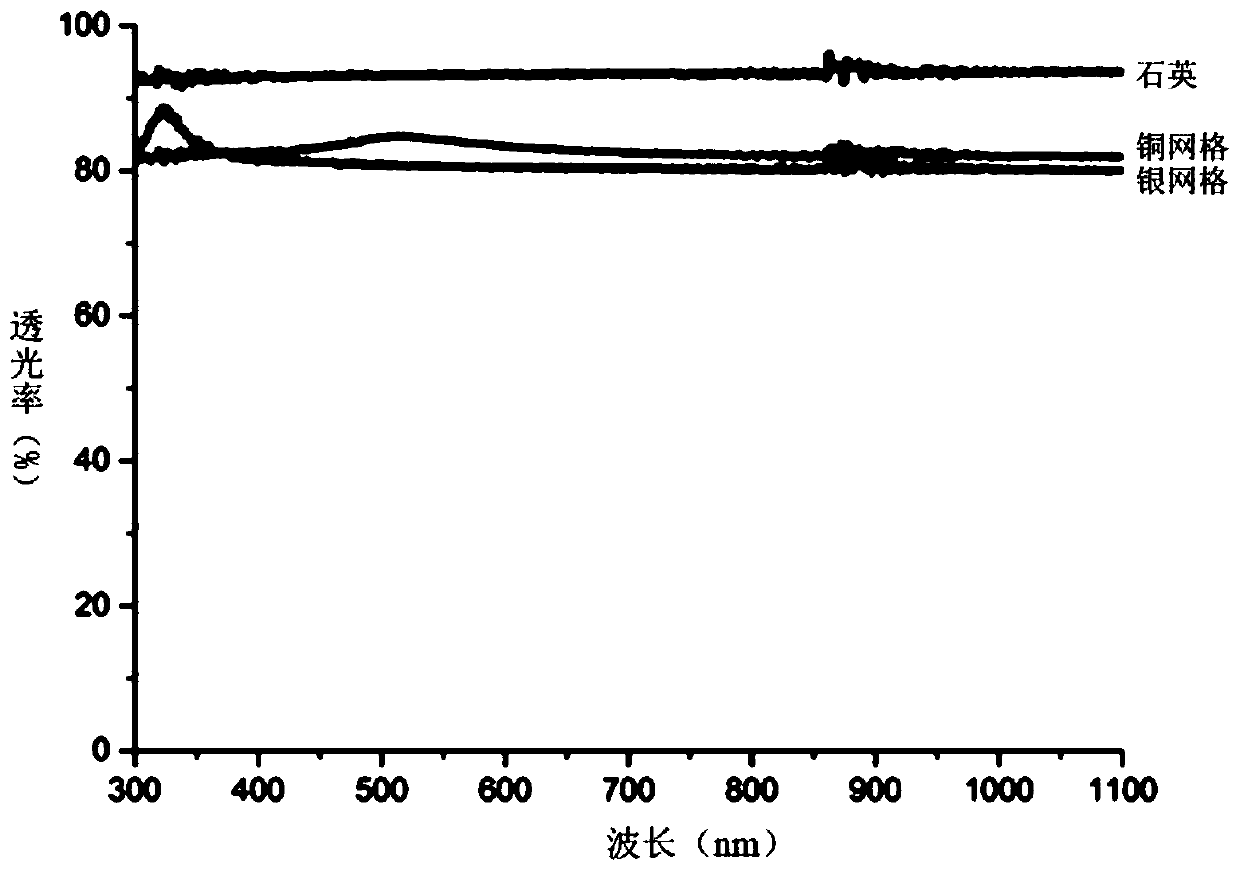

Ultra-thin metal grid-based transparent electrode and preparation method thereof

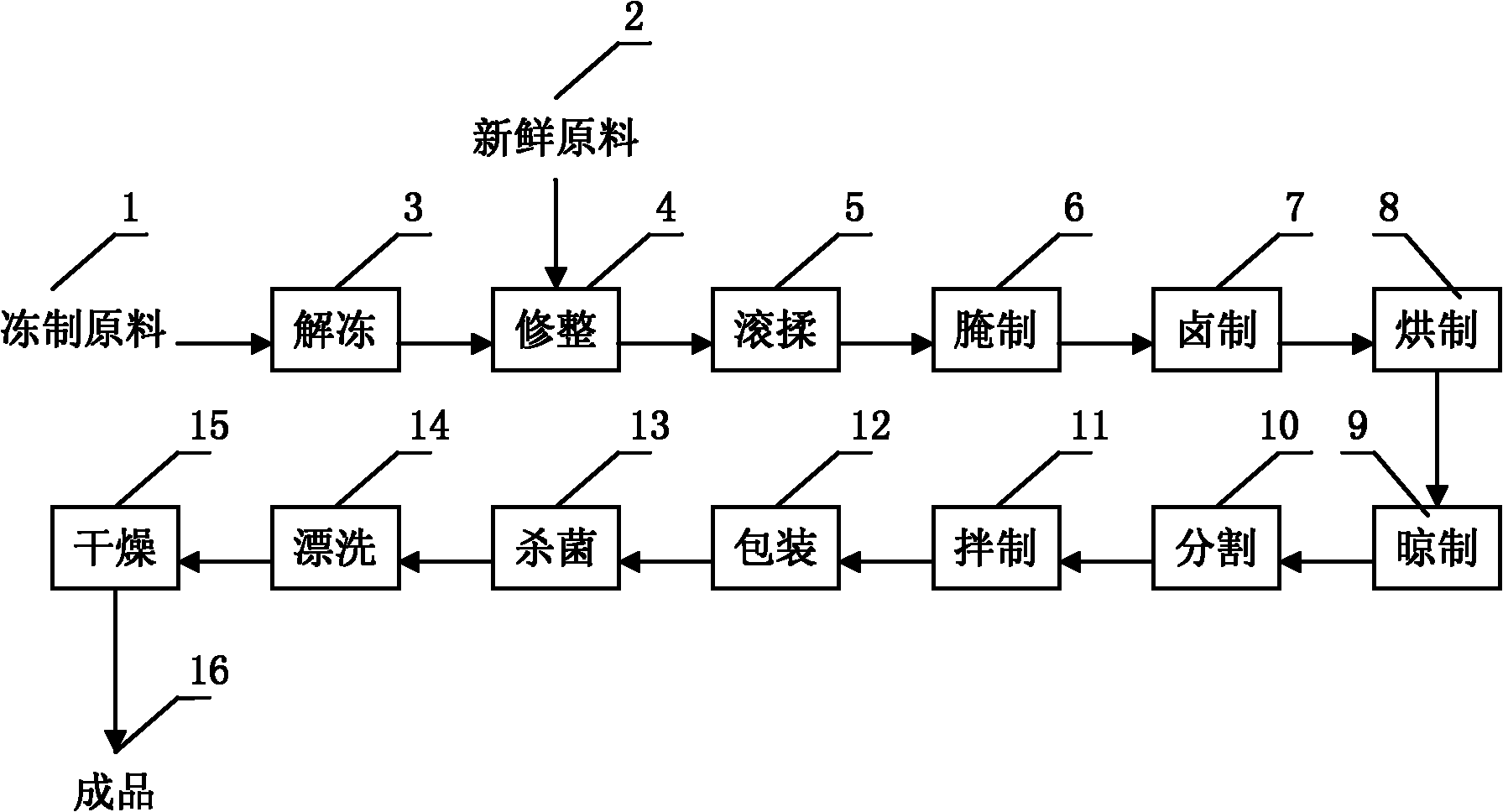

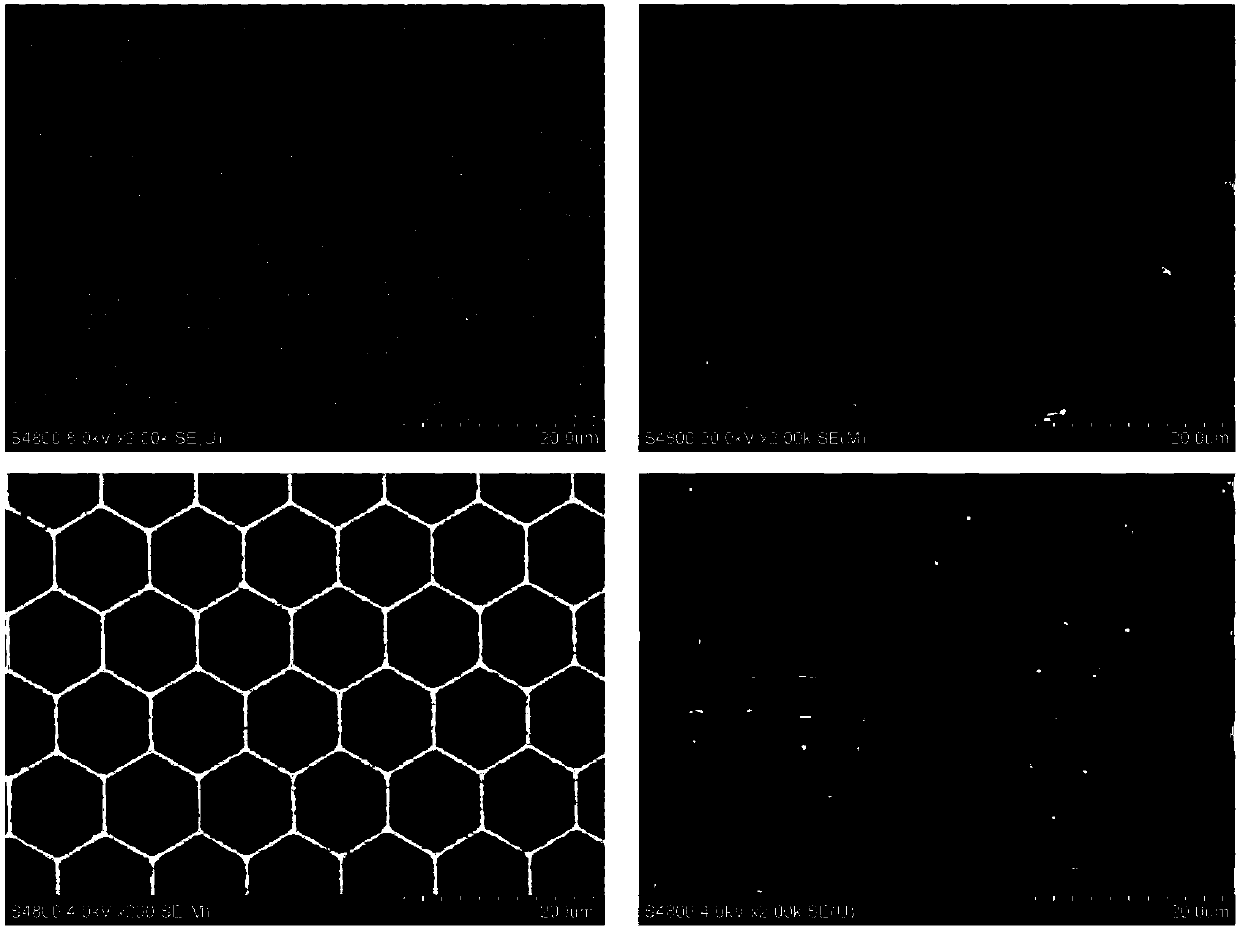

ActiveCN107610814AHigh light transmittanceGood electrical conductivityMaterial nanotechnologyConductive layers on insulating-supportsMetal gridSurface modification

The invention discloses an ultra-thin metal grid-based transparent electrode and a preparation method thereof, and relates to the technical field of a transparent electrode. The ultra-thin metal grid-based transparent electrode comprises a surface modified flexible transparent substrate; and a conductive metal grid layer with thickness of 1-10nm is deposited on the modified surface of the flexibletransparent substrate. The preparation method of the transparent electrode comprises the steps of grafting a layer of amino group on the surface of the substrate, forming a mask plate by photoresistor adhesive printing, depositing a metal layer with thickness of 1-10nm in the gap of the mask plate, and removing the mask plate to obtain the ultra-thin metal grid-based transparent electrode. By lowering the thickness of the metal grids, the light transmittance of the metal grids is improved; and meanwhile, the metal grids still have relatively high conductivity at the thickness of 1-10nm, so that the problem of "waxing and waning" between the conductivity and the light transmittance of the transparent electrode can be solved, and balance of the conductivity and the light transmittance is realized.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

