Manufacturing method of capacitive touch panel

A manufacturing method and touch panel technology, which are applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problems of long production cycle, low production efficiency and high production cost, so as to improve production efficiency and improve production efficiency. Reliable, flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

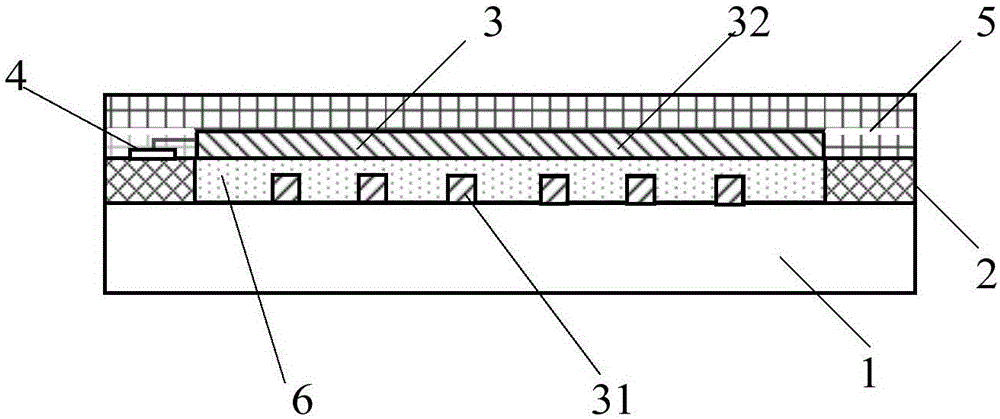

[0044] see figure 1 , an embodiment of the present invention provides a capacitive touch panel structure, including:

[0045] Substrate 1;

[0046] A light-shielding layer 2 is formed on the first surface of the substrate 1, and the first surface is any surface of the substrate 1;

[0047] A conductive layer 3 is formed on the first surface, and a metal layer 4 is formed on the first surface, the metal layer 4 is located on the side of the conductive layer 3, and the metal layer 4 is connected to the conductive layer 3;

[0048] A protective layer 5 is formed on the first surface, and the protective layer 5 covers the entire first surface, that is, covers the light shielding layer 2 , the protective layer 3 and the metal layer 4 .

[0049] Optionally, the conductive layer 3 includes a first conductive layer 31 and a second conductive layer 32; the first conductive layer 31 may be a horizontal conductive layer, and the second conductive layer 32 may be a vertical conductive l...

Embodiment 2

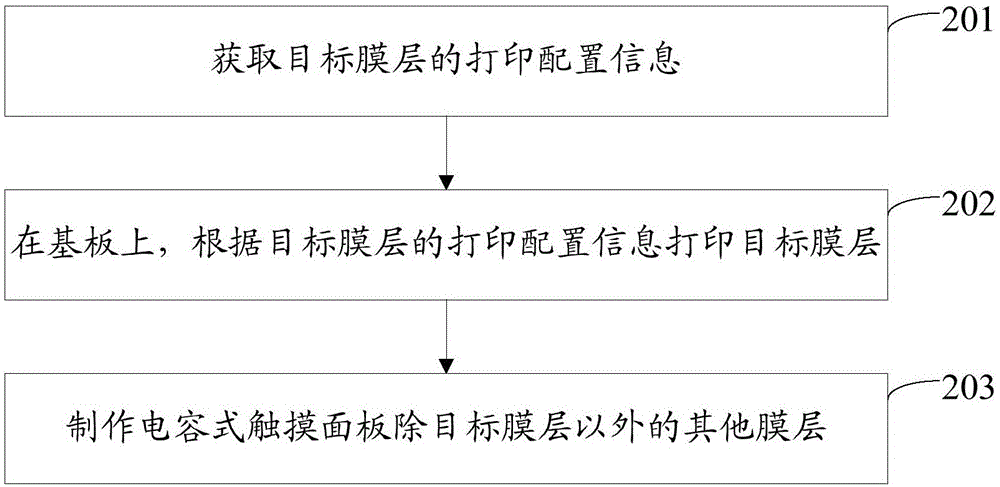

[0054] see figure 2 , a manufacturing method of a capacitive touch panel of the present invention, the manufacturing method comprising:

[0055] Step 201: Obtain the printing configuration information of the target film layer. The target film layer is a film layer in the capacitive touch panel whose area is smaller than the touch area of the capacitive touch panel. The printing configuration information includes at least the position and shape of the target film layer on the substrate and / or size.