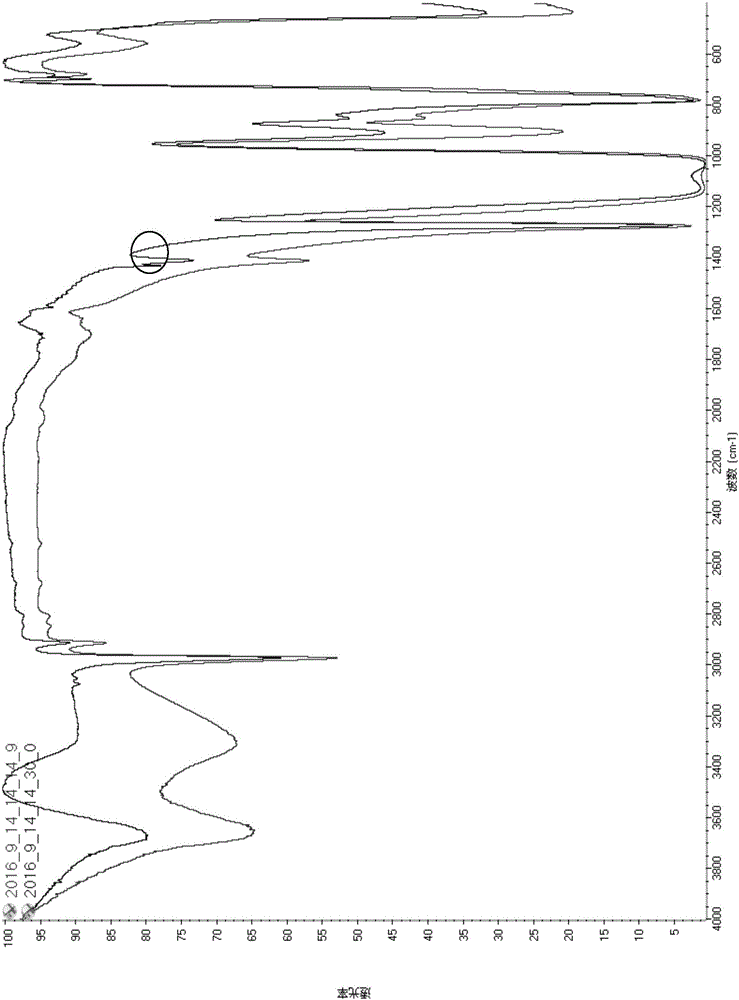

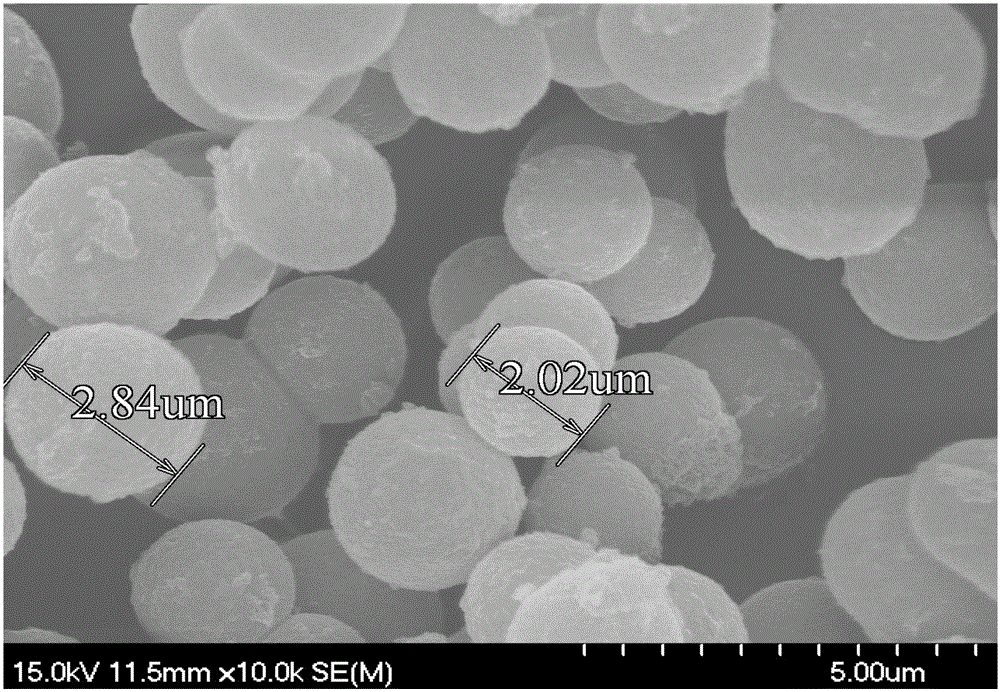

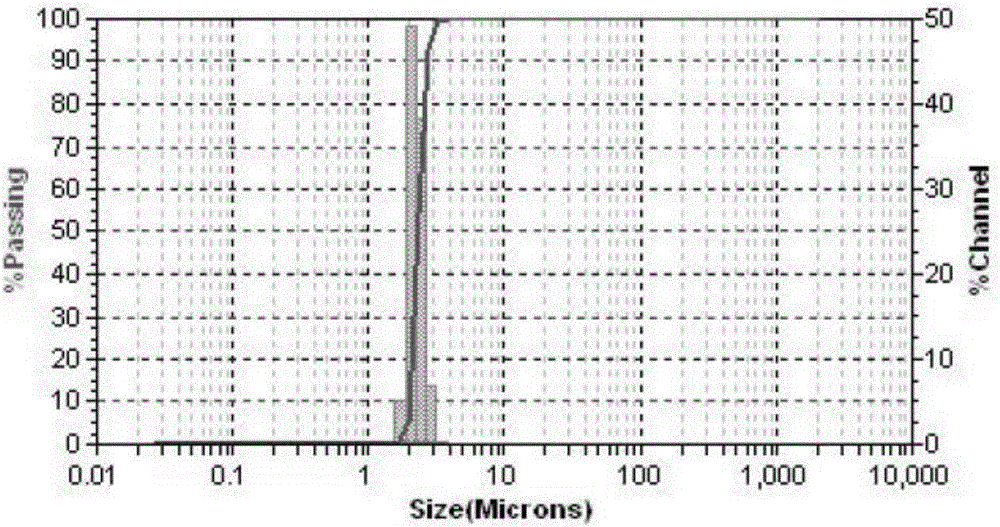

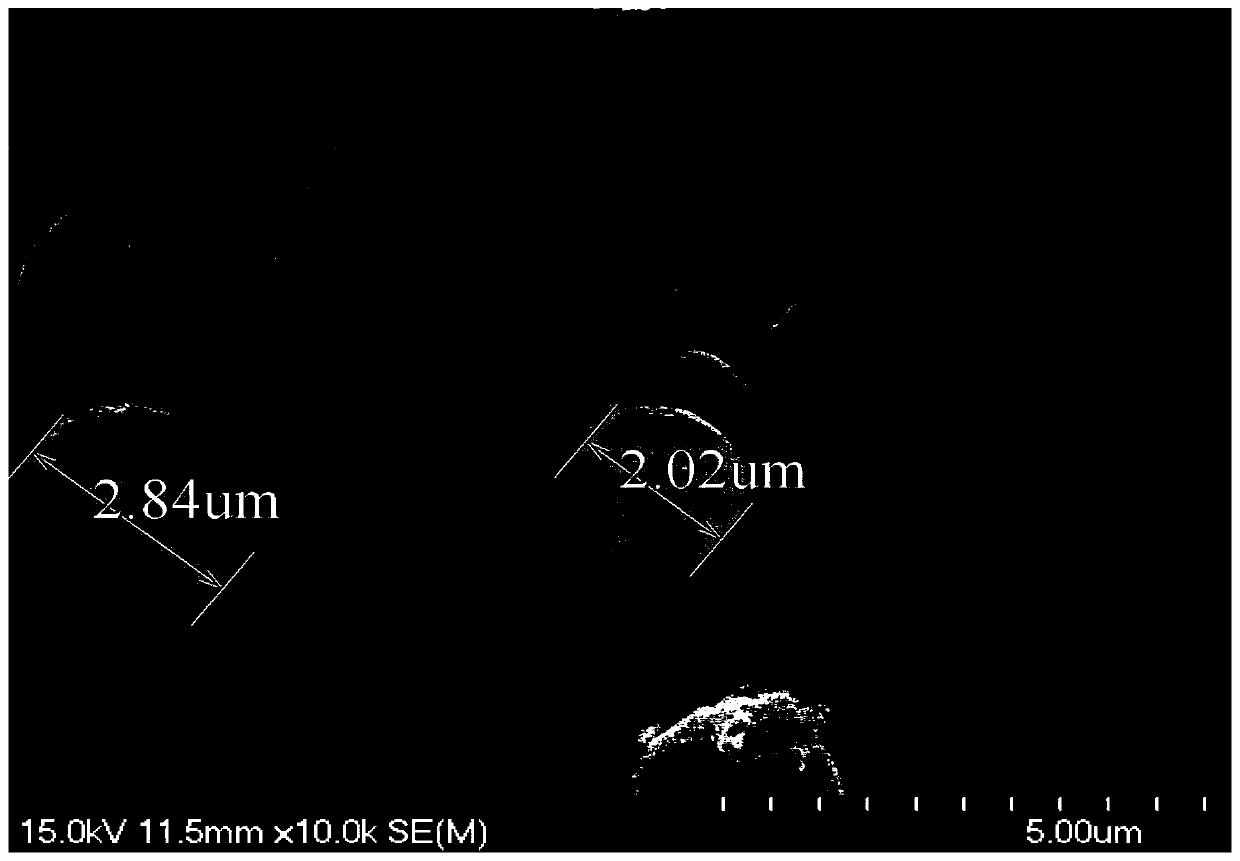

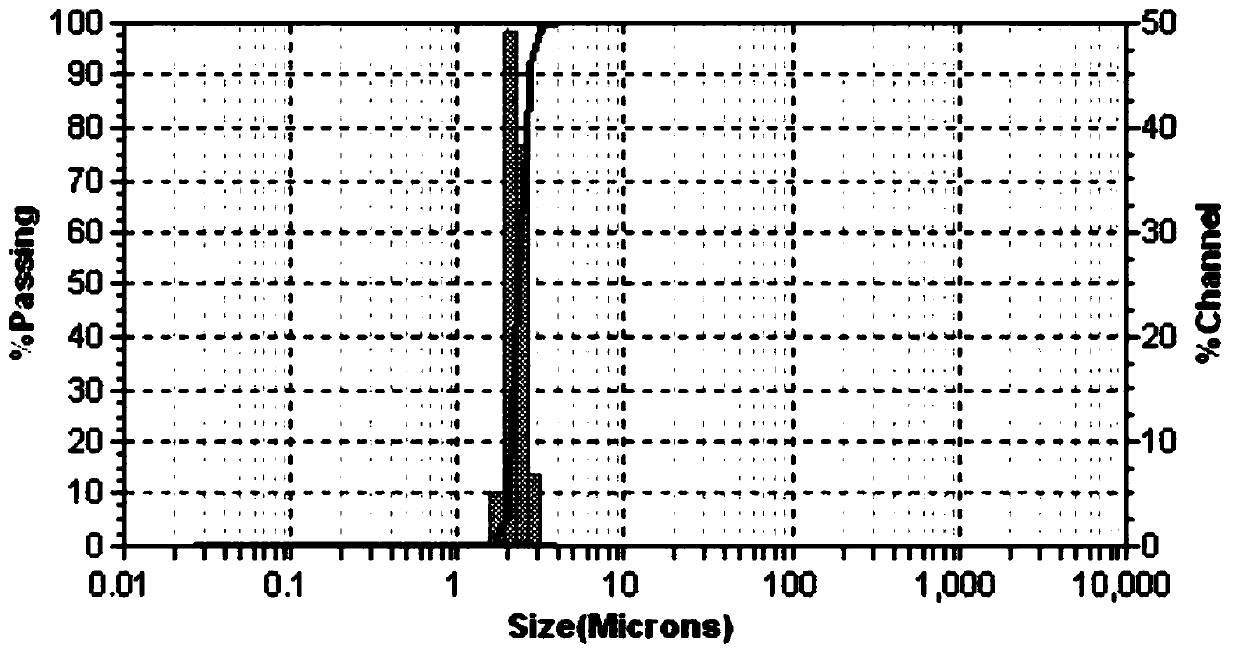

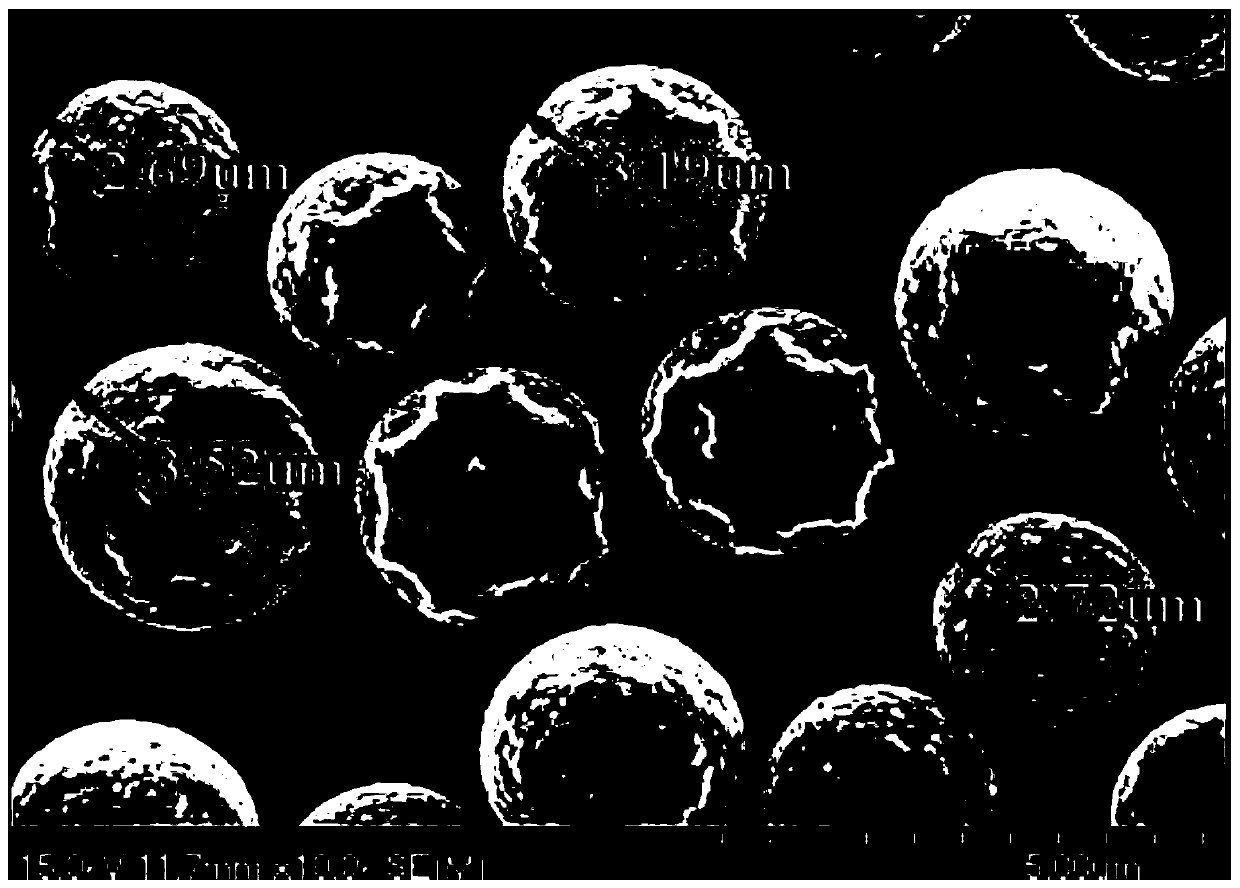

Preparation method of modified polysiloxane microspheres with controllable particle sizes

The invention provides a preparation method of modified polysiloxane microspheres. The preparation method comprises steps as follows: firstly, a silanol solution is obtained by mixing and hydrolyzing siloxane monomers, an acidic catalyst and water; the electrical conductivity of the water is 5-60 mu s / cm; an alkaline catalyst is added to the silanol solution obtained in the step, a condensation reaction is performed, the mixture is heated, a modifier is added for a reaction again, and the modified polysiloxane microspheres are obtained. The modified polysiloxane microspheres containing multiple active genes are prepared by adding the modifier; the particle sizes of the modified polysiloxane microspheres are controlled by adjusting the electrical conductivity of the raw material water, so that the prepared modified polysiloxane microspheres have narrower particle size distribution, are uniform in particle size and meet the demands of different products. Besides, the provided preparation method has higher product yield, adopts a simple process, is easy to operate, doesn't require organic solvents, is environment-friendly and facilitates large-scale production.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Metal interconnection layer with adjustable dielectric constants and manufacture method of metal interconnection layer

ActiveCN102938399AAdjustable dielectric constantHigh speedSemiconductor/solid-state device detailsSolid-state devicesInterconnectionDiffusion barrier

The invention provides a metal interconnection layer with adjustable dielectric constants. The metal interconnection layer comprises a barrier layer, a dielectric layer, metal wire layers and a metal diffusion barrier layer which are sequentially deposited, the metal wire layers are arranged in the dielectric layer, a closed gap is arranged at the position in the dielectric layer, and the position in the dielectric layer is located between the metal wire layers. The metal interconnection layer is simple in structure and low in cost, and a method is simple and convenient to implement; and by means of the metal interconnection layer, metal interlayer dielectric layer thin films with the low and adjustable dielectric constants can be obtained on the condition that dielectric layer thin films are fixed, device speeds are improved, and requirements of different products are met.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

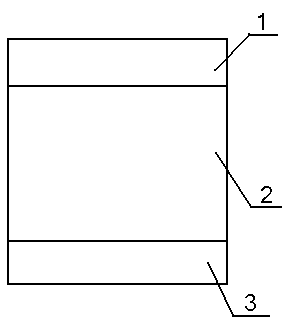

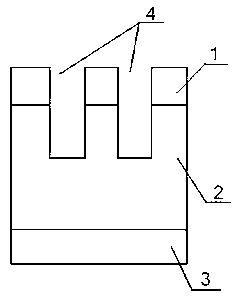

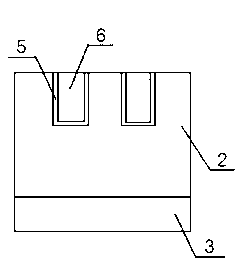

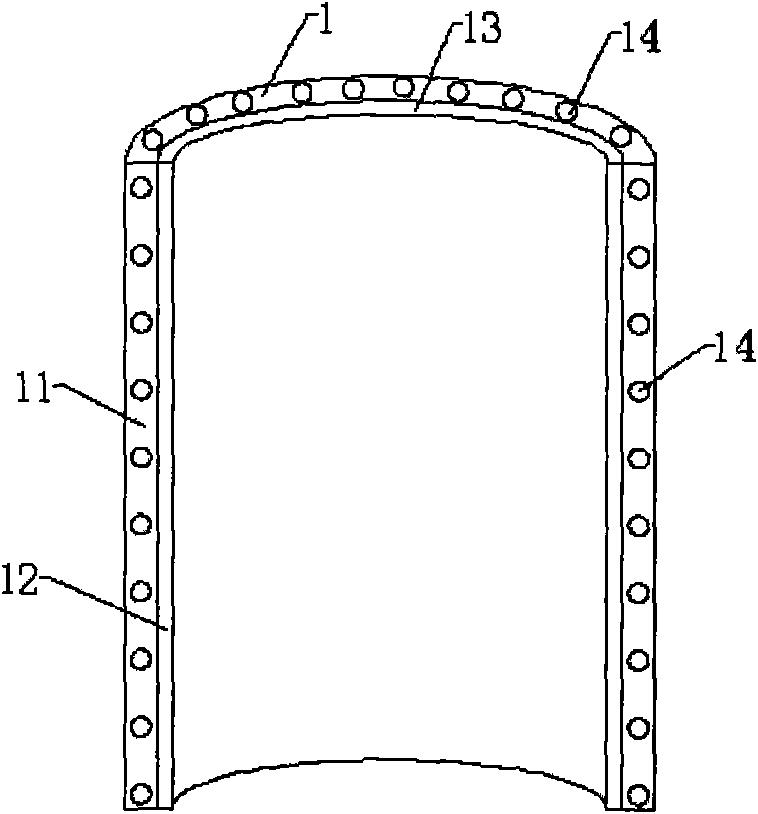

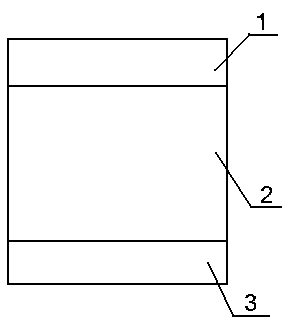

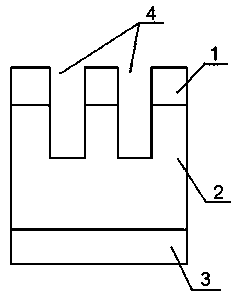

Combined septic tank

InactiveCN101580335AImprove sealing performanceSave resourcesBiological sludge treatmentCorrosion resistantHollow cylinder

The invention provides a combined septic tank. The septic tank is characterized by comprising a hollow cylinder connected by pieces with flange on the periphery, and end blocks which are provided with flange on the periphery and are connected on the end part of the hollow cylinder, wherein the pieces or / and the end blocks are provided with an inlet and an outlet. Series of the pieces and the corresponding end blocks with flange on the periphery in different arc lengths and different lengths can be produced according to requirement so as to conveniently assemble the cistern with required diameter and length according to requirement, thereby meeting the requirements of users on different products. The pieces and the end blocks can be piled, so the pieces and the end blocks occupy neither production space or storage space after production, nor transportation space to greatly reduce investment on workshops and warehouses and transportation cost; the sealability of the septic tank is effectively increased and the strength of the septic tank is enough, which can be made of corrosion-resistant waste plastics, saves resources, has low cost, and is worthy of popularization and application.

Owner:KUNMING PURETOWN ENVIRONMENTAL TECH

Epoxy resin-silicon carbide wear-resistant flame-retardant composite material and preparation method thereof

The invention relates to an epoxy resin-silicon carbide wear-resistant flame-retardant composite material and a preparation method thereof. According to the epoxy resin-silicon carbide wear-resistant flame-retardant composite material, silicon carbide which is subjected to surface modification, grafted with glycidyl methacrylate and bonded with a melamine salt flame retardant is dispersed in epoxy resin, and the addition amount of the silicon carbide with the surface modified with the flame retardant is 1-12 wt.% of the epoxy resin. The preparation method of the composite material comprises the following steps: carrying out surface modification grafting on silicon carbide, and bonding a flame retardant to the surface of the silicon carbide through a ring-opening reaction; dispersing the prepared silicon carbide particles of which the surfaces are modified with the flame retardant into epoxy resin to form an epoxy resin-silicon carbide uniform dispersion system; and adding a curing agent for epoxy resin curing treatment. The epoxy resin-silicon carbide wear-resistant flame-retardant composite material provided by the invention has excellent flame retardance, wear resistance and mechanical properties, and the preparation method is simple, mild in reaction condition and suitable for large-scale industrial production.

Owner:PINGDINGSHAN UNIVERSITY

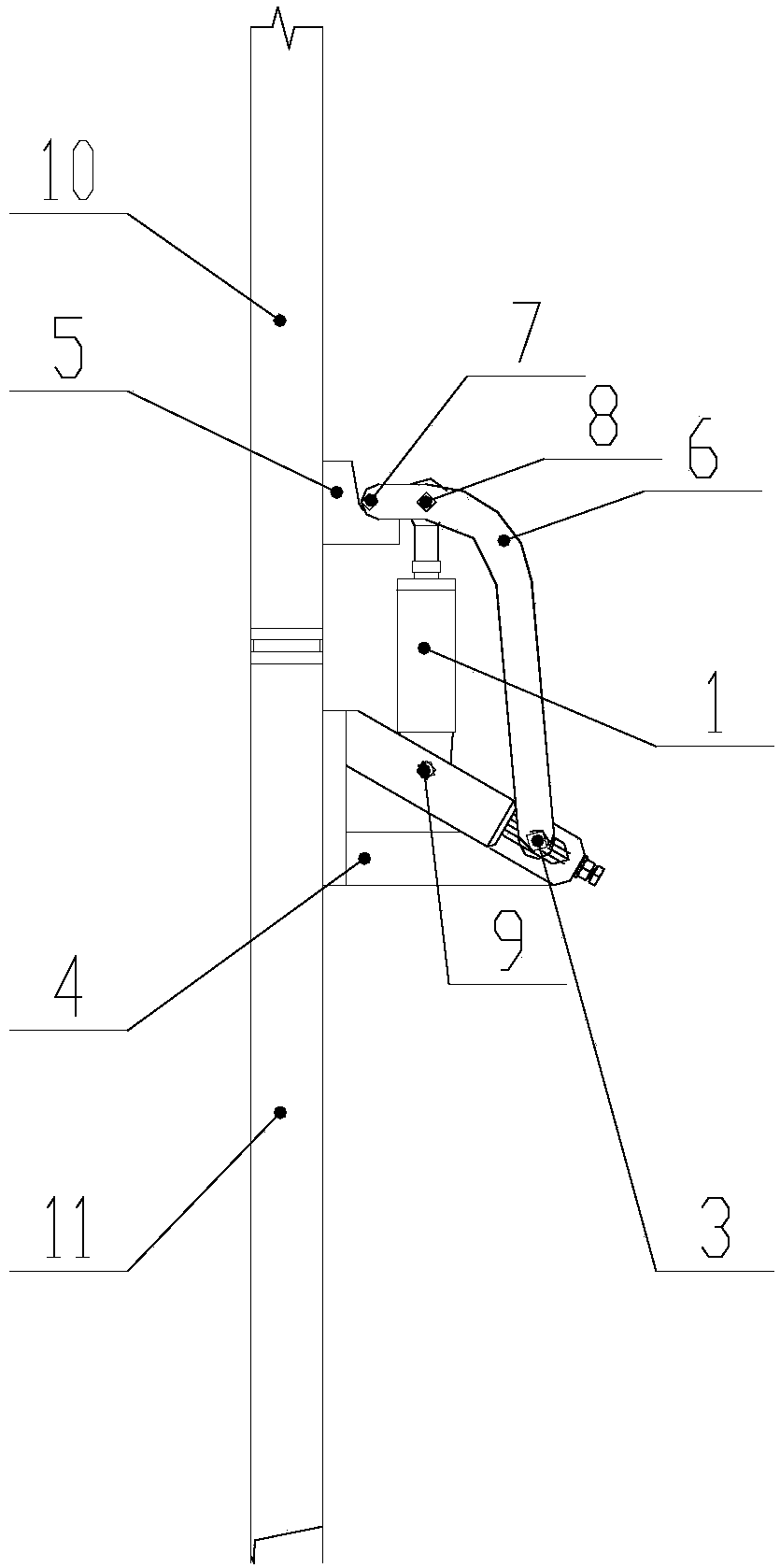

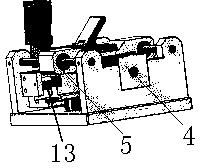

Mold closing and locking mechanism capable of adjusting clearance and closed mold clearance adjusting method

The invention provides a mold closing and locking mechanism capable of adjusting the clearance and a closed mold clearance adjusting method. The mold closing and locking mechanism capable of adjustingthe clearance comprises a support, a linear jacking and pulling driving device, a movable arm and a first hanging connection body; the support is installed on one of molds needing to be closed, and the first hanging connection body is installed on the other of the molds needing to be closed; the lower end of the movable arm is hinged to the support through a movable adjusting part, and the position, corresponding to the first hanging connection body, of the movable arm is provided with a second hanging connection body capable of being in hanging connection with the first hanging connection body; and the lower end of a seat body of the linear jacking and pulling driving device is hinged to the support through a first rotary shaft, and the upper end of a telescopic shaft of the linear jacking and pulling driving device is hinged to the movable arm through a second rotary shaft. According to the mold closing and locking mechanism, the clearance between the two molds can be conveniently adjusted according to the thickness and strength requirements of a product, moreover, manual hooking is not needed in the mold closing and opening processes, the mold closing and opening speed is high,the production efficiency is improved, and the product yield is increased.

Owner:SHANDONG SHUANGYI TECH

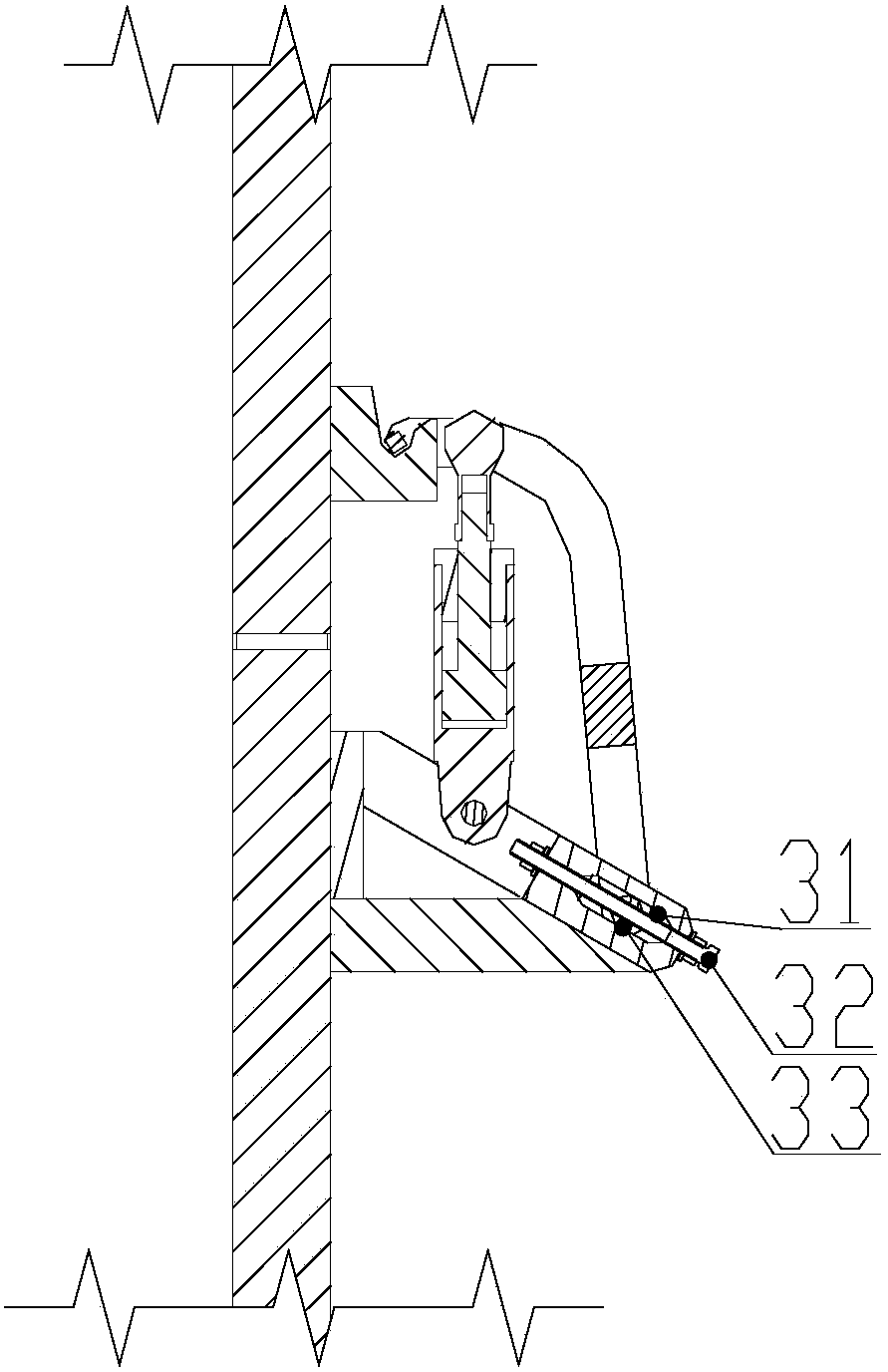

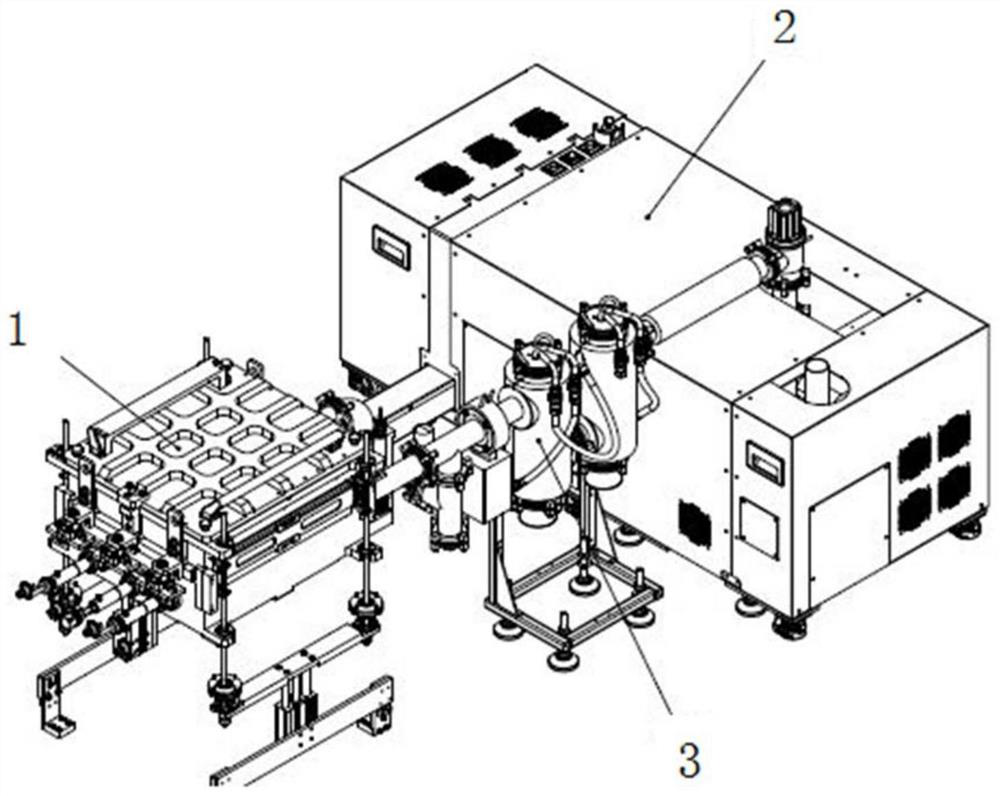

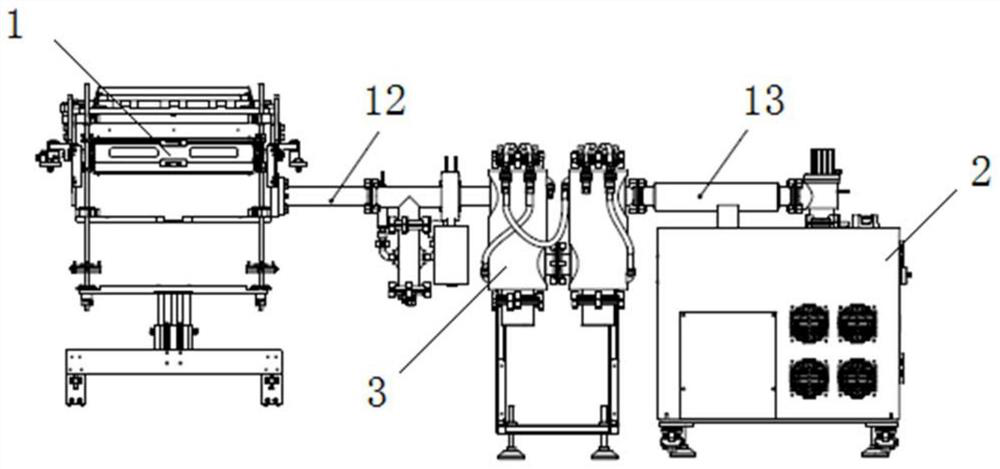

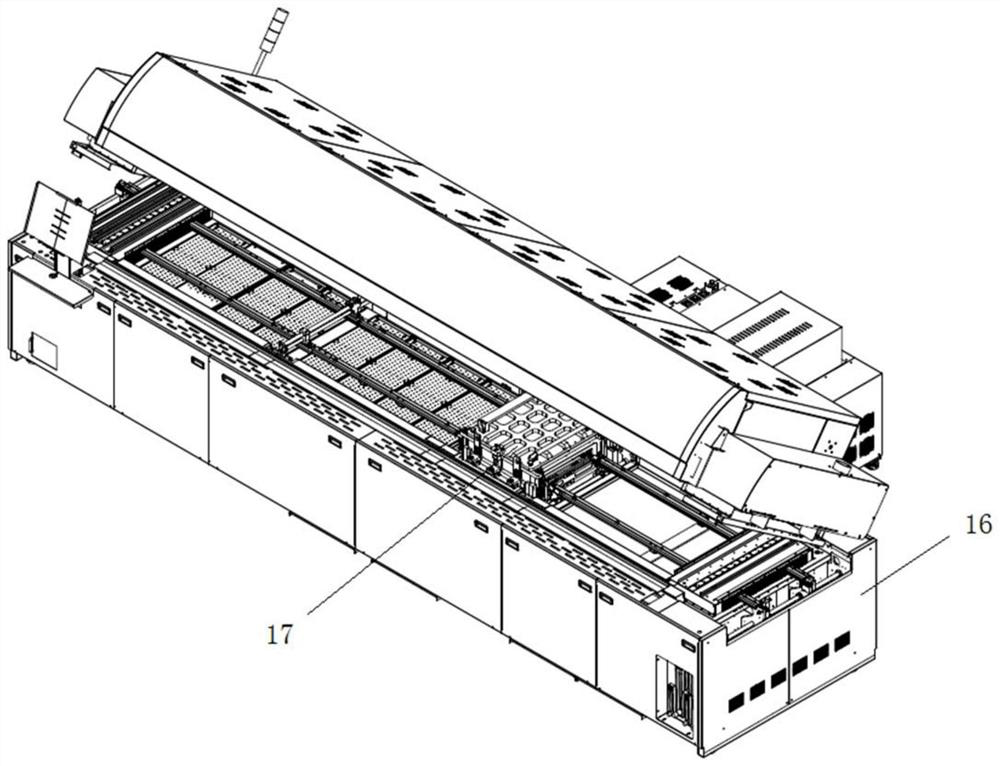

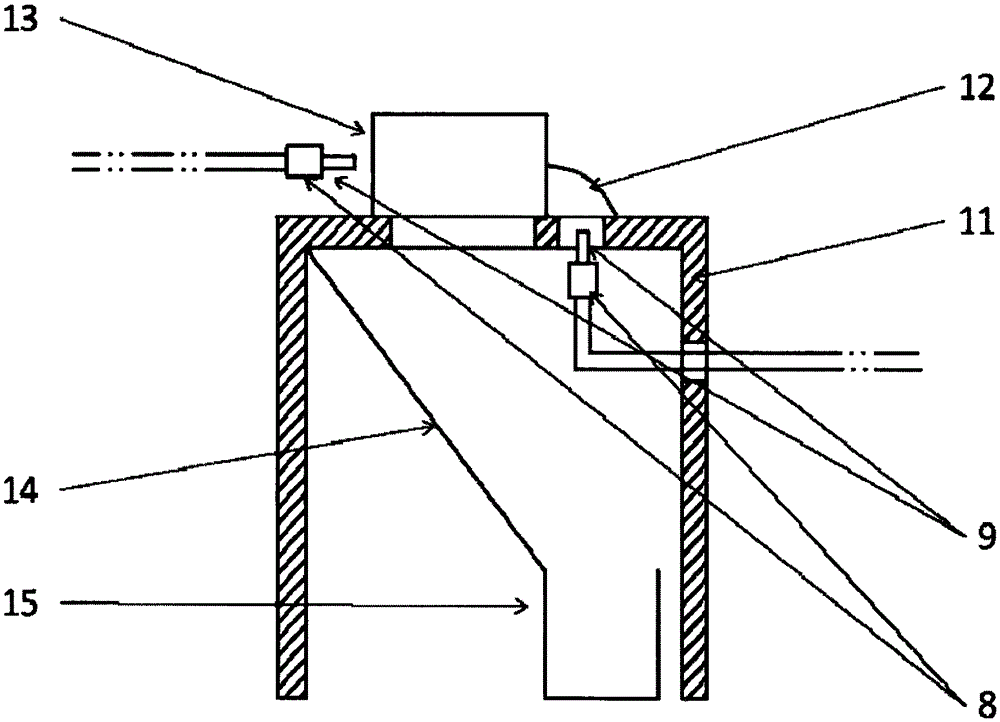

Vacuum device for reflow soldering furnace

PendingCN113163618AReduce in quantityImprove reliabilityPrinted circuit assemblingSoldering auxillary devicesEngineeringVacuum pump

The invention relates to a vacuum device for a reflow soldering furnace. The vacuum device is arranged at the position of an original heating module in a reflow area of the reflow soldering furnace and comprises a vacuum cavity, a cooling and collecting auxiliary device and a vacuum pump system which are sequentially connected, the vacuum cavity comprises a cavity body, a top cover and side door mechanisms, the cavity body is fixed in the reflow furnace, the top cover covers the top of the cavity body, the front end and the rear end of the cavity body are respectively provided with two through holes, the two side door mechanisms are movably arranged at the front end and the rear end of the cavity body and respectively cover the two through holes in a closed state, and the top cover, the cavity body and the side door mechanisms form a totally closed space. The cavity body is provided with a transmission assembly matched with a product transmission system of the reflow soldering furnace, and the two side door mechanisms correspond to the product input front end and the product output rear end of the reflow soldering furnace. Compared with the prior art, the device has the advantages of reducing the size and number of welding point cavities, reducing the damage rate, being high in applicability and the like.

Owner:上海朗仕电子设备有限公司

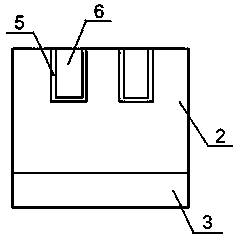

Screen printing device

The invention discloses a screen printing device. The screen printing device comprises a printing seat, a base and a supporting rod arranged on the top of the base, wherein the printing seat is movably arranged on the supporting rod through a movable block, an oil cavity is formed in the printing seat, a printing screen is arranged on the bottom of the oil cavity, a cavity cover is hinged to the top of the oil cavity, a scraper which is attached to the printing screen is arranged in the oil cavity, and the scraper is connected with a shifting piece which is arranged on the top of the printing seat. According to the screen printing device, the airtight oil cavity is adopted, an operator just needs to shift the shifting piece during operation, and oil paint is prevented from adhering to the operator; the printing screen is detachably connected with the printing seat, in this way, the printing screen can be replaced with printing screens with different patterns at any time, and adaptability is improved; meanwhile, the height of a silk screen base can be adjusted freely so that the requirements of different products can be met, and the screen printing device is simple in structure, convenient to use and economical.

Owner:TIANJIN ZHENGGUANG PRINTING

A kind of transparent electrode based on ultra-thin metal grid and preparation method thereof

ActiveCN107610814BHigh light transmittanceImprove conductivityMaterial nanotechnologyConductive layers on insulating-supportsThin metalPhotoresistor

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

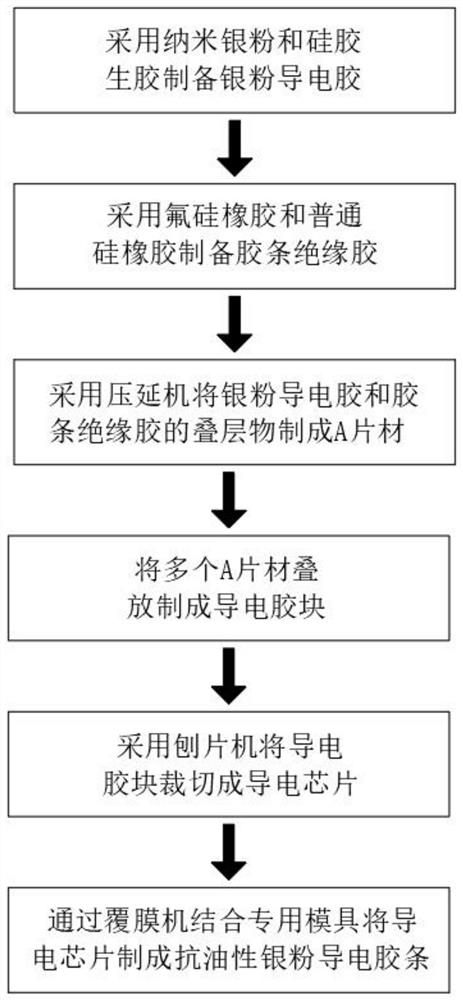

Method for manufacturing silver powder conductive adhesive tape capable of preventing oil absorption deformation and silver powder conductive adhesive tape thereof

ActiveCN113555166AMeet high performance requirementsLower resistanceConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersRubber materialSilica gel

The invention discloses a method for manufacturing a silver powder conductive adhesive tape capable of preventing oil absorption deformation, which comprises the following steps of: preparing silver powder conductive adhesive, preparing nano silver powder and raw silica gel, putting the nano silver powder and the raw silica gel into an internal mixer, fully stirring and mixing the nano silver powder and the raw silica gel through the internal mixer, uniformly adding the nano silver powder into the raw silica gel, and manufacturing the silver powder conductive adhesive; and preparing adhesive tape insulating glue, namely mixing fluorinated silicone rubber with common silicone rubber with the same hardness, and uniformly mixing by using an open mill, so that the two rubber materials are fully fused and uniformly mixed to prepare the adhesive tape insulating glue, wherein the insulating glue is made of a blend material of fluorosilicone rubber and common silicone rubber, has the special performance of fluorosilicone rubber such as oil resistance and aging resistance of fluorosilicone rubber, and has good compatibility of common silicone rubber, and the low-resistance conductive rubber strip with the oil resistance characteristic is manufactured.