[0056] Step 202: On the substrate, print the target film layer according to the printing configuration information of the target film layer.

[0057] Step 203: Fabricate other film layers of the capacitive touch panel except the target film layer.

[0058] In the embodiment of the present invention, by obtaining the printing configuration information of the target film layer, according to the printing configuration information of the target film layer, the target film layer of...

Embodiment 3

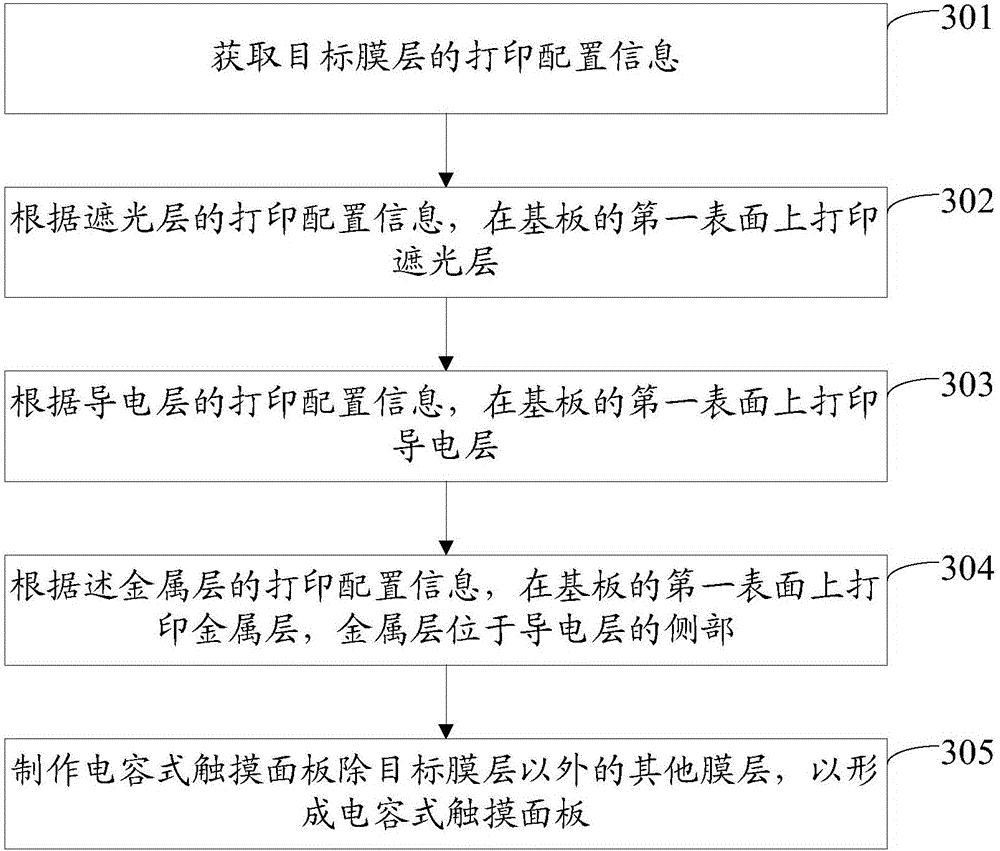

[0060] see image 3 , an embodiment of the present invention provides a method for manufacturing a capacitive touch panel, including:

[0061] Step 301: Obtain printing configuration information of a target film layer, where the target film layer is a film layer in a capacitive touch panel whose area is smaller than a touch area of the capacitive touch panel.

[0062] The target film layer may include at least one of a light shielding layer, a conductive layer and a metal layer. In this step, the printing configuration information of the target film layer configured by the user may be received, and the printing configuration information includes information such as the position, shape and / or size of the target film layer on the substrate.

[0063]Users can define a coordinate system on the substrate in advance, and then configure the printing configuration information of the target film layer through this coordinate system. For example, see Figure 4 , define a coordinate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com