Owner:东莞市松乔电子有限公司

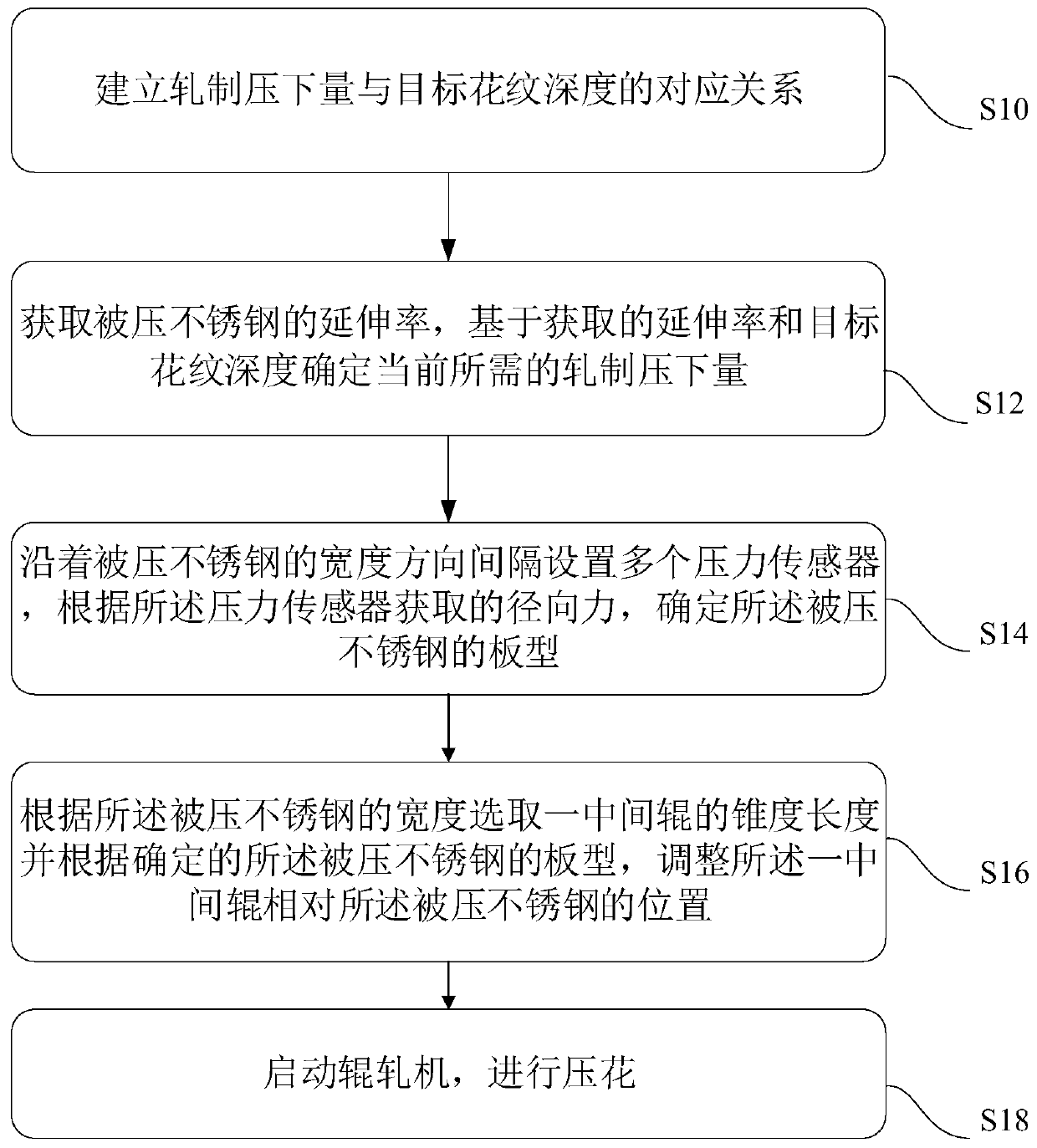

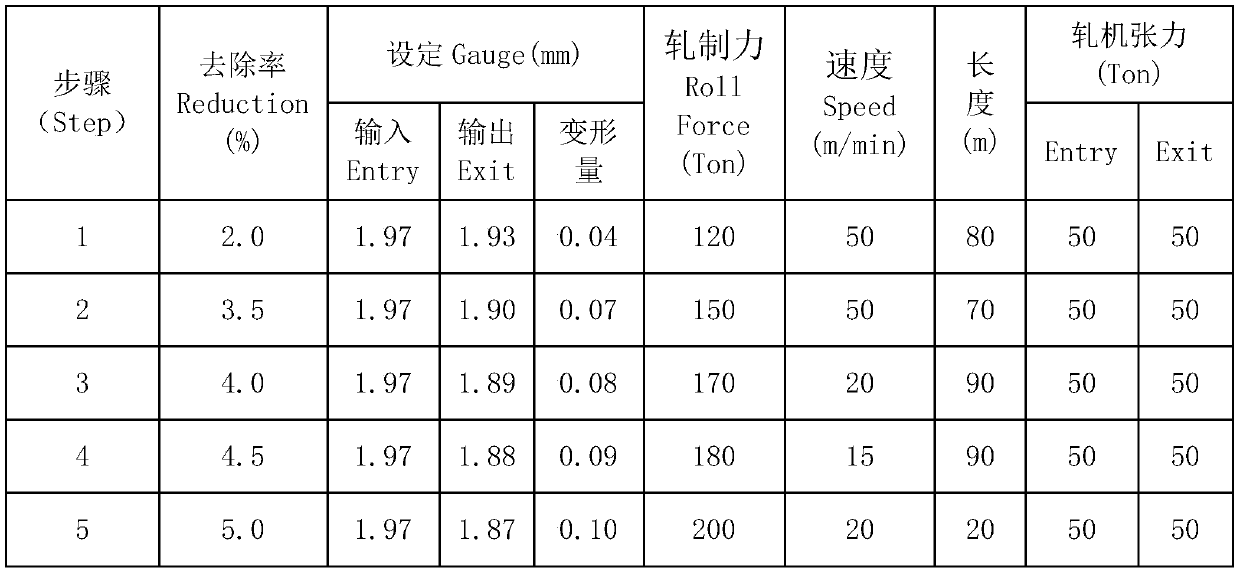

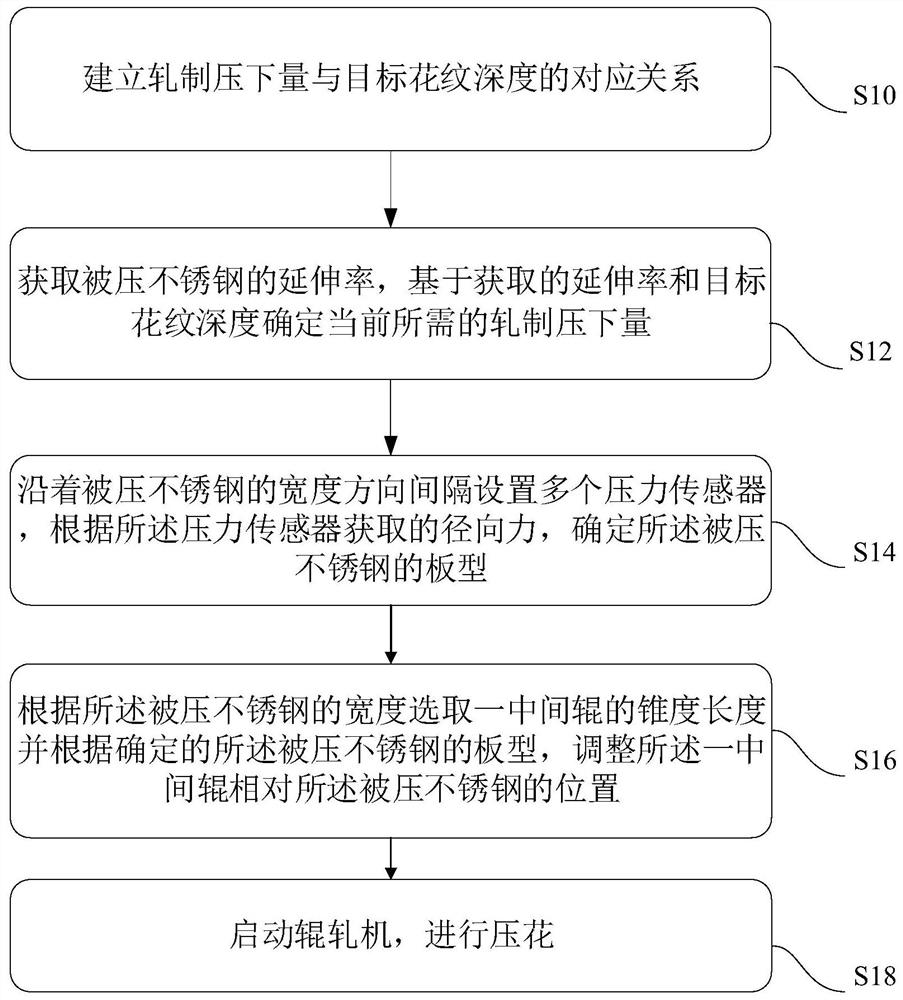

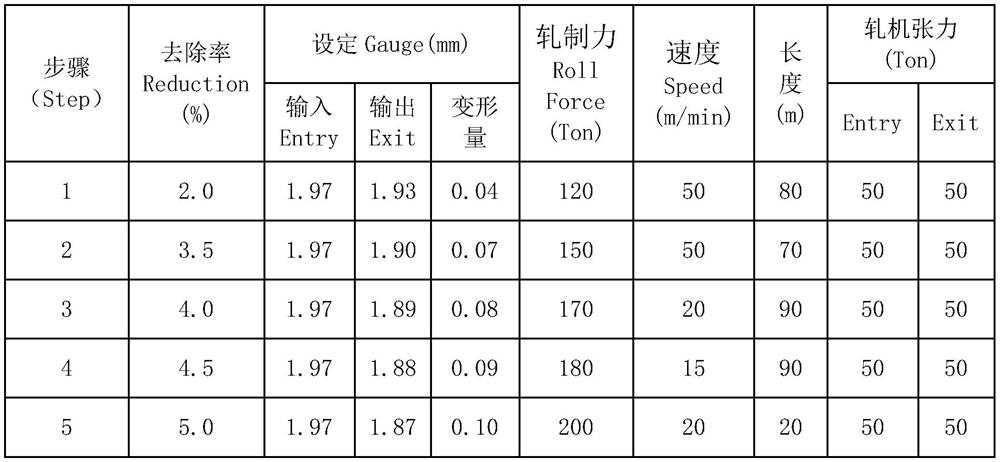

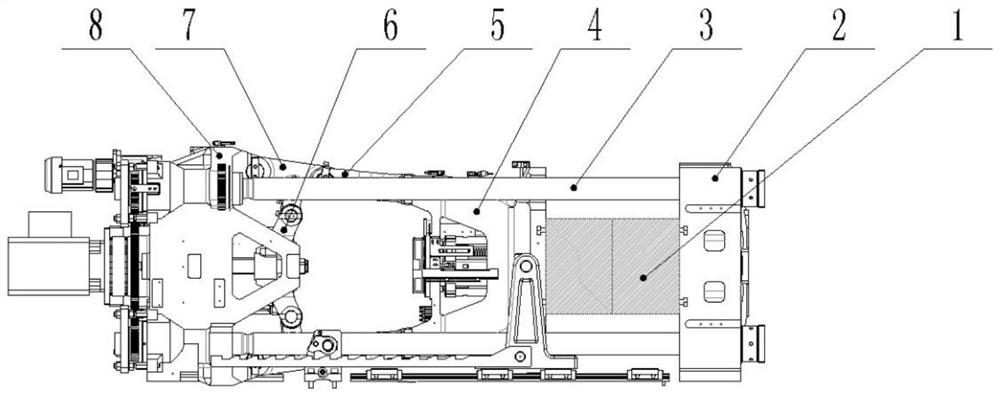

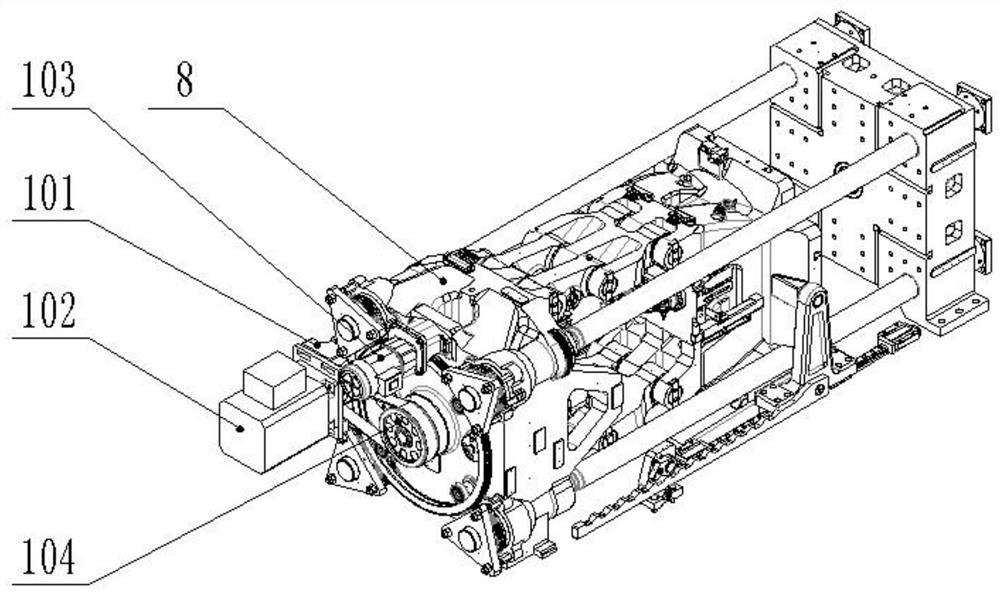

Stainless steel surface pattern depth control method

ActiveCN111266414AMeet the needs of different productsRoll force/gap control deviceMeasuring devicesSS - Stainless steelMaterials science

The invention discloses a stainless steel surface pattern depth control method. The stainless steel surface pattern depth control method comprises the steps that a corresponding relationship between the rolling reduction and the target pattern depth is established; the elongation of rolled stainless steel is acquired, and the current needed rolling reduction is determined on the basis of the acquired elongation and the target pattern depth; multiple pressure sensors are arranged in the width direction of the rolled stainless steel at intervals, and the plate type of the rolled stainless steelis determined according to the radial force acquired by the pressure sensors; the taper length of an intermediate roll is selected according to the width of the rolled stainless steel, and the position of the intermediate roll relative to the rolled stainless steel is adjusted according to the plate type of the rolled stainless steel; and a rolling mill is started to conduct embossing. According to the stainless steel surface pattern depth control method, the target pattern depth can be obtained after stainless steel surface treatment is conducted, and then the requirements of manufacturing different products in all industries are met.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

A metal interconnection layer with adjustable dielectric constant and its manufacturing method

ActiveCN102938399BAdjustable dielectric constantHigh speedSemiconductor/solid-state device detailsSolid-state devicesMetal interconnectDiffusion barrier

The invention provides a metal interconnection layer with adjustable dielectric constants. The metal interconnection layer comprises a barrier layer, a dielectric layer, metal wire layers and a metal diffusion barrier layer which are sequentially deposited, the metal wire layers are arranged in the dielectric layer, a closed gap is arranged at the position in the dielectric layer, and the position in the dielectric layer is located between the metal wire layers. The metal interconnection layer is simple in structure and low in cost, and a method is simple and convenient to implement; and by means of the metal interconnection layer, metal interlayer dielectric layer thin films with the low and adjustable dielectric constants can be obtained on the condition that dielectric layer thin films are fixed, device speeds are improved, and requirements of different products are met.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

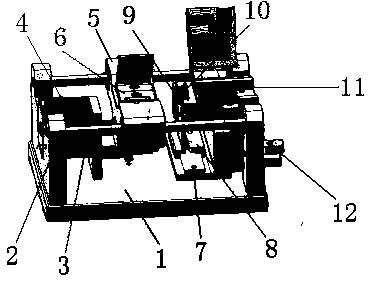

Intelligent optical fiber coating layer stripping and optical fiber cutting integrated cutting device

ActiveCN109239846BRealize the cutting operationAchieve fixed length cuttingCoupling light guidesFiberTemperature control

The invention discloses a cutting device integrating intelligent optical fiber coating layer stripping and optical fiber cutting, which includes a controller and a cutting machine. A wire link is arranged between the controller and the cutting machine. Two vertical plates, slide rails, motors, fixture bases, fixture chambers, mounting seats, handles, mounting blocks, cutting knives, heating chambers, differential heads, solenoid valves, hoses and vacuum installed on the two free ends of the bottom plate The valve, the clamp chamber is used to clamp the optical fiber, and the heating chamber is used to generate the temperature required for the stripping of the coating layer, which is stripped by the stripper; the controller includes a temperature control unit for controlling the temperature value of the heating chamber, which is used to control the temperature of the optical fiber The displacement control unit and the central processing unit for cutting or stripping the length, the temperature control unit and the displacement control unit are all connected to the central processing unit; the present invention integrates the stripping function of the optical fiber coating layer and the cutting function of the optical fiber, effectively improving the Fiber processing efficiency.

Owner:NANJING UNIV OF POSTS & TELECOMM

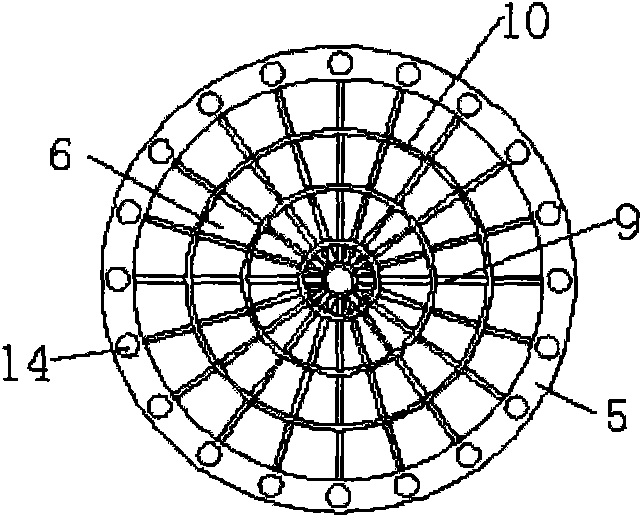

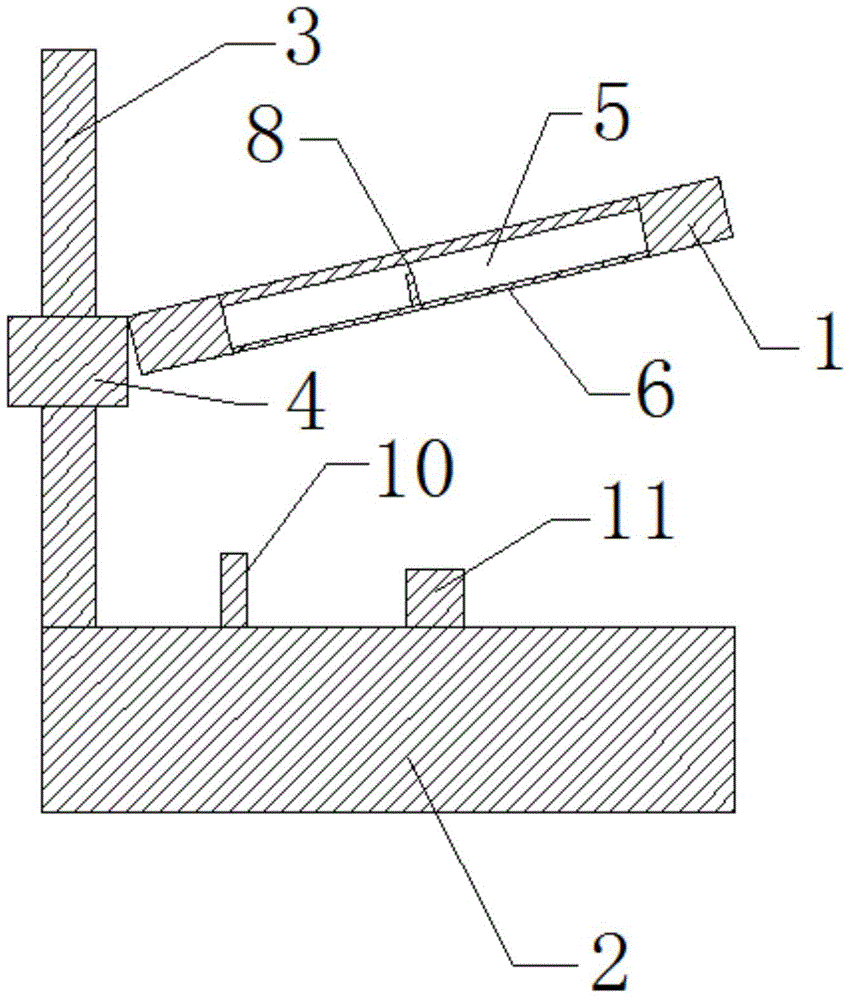

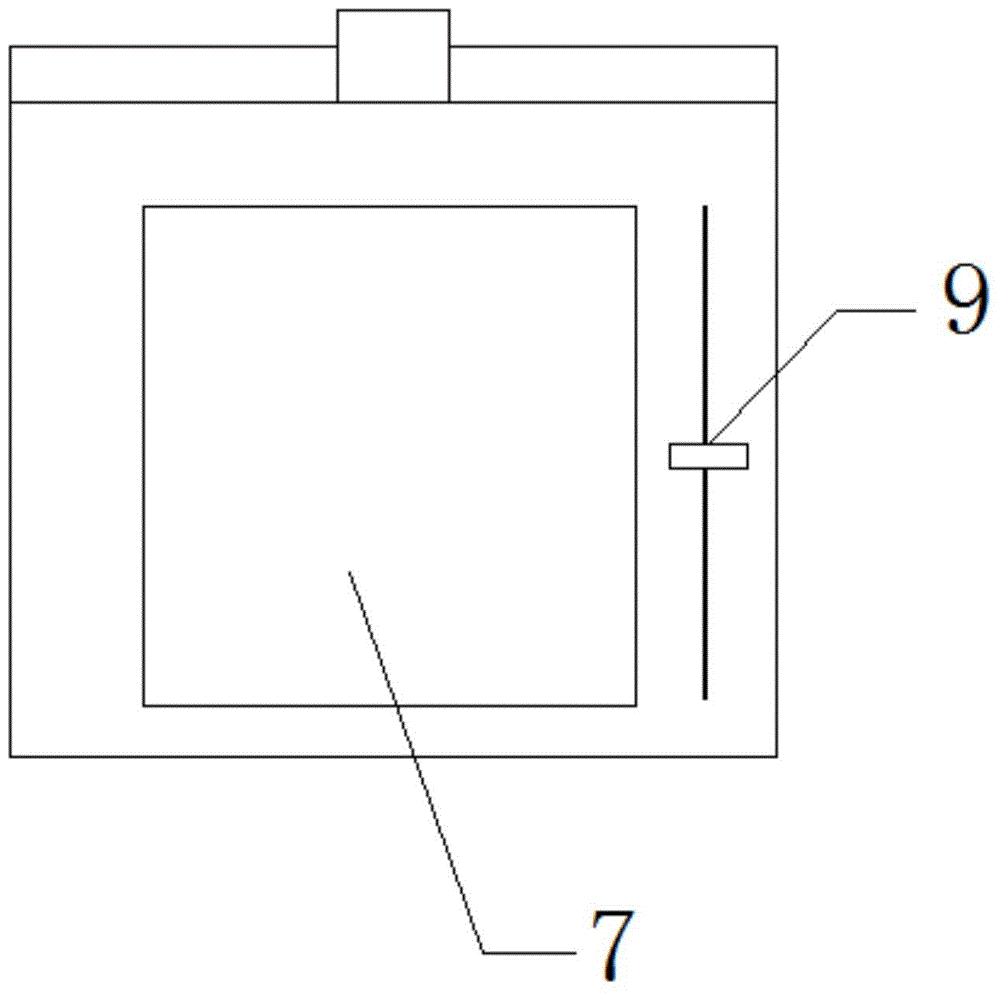

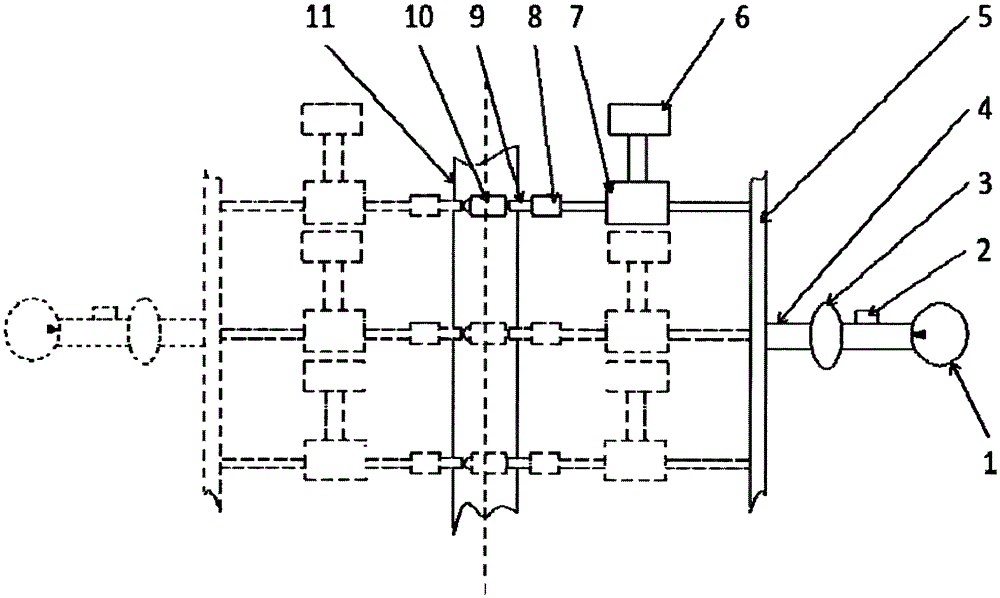

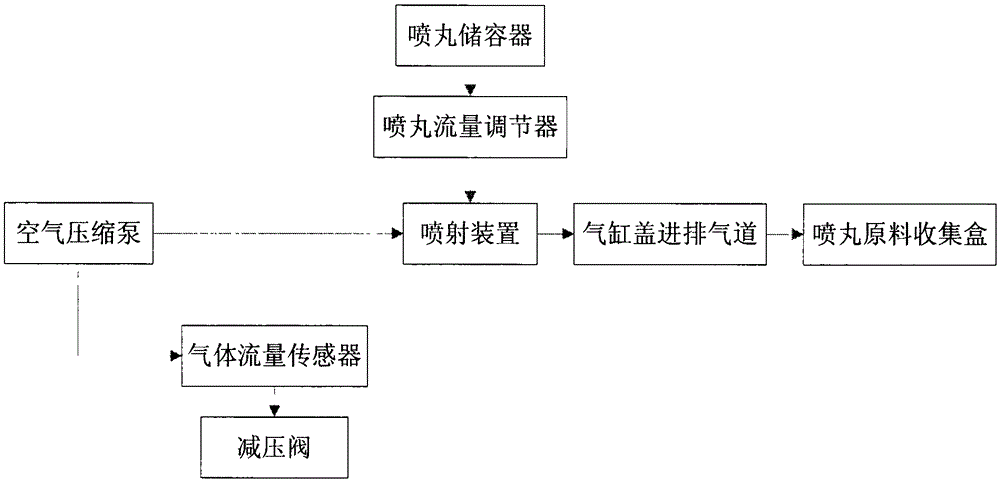

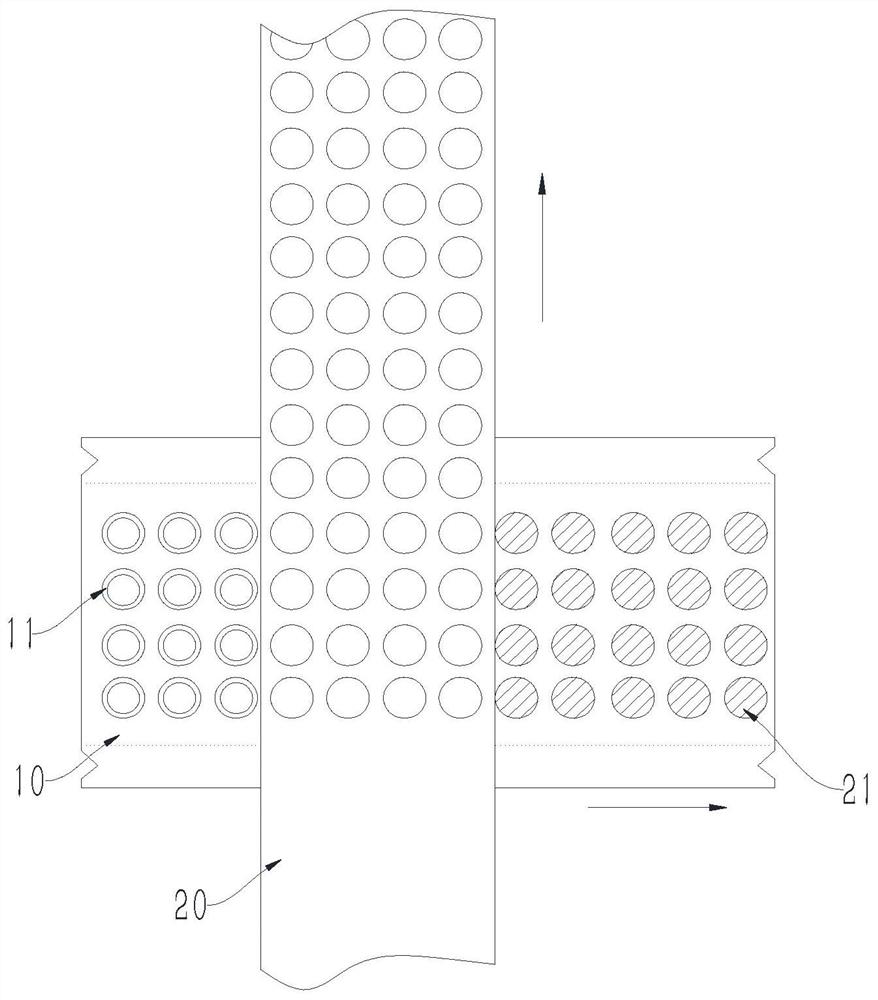

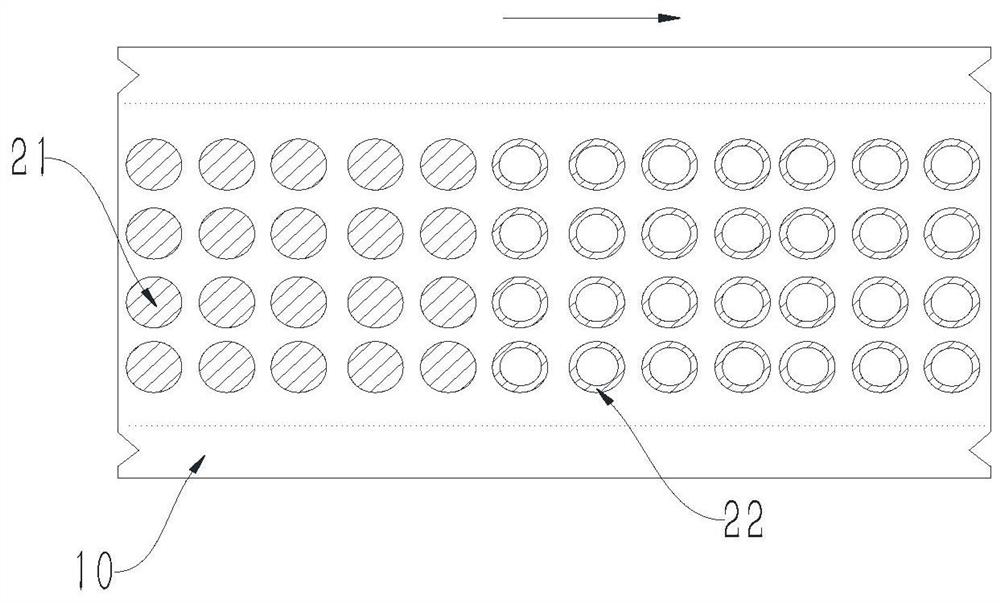

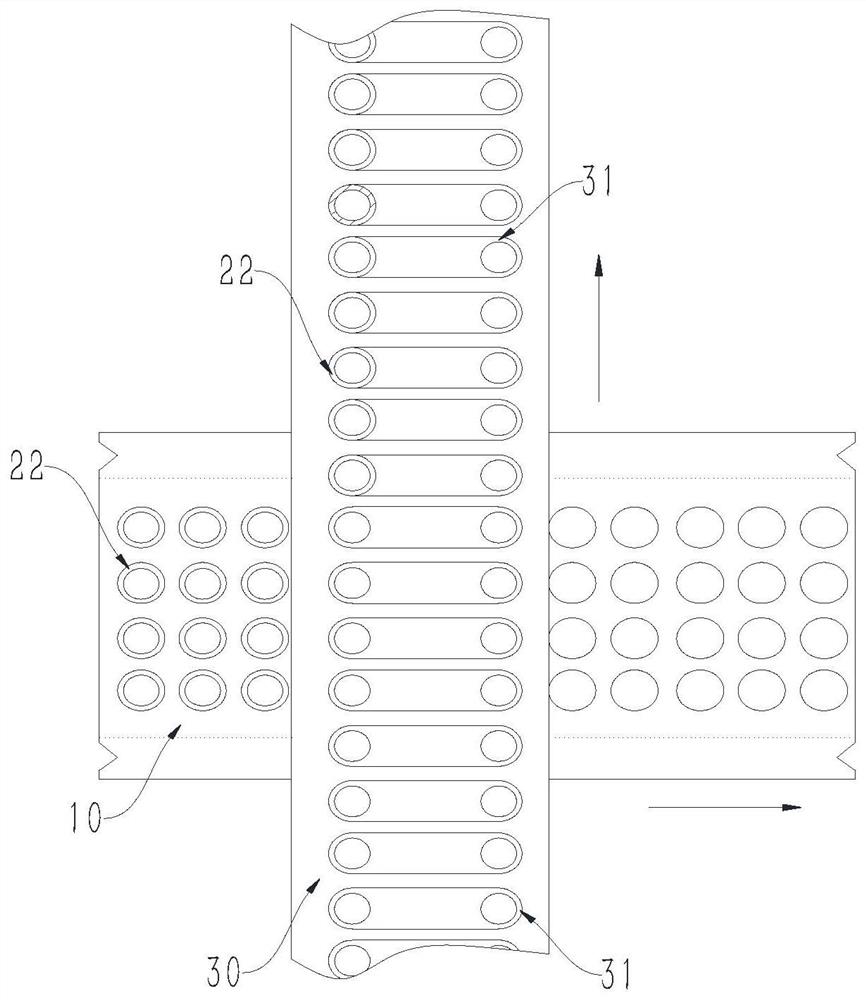

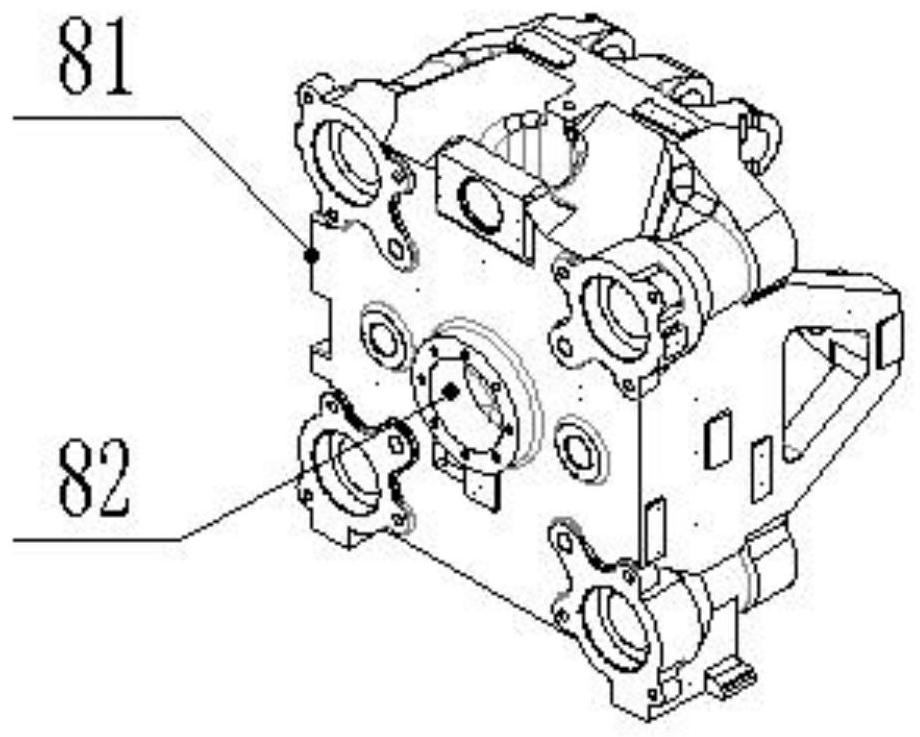

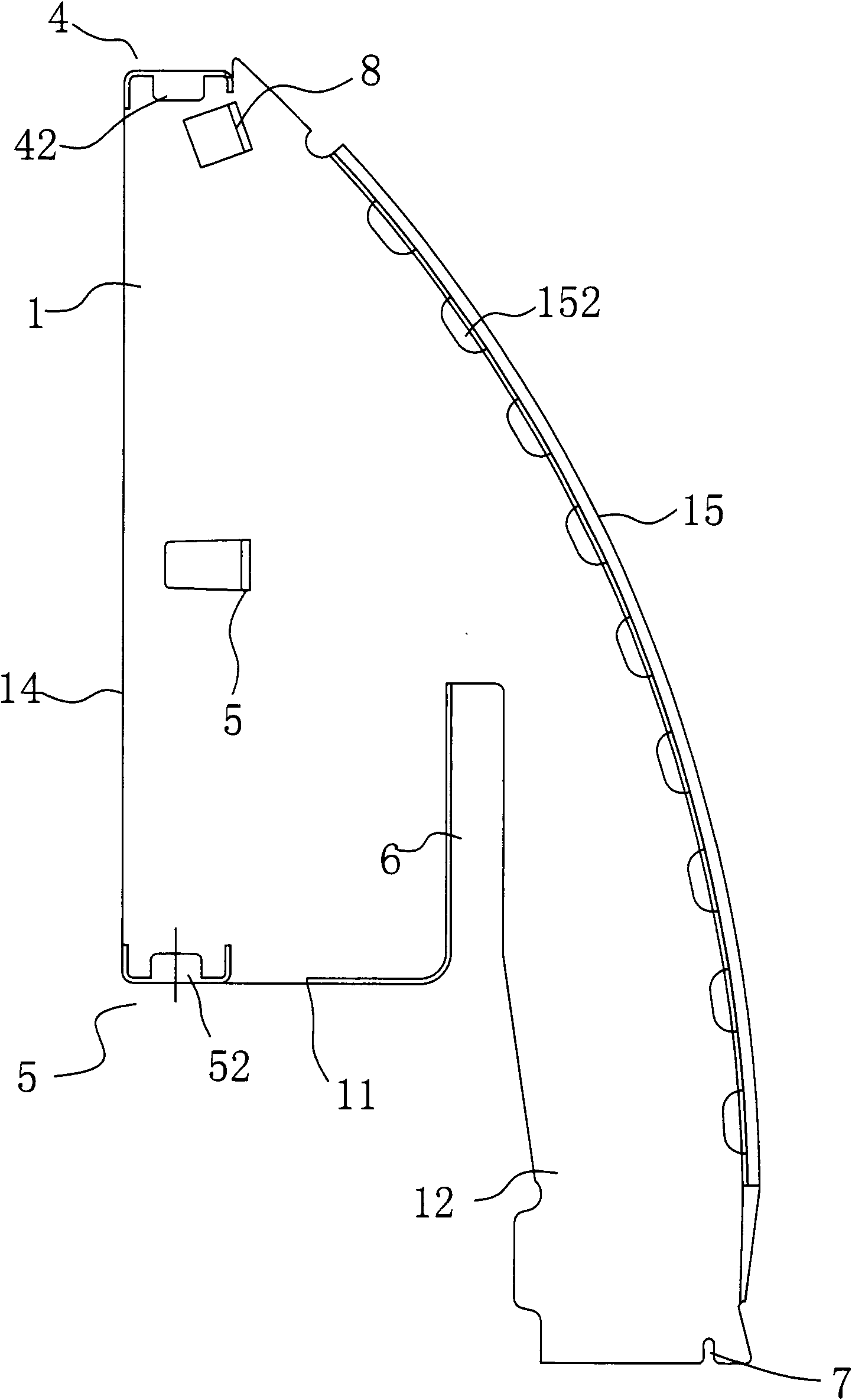

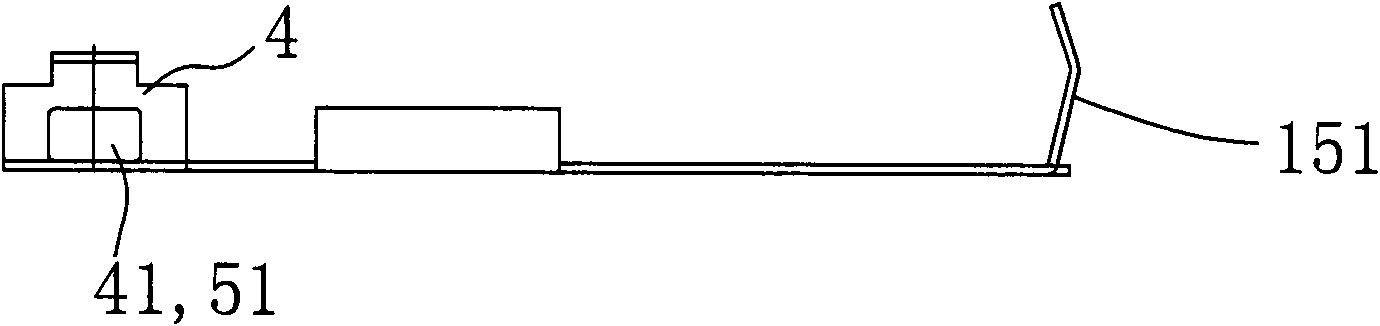

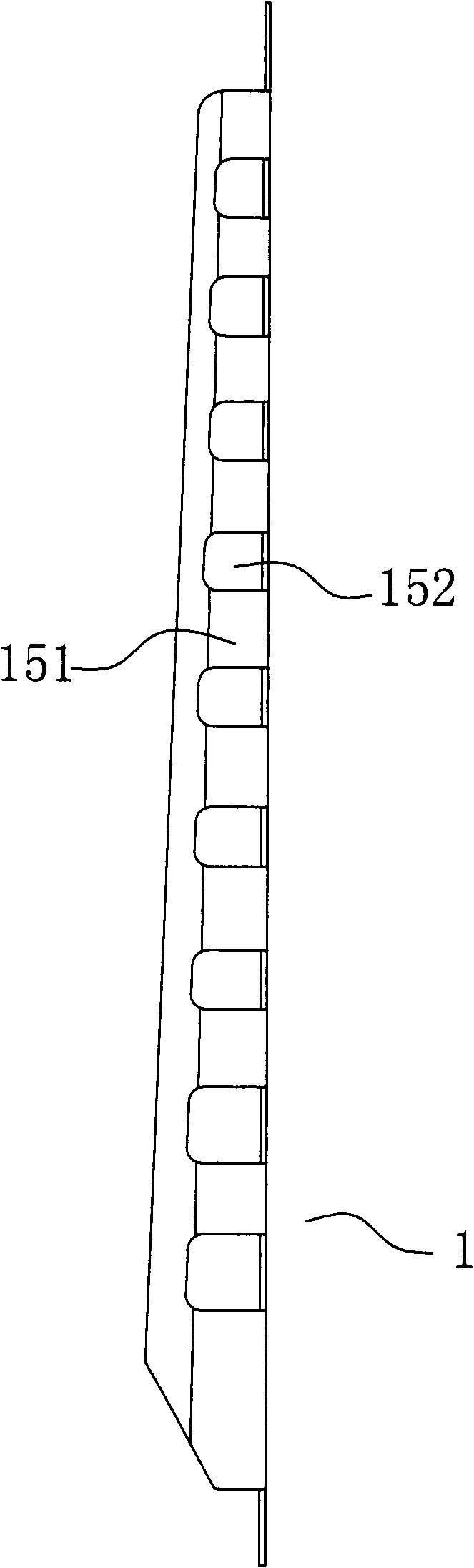

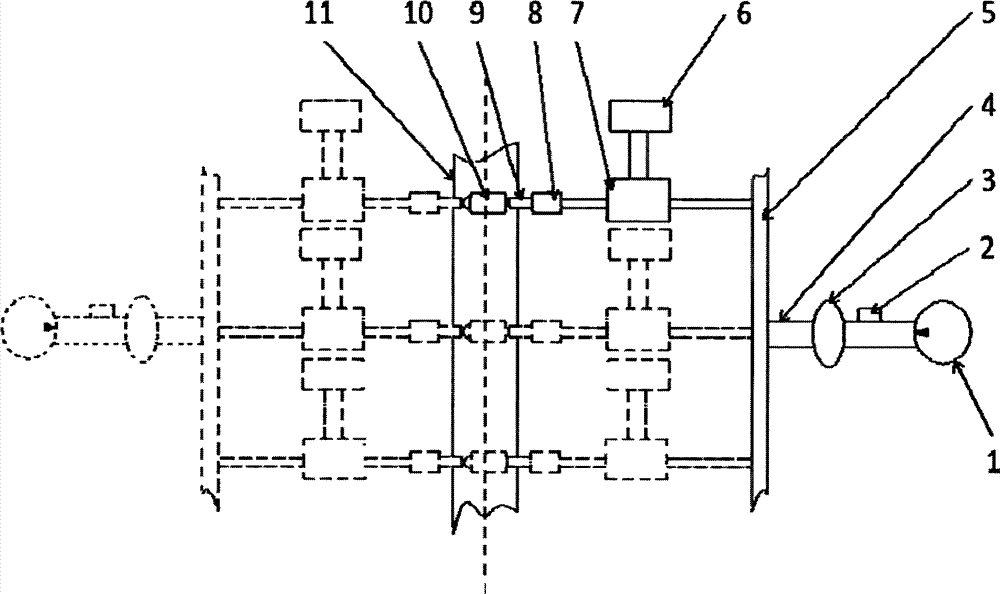

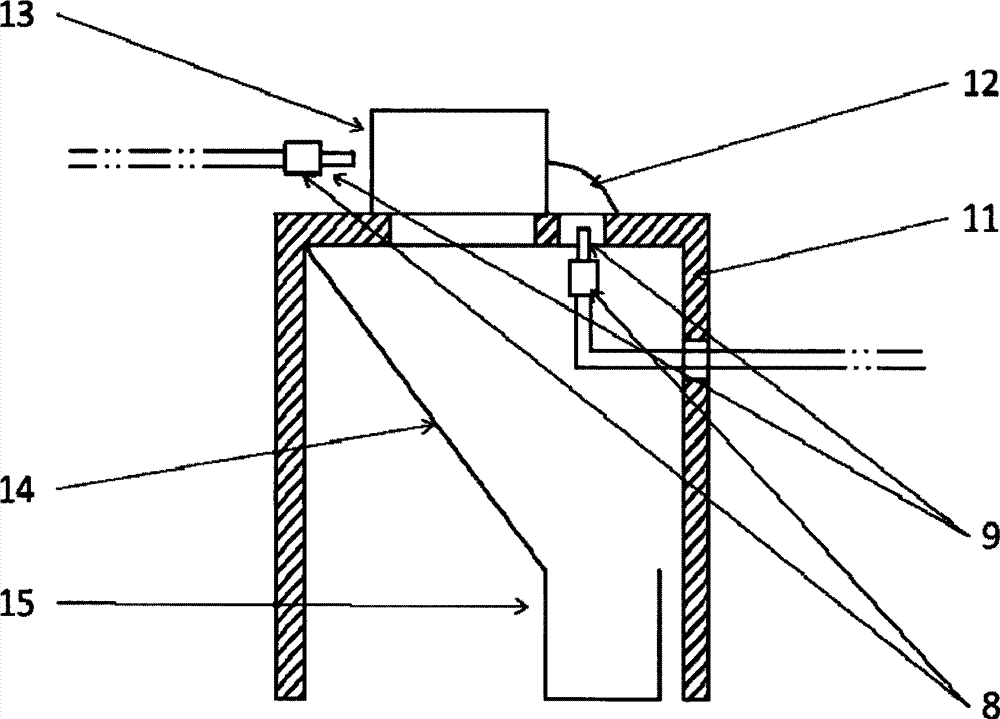

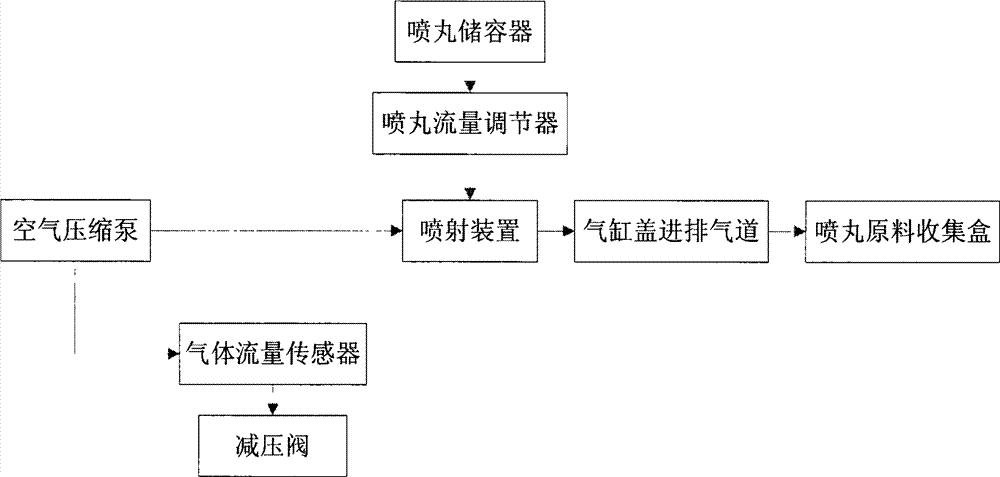

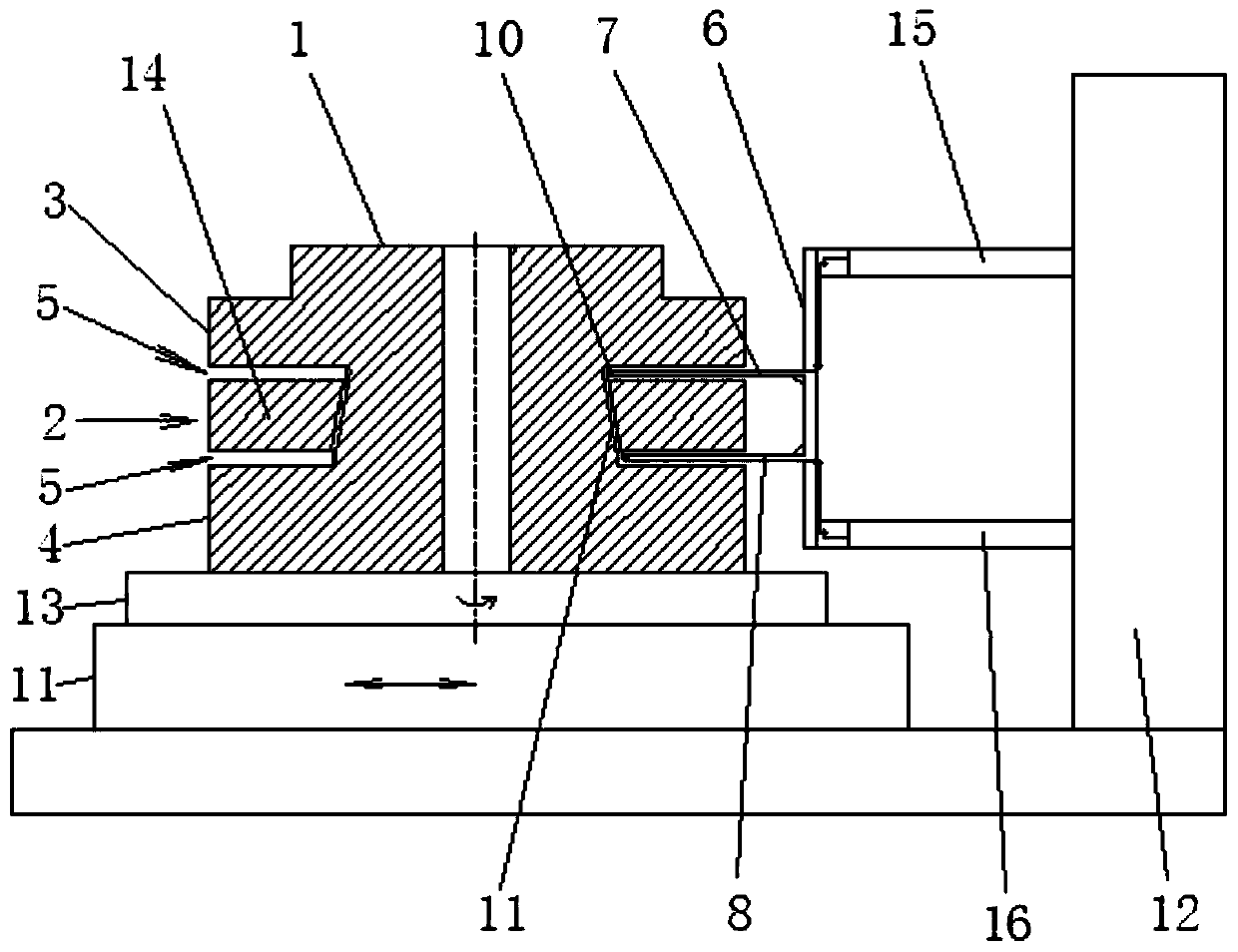

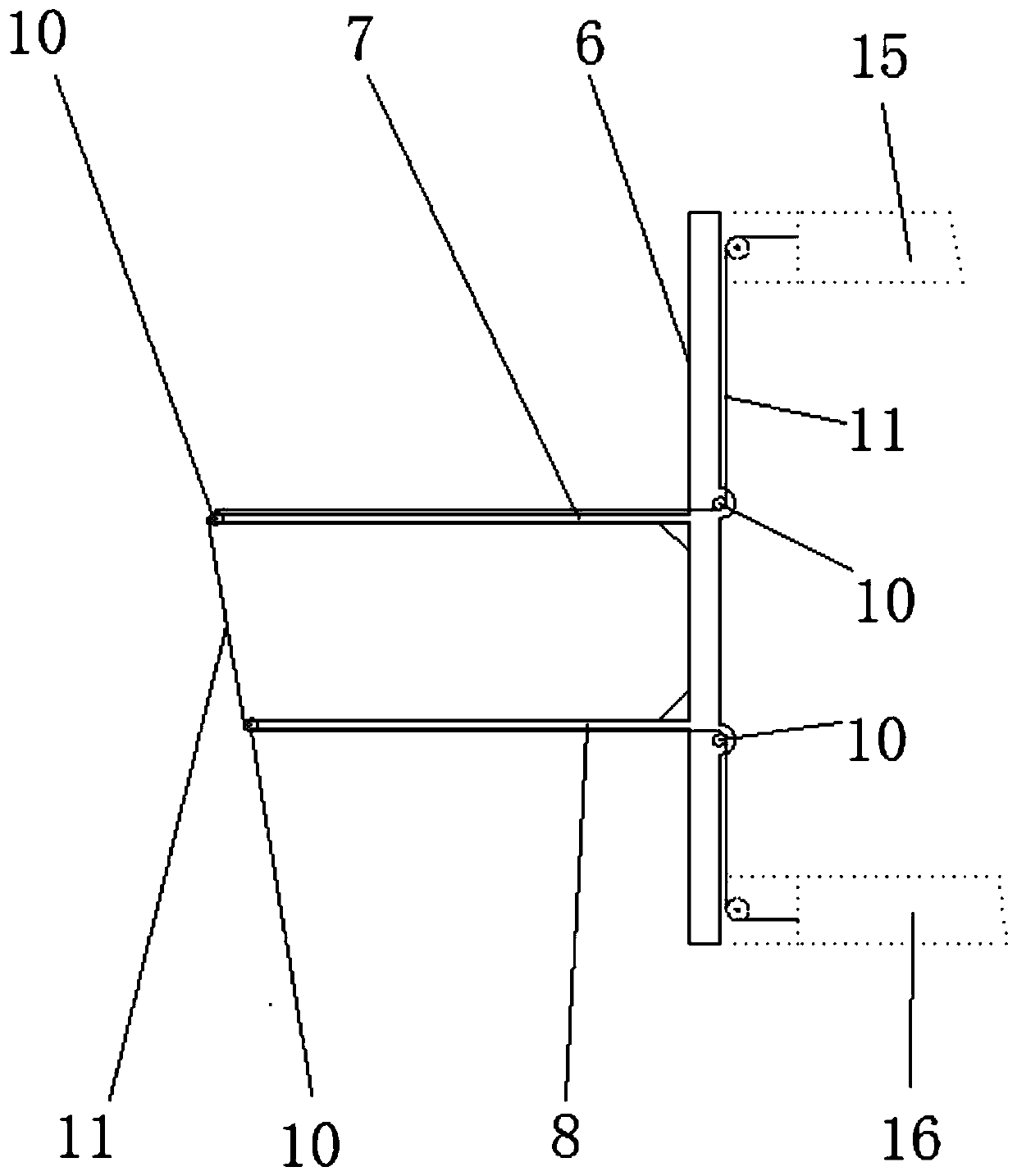

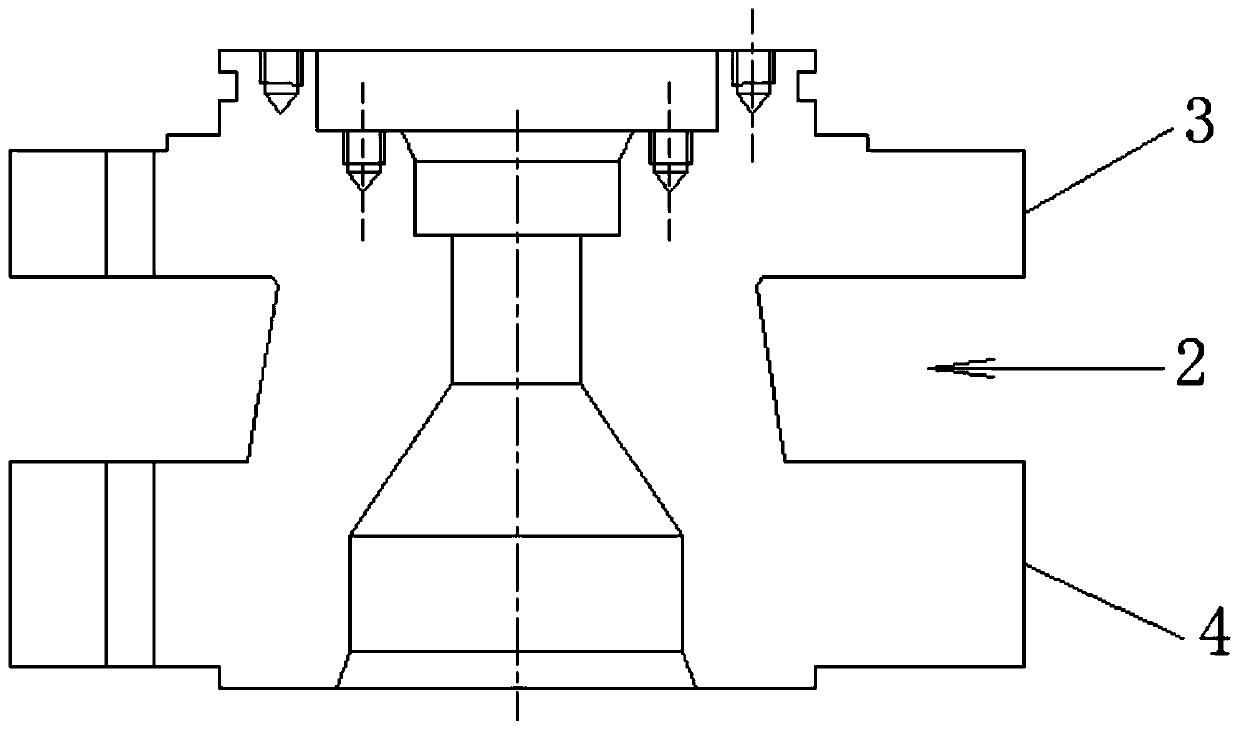

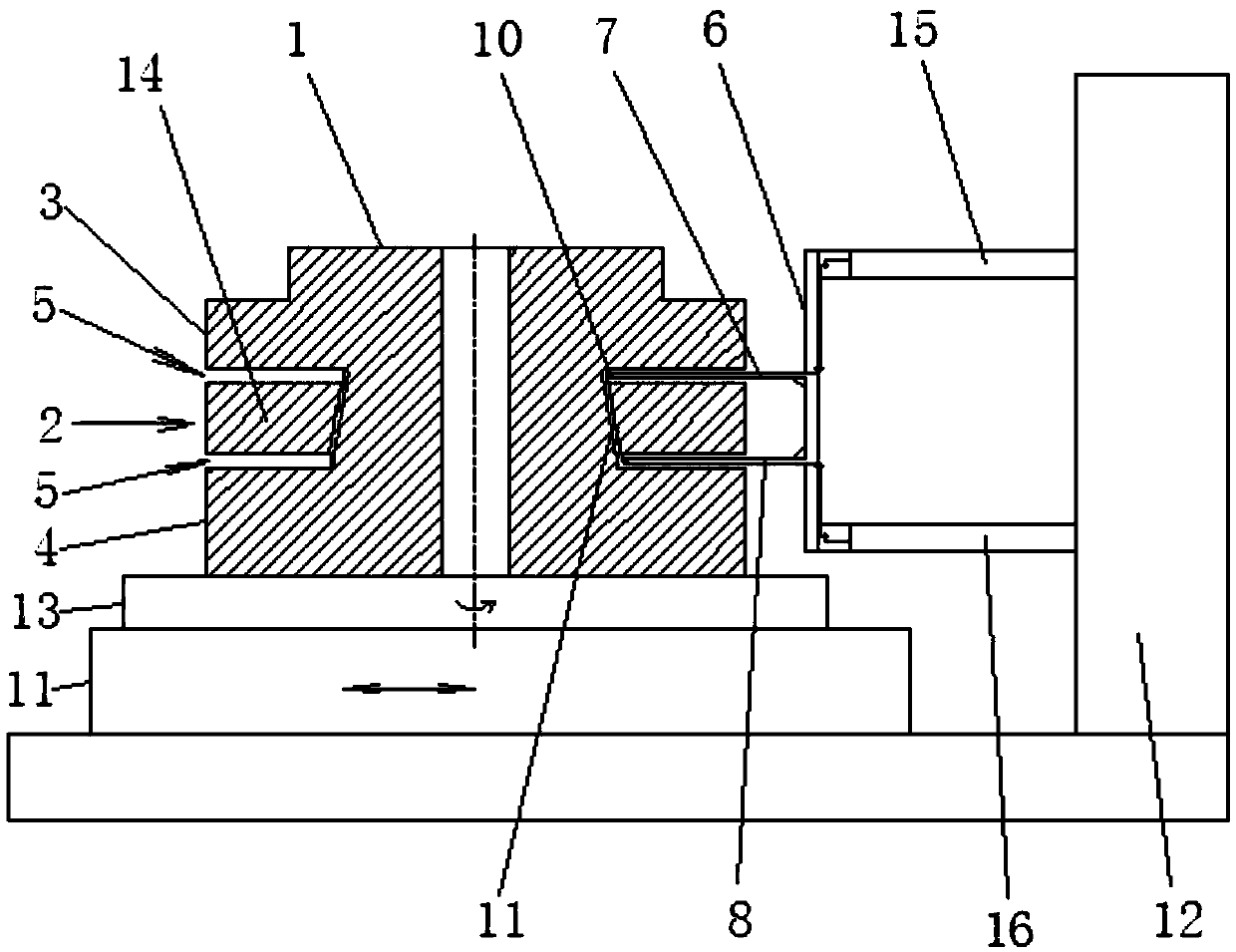

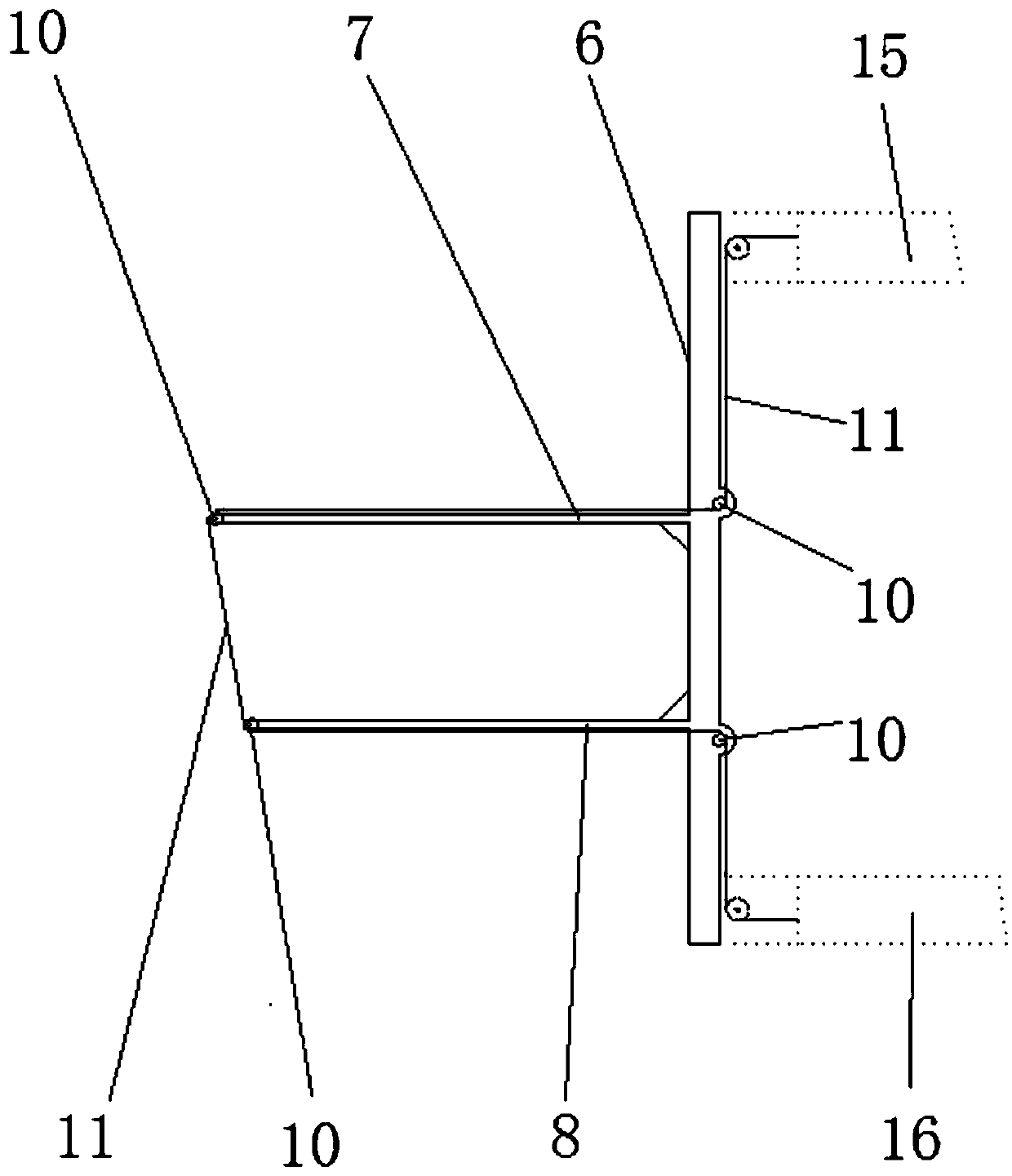

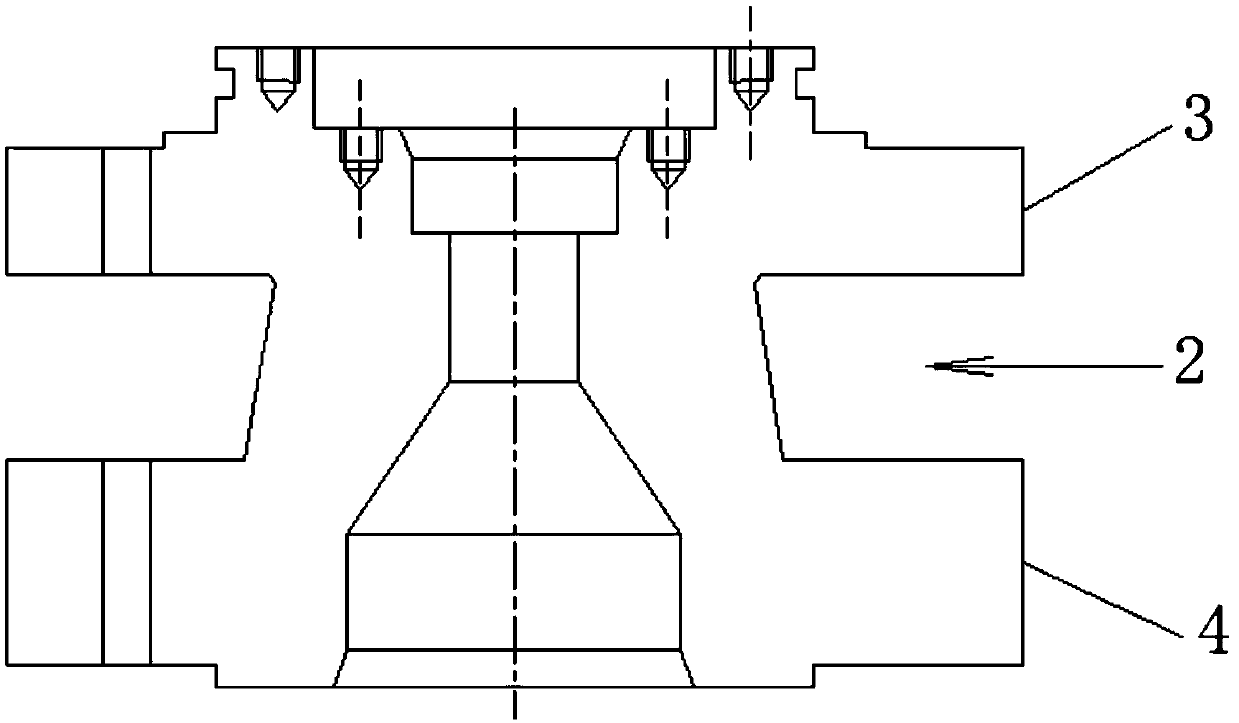

A device for improving the surface smoothness of the intake and exhaust ducts of the cylinder head of an internal combustion engine

ActiveCN103170919BImprove the finishImprove consistencyAbrasive feedersAbrasive machine appurtenancesAir compressionSurface finish

The invention relates to a device for improving surface smoothness of air inlet and outlet channels of a combustion motor cylinder cover. The device comprises an air compressor pump 1, a gas feeding pipeline 4, a shot blasting storing container 6, at least one spray gun 8, at least one nozzle 9 and an air cylinder cover 10, wherein the air cylinder cover is arranged on an air cylinder cover placing platform 11, and the air compressor pump 1 is connected with the spray gun 8 through the gas feeding pipeline 4; and the shot blasting storing container 6 is connected with the spray gun 8 which is connected with the nozzle 9, the nozzle 9 stretches into the air cylinder cover 10, an air inlet channel or an air outlet channel of the air cylinder cover 10 is aligned, and the air cylinder cover placing platform arranged below a valve base of the air cylinder cover 10 is provided with a through hole. The device is used for processing the air cylinder cover and has the cleaning function, the surface smoothness of the air outlet channel is improved, and improvement of the consistency of the air incoming of all cylinders of an engine is facilitated. The invention also discloses a method for improving the surface smoothness of the air inlet and outlet channels of the combustion motor cylinder cover.

Owner:CHINA NORTH ENGINE INST TIANJIN

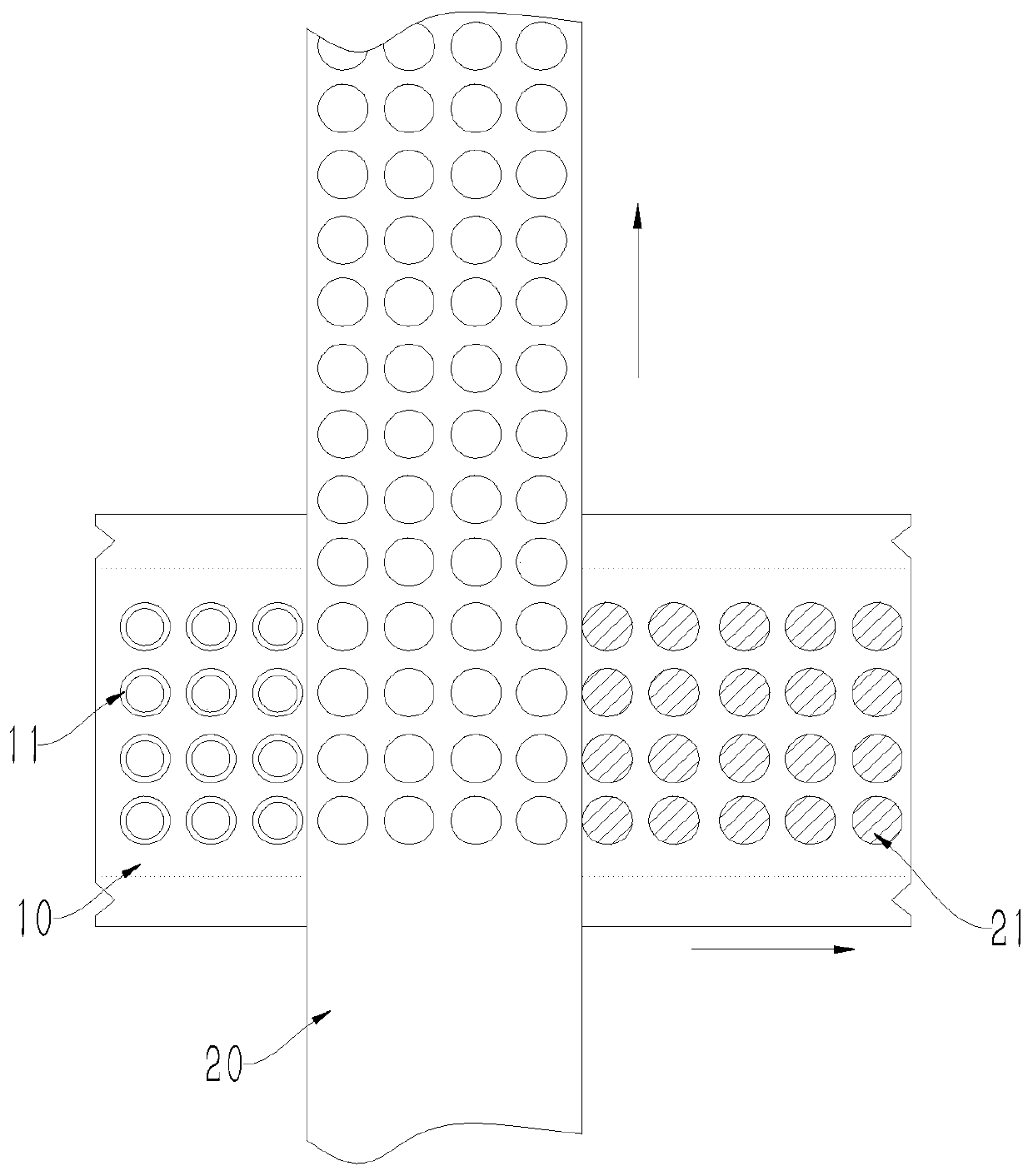

Cutting and gluing method of a ring-shaped metal material

ActiveCN111097839BTypesetting density is highIncrease profitDomestic articlesMetallic materialsMetal sheet

Owner:LINGSHENGCHENG TECH JIANGSU CO LTD

Depth control method of pattern on stainless steel surface

ActiveCN111266414BMeet the needs of different productsRoll force/gap control deviceMeasuring devicesSS - Stainless steelStress sensors

The invention discloses a method for controlling the surface pattern depth of stainless steel, which includes: establishing a corresponding relationship between a rolling reduction and a target pattern depth; obtaining the elongation of the pressed stainless steel, and determining the current required elongation based on the obtained elongation and the target pattern depth. A plurality of pressure sensors are arranged at intervals along the width direction of the pressed stainless steel, and the plate shape of the pressed stainless steel is determined according to the radial force obtained by the pressure sensors; The width selects the taper length of an intermediate roll and adjusts the position of the intermediate roll relative to the pressed stainless steel according to the determined plate shape of the pressed stainless steel; starts the rolling mill to carry out embossing. The invention can obtain the target pattern depth after the surface treatment of the stainless steel, so as to meet the needs of manufacturing different products in various industries.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

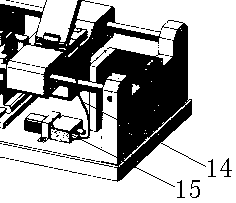

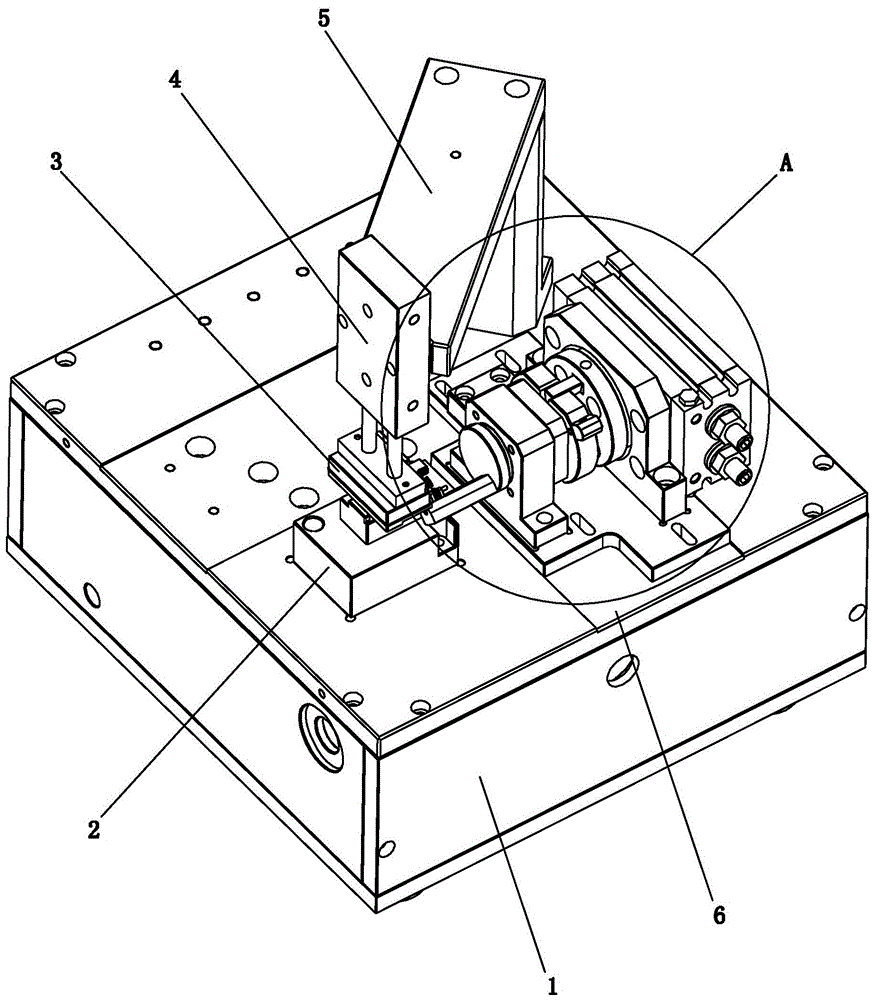

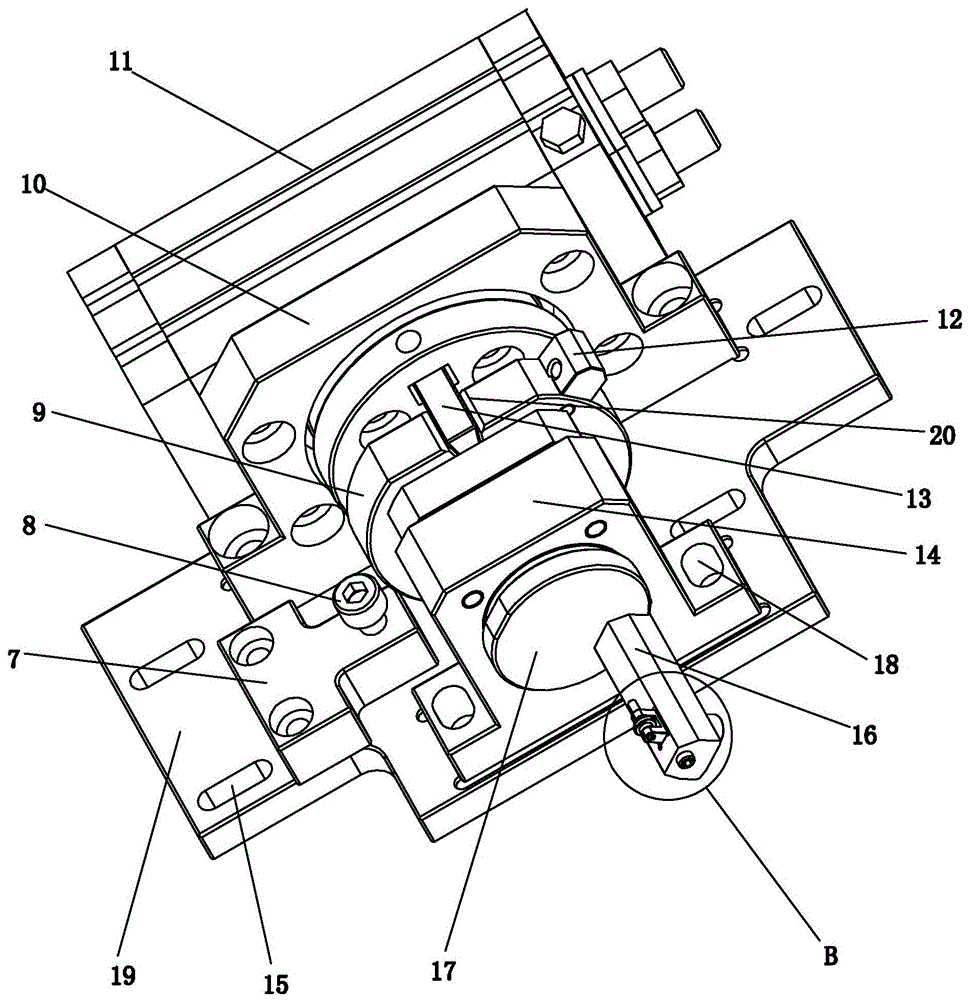

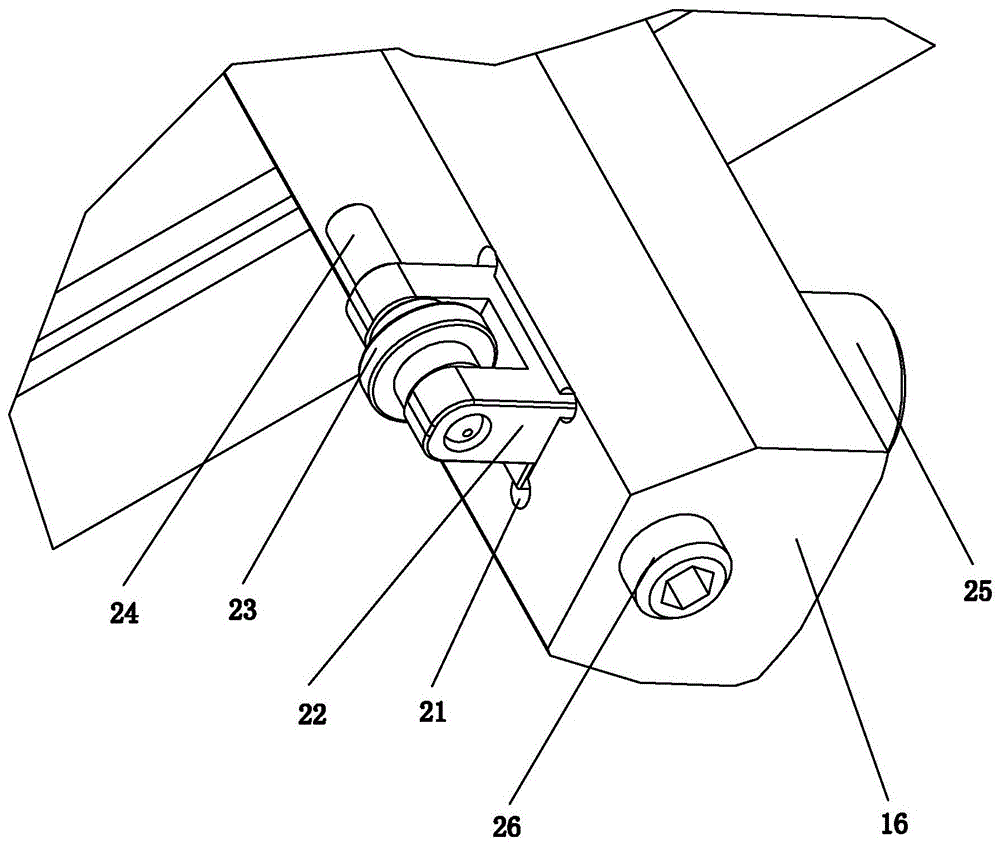

Linear guide rail-guided mold clamping mechanism compatible with various power combinations

PendingCN113071076AMeet the needs of different productsPreserve precise orientationEngineeringMechanical engineering

The invention discloses a linear guide rail-guided mold clamping mechanism compatible with various power combinations. The mold clamping mechanism comprises a mold clamping fixed plate, a mold clamping movable plate and a mold clamping tail plate, wherein pull rods are fixedly arranged at four corners of the mold clamping fixed plate, the pull rods penetrate through the mold clamping movable plate and are fixedly arranged on the mold clamping tail plate, and a mold is placed between the mold clamping movable plate and the mold clamping fixed plate; and a first mounting interface and a second mounting interface are formed in the mold clamping tail plate, the first mounting interface and the second mounting interface are used for mounting a hydraulic power assembly and an electric power assembly separately, and the output end of the hydraulic power assembly and the output end of the electric power assembly are connected with the left end and the right end of a cross head separately. Through novel structure layout, the linear guide rail-guided mold clamping mechanism can be compatible with various power combinations, and can be compatible with hydraulic power or electric power under the condition that the main body structure is not changed. Therefore, any power combination is achieved, and the requirements of different products are met. A full-hydraulic mold clamping mechanism, a hybrid power mold clamping mechanism or a full-electric mold clamping mechanism is achieved.

Owner:BORCH MACHINERY

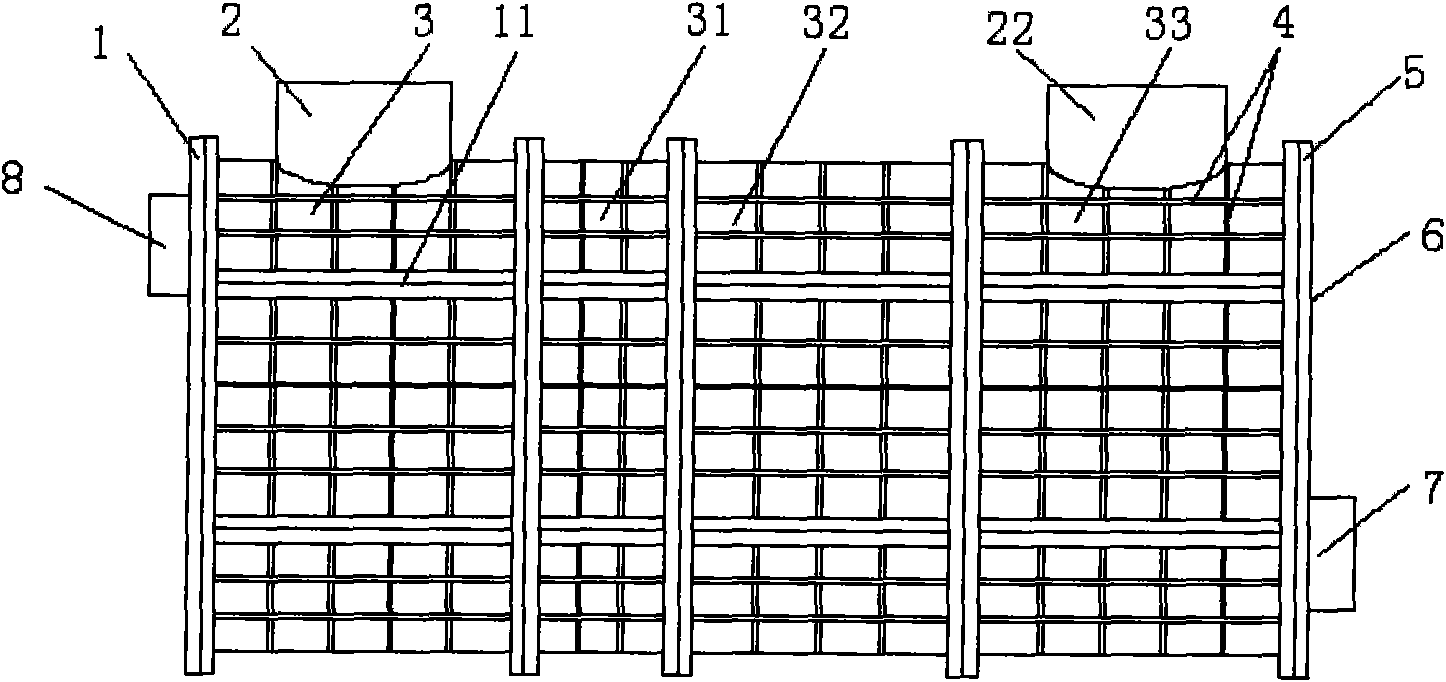

Nested radiator

InactiveCN101975385AReduce dosageEasy to moveLighting heating/cooling arrangementsLight fasteningsEngineeringThin sheet

The invention relates to the technical field of radiating products, in particular to a nested radiator composed of a plurality of radiating fins. The nested radiator comprises a plurality of radiating fins forming the main body structure of the radiator, a clamp ring for fixing the main body structure of the radiator and a connection piece for connecting the products needing radiation; the main body structure of the radiator comprises a plurality of radiating fins which are buckled with each other; an upper buckling position and a lower buckling position are formed at the upper and lower ends of one side of each radiating fin respectively; and two adjacent radiating fins are buckled with each other through the formed upper buckling position and lower buckling position to form the main body structure of the radiator. The nested radiator is formed by stamping a sheet aluminum alloy material, thus the using amount of the material is reduced and the cost is lowered. The nested radiator is made from the sheet material and has big enough radiating surface; and gaps and slots are formed between and on the radiating fins, thereby promoting airflow and increasing the radiating speed.

Owner:东莞市长安上名模具科技有限公司

Machine frame with variable roller speed ratio

The invention discloses a machine frame with variable roller speed ratio; the machine frame comprises a rack, an upper roller rotatingly arranged on the rack, a lower roller rotatingly arranged on the rack, and a driving mechanism for driving the upper roller or the lower roller to rotate; the upper roller is located above the lower roller; the upper roller and the lower roller are connected through a speed change gear box; according to the actual need, through adjusting the speed change gear box, the speed ratio of the upper roller and the lower roller is changed to meet different product needs, and products having different specifications and varieties can be processed.

Owner:JIANGYIN BEIHAI LSA

Shrapnel bending machine

ActiveCN104037589BAvoid scratchesSimple structureContact member manufacturingHigh volume manufacturingDrive shaft

The invention discloses a shrapnel bending machine, which belongs to the technical field of shrapnel bending. Including the frame, the frame is equipped with a positioning tool suitable for the injection molded part, the injection molded part is injected with a shrapnel, and the upper part of the positioning tool is provided with a pressure block driven by the first power device and used to compress the injection molded part; and the shrapnel The frame on the corresponding side is provided with a rotating shaft driven by the second power unit, and the rotating shaft is provided with a turning arm that deviates from the axis of the rotating shaft. Bending rollers are installed on the turning arm. The cross section does not intersect with the axis of the rotating shaft; in the initial state, the shrapnel is located above the bending roller, and the center of the pre-bending fillet of the shrapnel is basically located on the axis of the rotating shaft; both the first power device and the second power device are connected to the electronic control unit. The structure is simple, one-step bending is realized and the precision is high, the production efficiency is greatly improved, the production cycle is saved, the product quality is effectively guaranteed, the requirements of mass production are met, and the production cost is low.

Owner:GOERTEK INC

A preparation method of modified polysiloxane microspheres with controllable particle size

The invention provides a preparation method of modified polysiloxane microspheres. The preparation method comprises steps as follows: firstly, a silanol solution is obtained by mixing and hydrolyzing siloxane monomers, an acidic catalyst and water; the electrical conductivity of the water is 5-60 mu s / cm; an alkaline catalyst is added to the silanol solution obtained in the step, a condensation reaction is performed, the mixture is heated, a modifier is added for a reaction again, and the modified polysiloxane microspheres are obtained. The modified polysiloxane microspheres containing multiple active genes are prepared by adding the modifier; the particle sizes of the modified polysiloxane microspheres are controlled by adjusting the electrical conductivity of the raw material water, so that the prepared modified polysiloxane microspheres have narrower particle size distribution, are uniform in particle size and meet the demands of different products. Besides, the provided preparation method has higher product yield, adopts a simple process, is easy to operate, doesn't require organic solvents, is environment-friendly and facilitates large-scale production.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Device and method for improving surface smoothness of air inlet and outlet channels of combustion motor cylinder cover

ActiveCN103170919AImprove the finishImprove consistencyAbrasive feedersAbrasive machine appurtenancesSurface finishCombustion

The invention relates to a device for improving surface smoothness of air inlet and outlet channels of a combustion motor cylinder cover. The device comprises an air compressor pump 1, a gas feeding pipeline 4, a shot blasting storing container 6, at least one spray gun 8, at least one nozzle 9 and an air cylinder cover 10, wherein the air cylinder cover is arranged on an air cylinder cover placing platform 11, and the air compressor pump 1 is connected with the spray gun 8 through the gas feeding pipeline 4; and the shot blasting storing container 6 is connected with the spray gun 8 which is connected with the nozzle 9, the nozzle 9 stretches into the air cylinder cover 10, an air inlet channel or an air outlet channel of the air cylinder cover 10 is aligned, and the air cylinder cover placing platform arranged below a valve base of the air cylinder cover 10 is provided with a through hole. The device is used for processing the air cylinder cover and has the cleaning function, the surface smoothness of the air outlet channel is improved, and improvement of the consistency of the air incoming of all cylinders of an engine is facilitated. The invention also discloses a method for improving the surface smoothness of the air inlet and outlet channels of the combustion motor cylinder cover.

Owner:CHINA NORTH ENGINE INST TIANJIN

Sauced split duck leisure food and production method thereof

The invention discloses a production method for a sauced split duck leisure food. The method is characterized in that: the split duck and accessories thereof are adopted as raw materials; a production process of the method comprises defrosting, adjusting, rolling and kneading, sousing, bittern, baking, cutting, mixing, vacuum packaging, sterilizing, rinsing and drying. The raw materials for the sousing comprise, by weight, 100 parts of the split duck raw material, 0.80-1.20 parts of a salt substance, 0.005-0.50 parts of a flavor enhancer, 0.05-0.15 parts of a sweeting agent, 0.10-0.30 parts of a deodorization agent, 0.008-0.035 parts of a pigment, 0.005-0.06 parts of a preservative, 0.04-0.10 parts of a flavoring agent. The raw materials for the bittern comprise, by weight, 100 parts of the soused split duck, 0.20-0.40 parts of the flavor enhancer, 0.05-0.20 parts of a flavoring agent, 0.01-0.04 parts of a toner and 0.8-1.2 parts of a perfume. The products prepared by the method have delicious and rich fragrance, moderate salt taste, mellow flavor, a unique flavor of the sauced products.

Owner:CHENGDU FENGFENG FOOD CO LTD

Cutting and cementing method for annular metal material

ActiveCN111097839ATypesetting density is highIncrease profitDomestic articlesMetallic materialsStructural engineering

The invention discloses a cutting and cementing method for an annular metal material. The cutting and cementing method comprises the following steps that a plurality of annular glue pieces are attached to a carrier tape; the metal material is cut above the carrier tape, and obtained circular metal sheets fall on the annular glue pieces; the circular metal sheets are stamped from the upper part ofthe carrier tape, and annular metal sheets are obtained; and a handle material belt is placed above the carrier tape, the non-glue faces of the annular metal sheets are attached to a handle, and a product is obtained. According to the cutting and cementing method, the machining and assembling process of the annular material is optimized, the utilization rate and the assembling efficiency of the precious metal material can be improved, the product yield is increased, and the market competitiveness of the product is improved.

Owner:LINGSHENGCHENG TECH JIANGSU CO LTD

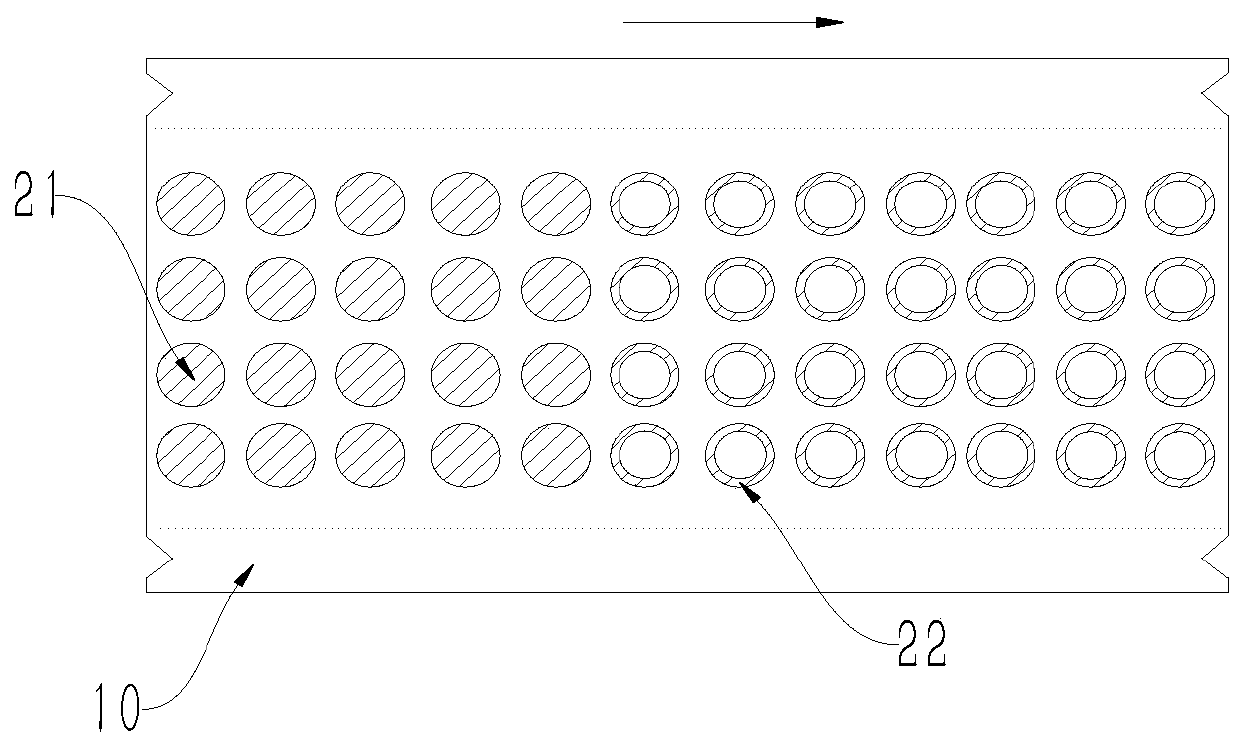

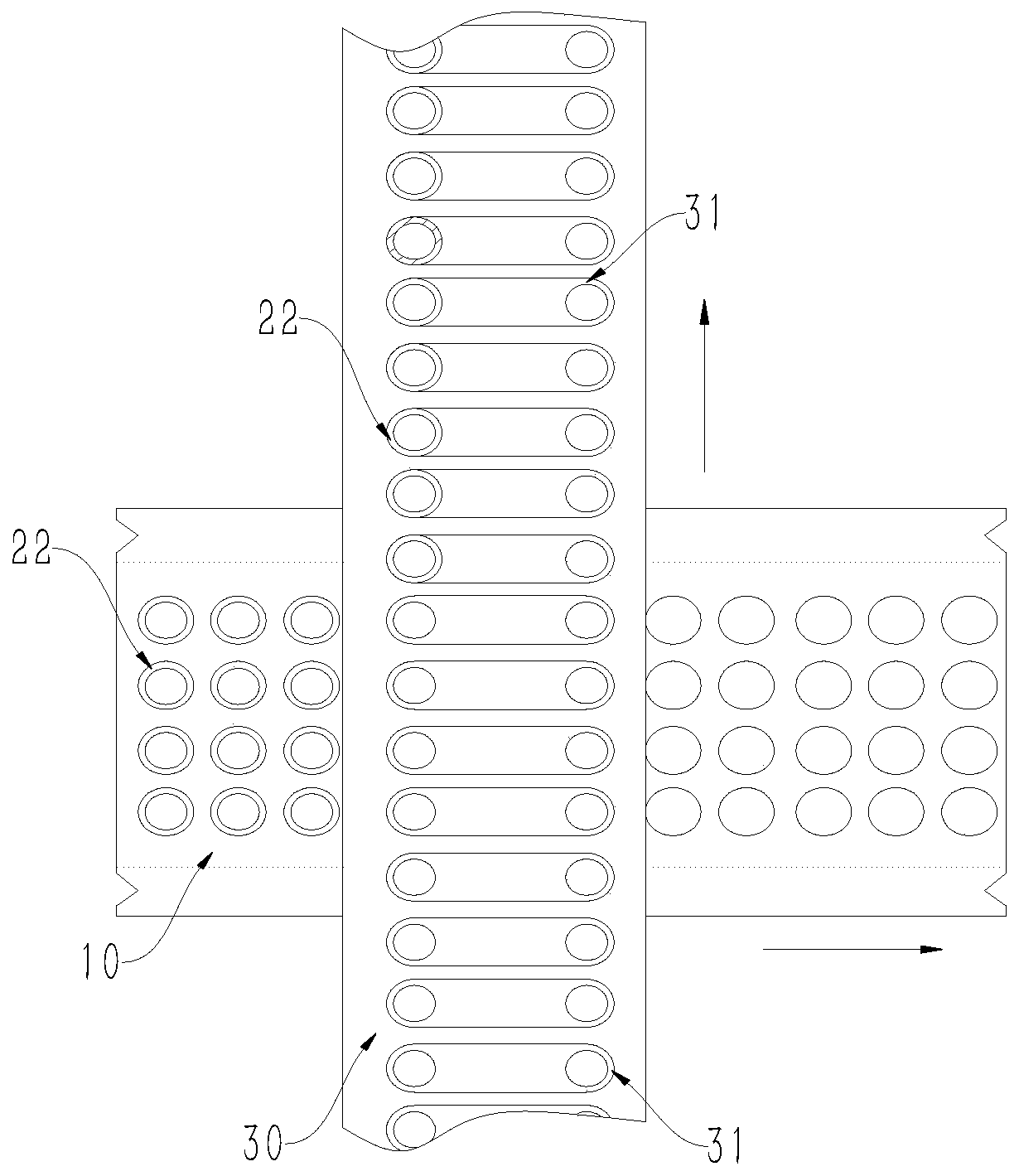

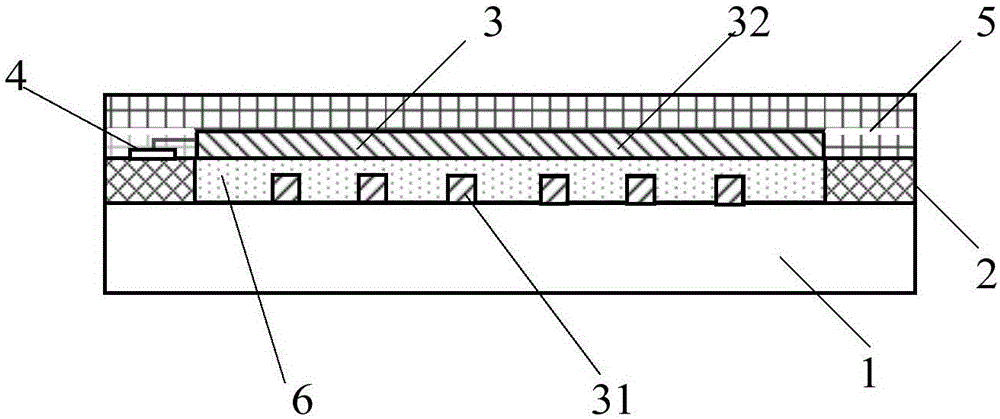

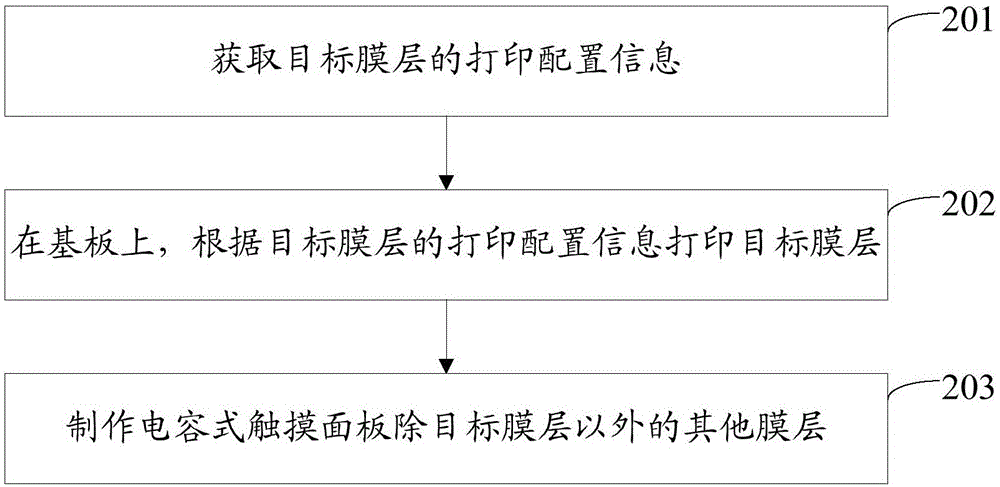

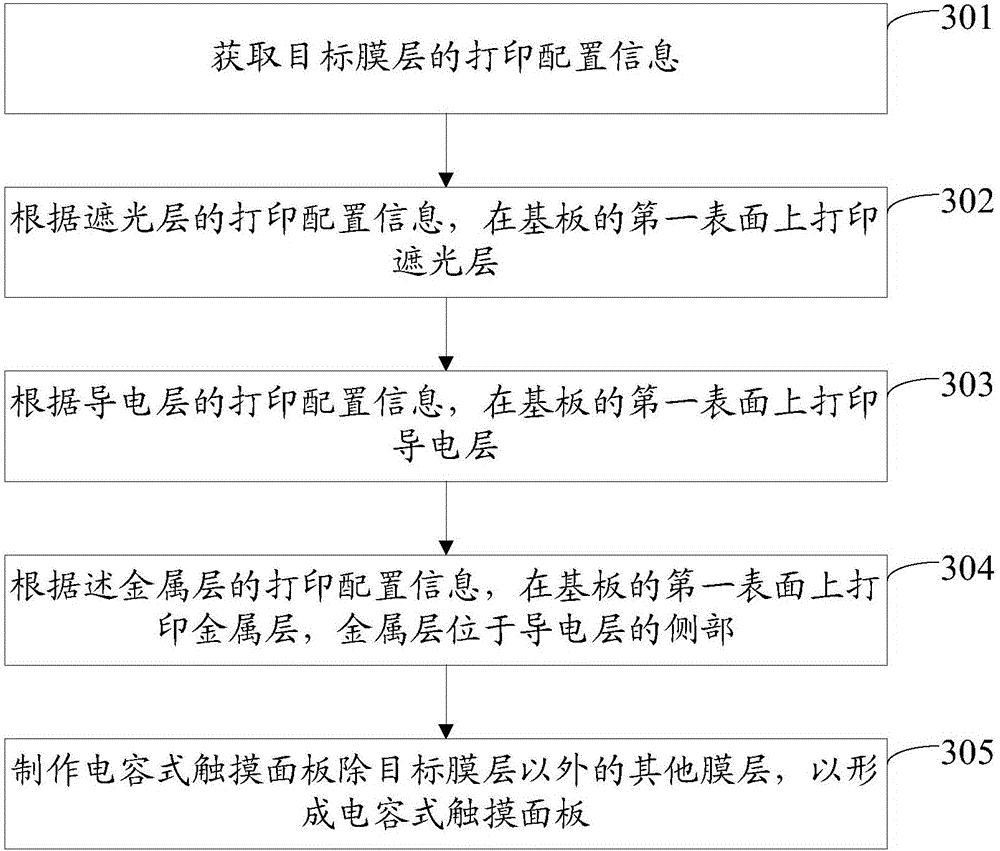

Manufacturing method of capacitive touch panel

ActiveCN106502483AShorten the production cycleIncrease productivityInput/output processes for data processingTouch panelMembranous layer

The invention discloses a manufacturing method of capacitive touch panel which belongs to the display field. The manufacturing method of capacitive touch panel comprises: the printing configuration information of the target membranous layer is obtained, wherein the target membranous layer is a membranous layer having a touch area smaller than the capacitive touch panel in the capacitive touch panel, and the printing configuration information includes at least the position, shape and / or size of the target membranous layer on the basilar plate; the target membranous layer is printed on the basilar plate according to the printing configuration information of the target membranous layer; and the other membranous layers of the capacitive touch panel are made except the target membranous layer. The method of capacitive touch panel has the advantages of shortening the production cycle, improving the production efficiency and reducing the production cost.

Owner:BOE TECH GRP CO LTD +1

Blank manufacturing process and tooling of a large double-head connecting shaft flange

ActiveCN109514210BIncrease profitRealize green manufacturingElectrical-based machining electrodesCouplingWire cutting

The invention relates to the technical field of machining, and discloses a large double-head shaft connecting flange blank manufacturing process and tool. The process comprises flange forging and flange rough machining after flange forging; and in the flange forging process, hammer forging is adopted for forging a double-head shaft connecting flange into a cylindrical forging blank. The flange rough machining process comprises the following process steps of (1) rough machining of a napping knife; (2) processing of a process groove; (3) preparation of a wire-electrode cutting guide frame; 4) wire-electrode cutting preparation; and (5) wire-electrode cutting of a neck section outer circle. Wire-electrode cutting processing is carried out to enable a cut rough machining allowance part on theneck section outer circle to form an allowance ring separated from a double-head shaft connecting flange body. By means of the large double-head shaft connecting flange blank manufacturing process andtool, the machining time is shortened, the processing cost is reduced, the utilization rate of raw materials is improved, resources are fully utilized, and green manufacturing is achieved.

Owner:江阴普洋重工有限公司

Large double-head shaft connecting flange blank manufacturing process and tool

ActiveCN109514210AIncrease profitRealize green manufacturingElectrical-based machining electrodesEngineeringProcessing cost

The invention relates to the technical field of machining, and discloses a large double-head shaft connecting flange blank manufacturing process and tool. The process comprises flange forging and flange rough machining after flange forging; and in the flange forging process, hammer forging is adopted for forging a double-head shaft connecting flange into a cylindrical forging blank. The flange rough machining process comprises the following process steps of (1) rough machining of a napping knife; (2) processing of a process groove; (3) preparation of a wire-electrode cutting guide frame; 4) wire-electrode cutting preparation; and (5) wire-electrode cutting of a neck section outer circle. Wire-electrode cutting processing is carried out to enable a cut rough machining allowance part on theneck section outer circle to form an allowance ring separated from a double-head shaft connecting flange body. By means of the large double-head shaft connecting flange blank manufacturing process andtool, the machining time is shortened, the processing cost is reduced, the utilization rate of raw materials is improved, resources are fully utilized, and green manufacturing is achieved.

Owner:江阴普洋重工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com